Method for producing high-purity bismuth oxide from bismuth-containing materials

A technology of bismuth oxide and bismuth hydroxide, applied in chemical instruments and methods, bismuth compounds, inorganic chemistry, etc., can solve the problems of complex process, large environmental pollution, high cost, etc., and achieve the effect of simple process and low reagent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

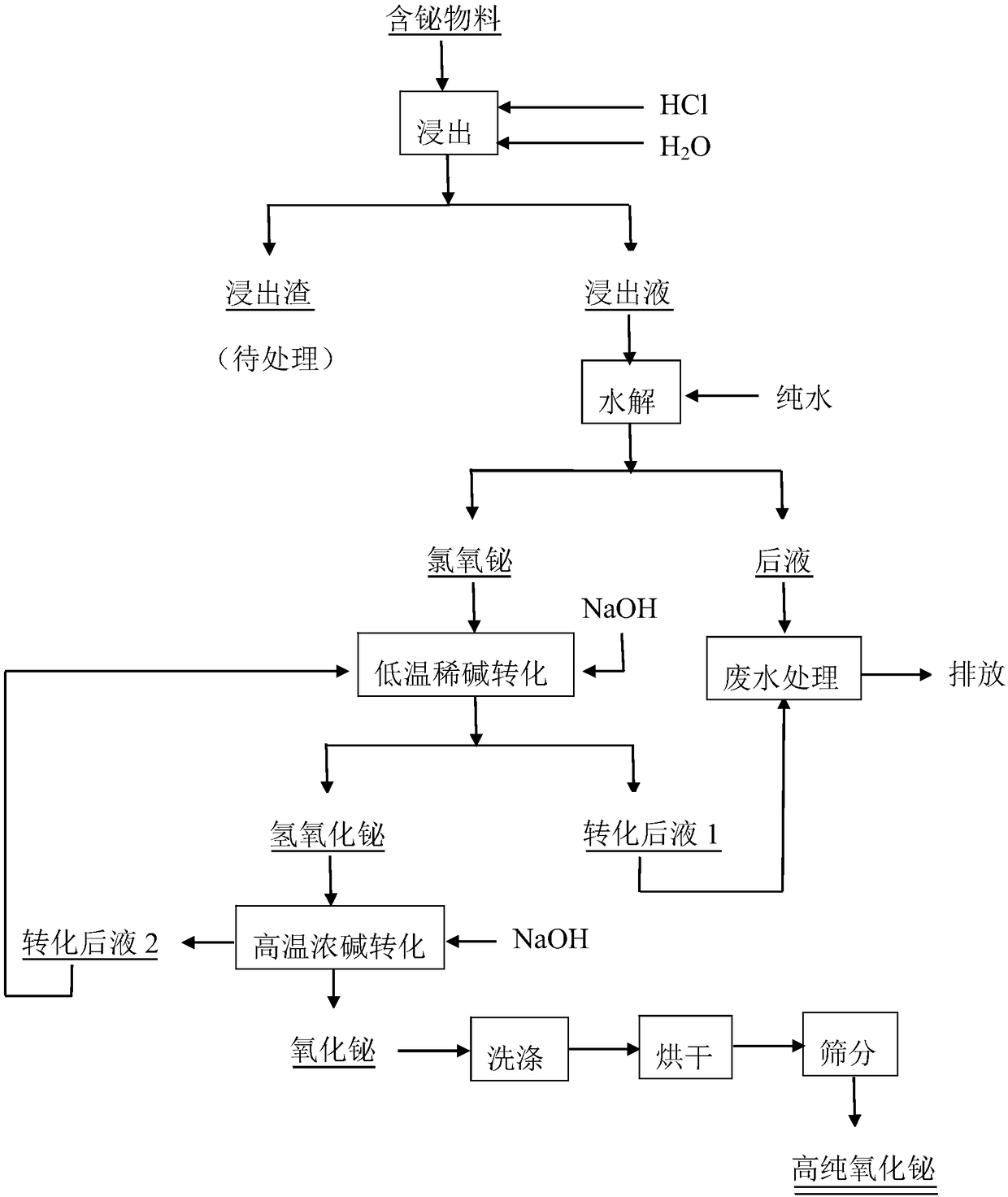

[0018] A method for producing high-purity bismuth oxide from bismuth-containing materials, comprising the following processes:

[0019] Leaching process: The bismuth-containing material is leached with hydrochloric acid solution, the concentration of hydrochloric acid is 150g / L, the liquid-solid ratio is 5:1 (mL / g), the leaching reaction time is 2h, and mechanical stirring is performed at the same time, and the stirring speed is 200 rpm The bismuth in the bismuth-containing material enters the solution in the form of bismuth chloride;

[0020] Hydrolysis process: add deionized water to the solution, dilute the solution to 5 times of the original, bismuth chloride undergoes a hydrolysis reaction to precipitate bismuth oxychloride, and after standing for 2 to 3 hours, filter out the bismuth oxychloride precipitate;

[0021] Low-temperature dilute alkali conversion: add dilute alkali to the separated bismuth oxychloride precipitate, dilute alkali is sodium hydroxide solution, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com