Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

101 results about "Chromia" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In Greek mythology, Chromia (/ˈkroʊmiə/; Ancient Greek: Χρωμία, Khrōmía) is the daughter of Itonus, son of Amphictyon, himself son of Deucalion. She was also, in some traditions, the mother of Aetolus, Paeon, Epeius and Eurycyda by Endymion.

Surface on a stainless steel matrix

InactiveUS7488392B2Not to damage surfaceSolid state diffusion coatingQuenching agentsChemical reactionSpinel

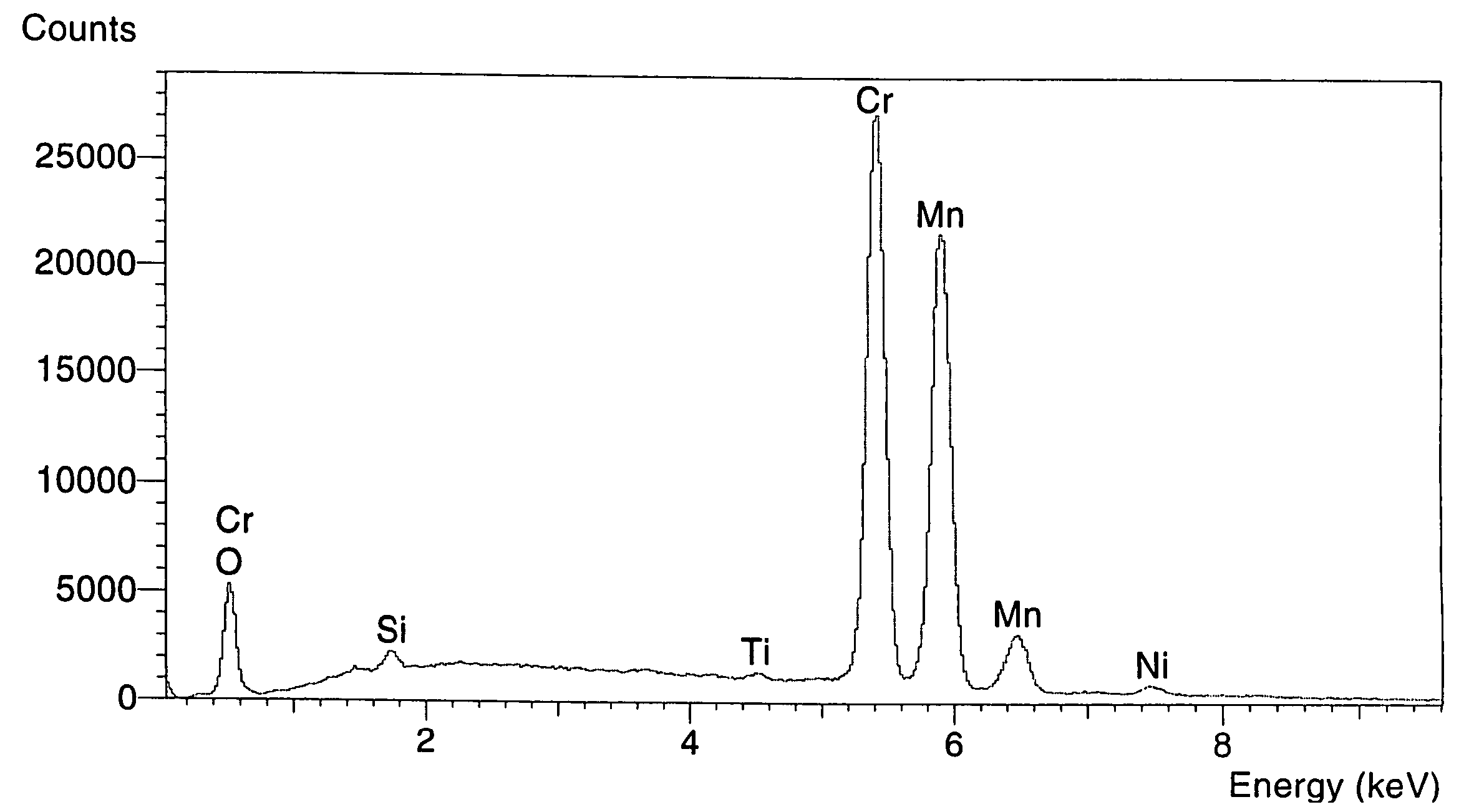

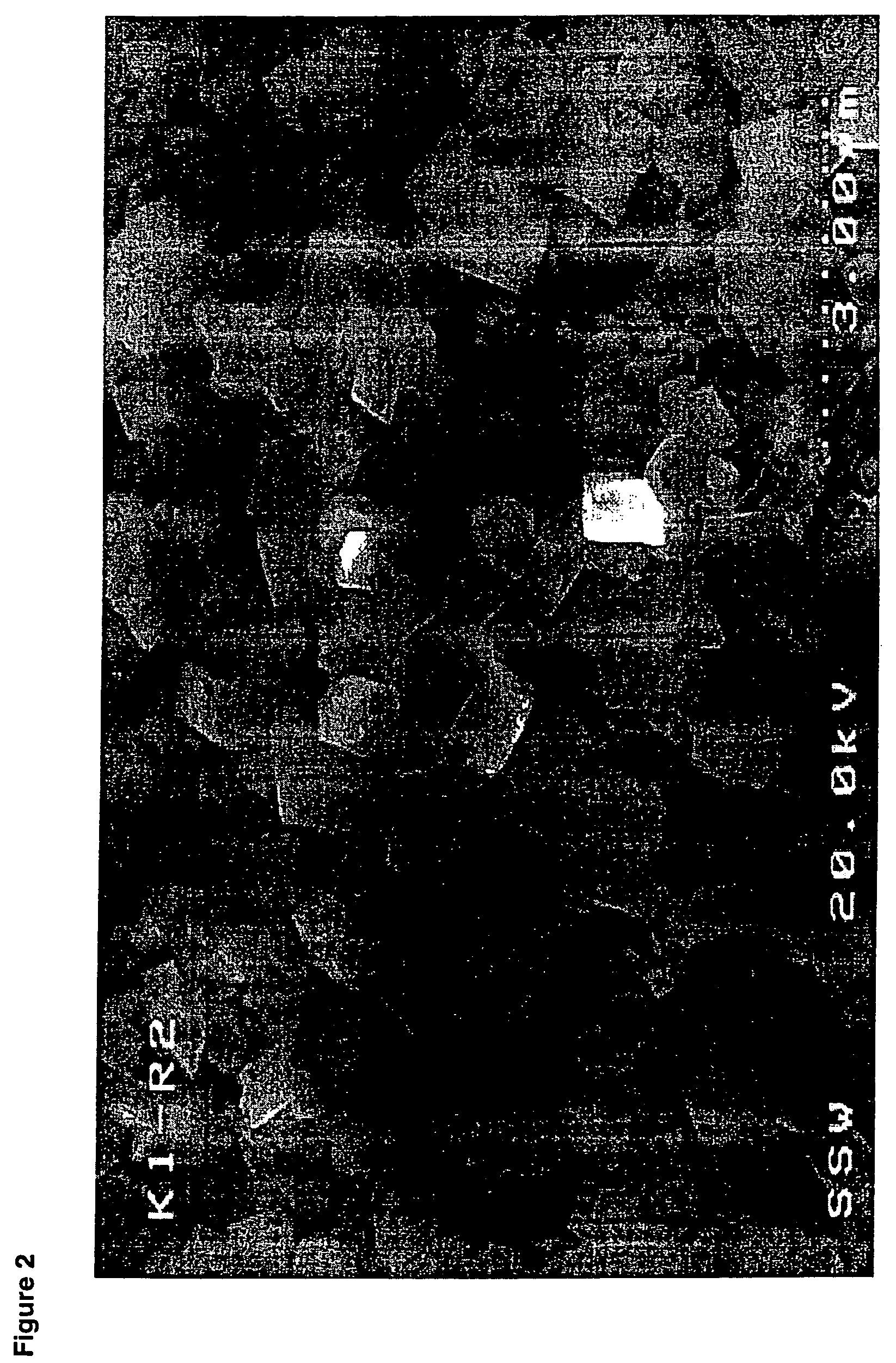

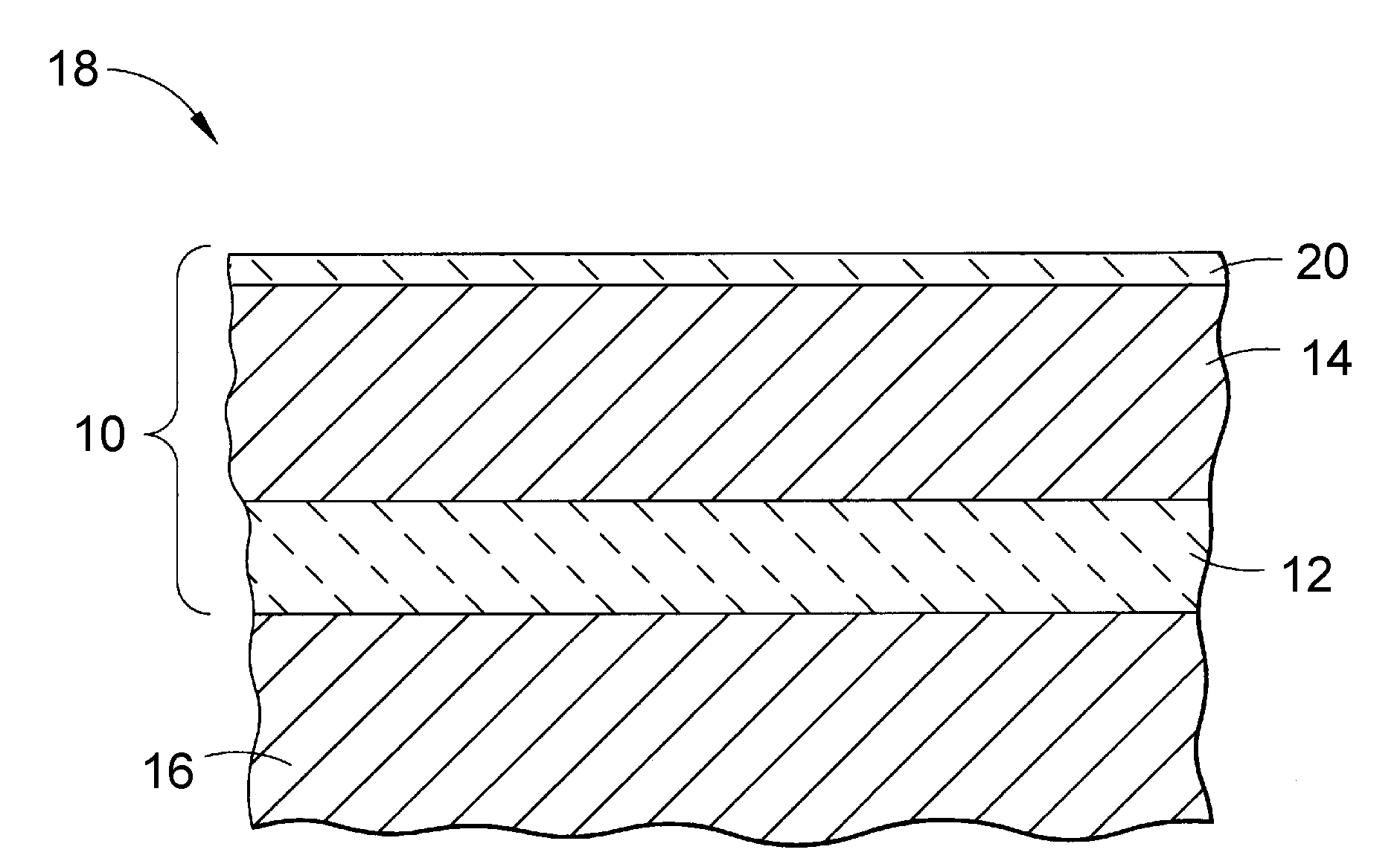

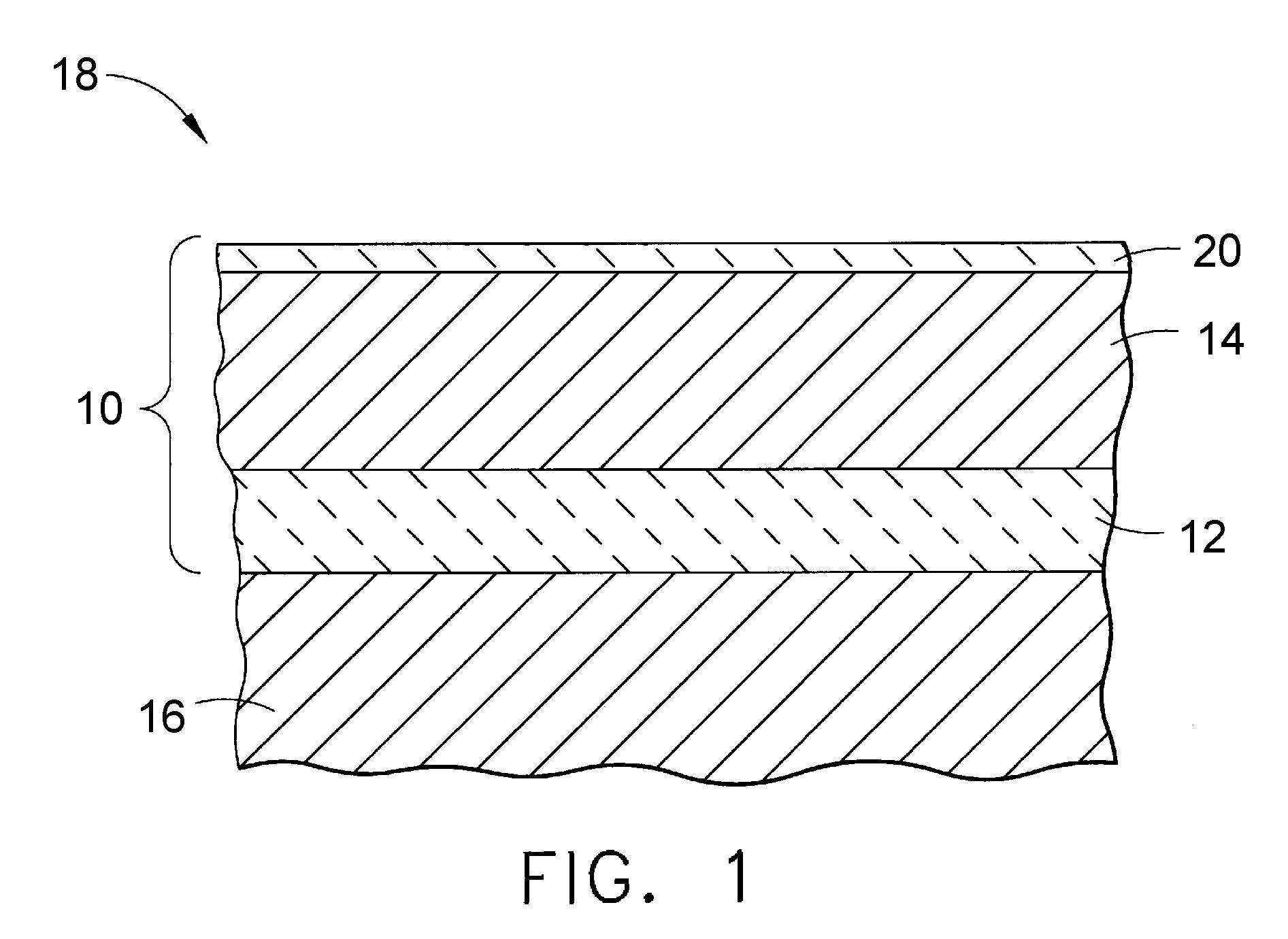

A stainless steel comprising at least 20 weight % of chromium and at least 1.0 weight % of manganese is adapted to support an overcoating having a thickness from 1 to 10 microns of a spinel of the formula MnxCr3−xO4 wherein x is from 0.5 to 2. Preferably the overcoating is on chromia and has stability against chemical reaction at temperatures at least 25° C. higher than the uncoated chromia.

Owner:NOVA CHEM (INT) SA

Erosion and corrosion-resistant coating system and process therefor

InactiveUS20090176110A1Improving solid particle and water droplet erosion characteristicImprove corrosion resistanceMolten spray coatingEngine fuctionsThermal sprayingCoating system

