Method for reducing content of residual alkali on surface of high-nickel cathode material of lithium-ion battery

A technology for lithium ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of decreased cycle performance, low cost performance, increased specific surface area of positive electrode materials, etc., and achieves less side reactions and simple processing technology. , The effect of improving processing performance and cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

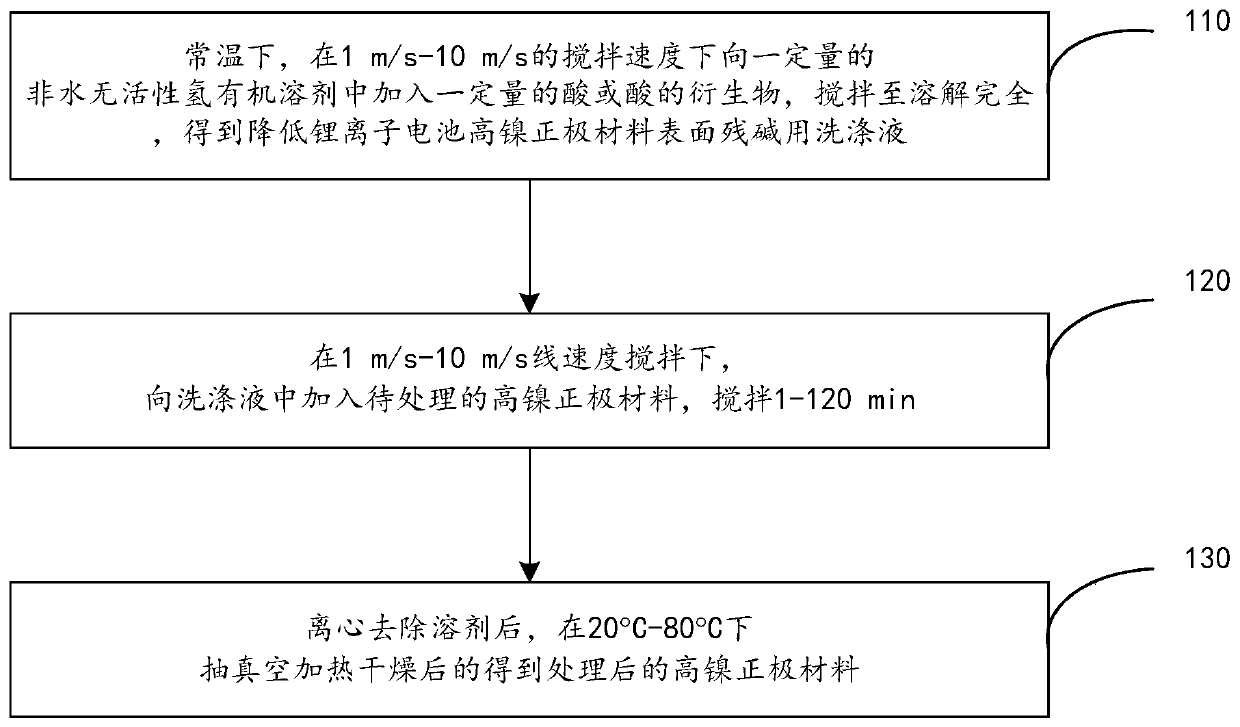

Method used

Image

Examples

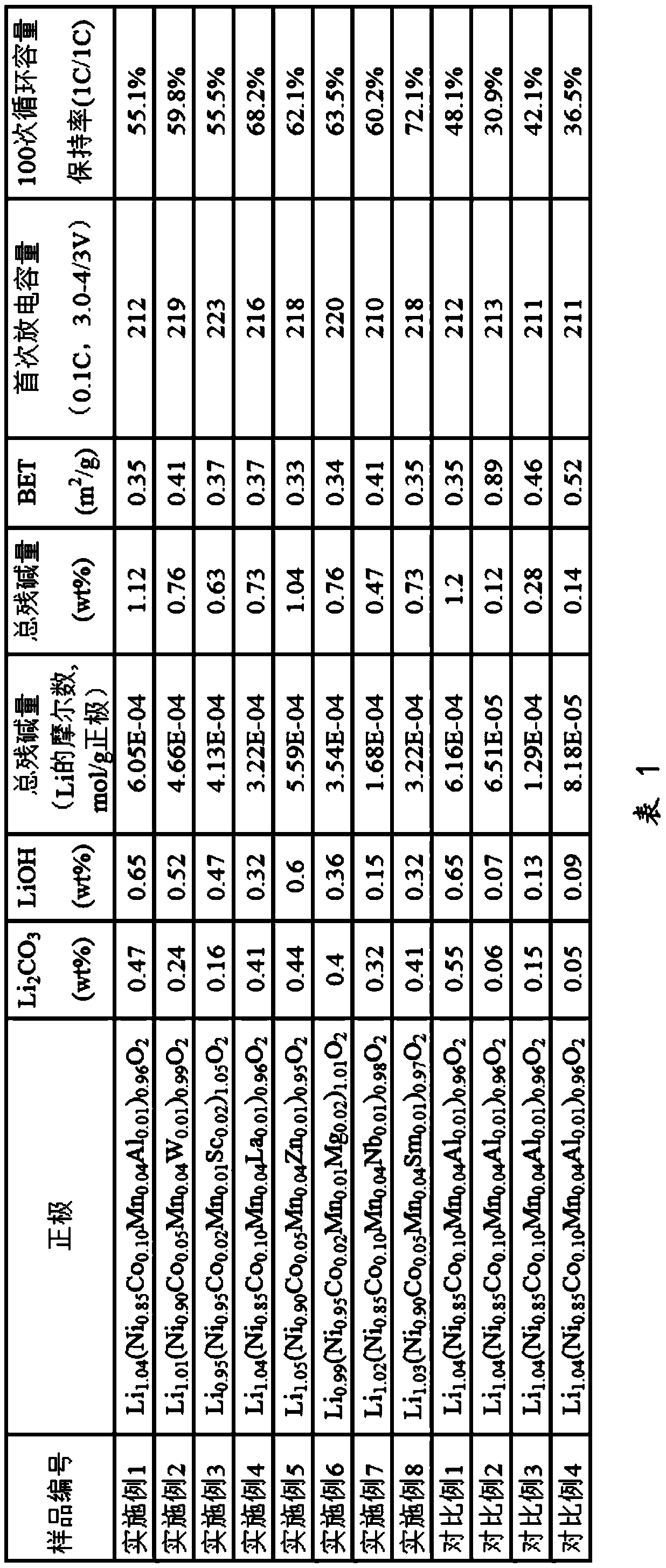

Embodiment 1

[0031] In this embodiment, the residual alkali treatment process on the surface of the high-nickel ternary positive electrode material is as follows:

[0032] In 100g 1,4-dioxane (1,4-dioxane), according to the high-nickel ternary cathode material Li to be treated 1.04 (Ni 0.85 co 0.10 mn 0.04 Al 0.01 ) 0.96 o 2 Add 1-pentanoic acid to 0.5 times the molar amount of residual lithium on the surface as the molar concentration target value, stir at a speed of 2m / s to dissolve it, and form a 1,4-dioxane solution of 1-pentanoic acid;

[0033] To a solution of 1-pentanoic acid in 1,4-dioxane was added 200 g of Li 1.04 (Ni 0.85 co 0.10 mn 0.04 Al 0.01 ) 0.96 o 2The powder was continuously stirred for 1 minute, the solvent was removed by centrifugation, and then dried under vacuum conditions at 30° C., and the treated high-nickel ternary positive electrode material was obtained after drying.

[0034] Assembling the processed high-nickel ternary cathode material into a lith...

Embodiment 2

[0037] In this embodiment, the residual alkali treatment process on the surface of the high-nickel ternary positive electrode material is as follows:

