Preparation method of modified positive electrode material, and lithium ion battery

A positive electrode material and modification technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of high price, serious volatilization of organic solvents, and serious human injury, and achieve reduction of gas production, reduction of residual alkali content, and improvement of The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

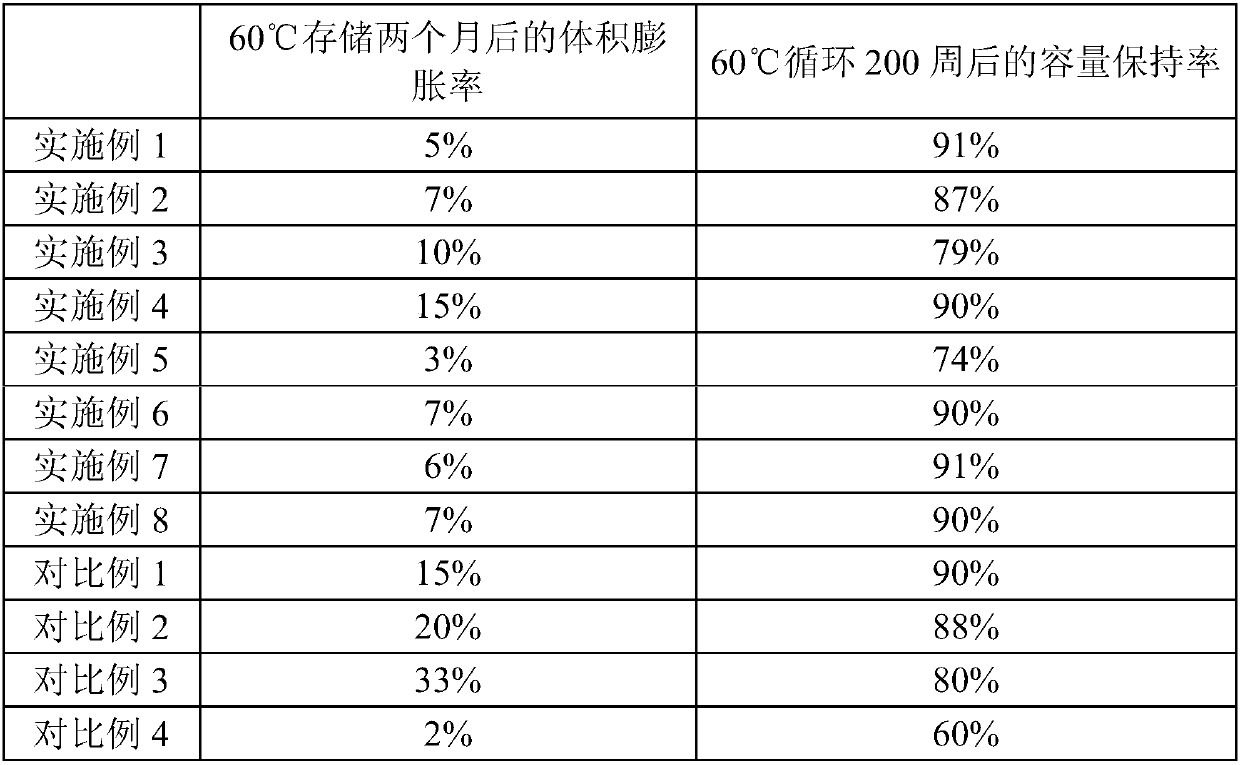

Examples

preparation example Construction

[0012] The preparation method of the modified positive electrode material according to the first aspect of the present invention comprises the steps of: mixing the layered positive electrode active material with an acid with a boiling point not greater than 600°C (corresponding to "the acid" below) and / or an acid with a boiling point not greater than 600°C The acid salt of the acid (corresponding to "the acid salt" below) is mixed and heated above the boiling point temperature or sublimation temperature of the acid, or heated to the decomposition temperature, boiling point temperature or sublimation temperature of the acid salt Heat treatment is performed above the temperature to make the acid and / or acid salt into a gaseous state to react with the residual base on the surface of the layered positive electrode active material to reduce the content of the residual base to obtain a modified positive electrode material. Wherein, "the decomposition temperature of the acid salt" ref...

Embodiment 1

[0038] (1) Preparation of positive electrode sheet

[0039] The positive electrode active material LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Mix with oxalic acid at a mass ratio of 1:0.05, and then ball mill and dry mix for 1 hour to prepare the mixture; put the above-prepared mixture in a muffle furnace, raise the temperature to 100°C under the condition of feeding air, and keep it warm 5h, then raised the temperature to 450°C, kept the temperature for 5h, and then cooled to room temperature to obtain the modified cathode material.

[0040] Mix the above-mentioned modified positive electrode material, binder polyvinylidene fluoride, and conductive agent acetylene black according to the mass ratio of 98:1:1, add N-methylpyrrolidone (NMP), and stir under the action of a vacuum mixer until the system is uniform Transparent to obtain the positive electrode slurry; apply the positive electrode slurry evenly on the aluminum foil of the positive electrode current collector with a thickness of ...

Embodiment 2

[0050] The preparation process of the lithium-ion battery is the same as in Example 1, the difference is that in the preparation of the positive electrode sheet, the positive active material is LiNi 0.6 co 0.2 mn 0.2 o 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com