Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

420 results about "Gold alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gold can alloy with almost all other metals, but most of the bodies thus formed are of little or no practical importance. Tin, zinc, arsenic and antimony unite with gold with contraction, and form pale yellow or grey coloured, hard, brittle and easily fusible alloys, of which all, except those containing zinc,...

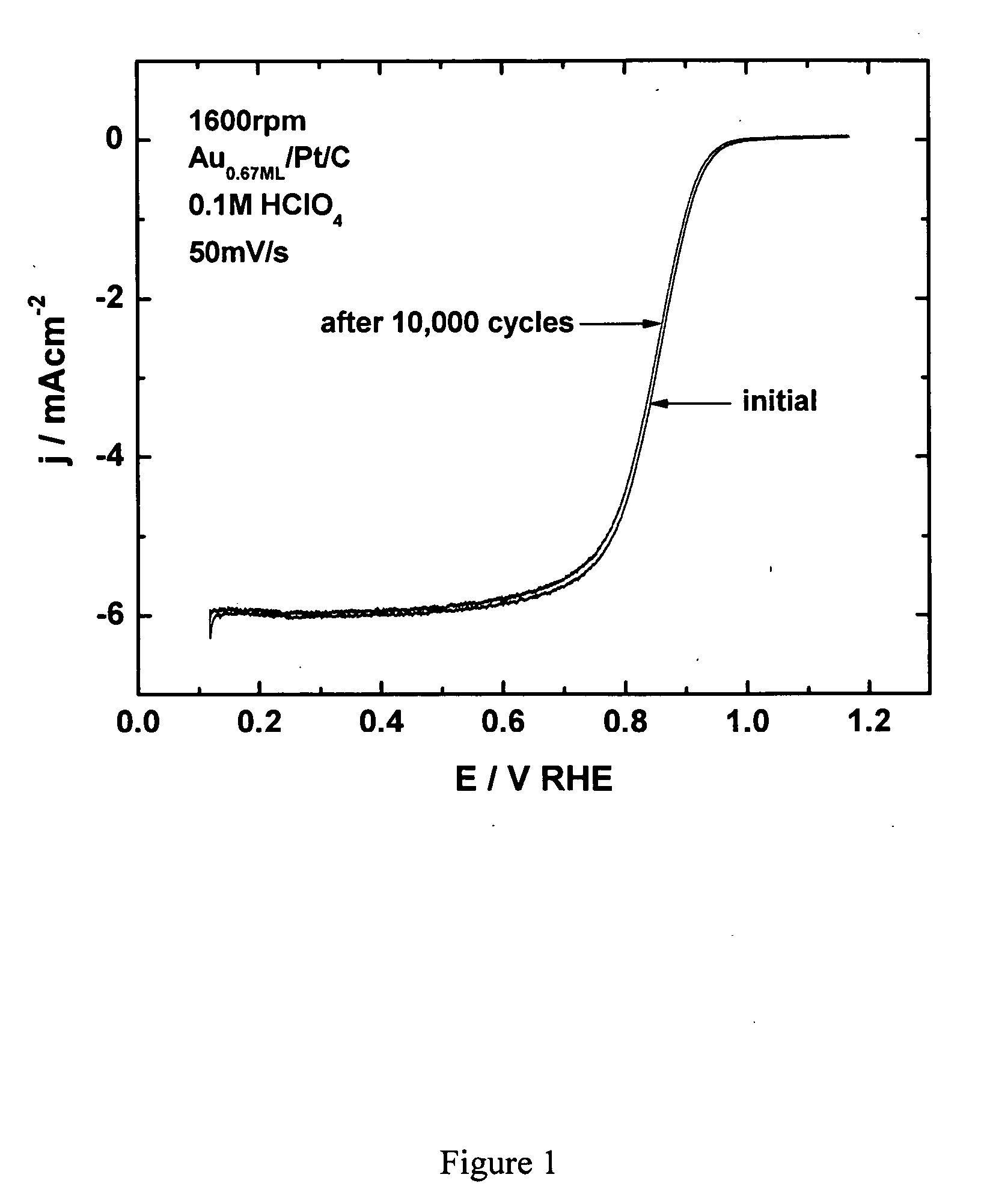

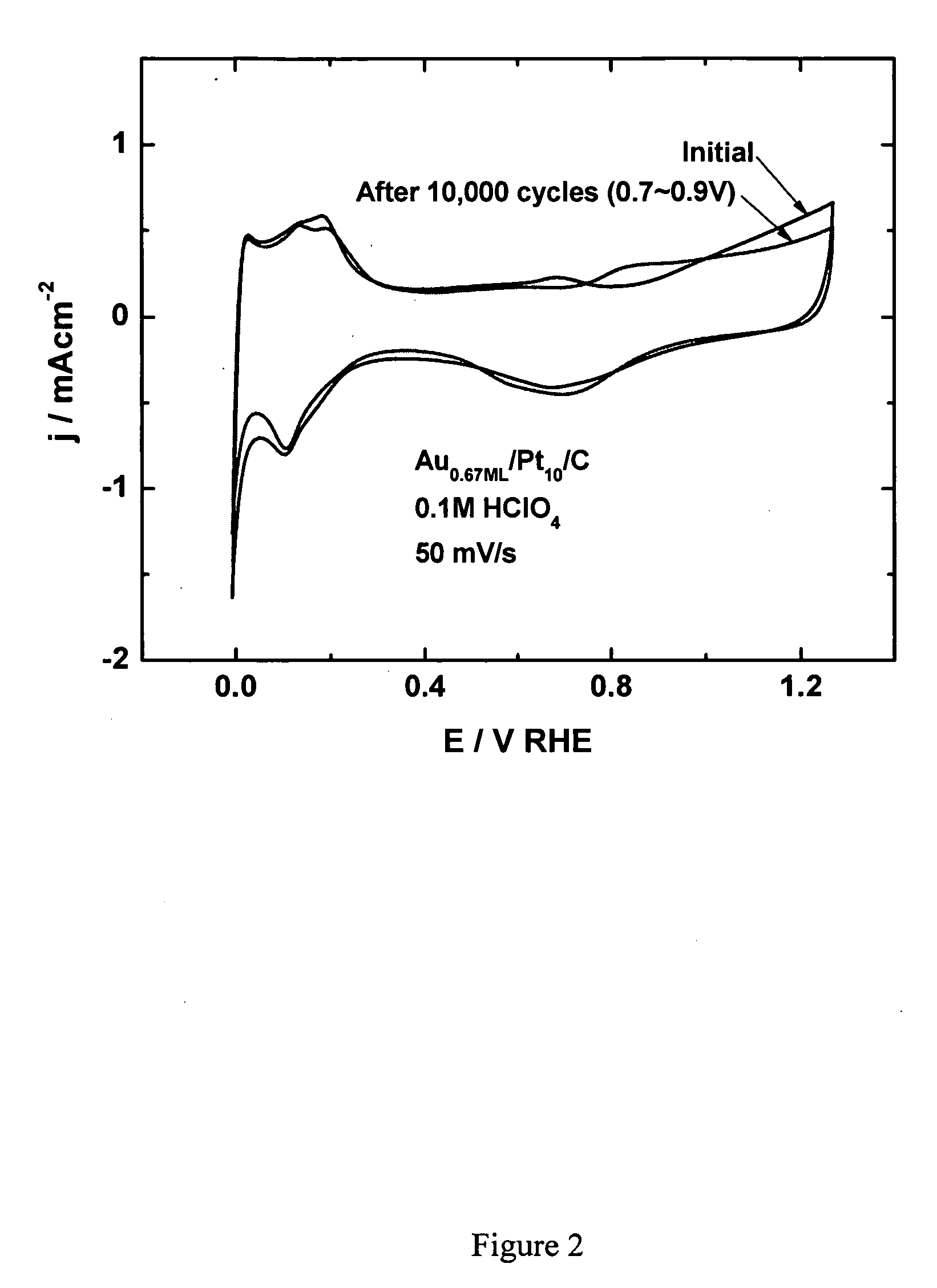

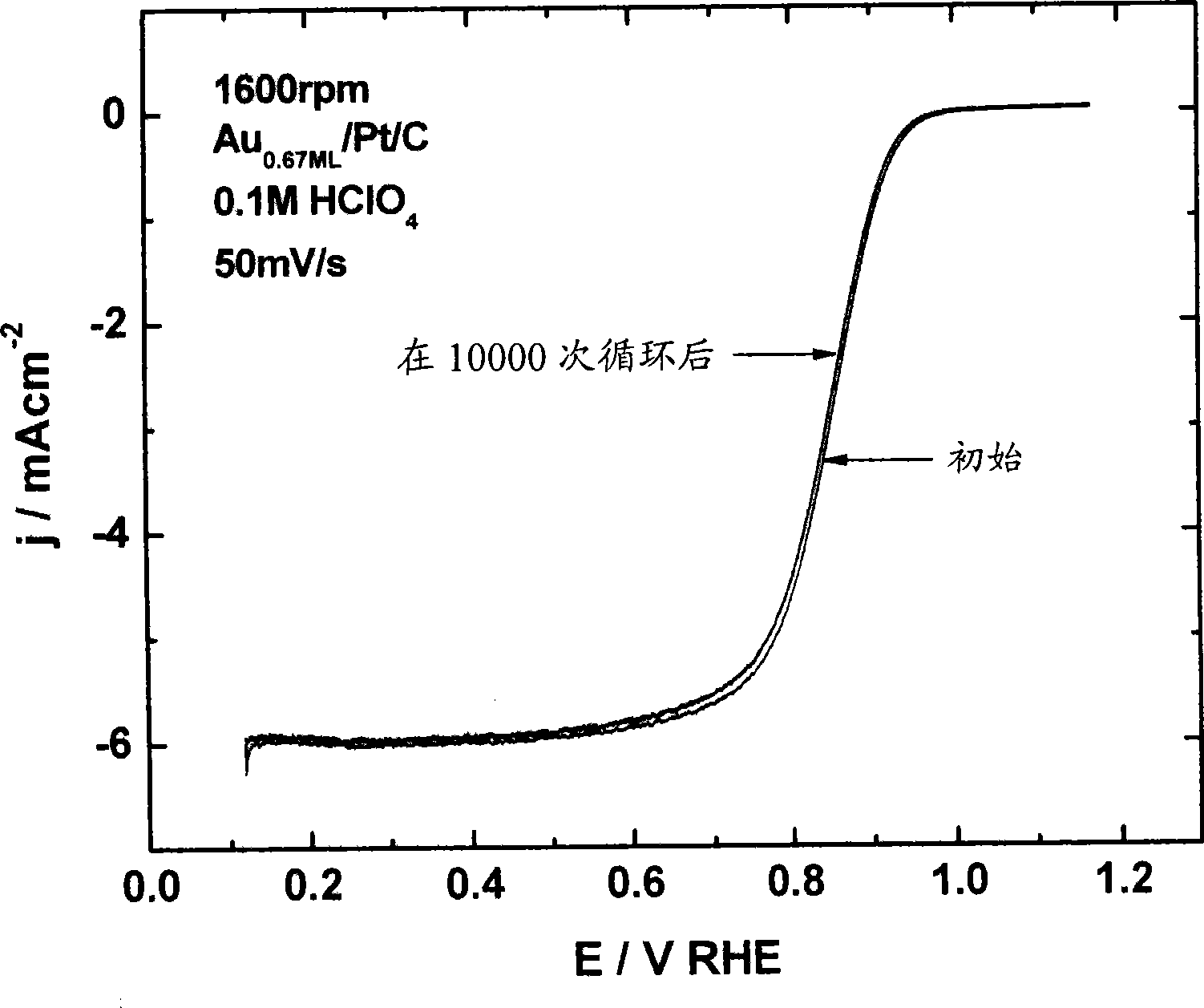

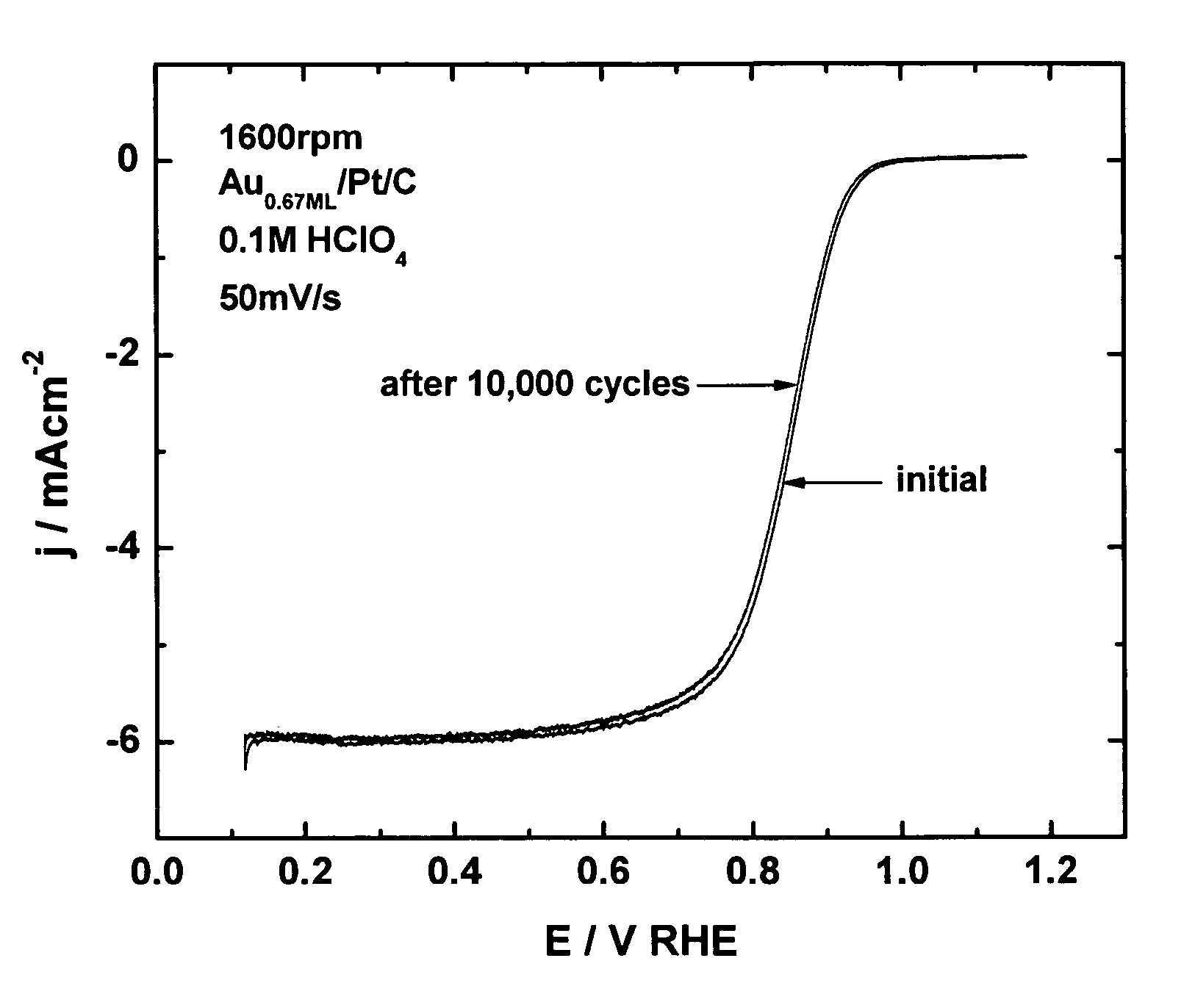

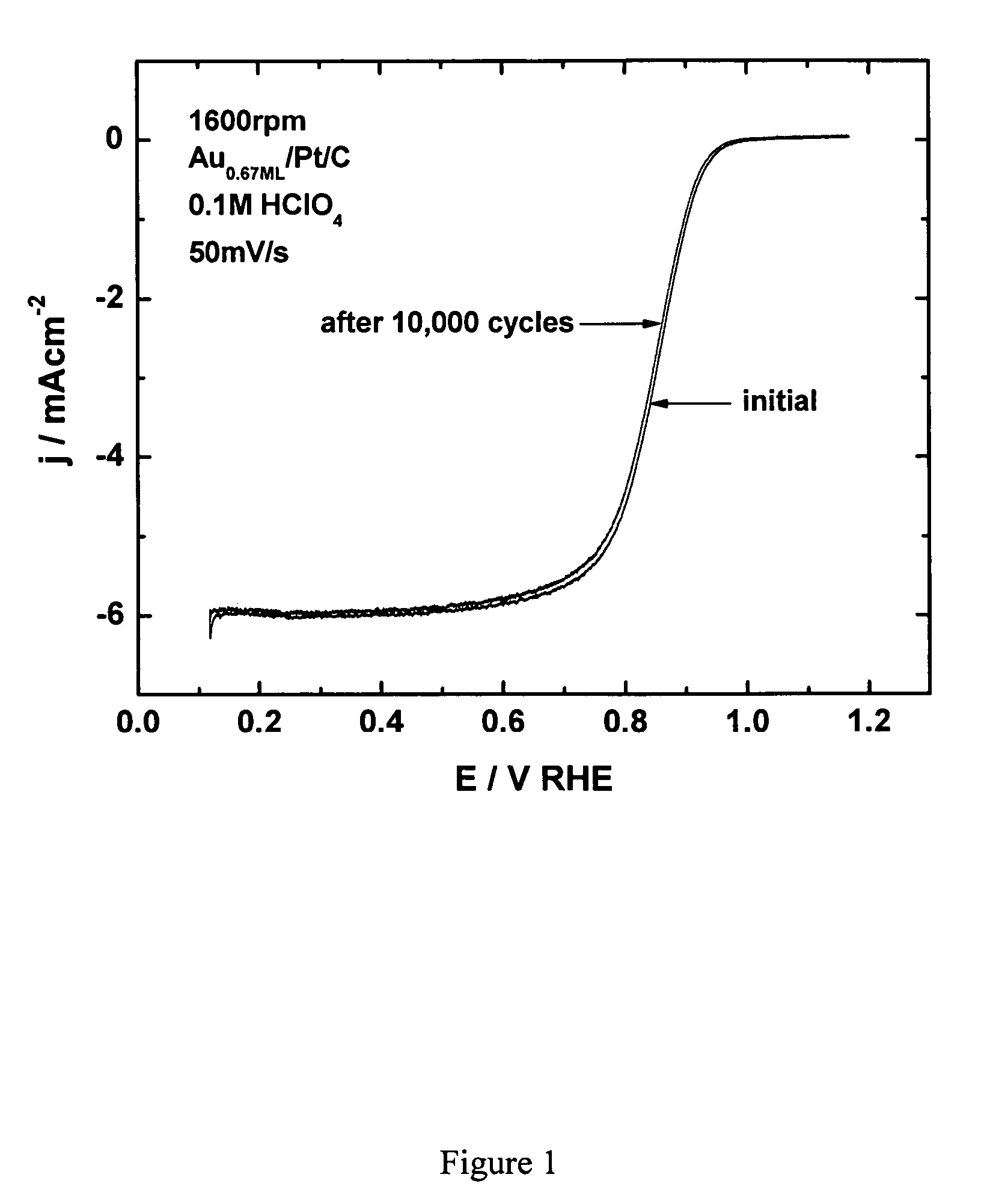

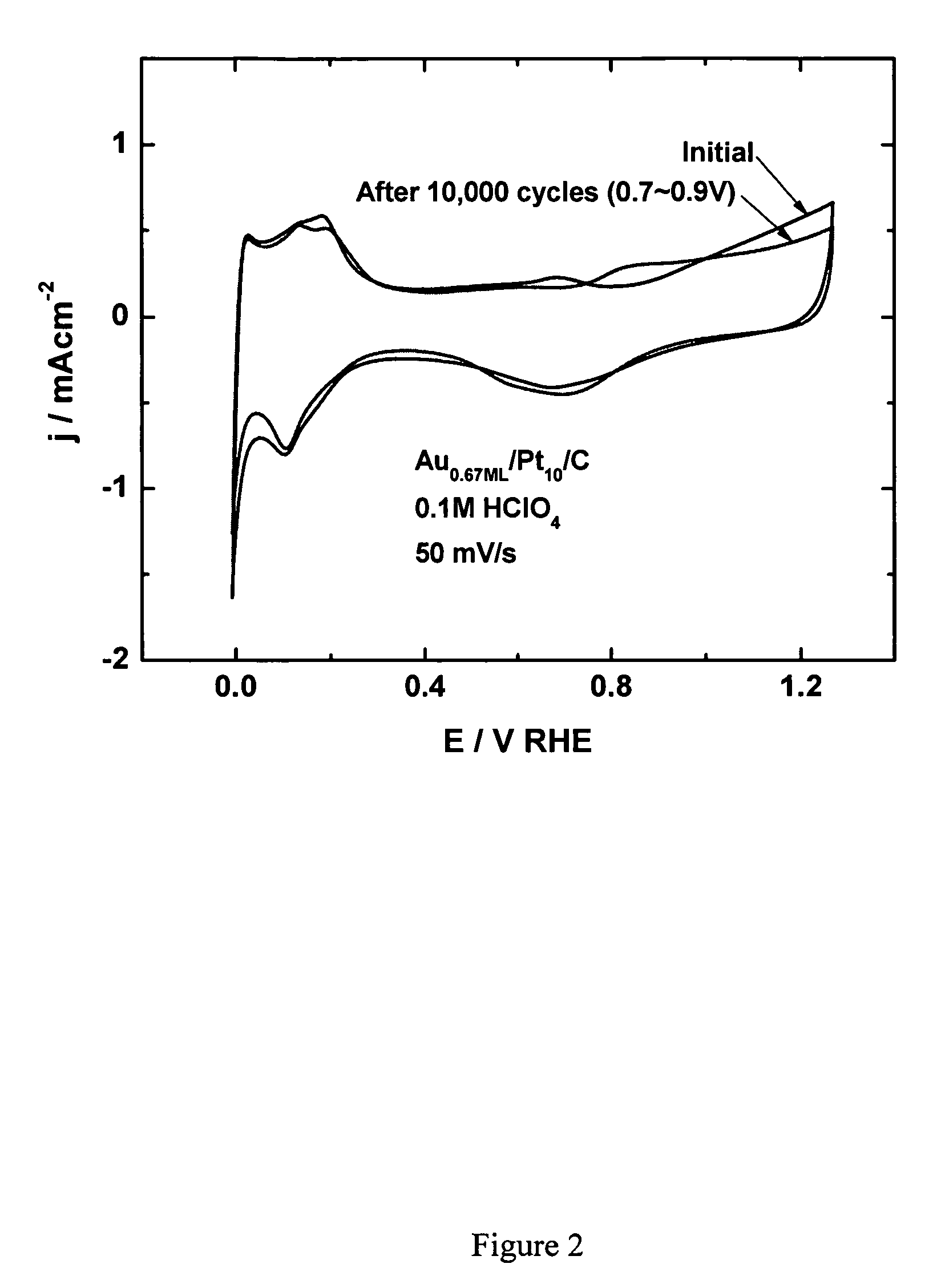

Electrocatalysts having gold monolayers on platinum nanoparticle cores, and uses thereof

InactiveUS20070026292A1Maintain efficiencyReduce loadMaterial nanotechnologyOrganic-compounds/hydrides/coordination-complexes catalystsPlatinumFuel cells

The invention relates to gold-coated particles useful as fuel cell electrocatalysts. The particles are composed of an electrocatalytically active core at least partially encapsulated by an outer shell of gold or gold alloy. The invention more particularly relates to such particles having a noble metal-containing core, and more particularly, a platinum or platinum alloy core. In other embodiments, the invention relates to fuel cells containing these electrocatalysts and methods for generating electrical energy therefrom.

Owner:BROOKHAVEN SCI ASSOCS

Low current high temperature switch contacts

A low ampere mechanical switch has a contact design creating a line of contact between the moveable and stationary contacts. The stationary contacts are stainless steel and the moveable contact is Inconel TM . Both contacts have a thin plating of gold alloy to provide for good mechanical strength at high temperature with a natural lubricating ability. The contact physical design provides good wiping action and mechanical contact while preventing troughing.

Owner:HONEYWELL INC

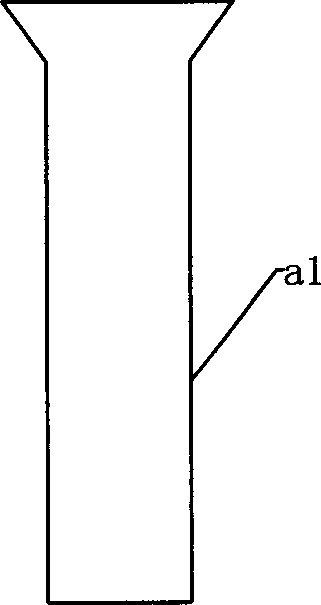

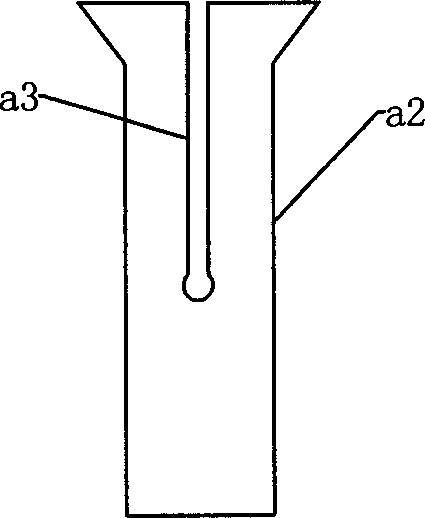

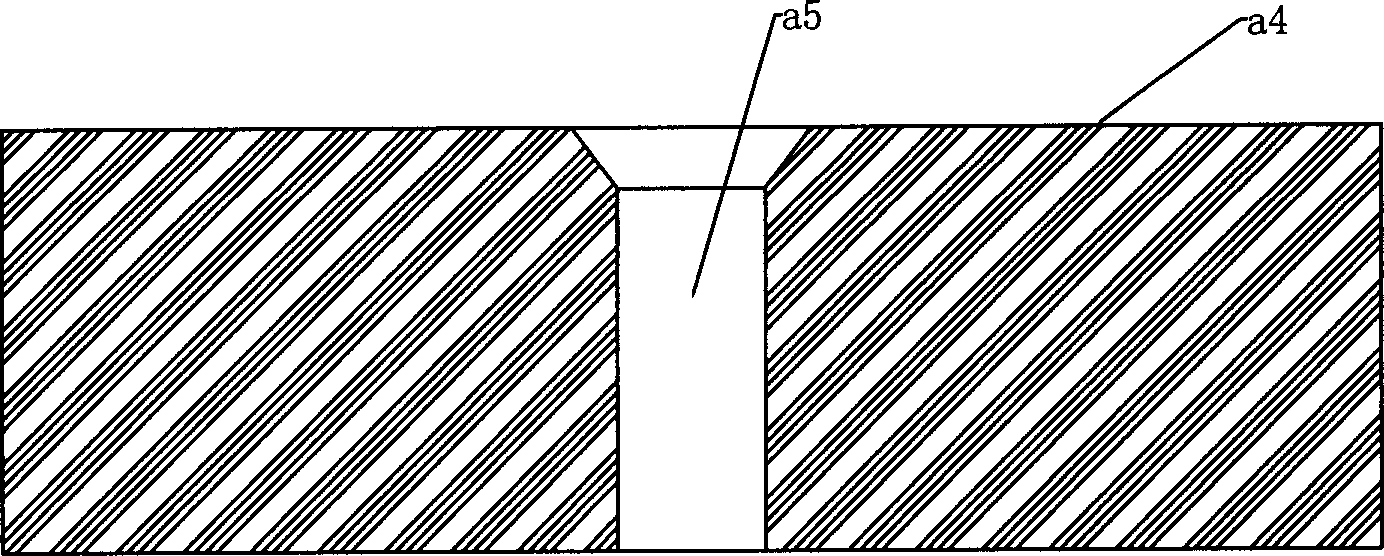

Method for mounting diamond, diocroma or the like in jadeite or jade

A method for inlaying the diamond or zircon onto jadeite includes such steps as blanking, drilling one or more blind or through holes, installing inlaying nail, cutting the inlaying nail, inlaying the diamond or zircon to said inlaying nail, wrapping the edge of inlaid diamond or zircon by an expanding sleeve made of gold alloy or stainless steel, grinding and polishing.

