Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about "Stannic chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

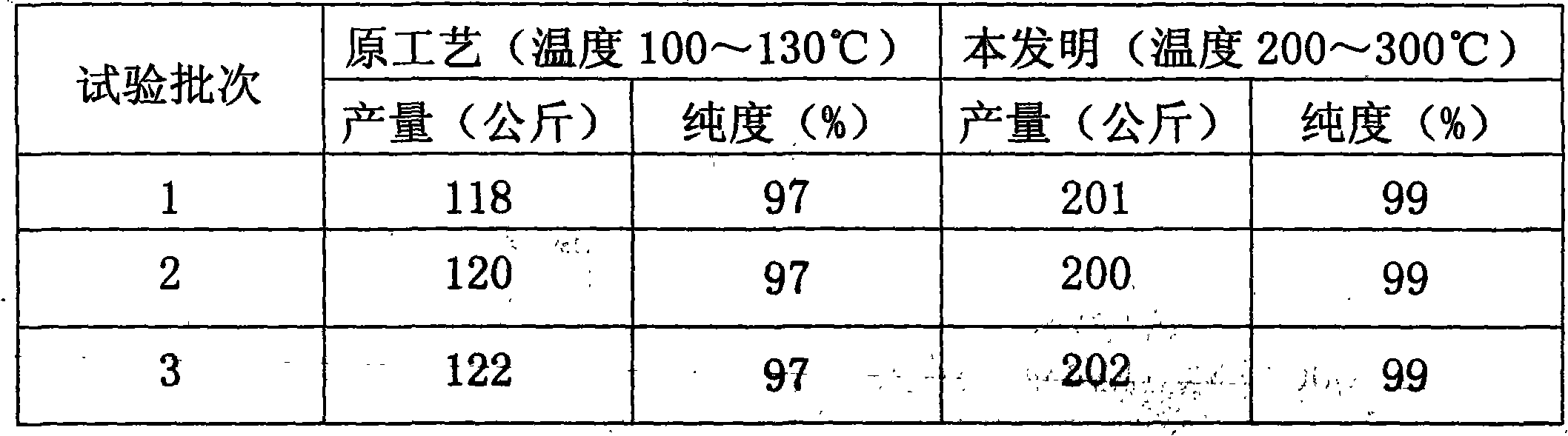

Production process of tin tetrachloride

The invention relates to a production process of tin tetrachloride, belonging to the technical field of tin tetrachloride production processes. The process comprises the following steps: 1, directly adding a tin ingot to the tin feeding port of a tin tetrachloride reaction kettle, and heating so as to melt the tin ingot into liquid tin; 2, continuously introducing nitrogen into the tin tetrachloride reaction kettle, and reacting chloride with the melted liquid tin so as to generate gaseous tin tetrachloride, wherein the nitrogen introducing port of the tin tetrachloride reaction kettle is below the liquid level of the liquid tin; 3, continuously adding the tin ingot from the tin feeding port according to reaction conditions, continuously melting the tin by utilizing the heat released in the process of reacting the chloride with the melted liquid tin, and controlling the reaction temperature at 200-300 DEG C through controlling a chloride feeding speed; and 4, introducing the gaseous tin tetrachloride generated in the tin tetrachloride reaction kettle into a condenser and recovering tin tetrachloride liquid. The process has the advantages of simple process flow, complete reaction and less possibility of chloride pollution; and the prepared tin tetrachloride has the advantages of high purity and high yield.

Owner:ZHAOYUAN SONGHE CHEM

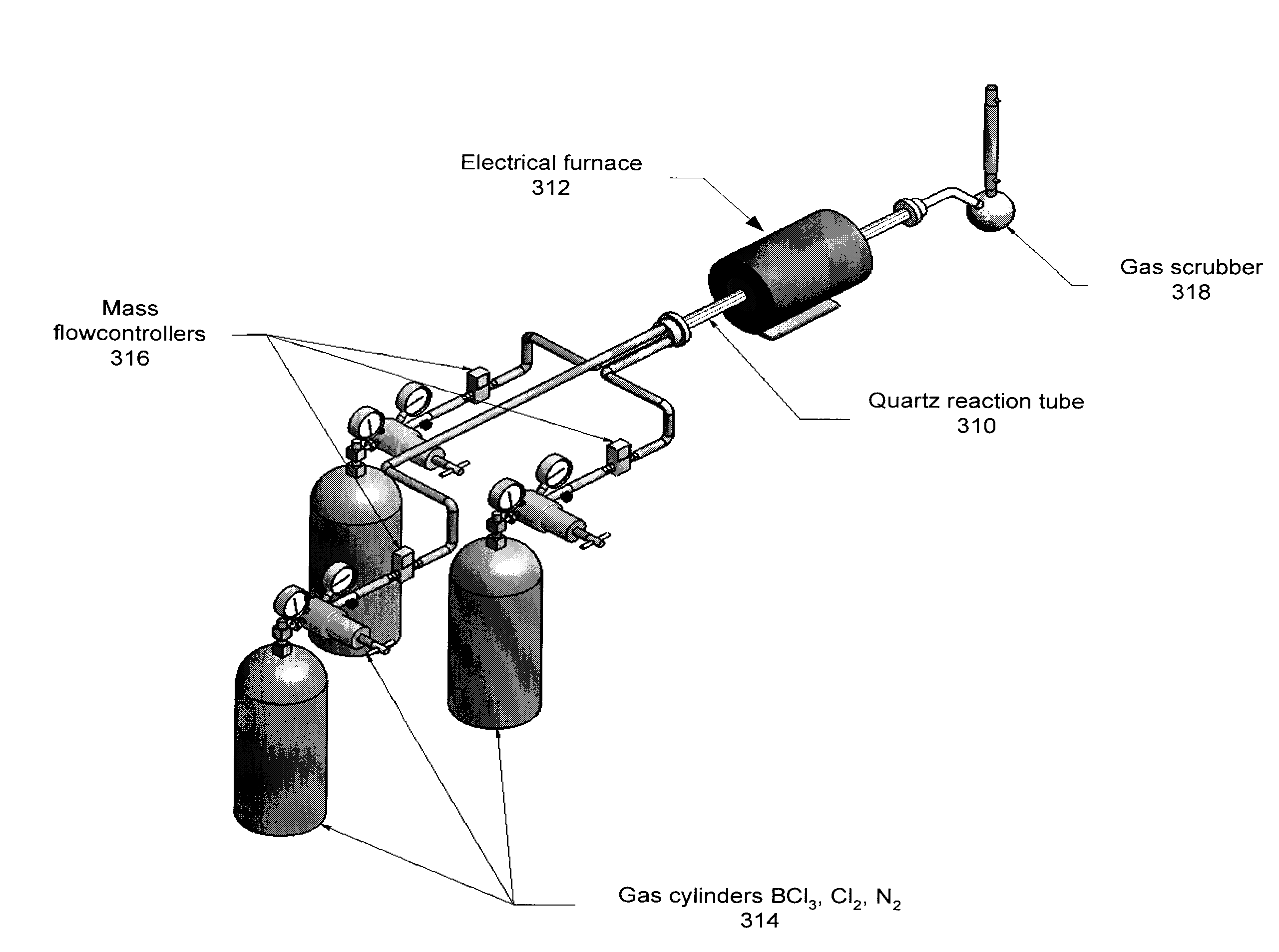

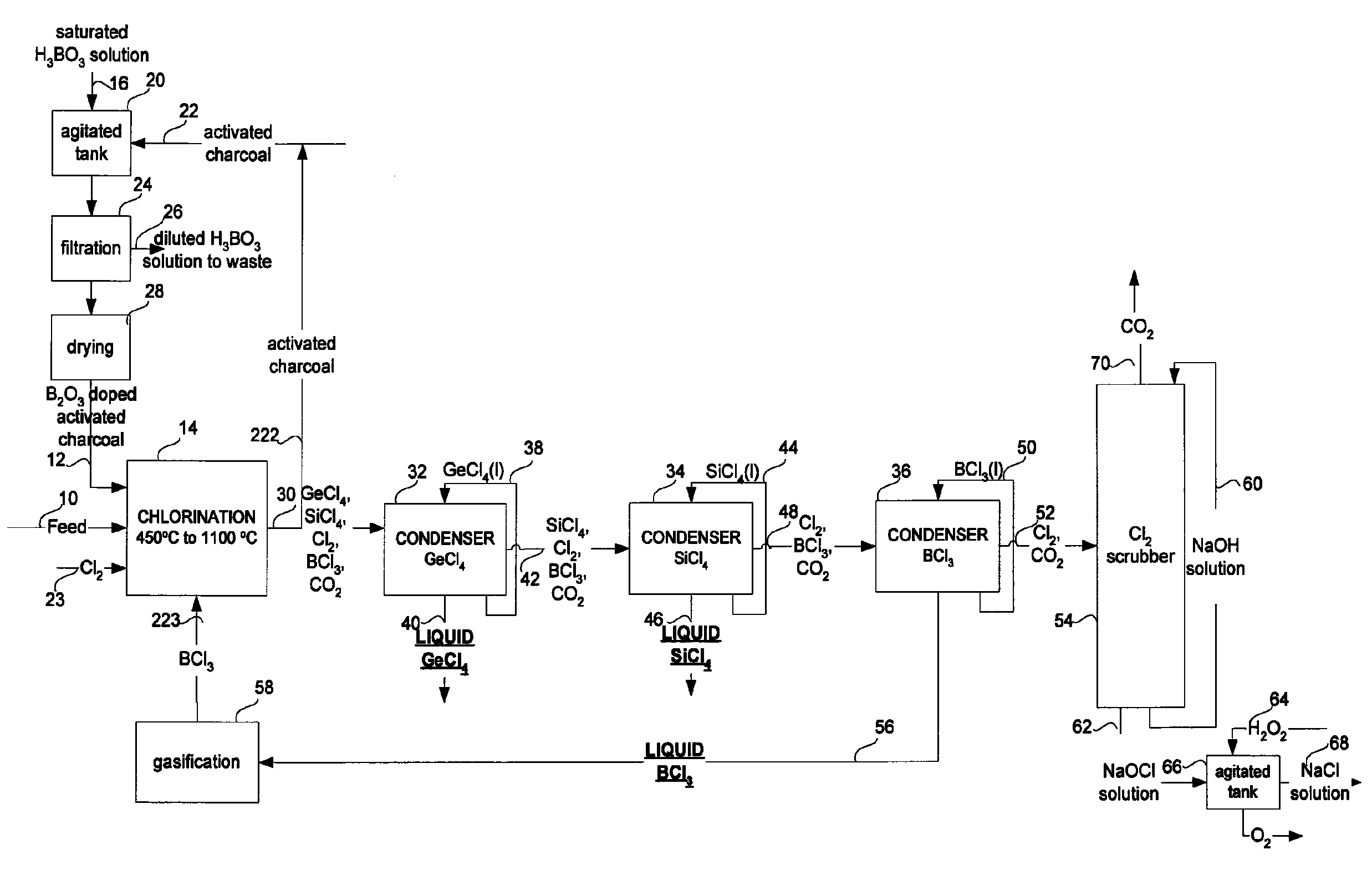

Gecl4 and/or sicl4 recovery process from optical fibers or glassy residues and process for producing sicl4 from sio2 rich materials

InactiveUS20100272625A1Reduce the temperatureSilicon halogen compoundsGermanium halidesBoronReducing agent

A method is provided for producing GeCl4 with or without SiCl4 from optical fibers, the method comprises the steps of: reacting comminuted optical fibers including germanium and optionally silicon oxides with a reagent including a solid carbonaceous reducing agent, chlorine and a boron compound to obtain a gaseous product including gaseous GeCl4, gaseous SiCl4, and gaseous BCl3 in accordance with the reactions: 2BCl3(g)+1.5GeO2=1.5GeCl4(g)+B2O3; 2BCl3(g)+1.5 SiO2=1.5 SiCl4(g)+B2O; B2O3+1.5C+3Cl2=2BCl3(g)+1.5CO2; and then condensing the gaseous GeCl4, BCl3 and optionally SiCl4 into liquid GeCl4, BCl3 and optionally SiCl4. The invention further provides a method for producing SiCl4 (and optionally GeCl4) from glass residues obtained from optical fiber manufacturing and wasted optical cables. The method includes the steps of: reacting comminuted glassy residues with a reagent including a solid carbonaceous reducing agent, a salt, a boron compound to obtain a gaseous product including SiCl4, BCl3, and optionally GeCl4; and then condensing the gaseous SiCl4, BCl3 (with or without GeCl4) into liquid SiCl4, BCl3 and GeCl4. There is also provided a method for producing SiCl4 from a SiO2 containing material.