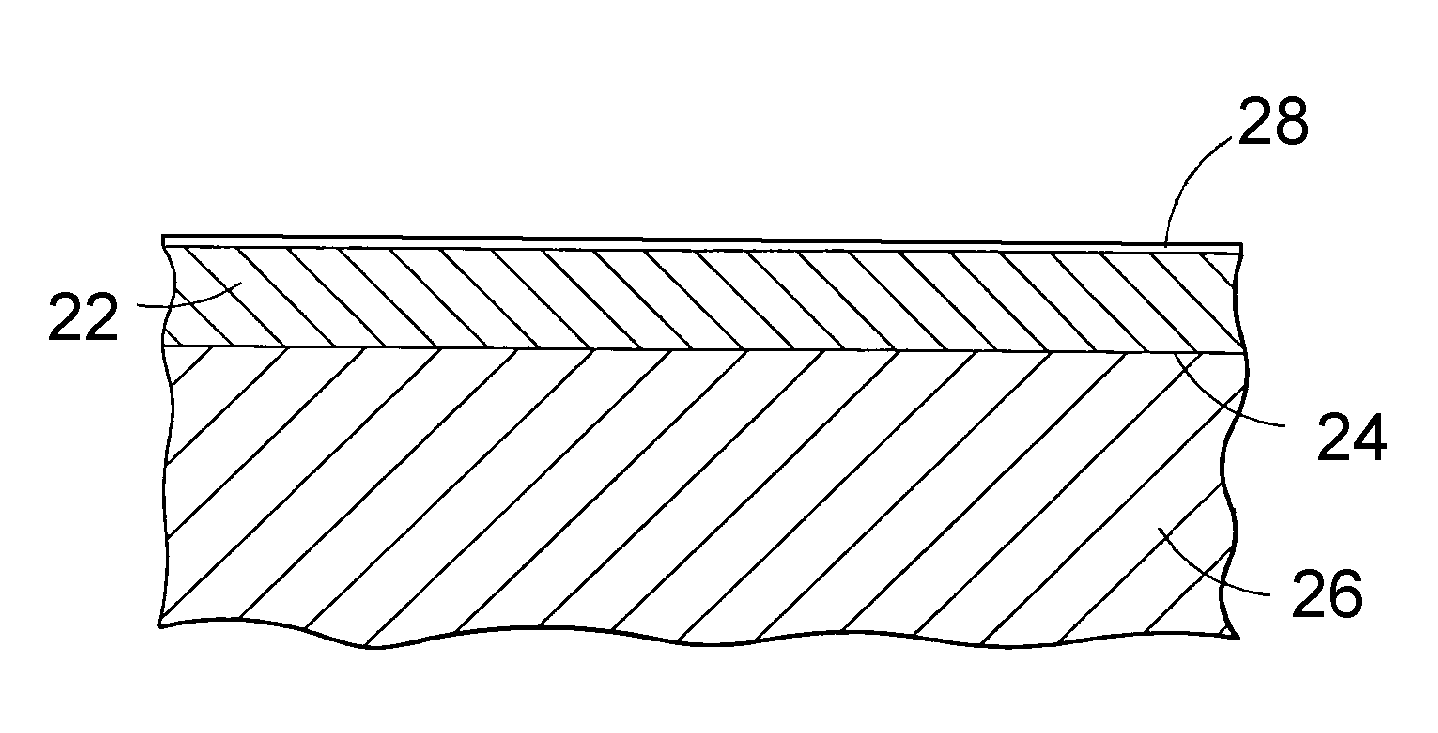

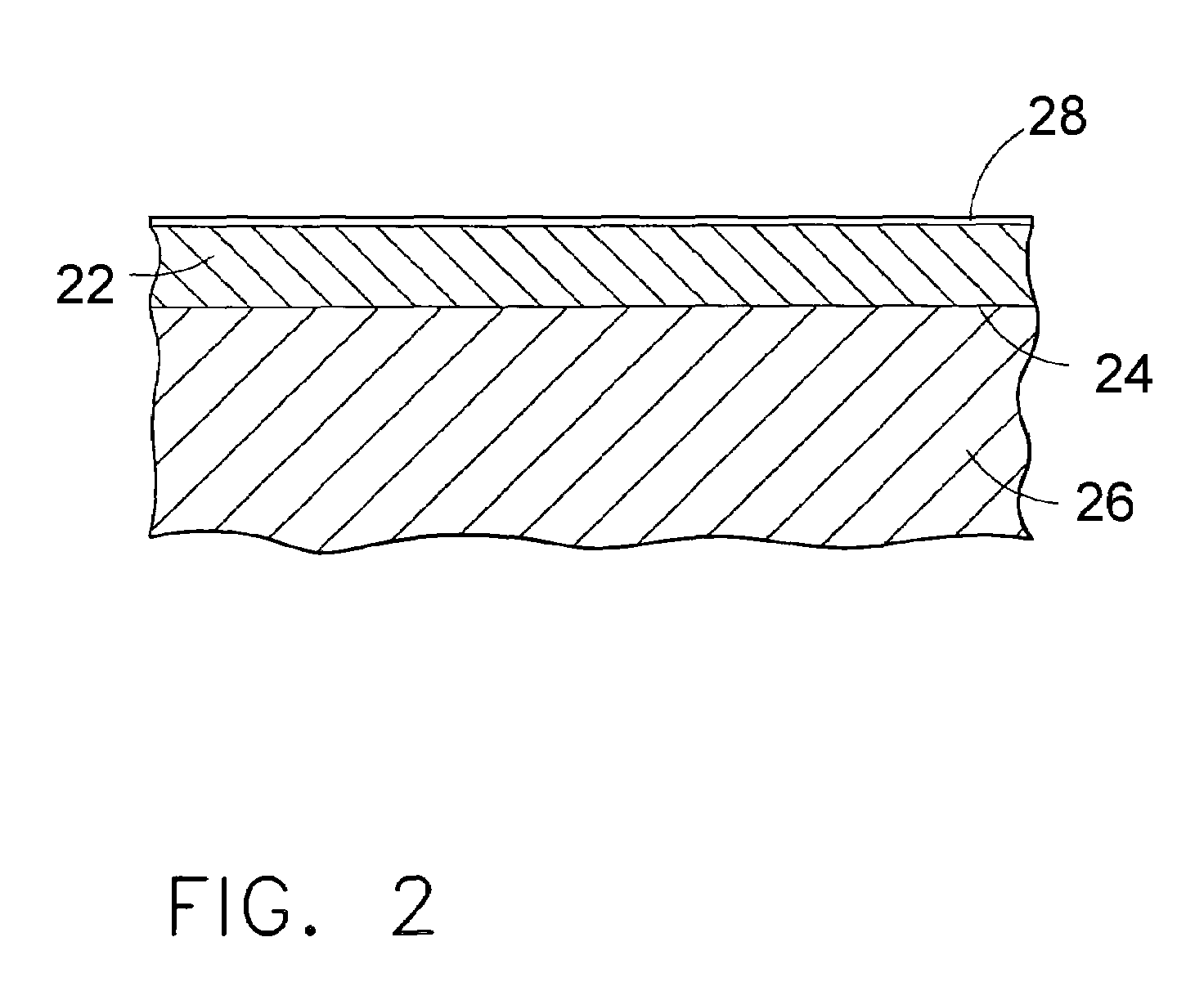

A coating system and process capable of providing erosion and corrosion-resistance to a component, particularly a steel compressor blade of an industrial gas turbine. The coating system includes a metallic sacrificial undercoat on a surface of the component substrate, and a ceramic topcoat deposited by thermal spray on the undercoat. The undercoat contains a metal or metal alloy that is more active in the galvanic series than iron, and electrically contacts the surface of the substrate. The ceramic topcoat consists essentially of a ceramic material chosen from the group consisting of mixtures of alumina and titania, mixtures of chromia and silica, mixtures of chromia and titania, mixtures of chromia, silica, and titania, and mixtures of zirconia, titania, and yttria.

Owner:GENERAL ELECTRIC CO

Turbine component protected with environmental coating

ActiveUS7364801B1Suitable for useReliable long-term protection from oxidation and hot corrosionMolten spray coatingPropellersSolid solutionCobalt

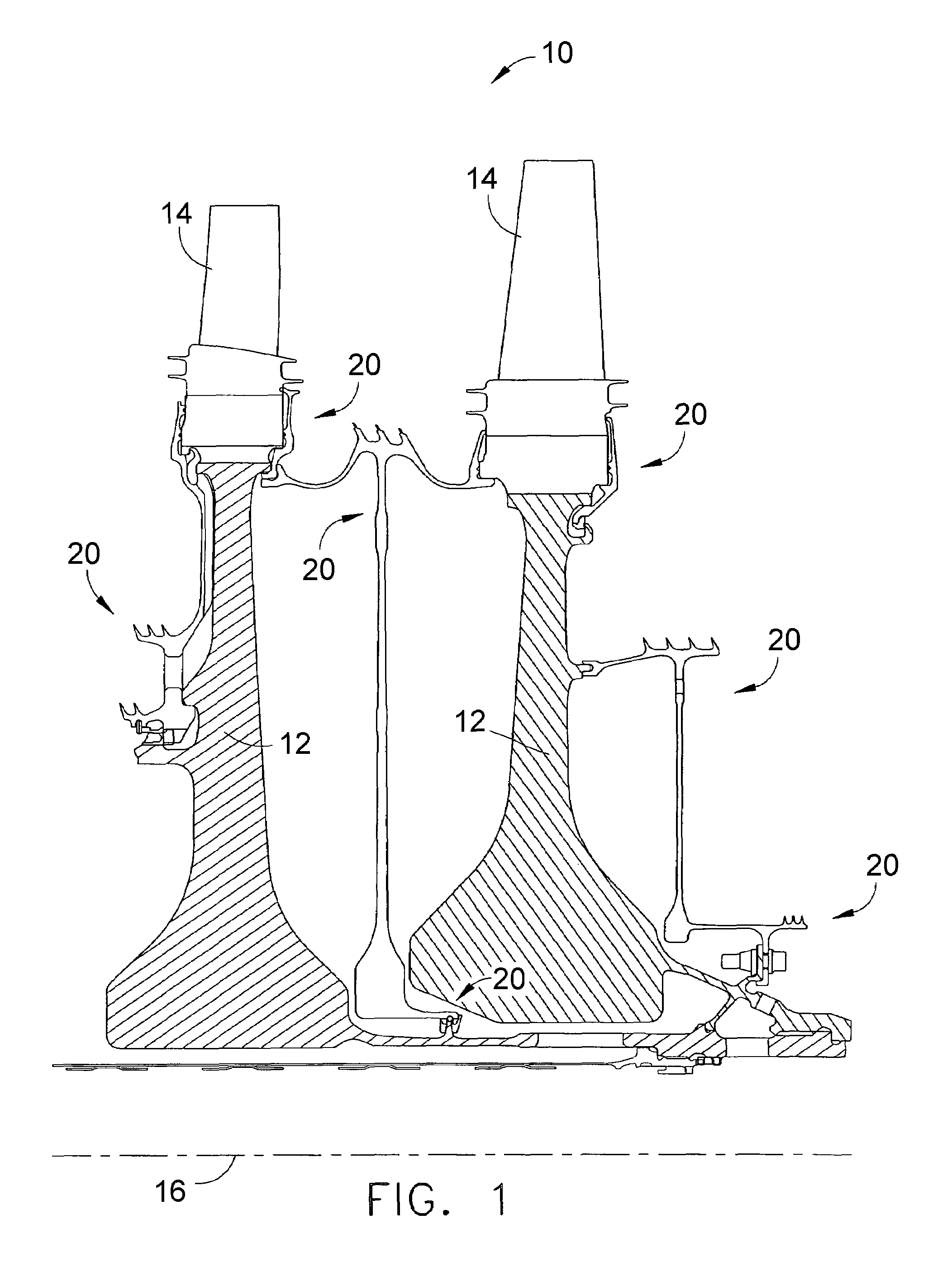

An environmental coating suitable for use on turbine components, such as turbine disks and turbine seal elements, formed of alloys susceptible to oxidation and hot corrosion. The environmental coating is predominantly a solid solution phase of nickel, iron, and / or cobalt. The coating contains about 18 weight percent to about 60 weight percent chromium, which ensures the formation of a protective chromia (Cr2O3) scale while also exhibiting high ductility. The coating may further contain up to about 8 weight percent aluminum, as well as other optional additives. The environmental coating is preferably sufficiently thin and ductile to enable compressive stresses to be induced in the underlying substrate through shot peening without cracking the coating.