Owner:李杰城

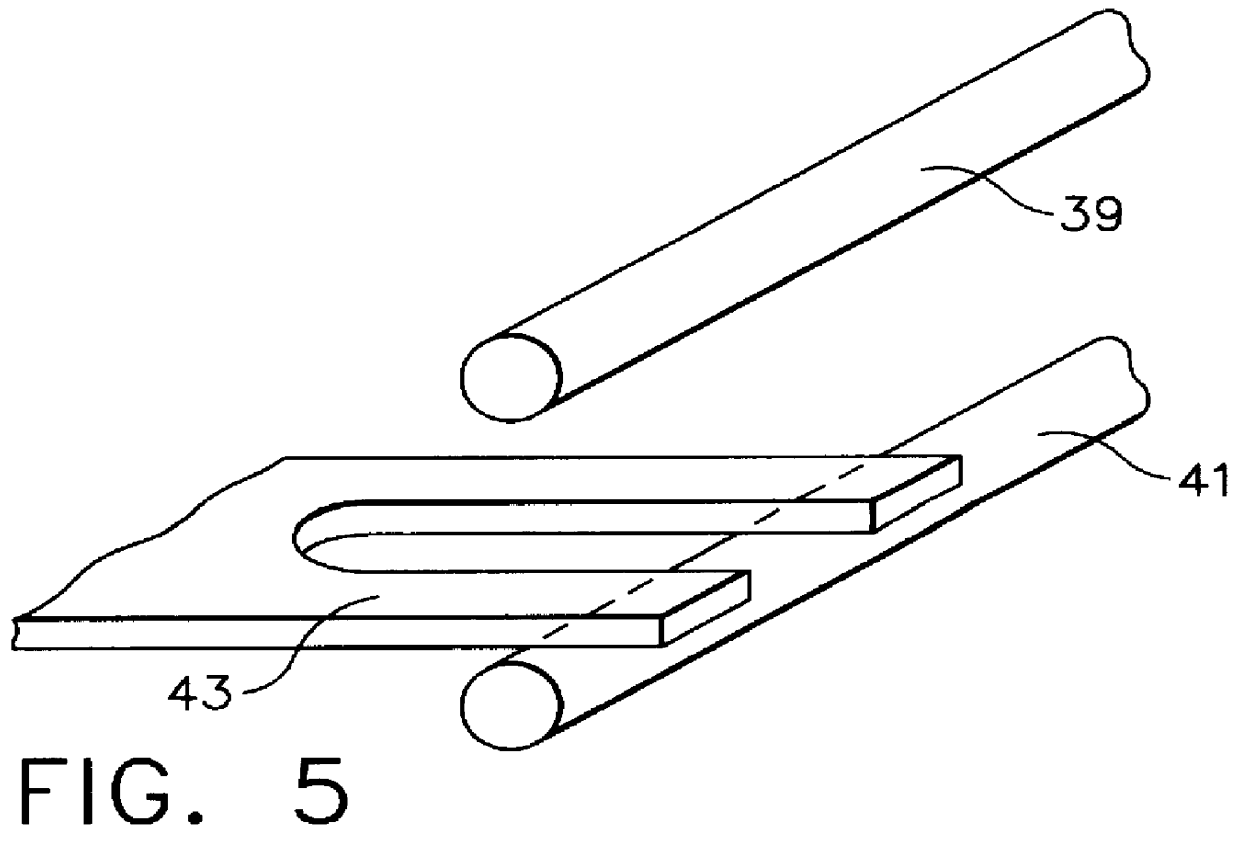

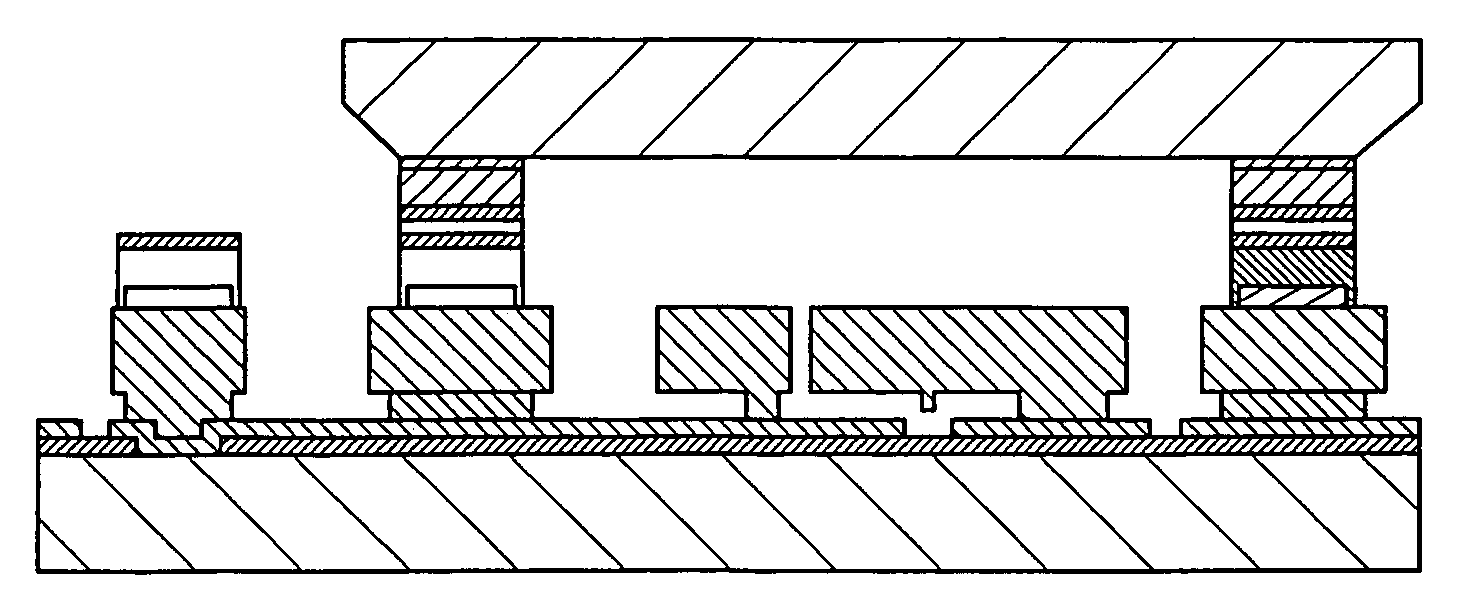

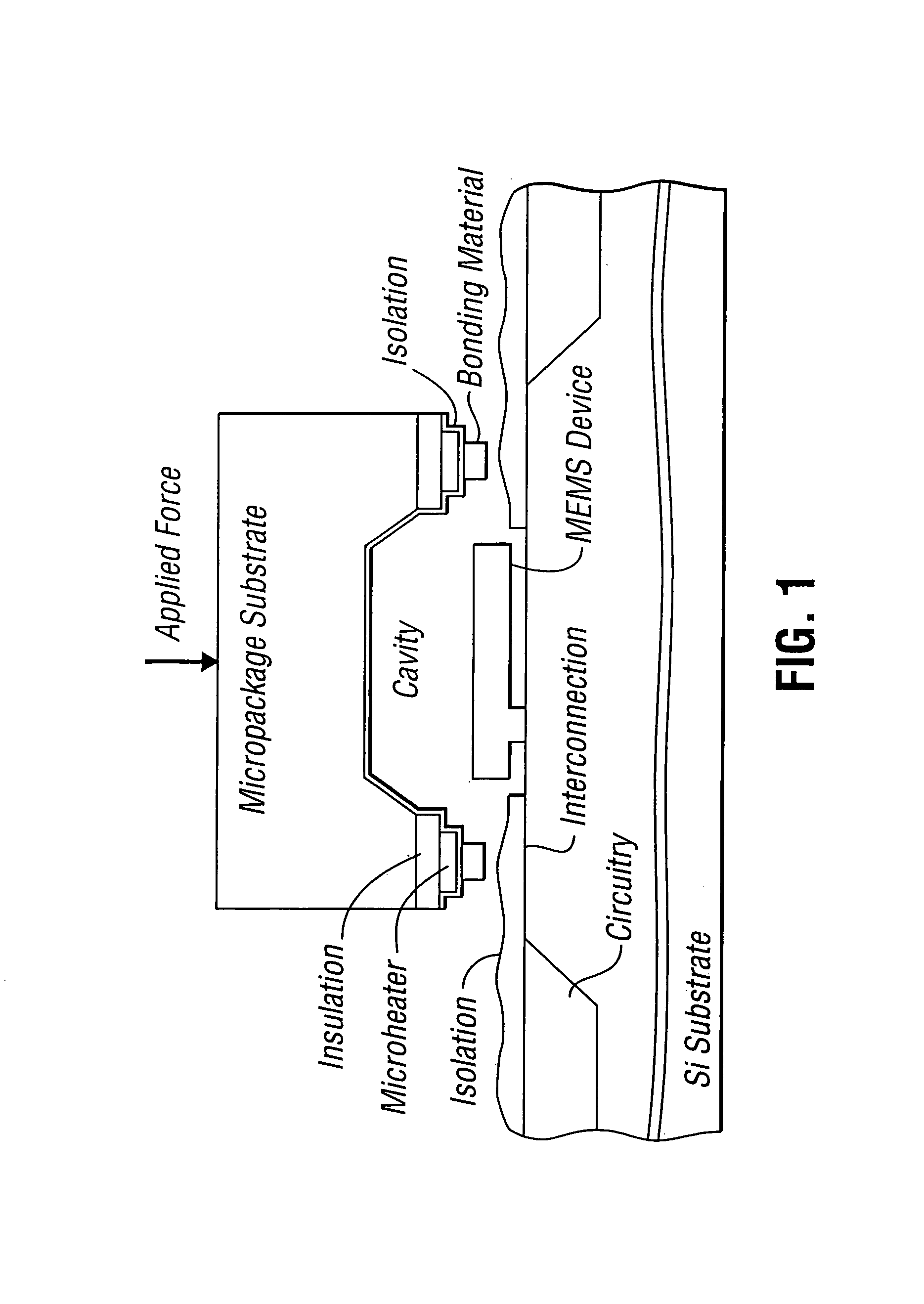

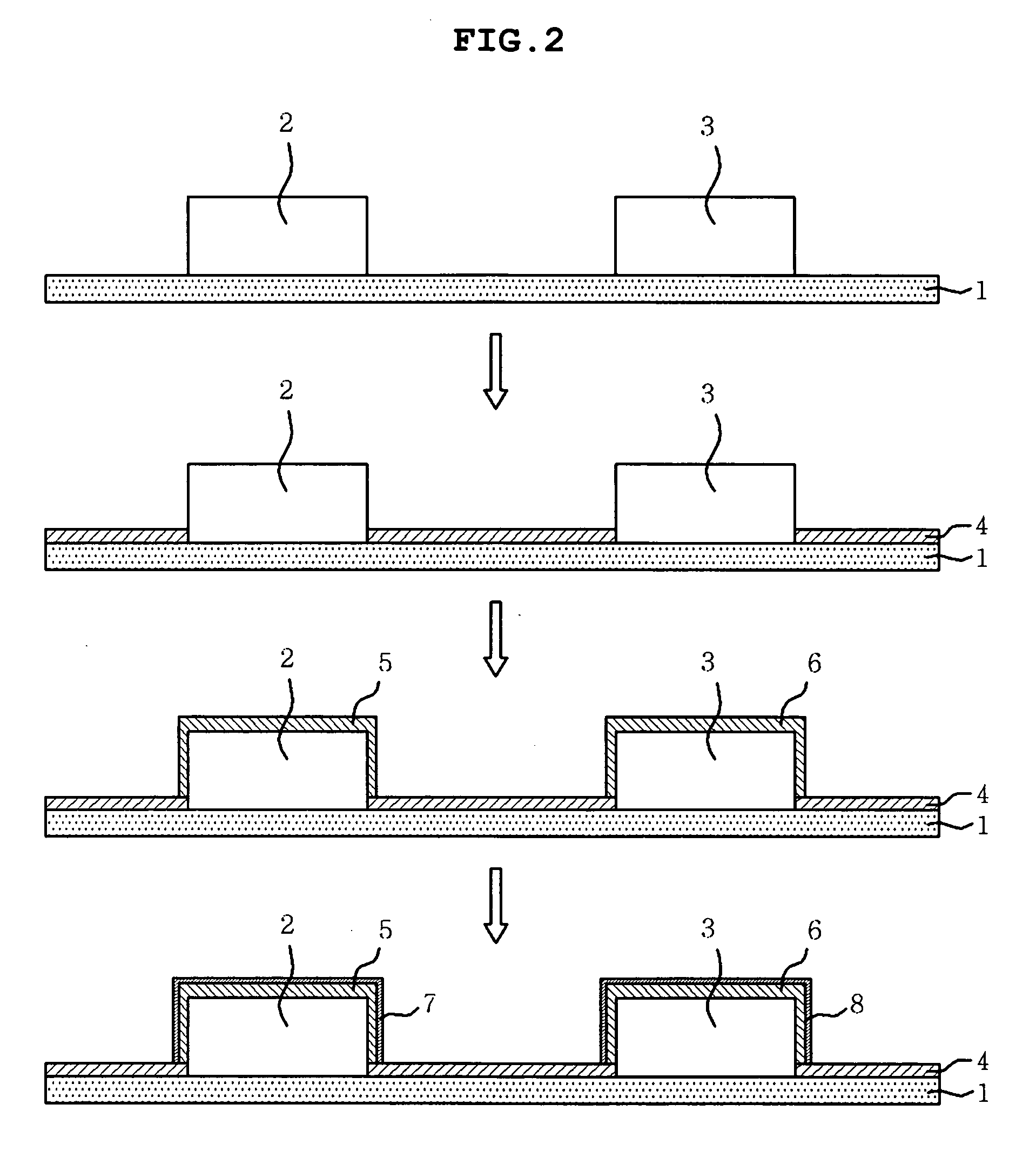

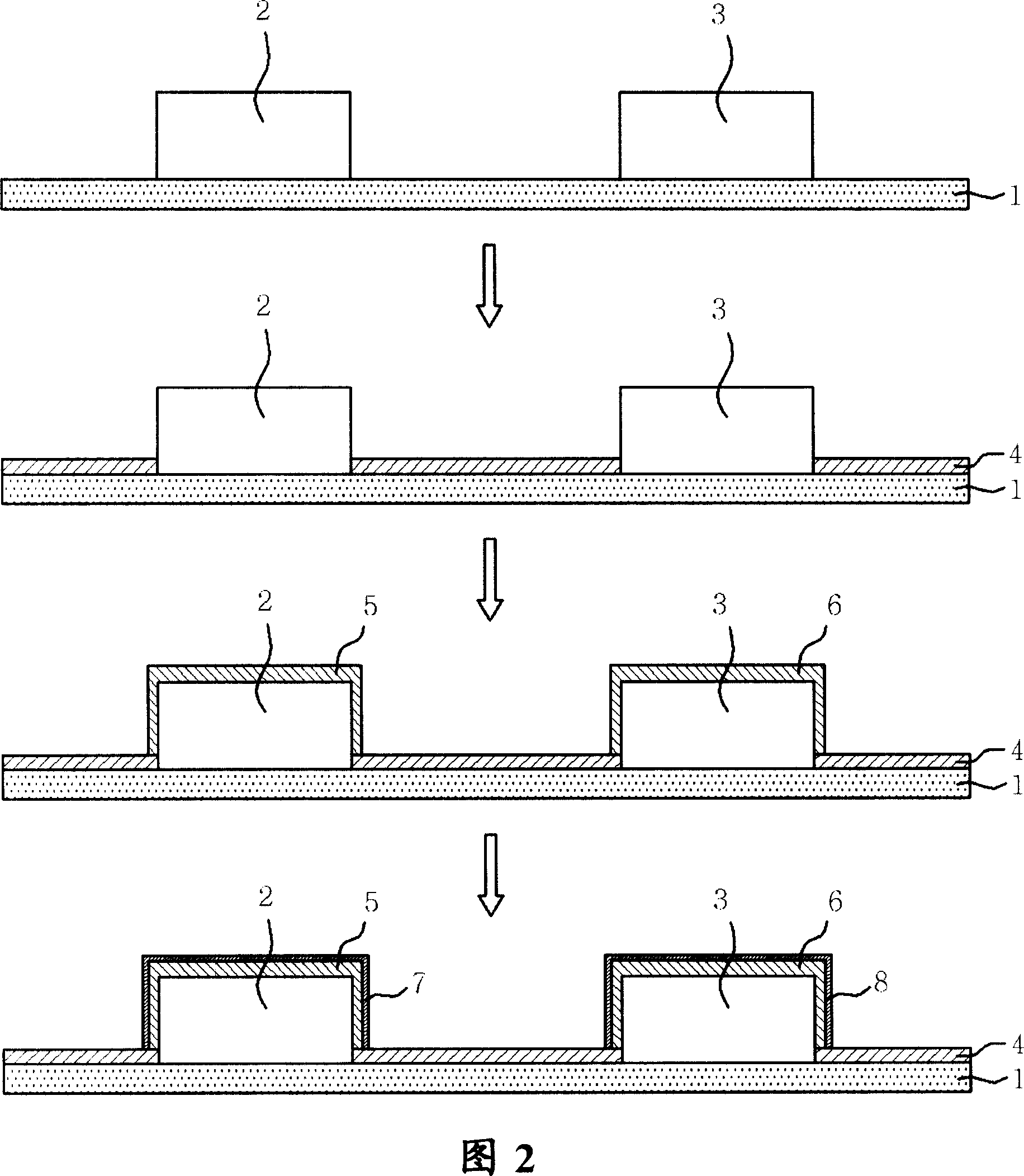

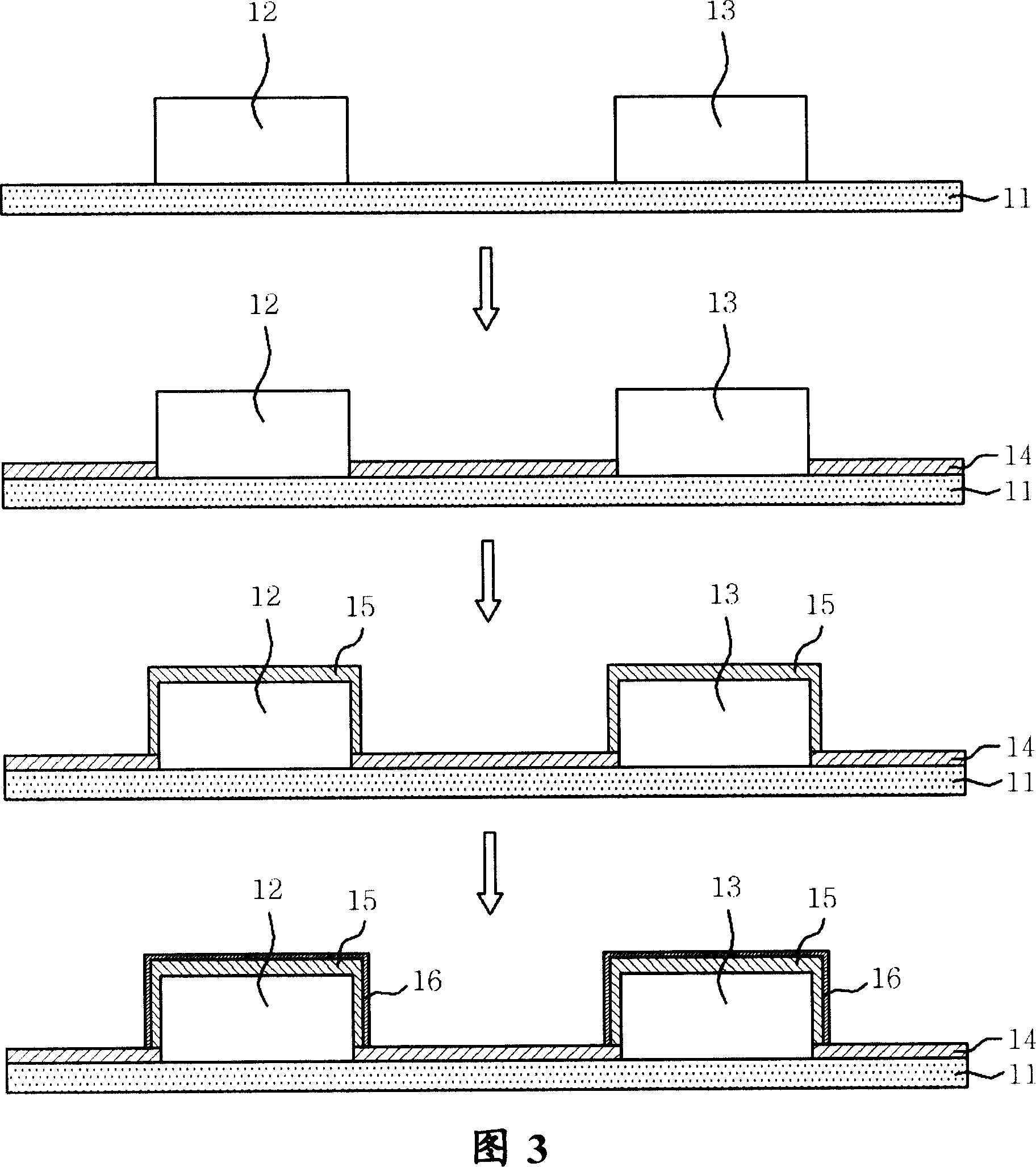

Wafer level packaging technique for microdevices

InactiveUS7138293B2Low cost processingLow costDecorative surface effectsSemiconductor/solid-state device detailsCadmium CationTin

A method is disclosed for fabricating a integrated device, such as a MEMS device. A first wafer is provided on an exposed surface with a layer of gold, gold alloy or gold compound. A second wafer is provided on its exposed surface with under-layer of gold, gold alloy or gold compound; and an over- of bismuth, bismuth alloy, a compound of bismuth, cadmium, cadmium alloy, a compound of cadmium compound, tin, tin alloy, or a compound of tin. The wafers are then brought into contact and bonded at their surfaces through the deposited layers.