Owner:INSTITUT NATIONAL DE LA RECHERCHE SCIENTIFIQUE

Normal-temperature synthesis method of tin tetrachloride

The invention discloses a normal-temperature synthesis method of tin tetrachloride. The normal-temperature synthesis method comprises the following steps: immersing tin into tin tetrachloride liquid, adding metallic carbon nanotubes, further introducing chlorine gas, controlling the temperature in a kettle at 20-30 DEG C, controlling the pressure at 1-3Pa and controlling the flow rate of chlorine gas at 1-3m<3> / h. Tin tetrachloride is prepared by adopting gas-liquid-solid heterogeneous reaction, the metallic carbon nanotubes are taken as an auxiliary catalyst, the yield is greatly improved in comparison with gas-solid heterogeneous reaction, the improving capability can be improved by 5 times or more, and continuous and stable production can be realized.

Owner:HAIMEN JINQILIN REDWOOD INVESTMENT DEV

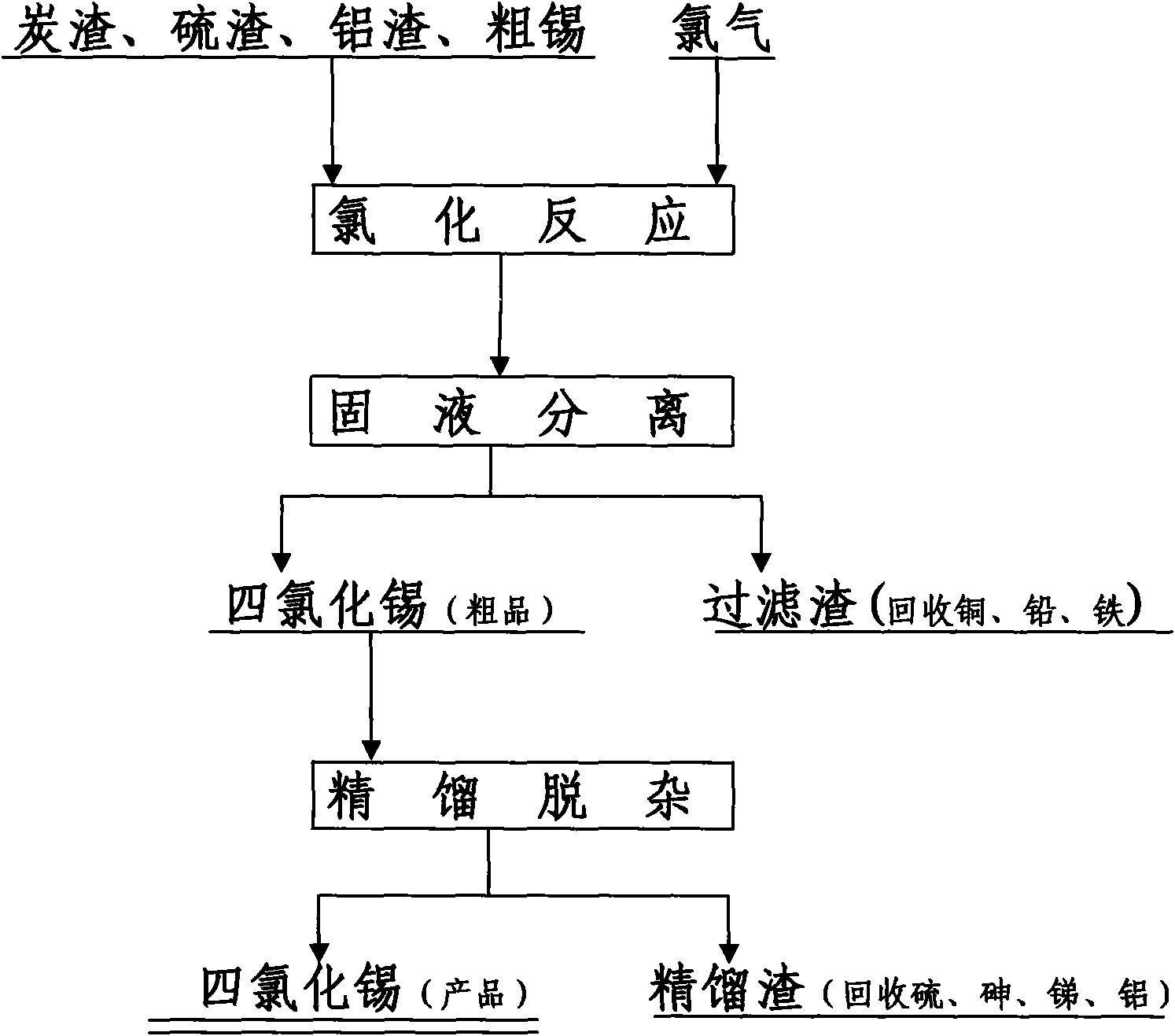

Method for producing stannic chloride

The invention relates to a method for producing stannic chloride, in particular to a method for producing the stannic chloride with low cost, belonging to a technique for producing inorganic compoundstannic chloride. The method comprises the technological steps: (1) crude tin pyro-refining and outputting carbon residue, sulphur residue, aluminium residue, or leading crude tin and chlorine gas tohave chlorination reaction in a closed reactor, and obtaining crude product of the stannic chloride; (2) carrying out solid-liquid separation on liquid crude product of the stannic chloride, using solid filter residue for recovering copper, lead and iron, carrying out rectification, impurity removal and separation on the liquid part, and obtaining the product of the stannic chloride. The method reduces the production cost of the stannic chloride, and comprehensively recover the carbon residue, the sulphur residue and the aluminium residue produced by crude tin pyro-refining or the valuable metals such as iron, arsenic, copper, lead, aluminum and the like as well as sulphur in the crude tin; furthermore, when the tin is recovered, impurities which are harmful to tin smelting can be avoidedturning back to the process of smelting tin, thus preventing vicious circle of the detrimental impurities.

