Preparation method of small-particle size ternary positive material precursor

A cathode material and precursor technology, which is applied in the field of preparation of small particle size ternary cathode material precursors, can solve the problems of poor stability, easy self-discharge, low tap density, etc., and achieves simple process operation, easy recycling, The effect of high tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

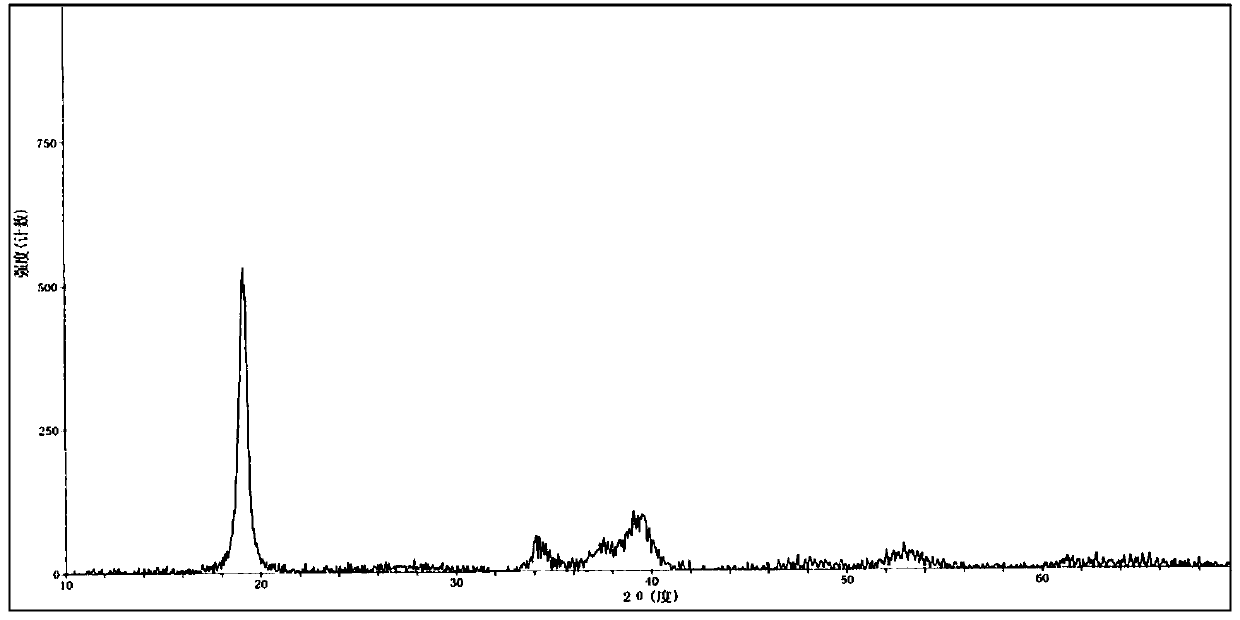

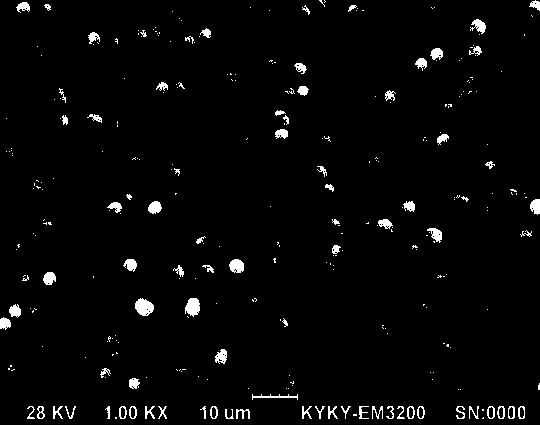

[0026] The invention discloses a preparation method of a small particle size ternary cathode material precursor, which comprises the following steps:

[0027] (1) Select nickel-cobalt-manganese liquid as the raw material to prepare mixed metal salt solution, add special reaction bottom liquid to the reactor in advance, and add the metal salt solution, complexing agent and precipitant solution in parallel to the reaction according to the stoichiometric ratio In the kettle; the temperature is controlled at 60°C; the pH is controlled at 11.5; the rotating speed is 200r / min; the whole reaction is carried out under N 2 under protection;

[0028] (2) The first time the kettle is full, the D50 particle size is controlled at 1~2μm. When the reactor is full, it will directly overflow from the overflow pipe to the prepared aging kettle, and the particle size in the reactor will grow to 3.5-4.0μm after 20 hours. Immediately stop feeding;

[0029] (3) Then mix the reactor slurry and the...

Embodiment 2

[0033] The invention discloses a preparation method of a small particle size ternary cathode material precursor, which comprises the following steps:

[0034] (1) Select nickel-cobalt-manganese liquid as the raw material to prepare mixed metal salt solution, add special reaction bottom liquid to the reactor in advance, and add the metal salt solution, complexing agent and precipitant solution in parallel to the reaction according to the stoichiometric ratio In the kettle; the temperature is controlled at 40°C; the pH is controlled at 11; the rotating speed is 500r / min; the whole reaction is carried out under the protection of N2;

[0035] (2) The first time the kettle is full, the D50 particle size is controlled at 1~2μm. When the reactor is full, it will directly overflow from the overflow pipe to the prepared aging kettle, and the particle size in the reactor will grow to 3.5-4.0μm after 15 hours. Immediately stop feeding;

[0036] (3) Then mix the reactor slurry and the ag...

Embodiment 3

[0040] The invention discloses a preparation method of a small particle size ternary cathode material precursor, which comprises the following steps:

[0041] (1) Select nickel-cobalt-manganese liquid as the raw material to prepare a metal mixed salt solution, add a special reaction bottom liquid to the reactor in advance, and add the metal salt solution, complexing agent and precipitant solution in parallel to the reaction according to the stoichiometric ratio In the kettle; the temperature is controlled at 20°C; the pH is controlled at 12; the rotating speed is 350r / min; the whole reaction is carried out under the protection of N2;

[0042] (2) The first time the kettle is full, the D50 particle size is controlled at 1~2μm. When the reactor is full, it will directly overflow from the overflow pipe to the prepared aging kettle, and the particle size in the reactor will grow to 3.5-4.0μm after 10 hours. Immediately stop feeding;

[0043] (3) Then mix the reactor slurry and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com