[0038] In 100g N-methylpyrrolidone (NMP), according to the high-nickel ternary cathode material Li to be treated 1.01 (Ni 0.90 co 0.05 mn 0.04 W 0.01 ) 0.99 o 2 1.0 times the molar amount of residual lithium on the surface is the molar concentration target value, add 1-butyric acid, stir at a speed of 8m / s to dissolve it, and form a N-methylpyrrolidone solution of 1-butyric acid;

[0039] Add 100g Li to the N-methylpyrrolidone solution of 1-butyric acid 1.01 (Ni 0.90 co 0.05 mn 0.04 W 0.01 ) 0.99 o 2 The powder was stirred for 5 minutes, and the solvent was removed by centrifugation, and then dried under vacuum at 80° C., and the treated high-nickel ternary positive electrode material was obtained after drying.

[0040] The treated high-nickel ternary positive electrode material was assembled with reference to the ...

Embodiment 3

[0042] In this embodiment, the residual alkali treatment process on the surface of the high-nickel ternary positive electrode material is as follows:

[0043] Into 400g dimethyl sulfoxide, according to the high-nickel ternary cathode material Li to be treated 0.95 (Ni 0.95 co 0.02 mn 0.01 sc 0.02 ) 1.05 o 2 0.5 times the molar amount of residual lithium on the surface is the molar concentration target value, and methanesulfonic acid is added, and the high-nickel ternary positive electrode material to be treated is Li 0.95 (Ni 0.95 co 0.02 mn 0.01 sc 0.02 ) 1.05 o 2 Add tungstophosphoric acid to 0.6 times the molar amount of residual lithium on the surface as the molar concentration target value, stir at a speed of 7m / s to dissolve it, and form a dimethyl sulfoxide solution of methanesulfonic acid and tungstophosphoric acid;

[0044] Add 100g Li to the DMSO solution of methanesulfonic acid and tungstophosphoric acid 0.95 (Ni 0.95 co 0.02 mn 0.01 sc 0.02 ) 1.05...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com