Owner:TELEDYNE DIGITAL IMAGING INC

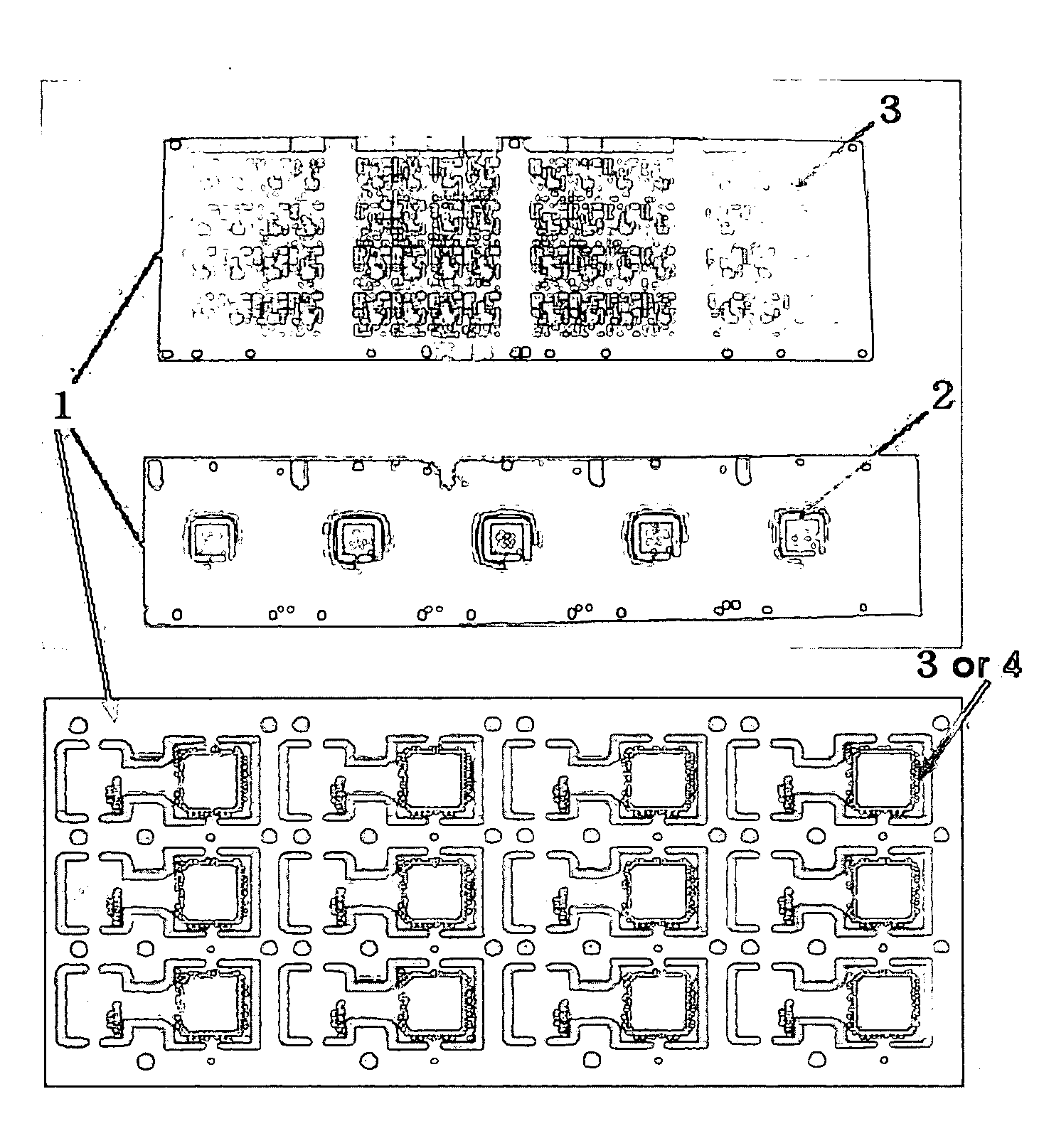

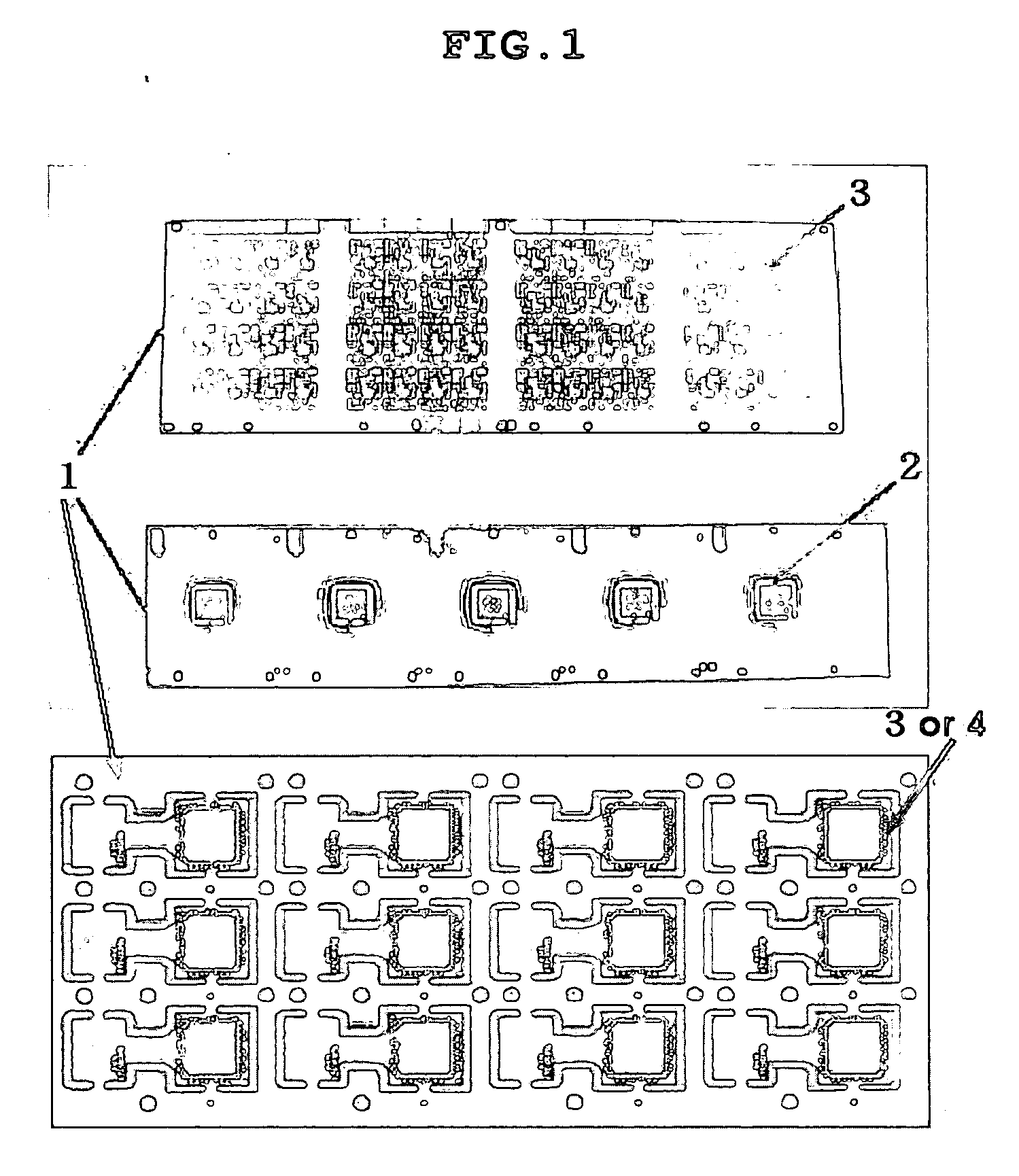

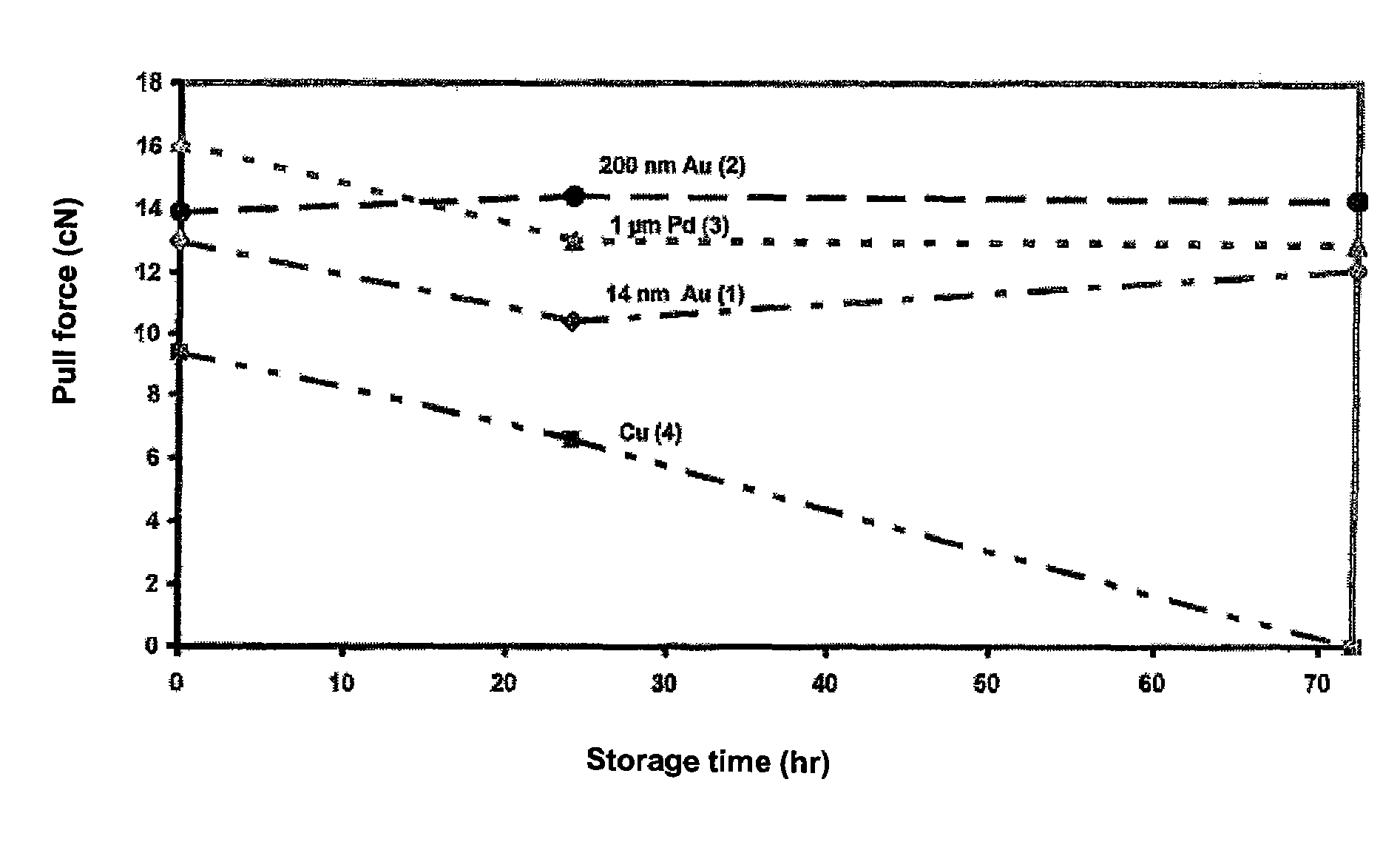

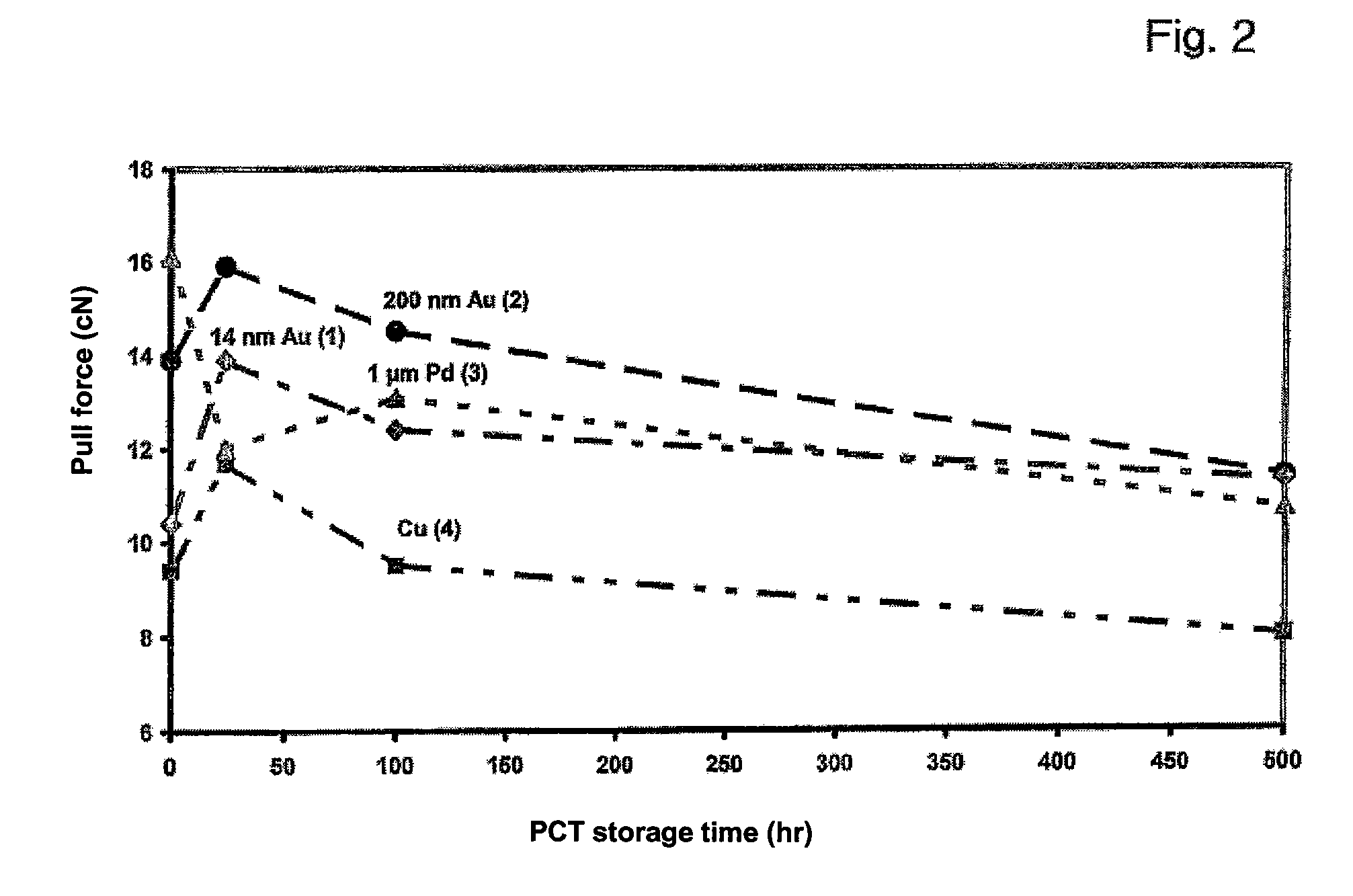

Method for plating printed circuit board and printed circuit board manufactured therefrom

InactiveUS20070104929A1Reduce thicknessDecreasing solderabilitySemiconductor/solid-state device detailsSolid-state devicesElectroless nickelCrazing

Disclosed herein are a method for plating a printed circuit board and the printed circuit board manufactured therefrom. In the method, a bare soldering or wire bonding portion of a copper (Cu)- or copper alloy layer, is plated with palladium (Pd) or a palladium alloy, and then gold (Au) or a gold alloy is deposited over the palladium or palladium alloy plated layer by an electroless substitution plating process based on ionization tendency. Having superior hardness, ductility and corrosion resistance, palladium is suitable for use between a connector and a substrate and meets requirements for the printed circuit board even when applied to a low thickness, greatly reducing the process time. Accordingly, the problem of black pad, which frequently occur on electroless nickel and electroless gold finish upon surface mount technology, can be perfectly solved. Particularly, fatal bending cracks can be prevented from occurring in the rigid-flexible or flexible printed circuit boards.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD +1

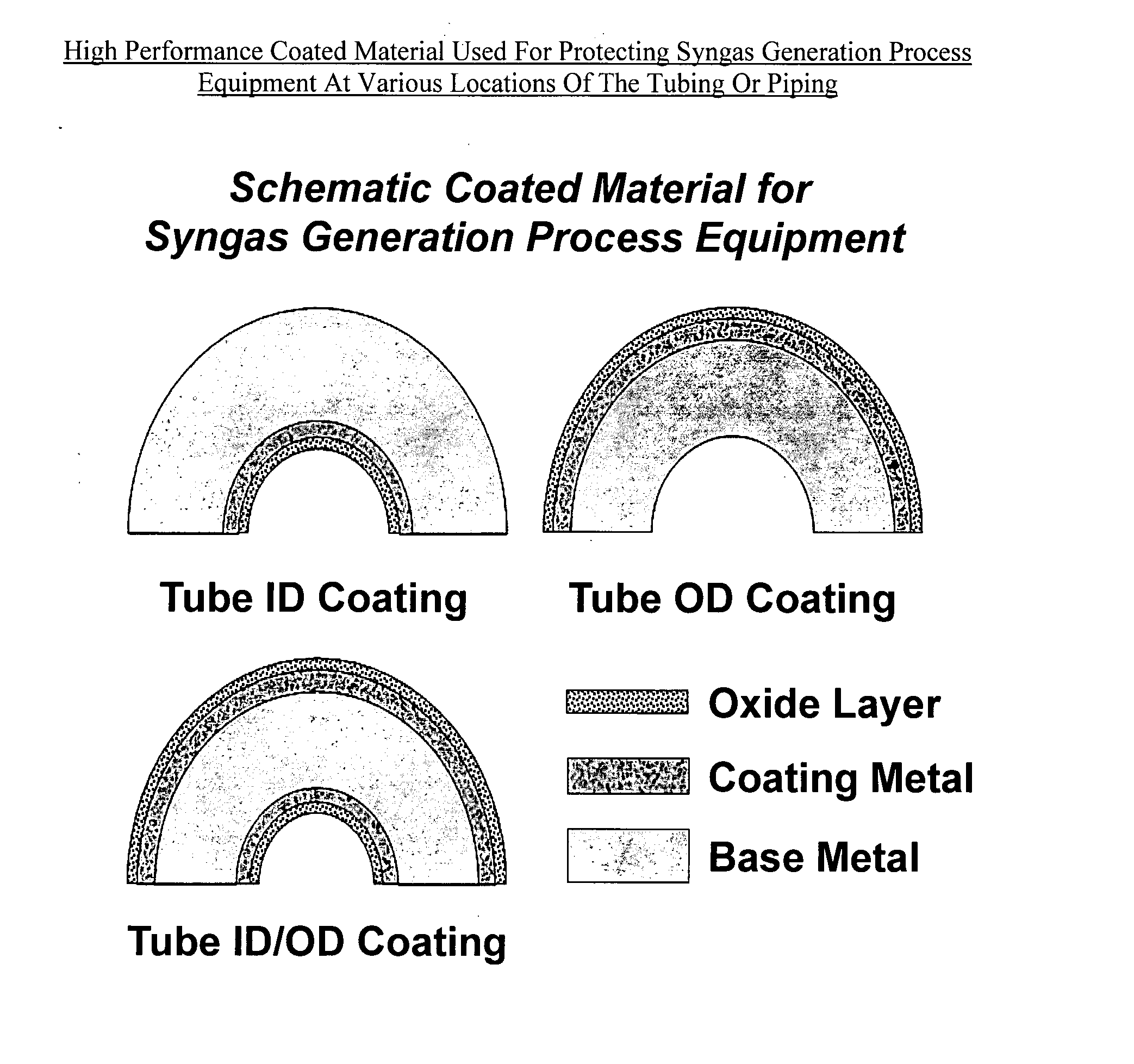

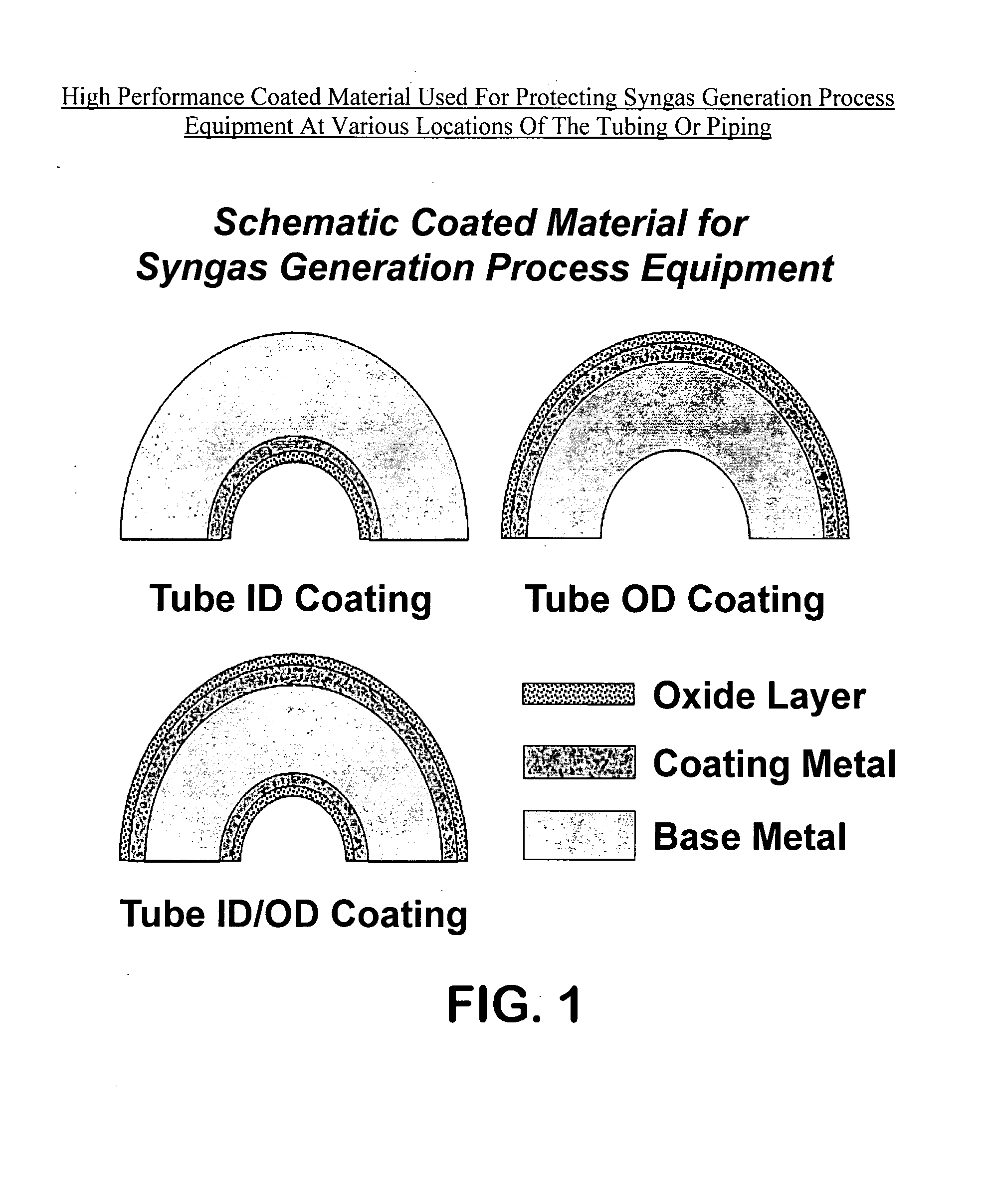

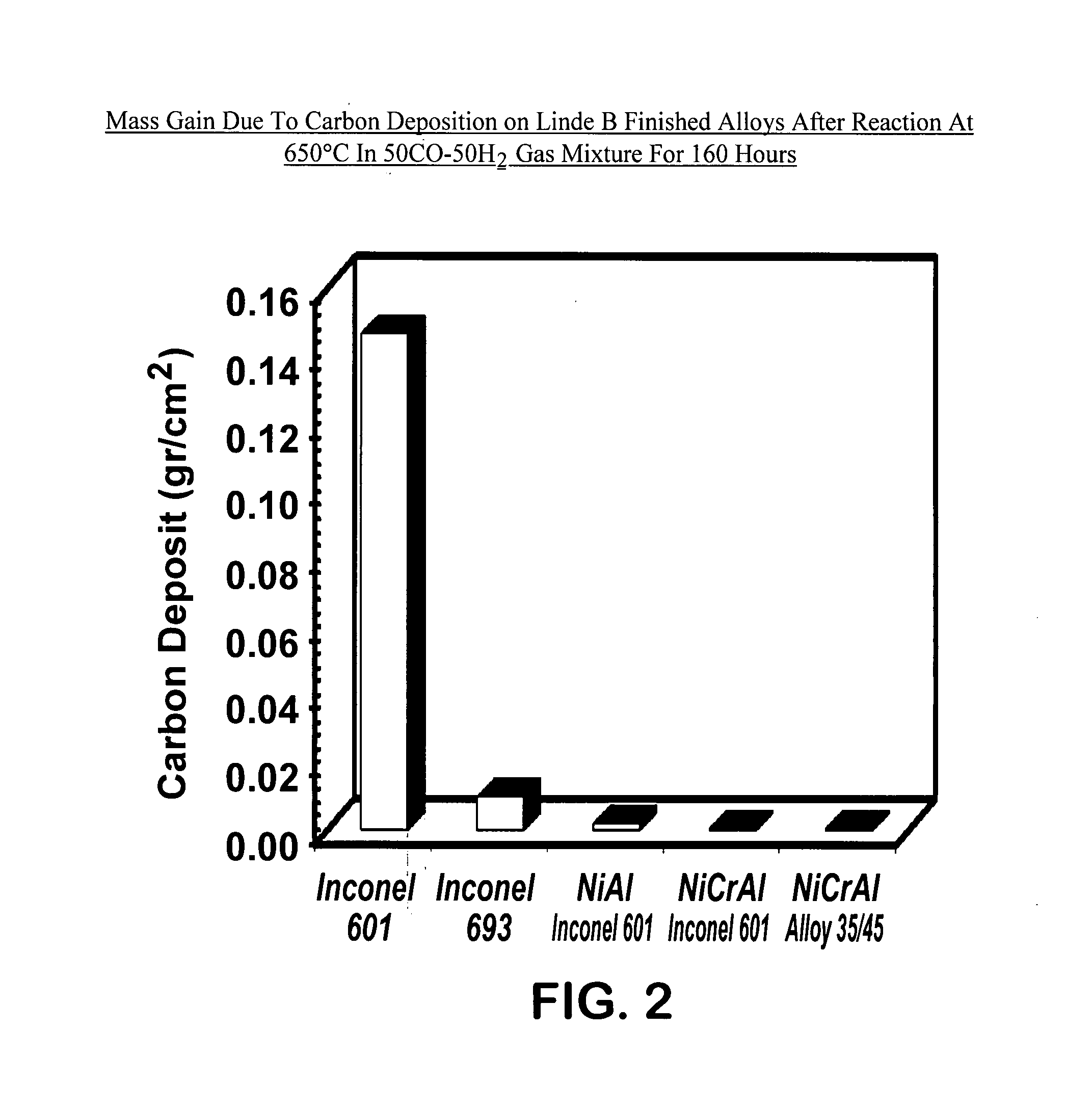

High performance coated material with improved metal dusting corrosion resistance

InactiveUS20080020216A1Improve the immunityReduce carbon depositionAnodisationLiquid surface applicatorsMulliteInconel

High performance coated metal compositions resistant to metal dusting corrosion and methods of providing such compositions are provided by the present invention. The coated metal compositions are represented by the structure (PQR), wherein P is an oxide layer at the surface of (PQR), Q is a coating metal layer interposed between P and R, and R is a base metal. P includes alumina, chromia, silica, mullite or mixtures thereof. Q includes Ni and Al, and at least one element selected from the group consisting of Cr, Si, Mn, Fe, Co, B, C, N, P, Ga, Ge, As, In, Sn, Sb, Pb, Sc, La, Y, Ce, Ti, Zr, Hf, V, Nb, Ta, Mo, W, Ru, Rh, Ir, Pd, Pt, Cu, Ag, Au and mixtures thereof. R is selected from the group consisting of carbon steels, low chromium steels, ferritic stainless steels, austenetic stainless steels, duplex stainless steels, Inconel alloys, Incoloy alloys, Fe—Ni based alloys, Ni-based alloys and Co-based alloys. Advantages exhibited by the disclosed coated metal compositions include improved metal dusting corrosion resistance at high temperatures in carbon-supersaturated environments having relatively low oxygen partial pressures. The coated metal compositions are suitable for use in syngas generation process equipment.

