Multiphase composite high-nickel ternary positive electrode material and preparation method thereof

A positive electrode material and high-nickel technology, which is applied in the field of multi-phase composite high-nickel ternary positive electrode materials and its preparation, can solve the problems of increased Ni/Li mixing degree, reduced electrochemical performance of materials, poor structural stability, etc., to achieve Reduce particle breakage, improve the first charge and discharge efficiency, and stabilize the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

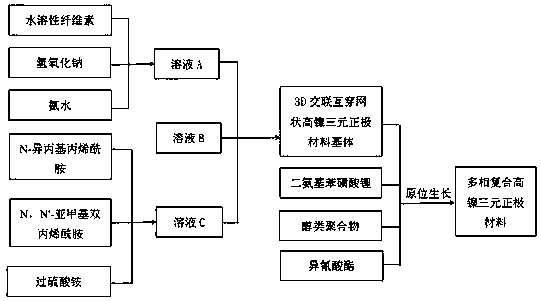

[0040] Carboxymethyl cellulose (CMC), sodium hydroxide, and urea were formulated into solutions A with mass fractions of 2%, 5%, and 10% respectively; lithium hydroxide, nickel sulfate, cobalt sulfate, and manganese sulfate were The molar ratio of metal elements is 1.02:0.8:0.1:0.1 dispersed in deionized water to prepare metal ion solution B; N-isopropylacrylamide, N,N'-methylene bisacrylamide and ammonium persulfate The mass fraction is respectively 6%, 0.3% and 0.8% solution C;

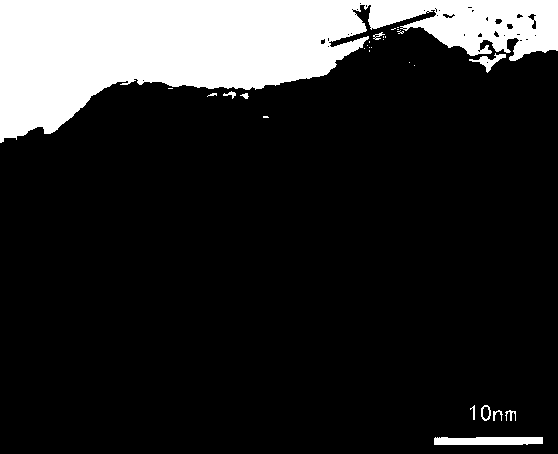

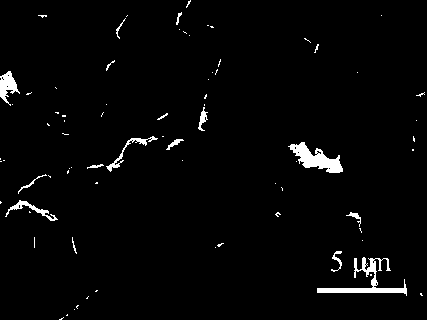

[0041] After synchronously adding solution A, solution B and solution C to the reactor, the temperature was raised to 30°C and the holding time was 12 hours; then the temperature was raised to 60°C and the holding time was 15 hours, and the composite solid D was obtained after cooling down. The composite solid D was transferred to a tube furnace, and was heat-treated at 800°C for 20 hours in a pure oxygen atmosphere to obtain a 3D cross-linked interpenetrating network high-nickel ternary cathode mat...

Embodiment 2

[0047] Prepare bagasse cellulose (SBC), sodium hydroxide, and urea into solutions A with mass fractions of 6%, 8%, and 16% respectively; lithium nitrate, nickel nitrate, cobalt nitrate, and manganese nitrate Molar ratio 1.06:0.85:0.12:0.03 Dispersed in deionized water, prepared as metal ion solution B; N-isopropylacrylamide, N,N'-methylenebisacrylamide, ammonium persulfate configured as mass fraction 1%, 0.1% and 0.1% solution C respectively;

[0048] After synchronously adding solution A, solution B and solution C to the reaction kettle, the temperature was raised to 50°C and the holding time was 6 hours; then the temperature was raised to 80°C and the holding time was 8 hours, and the composite solid D was obtained after cooling down. The composite solid D was transferred to a tube furnace, and heat-treated at a high temperature of 750°C for 15 hours in a pure oxygen atmosphere to obtain a 3D cross-linked interpenetrating network high-nickel ternary cathode material matrix. ...

Embodiment 3

[0051] Hydroxyethyl cellulose (HEC), sodium hydroxide, and urea were formulated into solutions A with mass fractions of 3%, 6%, and 13% respectively; lithium carbonate, nickel acetate, cobalt acetate, and manganese acetate were The element molar ratio is 1.12:0.9:0.07:0.03 dispersed in deionized water and prepared as metal ion solution B; Solutions C with fractions of 3%, 0.3% and 0.5%, respectively;

[0052] After synchronously adding solution A, solution B and solution C to the reaction kettle, the temperature was raised to 40°C and the holding time was 10 hours; then the temperature was raised to 70°C and the holding time was 10 hours, and the composite solid D was obtained after cooling down. The composite solid D was transferred to a tube furnace, and was heat-treated at 700°C for 15 hours in a pure oxygen atmosphere to obtain a 3D cross-linked interpenetrating network high-nickel ternary cathode material matrix.

[0053] Meta-bis(2,4-diaminobenzenesulfonate lithium), po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com