Owner:GENERAL ELECTRIC CO

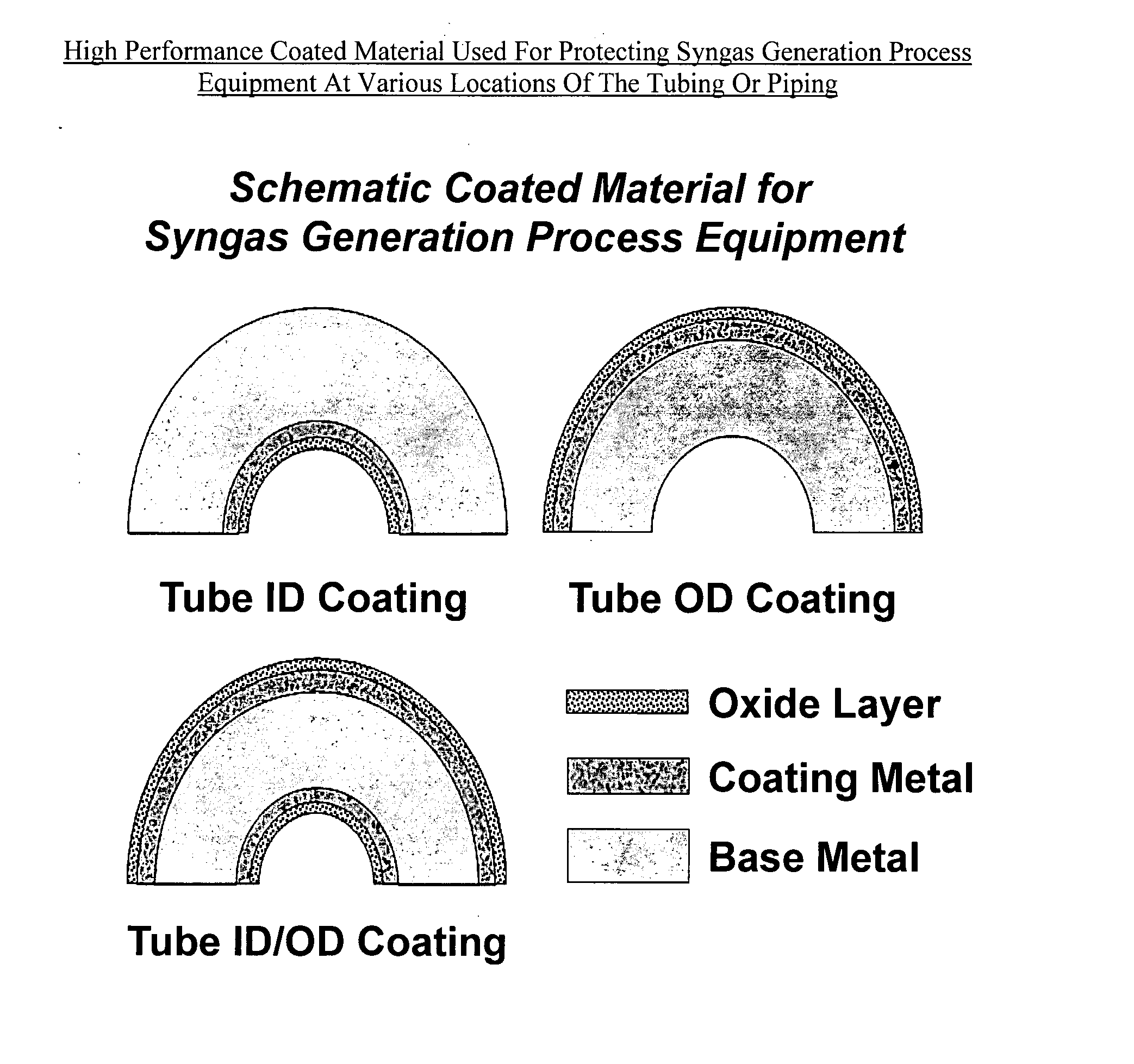

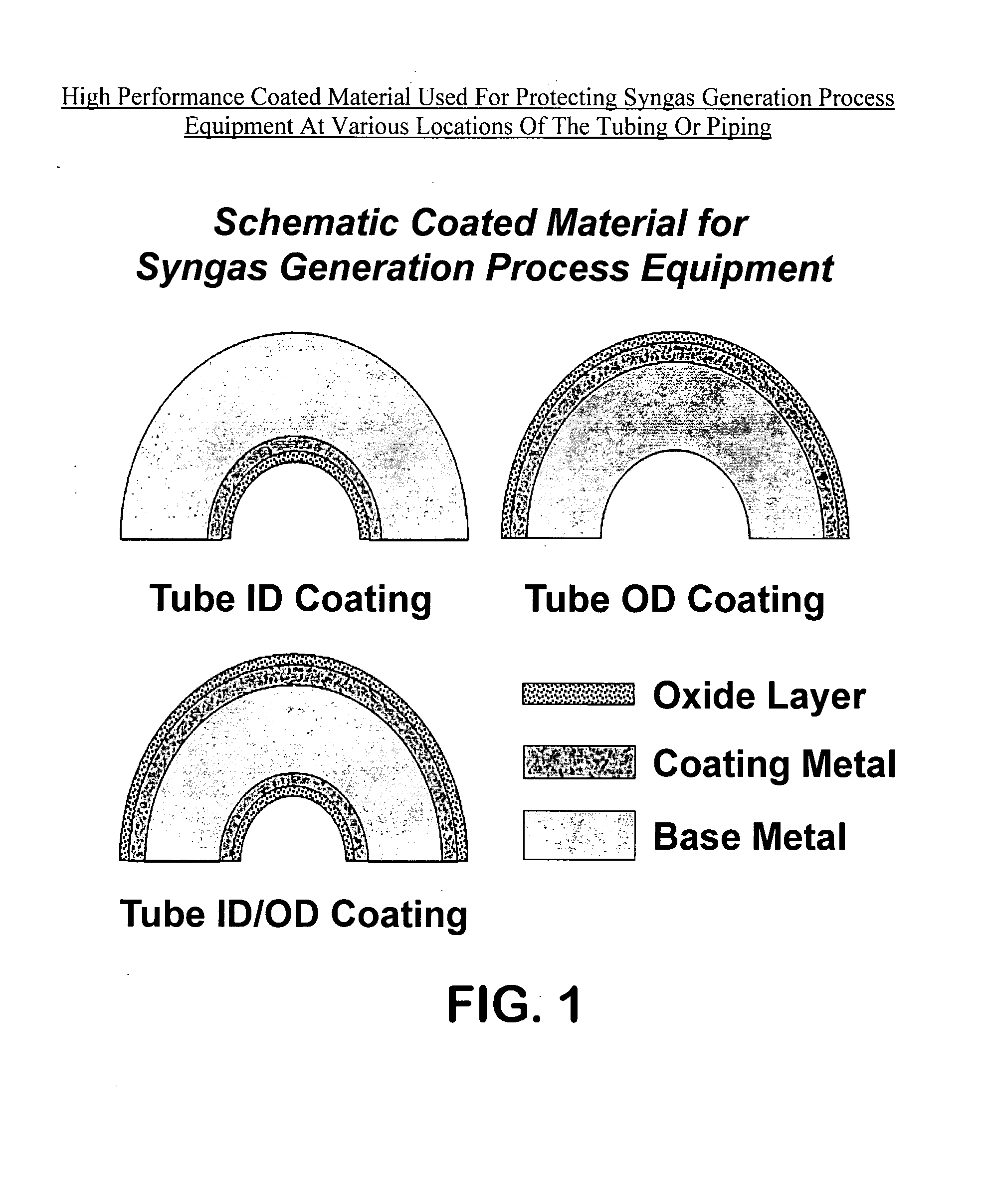

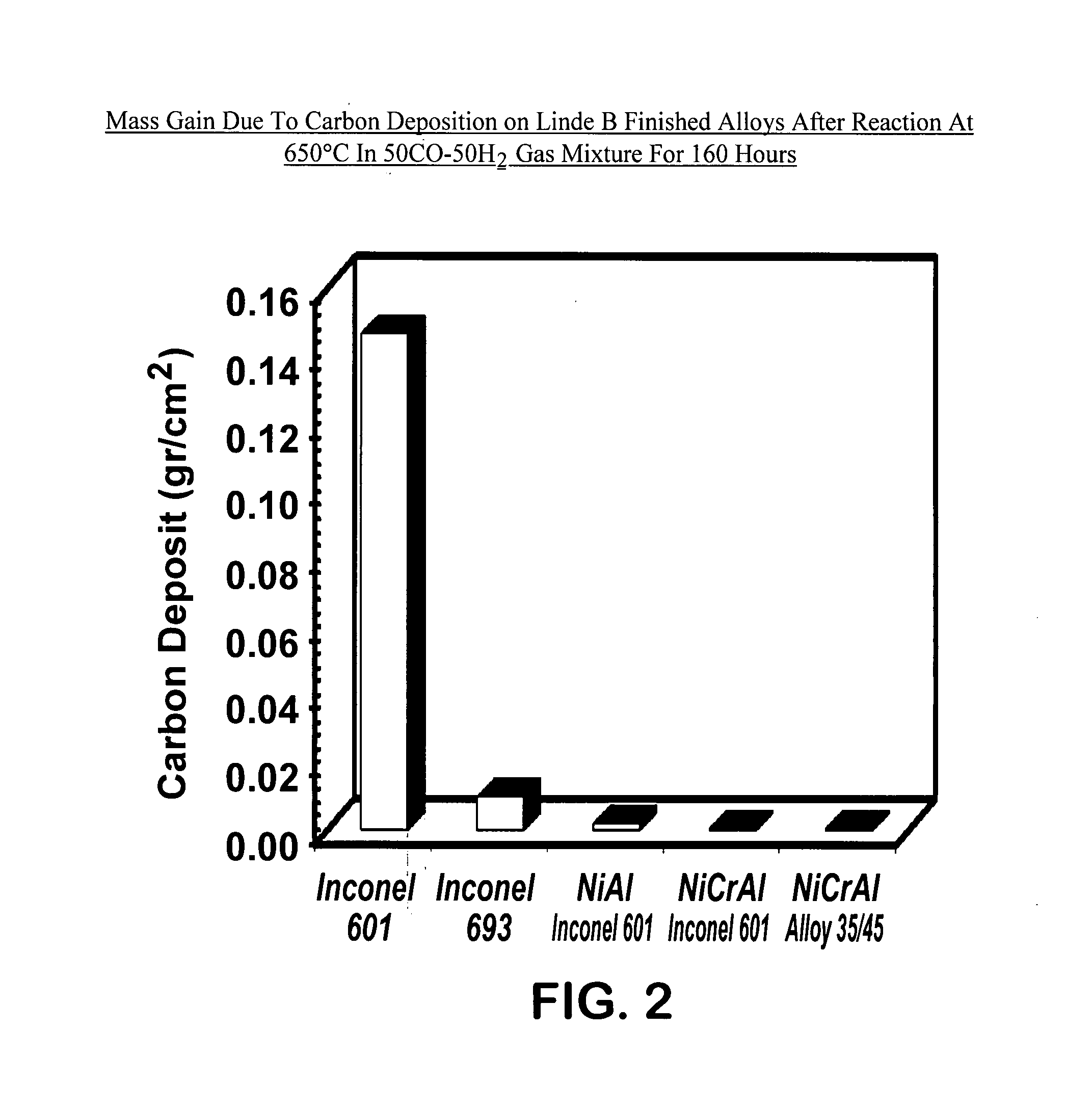

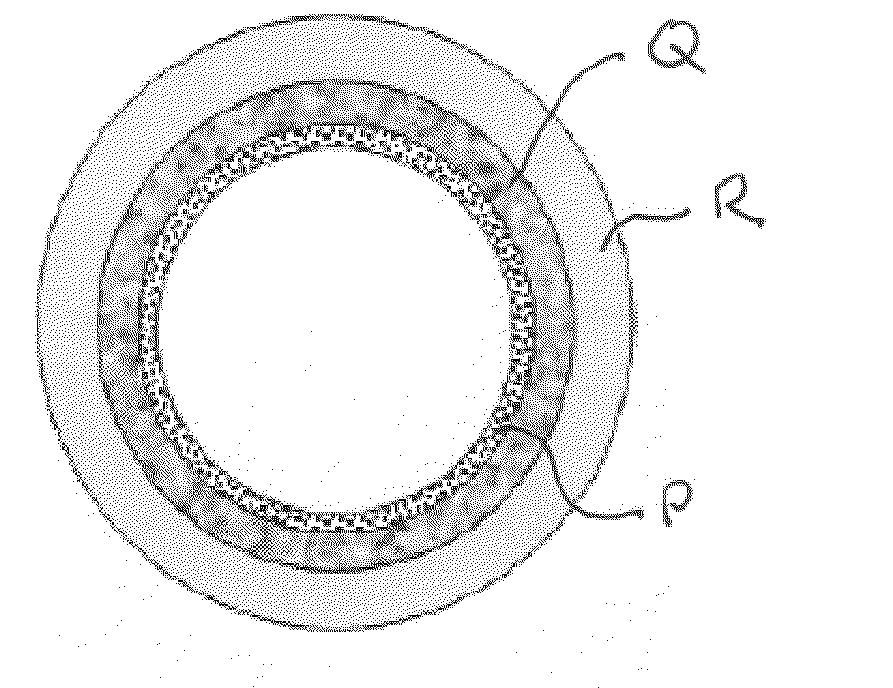

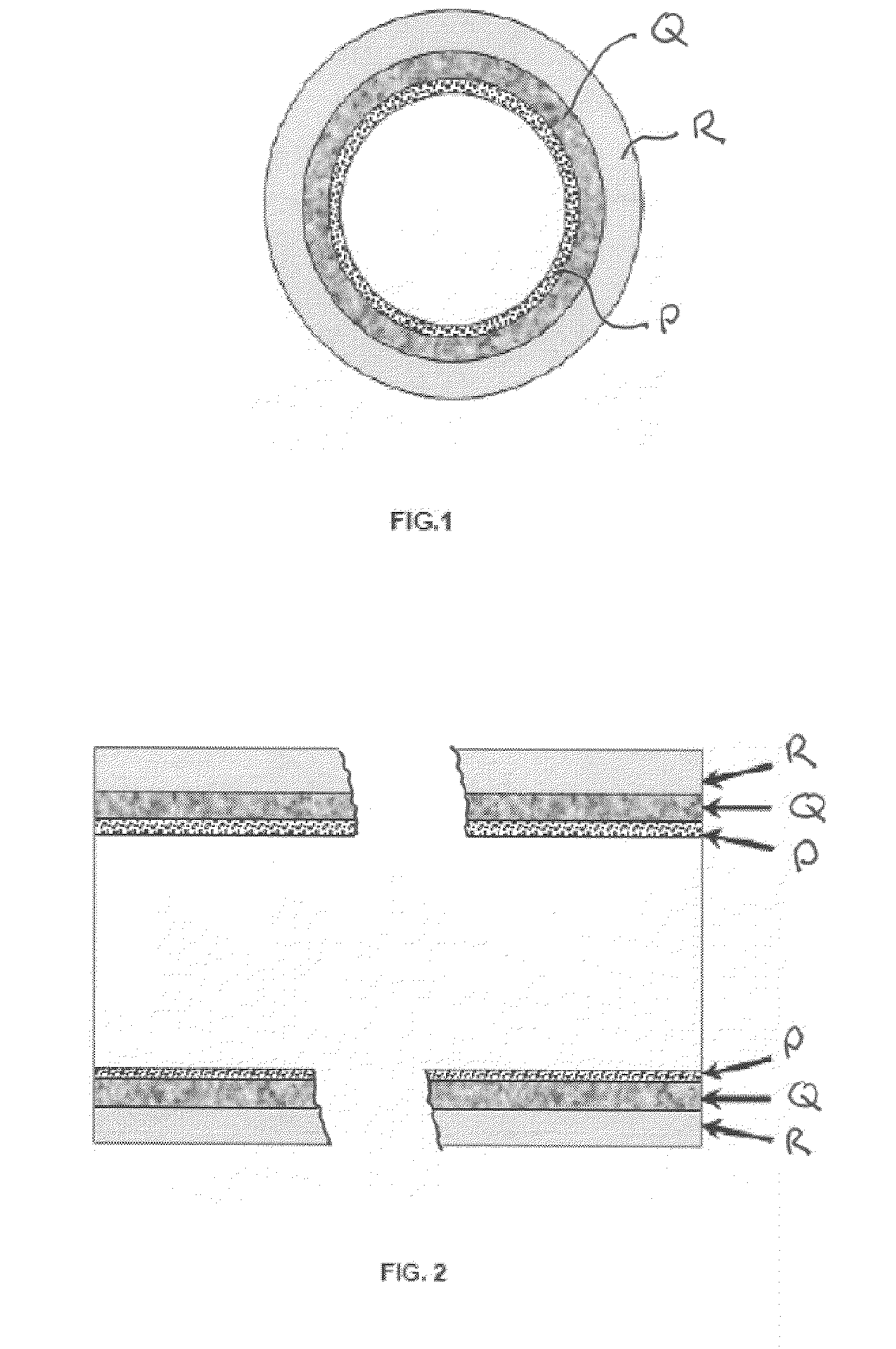

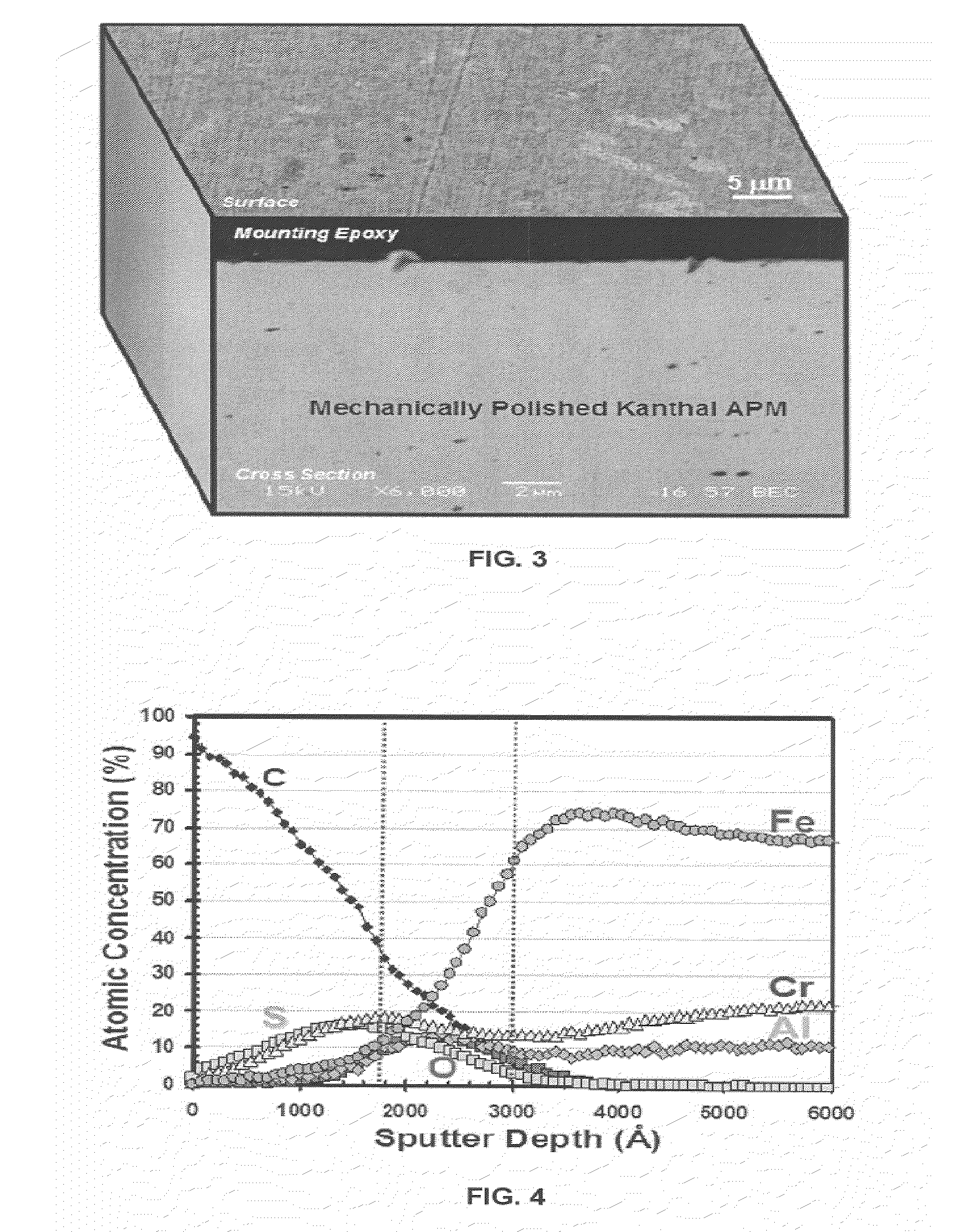

High performance coated material with improved metal dusting corrosion resistance

InactiveUS20080020216A1Improve the immunityReduce carbon depositionAnodisationLiquid surface applicatorsMulliteInconel

High performance coated metal compositions resistant to metal dusting corrosion and methods of providing such compositions are provided by the present invention. The coated metal compositions are represented by the structure (PQR), wherein P is an oxide layer at the surface of (PQR), Q is a coating metal layer interposed between P and R, and R is a base metal. P includes alumina, chromia, silica, mullite or mixtures thereof. Q includes Ni and Al, and at least one element selected from the group consisting of Cr, Si, Mn, Fe, Co, B, C, N, P, Ga, Ge, As, In, Sn, Sb, Pb, Sc, La, Y, Ce, Ti, Zr, Hf, V, Nb, Ta, Mo, W, Ru, Rh, Ir, Pd, Pt, Cu, Ag, Au and mixtures thereof. R is selected from the group consisting of carbon steels, low chromium steels, ferritic stainless steels, austenetic stainless steels, duplex stainless steels, Inconel alloys, Incoloy alloys, Fe—Ni based alloys, Ni-based alloys and Co-based alloys. Advantages exhibited by the disclosed coated metal compositions include improved metal dusting corrosion resistance at high temperatures in carbon-supersaturated environments having relatively low oxygen partial pressures. The coated metal compositions are suitable for use in syngas generation process equipment.

Owner:EXXON RES & ENG CO

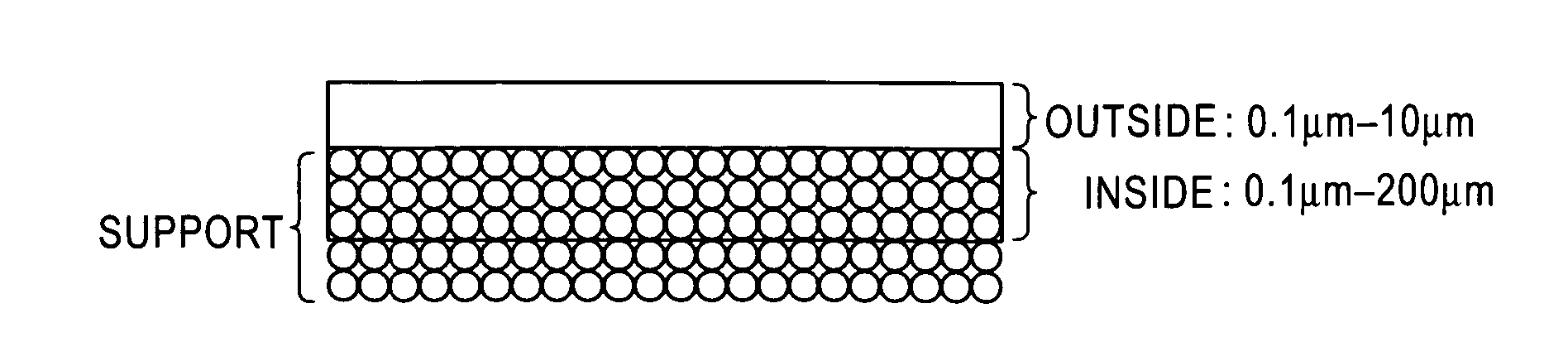

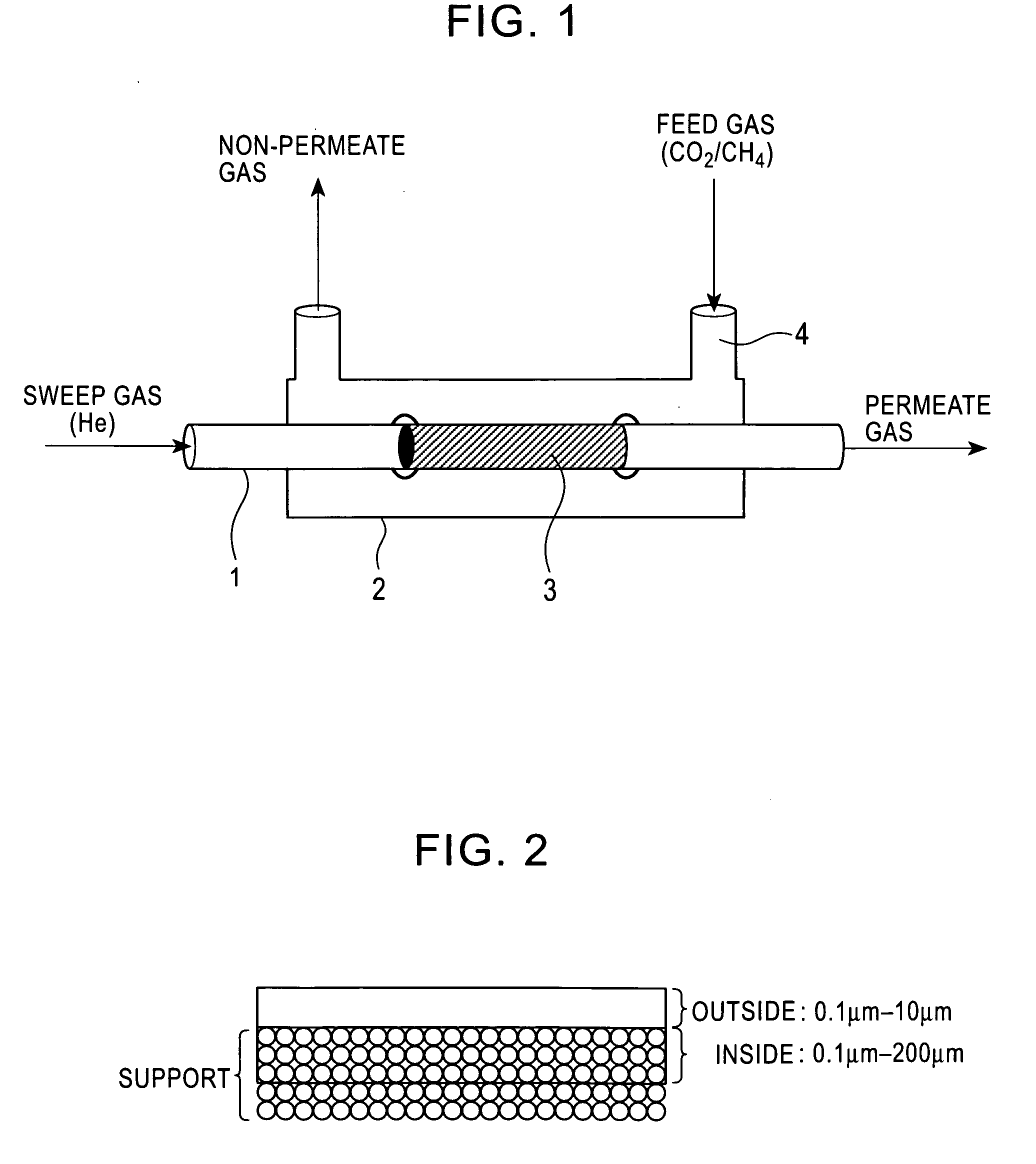

Zeolite membrane support and zeolite composite membrane

InactiveUS20050067344A1Formed satisfactorilySemi-permeable membranesLoose filtering material filtersSilicon dioxideMetallic substrate

A zeolite membrane support for supporting a zeolite membrane includes a metal substrate having a metal oxide layer at its surface. Preferably, the metal oxide layer has a thickness in the range of 1 nm to 10 μm and comprises chromia, silica, or alumina. Preferably, the metal substrate is porous, having a mean pore size in the range of 10 nm to 50 μm, and comprises an iron-based metal. A zeolite composite membrane includes the zeolite membrane support and a zeolite membrane which includes an external zeolite layer lying over the surface at and / or an internal zeolite layer lying in the pores at the metal oxide layer side of the zeolite membrane support. The zeolite membrane preferably has a composition satisfying the relationship SiO2 / Al2O3≦10.

Owner:KOBE STEEL LTD

High performance coatings and surfaces to mitigate corrosion and fouling in fired heater tubes

InactiveUS20100015564A1Reduce carburizationReduced form requirementsMuffle furnacesOther heat production devicesMulliteSpinel

A fired heater tube that is resistant to corrosion and fouling is disclosed. The fired heater tube comprises an advantageous high performance coated material composition resistant to corrosion and fouling comprises: (PQR), wherein P is an oxide layer at the surface of (PQR), Q is a coating metal layer interposed between P and R, and R is a base metal layer, wherein P is substantially comprised of alumina, chromia, silica, mullite, spinels, and mixtures thereof, Q comprises Cr, and at least one element selected from the group consisting of Ni, Al, Si, Mn, Fe, Co, B, C, N, P, Ga, Ge, As, In, Sn, Sb, Pb, Sc, La, Y, Ce, Ti, Zr, Hf, V, Nb, Ta, Mo, W, Re, Ru, Rh, Ir, Pd, Pt, Cu, Ag, Au and mixtures thereof, and R is selected from the group consisting of low chromium steels, ferritic stainless steels, austenetic stainless steels, duplex stainless steels, Inconel alloys, Incoloy alloys, Fe—Ni based alloys, Ni-based alloys and Co-based alloys.