Owner:EXXON RES & ENG CO

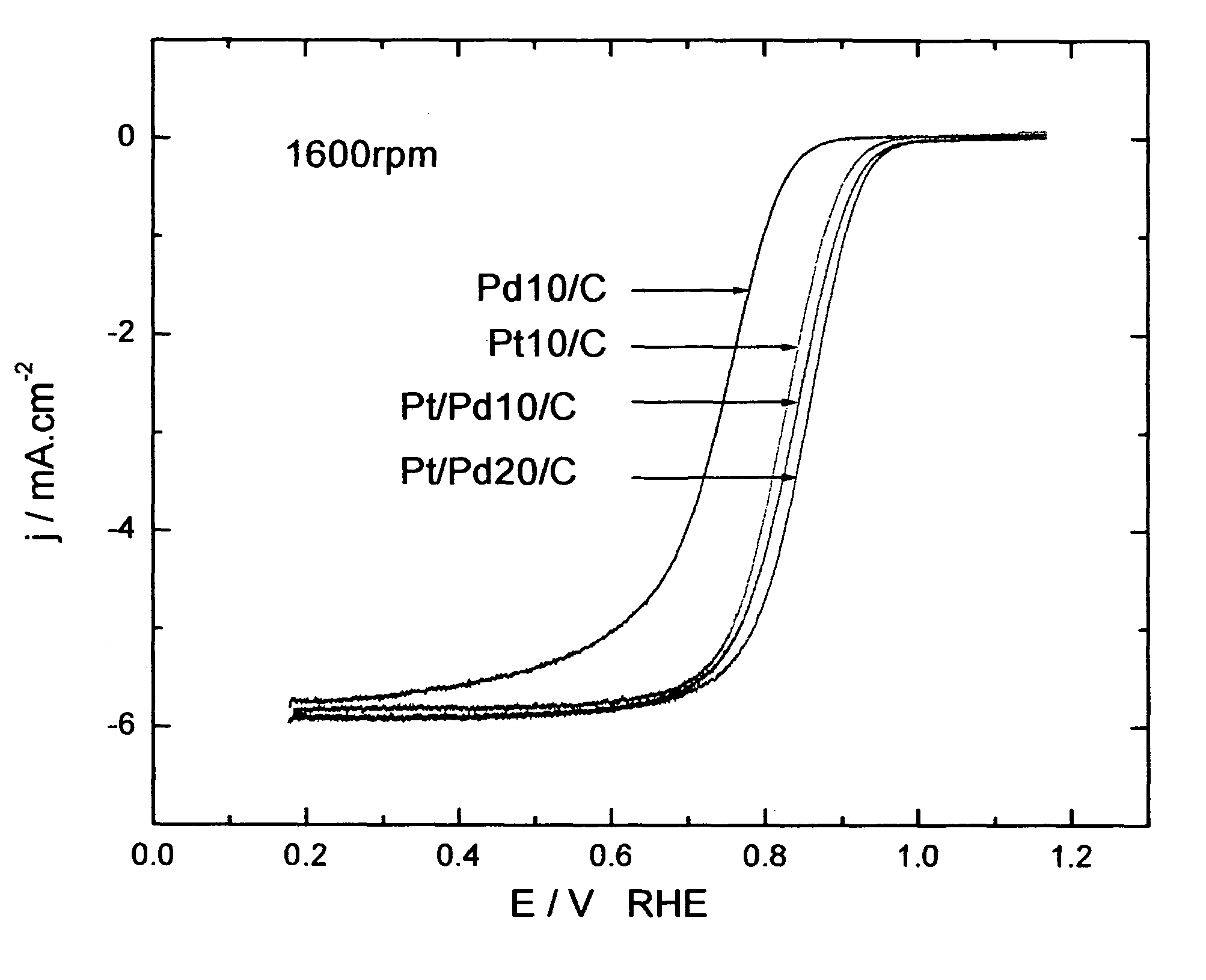

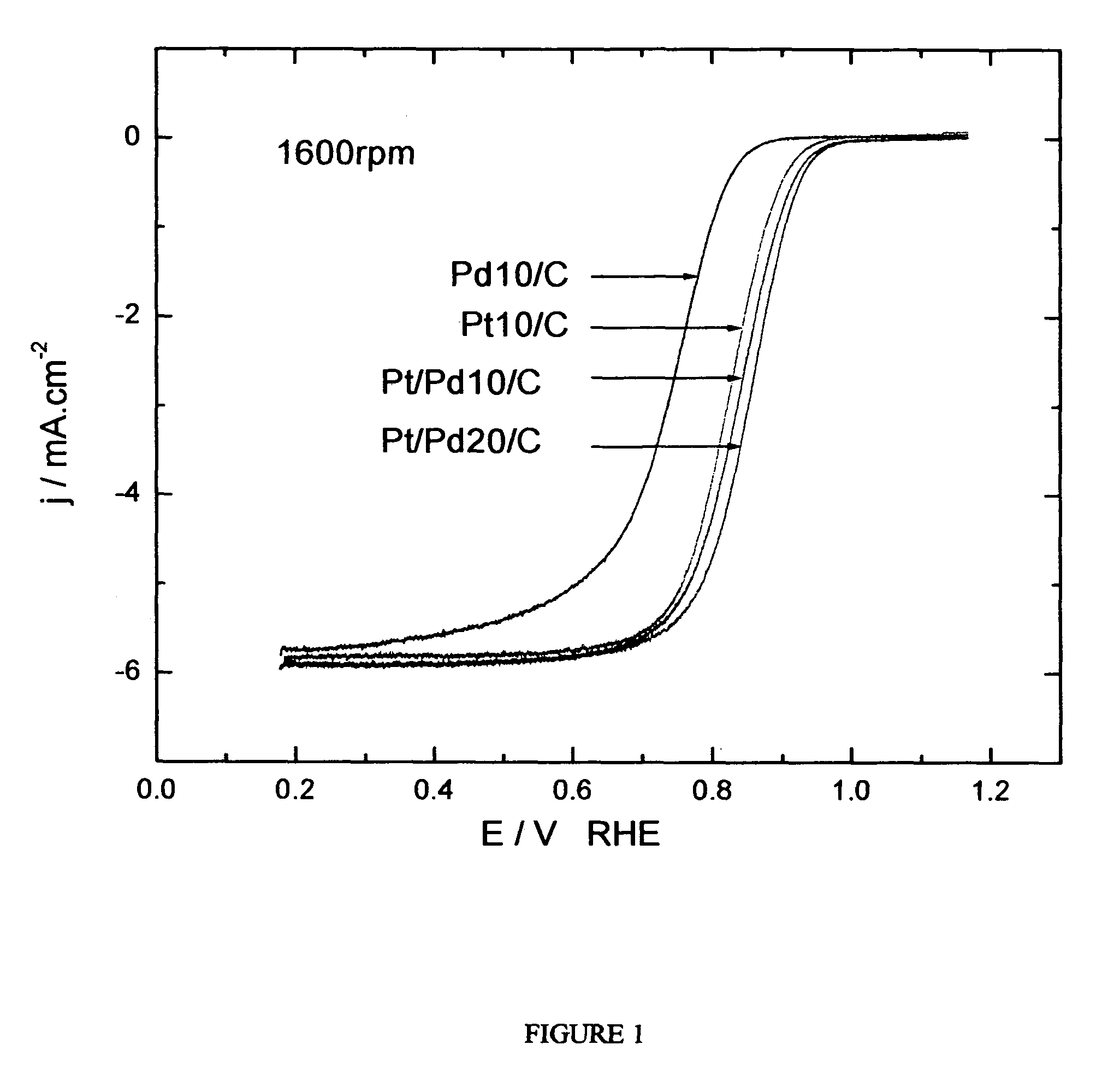

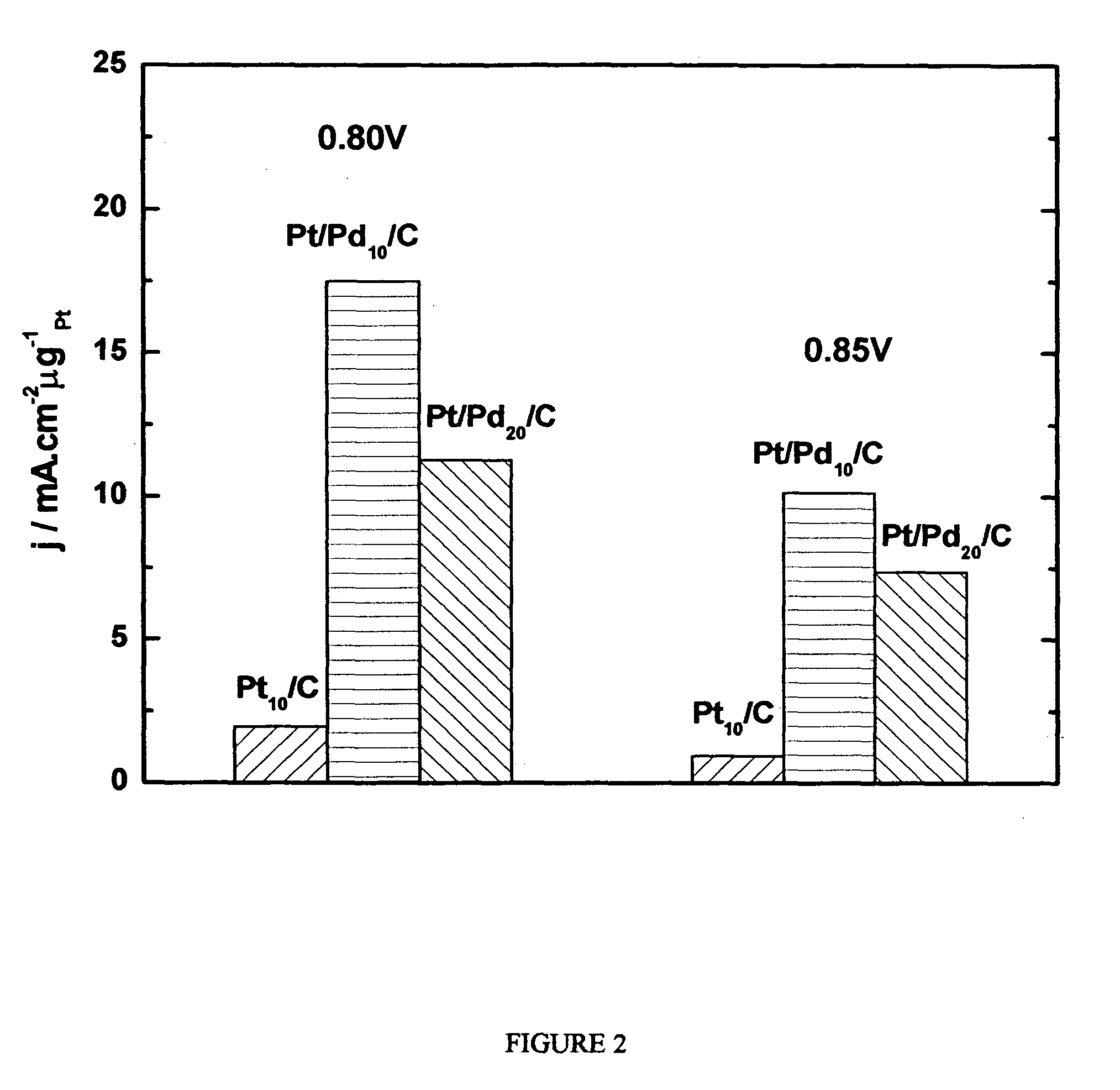

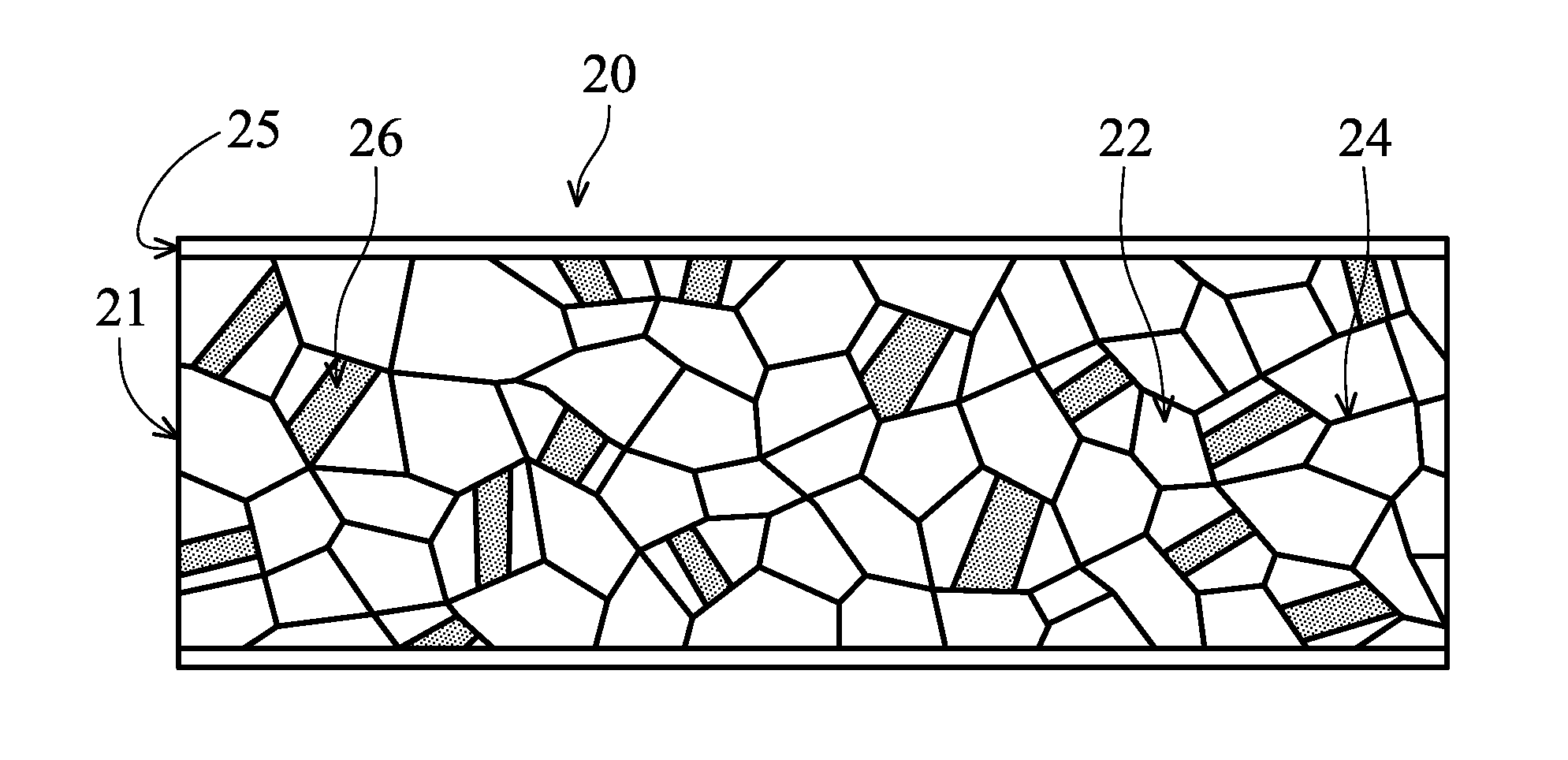

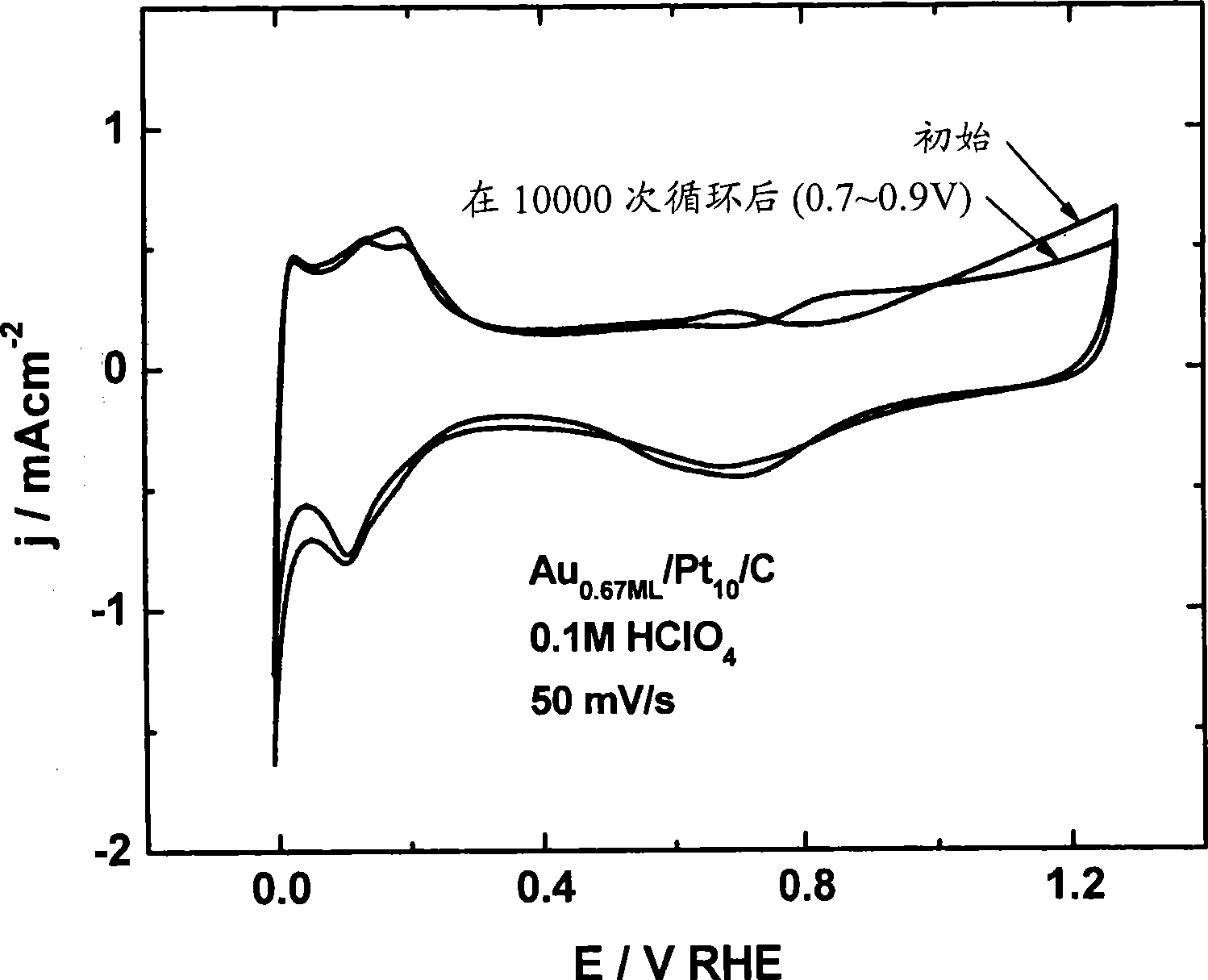

Electrocatalysts having platium monolayers on palladium, palladium alloy, and gold alloy core-shell nanoparticles, and uses thereof

ActiveUS7855021B2High catalytic activityReduce loadCell electrodesMetal-working apparatusRheniumMaterials science

The invention relates to platinum-coated particles useful as fuel cell electrocatalysts. The particles are composed of a noble metal or metal alloy core at least partially encapsulated by an atomically thin surface layer of platinum atoms. The invention particularly relates to such particles having a palladium, palladium alloy, gold alloy, or rhenium alloy core encapsulated by an atomic monolayer of platinum. In other embodiments, the invention relates to fuel cells containing these electrocatalysts and methods for generating electrical energy therefrom.

Owner:BROOKHAVEN SCI ASSOCS

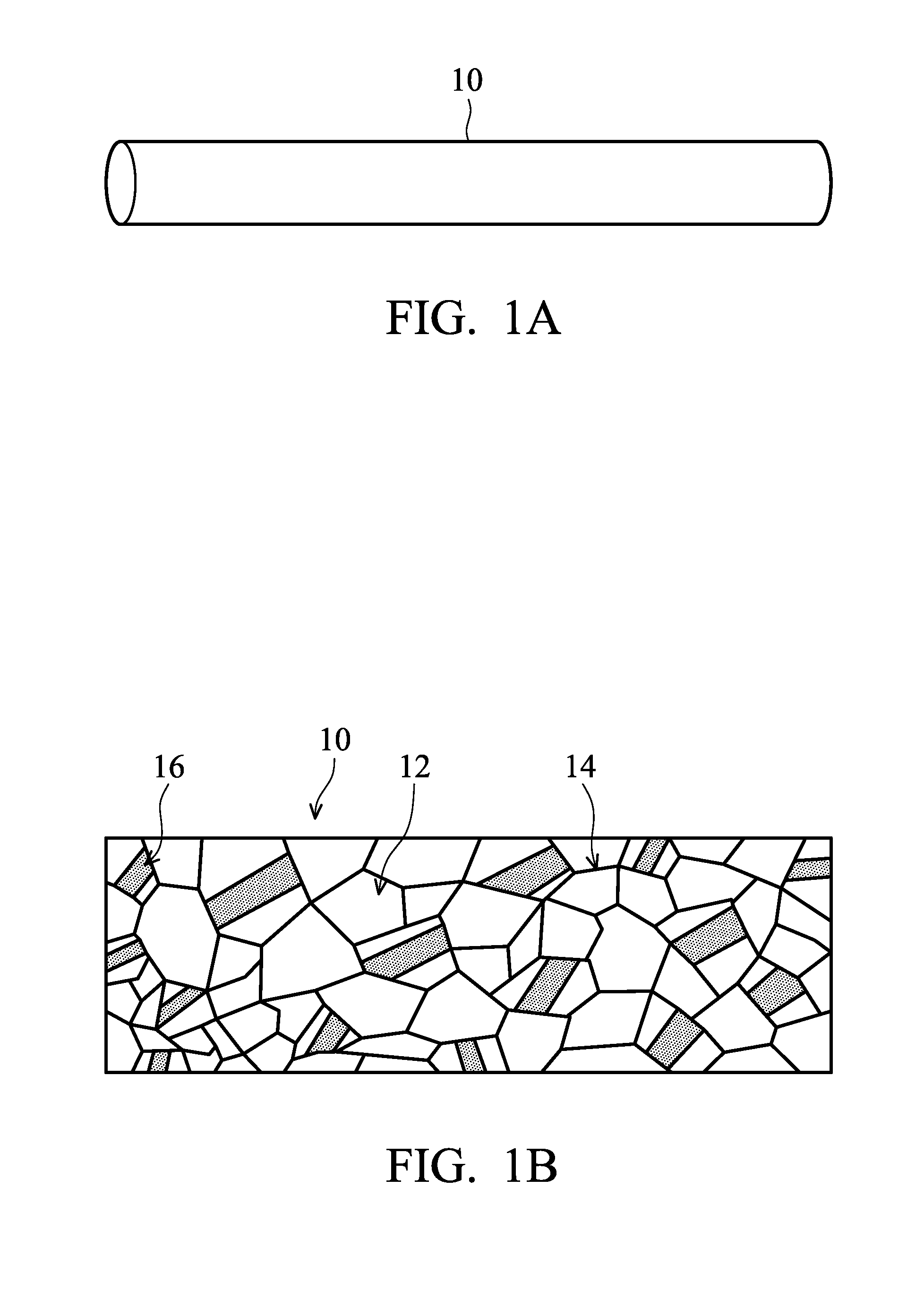

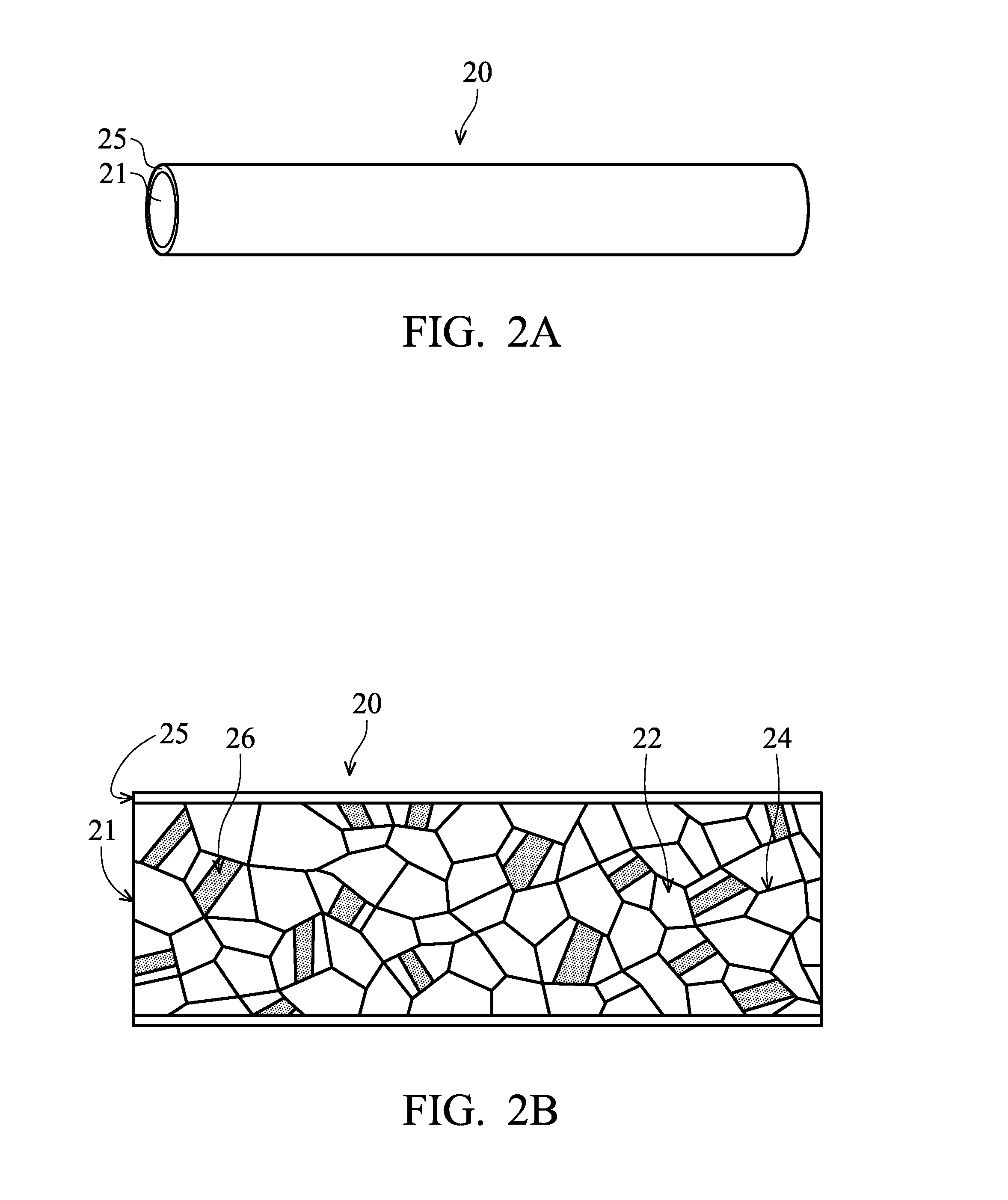

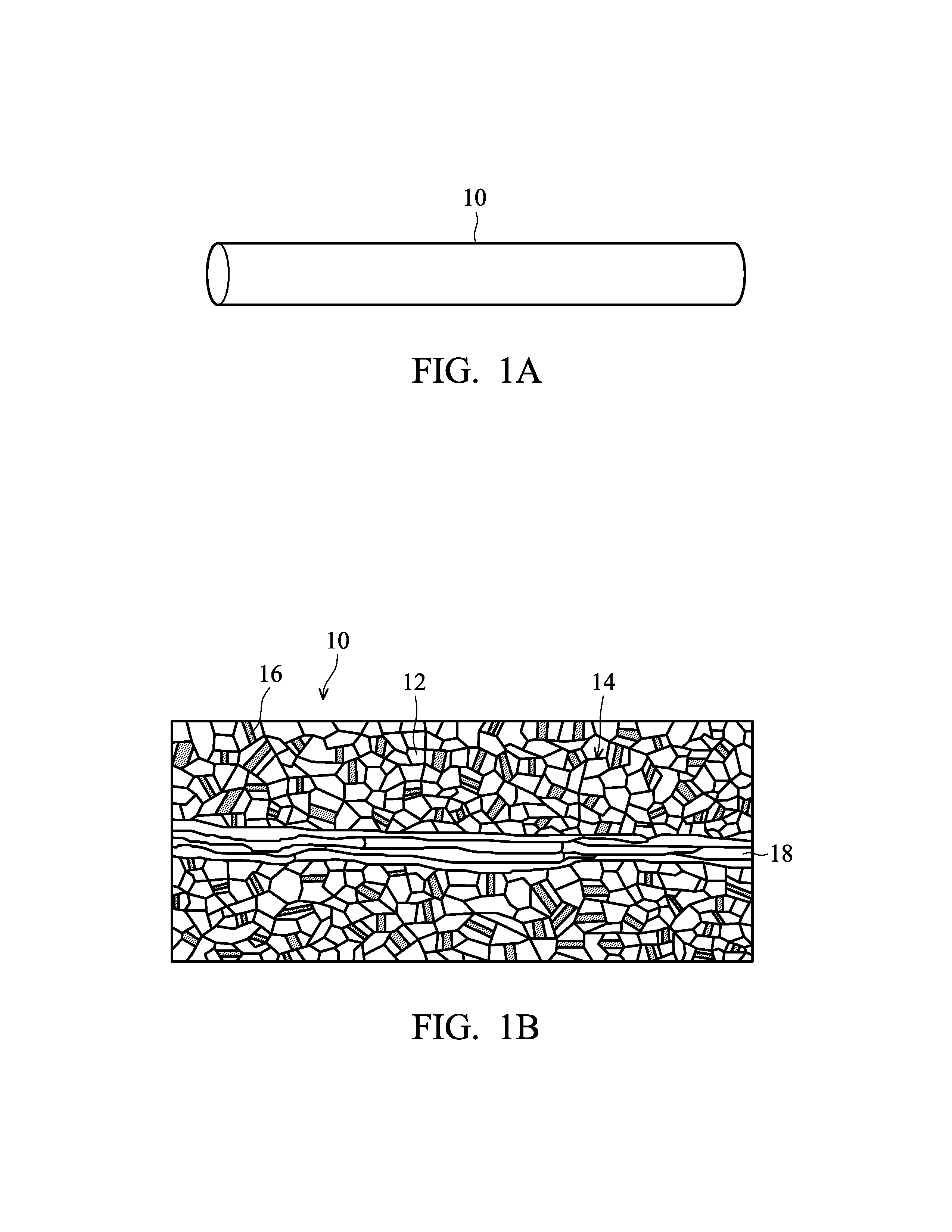

Copper-based alloy wire and methods for manufaturing the same

ActiveUS20140209215A1Semiconductor/solid-state device detailsVacuum evaporation coatingCopperPalladium alloy

A copper-based alloy wire made of a material selected from the group consisting of a copper-gold alloy, a copper-palladium alloy and a copper-gold-palladium alloy is provided. The alloy wire has a polycrystalline structure of a face-centered cubic lattice and consists of a plurality of equi-axial grains. The quantity of grains having annealing twins is 10 percent or more of the total quantity of the grains of the copper-based alloy wire.

Owner:WIRE TECH

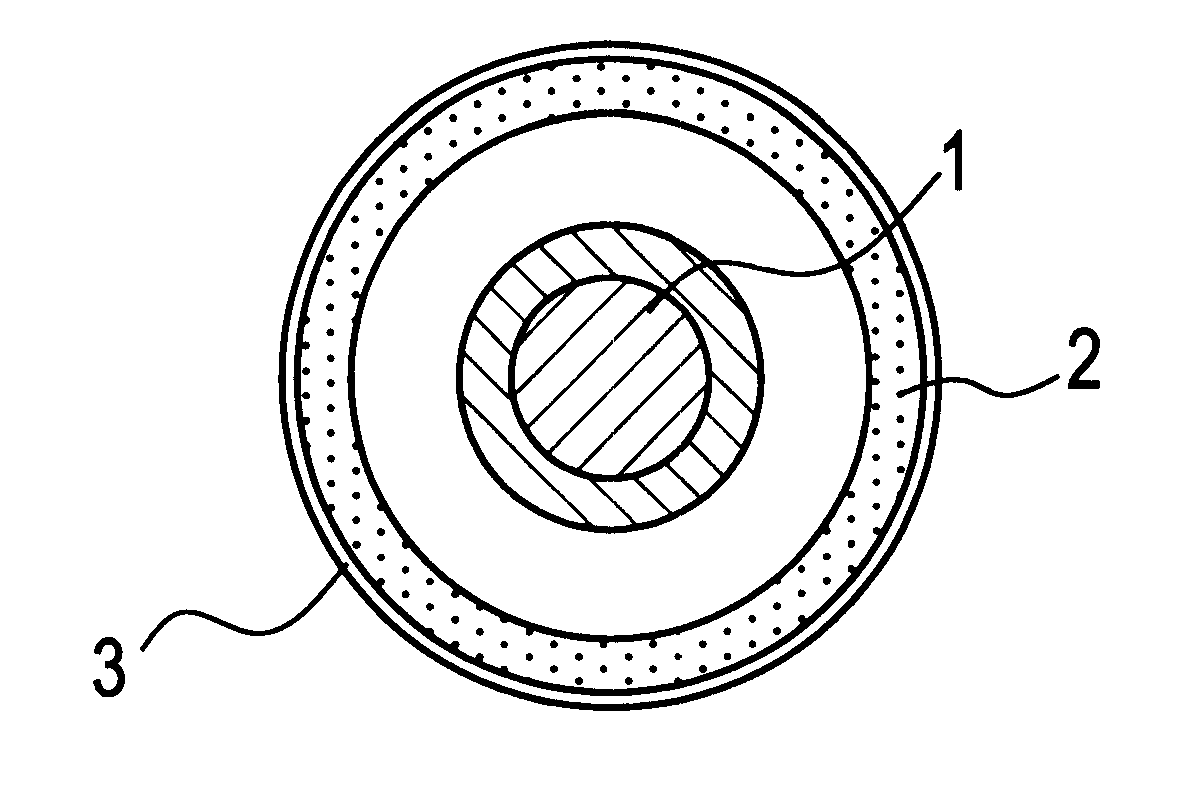

Gold coated signal cable

Signal cable for transmission of optical signals, especially in oil and gas wells, includes at least one elongated optical fiber, and an elongated, generally tubular container within which the optical fiber is disposed, the container having an inner wall and an outer wall, a space being defined between the optical fiber and the inner wall. At least one of the inner wall and the outer wall has a thin continuous surface coating of gold or a gold alloy.

Owner:OPTOPLAN

Copper bonding or superfine wire with improved bonding and corrosion properties

InactiveUS7645522B2Speed up the processThin gold jacketingSemiconductor/solid-state device detailsSolid-state devicesCopper wireHardness

A bonding or superfine wire is provided made of copper, with a gold enrichment on the surface thereof, in particular in an amount corresponding to a coating of at most 50 nm. The wire may be bonded by the ball / wedge method, has a copper-colored appearance, and the ball thereof after flame-off has a hardness of less than 95 according to HV0.002. In order to produce the bonding or superfine wire, a copper wire is coated with gold or a copper-gold alloy or gold is introduced into the surface of the copper wire. The wires are bonded to a semiconductor silicon chip.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

Electrocatalysts having gold monolayers on platinum nanoparticle cores, and uses thereof

InactiveCN101379639AGuaranteed efficacyReduce loadMaterial nanotechnologyCell electrodesPlatinumFuel cells

The invention relates to gold-coated particles useful as fuel cell electrocatalysts. The particles are composed of an electrocatalytically active core at least partially encapsulated by an outer shell of gold or gold alloy. The invention more particularly relates to such particles having a noble metal-containing core, and more particularly, a platinum or platinum alloy core. In other embodiments, the invention relates to fuel cells containing these electrocatalysts and methods for generating electrical energy therefrom.

