A ZSM-5 molecular sieve, a preparing method thereof and applications of the molecular sieve

A ZSM-5, molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of not exceeding 40, large grain size, easy to agglomerate, etc., and achieve the aspect ratio Large, good dispersion, regular appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

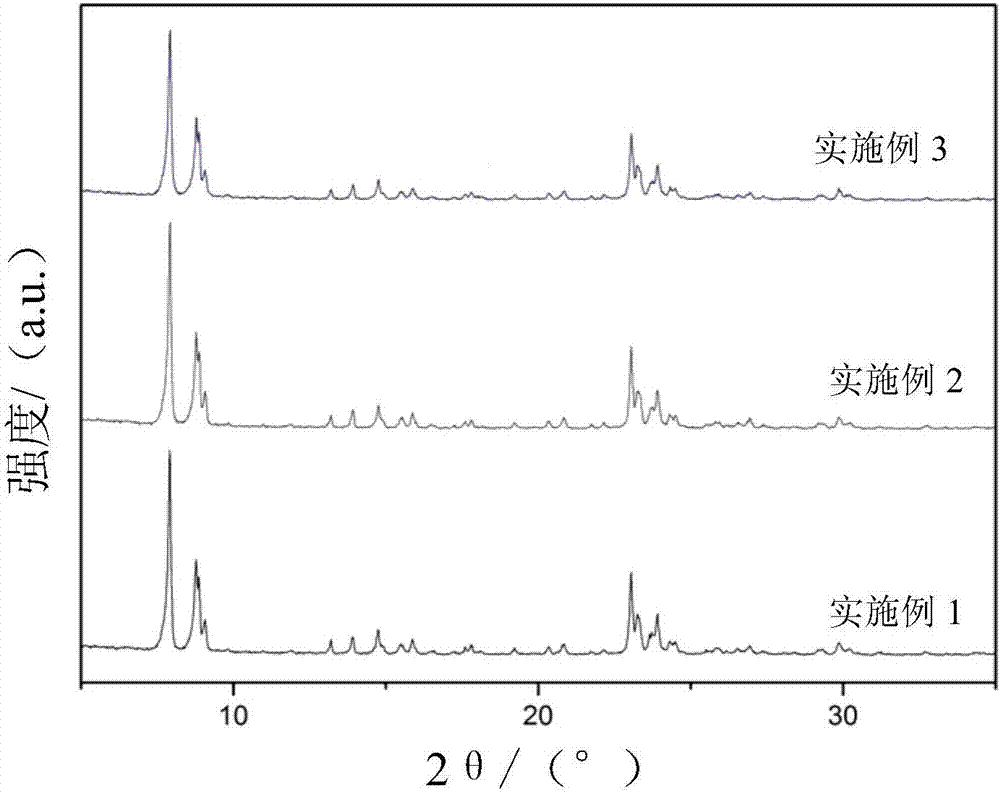

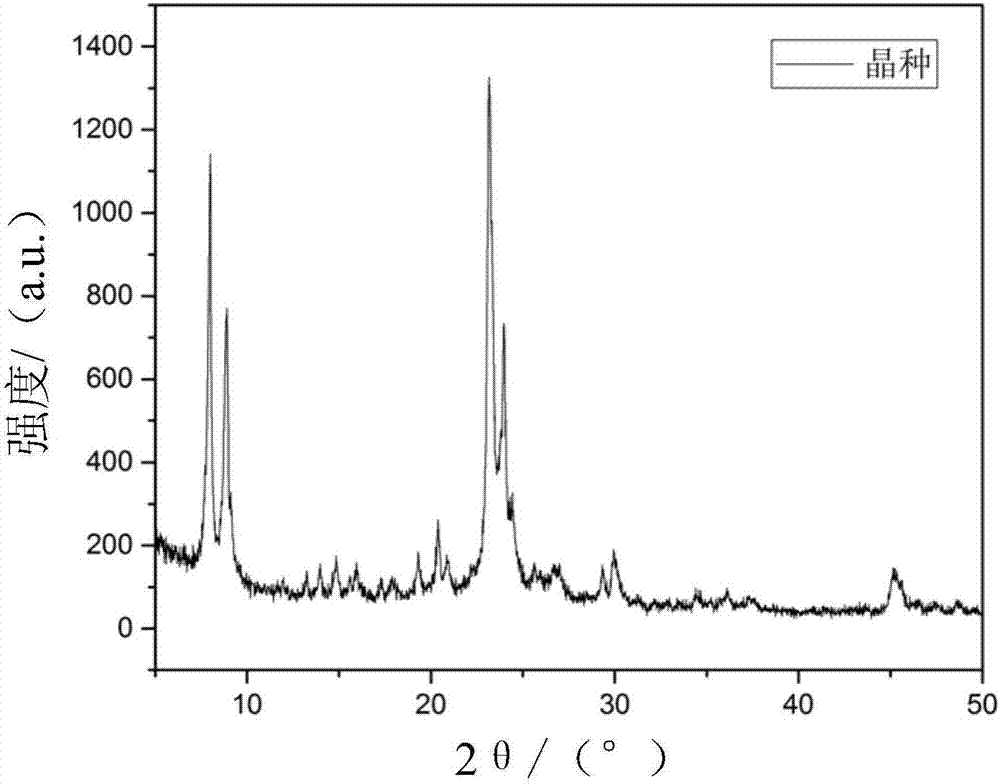

[0063] Dissolve 8.61g of ethanol in 17.36g of deionized water, add 0.84g of concentrated sulfuric acid to form a uniform mixed solution A; mix and stir for 10min at 60°C and then add 0.216g of aluminum sulfate (Al 2 (SO 4 ) 3 18H 2 (0), then add 0.19g seed crystals (silicon-aluminum ratio 90, particle size is 5 μm, average flake size 30nm, as figure 2 , Figure 6 shown). Continue to stir for 1h, finally add 10g water glass (19wt.%SiO 2 , Si / Na=1.11) and 10g deionized water. After aging for 6h, the mixed gel SiO 2 :Al 2 o 3 :Seed:Na 2 O:Alcohol:SO 4 2- :H 2 O=100:1:1.2:40:500:25:7000, crystallized at 140°C for 200h, filtered, washed and dried the crude product to obtain the original ZSM-5 molecular sieve powder (the average length of the sheet is 2μm, The average thickness is 340 μm). Related spectra such as figure 1 , 3 and 5. The silica-alumina ratio of the prepared molecular sieve is shown in Table 1.

Embodiment 2

