Method for preparing small-grain SAPO-11 molecular sieve

A SAPO-11, molecular sieve technology, applied in the direction of molecular sieve and alkali-exchanged phosphate, molecular sieve characteristic silicoaluminophosphate, etc., can solve the problems of increased cost and complex synthesis system, and achieves low synthesis cost and simple process steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 0.4 moles of phosphoric acid (as H 3 PO 4meter, the same below) was added to 5.1 moles of distilled water, placed in a constant temperature water bath at 35°C and mixed evenly, and 0.2 moles of pseudo-boehmite (as Al 2 o 3 After stirring and reacting to form a gel, slowly add a mixture of 0.12 moles of di-n-propylamine and 0.08 moles of diisopropylamine to the above-mentioned gel, and then add 0.08 moles of silica sol (based on SiO 2 meter, the same below), add acid to adjust the pH value to 3.5-7.0, and continue to stir to form a gel reaction mixture.

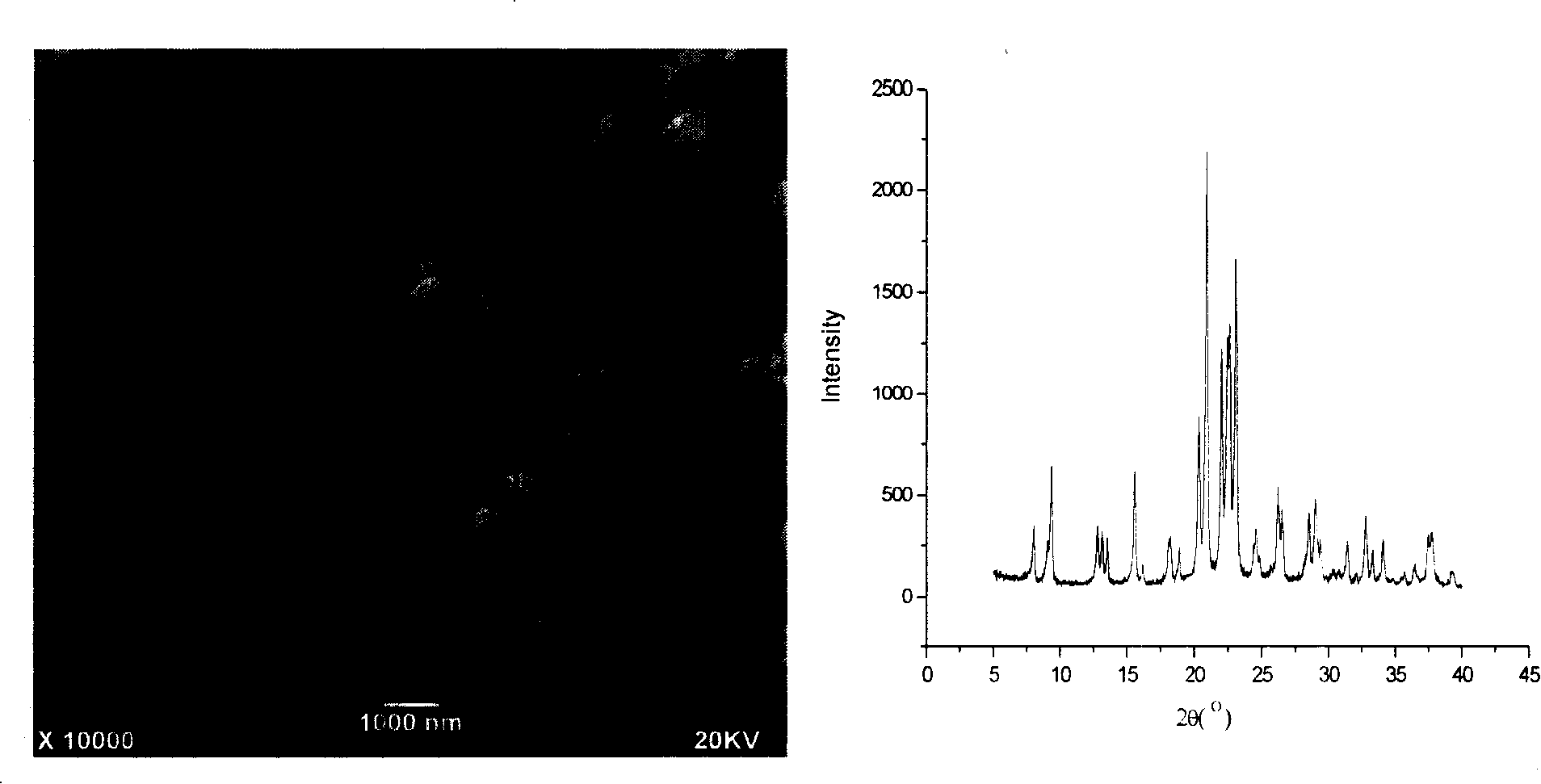

[0036] Put the above reaction mixture into a crystallization kettle with a polytetrafluoroethylene liner, first age at 130°C under autogenous pressure for 2.5 hours, then cool to room temperature, add 50% wt of distilled water and stir evenly, and then at 190°C Crystallization under autogenous pressure for 20 hours. Finally, the crystallized product is filtered, washed, and dried at 100-110°C to obtain the molecular...