Owner:云南锡业研究院有限公司研究设计院

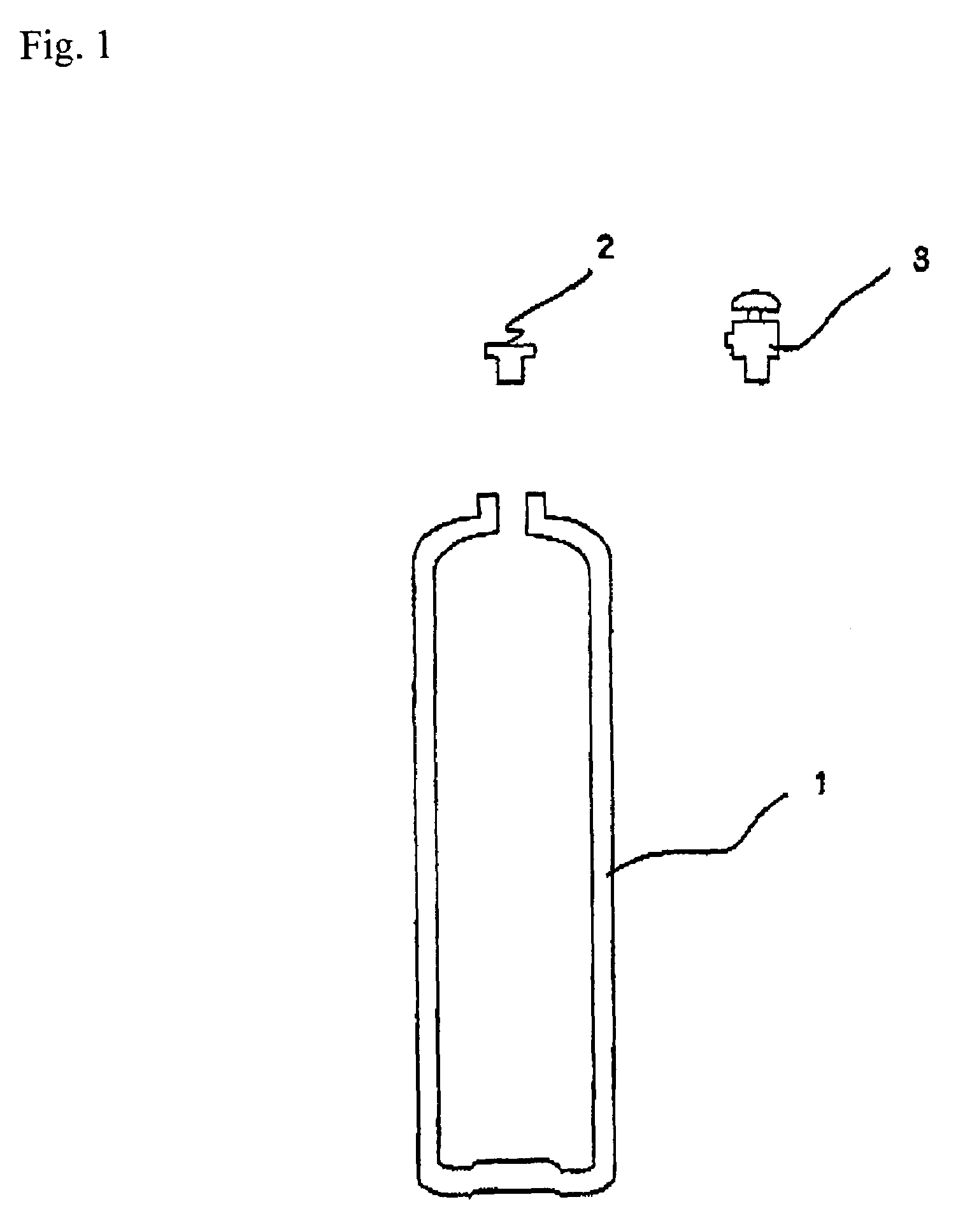

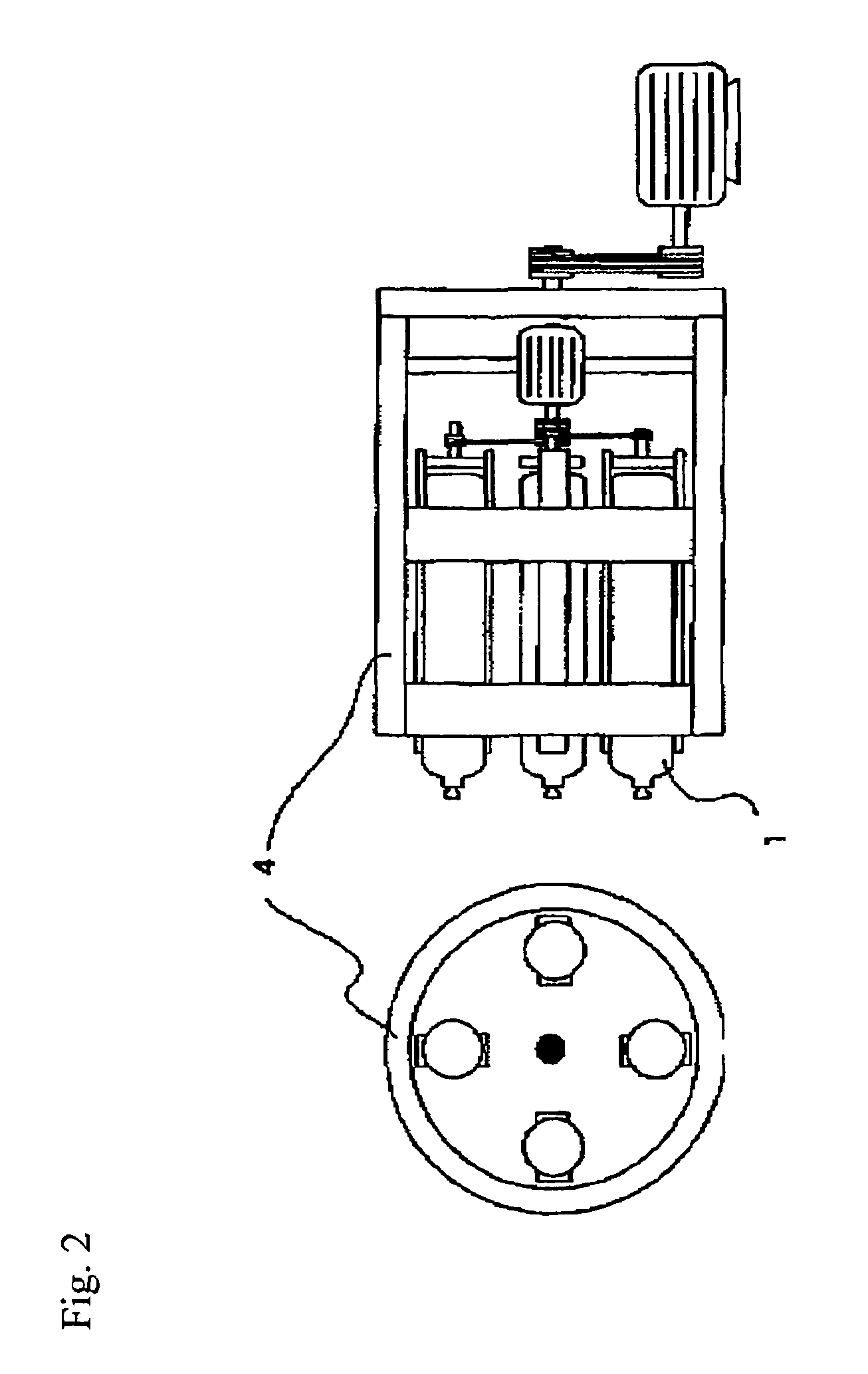

Processing method for high pressure gas container and halogen containing gas filled in said container

ActiveUS7021487B2Low purityInhibit productionDecorative surface effectsTitanium halidesX-rayProduct gas

A metal container to be filled with a halogen containing gas, with the inner surface processed with a polishing agent. The gas has a reduced purity decline by the increase of the water content or impurities from the inner surface of the container which is absorbed by the gas over the passage of time. The inner surface processing method is improved such that the value of dividing the area of the Si2s peak by the area of the Fe2p3 / 2 peak in the X-ray photoelectron spectrum of the gas container inner surface with the inner surface process with a polishing agent applied is 0.3 or less.

Owner:MITSUI CHEM INC

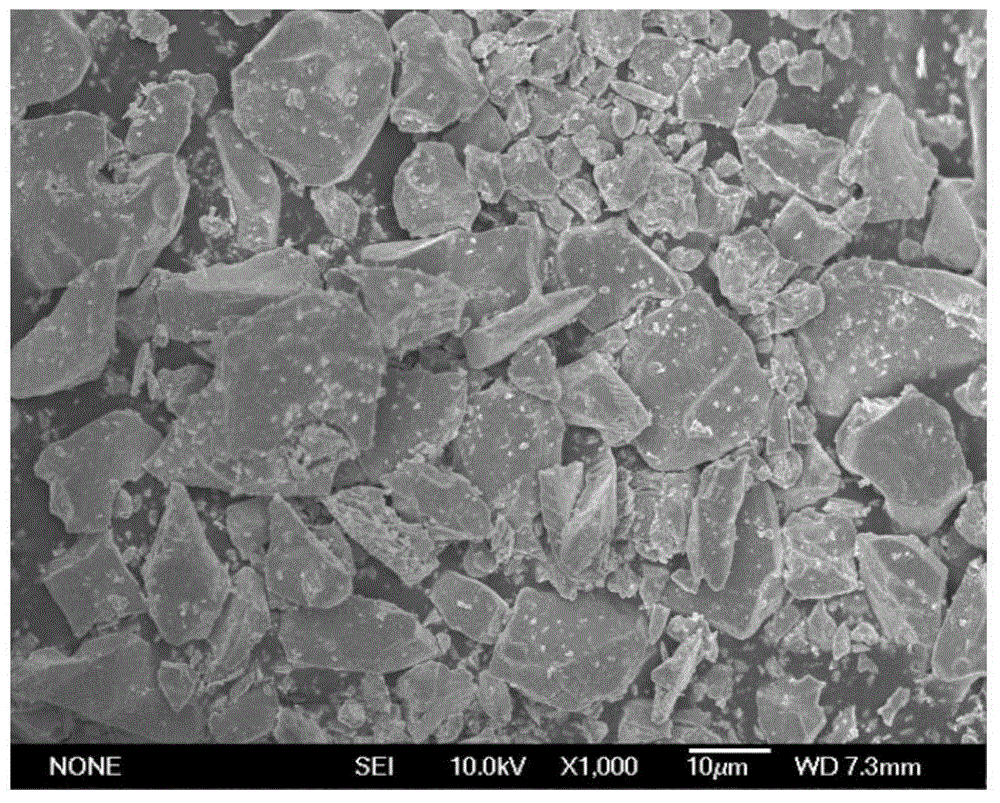

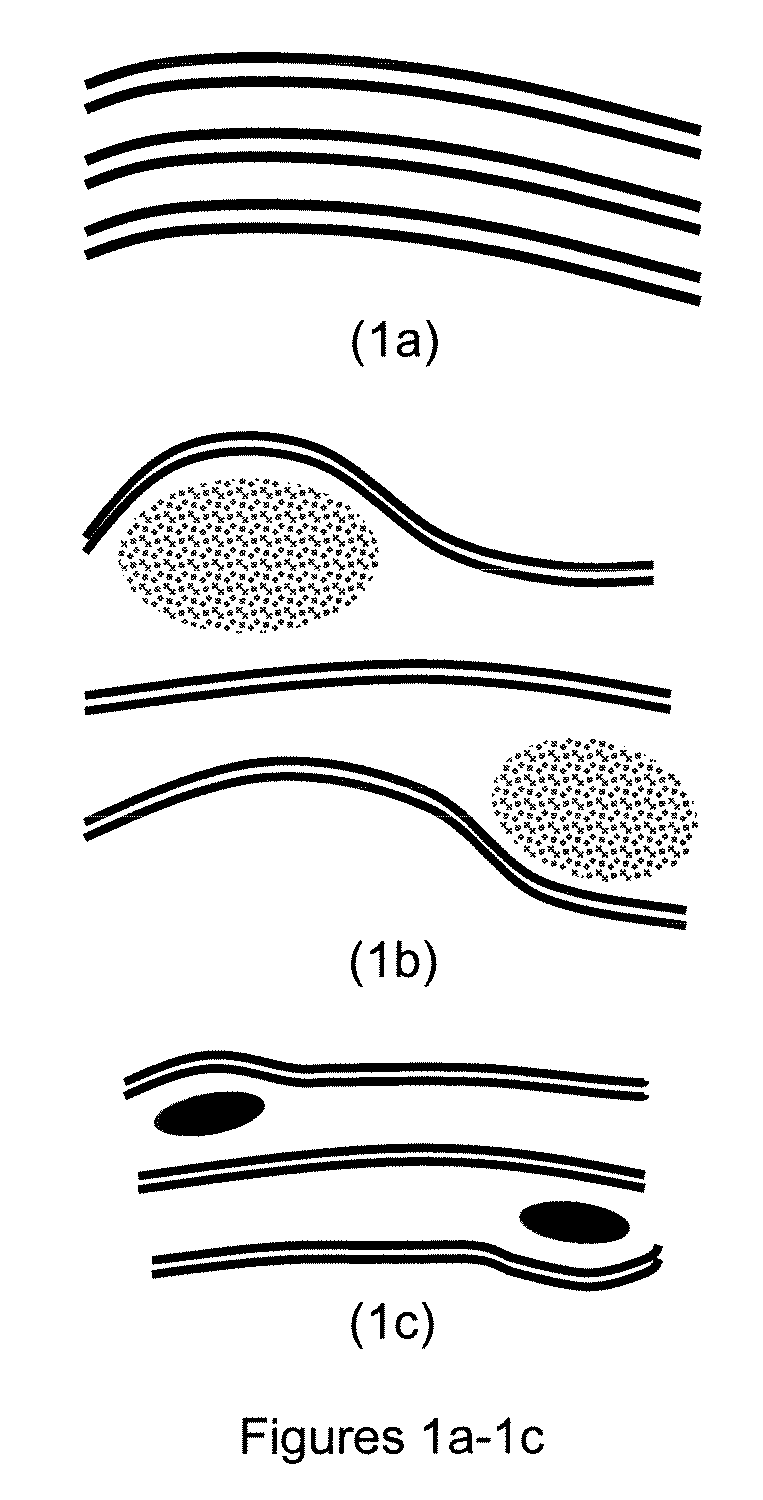

Method for preparing anisotropic particles and devices thereof

InactiveUS20100158790A1Simplified and more controllable procedureMaterial nanotechnologyCadmium sulfidesNonlinear opticsQuantum dot

The invention provides a simple and cost-effective method for preparing particles such as anisotropic semiconductor nanoparticles (e.g. CdS) and devices thereof. The method comprises (i) dispersing at least part of particle-forming reactants in a self-organized medium such as surfactant-aqueous solution system, and (ii) conducting a particle-forming reaction using the particle-forming reactants dispersed in the self-organized medium under shear condition to form the particles. The anisotropic property of the particles is controlled at least partially by the shear condition. The invention may be used to prepare quantum dots in a liquid crystal, and various devices such as nonlinear optics, optoelectronic devices, and solar cells, among others.

