Preparation method of lead tungstate powder with high scintillation property

A lead tungstate performance technology, applied in chemical instruments and methods, tungsten compounds, inorganic chemistry, etc., can solve the problems of inability to achieve high scintillation performance and low light yield of lead tungstate crystals, and achieve excellent scintillation performance, experimental The effect of low equipment requirements and high controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] a) First weigh lead acetate and sodium tungstate according to the stoichiometric ratio, and then use deionized water to prepare the weighed lead acetate and sodium tungstate respectively into lead acetate solution with a concentration of 0.05mol / L and sodium tungstate with a concentration of 0.05mol / L solution;

[0040] b) Stir and heat the lead acetate solution and the sodium tungstate solution, and control the heating temperature at 50-70°C;

[0041] c) adding ammonia water dropwise to adjust the pH value of the sodium tungstate solution to 9;

[0042] d) Pour the lead acetate solution into the separatory funnel, drop it into the sodium tungstate solution at a uniform rate, lead ions and tungstate ions react chemically to form lead tungstate precipitates;

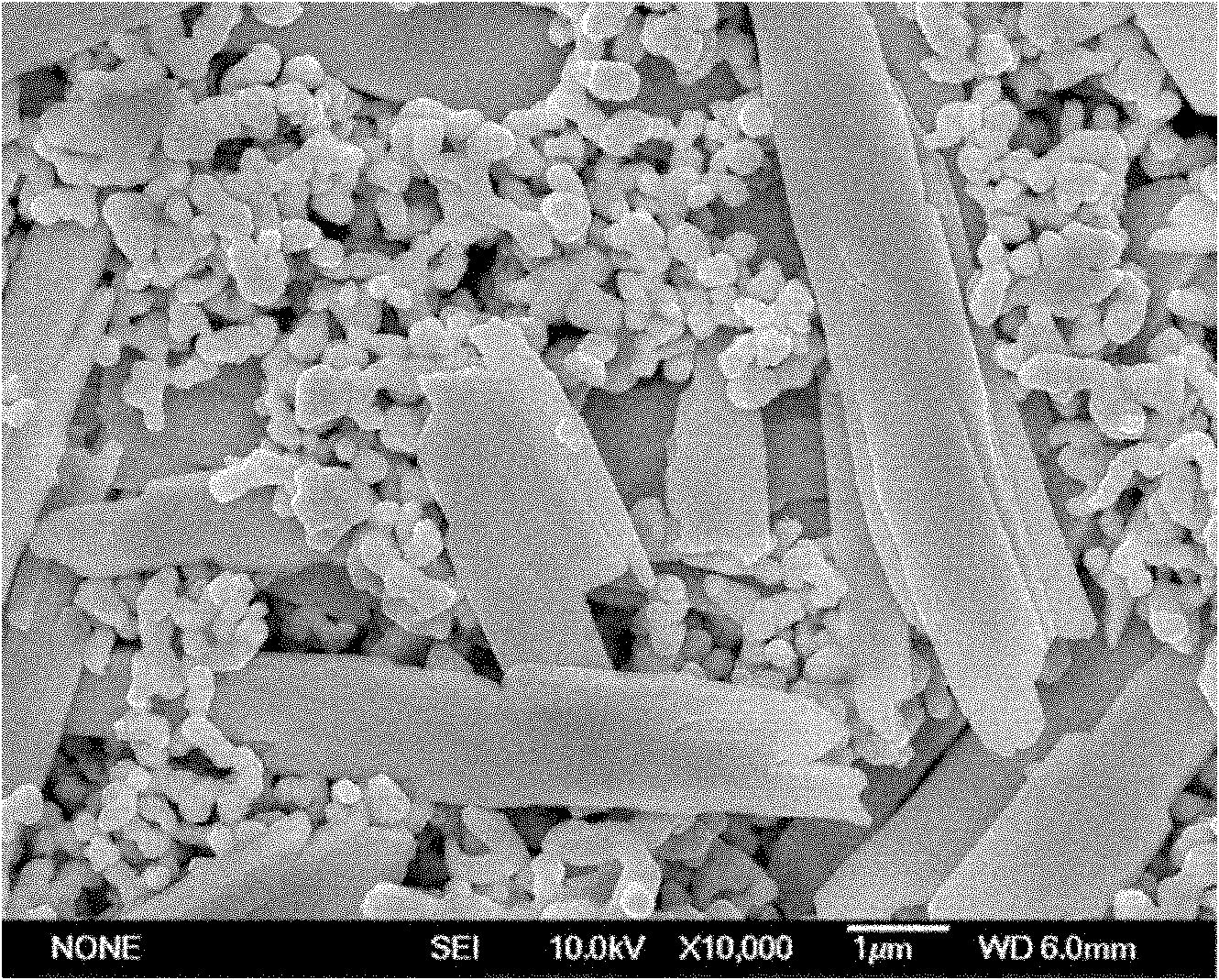

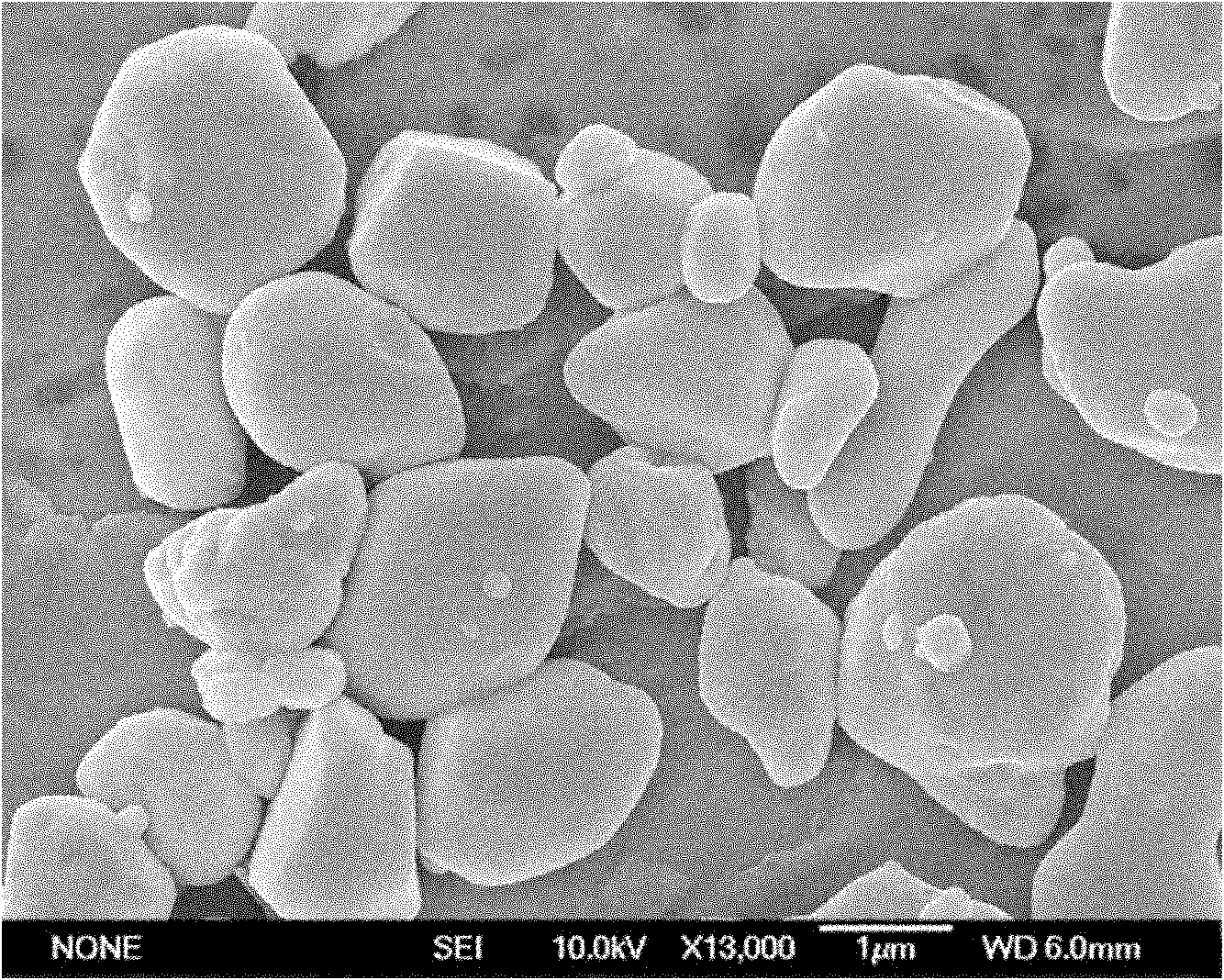

[0043] e) Dry the obtained lead tungstate precipitate at 80°C after repeated filtration and cleaning to obtain lead tungstate grains;