Owner:EXXON RES & ENG CO

Surface on a stainless steel matrix

InactiveUS20060086431A1Not to damage surfaceSolid state diffusion coatingFurnace typesManganeseSpinel

A stainless steel comprising at least 20 weight % of chromium and at least 1.0 weight % of manganese is adapted to support an overcoating having a thickness from 1 to 10 microns of a spinel of the formula MnxCr3-xO4 wherein x is from 0.5 to 2. Preferably the overcoating is on chromia and has stability against chemical reaction at temperatures at least 25° C. higher than the uncoated chromia.

Owner:NOVA CHEM (INT) SA

Refractory metal core coatings

InactiveUS7575039B2Trend downImprove the immunityFoundry mouldsFoundry coresTitanium nitrideDissolution

Owner:RTX CORP

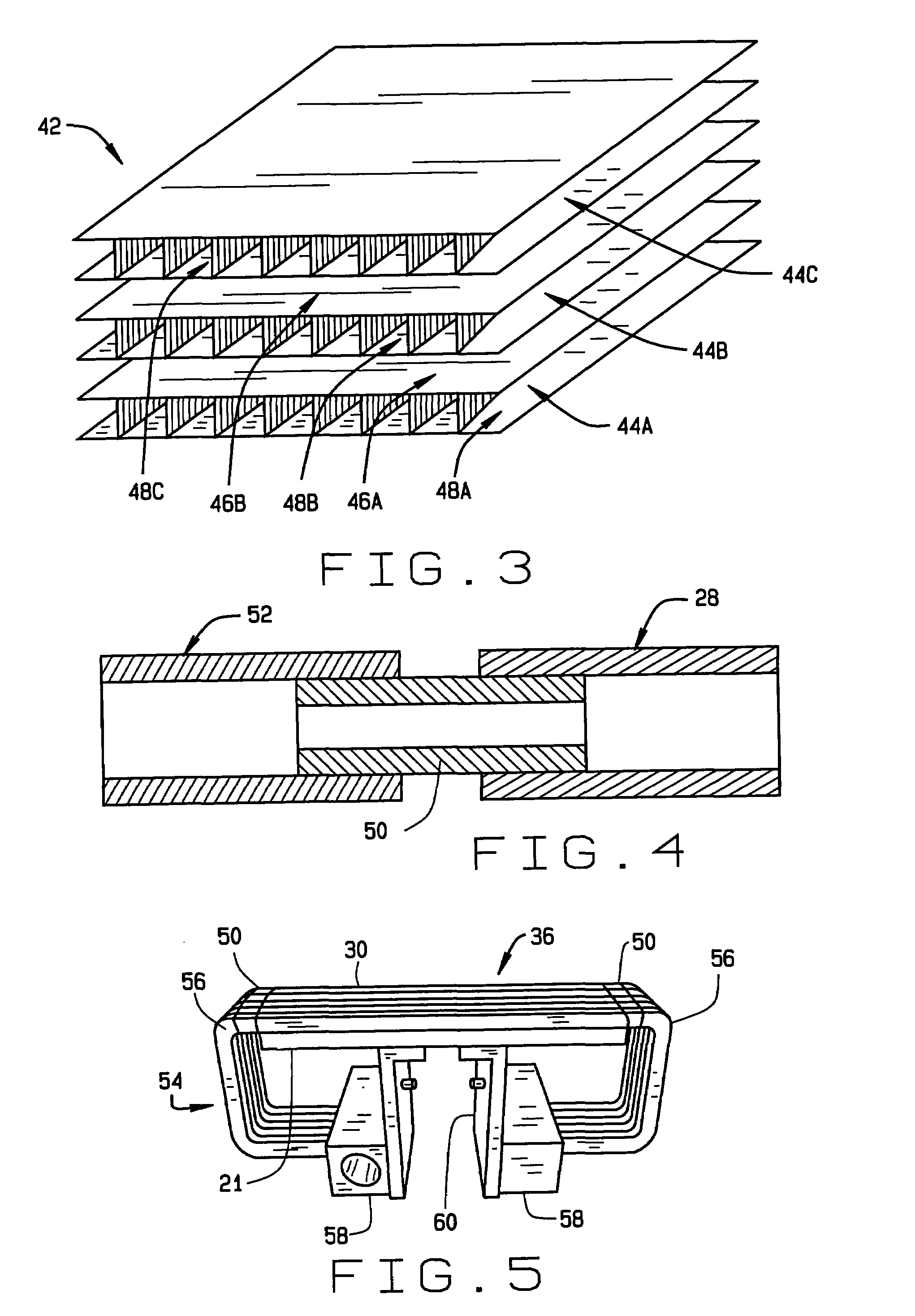

Prevention of chromia-induced cathode poisoning in solid oxide fuel cells (SOFC)

InactiveUS20050142398A1Minimize energy lossEnough timeCell electrodesFuel cell auxillariesFuel cellsChromium(III) hydroxide

A method is provided for increasing the life expectancy of a solid oxide fuel cell by preventing cathode poisoning due to chromium volatilization. Chromium hydroxide and oxyhydroxide formation and evaporation are prevented by continuously drying the cathode feed gas to low moisture levels. Power generation configurations that minimize the energy penalty associated with cathode gas drying are also disclosed.