Owner:RES INST FOR CHEM OF THE HUNGARIAN ACADEMY OF SCI +1

Method for producing high-purity anhydrous stannic chloride

InactiveCN101391804APrevent bringing inIncrease extrusion areaStannic chlorideHigh concentrationTetrachloride

A method for producing anhydrous tin tetrachloride with high concentration takes tin tetrachloride of industrial goods as raw materials and is characterized in that the manufacturing method includes the following steps: metallic tin is added as displacer; a quartz glass packing tower is adopted as a rectifying plant; the tin tetrachloride of industrial goods is rectified and purified; the temperature of the tower top of the packing tower is within 112 DEG C to 117 DEG C; the temperature of the tower bottom of the packing tower is within 125 DEG C to 135 DEG C. The method for manufacturing anhydrous tin tetrachloride with high concentration does not pollute environment; the manufacturing method is easy to control; by controlling reflux ration, the production of PPm, PPb, Mos grade tetrachloride is realized and the production cost thereof is low; and the reflux control technique is simple and convenient and is convenient for commercial process. The finished products can be widely applied to the fields such as materials for photovoltaic cell and materials for photovoltaic package, medicine, synthetic rubber and stabilizer for plastics and the like.

Owner:侯存虎

Method for producing tin chloride and elemental mercury by using mercury-containing waste catalyst

InactiveCN105883907AAvoid pollutionProcess efficiency improvementStannic chlorideDistillationWaste treatment

The invention relates to a method for producing tin chloride and elemental mercury by using a mercury-containing waste catalyst, which relates to the technical field of three-waste treatment and utilization of an organic industrial waste mercury catalyst. The tin chloride and elemental mercury can be obtained by the following three steps: the waste mercury catalyst is sent to a sealed-type distiller for distillation, mercuric chloride is directly sublimated to gas, then cooled to mercuric chloride liquid; then an above mercuric chloride solution and stannous chloride are subjected to a reaction, a mixing solution of tin chloride and the elemental mercury is generated; the mixing solution is subjected to enclosed pumping filtration to obtain a filter cake elemental mercury, then the filter cake elemental mercury is washed, dehydrated and packaged to obtain the elemental mercury product; and finally the tin chloride solution is sent to a normal pressure distiller for distillation, when tin chloride reaches a saturated solution, cooling crystals are discharged, and crushed and packaged to obtain the tin chloride crystals finished product. The method effectively prevents pollution of the waste mercury catalyst on environment, performs comprehensive utilization on the waste mercury catalyst, and provides high economic benefit for the enterprises at the same time.

Owner:常德湘大环保科技有限公司

GeCl4 and/or SiCl4 recovery process from optical fibers or glassy residues and process for producing SiCl4 from SiO2 rich materials

A method is provided for producing GeCl4 with or without SiCl4 from optical fibers, the method comprises the steps of: reacting comminuted optical fibers including germanium and optionally silicon oxides with a reagent including a solid carbonaceous reducing agent, chlorine and a boron compound to obtain a gaseous product including gaseous GeCl4, gaseous SiCl4, and gaseous BCl3 in accordance with the reactions: 2BCl3(g)+1.5GeO2=1.5GeCl4(g)+B2O3; 2BCl3(g)+1.5SiO2=1.5SiCl4(g)+B2O; B2O3+1.5C+3Cl2=2BCl3(g)+1.5CO2; and then condensing the gaseous GeCl4, BCl3 and optionally SiCl4 into liquid GeCl4, BCl3 and optionally SiCl4. The invention further provides a method for producing SiCl4 (and optionally GeCl4) from glassy residues obtained from optical fiber manufacturing and wasted optical cables. The method includes the steps of: reacting comminuted glassy residues with a reagent including a solid carbonaceous reducing agent, a salt, a boron compound to obtain a gaseous product including SiCl4, BCl3, and optionally GeCl4; and then condensing the gaseous SiCl4, BCl3 (with or without GeCl4) into liquid SiCl4, BCl3 and GeCl4. There is also provided a method for producing SiCl4 from a SiO2 containing material.

Owner:INSTITUT NATIONAL DE LA RECHERCHE SCIENTIFIQUE

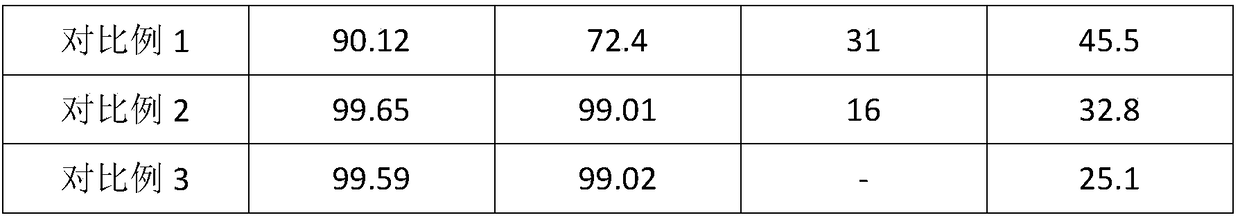

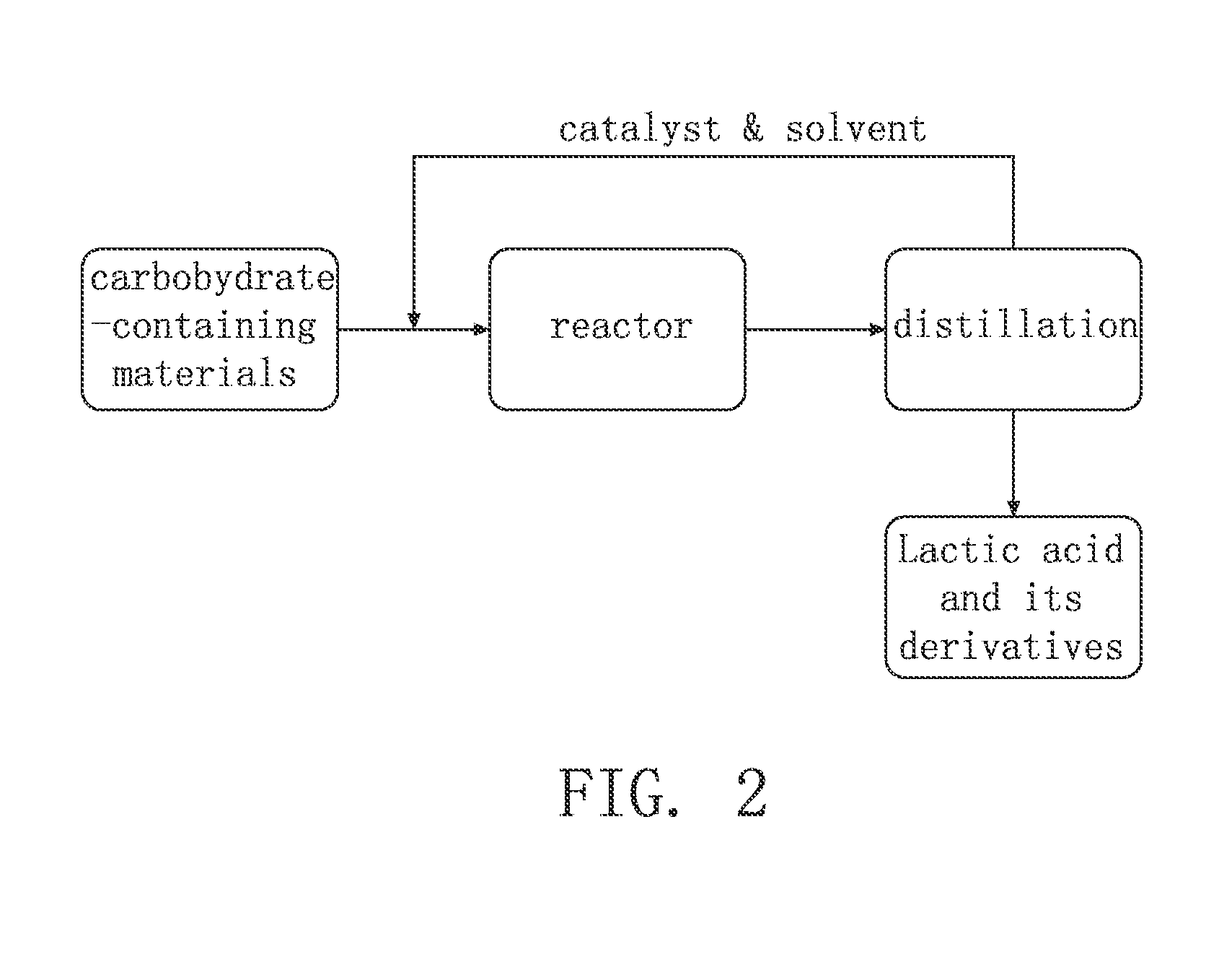

Method for synthesis of lactic acid and its derivatives

ActiveUS8835670B2Efficient and economicalMore environment-friendlyZinc halidesPhysical/chemical process catalystsMetal chlorideAlcohol

A method for synthesis of lactic acid and its derivatives is provided. First, a mixture is prepared, which includes: at least one carbohydrate-containing raw material, at least one alcohol, at least one composite catalyst containing metal chloride(s) (MCln) and tin-containing compound(s), and at least one solvent, wherein M is selected from a group consisting of Li+, Na+ K+, Mg2+, Ca2+, Sr2+, Ga3+, In3+, Sb3+, Bi3+, Cr3+, Mn2+, Fe2+, Co2+, Ni2+, Zn2+, and n represents 1, 2 or 3. Then, the mixture is heated to obtain lactic acid and its derivatives. By using the above catalyst and method, it is capable of converting carbohydrate-containing raw material to lactic acid and its derivatives directly in a more efficient and economical way.

Owner:MICROVAST POWER SYST CO LTD

Refining method of tin-lead contained scrap copper

The invention relates to a refining method of tin-lead contained scrap copper, and belongs to the technical field of reclaimed copper refining. The content of copper in the scrap copper raw material ranges from 80 to 90%, the content of tin-lead ranges from 6 to 10%, and a main treatment process comprises sorting pre-treatment, shearing, mixing, and controlled pressure high-temperature treatment.The scrap copper raw material is firstly subjected to sorting pre-treatment, a shearing machine is used for shearing, copper chloride is added in a high-temperature vacuum furnace for treatment underthe controlled-pressure condition that the pressure ranges from 0.01 to 0.8 atm at the temperature of 700 to 1100 DEG C, volatile matter is subjected to two-segment cooling, lead chloride and tin chloride are obtained, the tin-lead impurity content in the treated scrap copper can be greatly reduced, and the aim of purifying reclaimed copper is achieved.

