Polyaniline/polyethylene glycol-co-coated composite ternary positive electrode material and preparation and application thereof

A polyethylene glycol and cathode material technology, applied in the field of lithium ion batteries, can solve the problems of decreased ionic conductivity of materials, single coating of conductive polymers, uneven coating layers, etc., to improve stability and reduce residual alkali. The effect of simple content and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

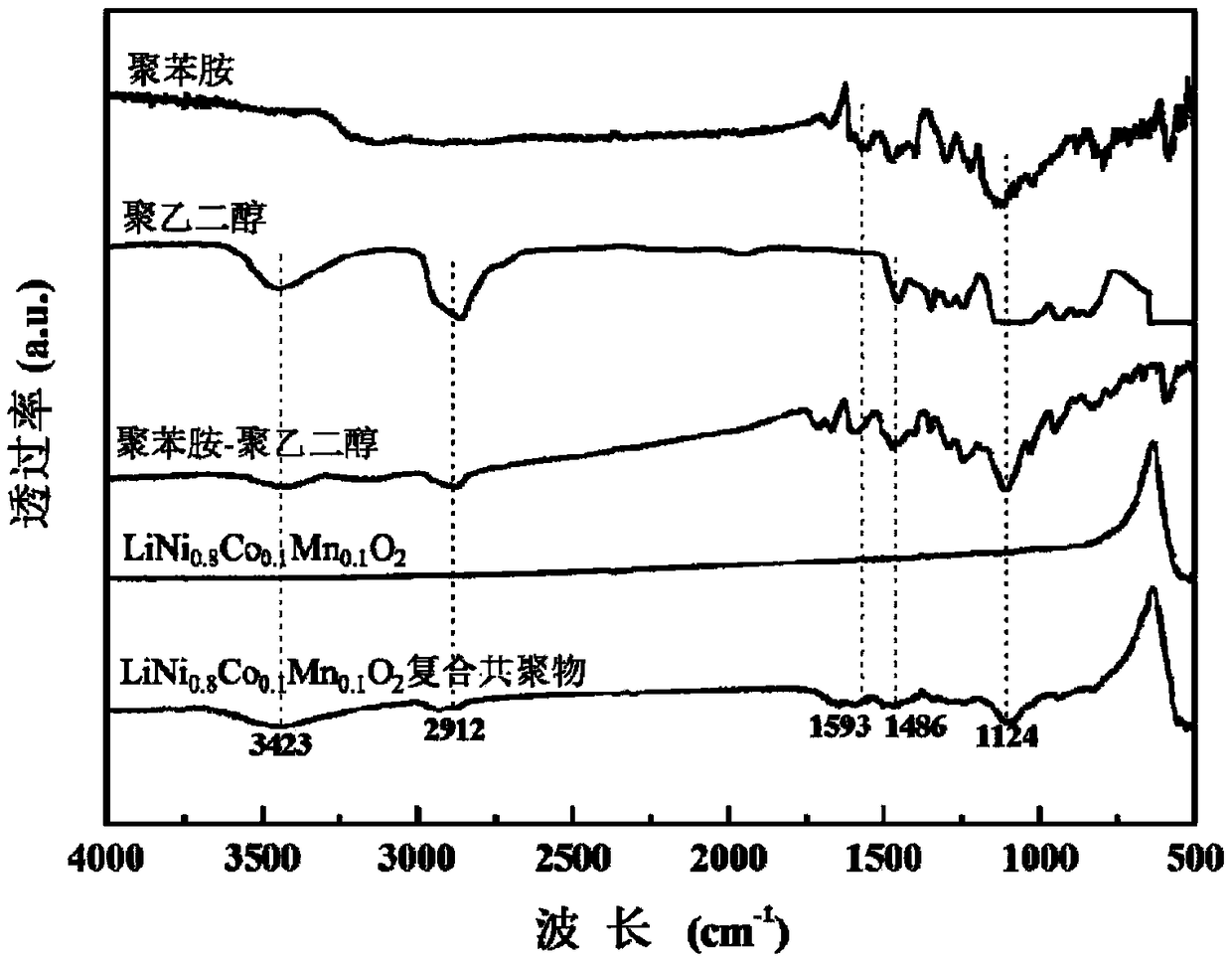

[0040] Conductive polymer polyaniline (5612-44-2, doped with hydrochloric acid, Shandong Jiaying) and polyethylene glycol (1000M w , Shanghai Sinopharm) was dispersed in N-methylpyrrolidone solvent (1:10) at a mass ratio of 1:1, and stirred in a water bath at 50°C for 10 minutes to obtain a dispersion; slowly add LiNi to the dispersion 0.8 co 0.1 mn 0.1 o 2 Ternary materials, reacted for about 15 minutes, vacuum dried at 100°C after suction filtration, and obtained polyaniline-polyethylene glycol surface-modified LiNi 0.8 co 0.1 mn 0.1 o 2 Composite material, wherein the coating amount of the polymer is 5wt%.