Embodiment 2

[0039] The preparation of the gel reaction mixture was the same as in Example 1. Put the reaction mixture into a crystallization kettle with a polytetrafluoroethylene liner, age at 150°C for 2 hours under autogenous pressure, then cool to room temperature, add 60% by weight of distilled water and stir evenly, and then at 190°C Crystallization under autogenous pressure for 24 hours. Finally, the crystallized product is filtered, washed, and dried at 100-110°C to obtain the molecular sieve powder.

[0040] Get part crystallization product to measure by X-ray diffraction and SEM, the result is as follows: figure 2 shown. It shows that the silicoaluminophosphate molecular sieve synthesized by this method has an AEL structure, is a SAPO-11 molecular sieve, and its grain size is 300-400 nm.

Embodiment 3

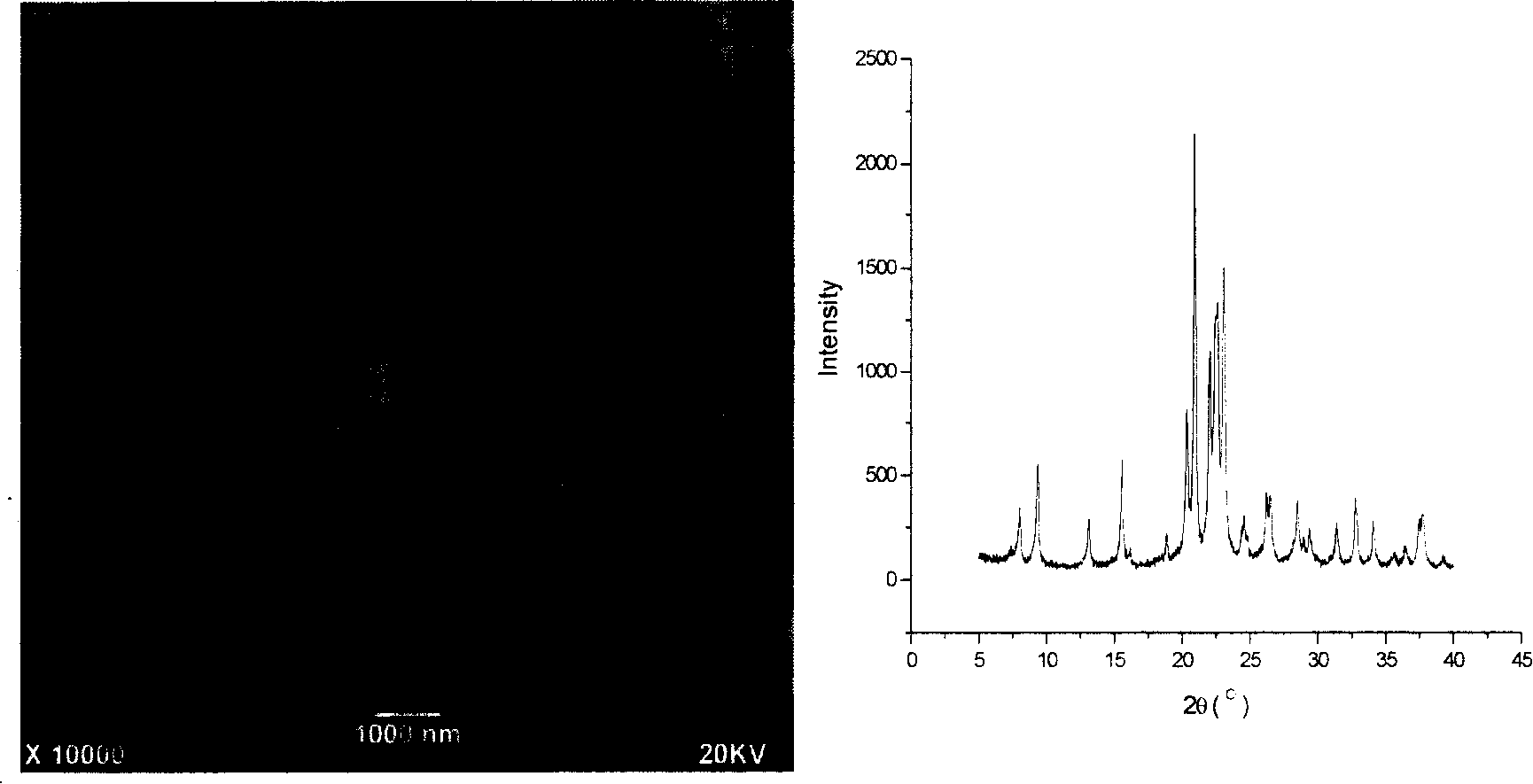

[0042] The preparation of the gel reaction mixture was the same as in Example 1. Put the reaction mixture into a crystallization kettle with a polytetrafluoroethylene liner, first age at 175°C under autogenous pressure for 1.5 hours, then partially cool to room temperature, add 40% distilled water and stir evenly, and then at 190°C Crystallization under autogenous pressure for 28 hours. Finally, the crystallized product is filtered, washed, and dried at 100-110°C to obtain the molecular sieve powder.

[0043] Get part crystallization product to measure by X-ray diffraction and SEM, the result is as follows: image 3 shown. It shows that the silicoaluminophosphate molecular sieve synthesized by this method has an AEL structure, is a SAPO-11 molecular sieve, and its grain size is 500-800nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com