Owner:UNIV OF SCI & TECH BEIJING

Method for Synthesis of Lactic Acid and Its Derivatives

ActiveUS20140058130A1Efficient and economicalMore environment-friendlyZinc halidesPhysical/chemical process catalystsMetal chlorideAlcohol

A method for synthesis of lactic acid and its derivatives is provided. First, a mixture is prepared, which includes: at least one carbohydrate-containing raw material, at least one alcohol, at least one composite catalyst containing metal chloride(s) (MCln) and tin-containing compound(s), and at least one solvent, wherein M is selected from a group consisting of Li+, Na+ K+, Mg2+, Ca2+, Sr2+, Ga3+, In3+, Sb3+, Bi3+, Cr3+, Mn2+, Fe2+, Co2+, Ni2+, Zn2+, and n represents 1, 2 or 3. Then, the mixture is heated to obtain lactic acid and its derivatives. By using the above catalyst and method, it is capable of converting carbohydrate-containing raw material to lactic acid and its derivatives directly in a more efficient and economical way.

Owner:MICROVAST POWER SYST CO LTD

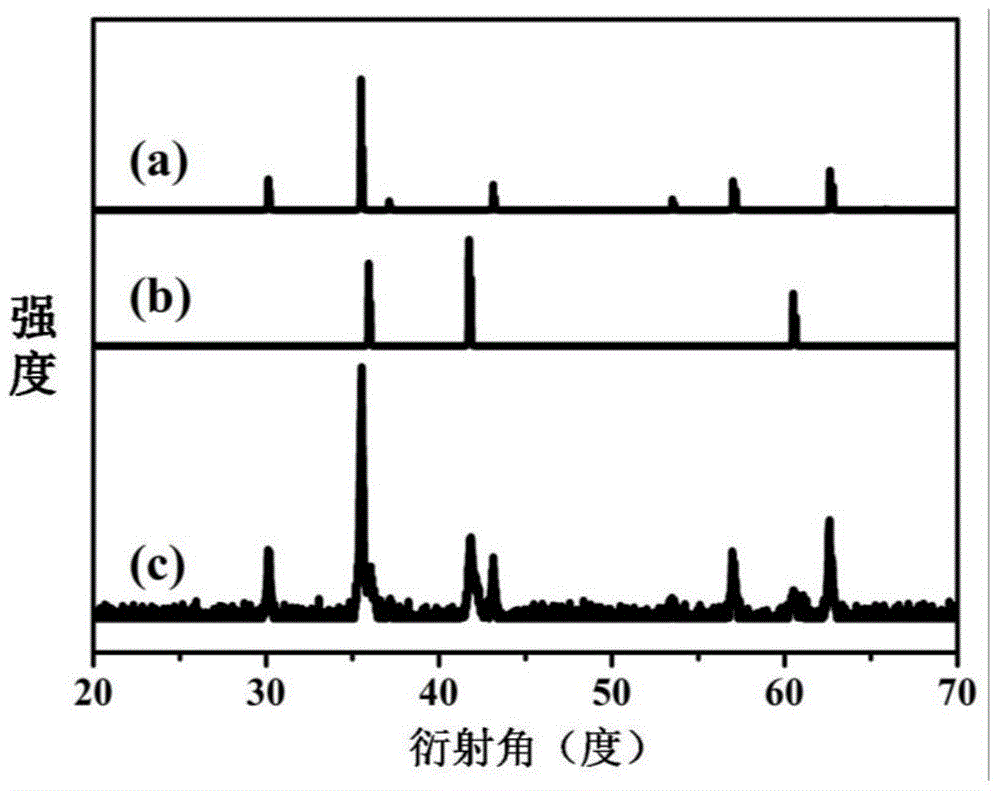

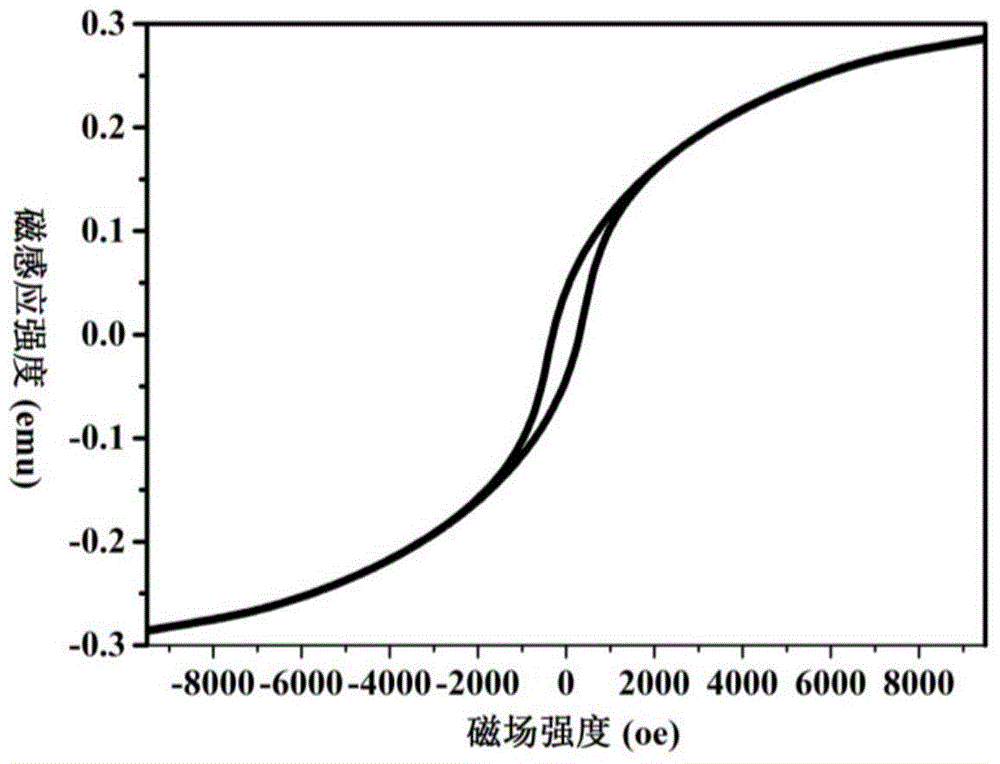

Method for preparing active iron oxide powder materials by means of vacuum aluminothermic reduction

The invention relates to a method for preparing active iron oxide powder materials by means of vacuum aluminothermic reduction. Iron sesquioxide micro-powder is used as a raw material, aluminum micro-powder is used as a reducing agent, and the iron oxide powder materials can be manufactured by the aid of a vacuum aluminothermic reduction process. The method includes preparing steps of 1, uniformly mixing the iron sesquioxide micro-powder, namely, the raw material, and the aluminum micro-powder, namely, the reducing agent, with each other to obtain mixtures for standby application; 2, placing the mixtures obtained in the step 1 in the center of a clean porcelain boat; 3, placing the porcelain boat prepared in the step 2 in the middle of a high-temperature tube furnace, sealing the tube furnace, pumping the high-temperature tube furnace by the aid of a vacuum pump to enable the high-temperature tube furnace to be in an internal negative-pressure state and keeping the vacuum degree of the high-temperature tube furnace lower than or equal to 5pa; 4, heating the high-temperature tube furnace until the temperature of the high-temperature tube furnace reaches 900-1000 DEG C, keeping the raw material and the reducing agent reacting to each other for certain reaction time, then stopping heating the high-temperature tube furnace, cooling the high-temperature tube furnace until the temperature of the high-temperature tube furnace reaches the room temperature and taking products out of the high-temperature tube furnace. The method has the advantages that technologies are simple and controllable, prepared active iron oxide (FeO / Fe<3>O<4>, FeO, Fe / FeO) powder is high in purity and low in cost, and requirements of actual production can be met.

Owner:DONGGUAN PUREMATE ENVIRONMENTAL PROTECTION TECH CO LTD

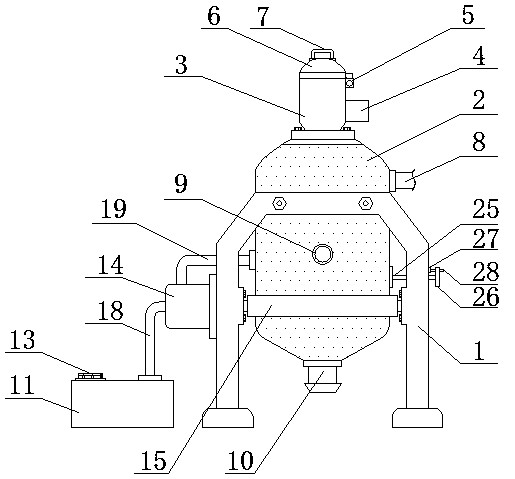

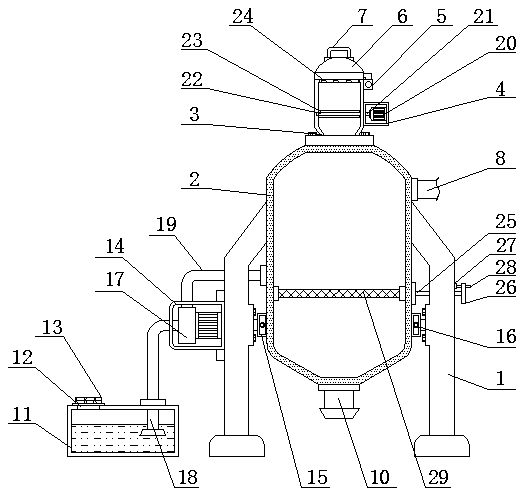

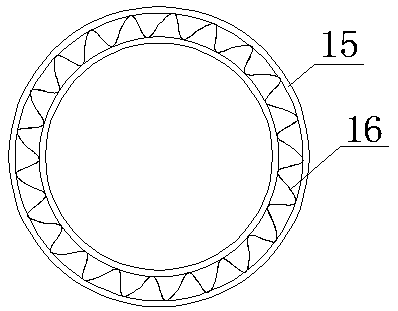

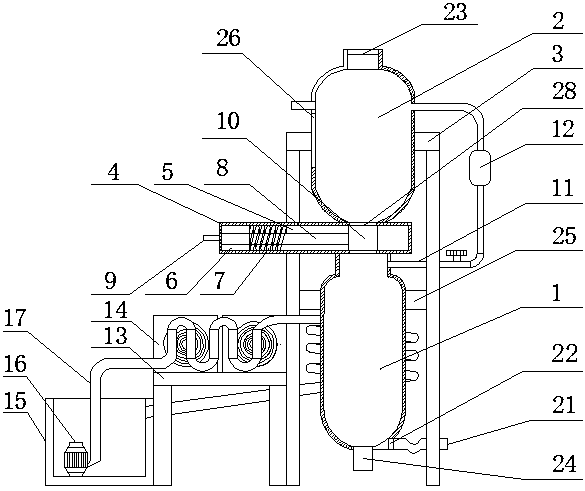

Synthesis method for stannic chloride

InactiveCN109534390AImprove practicalityAchieve neutralizationDispersed particle separationChemical/physical/physico-chemical processesActivated carbonCalcium hydroxide

The invention relates to the technical field of preparation equipment of stannic chloride and discloses a synthesis method for stannic chloride. The preparation equipment comprises support legs and areaction purifying tank; a reaction kettle main body is fixedly sleeved in the support legs; a connecting cylinder is fixedly connected with the top of the reaction kettle main body; a lateral box isfixedly arranged on the right side of the connecting cylinder. The reaction purifying tank, an activated carbon adsorption net and an acid-proof sucking pump are arranged in a synthesis device of stannic chloride; under the action of the acid-proof sucking pump, gas in the reaction kettle main body can be extracted through a right-angle pipe and then is guided into the reaction purifying tank through a connecting pipe, and unreacted chlorine can react with calcium hydroxide in the reaction purifying tank, so that the neutralization of chlorine can be realized; the activated carbon adsorption net is used for absorbing and purifying gas discharged from the reaction purifying tank, so as to avoid pollution to surrounding air.

