High-speed rail contact system complete compensating door type elastic chain type hanging construction method

A high-speed railway and catenary technology, applied in the direction of overhead lines, etc., can solve problems such as failure to ensure normal operation, difficulty in pantograph-catenary contact performance, and reduced flow quality, so as to facilitate construction organization, fast construction speed, and pantograph-catenary flow good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

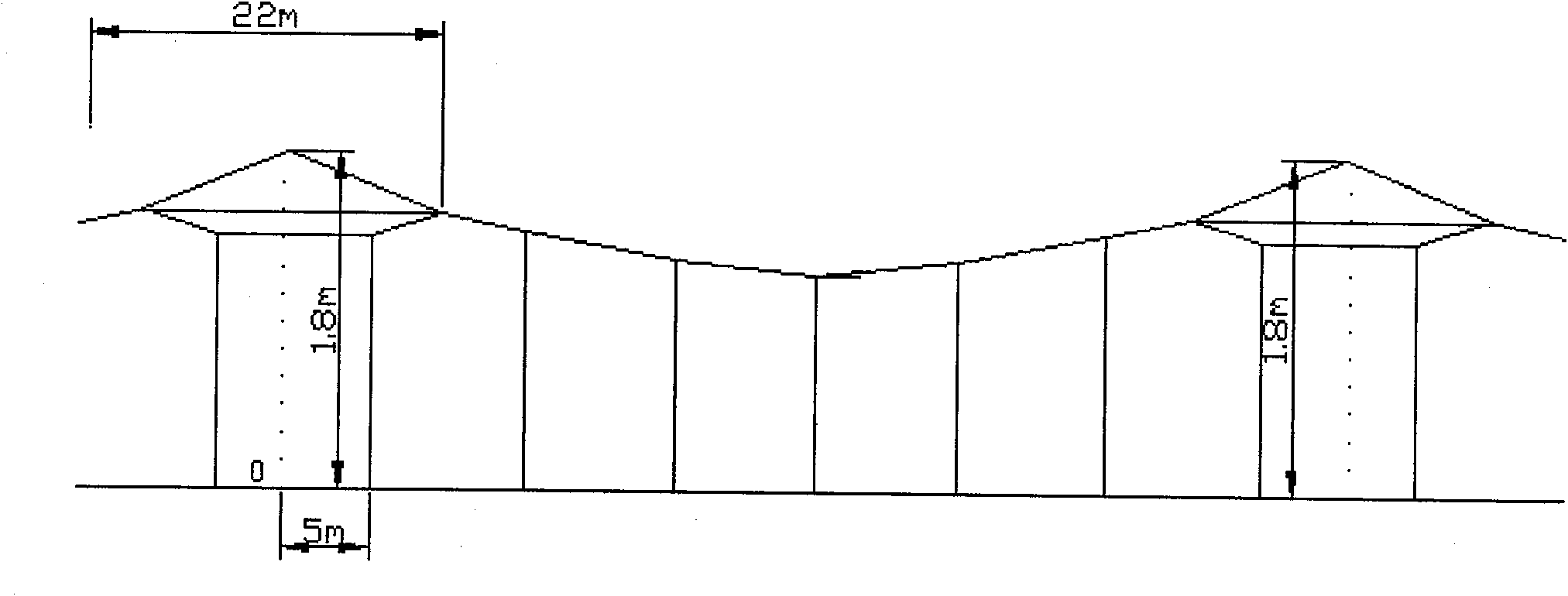

[0063] After the catenary cable is erected and poured into the catenary cable seat, install the central anchor of the catenary cable, and adjust the pre-deflection of the arm and arm according to the ambient temperature. The pre-deflection of the arm and arm is calculated according to the following formula:

[0064] E=L×α×(t safety-t level);

[0065] If the span of the pillars is 50 meters, the design average temperature is 25 degrees, the installation environment temperature is 40 degrees, and the coefficient of linear expansion α is 0.000017; then the pre-deflection dimensions from the center anchor to the two sides of the wrist arm are:

[0066] E1=50*0.000017*(40-25)=0.01275m;

[0067] E2 = 0.0255m;

[0068] E3 = 0.03825m;

[0069] E4=0.051m;

[0070] …………

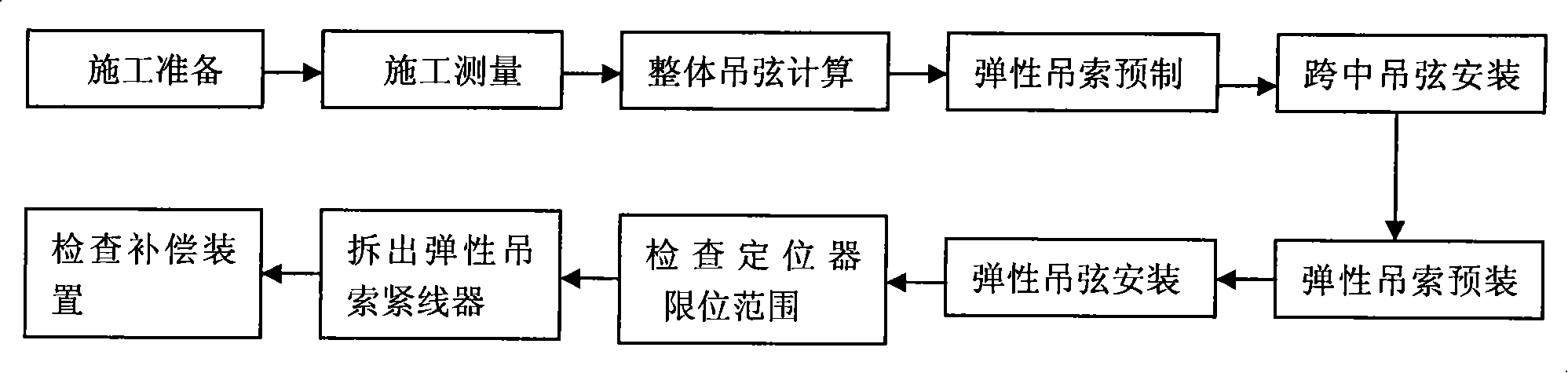

[0071]Next, construction measurement and parameter determination are carried out, which include: pillar number, number of spans of this anchor section, tension of contact line, tension of catenary cable...

Embodiment 2

[0090] After the catenary cable is erected and poured into the catenary cable seat, install the central anchor of the catenary cable, and adjust the pre-deflection of the arm and arm according to the ambient temperature. The pre-deflection of the arm and arm is calculated according to the following formula:

[0091] E=L×α×(t safety-t level);

[0092] If the span of the pillars is 60 meters, the design average temperature is 25 degrees, the installation environment temperature is 5 degrees, and the linear expansion coefficient α is taken as 0.000017; then the offset dimensions of the wrist arm to the middle anchor direction are:

[0093] E1=60*0.000017*(5-25)=0.02m;

[0094] E2 = 0.04m;

[0095] E3 = 0.06m;

[0096] E4=0.08m;

[0097] …………

[0098] Next, construction measurement and parameter determination are carried out, which include: pillar number, number of spans of this anchor section, tension of contact line, tension of catenary cable, tension of elastic sling, self-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com