Golden ornament and its manufacturing method

A manufacturing method and decoration technology, applied in metal material coating process, ion implantation plating, coating, etc., to achieve excellent adhesion, reduce usage, and maintain the effect of golden tone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0107]Hereinafter, the present invention will be described by way of examples, but the present invention is not limited by these examples. In addition, the corrosion resistance test and the abrasion test in the examples were implemented by the following methods.

[0108] (1) Corrosion resistance test

[0109] The corrosion resistance test was performed in accordance with JIS H8502 (CASS test). The test time is 96 hours. When the rating value in the rating number standard chart is above 9.8, the corrosion resistance evaluation of the test surface is qualified.

[0110] (2) Abrasion test

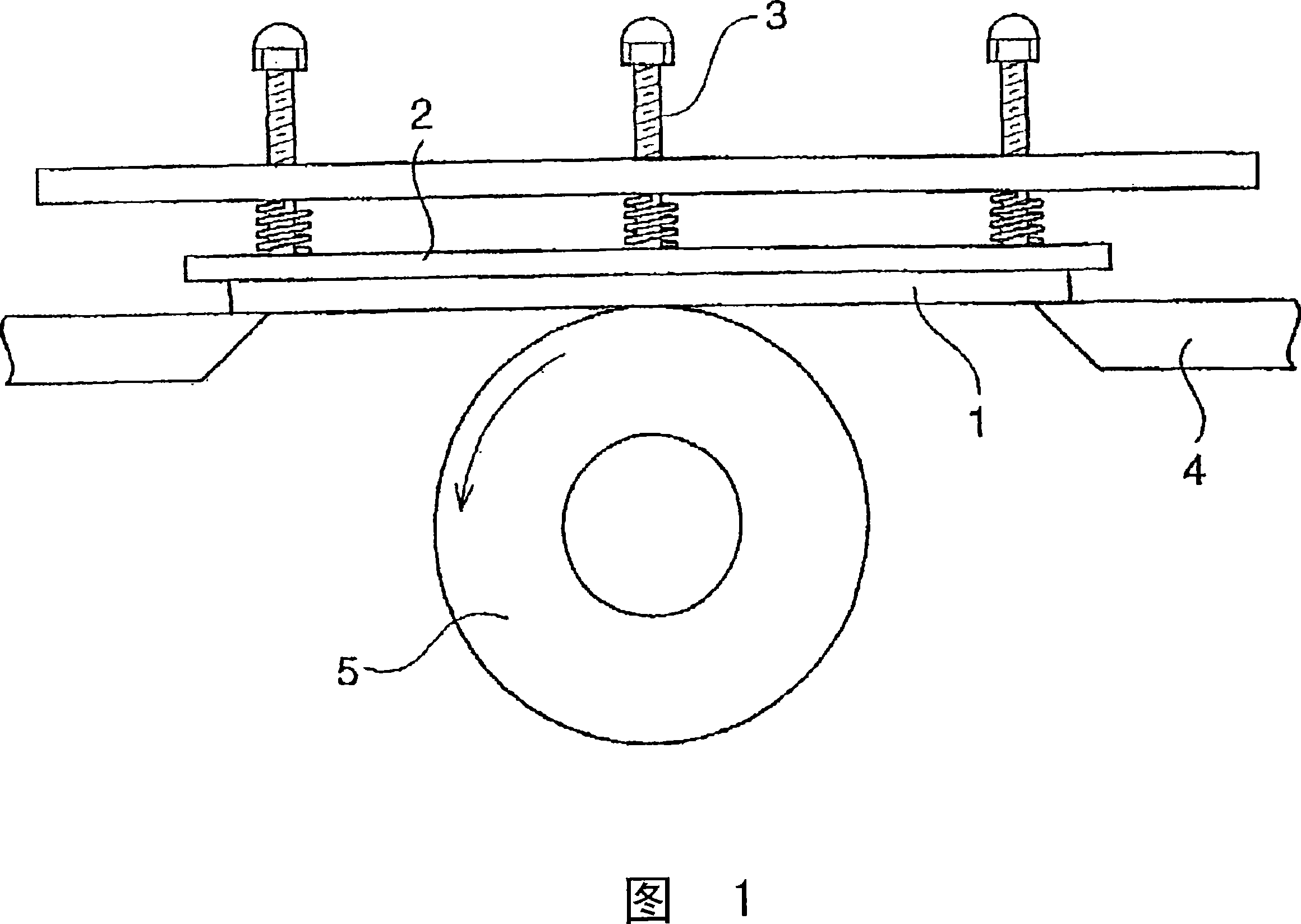

[0111] As shown in FIG. 1 , the test piece 1 formed with the coating film is fixed on the opening of the test piece processing table 4 by using the test piece pressing plate 2 and the test piece pressing screw 3 , with the coating film forming surface facing downward. Next, stick grinding paper (not shown in the figure) on the grinding wheel 5 . An upward load is applied to the abrasive wh...