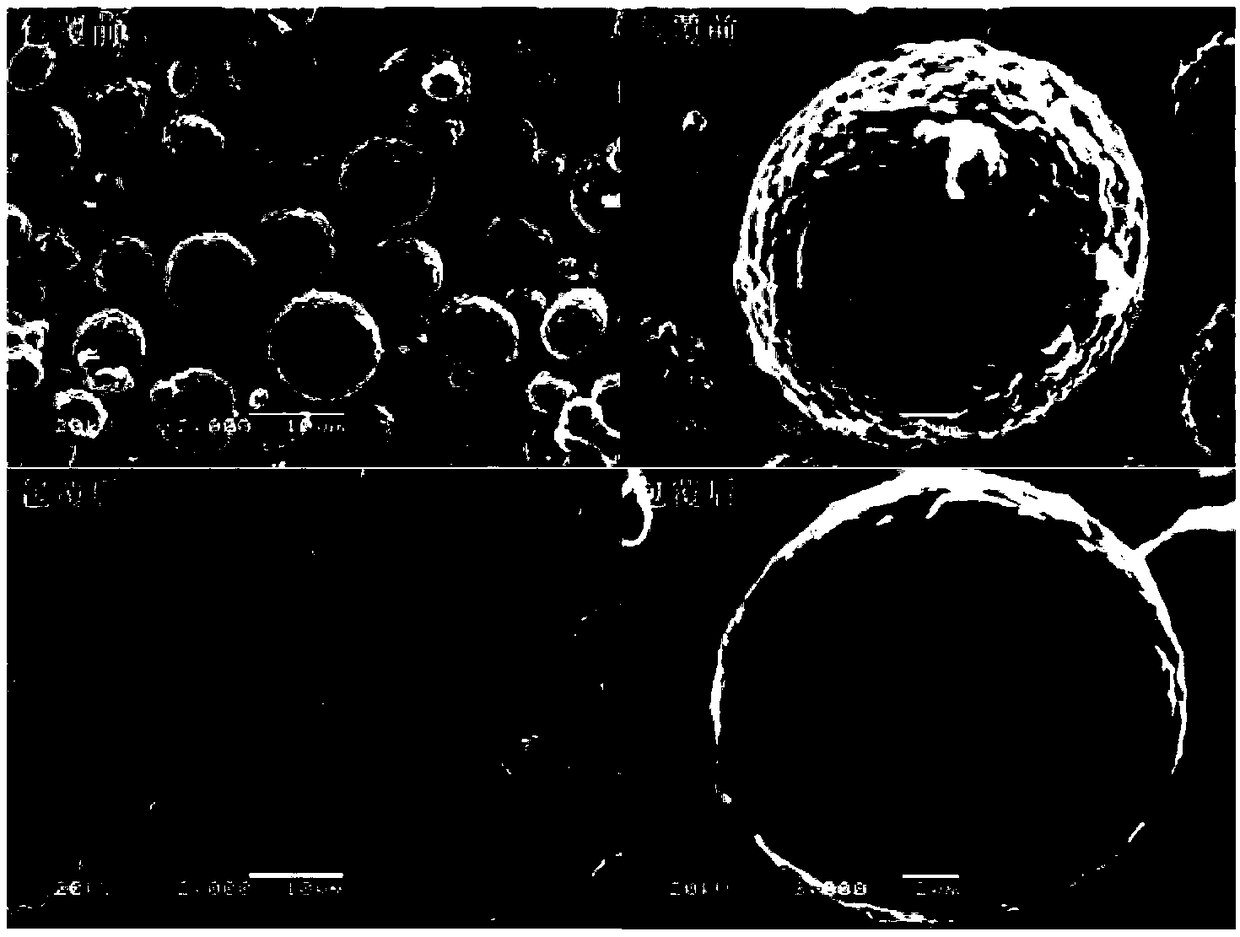

[0041] figure 1 SEM images of ternary materials before and after modification. Depend on figure 1 It can be seen that the morphology of the material after modification basically does not change, and they are all spherical particles, indicating that the coating process will not damage the overall shape of the material; it can be seen from the figure that the pri...

Embodiment 2

[0046] Conductive polymer polyaniline (5612-44-2, doped with sulfuric acid, Shandong Jiaying) and polyethylene glycol (2000M w , Shanghai Sinopharm) was dispersed in a xylene solvent (1:15) at a mass ratio of 2:1, and stirred in a water bath at 60°C for 15 minutes to obtain a dispersion; slowly add LiNi to the dispersion 0.6 co 0.2 mn 0.2 o 2 Ternary materials, reacted for about 20 minutes, vacuum dried at 110°C after suction filtration, and obtained polyaniline-polyethylene glycol surface-modified LiNi 0.6 co 0.2 mn 0.2 o 2 Composite material, wherein the coating amount of polymer is 4wt%.

