Femtosecond laser preparation method for uniform and thick mesoporous titanium oxide nanometer particle film

A nanoparticle and thin film preparation technology, applied in nanotechnology, ion implantation plating, coating and other directions, can solve the problems of low film adhesion, complicated operation, etc., and achieve the convenience of doping or compounding other materials and the particle deposition efficiency Increase and improve the effect of single pulse energy and pulse width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

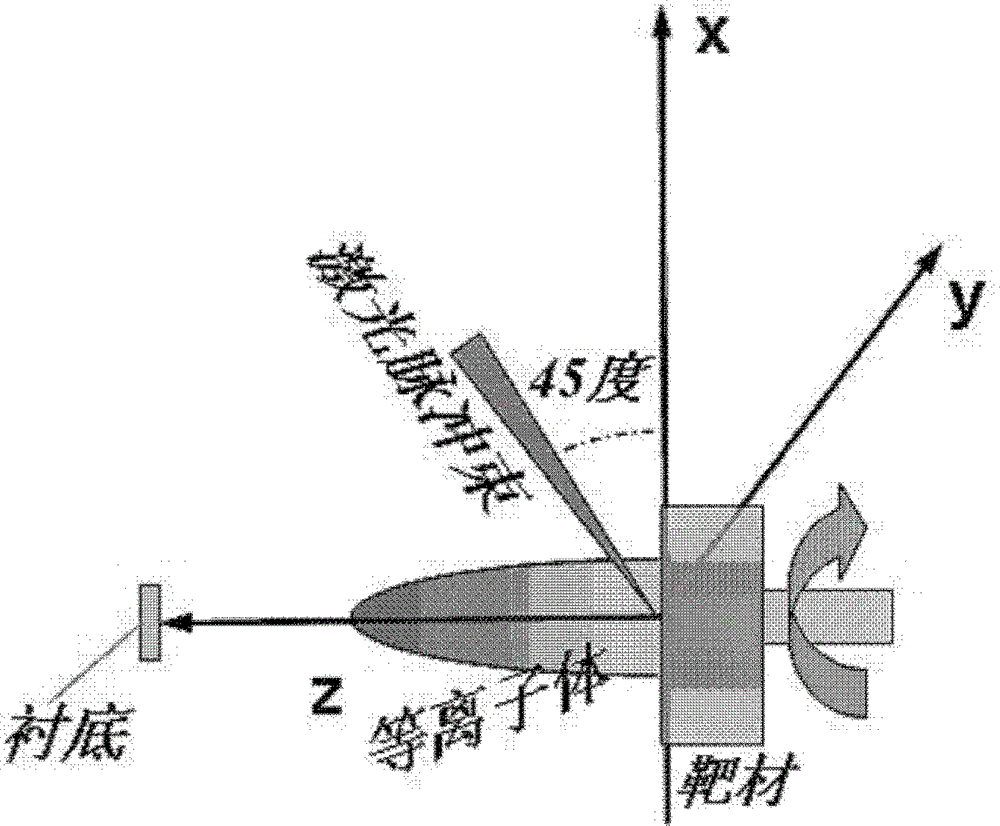

[0040] Using a femtosecond laser sputtering deposition device ( figure 1 ), using a Nd:Glass femtosecond frequency-doubled pulse laser with a pulse width of 300fs, a center wavelength of 537nm, a repetition rate of 33Hz, and a single pulse energy of 0.8mJ. Energy attenuator, gold-plated mirror, plano-convex focusing objective lens and silicon oxide transmission window in the vacuum target chamber, finally focusing on the target surface at an angle of 45 degrees vertical to the target surface, with an air pressure of 10 - 7 mbar, the laser beam is controlled by computer software to sweep the gold-plated surface within 1cm outside the center point of the rutile phase titanium oxide (99.99%) target surface, and the marble substrate with a diameter of 1cm is used as the substrate, and the distance between the substrate and the target is 35cm. The energy flux density is about 0.36J / cm 2 The laser beam irradiates the target, and the deposition time is 10 seconds. Titanium oxide na...

Embodiment 2

[0042] Using a femtosecond laser sputtering deposition device ( figure 1 ), using a Nd:Glass femtosecond frequency-doubled pulse laser with a pulse width of 300fs, a center wavelength of 537nm, a repetition rate of 33Hz, and a single pulse energy of 0.8mJ. Energy attenuator, gold-plated mirror, plano-convex focusing objective lens and silicon oxide transmission window in the vacuum target chamber, finally focusing on the target surface at an angle of 45 degrees vertical to the target surface, with an air pressure of 10 - 7 mbar, the laser beam is controlled by computer software to sweep the gold-plated surface within 1cm outside the center point of the rutile phase titanium oxide (99.99%) target surface, and the 0.5×1cm titanium foil after physical grinding and polishing is used as the substrate, the substrate and the target The distance is 35cm, and the energy flux density is 1.4J / cm 2 The laser beam irradiates the target, and the nanoparticles are sputtered and deposited f...

Embodiment 3

[0044] Using a femtosecond laser sputtering deposition device ( figure 1 ), using a Nd:Glass femtosecond frequency-doubled pulse laser with a pulse width of 300fs, a center wavelength of 537nm, a repetition rate of 33Hz, and a single pulse energy of 0.8mJ. Energy attenuator, gold-plated mirror, plano-convex focusing objective lens and silicon oxide transmission window in the vacuum target chamber, finally focusing on the target surface at an angle of 45 degrees vertical to the target surface, with an air pressure of 10 - 7 mbar, the laser beam is controlled by computer software to sweep the gold-plated surface within 1cm outside the center point of the rutile phase titanium oxide (99.99%) target surface, and the 0.5×1cm titanium foil after physical grinding and polishing is used as the substrate, the substrate and the target The distance is 35cm, and the energy flux density is 1.4J / cm 2 The laser beam irradiates the target, the nanoparticles are sputtered and deposited for 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com