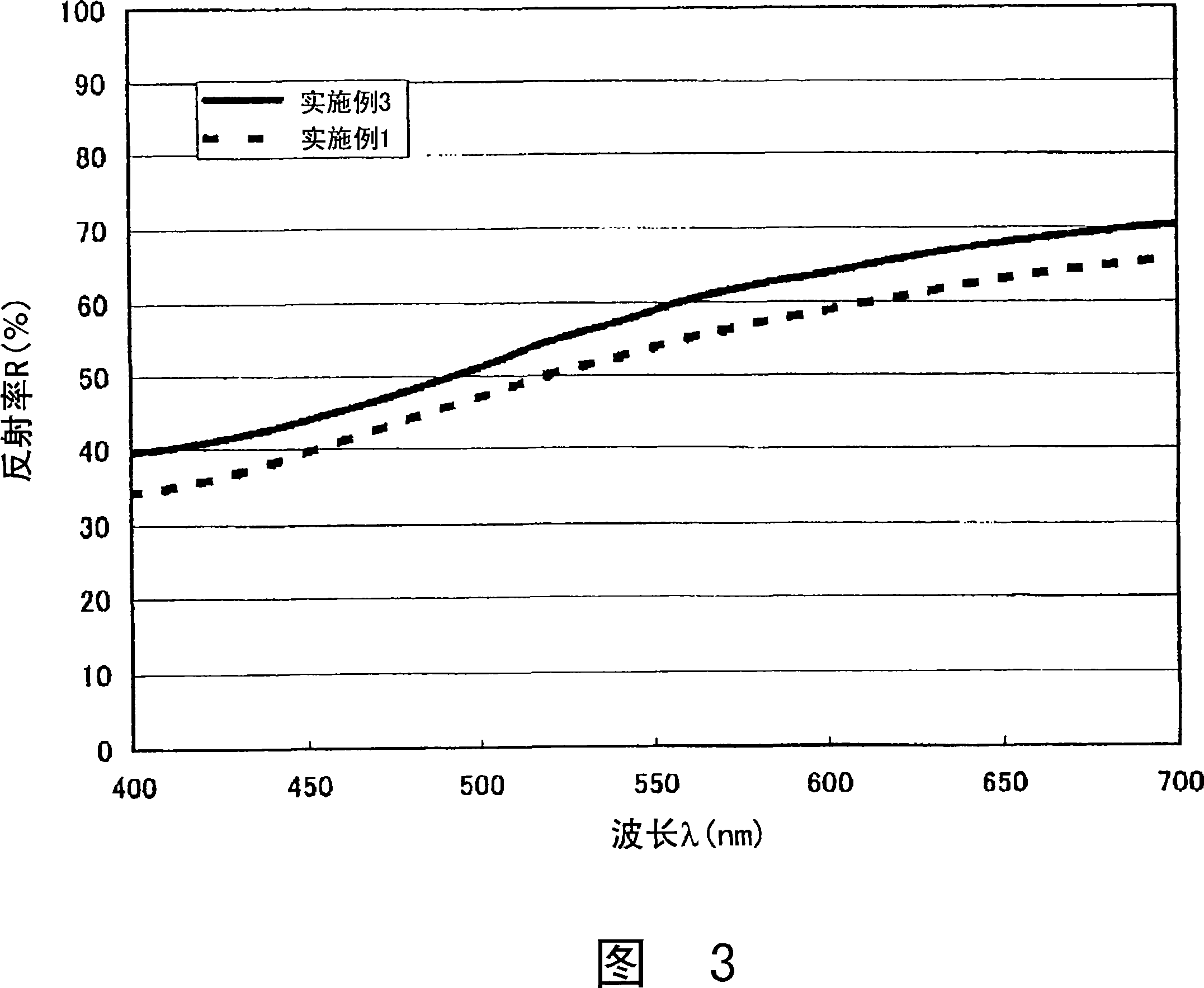

Embodiment 1

[0123] A polished watch case obtained by machining stainless steel (SUS316L) was cleaned and degreased with an organic solvent, and the base material was placed in an ion plating apparatus.

[0124] Next, after evacuating the inside of the apparatus to 1.3 mPa, argon gas was introduced to 0.13 Pa. In this argon atmosphere, plasma was generated by a plasma gun provided inside the apparatus, and then titanium was evaporated for 10 minutes to form a Ti coating film with a film thickness of 0.2 μm on the surface of the watch base material.