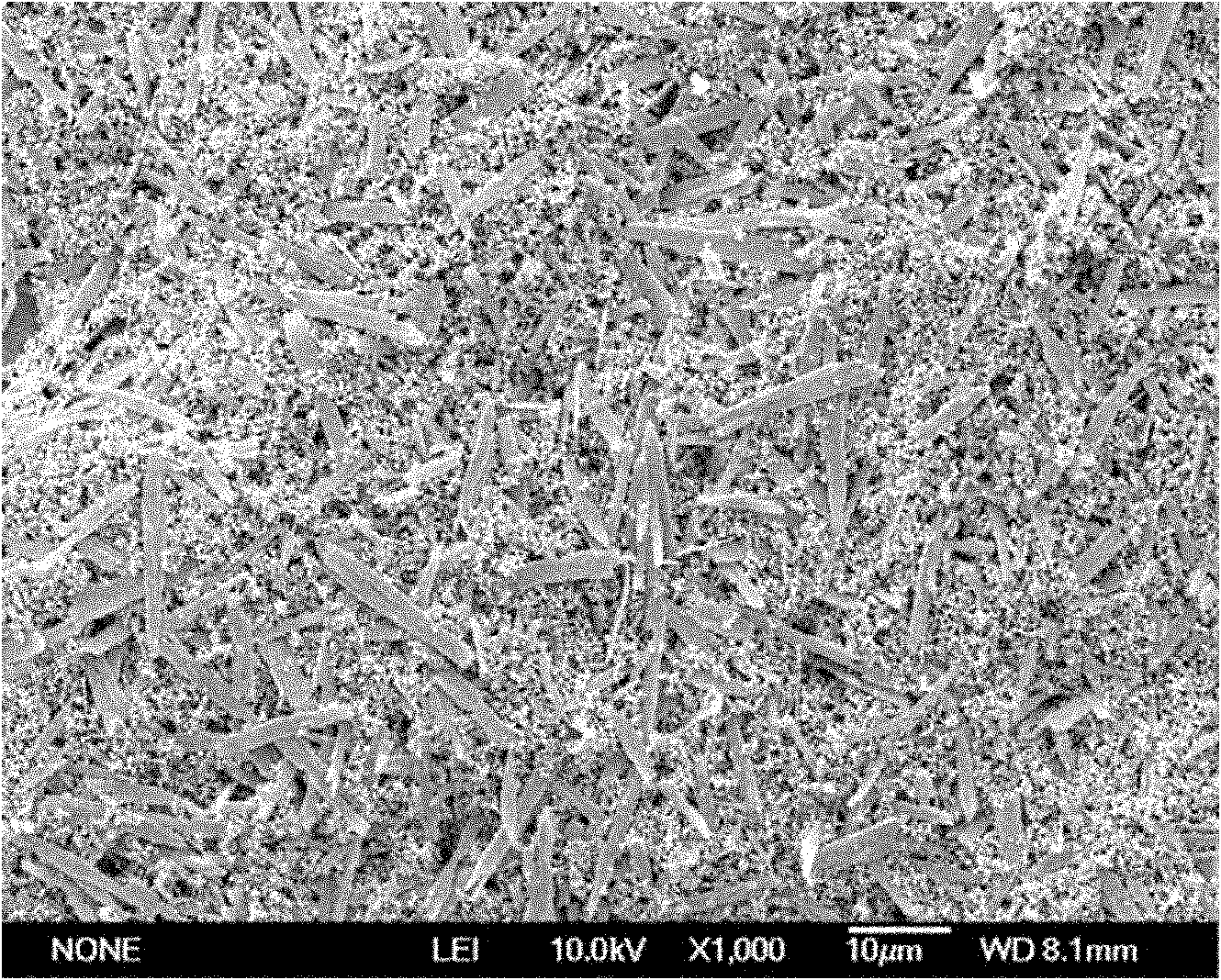

[0044] f) Heat treatment of lead tungstate grains at different temperatures,...

Embodiment 2

[0052] a) First weigh lead acetate and sodium tungstate according to the stoichiometric ratio, and then use deionized water to prepare the weighed lead acetate and sodium tungstate respectively into lead acetate solution with a concentration of 0.05mol / L and sodium tungstate with a concentration of 0.05mol / L solution;

[0053] b) Stir and heat the lead acetate solution and the sodium tungstate solution, and control the heating temperature at 50-70°C;

[0054] c) adding ammonia water dropwise to adjust the pH value of the sodium tungstate solution to 7;

[0055] d) Pour the lead acetate solution into the separatory funnel, drop it into the sodium tungstate solution at a uniform rate, lead ions and tungstate ions react chemically to form lead tungstate precipitates;

[0056] e) Dry the obtained lead tungstate precipitate at 80°C after repeated filtration and cleaning to obtain lead tungstate grains;

[0057] f) heat-treating the lead tungstate grains at 500°C to obtain lead tu...

Embodiment 3

[0059] The difference between this example and Example 2 is "step c) adding ammonia water dropwise to adjust the pH value of the sodium tungstate solution to 11", and the rest of the content is the same as that described in Example 2.

[0060] Figure 7 It is the relationship diagram of the luminous peak position and luminous intensity of the lead tungstate powder prepared at different pH values. It can be seen that the lead tungstate powder prepared under the condition of pH=7 has good scintillation performance, but the performance Slightly lower than the lead tungstate powder prepared under the condition of pH=9; the lead tungstate powder prepared under the condition of pH=11 is basically the same as the lead tungstate powder prepared under the condition of pH=9 The scintillation performance; and with the increase of pH value, the luminescence peak position of the prepared lead tungstate powder will be slightly red-shifted, and the red-shift range is 460-490nm, but it still ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com