Owner:GENERAL ELECTRIC CO

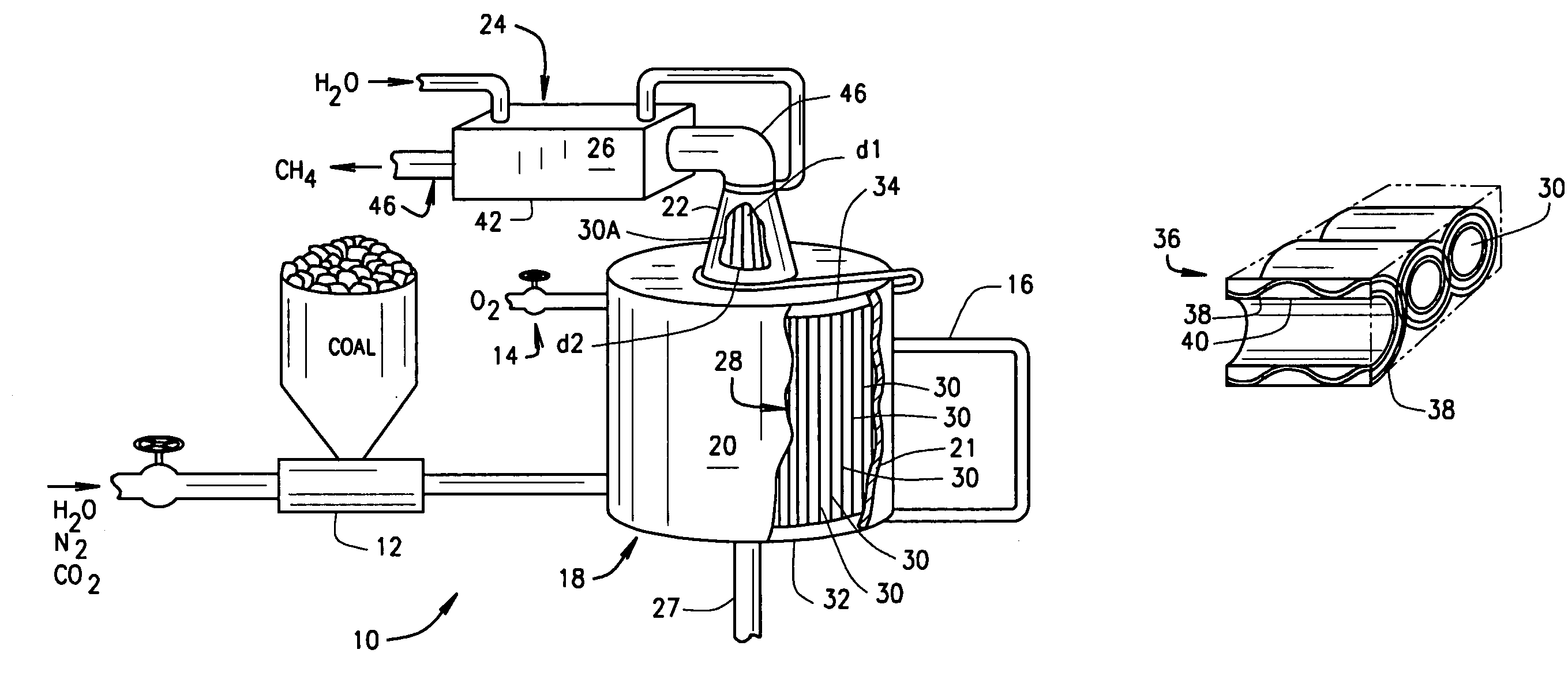

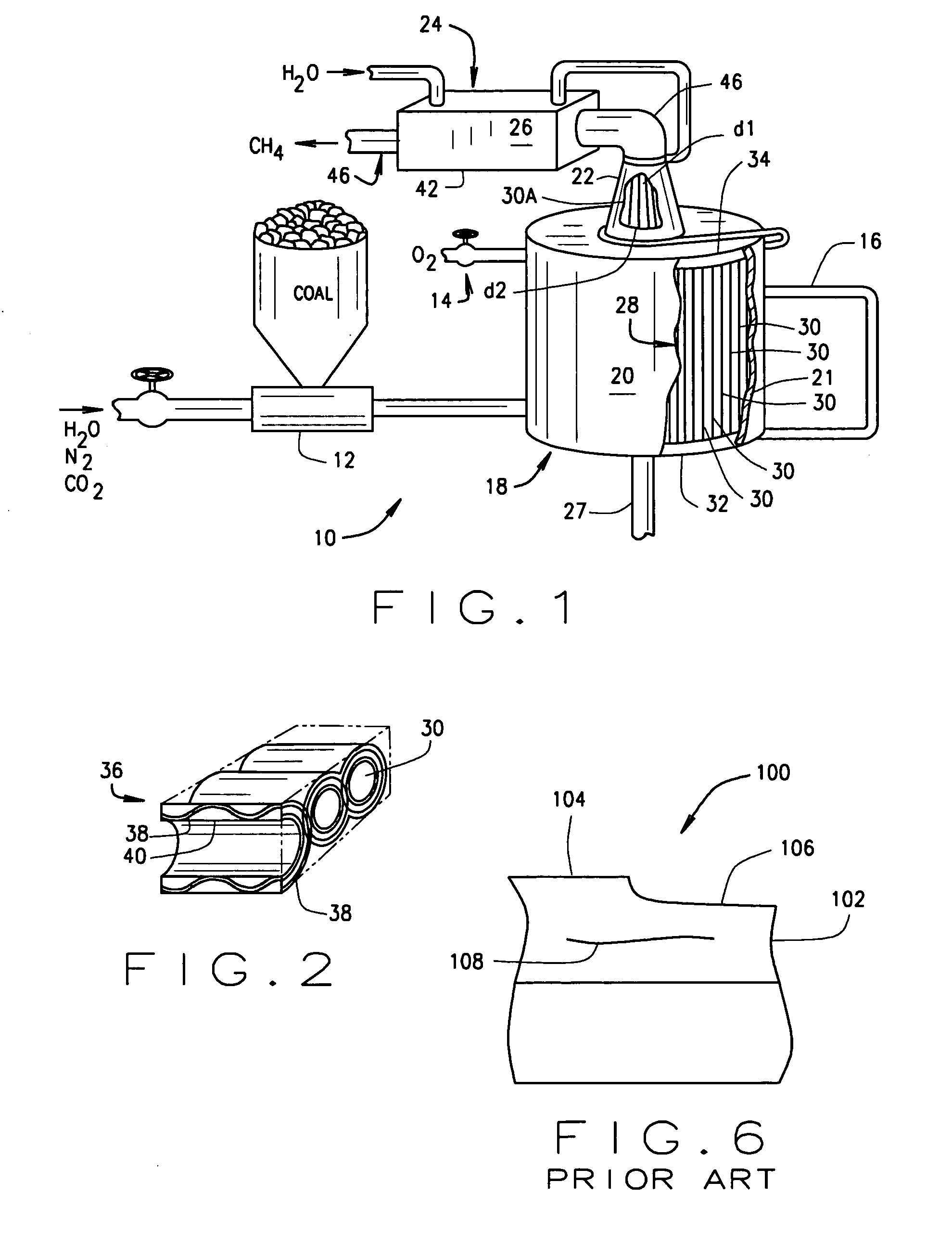

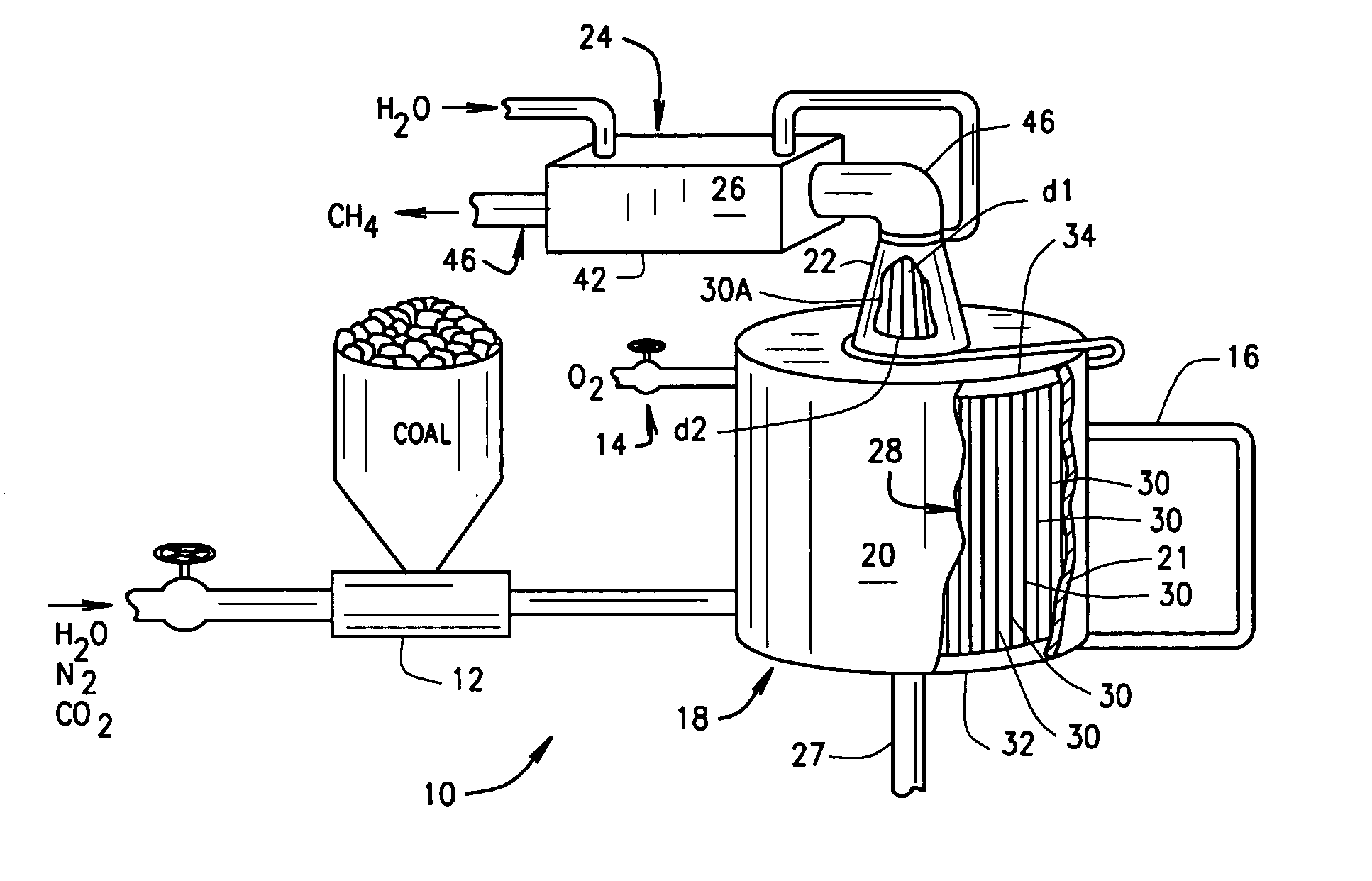

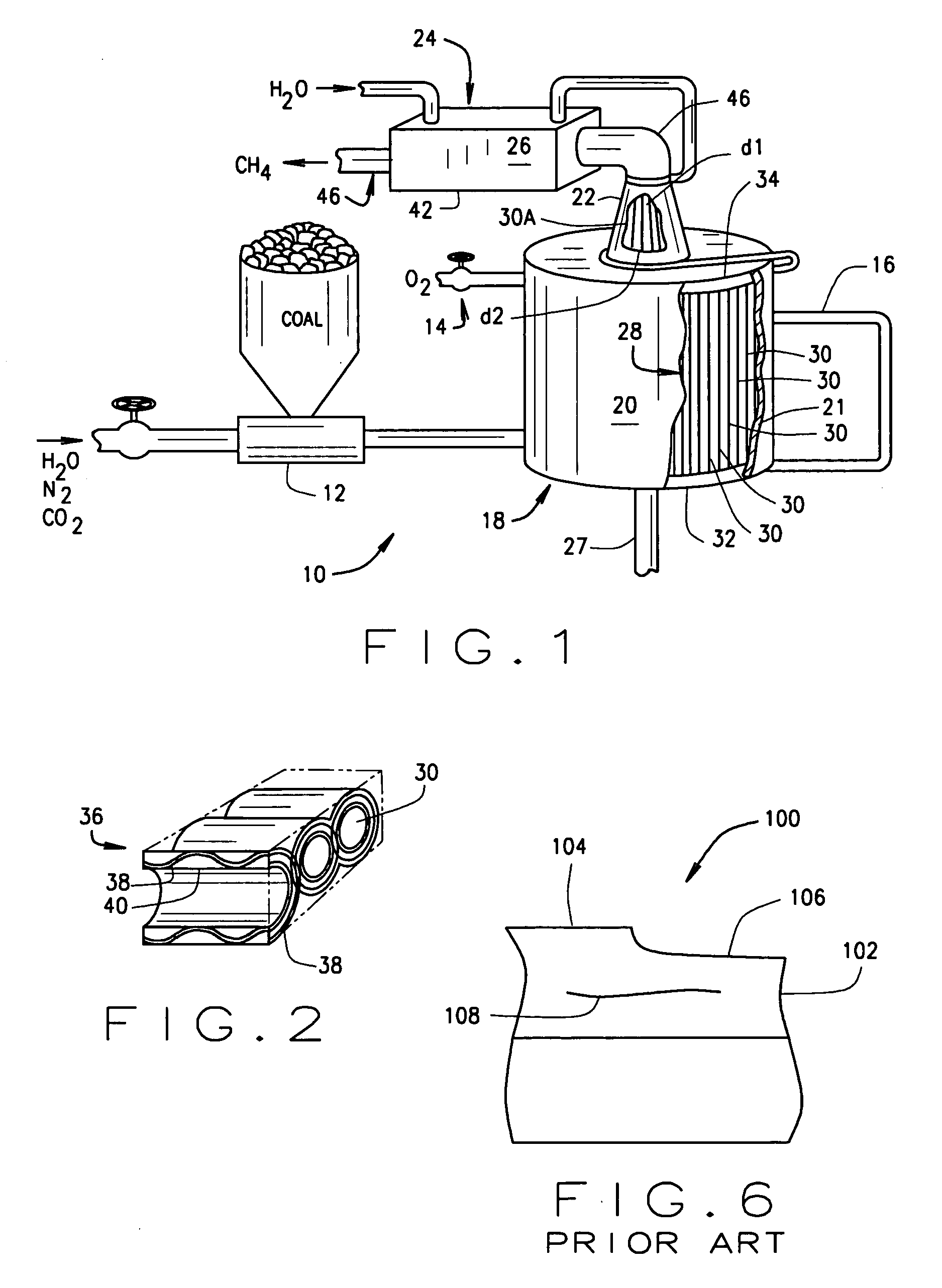

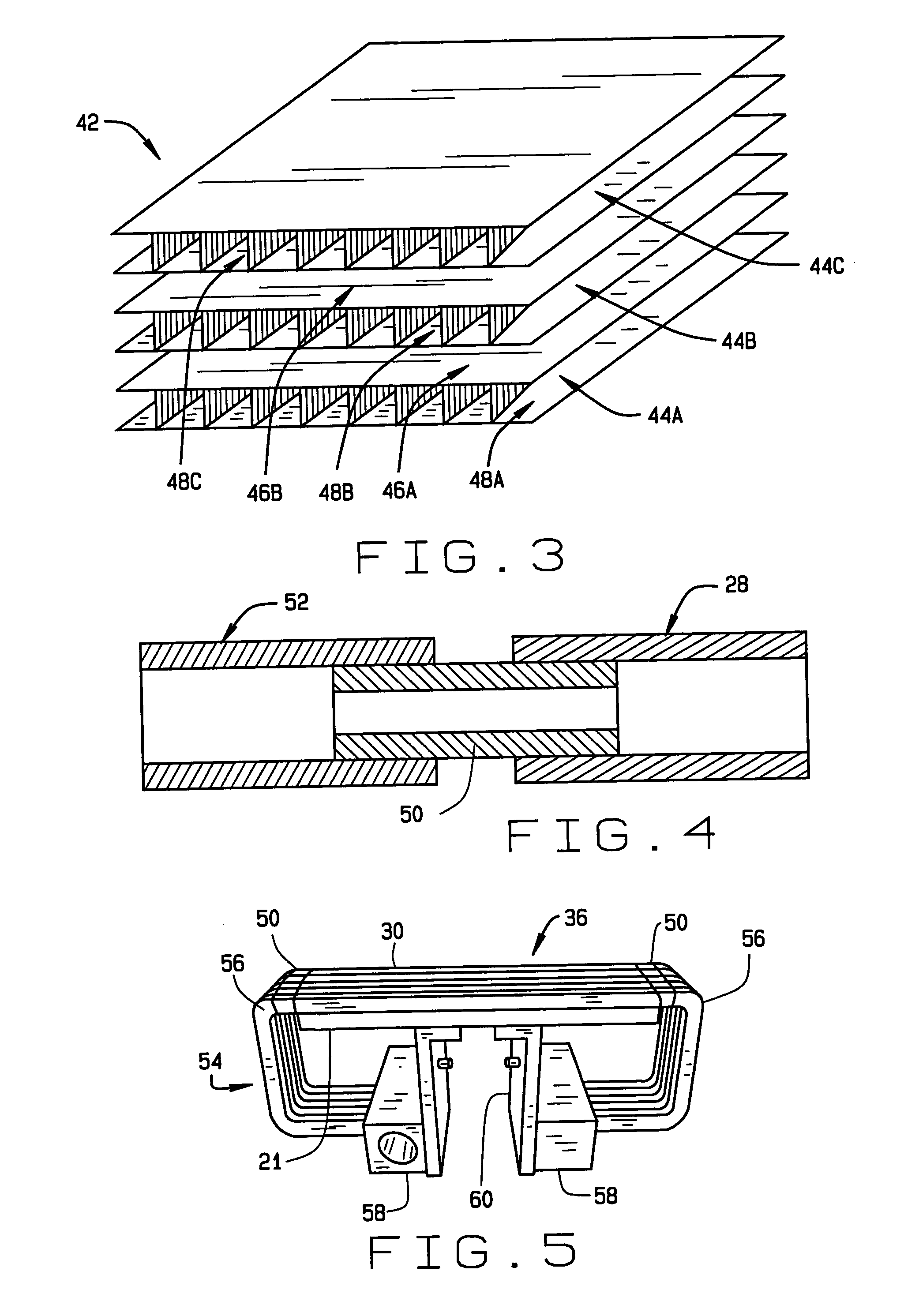

Regeneratively cooled synthesis gas generator

InactiveUS6920836B2Low costImprove reliabilityGasifier mechanical detailsCorrosion preventionYarnFiber

A coolant liner for a carbonaceous fuel (coal or petcoke) gasification vessel including a ceramic composite panel and a method of cooling a vessel. The panel includes at least two layers of woven yarns of fibrous material and walls extending between the layers. Accordingly, the layers and the walls define coolant channels that extend in a warp direction. Moreover, one of the layers may be less than about 0.08 inches thick. Materials used to create the composite panel may include alumina, chromia, silicon carbide, and carbon. Additionally, the liners may be shaped in an arc or have coolant channels which vary in diameter in the warp direction. Additionally, the liner may abut a structural closeout of the vessel. The coolant liner provides a significantly more durable component than previously employed liners and is especially well suited to demanding service environments.

Owner:GAS TECH INST +1

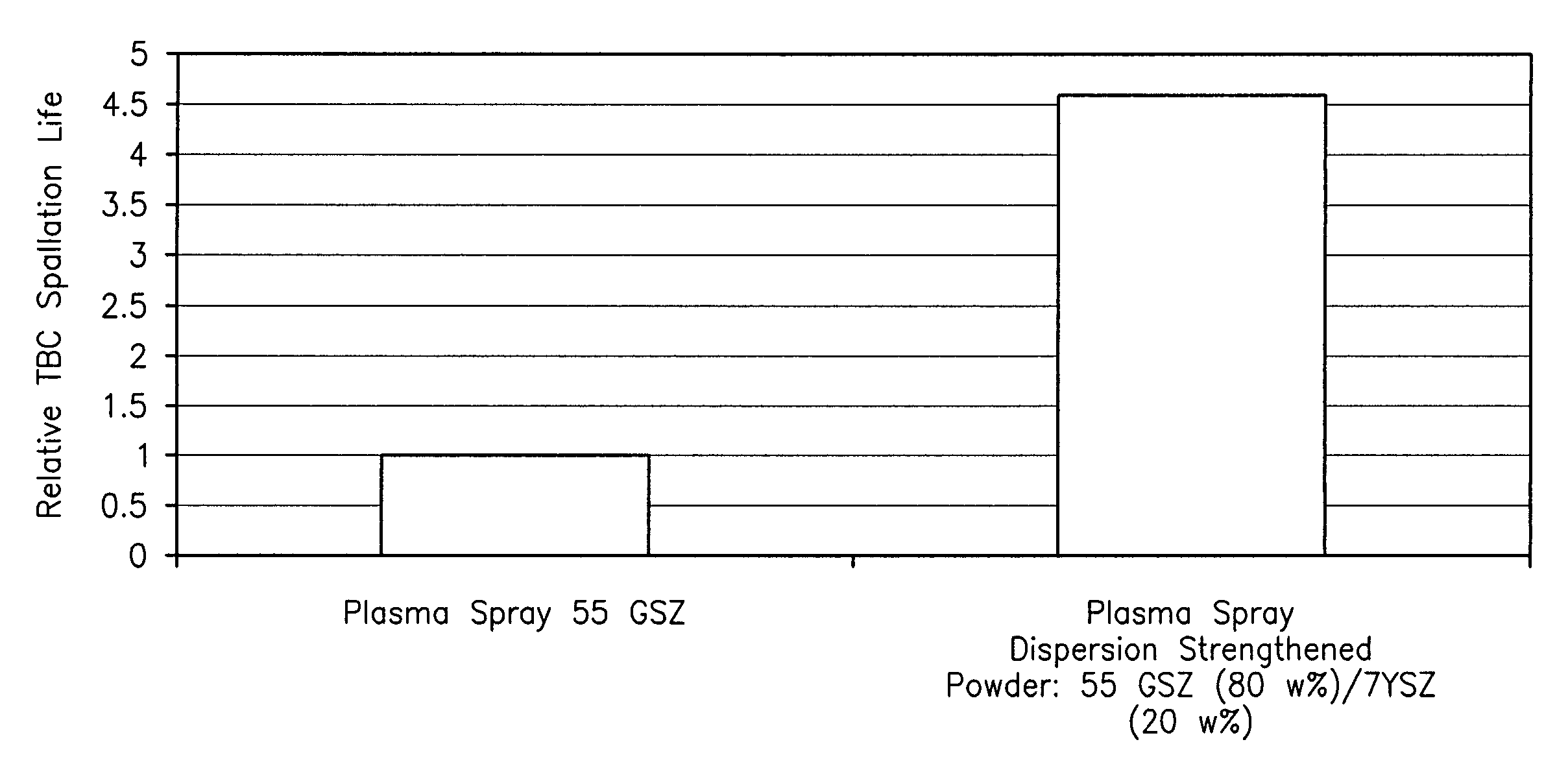

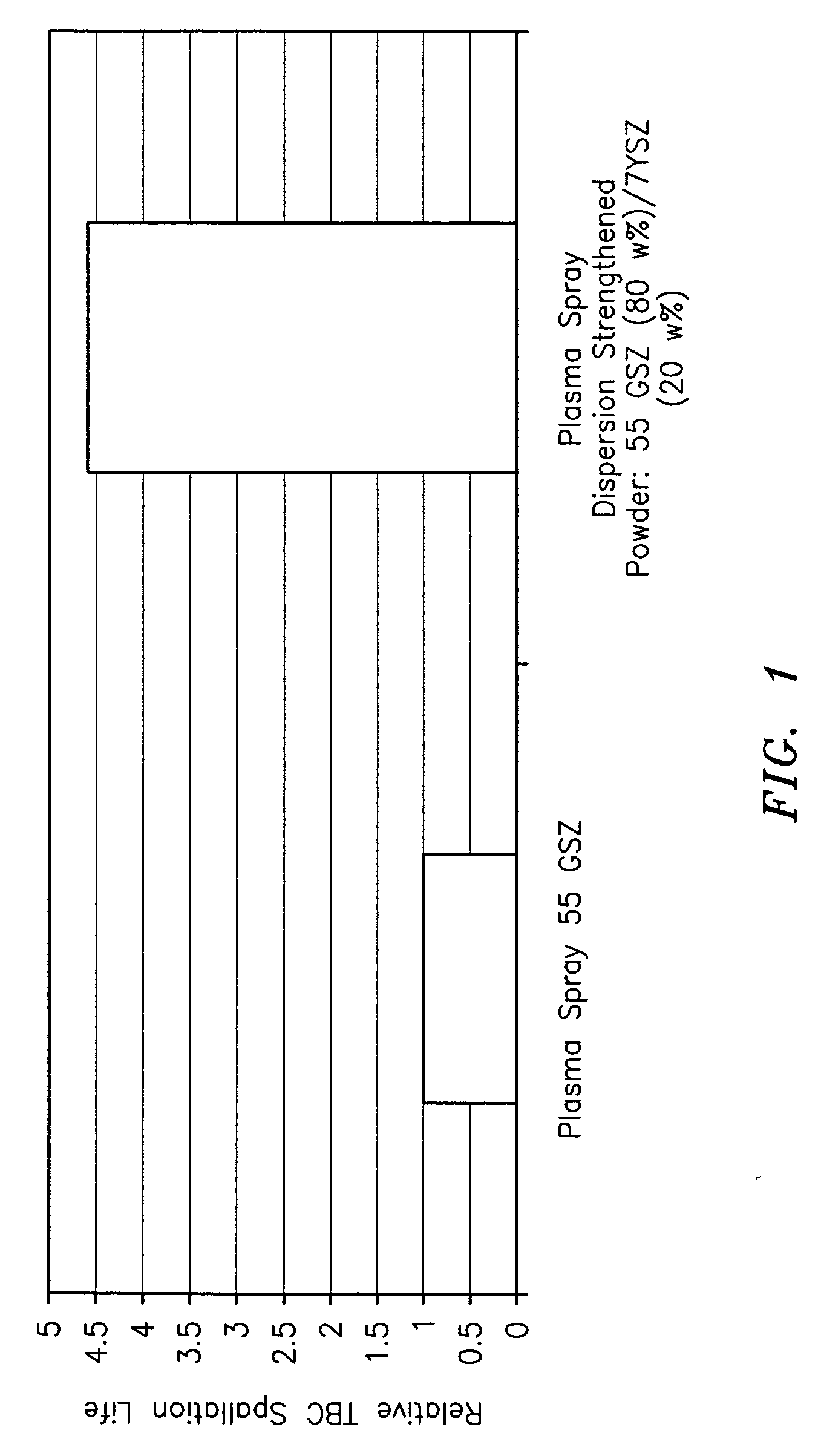

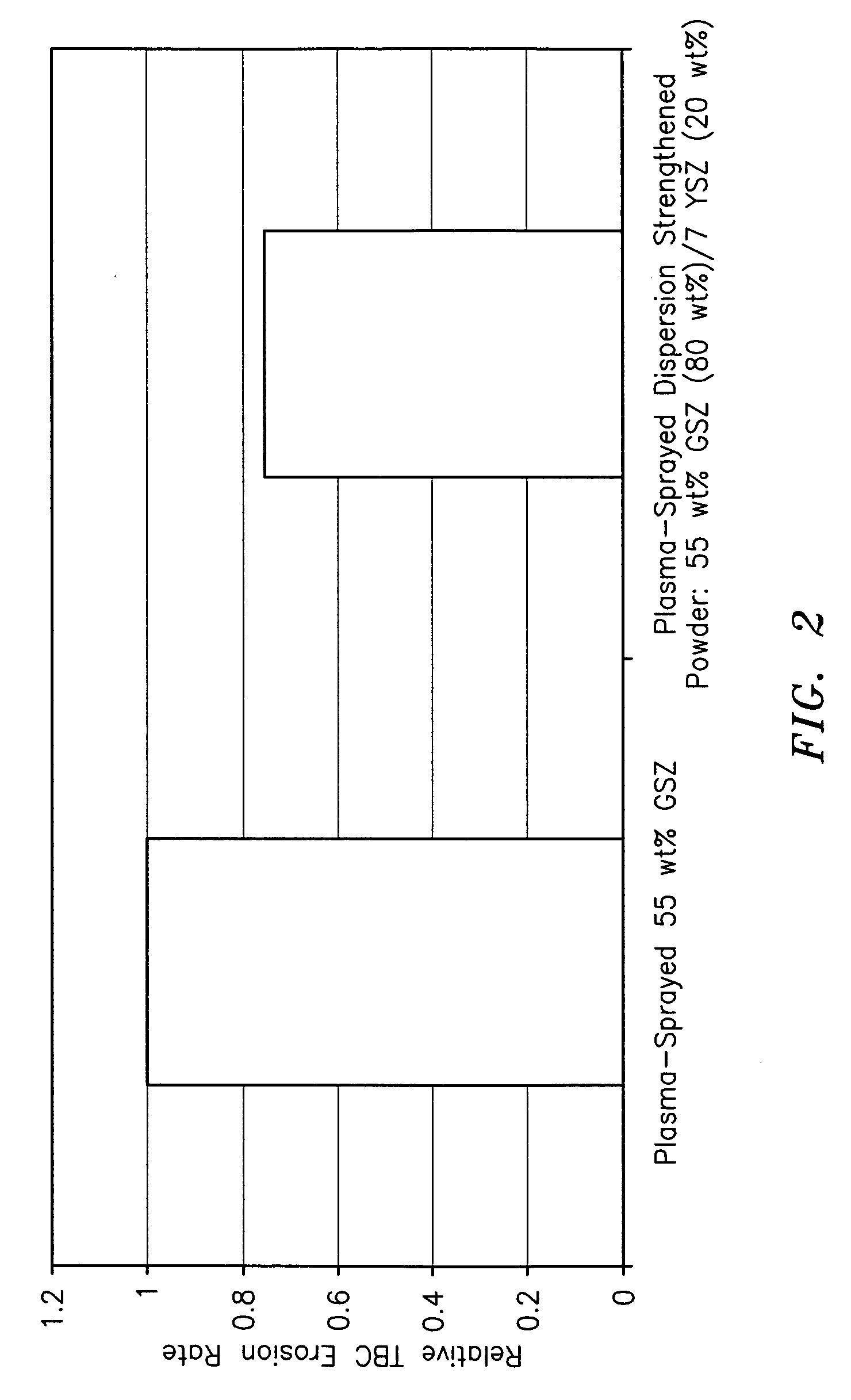

Dispersion strengthened rare earth stabilized zirconia

ActiveUS20060024527A1Desirable mechanical propertyLiquid surface applicatorsMolten spray coatingRare earthGadolinium

A process for forming a coating on a substrate, such as a turbine engine component, is provided. The process comprises the steps of: providing a first rare earth oxide stabilized zirconia composition; providing a second composition selected from the group consisting of a yttria stabilized zirconia composition, a ceria stabilized zirconia composition, alumina, a chromia-alumina composition, a gadolinia stabilized zirconia composition, and mixtures thereof; blending the first rare earth oxide stabilized zirconia composition with the second composition to form a blended powder; and depositing the blended powder onto the substrate. Articles having the coating formed from the above process are also described.

Owner:RAYTHEON TECH CORP

Regeneratively cooled synthesis gas generator

InactiveUS20050072341A1Low costImprove reliabilityGasifier mechanical detailsFurnace cooling arrangementsYarnFiber

A coolant liner for a carbonaceous fuel (coal or petcoke) gasification vessel including a ceramic composite panel and a method of cooling a vessel. The panel includes at least two layers of woven yarns of fibrous material and walls extending between the layers. Accordingly, the layers and the walls define coolant channels that extend in a warp direction. Moreover, one of the layers may be less than about 0.08 inches thick. Materials used to create the composite panel may include alumina, chromia, silicon carbide, and carbon. Additionally, the liners may be shaped in an arc or have coolant channels which vary in diameter in the warp direction. Additionally, the liner may abut a structural closeout of the vessel. The coolant liner provides a significantly more durable component than previously employed liners and is especially well suited to demanding service environments.

