Organic chloride removing method for waste cooking oil

A technology for catering waste oil and organochlorine, which is applied in the direction of fat oil/fat refining, fat production, fatty acid production, etc. It can solve the problems of low organic chlorine removal rate, immaturity, and damage to equipment and pipelines, so as to improve the dechlorination effect, The effect of low cost and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

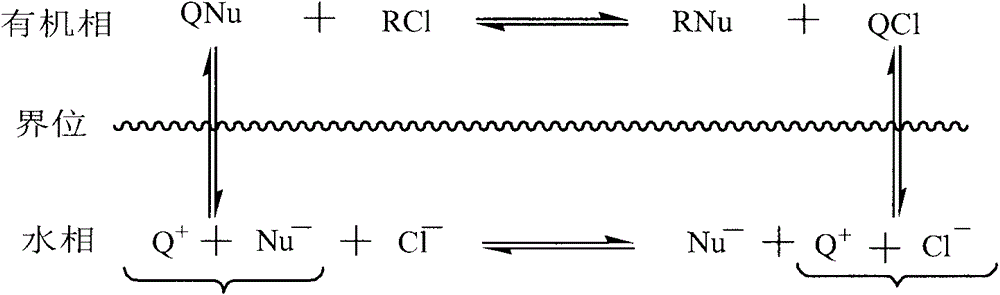

Method used

Image

Examples

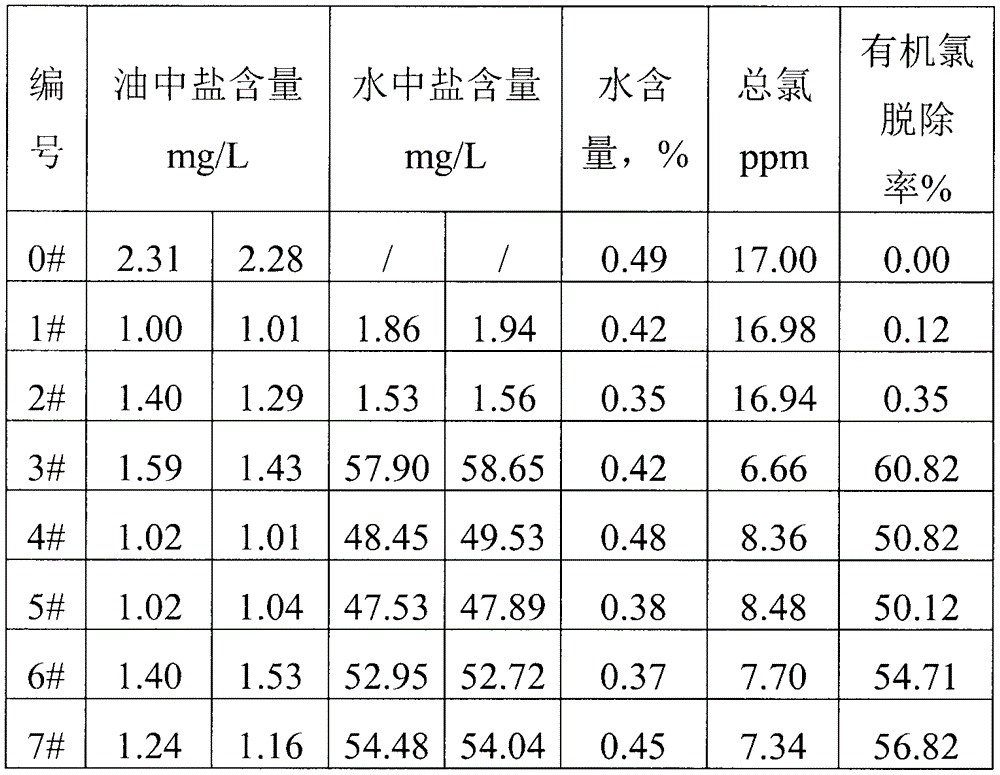

Embodiment 1

[0039] Base oil preparation: The base oil is obtained after three consecutive desalination and dehydration of the raw material of waste catering oil. The base oil test can fully eliminate the influence of inorganic chlorine, and verify the test effect more conveniently and quickly.

[0040] Pre-desalination and dehydration test conditions: temperature 90°C, electric field strength 1300V / cm, water injection 12wt%, shaking 200 times, residence time 30min. There are three stages of pre-desalting, and the pre-desalting conditions of each stage are the same.