Owner:LIUZHOU HAOXIANGTE SCI & TECH

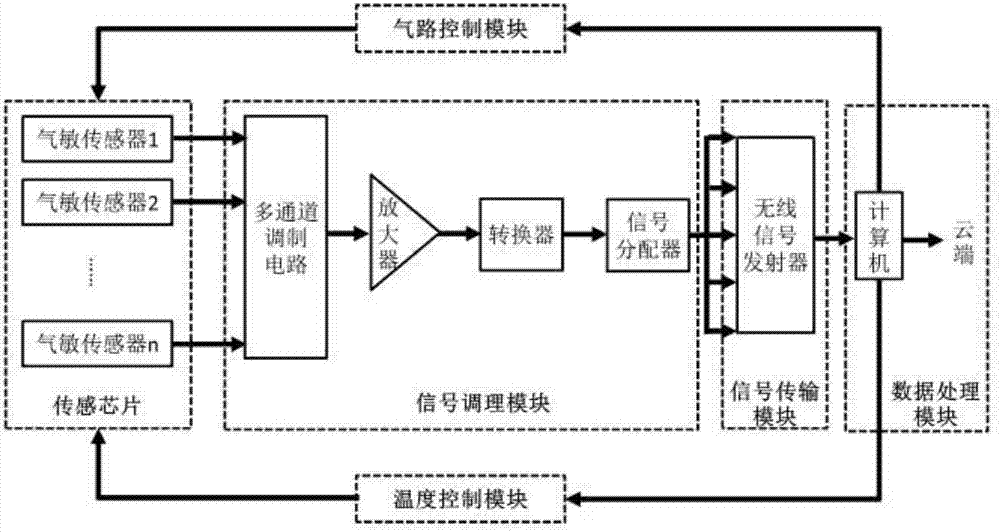

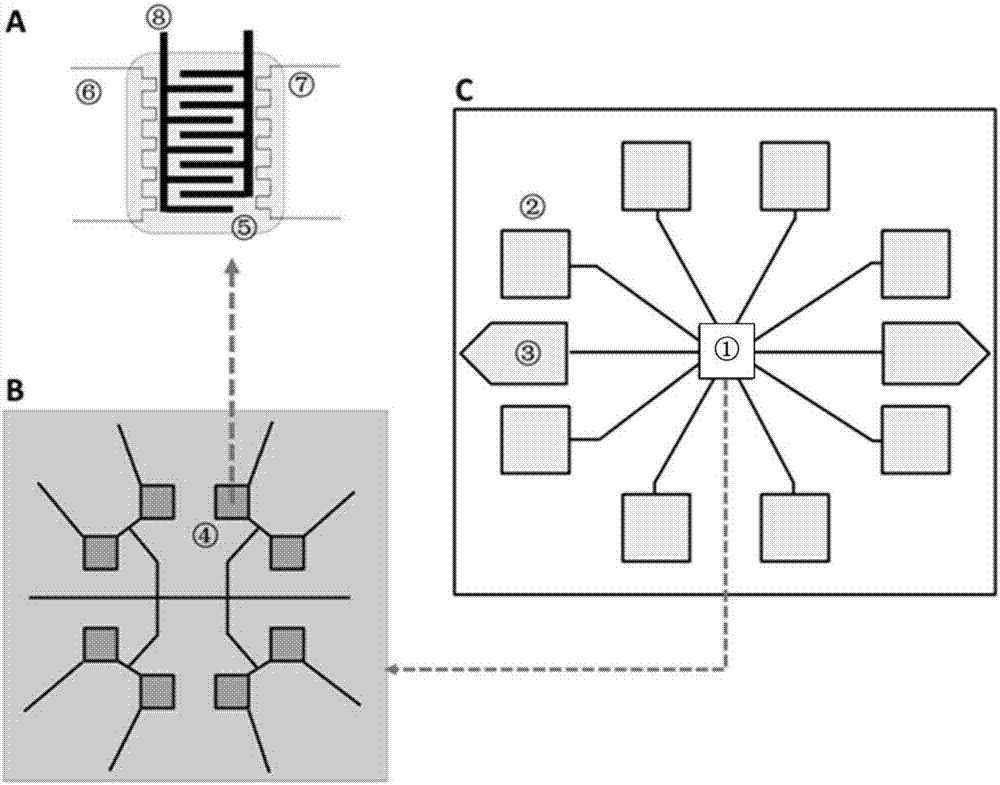

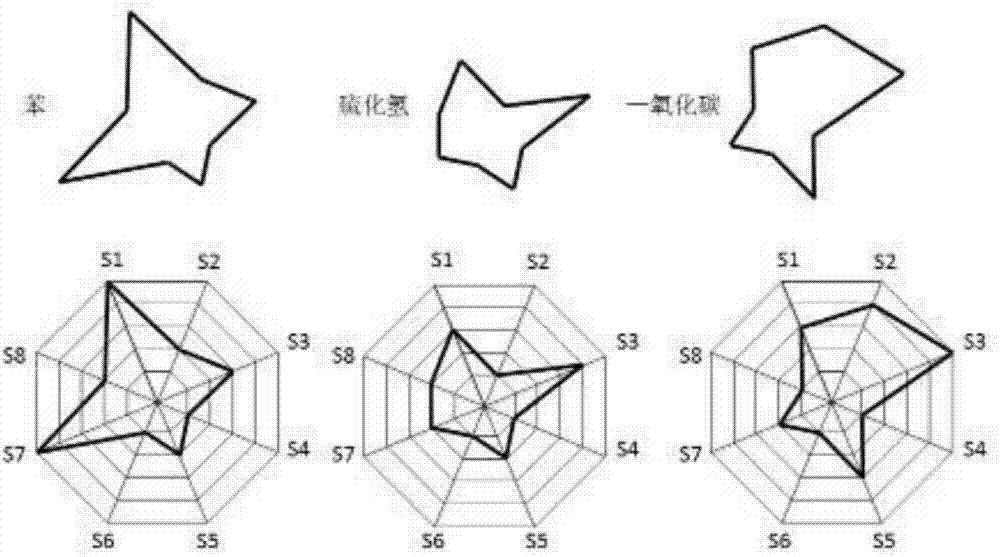

Fingerprint recognition system for comprehensive state of hazardous atmosphere

ActiveCN106940340AImprove accuracyZinc halidesGallium/indium/thallium compoundsEnvironmental resource managementSignal conditioning

The invention relates to a fingerprint recognition system for the comprehensive state of a hazardous atmosphere. The fingerprint recognition system mainly overcomes the problem that conventional single-sensor monitoring systems do not have multipath detection capability, cannot realize recognition of the state of complex atmospheres, real-time early warning, and lack in wireless signal transmission, cloud signal storage, big data analysis and self-learning. The fingerprint recognition system for the comprehensive state of the hazardous atmosphere comprises a sensing chip, a signal conditioning module, a signal transmission module, an air-passage control module, a temperature control module and a data processing module. With such a technical scheme, the above problem is overcome, and the fingerprint recognition system is applicable to fingerprint recognition of the comprehensive state of the hazardous atmosphere.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation process for tin tetrachloride

InactiveCN109678200AEasy to cutTroubleshoot issues that require a stop reactionStannic chlorideTetrachlorideMaterials science

The invention relates to the technical field of preparation devices of chemical raw materials and discloses a preparation process for tin tetrachloride. A device comprises a reaction chamber, a tin storage chamber and a support frame, wherein the tin storage chamber penetrates the middle of the support frame and extends into the support frame and is fixedly connected with the support frame, the bottom of the tin storage chamber is fixedly connected with a connecting plate, a cavity is formed in the connecting plate, the left side in the cavity is fixedly connected with a fixed block, and the right side of the fixed block is fixedly connected with a spring. According to the preparation process for tin tetrachloride, by arranging the connecting plate, the cavity, the fixed block, a spring, aconnecting rod, a handle, a movable block, a disc, motors and flame guns, the problem that a reaction needs to be stopped during charging in a production process of tin tetrachloride production equipment is solved, and production efficiency is increased; an operator is not needed to hold one flame gun to heat a reaction tank, operation is convenient, and heating is uniform.

Owner:LIUZHOU HAOXIANGTE SCI & TECH

Method for preparing anisotropic particles and devices thereof

The invention provides a simple and cost-effective method for preparing particles such as anisotropic semiconductor nanoparticles (e.g. CdS) and devices thereof. The method comprises (i) dispersing at least part of particle-forming reactants in a self-organized medium such as surfactant-aqueous solution system, and (ii) conducting a particle-forming reaction using the particle-forming reactants dispersed in the self-organized medium under shear condition to form the particles. The anisotropic property of the particles is controlled at least partially by the shear condition. The invention may be used to prepare quantum dots in a liquid crystal, and various devices such as nonlinear optics, optoelectronic devices, and solar cells, among others.