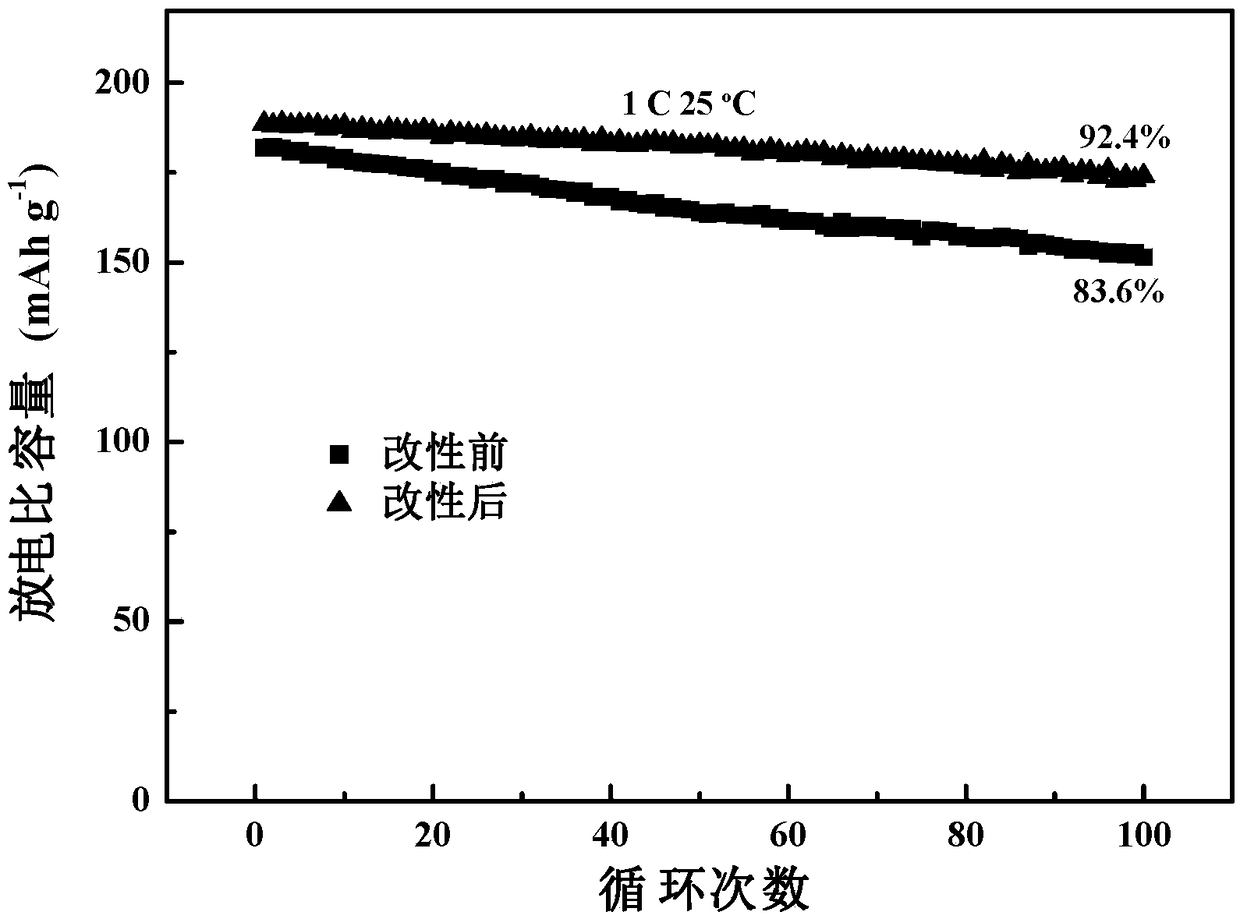

[0047] Figure 5 It is the cycle curve graph of positive electrode ternary material before and after modification under 1C current density, 25°C and 2.8-4.3V voltage range, which is determined by Figure 5 It can be seen that after the material before modification is cycled 100 times at 1C, the capacity of the material increases from 172.7mAh g -1 Rapidly decays to 145.4mAh·g -1...

Embodiment 3

[0049] Conductive polymer polyaniline (5612-44-2, doped with salicylic acid, Shandong Jiaying) and polyethylene glycol (3000M w , Shanghai Sinopharm) was dispersed in xylene solvent (1:20) at a mass ratio of 3:1, and stirred in a water bath at 70°C for 15 minutes to obtain a dispersion; slowly add LiNi to the dispersion 0.5 co 0.2 mn 0.3 o 2 Ternary materials, reacted for about 25 minutes, vacuum dried at 90°C after suction filtration, and obtained polyaniline-polyethylene glycol surface-modified LiNi 0.5 co 0.2 mn 0.3 o 2 Composite material, wherein the coating amount of polymer is 6wt%.

[0050] Figure 6 It is the cycle curve graph of positive electrode ternary material before and after modification under 1C current density, 25°C and 2.8-4.3V voltage range, which is determined by Figure 6It can be seen that after the material before modification was cycled 100 times at 1C, the capacity of the material increased from 159.7mAh g -1 Rapidly decays to 130.5mAh·g -1 ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com