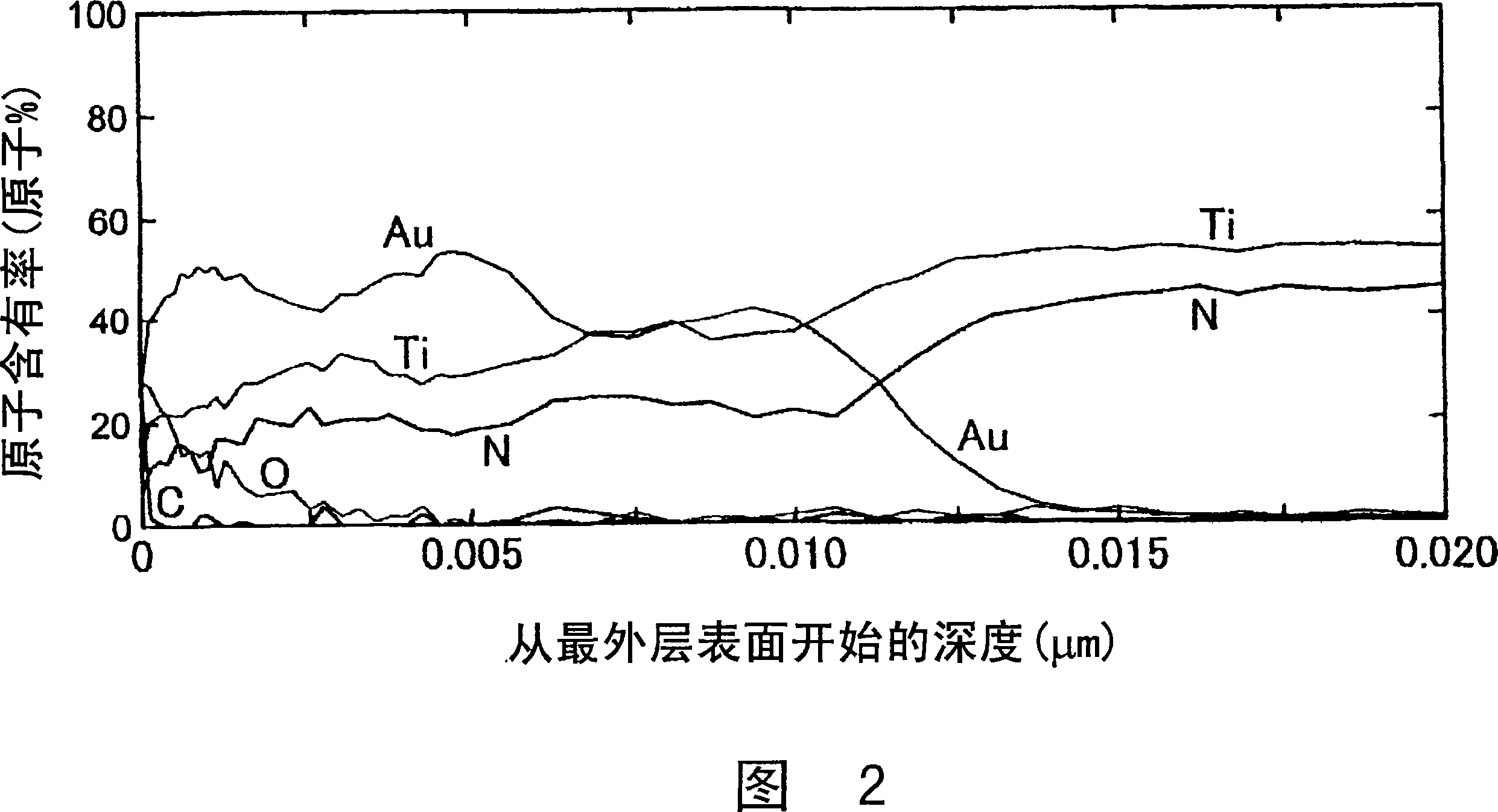

[0125] Next, titanium was evaporated under the same conditions as in the formation of the above-mentioned Ti coating film, while changing the introduced gas from argon to a mixed gas of nitrogen and argon. At this time, under the condition that the gas flow rate is kept constant at 300 sccm, the flow rate ratio of nitrogen gas to argon gas (N 2 / Ar) increased from 0 to 2.0 in 35 minutes. In this way, a TiN gradient coating film with a film t...

Embodiment 2

[0134] A polished watch case obtained by machining stainless steel (SUS316L) was cleaned and degreased with an organic solvent, and the base material was placed in an ion plating apparatus.

[0135] Next, after evacuating the inside of the apparatus to 1.3 mPa, argon gas was introduced to 0.13 Pa. In this argon atmosphere, plasma was generated by a plasma gun provided inside the apparatus, and then titanium was evaporated for 10 minutes to form a Ti coating film with a film thickness of 0.2 μm on the surface of the watch base material.

[0136] Next, titanium was evaporated under the same conditions as in the formation of the above-mentioned Ti coating film, while changing the introduced gas from argon to a mixed gas of nitrogen and argon. At this time, under the condition that the gas flow rate is kept constant at 300 sccm, the flow rate ratio of nitrogen gas to argon gas (N 2 / Ar) increased from 0 to 2.0 in 35 minutes. In this way, a TiN gradient coating film with a film t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com