Owner:RES INST FOR CHEM OF THE HUNGARIAN ACADEMY OF SCI +1

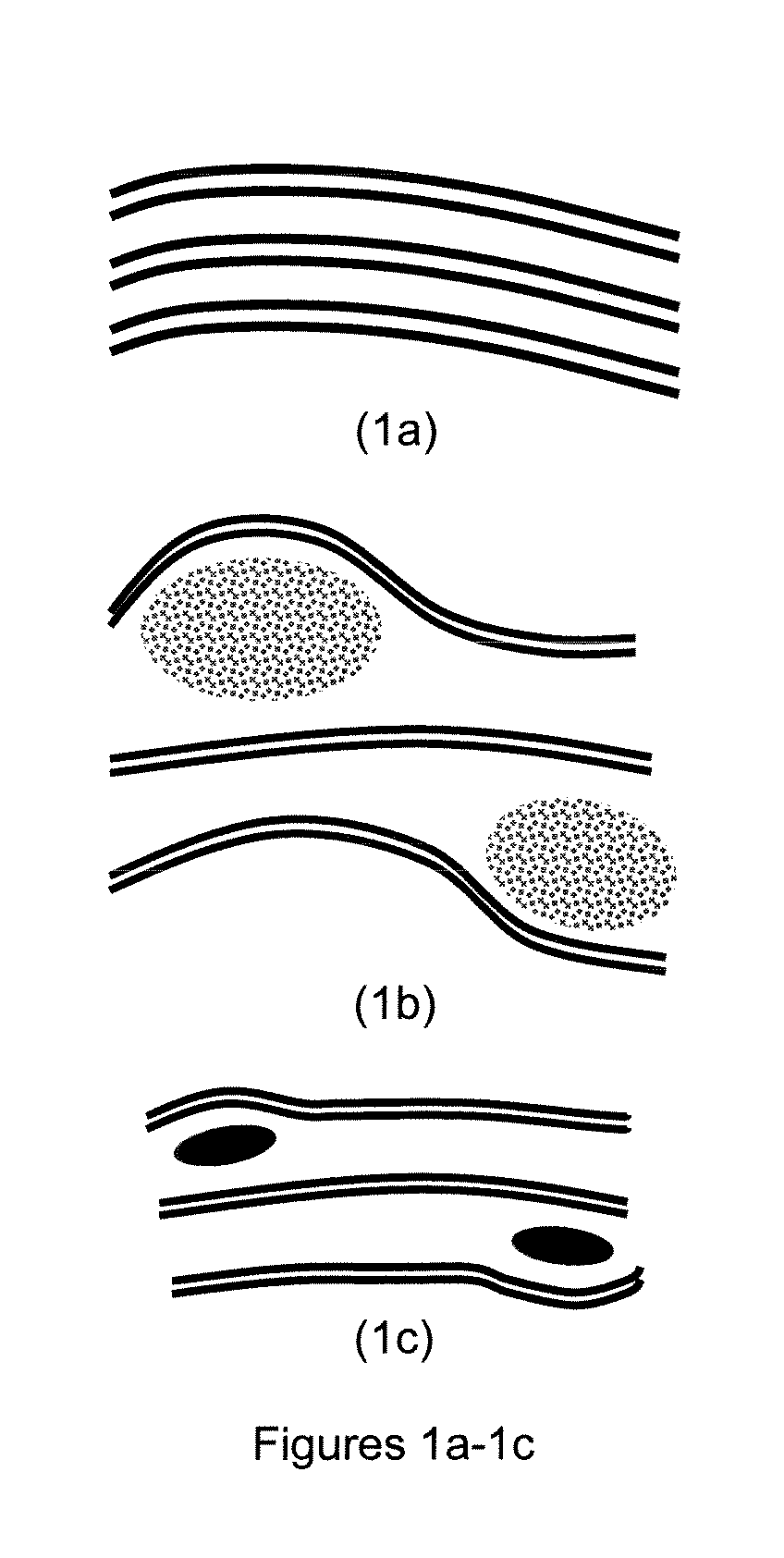

Elastomeric copolymers based on [bis(trihydrocarbylsilyl)aminosilyl]-functionalized styrene and their use in the preparation of rubbers

The present invention relates to the use of specific styrene derivatives in the production of an elastomeric copolymer. The invention further relates to a method for producing an elastomeric copolymerand an elastic copolymer. Moreover, the invention relates to a method for preparing a rubber comprising vulcanizing the elastomeric copolymer, and a rubber as obtainable according to the method. Further, the invention relates to a rubber composition, a tire component comprising the rubber composition, and a tire comprising the tire component.

Owner:SYNTHOS

Purification of TiCl4 through the production of new co-products

The present disclosure relates to reacting tin metal with crude TiCl4 containing arsenic to produce pure TiCl4, SnCl4, and an arsenic solid co-product. In some embodiments, the contaminant vanadium is removed as well. The reaction is preferably done in a continuous fashion in two stages for maximum through-put and utility at an elevated temperature. Distillation can be used to purify the TiCl4 produced and simultaneously yield a purified SnCl4 product. The synthesis of SnCl4 in this method utilizes waste chloride to save virgin chlorine which would otherwise be used.

Owner:THE CHEMOURS CO FC LLC

Synthesis method of molybdenum trichloride

PendingCN114132963AImprove qualityEmission reductionStannic chlorideMolybdenum halidesTetrachlorideMolybdenum(III) chloride

The invention discloses a process for preparing molybdenum trichloride, which comprises the following steps of: (1) mixing excessive molybdenum pentachloride and stannous chloride powder, and heating the mixed material in a reactor to carry out replacement reaction to generate molybdenum trichloride and stannic chloride; (2) gasifying the generated stannic chloride, leaving the reactor, entering a cooling system for receiving and cooling to obtain stannic chloride liquid; (3) after the reaction is completed, switching a cooling system into a molybdenum pentachloride receiver, heating the reactor to a certain temperature, and gasifying redundant molybdenum pentachloride into the molybdenum pentachloride receiver; and (4) cooling the reactor, and discharging to obtain a molybdenum trichloride product. And (5) hermetically filtering the tin tetrachloride liquid to obtain a tin tetrachloride product and molybdenum pentachloride filter residues, wherein the molybdenum pentachloride filter residues and cooled and collected molybdenum pentachloride can be recycled as reaction raw materials. According to the method, the yield of molybdenum trichloride is increased, meanwhile, the production cost is reduced, the purity of the by-product tin tetrachloride exceeds 99%, the waste gas amount in the production process is greatly reduced, and the method belongs to a green and environment-friendly process.

Owner:湖南省华京粉体材料有限公司

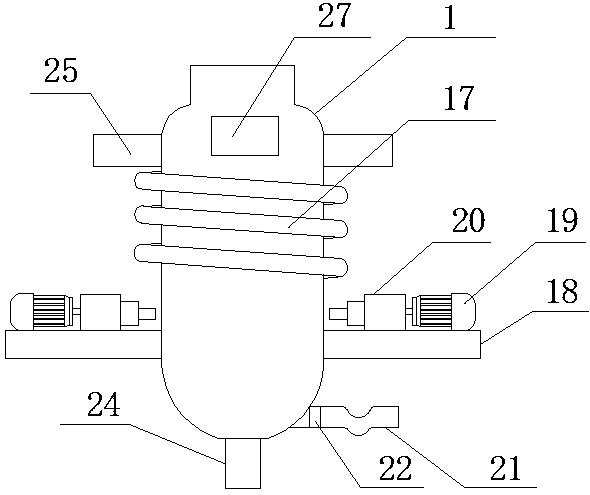

Application of tin hemispheres in preparation of tin chemical products

InactiveCN106882836AReduce labor intensityFlat surfaceTin organic compoundsFoundry mouldsIngotChemical products

The application of tin hemispheres in the preparation of tin chemical products is to make tin ingots into hemispherical tin raw materials for the synthesis of tin-containing chemical products. The invention can reduce friction and corrosion of equipment, reduce equipment investment, reduce labor intensity of workers, reduce energy consumption, improve production efficiency and product quality stability.

Owner:YUNNAN TIN

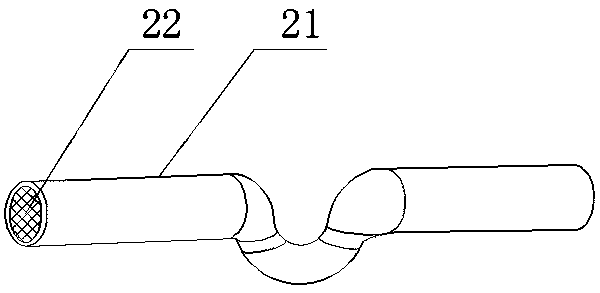

A kind of synthetic method of tin tetrachloride

The invention relates to the field of tin deep processing, in particular to a synthetic method of stannic chloride. The synthetic method includes the following steps that tin granules are fused; fluid obtained after fusion is vertically sprayed to the surface of a roller rotating at a high speed from top to bottom through a nozzle; the fluid is thrown to an atomizing chamber on one side under rotation of the roller, and tin drops are formed; chlorine is introduced into the atomizing chamber from bottom to top to react with the tin drops; chlorine remaining after the reaction is discharged from the upper side of the atomizing chamber and is collected; liquid stannic chloride generated in the reaction flows out from the lower side of the atomizing chamber and is collected. According to the synthetic method, the sprayed fluid is smashed under the centrifugal force of the rotating roller, then the tin drops are impacted by high-speed chlorine, the tin drops and chlorine are sufficiently mixed and react, generated stannic chloride can flow to the bottom of the atomizing chamber from top to bottom all the time under the effect of gravity, the reaction is sufficient, and thus the quality of the product can be improved; besides, continuous production can be achieved, and thus the yield can be increased.

Owner:盐城金穗亚克力有限公司

A kind of refining method of scrap copper containing tin and lead

The invention relates to a refining method of tin-lead contained scrap copper, and belongs to the technical field of reclaimed copper refining. The content of copper in the scrap copper raw material ranges from 80 to 90%, the content of tin-lead ranges from 6 to 10%, and a main treatment process comprises sorting pre-treatment, shearing, mixing, and controlled pressure high-temperature treatment.The scrap copper raw material is firstly subjected to sorting pre-treatment, a shearing machine is used for shearing, copper chloride is added in a high-temperature vacuum furnace for treatment underthe controlled-pressure condition that the pressure ranges from 0.01 to 0.8 atm at the temperature of 700 to 1100 DEG C, volatile matter is subjected to two-segment cooling, lead chloride and tin chloride are obtained, the tin-lead impurity content in the treated scrap copper can be greatly reduced, and the aim of purifying reclaimed copper is achieved.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method and application of tin tetrachloride

ActiveCN108704669APreparation from carboxylic acid saltsOrganic compound preparationTetrachlorideMesoporous silica

The invention provides a preparation method of tin tetrachloride. The preparation method comprises the following steps: adding tin, tin tetrachloride solution and mesoporous silicon dioxide into a reaction kettle, introducing chlorine, controlling the temperature in the kettle to be less than 100 DEG C, controlling the pressure at 0.5MPa, controlling the flow rate of the chlorine at 31m<3> / h, andreacting for 16 hours; and obtaining tin tetrachloride, wherein mesoporous silicon dioxide is SBA-15 mesporous silicon dioxide; and a weight ratio of tin to tin tetrachloride solution to mesoporous silicon dioxide is 1: (0.5 to 1.5): (0.2 to 0.7).

