Reclamation of ammonium sulfocyanate and ammonium thiosulfate from coke oven gas ammonia liquid phase catalysis waste water

A technology of liquid phase catalysis and coke oven gas, which is applied in the fields of thiocyanate, thiosulfate/dithionite/polythionate, water/sewage treatment, etc., which can solve the problem of small device scale and equipment utilization rate Low, unable to implement continuous production and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Recovery of ammonium thiocyanate and ammonium thiosulfate from coke oven gas ammonia water liquid-phase catalytic desulfurization and decyanation wastewater

[0074] (1) Evaporation and solid-liquid separation

[0075] Evaporation: 1000 grams of decolorized wastewater [NH 4 CNS23.78%, (NH 4 ) 2 S 2 o 3 7.26%, (NH 4 ) 2 SO 4 5.81%, H 2 O63.15%], add 1000 grams of circulating mother liquor, evaporate under reduced pressure at 75-80 ° C, and remove 632 grams of water to obtain concentrated slurry.

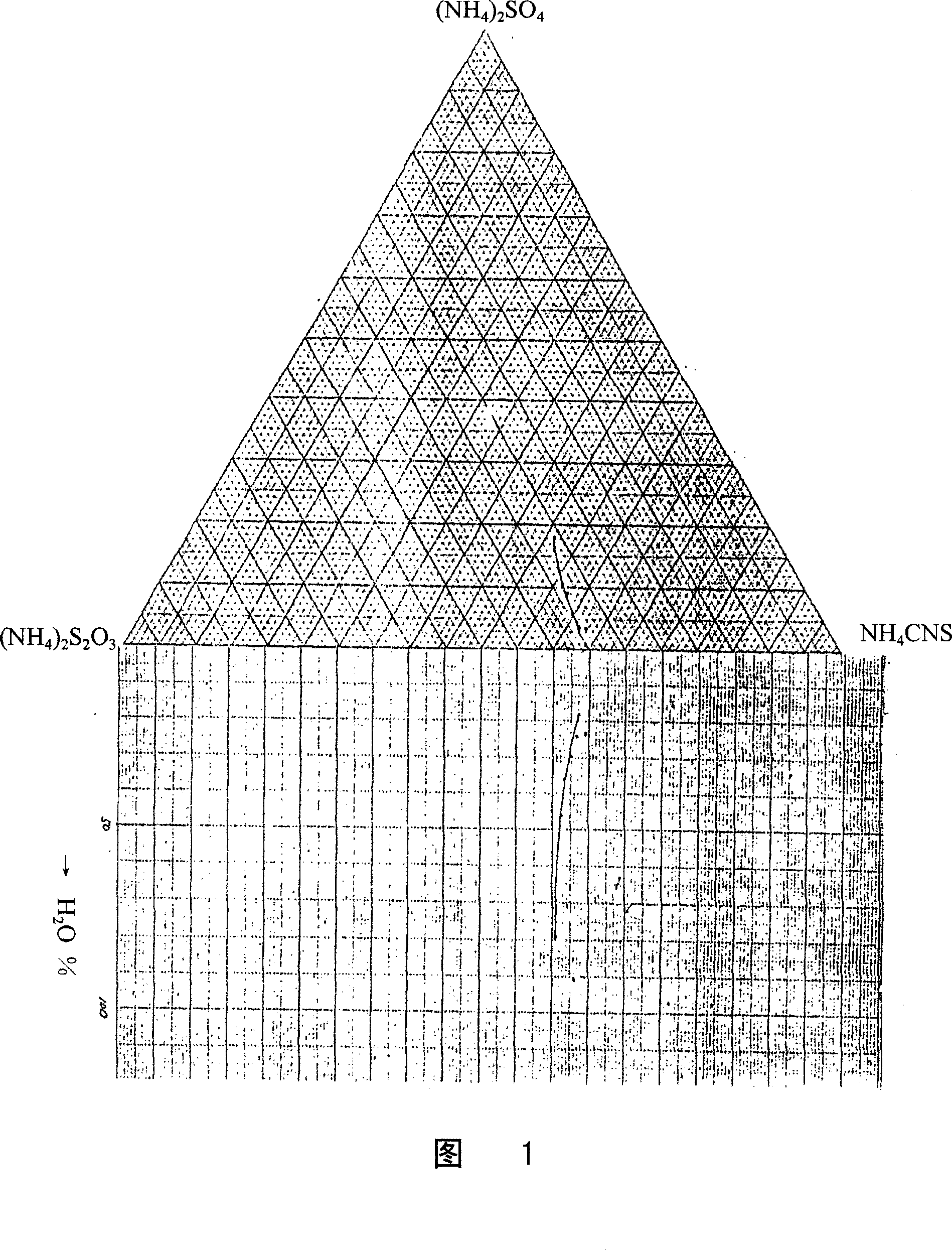

[0076] Solid-liquid separation: the concentrated slurry was separated at 45-60° C. to obtain 1267 grams of the first liquid phase and 100 grams of the first filter cake. Wherein the content of each component in the first filter cake is as follows: NH 4 CNS7.24%, (NH 4 ) 2 S 2 o 3 29.02%, (NH 4 ) 2 SO 4 55.49%, H 2 O4.57%, insoluble matter 3.68% (Fig. 2).

[0077] (2) NH 4 CNS crystallization separation

[0078] 1267 g of the first liquid phase was cooled to...

Embodiment 2

[0084] Recovery of ammonium thiocyanate from coke oven gas ammonia water liquid-phase catalytic desulfurization and decyanation wastewater

[0085] (1) Evaporation and solid-liquid separation

[0086] Evaporation: 5750 g of decolorized wastewater [NH 4 CNS13.18%, (NH 4 ) 2 S 2 o 3 8.40%, (NH 4 ) 2 SO 4 4.14%, H 2 [074.28%], add 1490 grams of circulating mother liquor returned, concentrate under reduced pressure at 73-81 ° C, remove 4684 grams of water, and obtain concentrated slurry.

[0087] Solid-liquid separation: the concentrated slurry was separated at 45-60° C. to obtain 1938 grams of the first liquid phase and 481 grams of the first filter cake. (figure 2)

[0088] (2) NH 4 CNS crystallization separation

[0089] 1938 grams of the first liquid phase was cooled to 25-30 ° C, and 335 grams of finished product NH4CNS were separated. The composition of the finished product is as follows: NH 4 CNS96.55%, (NH 4 ) 2 S 2 o 3 0.72%, (NH 4 ) 2 SO 4 0.37%, H ...

Embodiment 3

[0091] Recovery of ammonium thiosulfate from coke oven gas ammonia water liquid phase catalytic desulfurization and decyanation wastewater

[0092] (1) Dissolution (NH 4 ) 2 S 2 o 3

[0093] 100 grams of mother liquor and 4.15 grams of water after reclaiming ammonium thiosulfate are added to 100 grams of the first filter cake after extracting ammonium thiocyanate, and the above materials are stirred, heated to 90°C for dissolution (NH 4 ) 2 S 2 o 3 , the composition of the first residue is: (NH 4 ) 2 S 2 o 3 52.80%, NH 4 CNS1.35%, (NH 4 ) 2 SO 4 24.77%, H 2 O15.22%, water insoluble matter 5.86%. Through liquid-solid separation, 43 grams of the second filter cake and 157 grams of the second liquid phase were obtained. The main components in the second filter cake are ammonium sulfate, water insoluble matter and attached liquid. (NBM in Figure 4)

[0094] (2)(NH 4 ) 2 S 2 o 3 crystal separation

[0095] Add (NH 4 ) 2 S 2 o 3 About 16 grams of finished...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com