Owner:BROOKHAVEN SCI ASSOCS

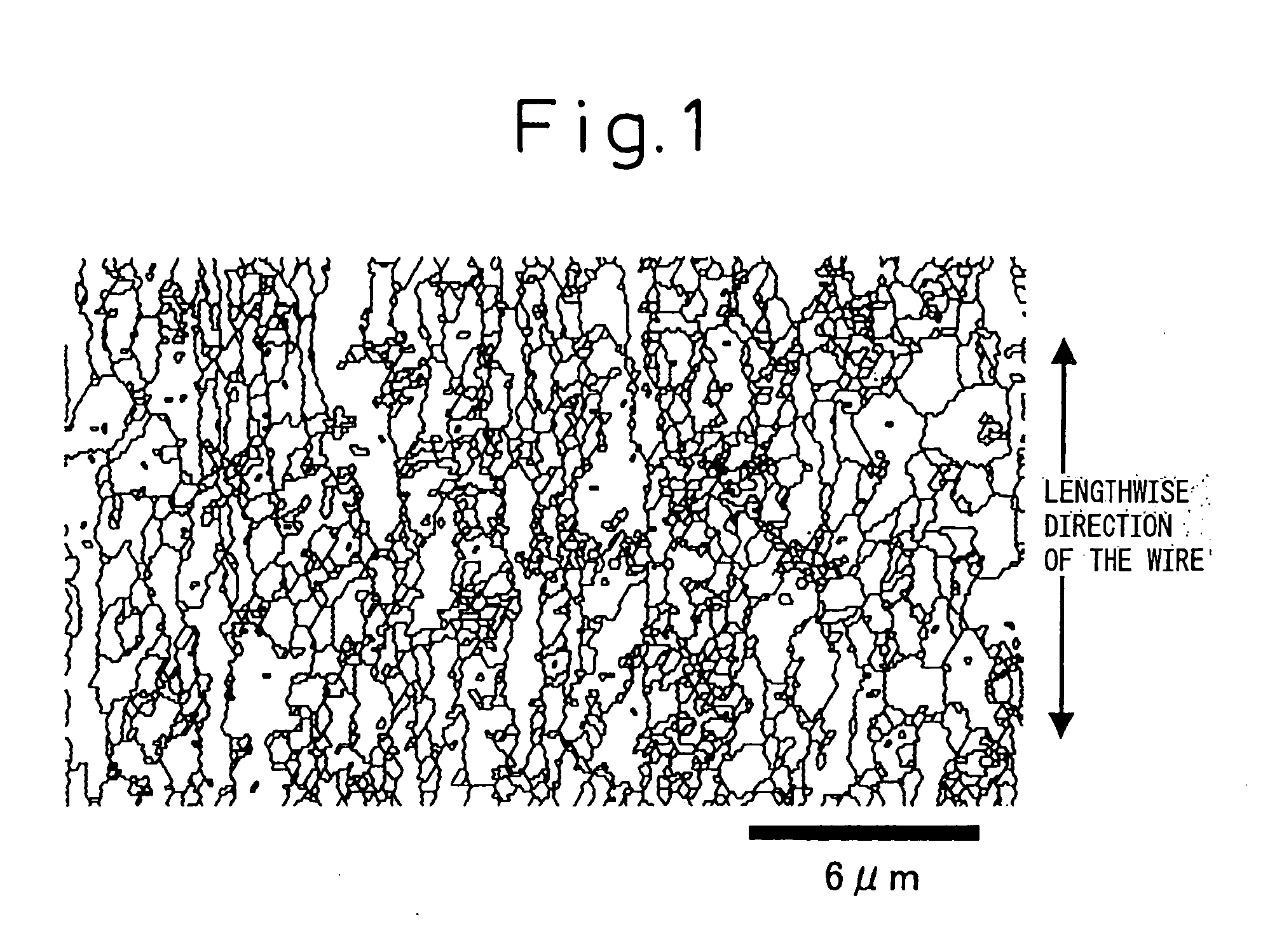

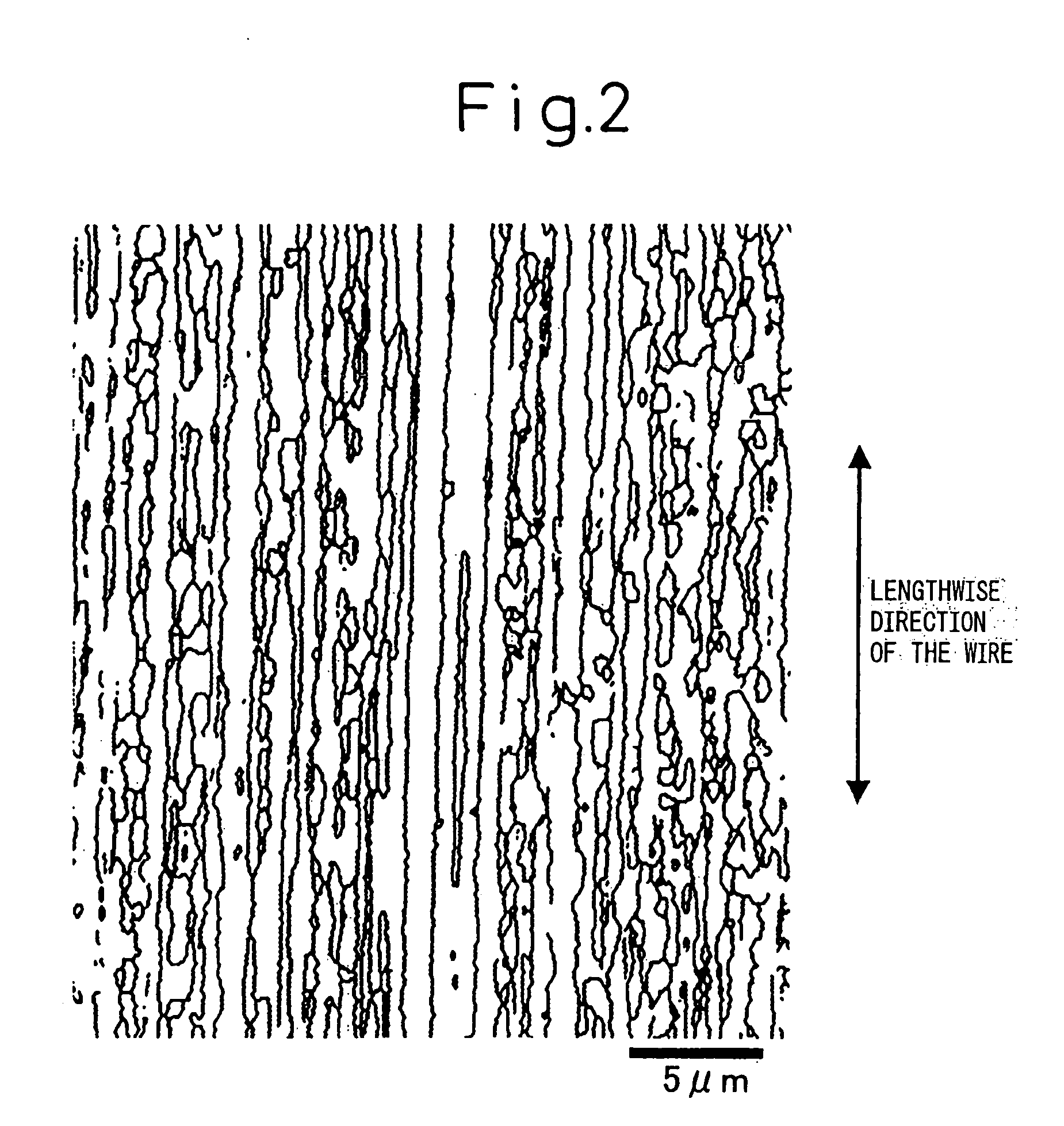

Gold alloy bonding wire for semiconductor device and process for producing the same

ActiveUS20050079347A1Solid-state devicesSemiconductor/solid-state device manufacturingDevice materialCrystal orientation

Gold bonding wires for semiconductor devices featuring increased strength and modulus of elasticity, stable loop shapes, suppressing the flow of wires, suppressing the leaning, and totally improved junctions of the wedge junction portions or wear characteristics for realizing a narrow-pitch connection, and enhanced the productivity on an industrial scale, and a method of producing the same. A gold bonding wire for a semiconductor device has a crystal grain structure in cross section in the lengthwise direction of the bonding wire, wherein a ratio of the area of crystal grains having an orientation [111] to the area of crystal grains having an orientation [100] is not smaller than 1.2 in the crystal orientations in the lengthwise direction of the wire.

Owner:NIPPON STEEL CORP

Alloy wire and methods for manufacturing the same

InactiveUS20130171470A1Semiconductor/solid-state device detailsSolid-state devicesCrystal twinningSilver-palladium alloy

An alloy wire made of a material selected from one of a group consisting of a silver-gold alloy, a silver-palladium alloy and a silver-gold-palladium alloy is provided. The alloy wire is with a polycrystalline structure of a face-centered cubic lattice and includes a plurality of grains. A central part of the alloy wire includes slender grains or equi-axial grains, and the other parts of the alloy wire consist of equi-axial grains. A quantity of the grains having annealing twins was 20 percent or more of the total quantity of the grains of the alloy wire.

Owner:WIRE TECH CO LTD

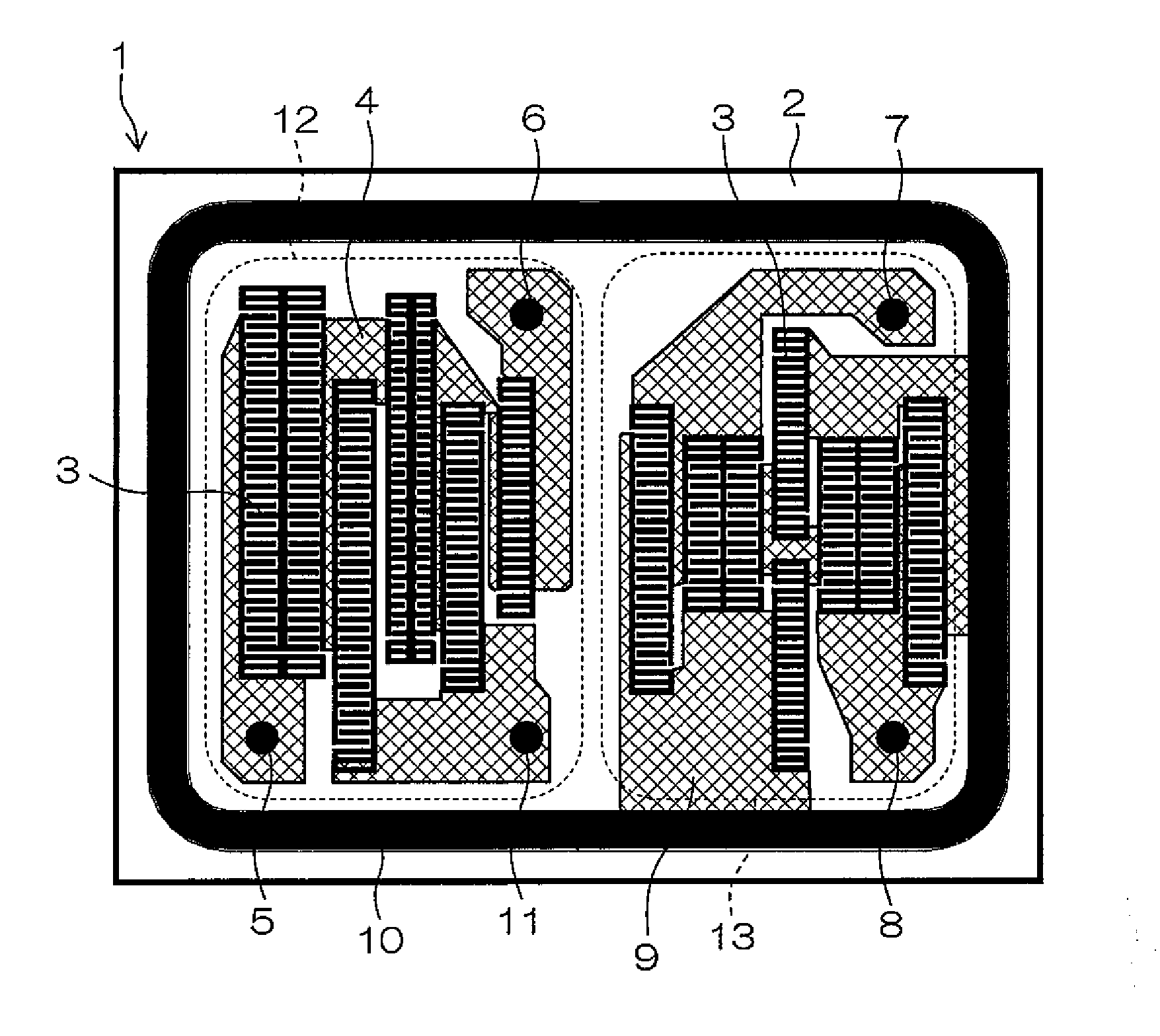

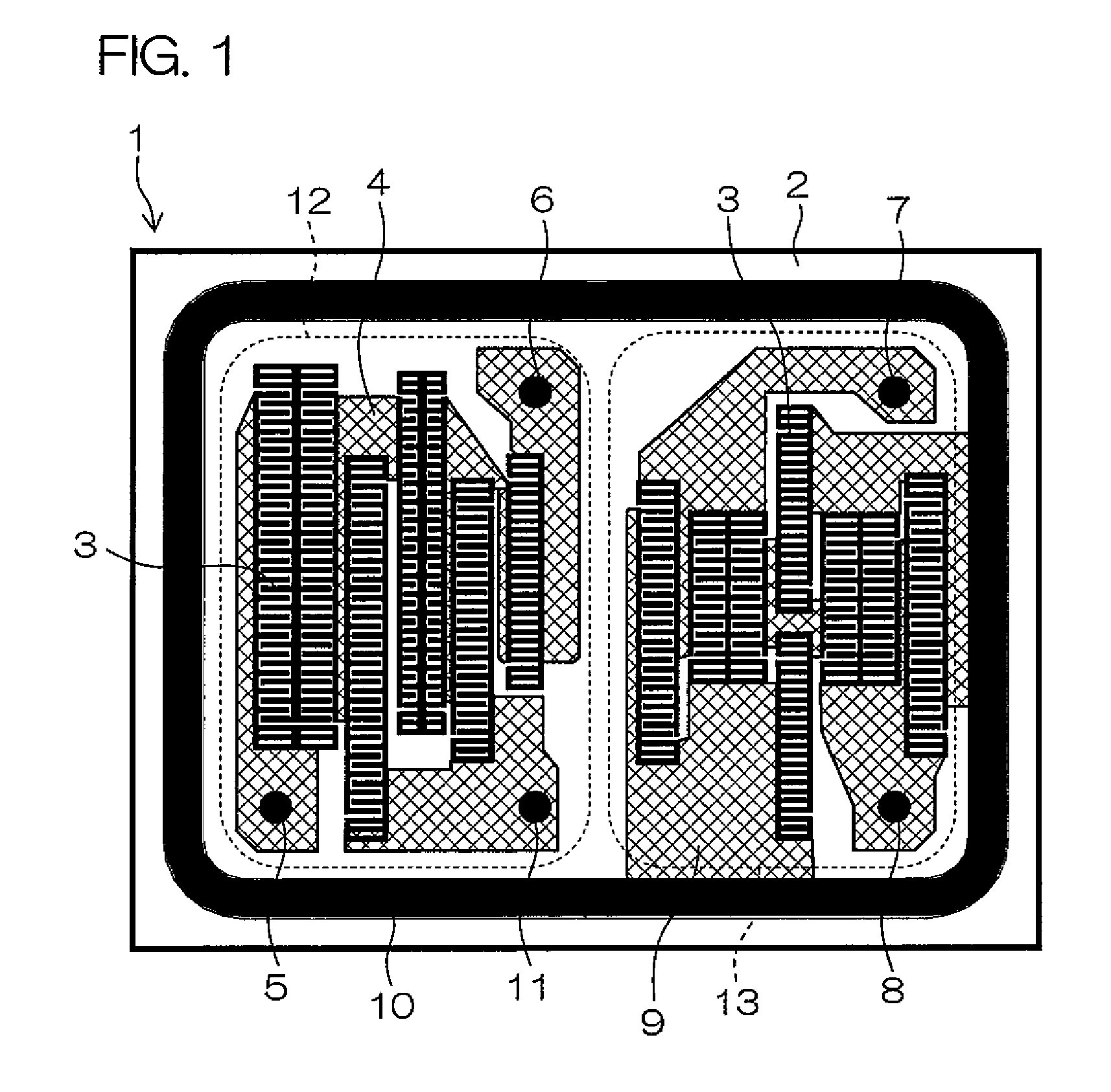

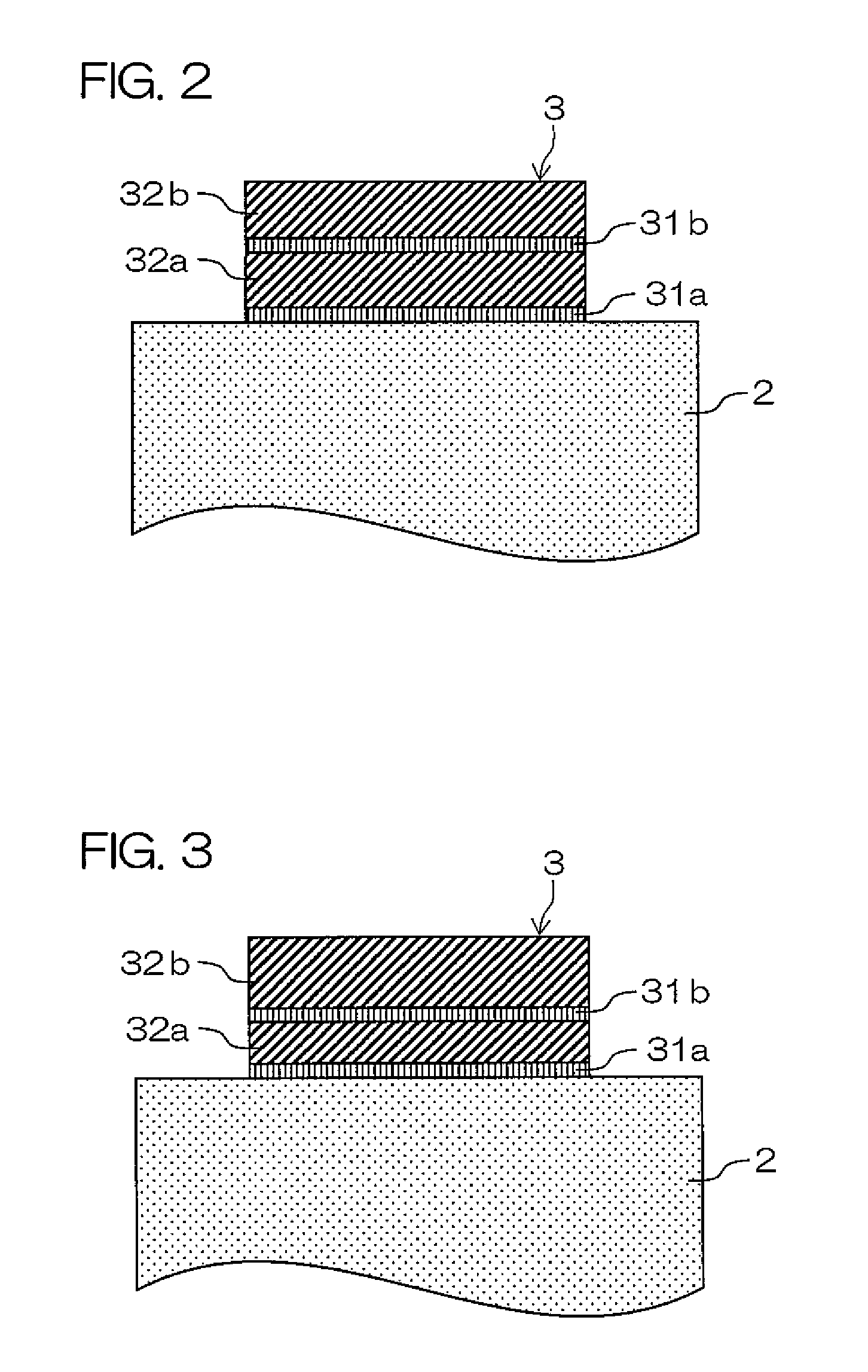

Surface Acoustic Wave Element and Communication Device

ActiveUS20090243430A1High Power Handling CapabilityLow densityPiezoelectric/electrostriction/magnetostriction machinesImpedence networksTitaniumAcoustic wave

An IDT electrode (3) on a piezoelectric substrate (2) has an electrode including first metal layers (31a, 31b) formed of titanium or a titanium alloy, or chromium or a chromium alloy and second metal layers (32a, 32b) formed of aluminum or an aluminum alloy, copper or a copper alloy, or gold or a gold alloy, which are laminated alternately. The orientation degrees in the first metal layer (31a) that is closest to the surface of the piezoelectric substrate (2) in the first metal layers (31a, 31b) and the second metal layer (32a) that is closest to the surface of the piezoelectric substrate (2) in the second metal layers (32a, 32b) are higher than the orientation degrees in the upper metal layers. As compared with the prior art where the orientation degrees in the first metal layers (31a, 31b) and the second metal layers (32a, 32b) are not considered, the power handling capability of the IDT electrode (3) can be significantly improved.

Owner:KYOCERA CORP

Electrocatalysts having gold monolayers on platinum nanoparticle cores, and uses thereof

InactiveUS7704919B2Maintain efficiencyReduce loadMaterial nanotechnologyOrganic-compounds/hydrides/coordination-complexes catalystsPlatinumFuel cells

The invention relates to gold-coated particles useful as fuel cell electrocatalysts. The particles are composed of an electrocatalytically active core at least partially encapsulated by an outer shell of gold or gold alloy. The invention more particularly relates to such particles having a noble metal-containing core, and more particularly, a platinum or platinum alloy core. In other embodiments, the invention relates to fuel cells containing these electrocatalysts and methods for generating electrical energy therefrom.