Owner:GAS TECH INST +1

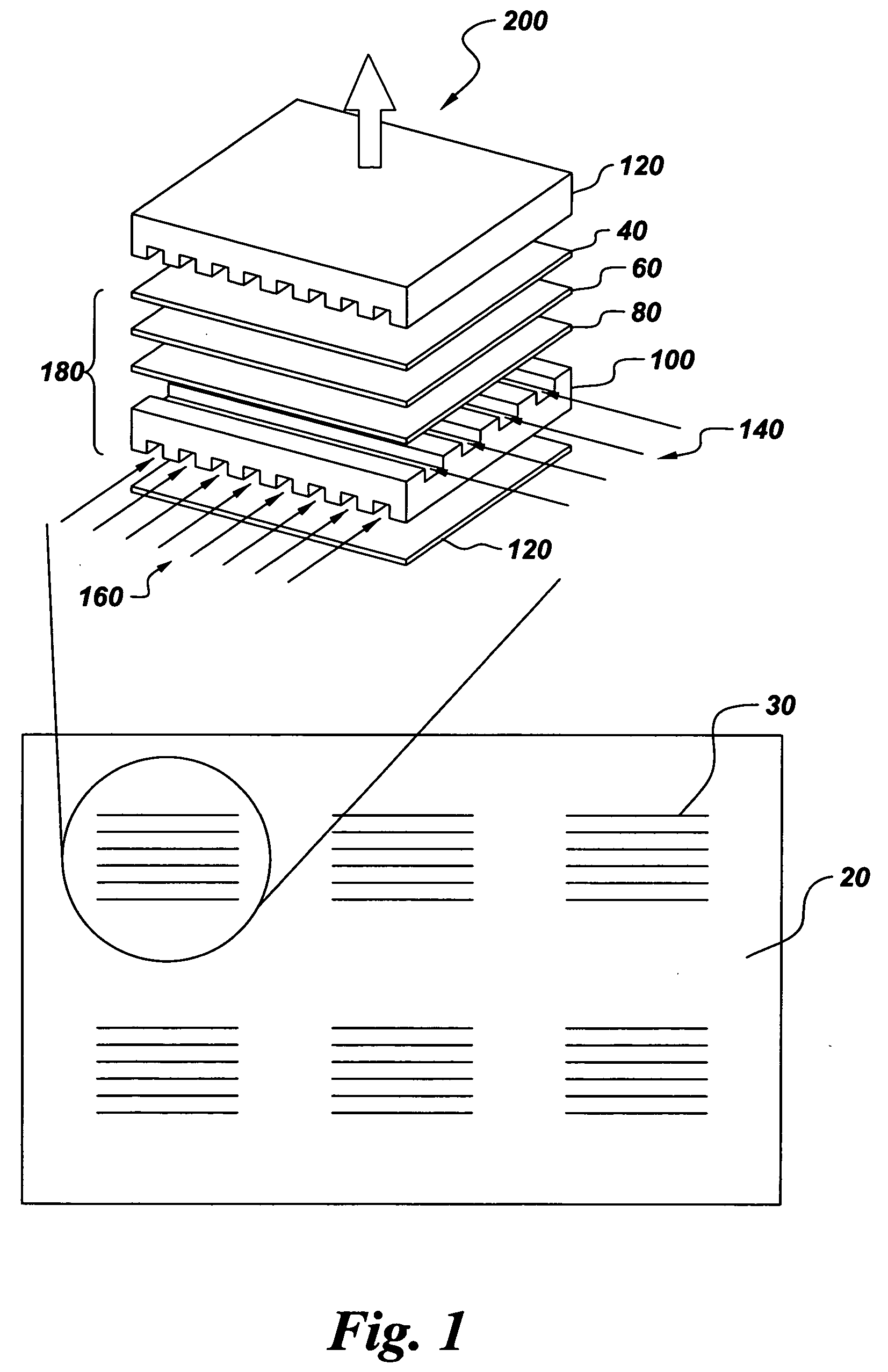

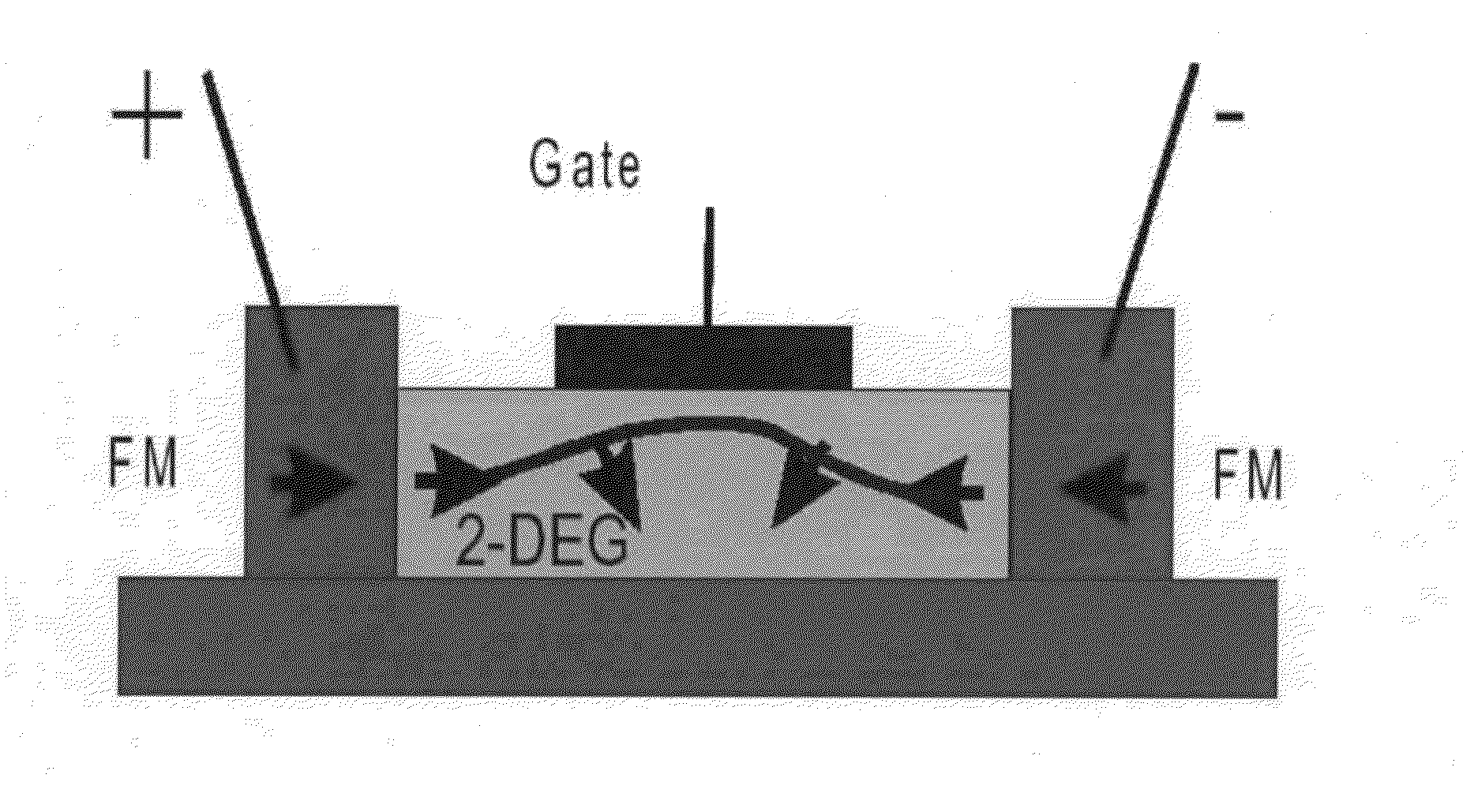

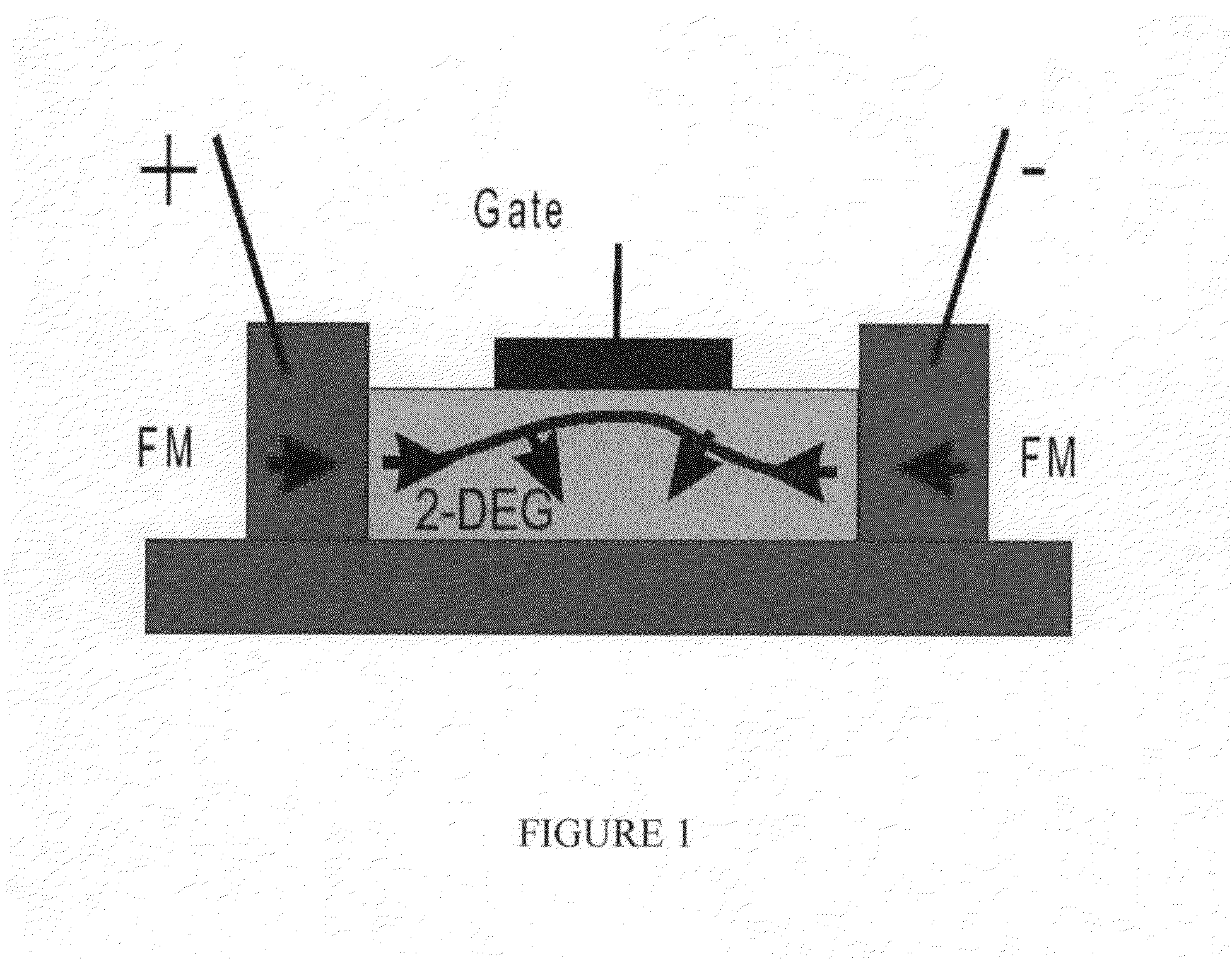

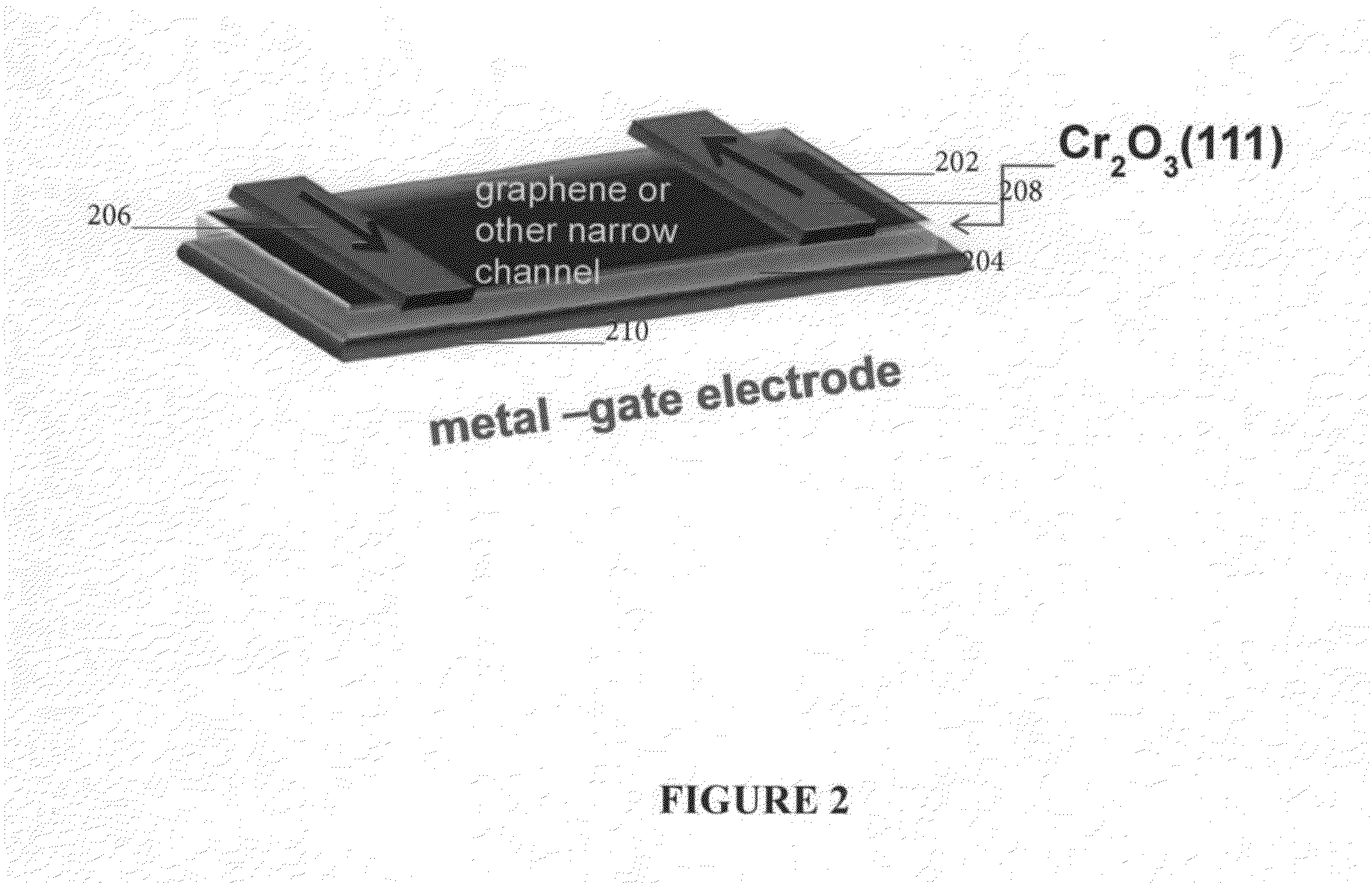

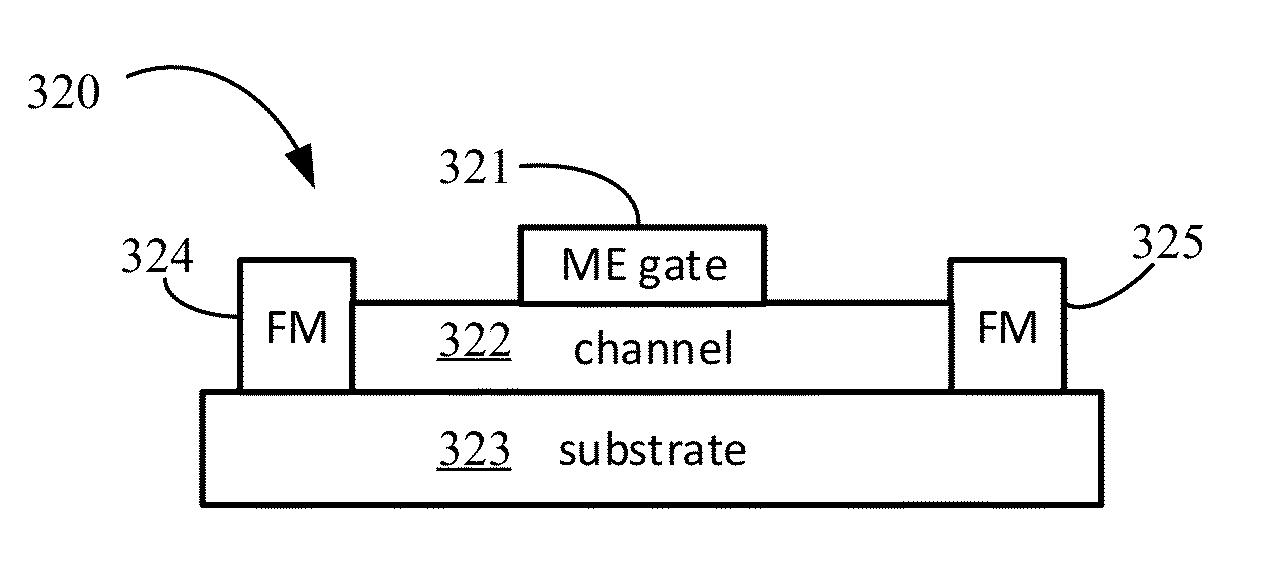

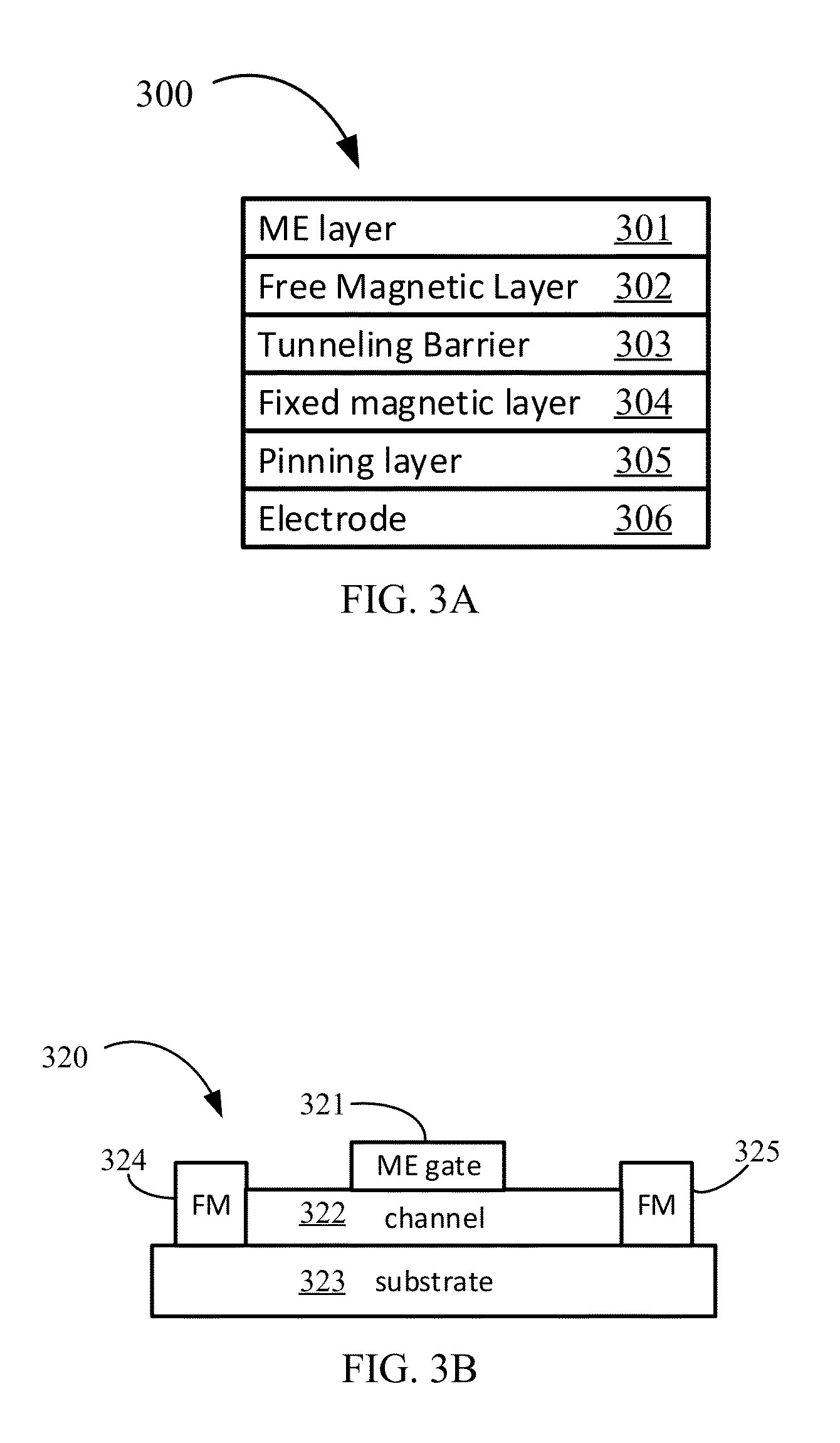

Magneto-Electric Voltage Controlled Spin Transistors

The invention relates to a magneto-electric spin-FET including a gate film of chromia and a thin film of a conductive channel material which may be graphene, InP, GaAs, GaSb, PbS, MoS2, WS2, MoSe2, WSe2 and mixtures thereof. The chromia, or other magneto-electric, and conduction channel material are in intimate contact along an interface there between. The resulting magneto-electric device may be voltage-controlled and provide non-volatile memory.

