Preparation method of spherical aluminum hypophosphite

A technology of aluminum hypophosphite and sodium hypophosphite, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as the decline of mechanical properties, reduce the decline of mechanical properties, improve the flame retardant effect, and crystal form regular effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Formula (parts by weight): sodium hypophosphite 90, aluminum sulfate octadecahydrate 110, water 200, melamine cyanurate 5, polyacrylamide 2.5.

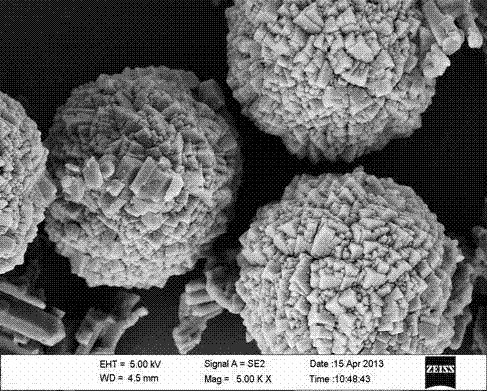

[0020] Preparation method: Weigh the raw materials according to the above-mentioned parts by weight, first add water as a solvent into the reaction vessel, start stirring, add aluminum sulfate octadecahydrate and melamine cyanurate into the reaction kettle, add polyacrylamide at the same time, stir evenly and heat up to 60 °C. After ℃, sodium hypophosphite was added, and the temperature was raised to 80 ℃ with stirring, and then the temperature was maintained, and the stirring reaction was continued for 4 hours to generate aluminum hypophosphite slurry. The aluminum hypophosphite slurry is filtered, dried and pulverized to obtain spherical aluminum hypophosphite with a particle size of 3.8 microns. The electron microscope photos of this example are shown in figure 1 .

Embodiment 2

[0022] Formula (parts by weight): 100 sodium hypophosphite, 120 aluminum sulfate octadecahydrate, 250 water, 30 melamine cyanurate, 1.8 sodium dodecylbenzenesulfonate.

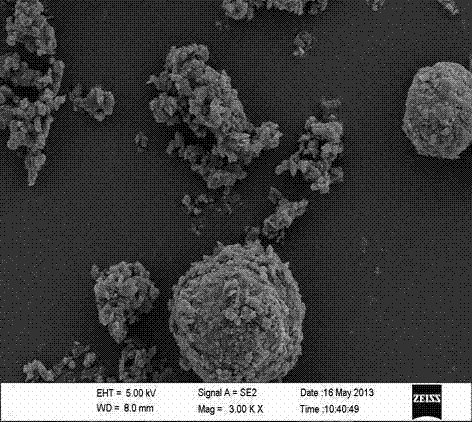

[0023] Preparation method: weigh the raw materials according to the above-mentioned parts by weight, firstly add water into the reaction vessel as a solvent, start stirring, add aluminum sulfate octadecahydrate and melamine cyanurate into the reaction kettle, and add sodium dodecylbenzenesulfonate simultaneously, After stirring, the temperature was raised to 65°C, sodium hypophosphite was added, and the temperature was raised to 90°C after stirring, and then the temperature was maintained. The aluminum hypophosphite slurry was filtered, dried and pulverized to obtain spherical aluminum hypophosphite with a particle size of 4.7 microns. The electron microscope photos of this example are shown in figure 2 .

Embodiment 3

[0025] Formulation (parts by weight): 105 sodium hypophosphite, 100 aluminum sulfate octadecahydrate, 230 water, 40 melamine cyanurate, 2 citric acid.

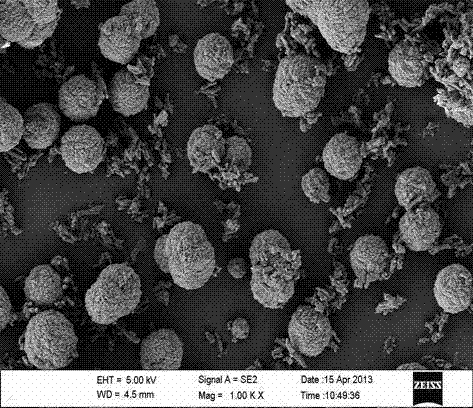

[0026] Preparation method: weigh the raw materials according to the above weight parts, firstly add water as a solvent into the reaction vessel, start stirring, add aluminum sulfate octadecahydrate and melamine cyanurate into the reaction kettle, add citric acid at the same time, stir evenly and heat up to 75 ℃ Then, sodium hypophosphite was added, and the temperature was raised to 95 °C with stirring, and then the temperature was kept warm, and the reaction was continued for 5 h to generate aluminum hypophosphite slurry. The aluminum hypophosphite slurry was filtered, dried and pulverized to obtain spherical aluminum hypophosphite with a particle size of 5.4 microns. The electron microscope photos of this example are shown in image 3 .

[0027] Comparative example (traditional preparation process)

[0028] First, ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com