Owner:BROOKHAVEN SCI ASSOCS

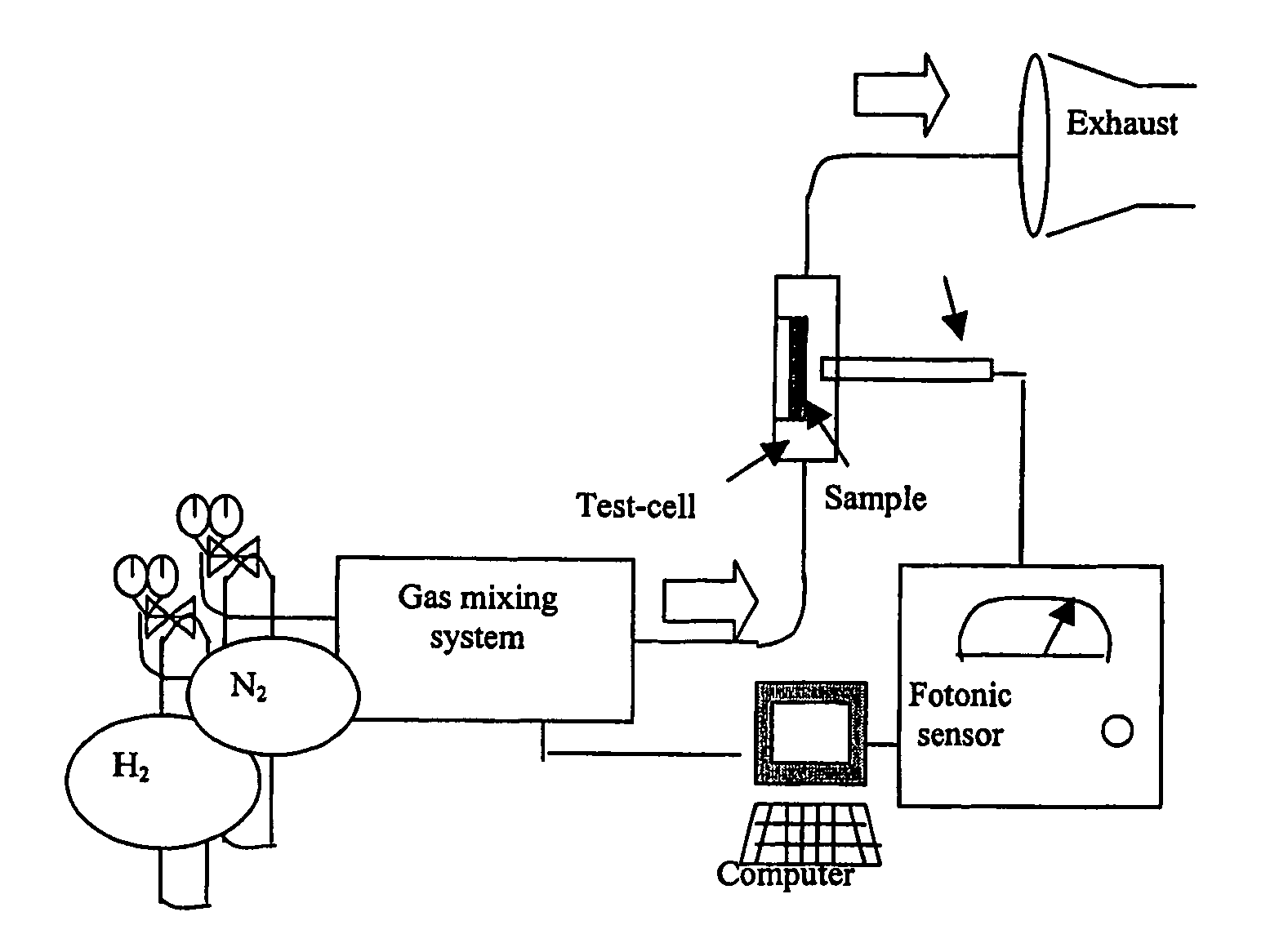

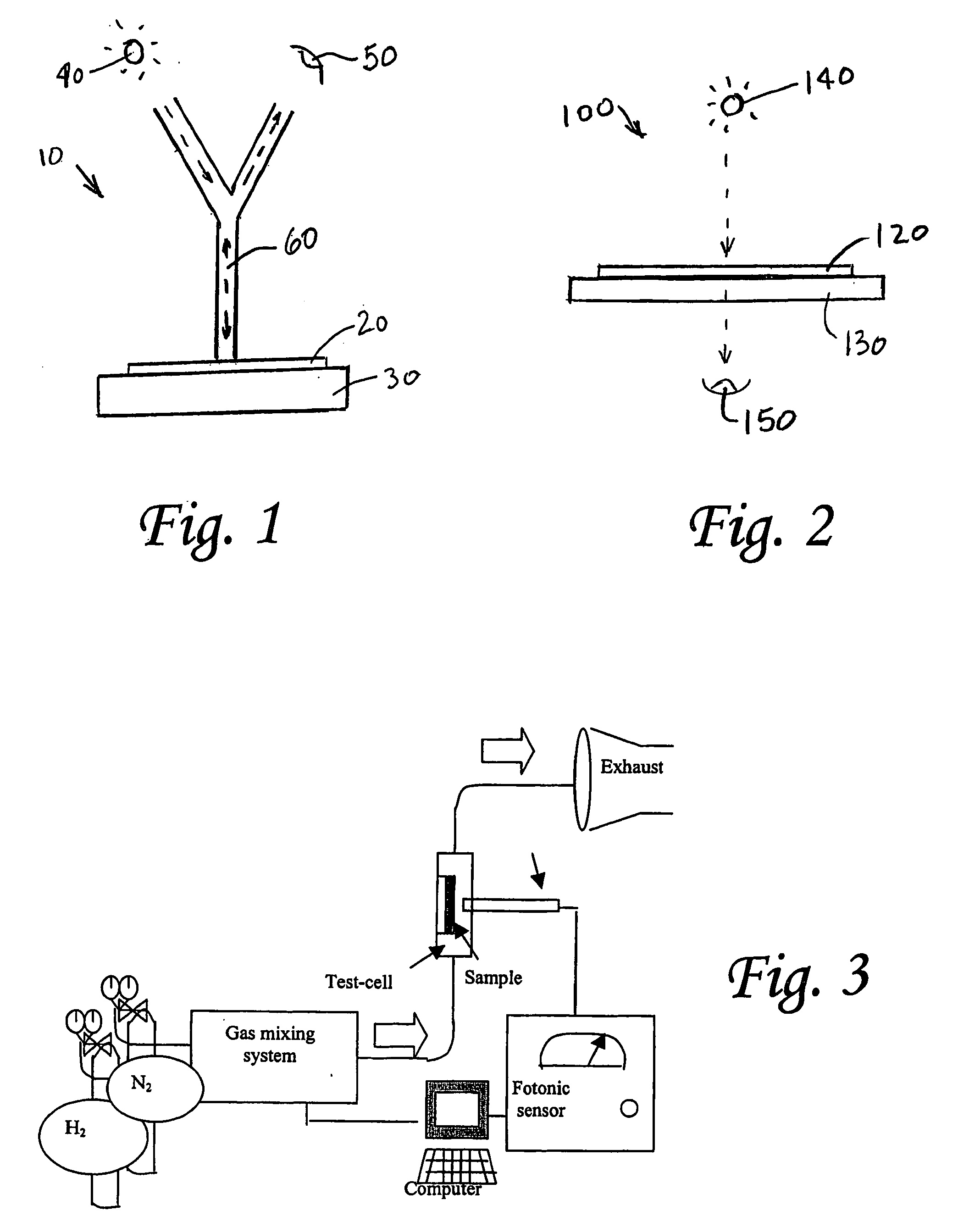

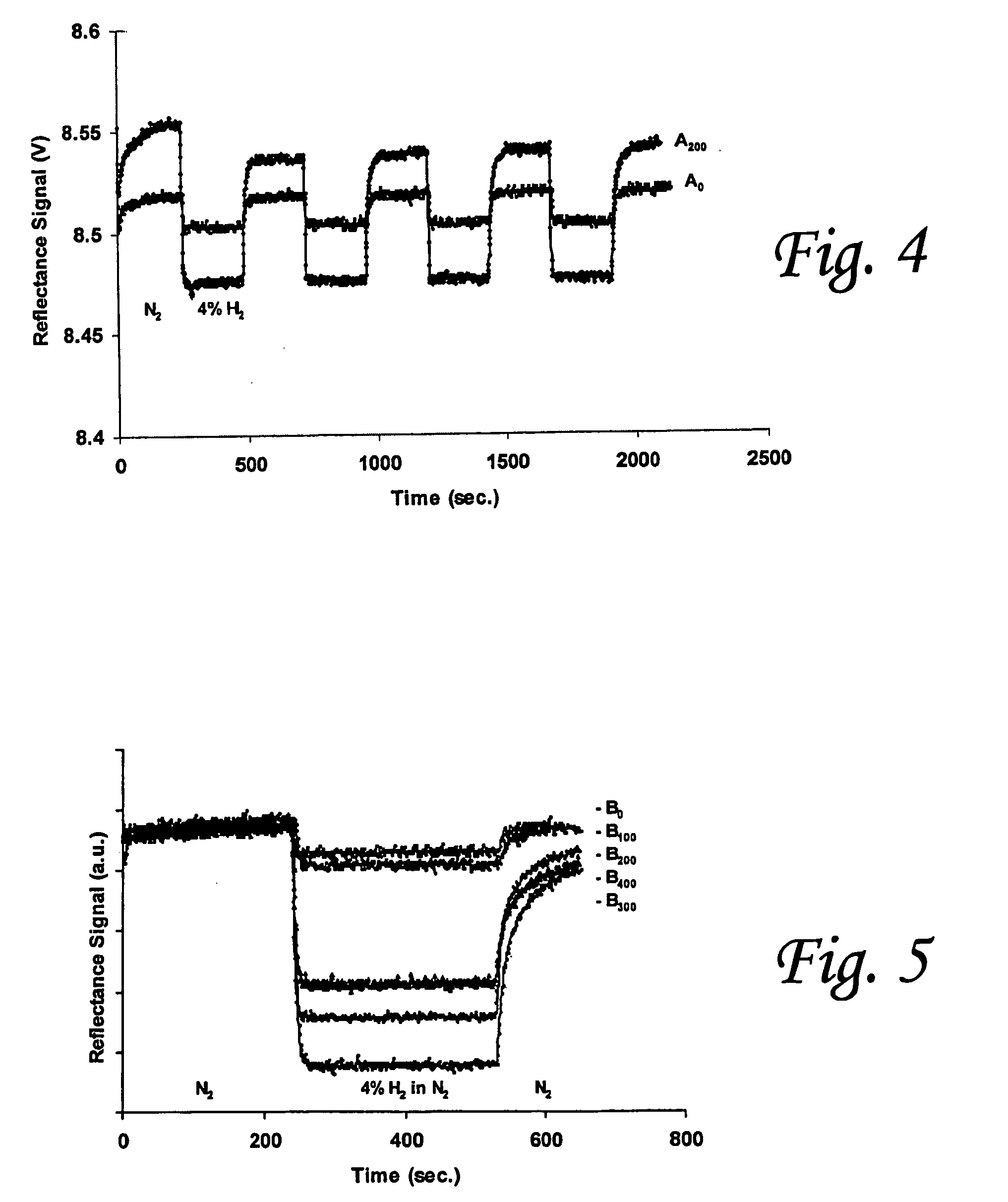

Methods for forming palladium alloy thin films and optical hydrogen sensors employing palladium alloy thin films

InactiveUS20050169807A1Reduce residual stressAnalysis using chemical indicatorsWeather/light/corrosion resistanceCelsius DegreeAlloy thin film

Methods for forming hydrogen sensing materials include forming a palladium alloy thin film having less than about 83 atomic percent of palladium, and annealing the palladium alloy thin film to relieve residual stress and increase atomic intermixing of the nanorystaline lattice, while maintaining a grain size close to the grain size of the nonannealed palladium alloy thin film. For example, the sensing material may include a palladium-gold alloy thin film having about 60 atomic percent of palladium and about 40 atomic percent of gold. The palladium-gold alloy thin film is then annealed at a temperature of about 200 degrees Celsius for 1 hour. Methods for detecting hydrogen containing gas in which the hydrogen sensing material is maintained in a single phase when exposed to the hydrogen containing gas, and optical hydrogen sensors are also disclosed.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Method for plating printed circuit board and printed circuit board manufactured therefrom

InactiveCN1956632AReduce thicknessImprove solderabilitySemiconductor/solid-state device detailsSolid-state devicesElectroless nickelCrazing

Owner:SAMSUNG ELECTRO MECHANICS CO LTD +1

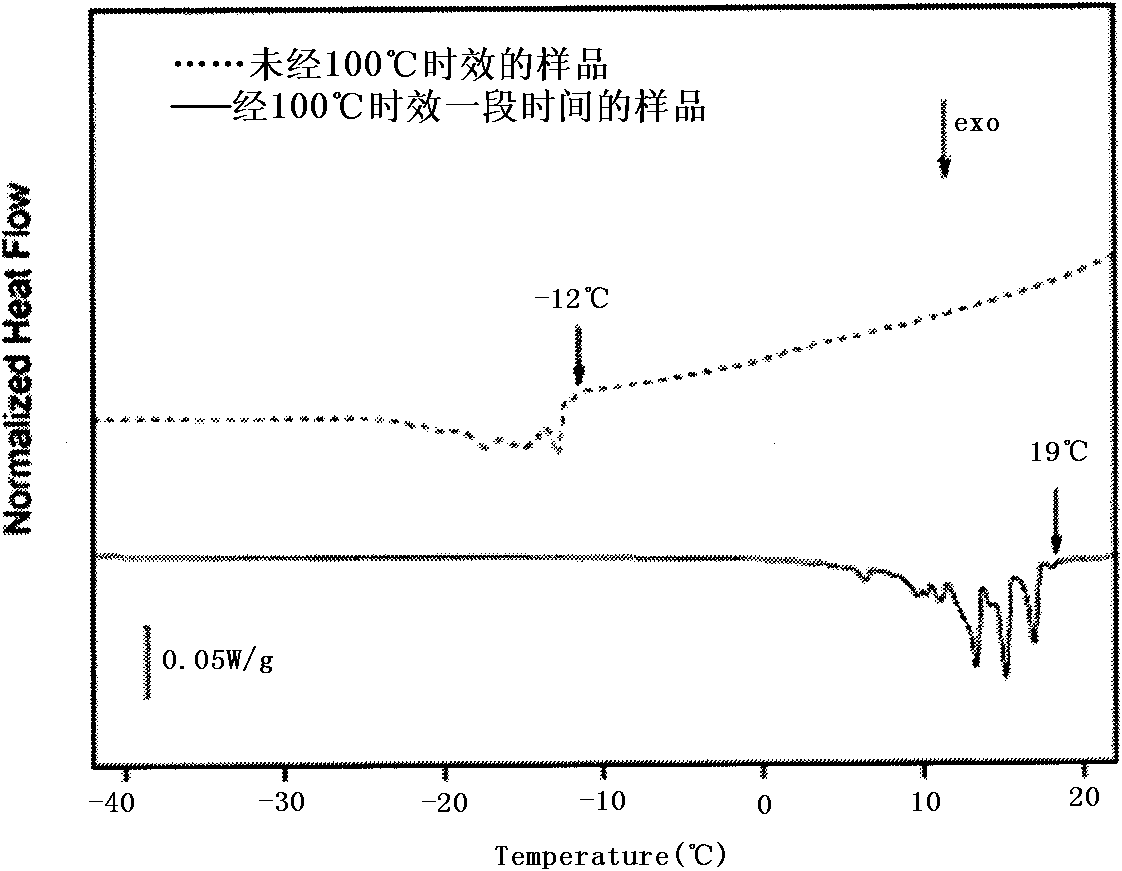

Gold alloy with 18k span effect and preparation method thereof

The invention discloses a gold alloy with 18k span effect and a preparation method thereof in the technical field of noble metal alloy thermal treatment. The gold alloy comprises the following components according to weight percentage: 75.00 to 82 percent of Au, 13.1 to 19.01 percent of Cu and 4.0 to 6.0 percent of Al. The gold alloy with 18k span effect and the preparation method thereof can obtain martensitic phase transformation without ageing; the obtained 18k span has good stability at room temperature and the temperature of the reversible martensitic phase transformation is above 60 DEG C.

Owner:SHANGHAI JIAO TONG UNIV +1

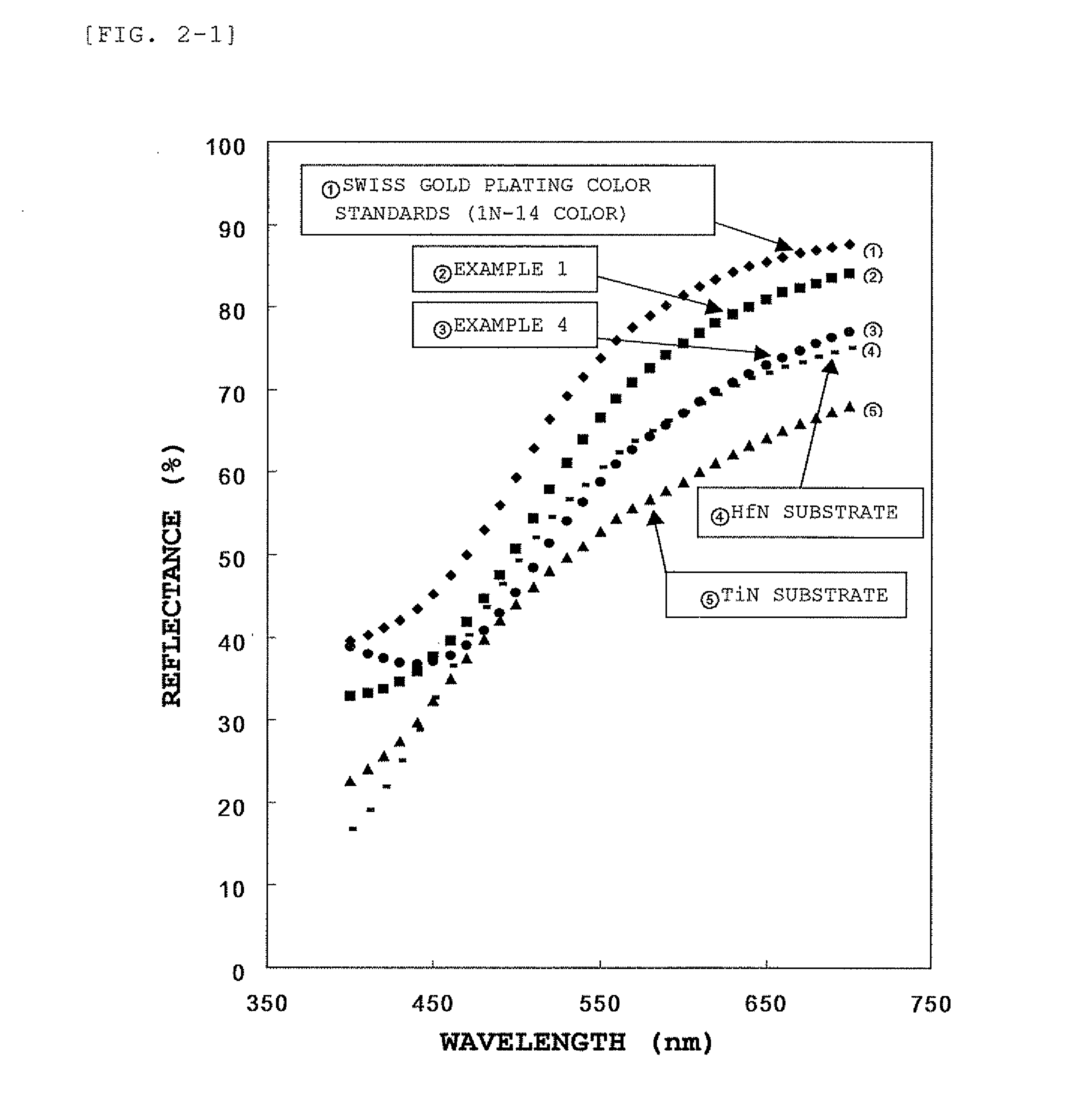

Decorative Part and Process for Producing the Same

ActiveUS20100086756A1High hardnessAvoid influenceVacuum evaporation coatingSputtering coatingHafniumTitanium

A decorative part and a process for producing the decorative part. A first nitride layer containing at least one metal selected among hafnium, titanium, and zirconium is formed on the surface of a decorative part comprising a soft base made of a material selected among stainless steel, titanium and titanium alloys, brass, etc., and a second nitride layer containing at least one metal which is selected among hafnium, titanium, and zirconium and is different from that in the first nitride layer is formed on the first nitride layer to thereby form a primer layer. A multilayered hardened layer including a gold alloy layer is further formed as a finish layer on the primer layer.

Owner:CITIZEN WATCH CO LTD

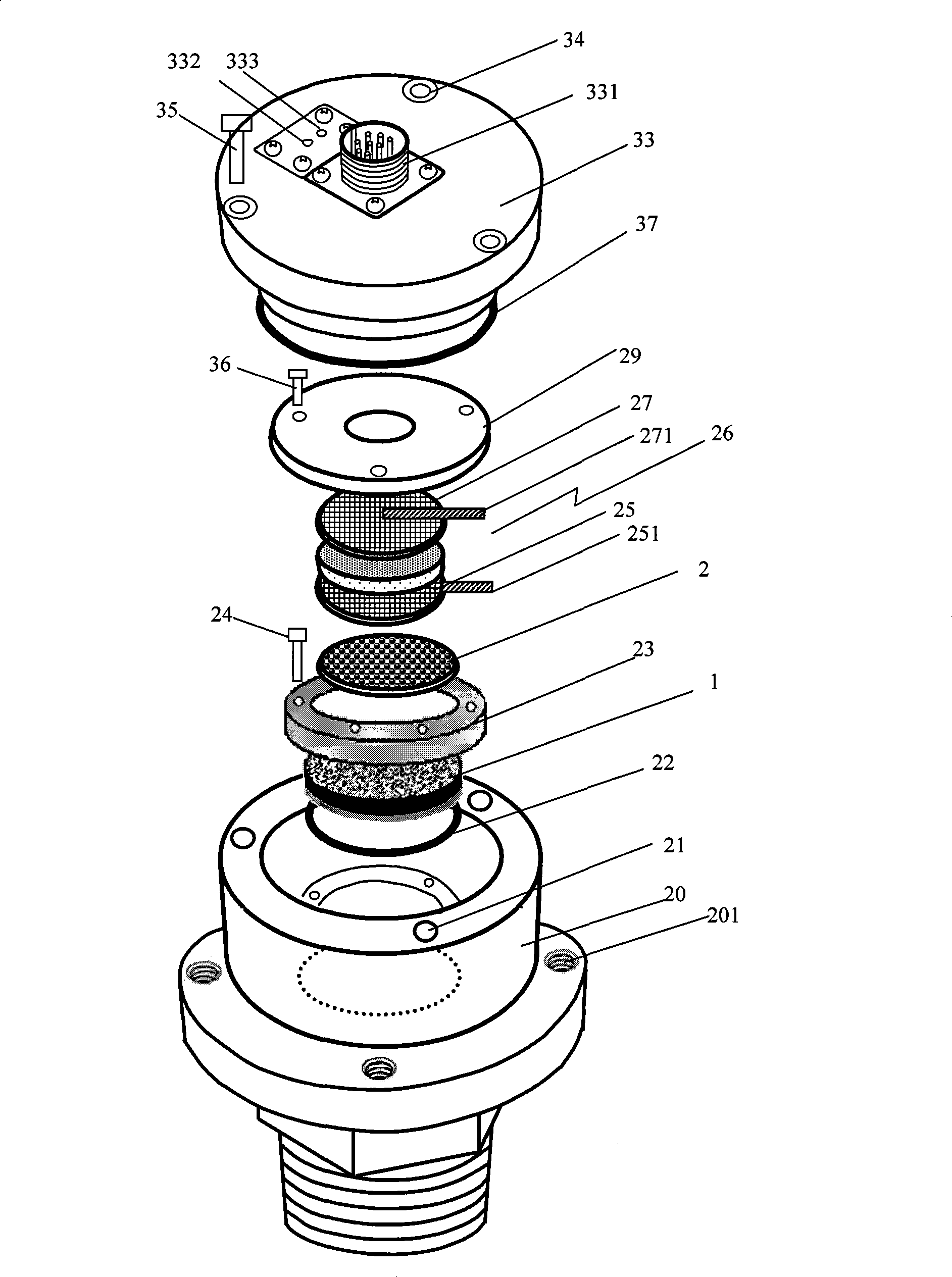

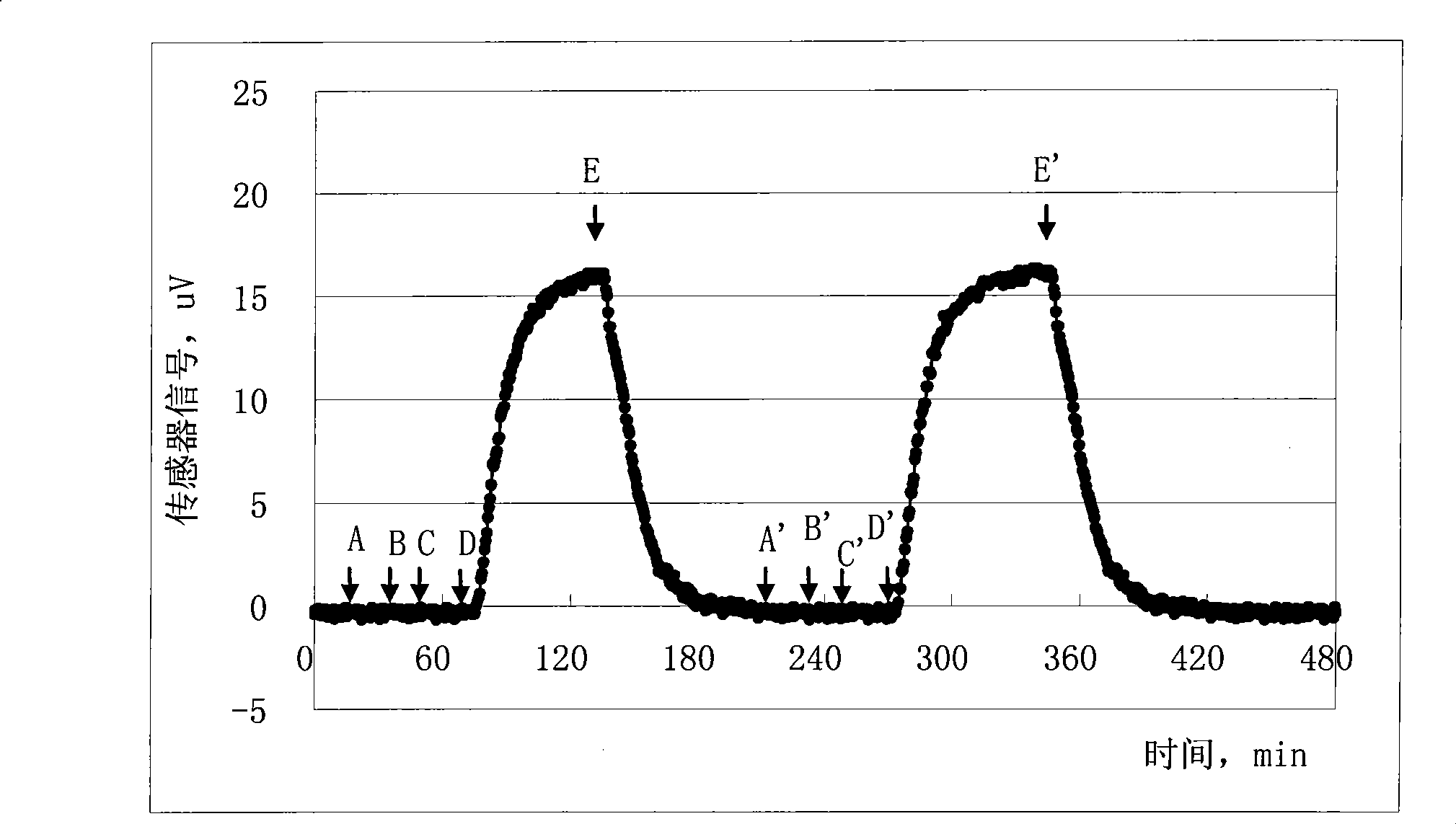

Gas sensor for monitoring gas content in insulating oil

InactiveCN101363813AImproved cross sensitivityReduce concentrationSemi-permeable membranesMaterial electrochemical variablesHigh concentrationAmbient pressure

The invention relates to a gas sensor for monitoring the gas content in insulating oil, in particular to a gas sensor for the online monitoring of the acetylene gas content in insulating oil. The gas sensor comprises a hollow-structure integrated casing, and combined type oil-gas separation membrane and a fuel cell type gas sensing component which are installed inside the casing; wherein a selective electrocatalysis filtering layer for filtering interfering gas is also installed between the combined type oil-gas separation membrane and the fuel cell. Identical gas diffusion electrodes formed by gold alloy (Au) clectrocatalyst are adopted for the anode and the cathode of the selective acetylene fuel cell. The activity of the selective electrocatalysis filtering layer to the interfering gas is higher than the fuel cell itself to the interfering gas; with the increasing of the activity ratio, the filtering effect is also improved. The gas sensor is resistant to various ambient pressure and temperature changes, and the content of low concentration acetylene gas can be correctly and stably monitored in the environment with high concentration interfering gas such as hydrogen gas, carbon monoxide and ethylene gas.

Owner:ASENSOR TECH

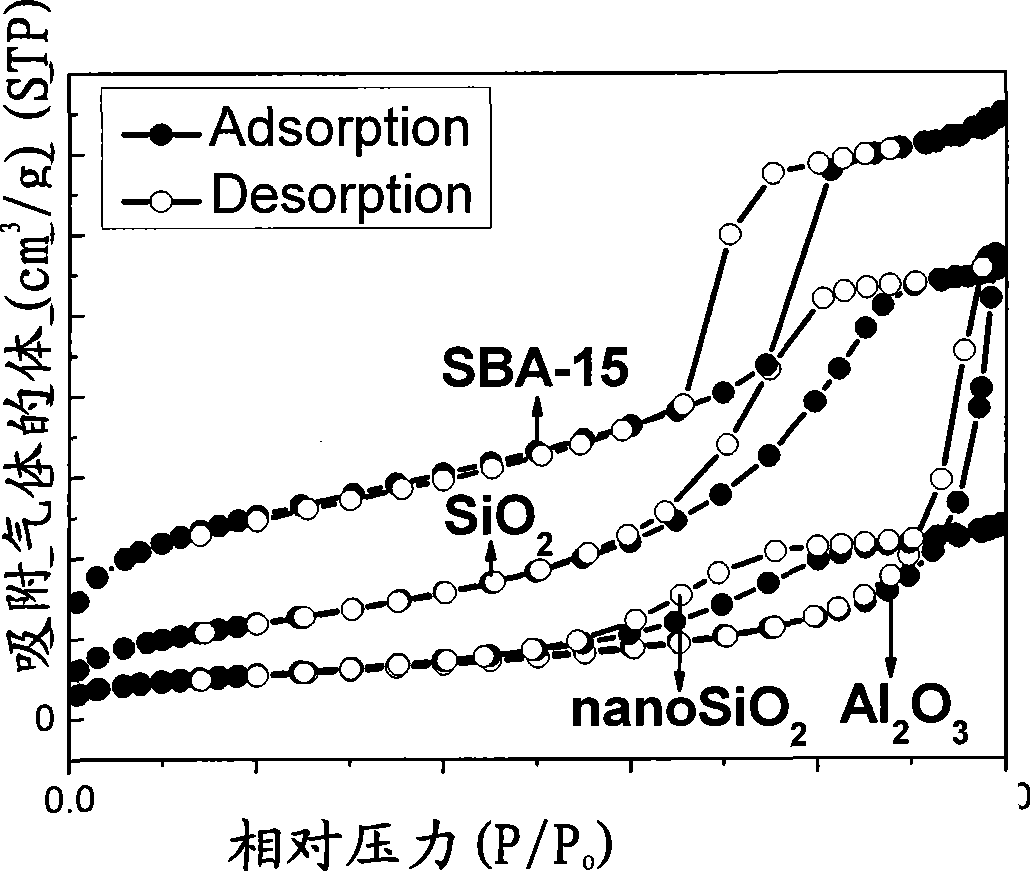

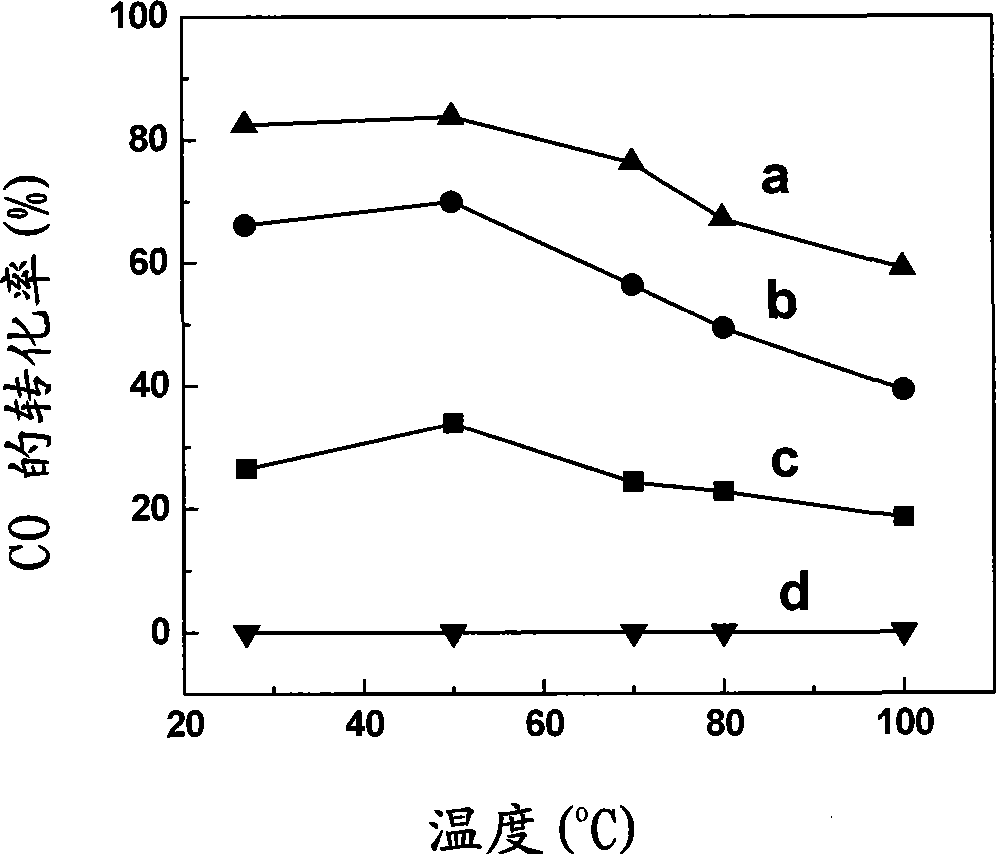

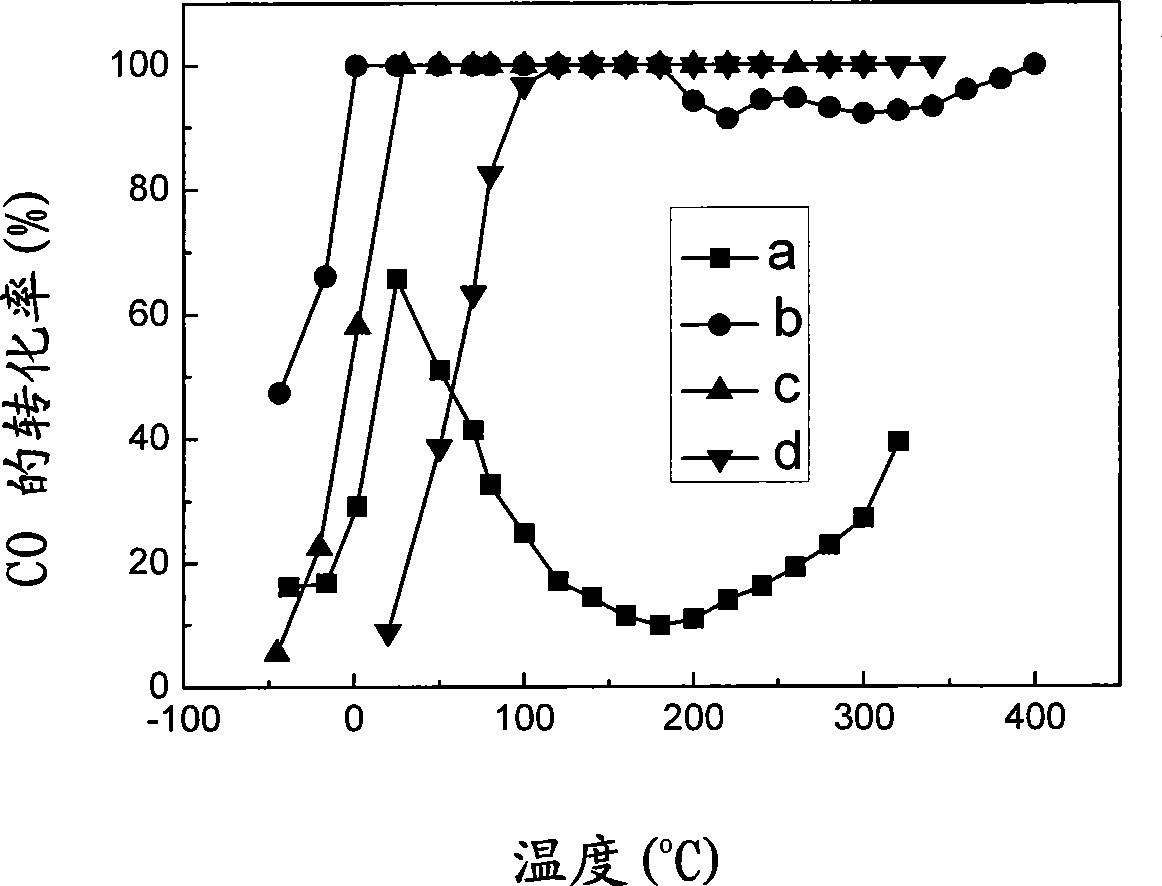

Method for preparing gold alloys-containing catalyst

ActiveCN101411987AGood dispersionSmall particle sizeMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsSolventHigh activity

