Horizontal continuous crystallization method adopting return current technique

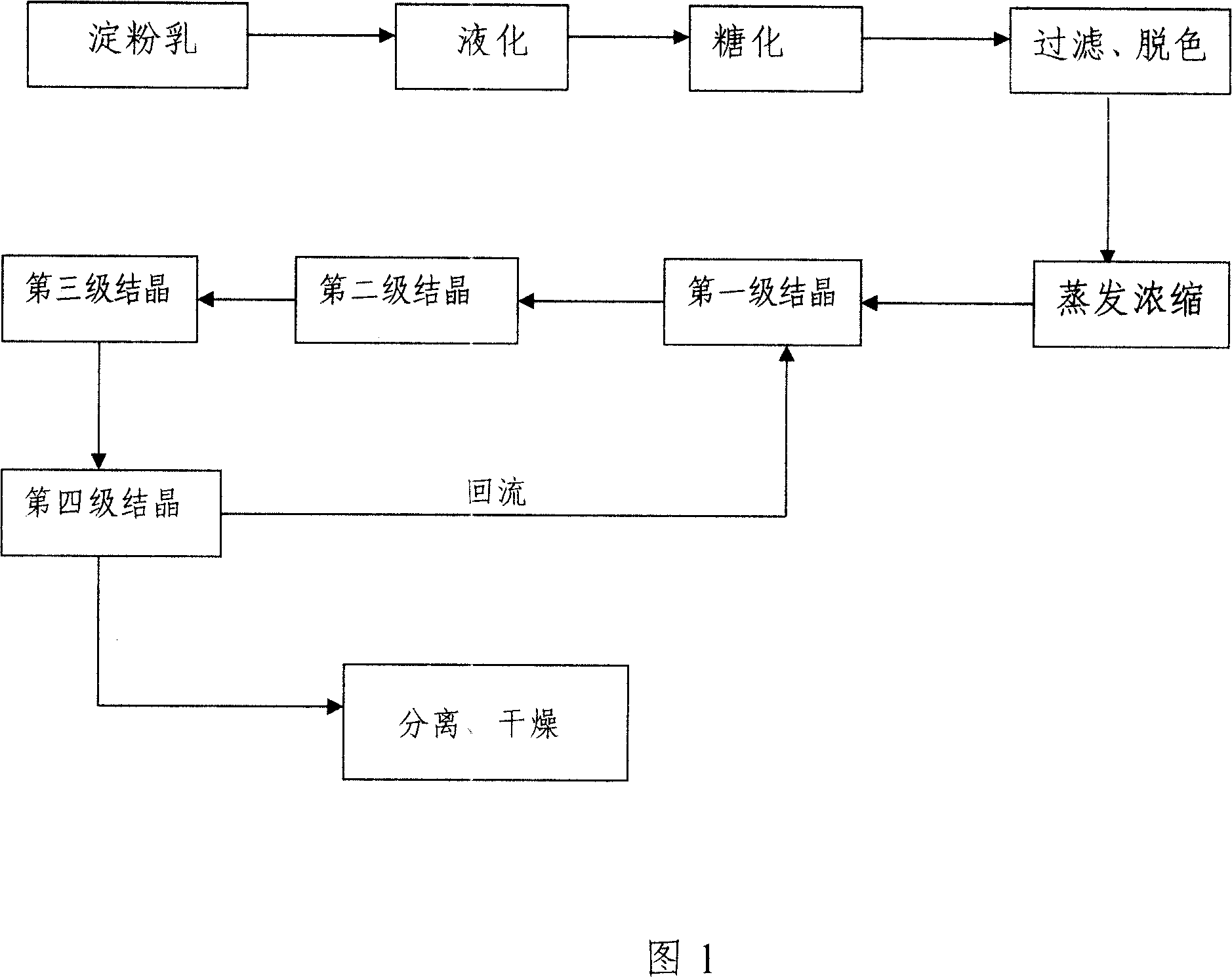

A horizontal crystallization and crystallization technology, applied in the application, sugar production, sugar production and other directions, can solve the problems of poor product quality, low yield of crystallized glucose, and easy agglomeration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention is further described below.

[0009] There are 4 to 5 horizontal crystallization tanks connected in series. According to needs, horizontal crystallization tanks can be 3 to 6 connected in series.

[0010] The temperature of the sugar liquid entering the first-stage horizontal crystallization tank is 46°C-48°C, and the flow rate is 1.8-3m 3 / h. This is the optimum feed temperature and flow rate.

[0011] A small part of the magma flows back from the final horizontal crystallization tank to the feed end of the first horizontal crystallization tank at a flow rate of 0.5 to 0.8 m 3 / h.

[0012] Same as the prior art, in the horizontal crystallization tank in the present invention, there must be a stirring device composed of a stirring paddle, a stirring shaft, etc., as well as a cooling device, a feeding device, and a crystal that is matched with the final horizontal crystallization tank. Continuous extraction device (crystal separator). In addit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com