[0041] Considering that the content of inorganic chlorine in the base oil is very low, it is assumed that all the residual chlorine is organic chlorine, and the total chlorine m is analyzed and detected. 0 is 17ppm. After the dechlorination reaction and electro-stripping, the upper oil sample and the lower water sample were taken for salt and water analysis, and the upper oil sample was taken for total chlorine analysis. Co...

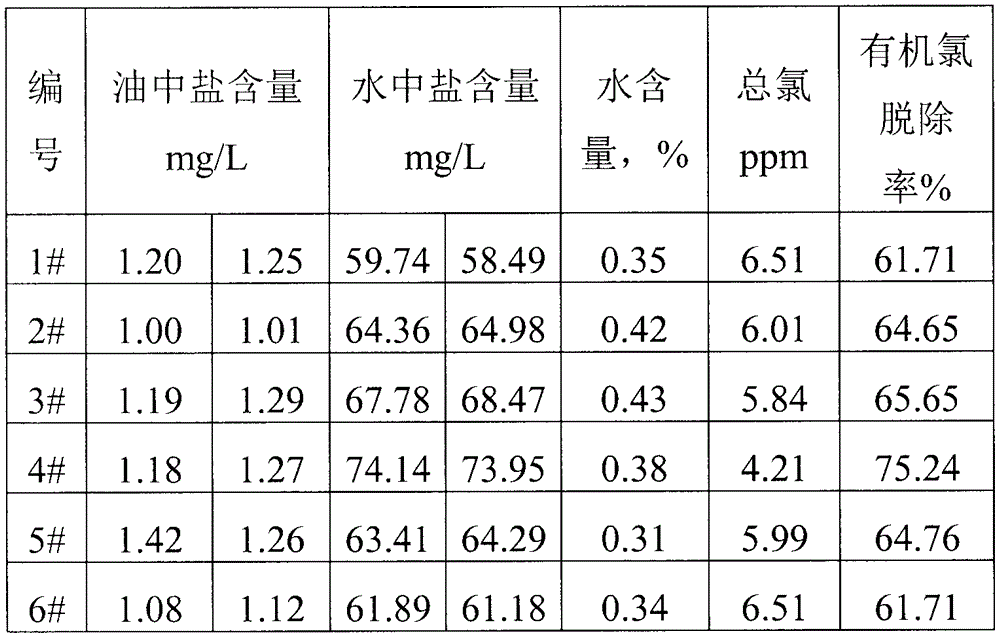

Embodiment 2

[0062] Use benzyltrimethylammonium hydroxide as the organochlorine transfer agent B, the base oil used is the same as in Example 1, select a different type of organochlorine transfer agent A, and the auxiliary agent C is compounded with B benzyltrimethylammonium hydroxide , dosage remains unchanged, still 170ppm, agent-to-chlorine ratio (mass ratio)=10: 1, operating procedure is identical with embodiment 1, other technological conditions are constant, investigates different types of organochlorine conversion agent A to dechlorination performance The experimental results are shown in Table 2.

[0063] The proportion of dechlorination agent added to each component is:

[0064] The components of 1# dechlorination agent are: A sodium ethylate 70%wt, B benzyltrimethylammonium hydroxide 20wt%, C glycerin 10%wt;

[0065] 2# dechlorination agent components are: A sodium methoxide 70%wt, B benzyltrimethylammonium hydroxide 20wt%, C glycerol 10%wt;

[0066] 3# dechlorination agent com...

Embodiment 3

[0074] Adopt A (potassium methylate)-B (benzyltrimethylammonium hydroxide)-C (glycerol) as compound system, change the ratio of A, B, operation procedure is the same as embodiment 2, investigate A, B The effect of the ratio on the dechlorination performance, the experimental results are shown in Table 3. Electrodesalination conditions are the same as those in Examples 1 and 2 above. The base oil used is the same as in Example 1.

[0075] The amount of dechlorination agent added is 170ppm, and the ratio of agent to chlorine (mass ratio) is 10: 1, and the proportions of the components of the dechlorination agent added are respectively:

[0076] 1#A Potassium methoxide 70%wt, B benzyltrimethylammonium hydroxide 20%wt, C glycerol 10%wt;

[0077] 2#A Potassium methoxide 65%wt, B benzyltrimethylammonium hydroxide 25%wt, C glycerol 10%wt;

[0078] 3#A Potassium methoxide 60%wt, B benzyltrimethylammonium hydroxide 30%wt, C glycerin 10%wt;

[0079] 4#A Potassium methoxide 55%wt, B ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com