The invention relates to a method for preparing an auric alloy catalyst with high dispersion, high thermal stability and high activity. Firstly, a group which can complexate metallic ions is grafted on the surface of an oxhydryl-containing carrier; secondly, according to certain percentage, the carrier is dispersed in a solution containing aurum and another or a plurality of metal precursors so that the carrier carries out synchronous or substep complexation on the metallic ions; through certain steps of filtering and washing, the carrier complexated with the metallic ions is re-dispersed in a solvent with certain amount and is added with a reducing agent with proper amount for deoxidation; and finally, collected solid powder is treated for 0.5 to 6 hours under the atmosphere of hydrogen gas at a temperature of between 400 and 600 DEG C to obtain the auric alloy catalyst with high dispersion, high thermal stability and high activity. The auric alloy catalyst shows high activity in the oxidation reaction of carbon monoxide and the oxidation reaction of ethanol.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Process for manufacturing precious metal artifacts

A wedding ring is manufactured by a process comprising the production of a metal powder by the atomizing of a stream of molten precious metal, for example a gold alloy, the compaction of the metal powder into a hollow cylindrical body, the sintering of the compacted body, optionally the compression of the sintered body into a more toroidal shape, optionally the sintering of the toroidal body and the subjecting of the body to ring-rolling and annealing. The powder that is compacted any also comprise a minor proportion of precious-metal powder obtained by means other than atomization. The process may also be applied to the manufacture of artifacts other than rings by compacting the powder into an appropriate shape and modifying the compressing step, if employed, as appropriate to the intended product; in such embodiments, the ring-rolling step may be replaced by an appropriate step of further modifying the shape and / or dimension of the body. or may be omitted entirely.

Owner:ENGELHARD CLAL UK

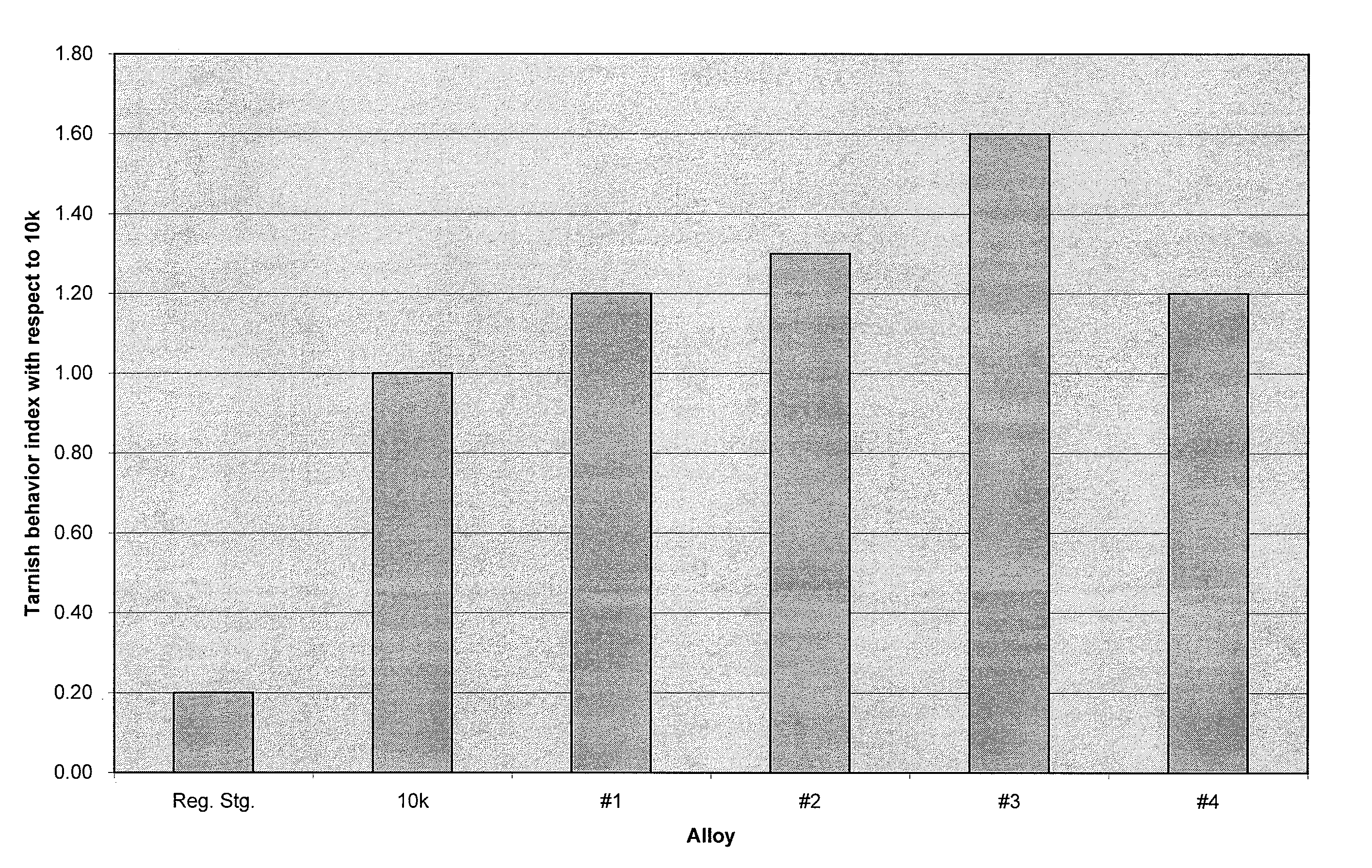

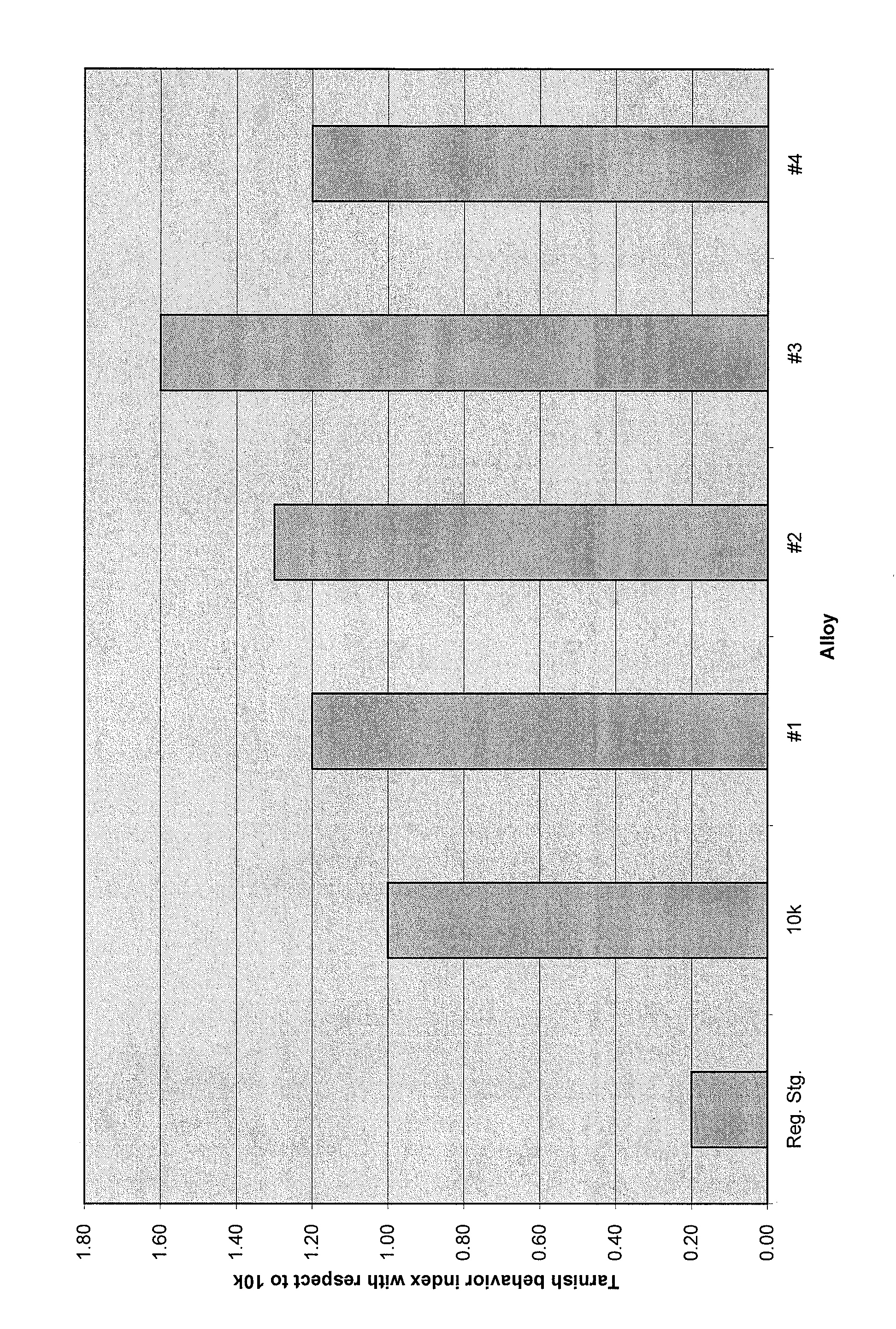

Silver alloy with high tarnish resistance

A high tarnish resistant silver alloy composition formulated for jewelry and flatware manufacture is provided. In certain implementations, the alloy contains about 92%-97% by weight silver, about 0.25%-3.5% by weight palladium, about 0%-3.5% by weight platinum, about 0%-2.5% by weight gold, about 0.1%-1.0% by weight copper, about 0.5%-3.5% by weight zinc, about 0.1%-1.5% by weight tin, about 0.25%-1.5% by weight indium, about 0.03%-1.1% by weight silicon, about 0%-0.5% by weight germanium, about 0.15%-0.5% by weight gallium, about 0.25%-0.5% by weight cobalt and about 0%-0.5% by weight ruthenium. These unique combinations of elements result in the alloys with the tarnish resistance superior to typical 10K gold alloy.

Owner:STERILITE

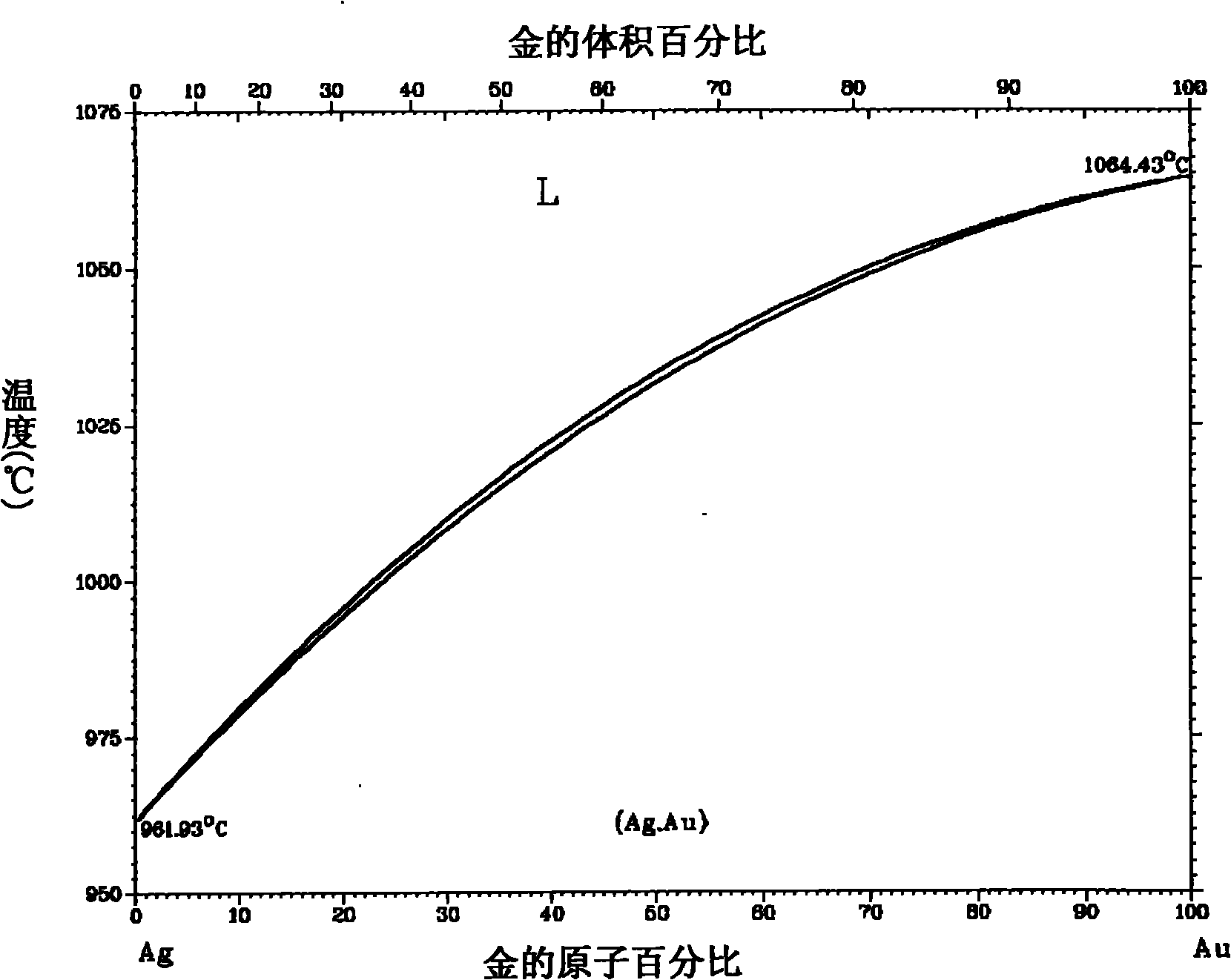

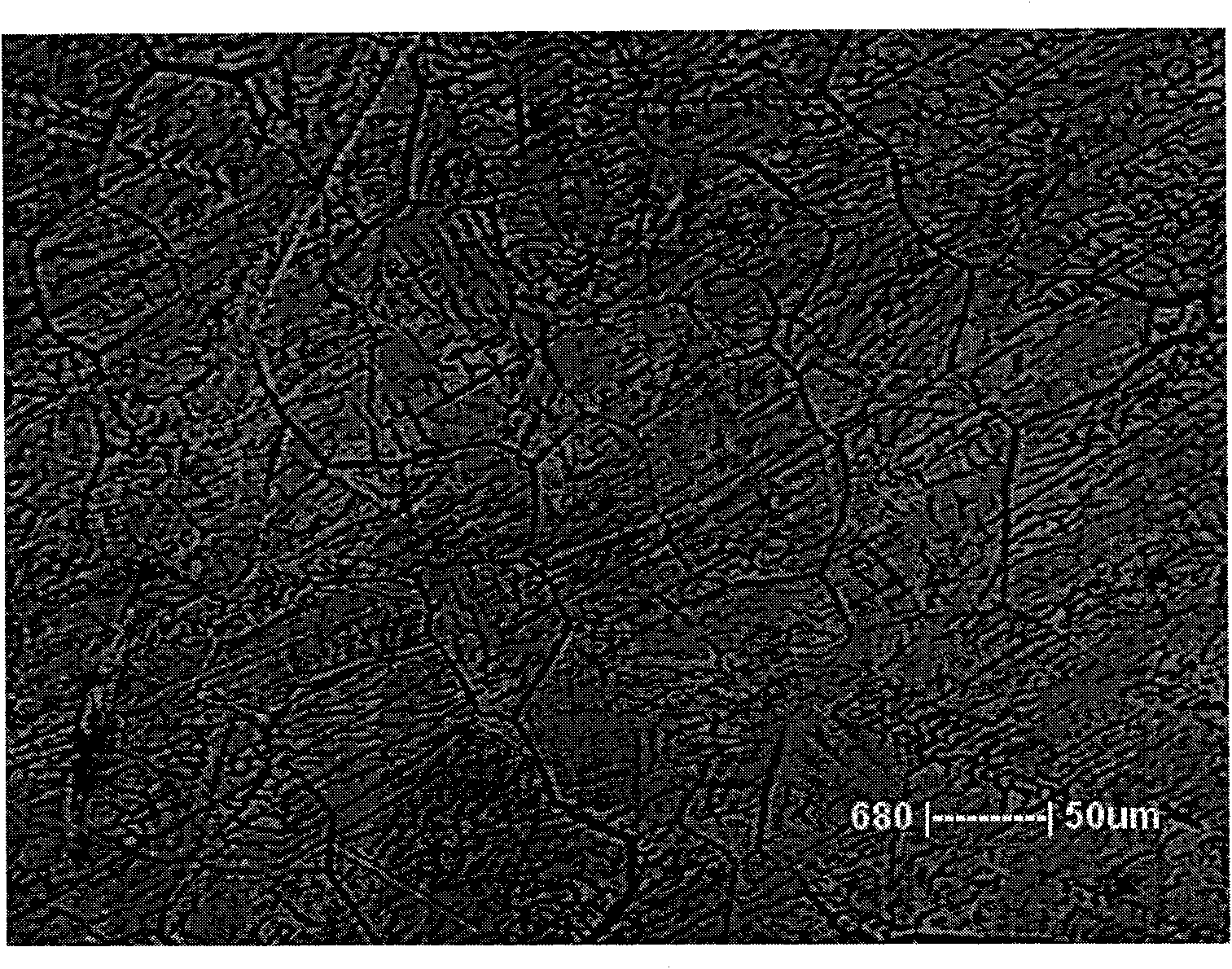

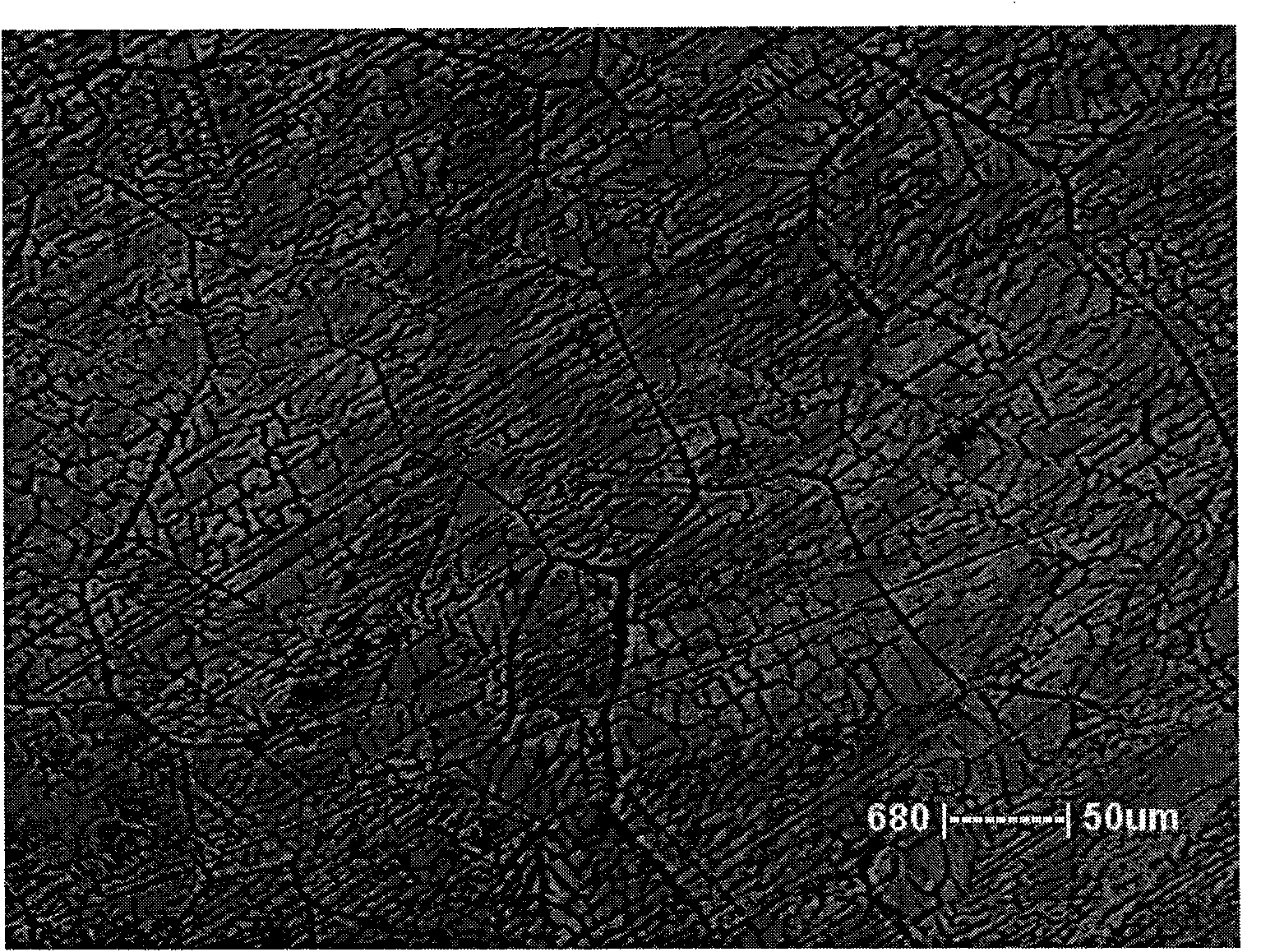

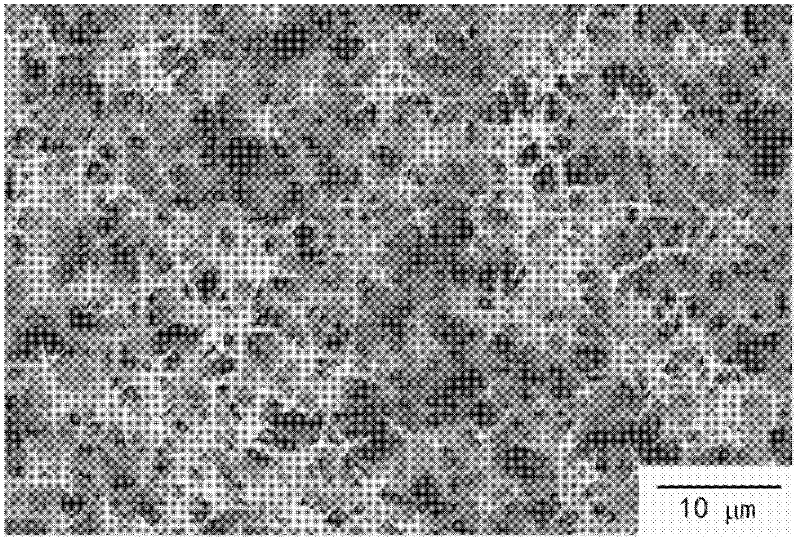

Silver-gold alloy target material, manufacturing method and application thereof

InactiveCN101805835AReduce manufacturing costGrain refinementVacuum evaporation coatingSputtering coatingIngotCasting defect

The invention discloses a silver-gold alloy target material, a manufacturing method and application thereof. The manufacturing method comprises the following steps: putting a target raw material into a melting furnace and heating to be melted; casting the melted melting soup; hot forging ingots formed after the casting; cold rolling blanks formed after the hot forging; and hot treating the blanks formed after the cold rolling to obtain the silver-gold alloy target material with small grains. Through the method provided by the invention, the target material has fine grains, and casting defects can be effectively removed, so that the target material can not produce the problems such as uneven dust particles and components in the sputtering process and the like.

Owner:SOLAR APPLIED MATERIALS TECHNOLOGY CORPORATION

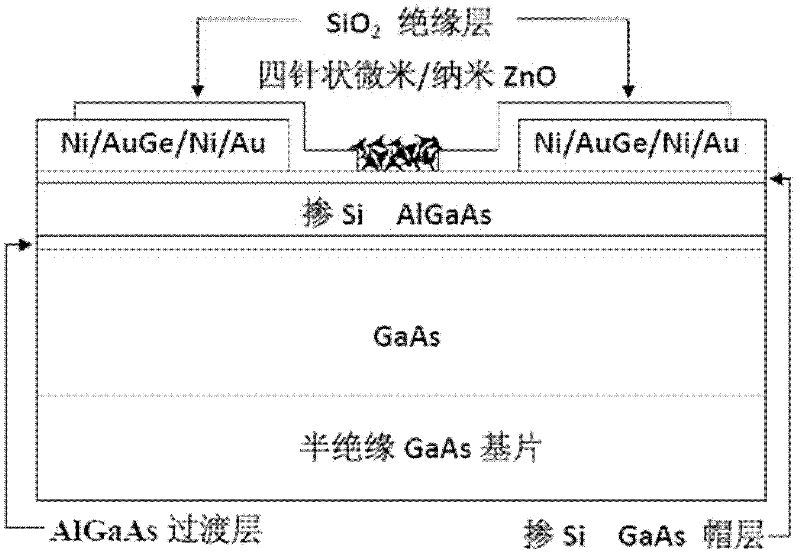

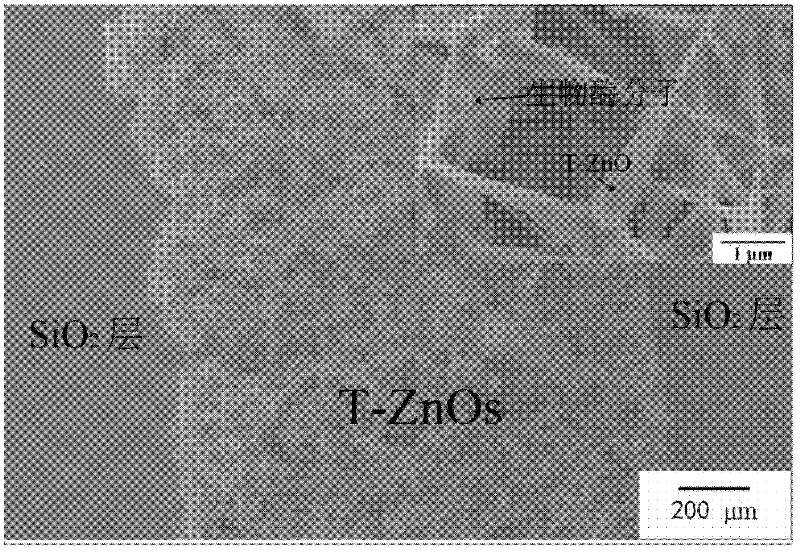

Biosensor base on zinc oxide and high electron mobility transistor and its preparation method

InactiveCN102313765ASimple manufacturing processShort response timeMaterial electrochemical variablesSilicon dioxideMaterials science

The invention provides a biosensor base on zinc oxide and high electron mobility transistor and its preparation method, which belongs to the nano-material application field. The invention is characterized by using a molecular beam epitaxy (MBE) system to prepare an AlGaAs / GaAsHEMT layered structure. A method of heat vapor plating is used to prepare a nickel / gold-germanium / nickel / gold alloy electrode, a silica insulating layer is deposited on the surface of the device to obtain the AlGaAs / GaAsHEMT. A gas-solid method is used for preparing T-ZnO. T-ZnO is modified on a grid electrode of HEMT and a bio-enzyme solution and a Nafion solution are added add drop by drop on a T-ZnO layer. The prepared device is placed at the low temperature for a period of time and then can detect the concentration of the solution to the corresponding biological solution. The invention has the advantage that the prepared device is capable of modifying different biological enzyme through the grid electrode to detect the concentration of the solution to the corresponding biological solution, and has the merits of high sensitivity, low detection limitation, wide detection scope, fast response speed, simple structure and stable performance, so that the biosensor provides the possibility to an practical application.