Owner:QUANTUM DEVICES +1

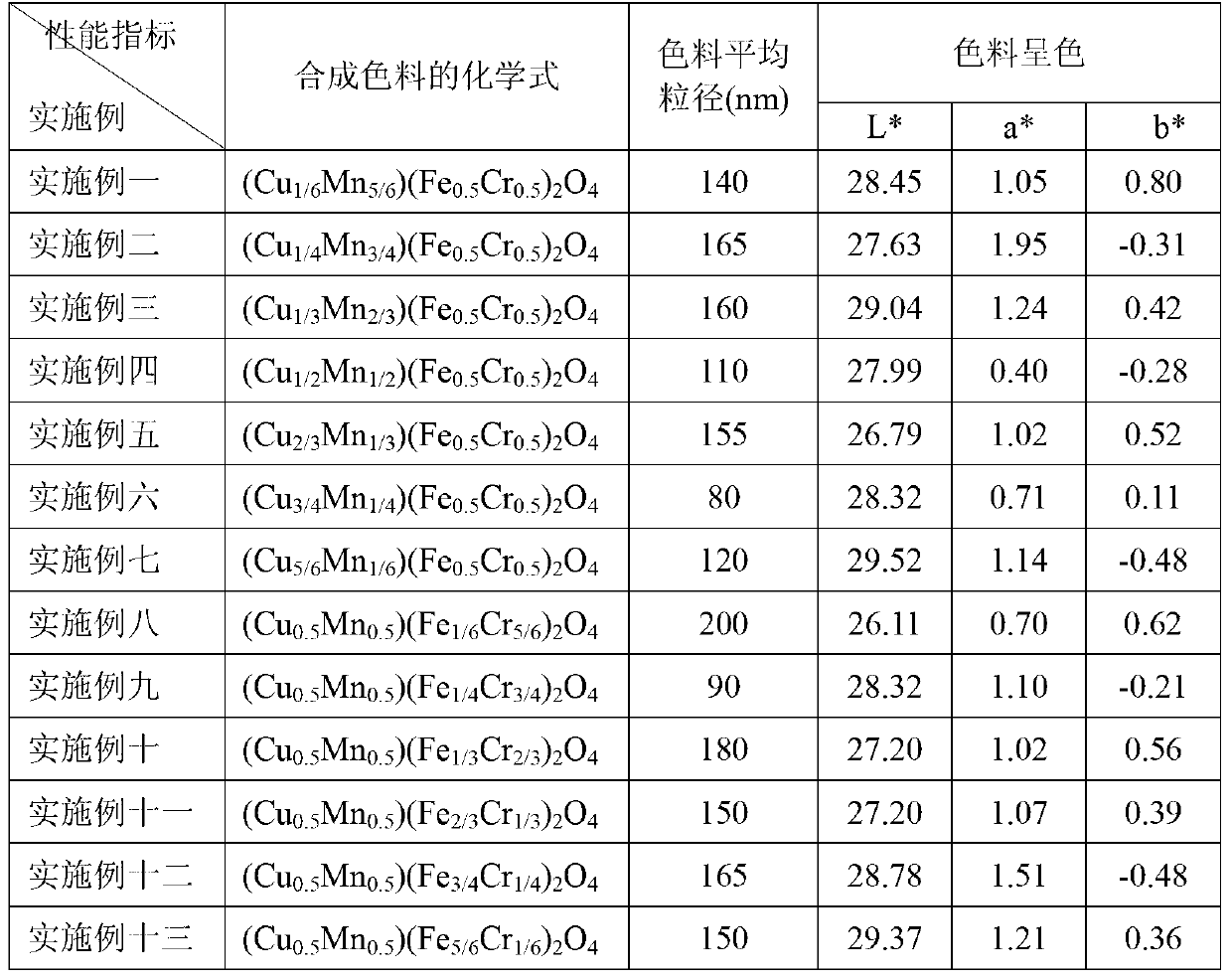

Cu-Mn-Fe-Cr cobalt-free black ceramic pigment and preparation method thereof

The invention discloses a Cu-Mn-Fe-Cr cobalt-free black ceramic pigment which is expressed by a general formula (CuxMn1-x)(FeyCr1-y)2O4, wherein x and y represents mole fractions; x is 0-1; y is 0-1; and when x and y are different in value, the products are different in blackness. Besides, the invention also discloses a preparation method of the Cu-Mn-Fe-Cr cobalt-free black ceramic pigment. The ceramic pigment disclosed by the invention is small in particle size and uniform in distribution, has high and stable coloration capability, and can meet developing application requirements. Besides, the ceramic pigment is simple in preparation process and controllable in color and shape; and the whole process is easy to control and realize, and the product quality is stable, thereby being beneficial to large-scale popularization and application.

Owner:广西恒特新材料科技有限责任公司

Micro-electrolytic filler containing catalyst

Owner:ZHEJIANG BOHUA ENVIRONMENTAL TECH & ENG

Erosion and corrosion-resistant coating system and process therefor

InactiveCN101481800AImprove antifouling performanceExtend your lifeMolten spray coatingEngine fuctionsThermal sprayingCoating system

The present invention relates to a erosion and corrosion-resistance coating system and process thereof. A coating system and process capable of providing erosion and corrosion-resistance to a component, particularly a steel compressor blade of an industrial gas turbine. The coating system includes a metallic sacrificial undercoat on a surface of the component substrate, and a ceramic topcoat deposited by thermal spray on the undercoat. The undercoat contains a metal or metal alloy that is more active in the galvanic series than iron, and electrically contacts the surface of the substrate. The ceramic topcoat consists essentially of a ceramic material chosen from the group consisting of mixtures of alumina and titania, mixtures of chromia and silica, mixtures of chromia and titania, mixtures of chromia, silica, and titania, and mixtures of zirconia, titania, and yttria.

Owner:GENERAL ELECTRIC CO

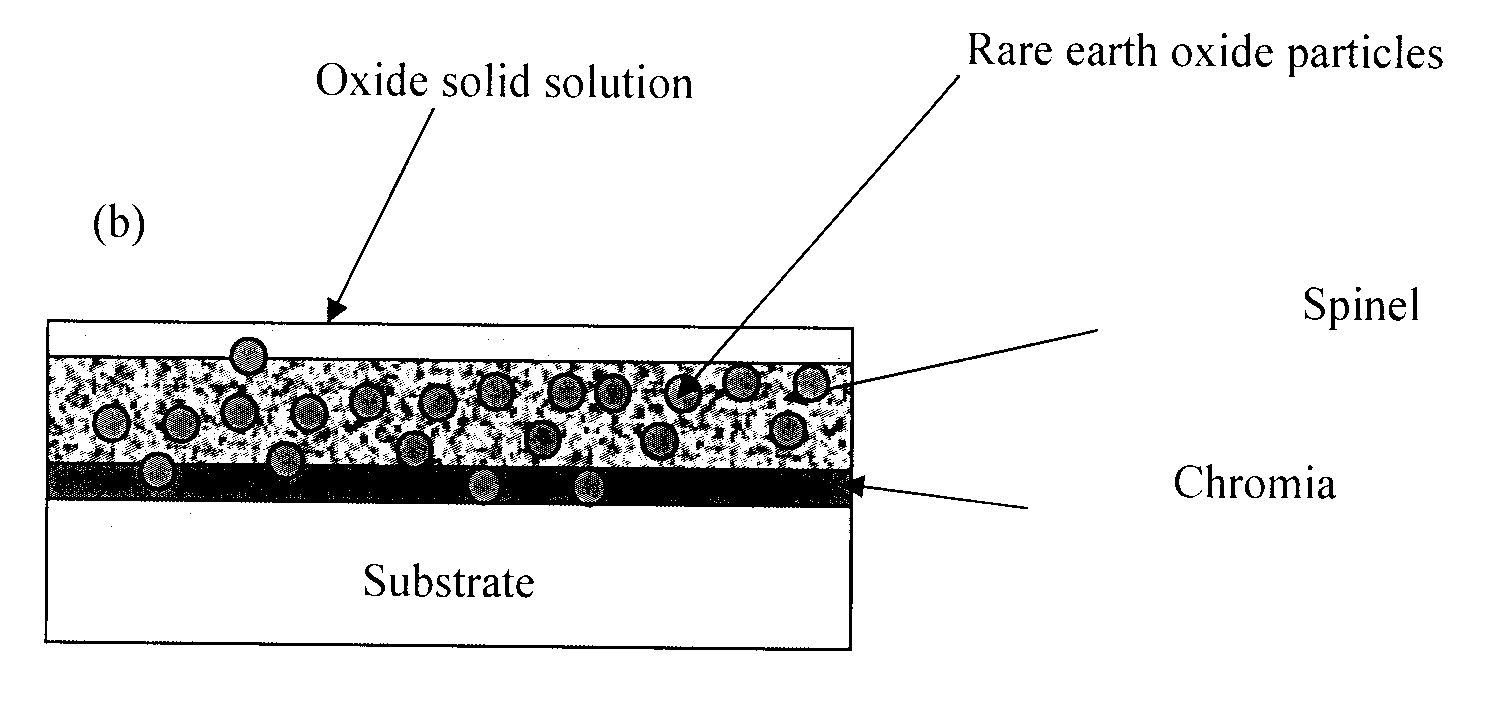

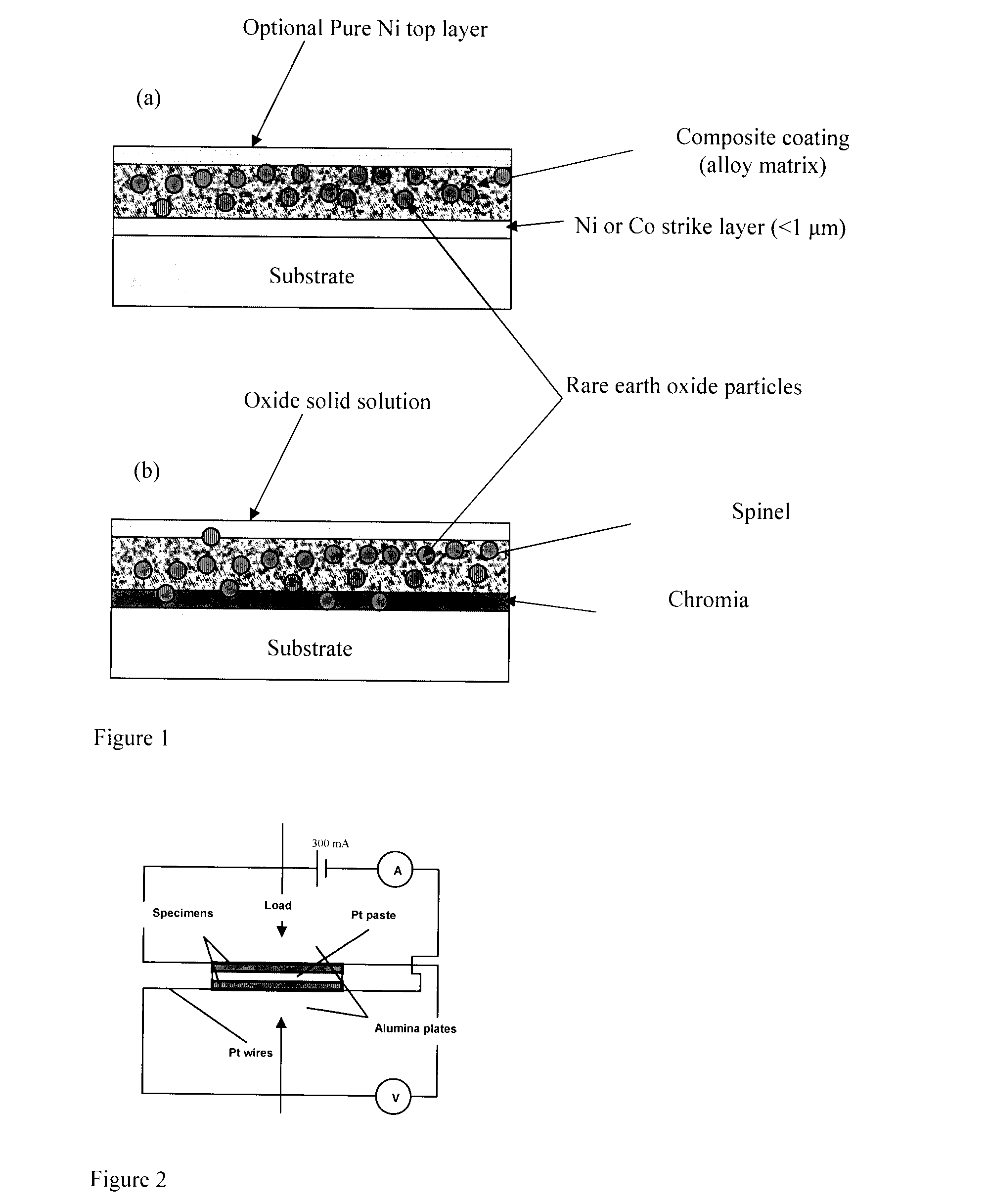

Composite coatings for oxidation protection

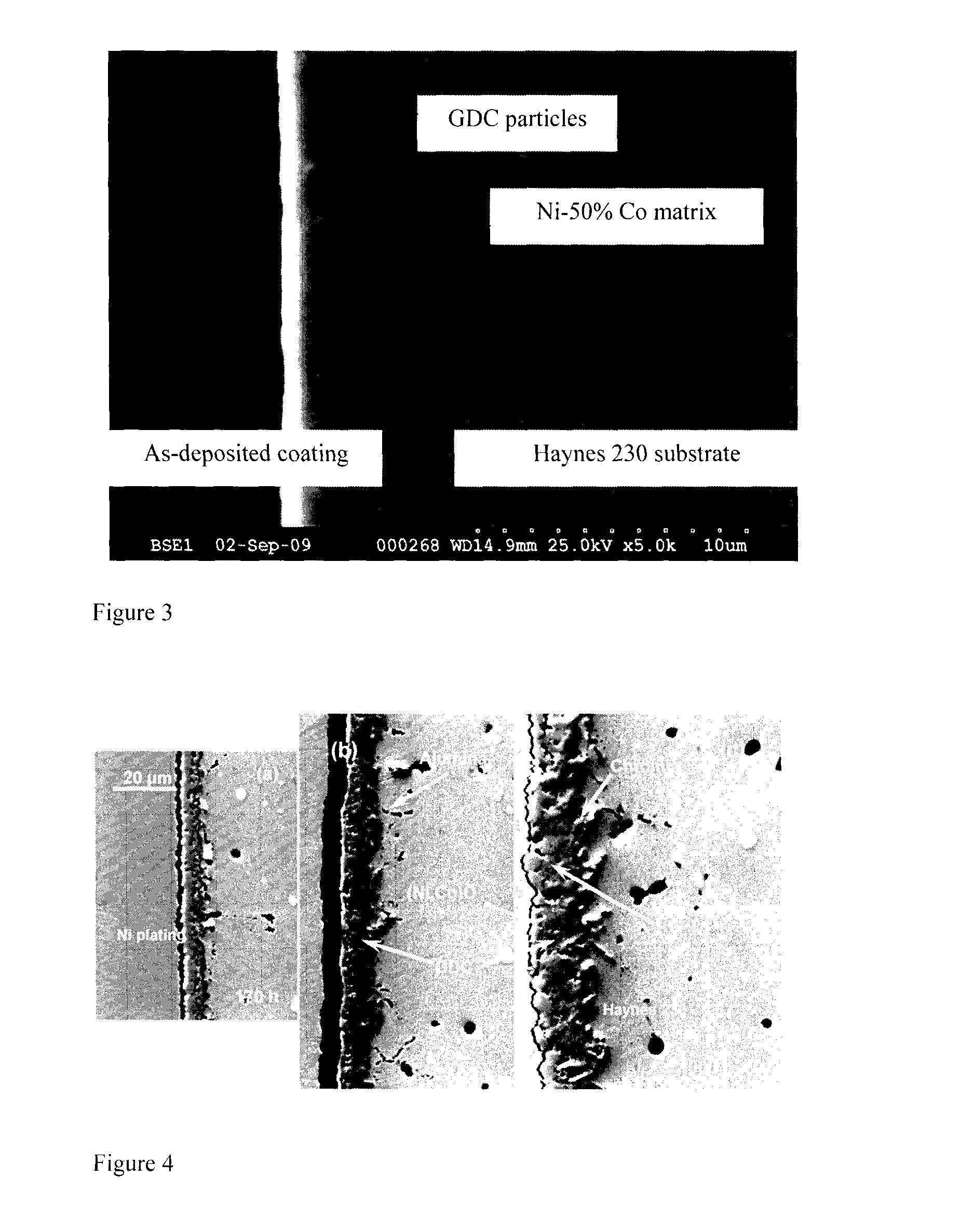

InactiveUS20130004881A1Reduce contact resistanceImprove the immunityChromatisationFuel cells groupingMischmetalRare earth

The invention disclosed relates to an oxidized metal matrix composite coated substrate, comprising a substrate made of a material selected from the group consisting of a chromia-forming Fe, Ni and / or Co based alloy containing an amount of Cr ranging from 16 to 30 wt %, and an oxide-dispersion strengthened Cr-based alloy and a plain Cr-based alloy, and an oxidized metal matrix composite coating comprising at least two metals and reactive element oxide particles in the form of a tri-layer scale on the substrate surface comprising an inner chromia layer, an intermediate layer of a spinel solid solution formed by Cr and one or more of the deposited metals selected from the group consisting of Ni, Co, Cu, Mn, Fe and Zn and a mixture thereof, and an electrically conductive top layer comprising oxides of one or more deposited metals selected from the group consisting of Ni, Co, Cu, Fe, Mn, Zn and a mixture thereof, which is substantially free from Cr ions, and wherein one or more of such layers contain particles of doped or undoped oxides of a rare earth metal selected from the group consisting of Ce, Y, La, Hf, Zr, Gd and a mixture thereof.

Owner:NAT RES COUNCIL OF CANADA

Method for preparing a pearlescent pigment by coating metal oxides on the synthesized mica

InactiveUS20040096579A1Good dispersionExcellent in weatherproof and chemical resistance and physical propertyLiquid surface applicatorsCoatingsSURFACTANT BLENDChromia

Disclosed is a method for preparing a pearlescent pigment by coating metal oxides on the synthesized mica, involving the steps of grinding the synthesized mica by agitating the mica with water in a water mixer to a particle size between 100 and 500 mum and separating the mica, dispersing the separated particles of the synthesized mica in water and adding acid thereto to adjust pH between 1 and 4, adding the metal oxide precursors and a basic aqueous solution thereto while maintaining said pH range until the desired color is attained, and thereby forming at least one hydrous metal oxide layer on the particles of the synthesized mica, and filtering, water-washing, drying and calcining the synthesized mica coated with the metal oxide layer. The method may further involve the step of further pulverizing the synthesized mica roughly ground in a water mixer by using a conventional wet pulverizer so that less than 100 mum of the synthesized mica may be used as a base material. The suitable surfactants can be used in a water mixer as well as a conventional wet pulverizer. The pearlescent pigment prepared according to the present invention has excellent luster and chroma, since a coating layer of metal oxides is smooth and the dispersibility of the particles is excellent.