[0065] Dissolve 8.61g of ethanol in 17.36g of deionized water, add 0.76g of concentrated sulfuric acid to form a uniform mixed solution A; mix and stir for 10min at 60°C and then add 0.072g of aluminum sulfate (Al 2 (SO 4 ) 3 18H 2 O), then add 0.19g seed crystals (silicon to aluminum ratio 120, average particle size 4 μm, average flake size 20nm). Continue to stir for 1h, finally add 10g water glass (19wt.%SiO 2 , Si / Na=1.11) and 10g deionized water. After 6h of stirring, the mixed gel SiO 2 :Al 2 o 3 :Seed:Na 2 O:Alcohol:SO 4 2- :H 2 O=100:0.5:1.5:30:300:15:5000, crystallized at 140°C for 120h, filtered, washed and dried the crude product to obtain ZSM-5 molecular sieve powder (the average length of the sheet is 1.5μm , with an average thickness of 280 μm).

Embodiment 3

[0067] Dissolve 8.61g of ethanol in 17.36g of deionized water, add 0.84g of concentrated sulfuric acid to form a uniform mixed solution A; mix and stir for 10min under the condition of 60°C, and then add 0.043g of aluminum sulfate (Al 2 (SO 4 ) 3 18H 2 O), then add 0.19g seed crystals (silicon to aluminum ratio 154, average particle size 3 μm, average flake size 15 nm). Continue to stir for 1h, finally add 10g water glass (19wt.%SiO 2 , Si / Na=1.11) and 10g deionized water. After 6h of stirring, the mixed gel SiO 2 :Al 2 o 3:Seed:Na 2 O:Alcohol:SO 4 2- :H 2 O=100:0.3:2:40:700:30:7000, crystallize at 140°C for 72h, filter, wash and dry the crude product to obtain ZSM-5 molecular sieve powder (the average length of the sheet is 1.2μm , with an average thickness of 220 μm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com