Owner:UNIV OF SCI & TECH BEIJING

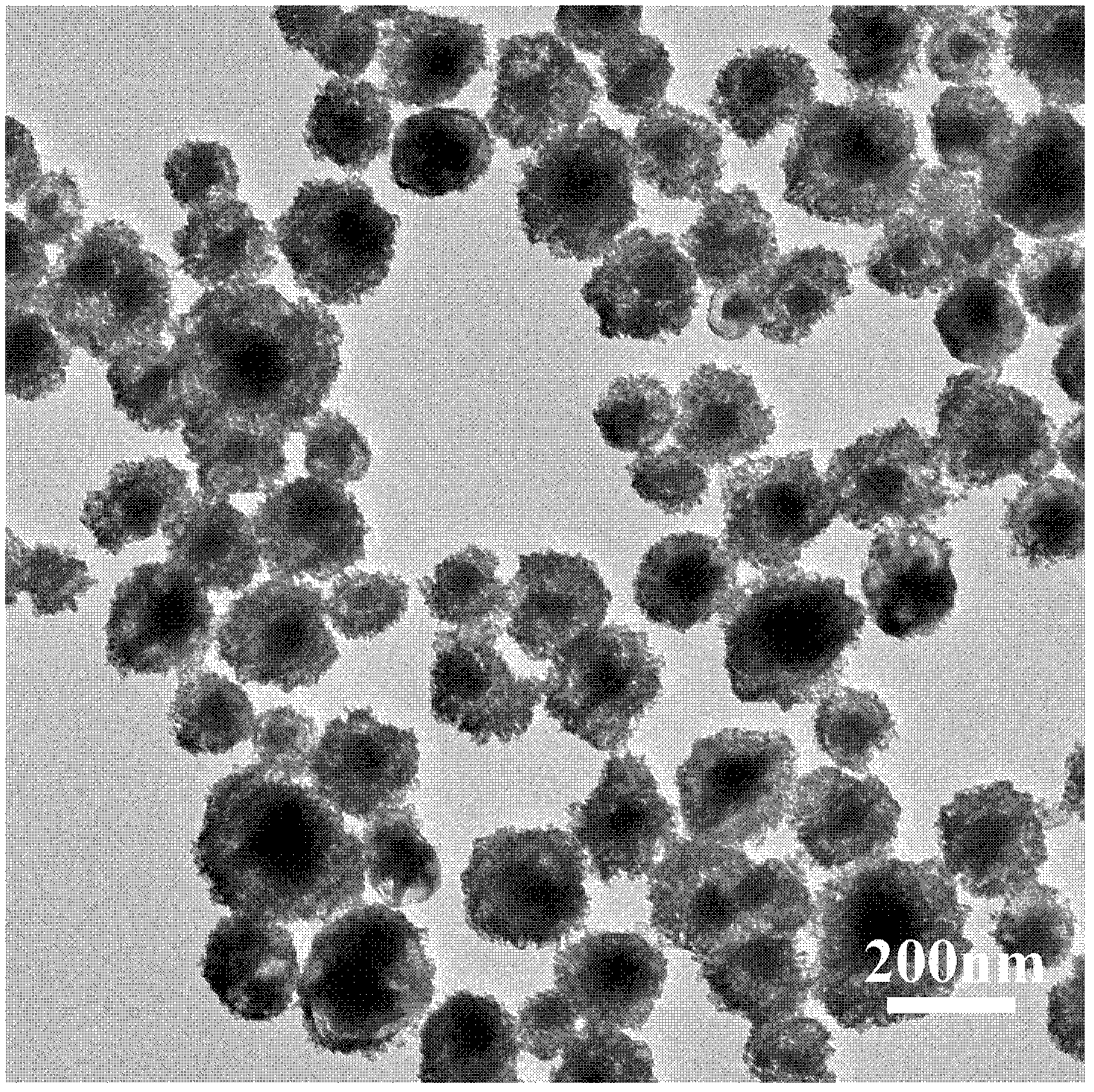

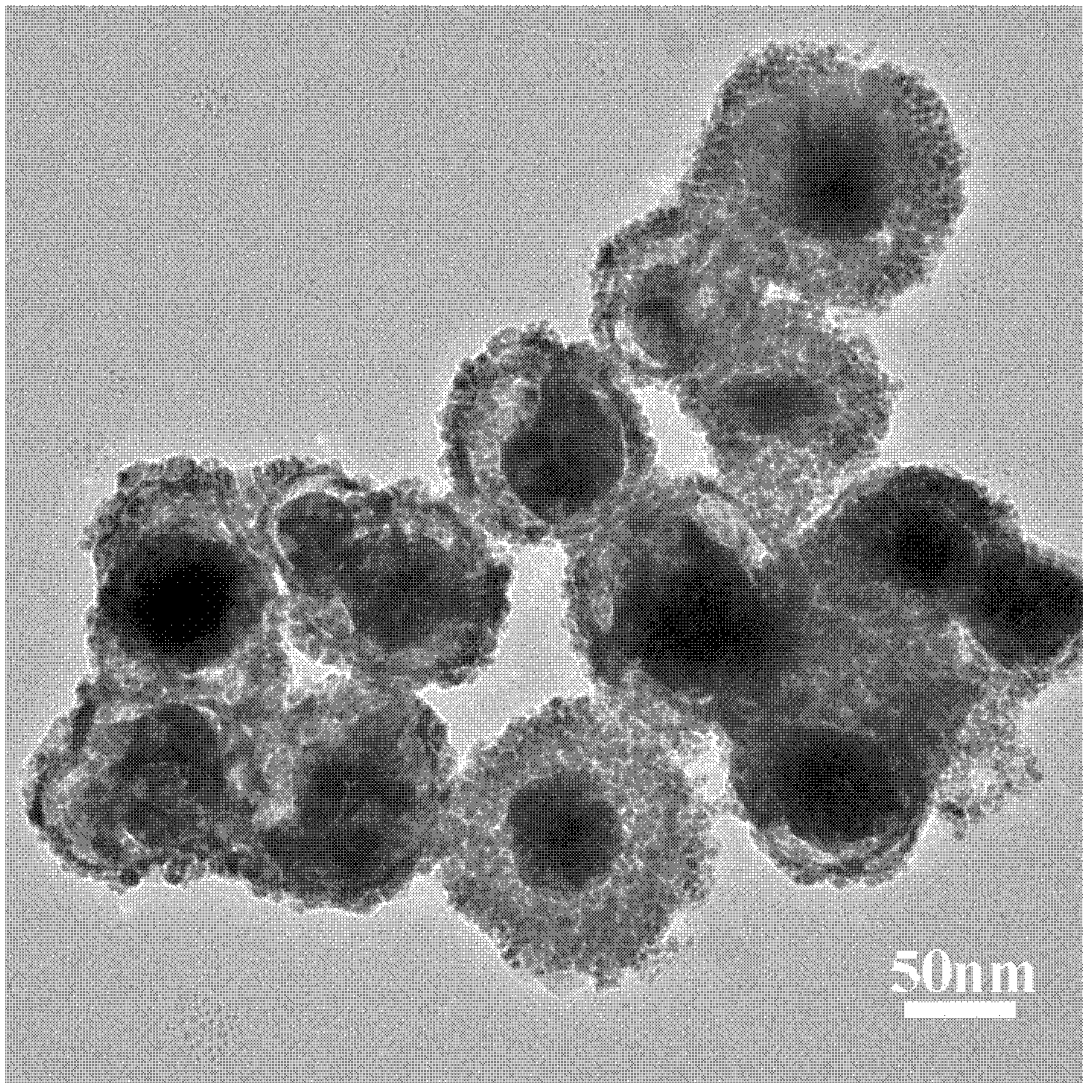

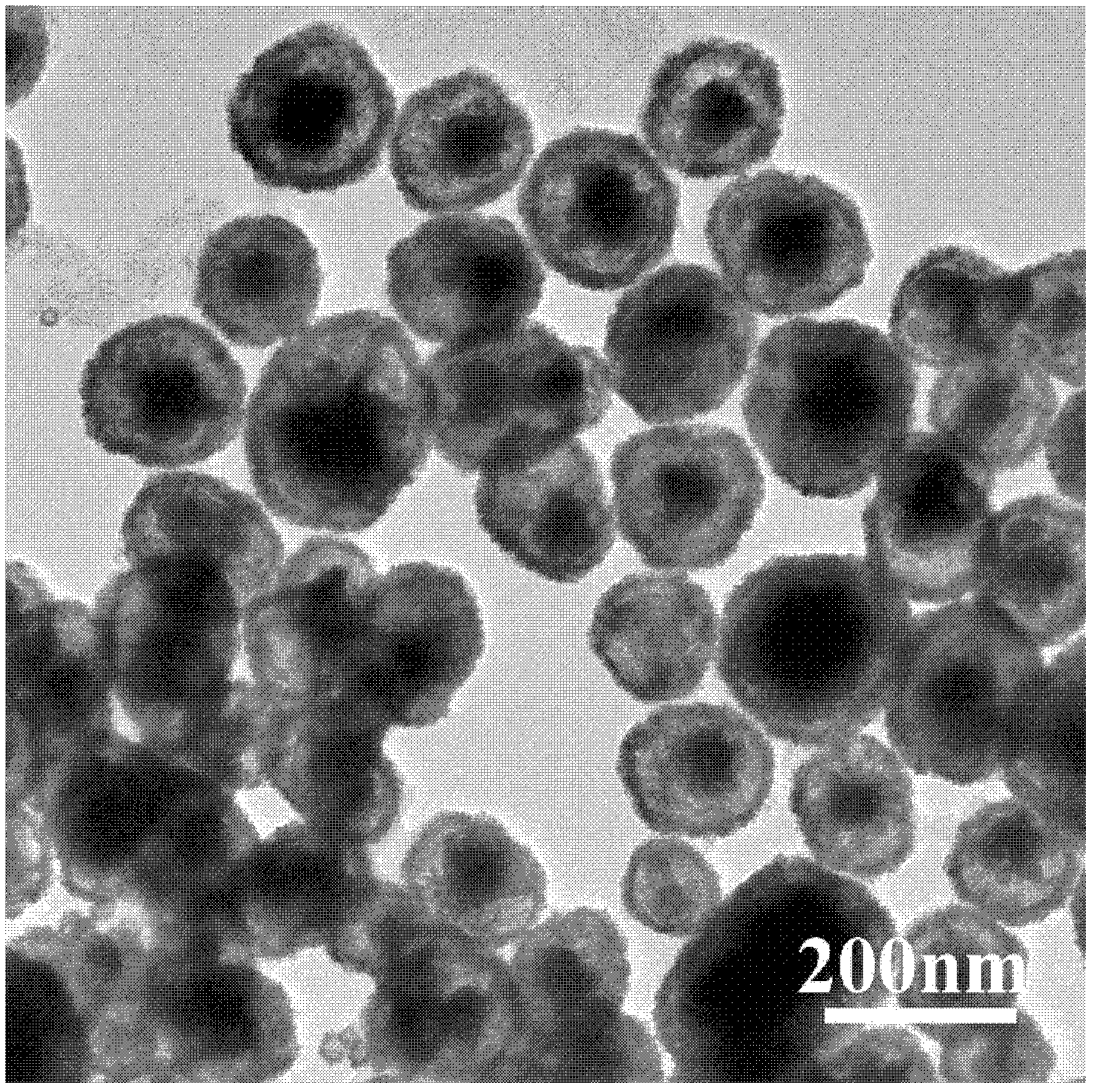

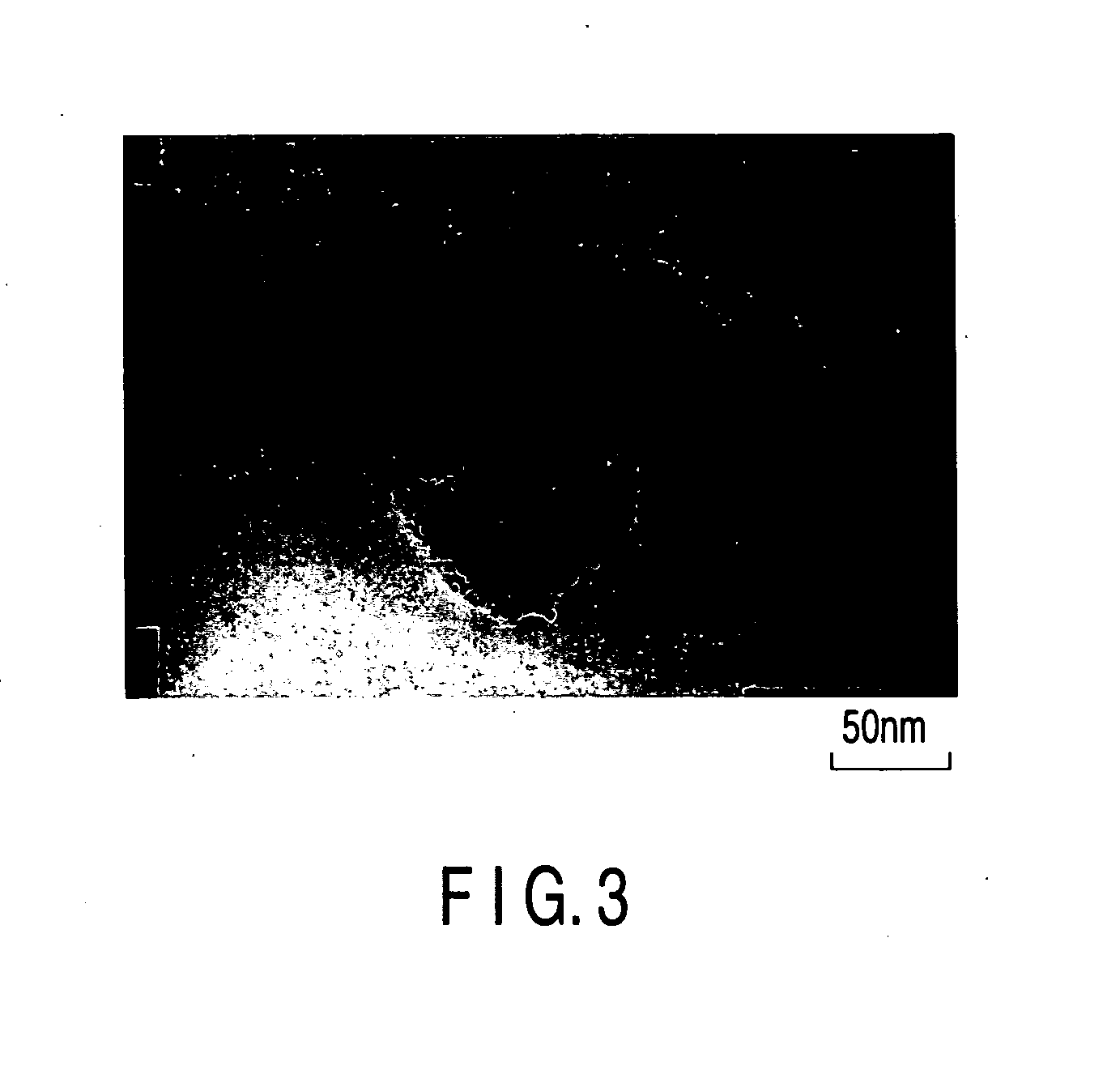

Porous core-shell nano auriferous alloy and preparation method for same

InactiveCN102581273ALarge specific surface areaImprove catalytic performanceMaterial nanotechnologySingle crystalNanostructure

The invention discloses a porous core-shell nano auriferous alloy and a preparation method for the same. The alloy comprises an Au (gold) core and a metal shell of a porous structure, the thickness of the shell ranges from 25nm to 35nm, and components of the shell consist of Au, Pd (palladium), Pt (platinum) and alloy of Au, Pd and Pt. Compared with the prior art, the method is used for preparing a porous core-shell auriferous alloy nano structure by using low-valence (univalent or divalent) noble metal saline solution as raw materials. The method is simple, controllable, high in reproducibility and generally applicable, and purity approximates 100%. Compared with a monocrystal core-shell nano structure, the porous core-shell auriferous alloy nano structure is larger in specific surface area and more excellent in catalysis, and can be used for heterogeneous catalysis and used as electrode materials for electro-catalysis and fuel cells.

Owner:ANHUI NORMAL UNIV

Dental alloys

InactiveUS20050158693A1High yield strengthImprove polishing effectImpression capsArtificial teethDenturesDental porcelain material

A dental alloy that comprises little or no amounts of noble metals. The alloys herein are designed to be a substitute for gold alloys in the fabrication of prosthetic dental appliances employing porcelain to metal bonds. The alloys are based on a combination of iron and chromium with a lesser inclusion of other elements to provide a high yield strength and to provide a durable impact resistant bond with dental porcelain.

Owner:PRASAD ARUN +1

Manufacturing method of ceramic/copper composite material throat insert

InactiveCN102248168AImprove anti-ablationImprove thermal shock resistanceTurbinesOther manufacturing equipments/toolsTungstenLiquid copper

The invention relates to a manufacturing method of a ceramic / copper composite material throat insert, comprising preparation of a ceramic skeleton and infiltration of a copper alloy, wherein the preparation of the ceramic skeleton comprises the steps of ball milling, pelletizing, moulding, presintering and degreasing as well as high temperature sintering, and a porous ceramic skeleton blank used for preparing a throat insert is prepared; and the infiltration of the copper alloy comprises that Cu-Ni-Ag-Au alloy powder accounting for 36-38% of the weight of the porous ceramic skeleton blank is infiltrated into the porous ceramic skeleton blank at a high temperature, and the Cu-Ni-Ag-Au alloy is in composition of Cu-2.5Ni-1.45Ag-0.15Au in percent by weight. The manufacturing method provided by the invention is simple and is convenient to operate, the prepared ceramic / copper composite material has high thermal conductivity, low thermal expansion coefficient, low density and excellent anti-erosion property, a high-strengthen ceramic skeleton material is designed, the proportion of an infiltration agent is adjusted, the wettability of liquid copper / ceramic is improved, the light copper / ceramic throat insert composite material with excellent anti-erosion property can be prepared, and a high-density tungsten-copper throat insert composite material can be replaced, thus the ceramic / copper composite material throat insert is applicable to industrial production.

Owner:CENT SOUTH UNIV

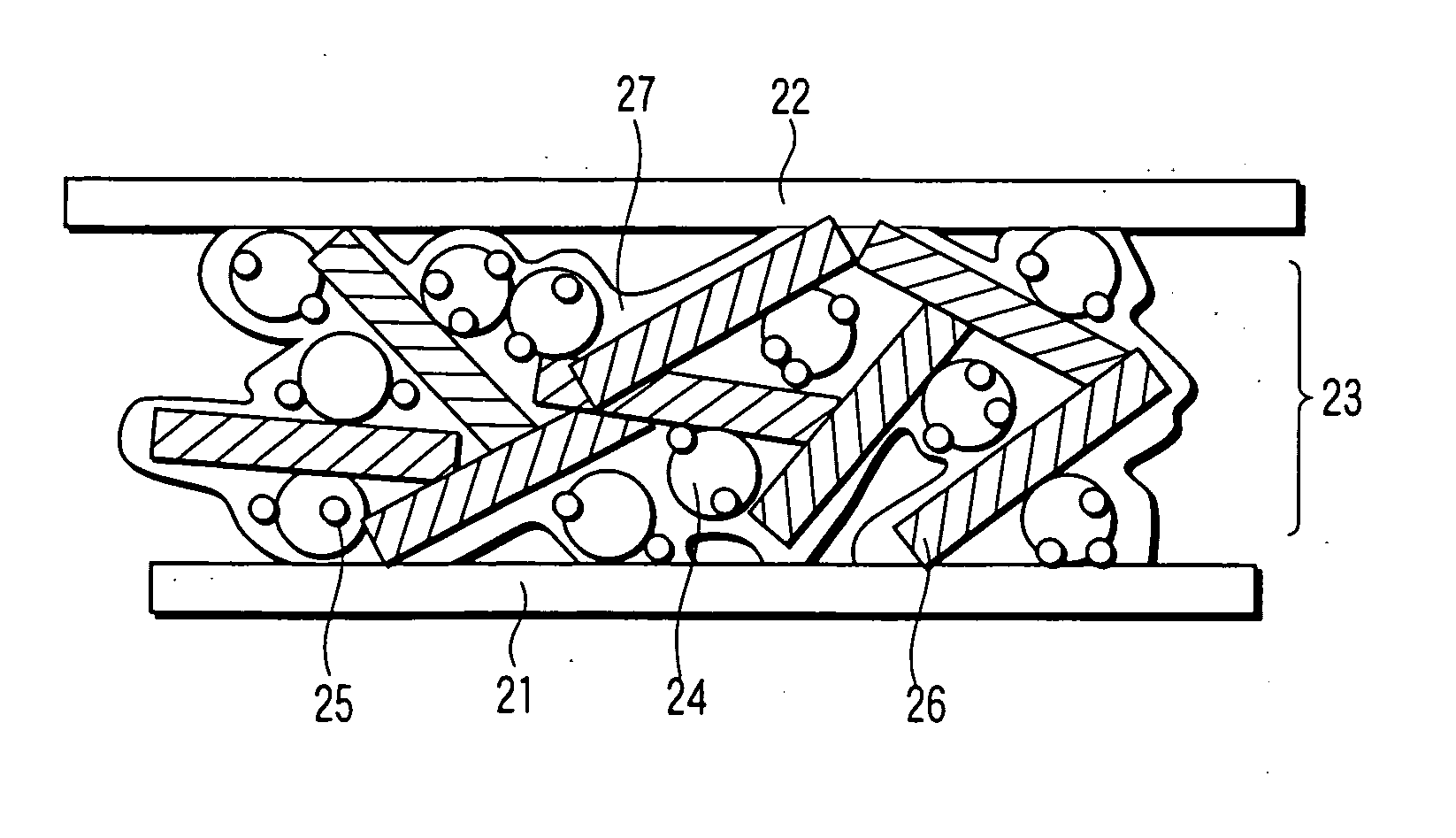

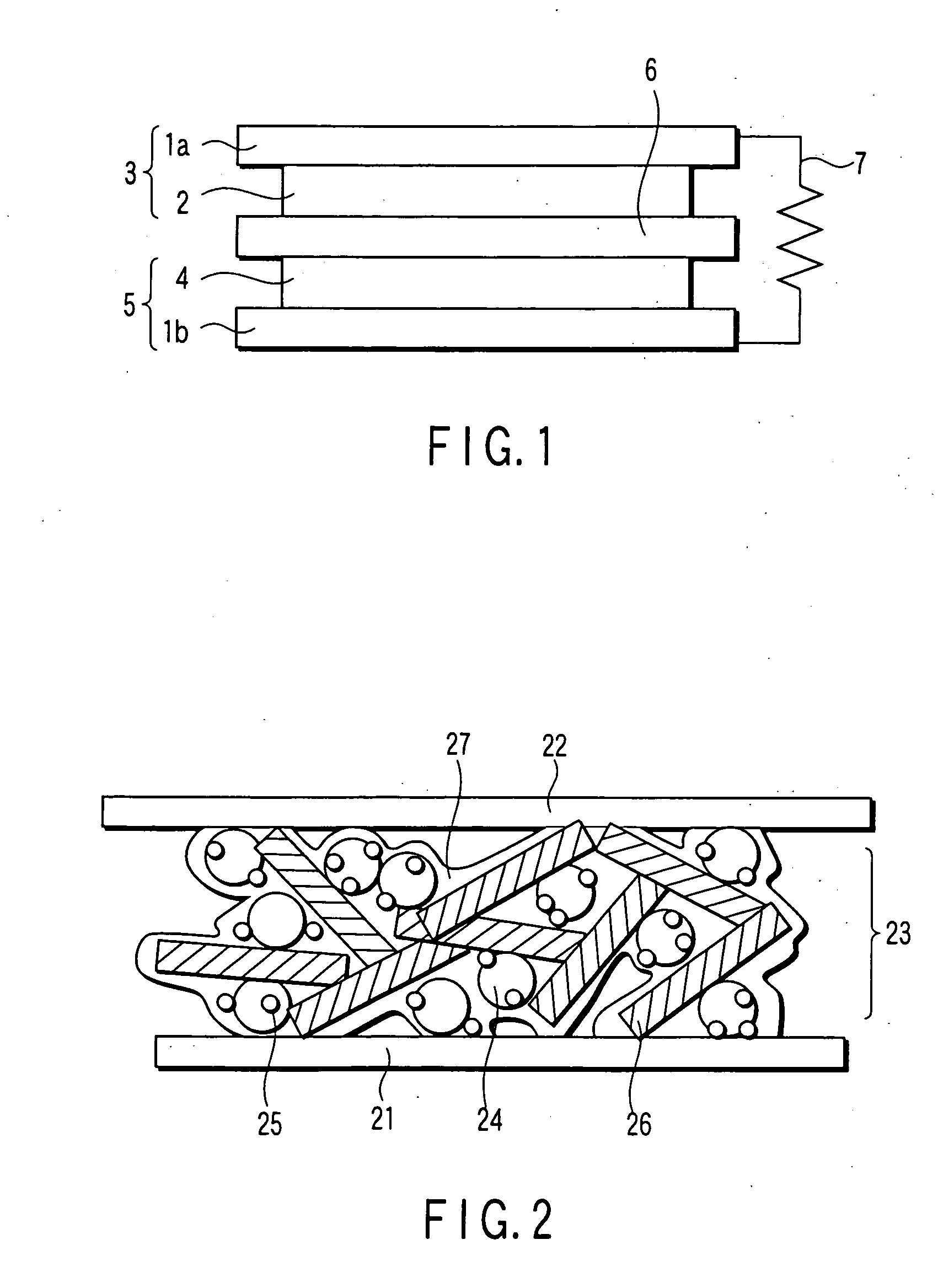

Catalyst, electrode, membrane electrode assembly and fuel cell

InactiveUS20060210864A1Improve power generation efficiencyActive material electrodesSolid electrolyte fuel cellsPlatinumFuel cells

Disclosed is a catalyst, including a catalyst particle containing at least one component selected from the group consisting of gold, platinum and an gold alloy, the gold alloy containing gold and at least one element selected from transition metal elements of the fourth period, fifth period and sixth period of the Periodic Table, and a catalyst carrier carrying the catalyst particle and containing a perovskite type oxide represented by general formula (1) given below: A(1-x)BxTiOy (1) where the element A is at least one element selected from the group consisting of Ca, Sr and Ba, the element B is at least one element selected from the group consisting of La, Nd, Sm, Eu, Gd, Dy, Ho, Er, Tm, Yb, and Lu, the molar ratio x satisfies 0<x<1, and the molar ratio y satisfies 2.7≦y≦3.

Owner:KK TOSHIBA

Process of direct powder rolling of blended titanium alloys, titanium matrix composites, and titanium aluminides

The invention relates to manufacturing of fully dense strips, plates, sheets, and foils from titanium alloys, titanium metal matrix composites, titanium aluminides, and flat multilayer composites of said materials by direct powder rolling of blended powders followed by sintering. The resulting titanium alloy flat products have properties that meet or exceed the conventional ingot metallurgy alloys and are suitable for aerospace, automotive, sporting goods, and other applications. The process includes: (a) providing C.P. titanium matrix powder and at least one powder of alloying components, (b) mechanical activation by attrition of all alloying components, (c) blending titanium powder with attrited alloying powders obtained in step (b), (d) cold direct powder rolling in a mill with horizontally-positioned rolls with different diameters to achieve density of the rolled strip of 60±20% of the theoretical value with subsequent densification by re-rolling green strip, (e) densification by cold re-rolling of the green strip, (f) multiple cold re-rolling, and (g) sintering.

Owner:ADMA PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com