Owner:启东市强强贸易有限公司

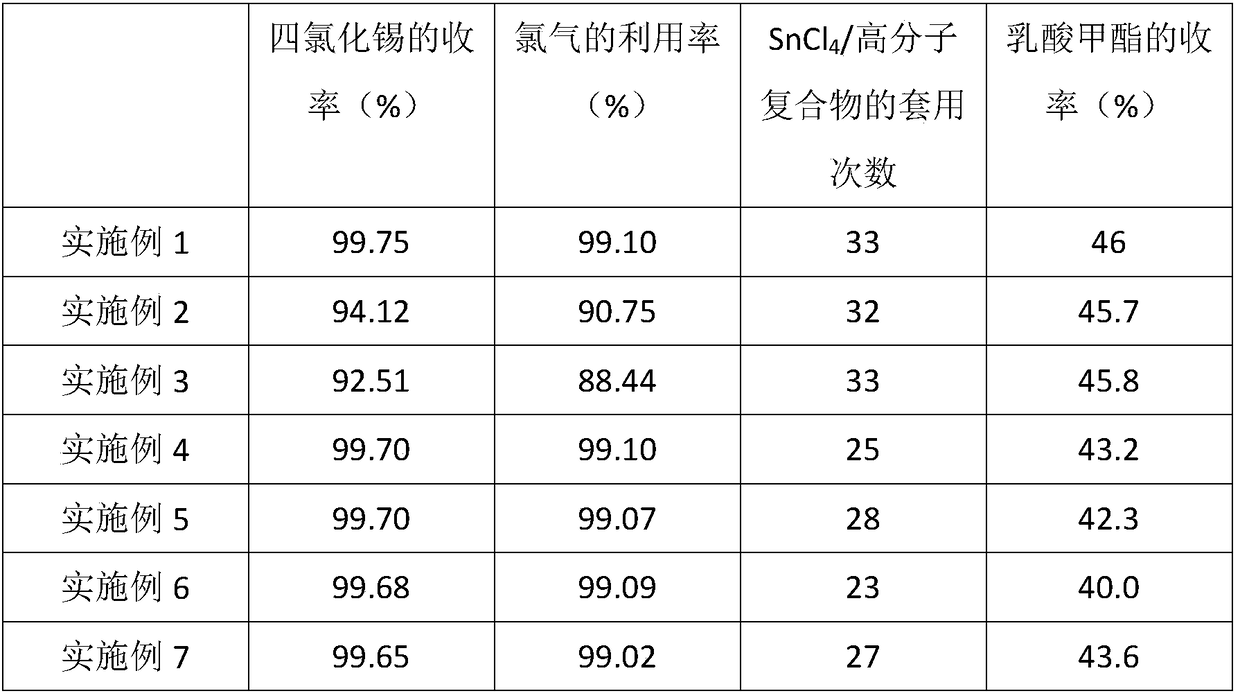

Method for synthesis of lactic acid and its derivatives and catalyst for preparing same

ActiveUS20150329458A1Cheap preparationImprove reaction speedCobalt halidesCarboxylic acid esters preparationPolymer scienceAlcohol

The present disclosure provides a catalyst for preparing lactic acid and derivatives thereof, comprising at least one of metallic compounds MXn, wherein M is selected from Na, K, Mg, Ca, Sr, Ba, Al, Ga, In, Sn, Sb, Bi, Cr, Mn, Fe, Co, Ni and Zn, and n is an integer of 1 to 6. The present disclosure further provides a method for synthesis of lactic acid and derivatives thereof, wherein at least one raw material including carbohydrates, at least one alcohol, at least one of the aforesaid catalysts and at least one solvent are heated to react to prepare lactic acid and derivatives thereof.

Owner:MICROVAST POWER SYST CO LTD

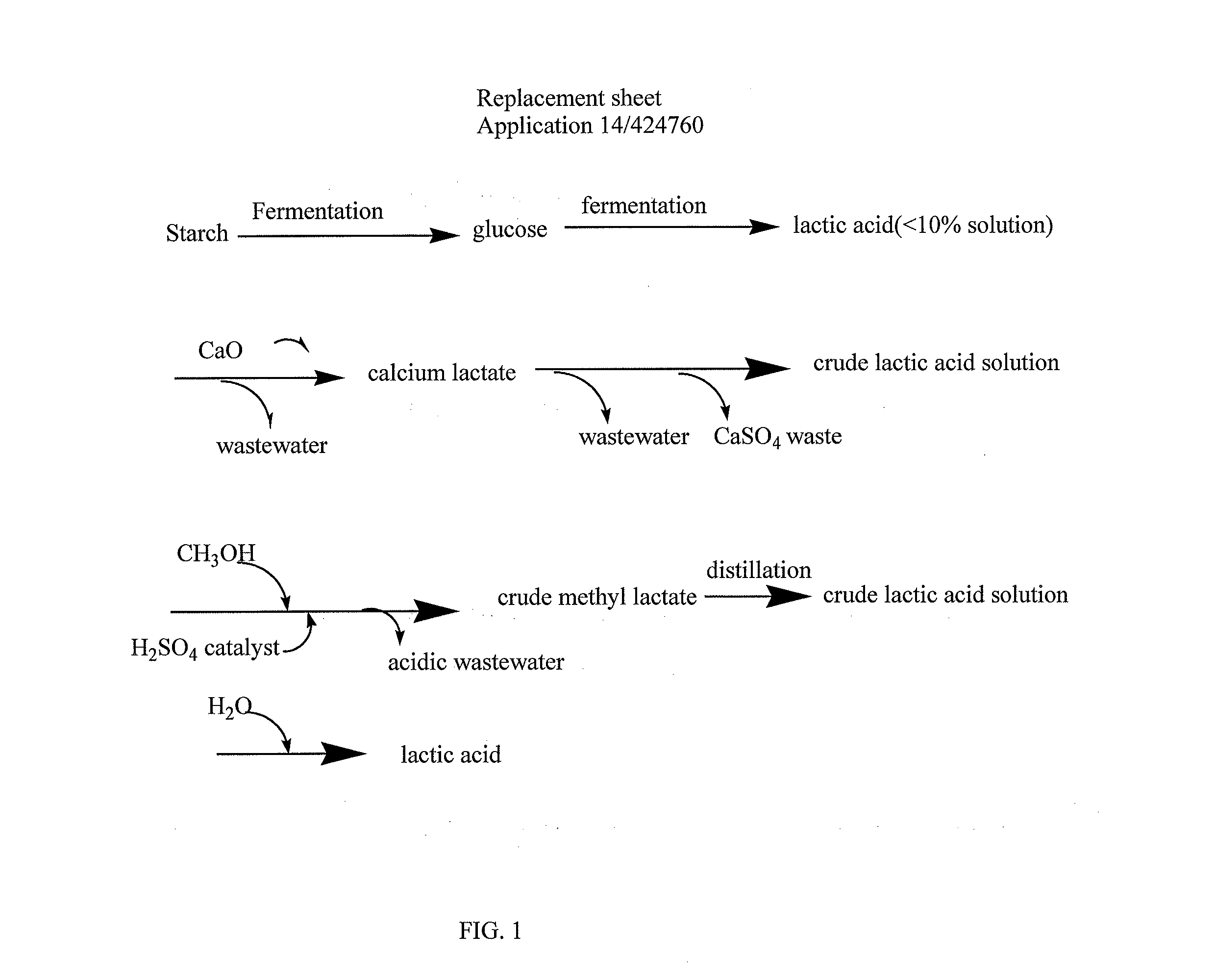

Tin tetrachloride production device with wave tube reactor

InactiveCN105731530ARealize continuous productionNo pollution in the processStannic chlorideTetrachlorideCyclonic separation

The invention discloses a tin tetrachloride production device with a wave tube reactor. The tin tetrachloride production device comprises a tin smelting furnace, a pressurizing tank, a condensing tube, a chlorine gas storage tank, a cyclone separating tank and a product storage tank, wherein the tin smelting furnace is connected to the pressurizing tank; the interior of the tin smelting furnace is provided with the wave tube reactor; the wave tube reactor comprises a reaction pipeline with a tube body as a wave tube body, two inlet tubes and a product outlet tube; the bottom of the pressurizing tank is connected with a tin liquor feeding tube; the tail end of the tin liquor feeding tube is connected to any inlet tube of the wave tube reactor; the outlet of the chlorine gas storage tank is connected with a tee joint; one outlet of the tee joint is connected to the other inlet tube of the wave tube reactor through the chlorine gas inlet tube; another outlet of the tee joint is connected to the top of the cyclone separating tank; the product outlet tube of the wave tube reactor is connected to the cyclone separating tank through the condensing tube; the bottom of the cyclone separating tank is connected to the product storage tank. The tin tetrachloride production device not only can realize continuous production, but also can be high in reaction speed, high in yield and almost free of pollution on environment.

Owner:NANYANG NORMAL UNIV

Method for preparing anhydrous stannic chloride

The invention relates to the field of deep processing of tin, in particular to a process for preparing anhydrous stannic chloride. The process comprises the following steps: tin particles are melted; a fluid formed after melting of the tin particles is perpendicularly sprayed to the surface of a roller rotating at a high speed from top to bottom through a spray nozzle; the fluid is thrown to an atomization chamber on one side due to rotation of the roller, and tin drops are formed; chlorine is introduced to the atomization chamber from bottom to top to be subjected to a reaction with the tin drops; the mixture is sprayed to a collection chamber on one side of the atomization chamber; chlorine is collected from the upper side of the collection chamber; liquid stannic chloride is collected from the lower side of the collection chamber; the collected chlorine is conveyed to the atomization chamber again to be recycled; the collected liquid stannic chloride is gasified and condensed, and the anhydrous stannic chloride is obtained. The sprayed fluid is broken under centrifugal force of the rotating roller, chlorine collides with the tin drops at a high speed and is mixed sufficiently with the tin drops to be subjected to a reaction, the reactants can be sufficiently mixed and then sprayed to the collection chamber through a sprayer, and collection of a product and chlorine is greatly facilitated.

Owner:广东千千省化工有限公司

Method for removing water and purifying chloride

PendingCN114772638AContact speedEasy liquid dispensingArsenic halidesAntimony halidesMolecular sieveEnvironmental engineering

The invention belongs to the technical field of industrial raw material purification, and discloses a water removal and purification method of chloride. The method comprises the following steps: adding concentrated sulfuric acid into dechlorinated chloride, stirring and mixing, standing for layering, then taking the chloride at the lower layer, deeply dewatering through a molecular sieve, further feeding the obtained dewatered chloride into a metal rectifying tower for impurity removal, and thus obtaining the dewatered and purified chloride. The water removal and purification method is simple in process and efficient in water removal, effectively solves a series of problems of kettle cracking, pipeline blockage, sediment and the like caused by chloride with water, improves the operation stability of equipment, and reduces the safety risk. Meanwhile, the chloride subjected to water removal directly enters metal equipment for rectification and impurity removal, and the chloride subjected to impurity removal and purification through the metal equipment can also meet the requirement for the purity of 6N or above.

Owner:广东先导微电子科技有限公司

A kind of method for preparing anhydrous tin tetrachloride

Owner:广东千千省化工有限公司

Purification of TiCl4 through the production of new co-products

Owner:THE CHEMOURS CO FC LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Elastomeric copolymers based on [bis(trihydrocarbylsilyl)aminosilyl]-functionalized styrene and their use in the preparation of rubbers Elastomeric copolymers based on [bis(trihydrocarbylsilyl)aminosilyl]-functionalized styrene and their use in the preparation of rubbers](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/b18e42c0-c08b-4468-84d0-f883022c5707/FDA0001500525320000011.png)

![Elastomeric copolymers based on [bis(trihydrocarbylsilyl)aminosilyl]-functionalized styrene and their use in the preparation of rubbers Elastomeric copolymers based on [bis(trihydrocarbylsilyl)aminosilyl]-functionalized styrene and their use in the preparation of rubbers](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/b18e42c0-c08b-4468-84d0-f883022c5707/FDA0001500525320000021.png)

![Elastomeric copolymers based on [bis(trihydrocarbylsilyl)aminosilyl]-functionalized styrene and their use in the preparation of rubbers Elastomeric copolymers based on [bis(trihydrocarbylsilyl)aminosilyl]-functionalized styrene and their use in the preparation of rubbers](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/b18e42c0-c08b-4468-84d0-f883022c5707/FDA0001500525320000031.png)