Owner:CQV

Multi-layered dehydrogenation catalyst system and process of use

A system for dehydrogenating a C3 or C4 hydrocarbon feed stream containing a first and second layer of catalysts placed in the hydrocarbon feed stream, wherein the feed stream first passes through the first layer and then the second layer of catalysts and wherein the catalysts of the first layer contain from about 50 to about 90 percent by weight of an eta-alumina carrier, from about 10 to about 50 percent by weight of chromia and from about 0.1 to about 5 percent by weight of a zirconium compound and wherein the catalysts of the second layer of catalysts contain from about 50 to about 90 percent by weight of an eta-alumina carrier and from about 10 to about 50 percent by weight of chromia, without an added zirconium compound.

Owner:SUD CHEM INC

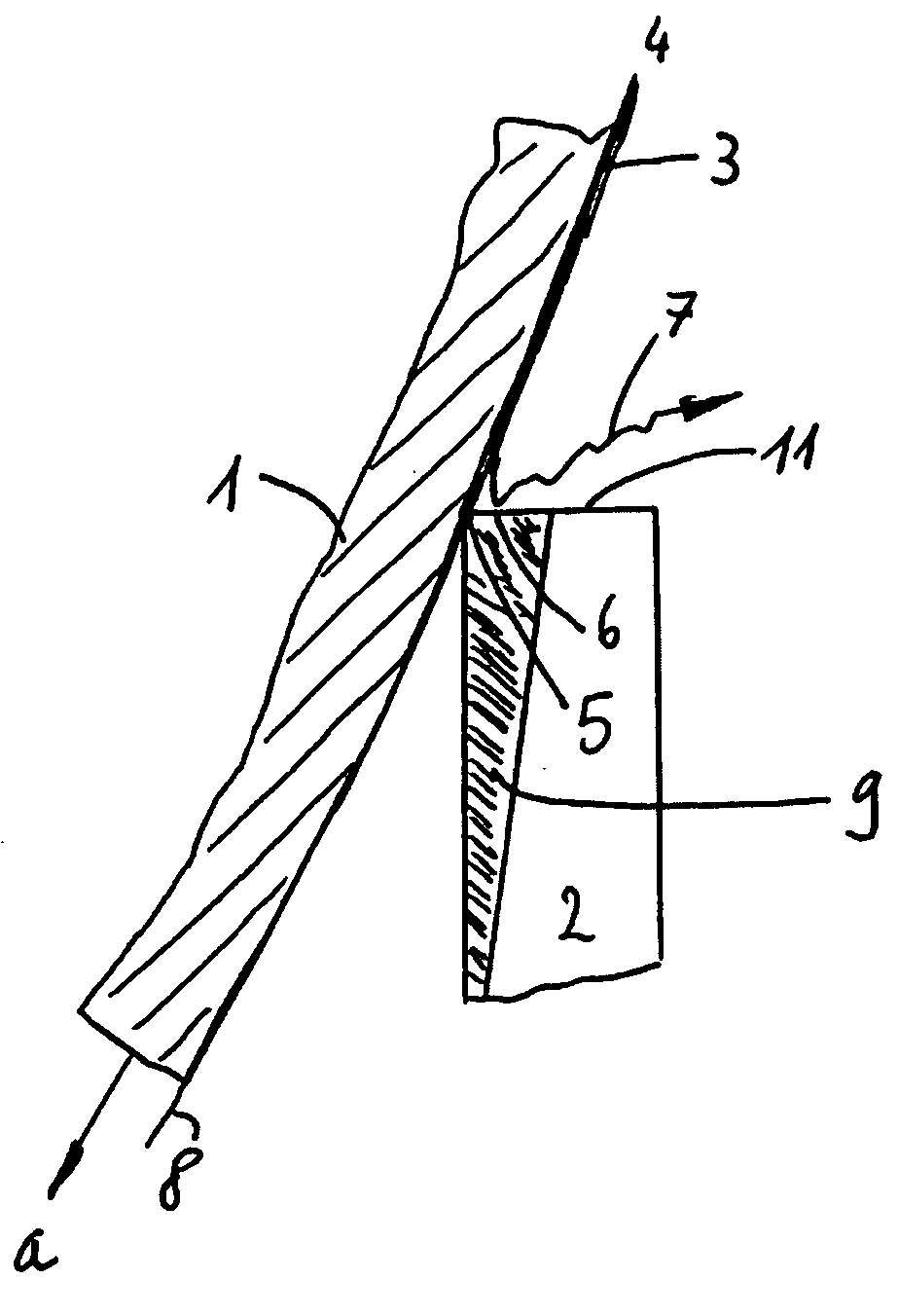

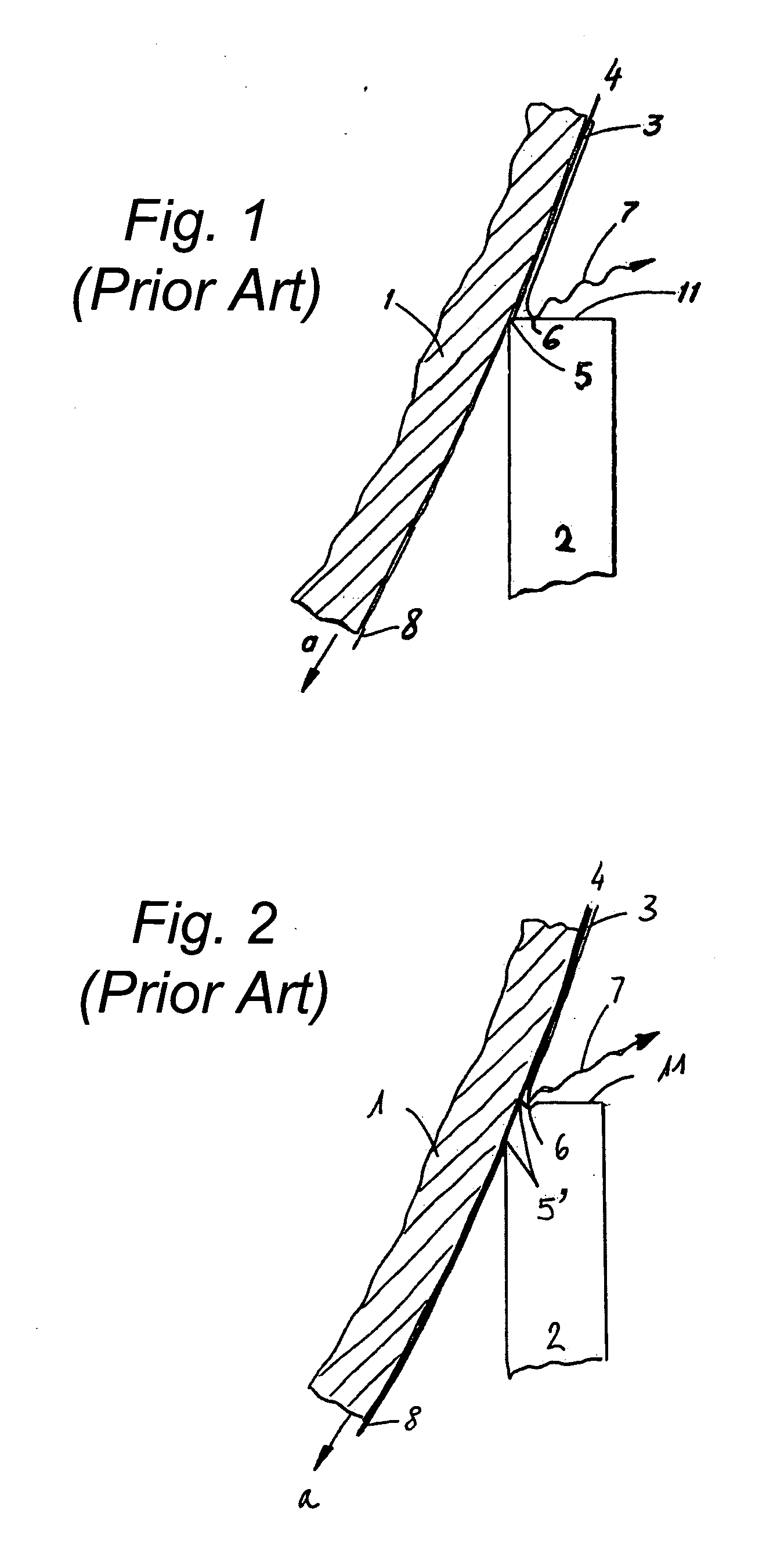

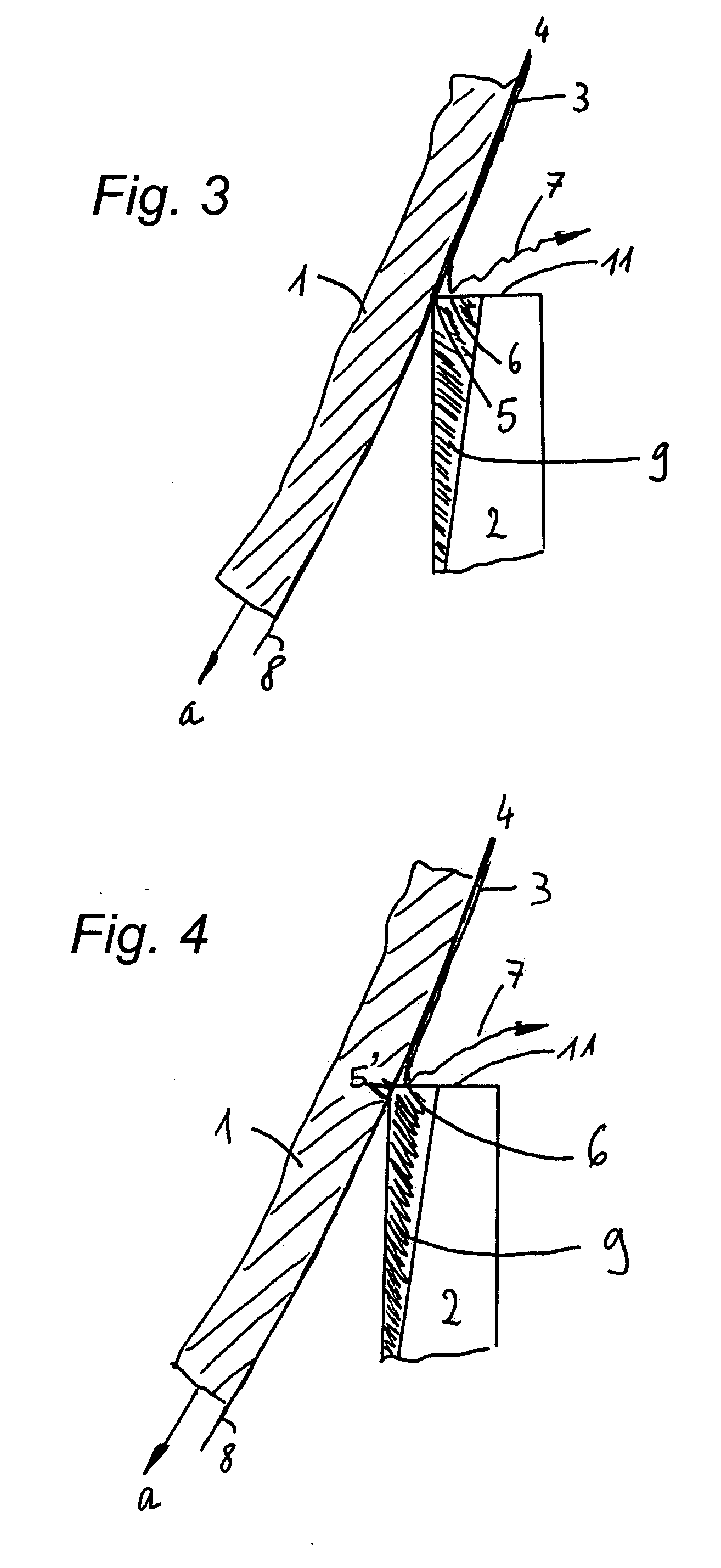

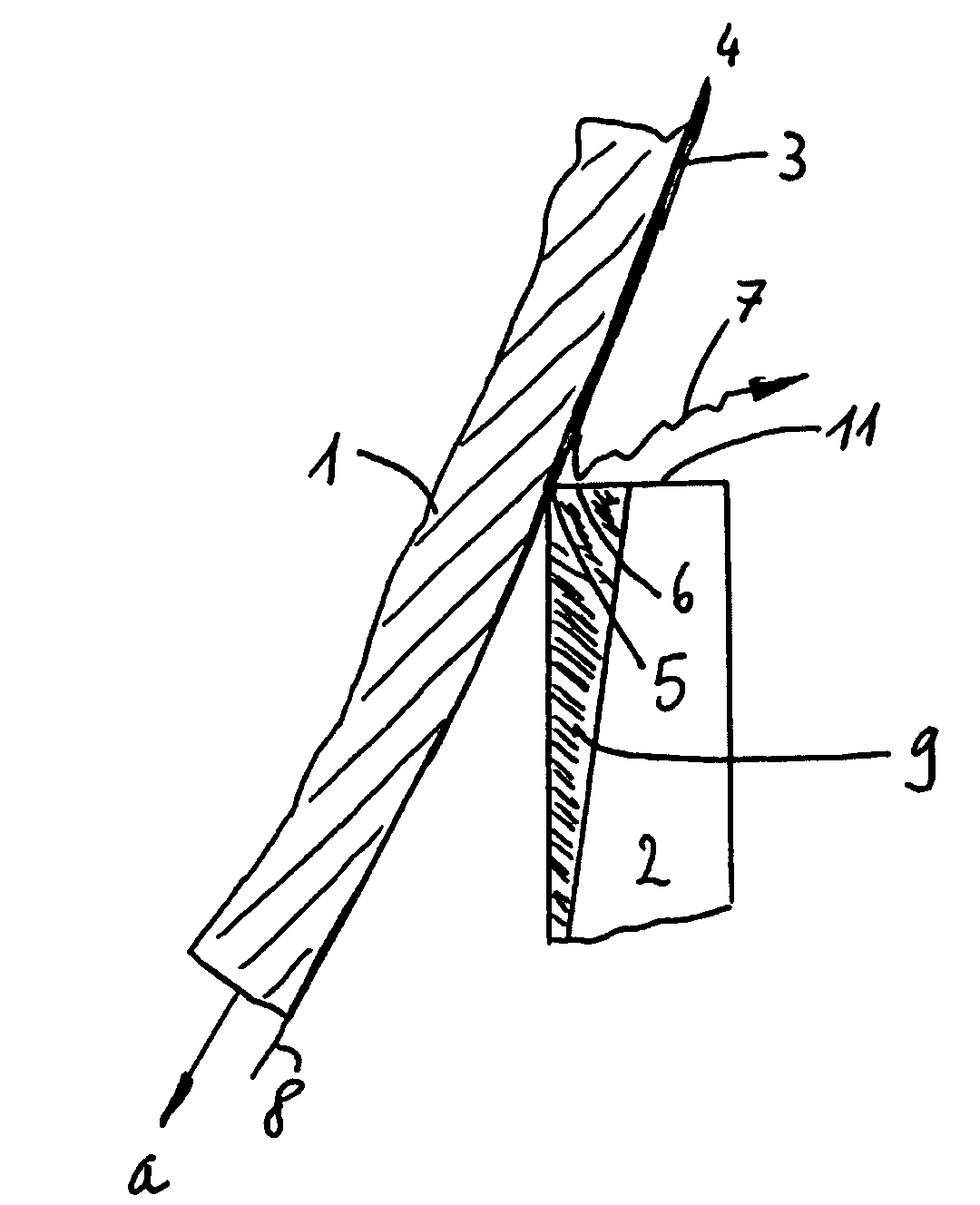

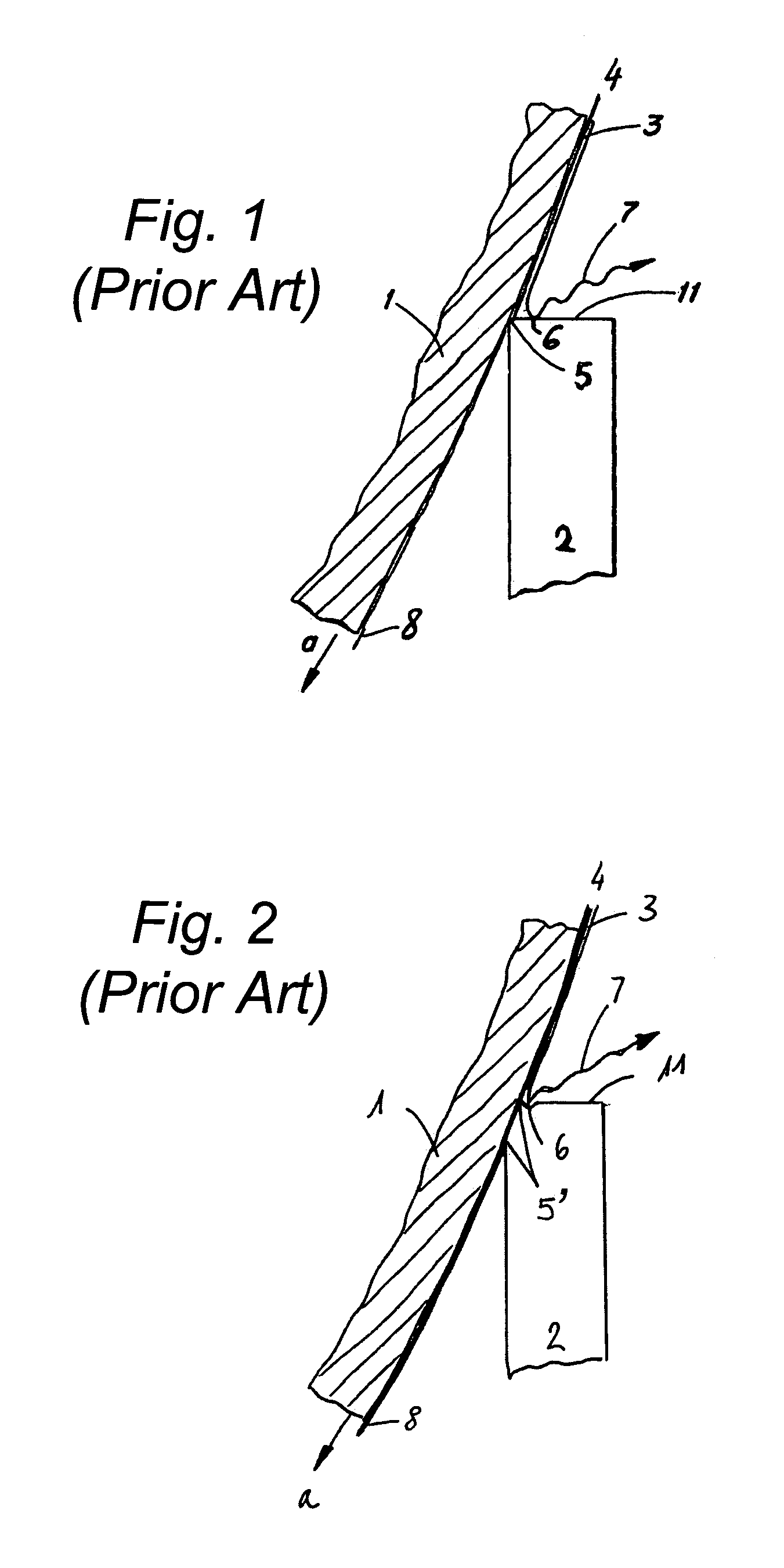

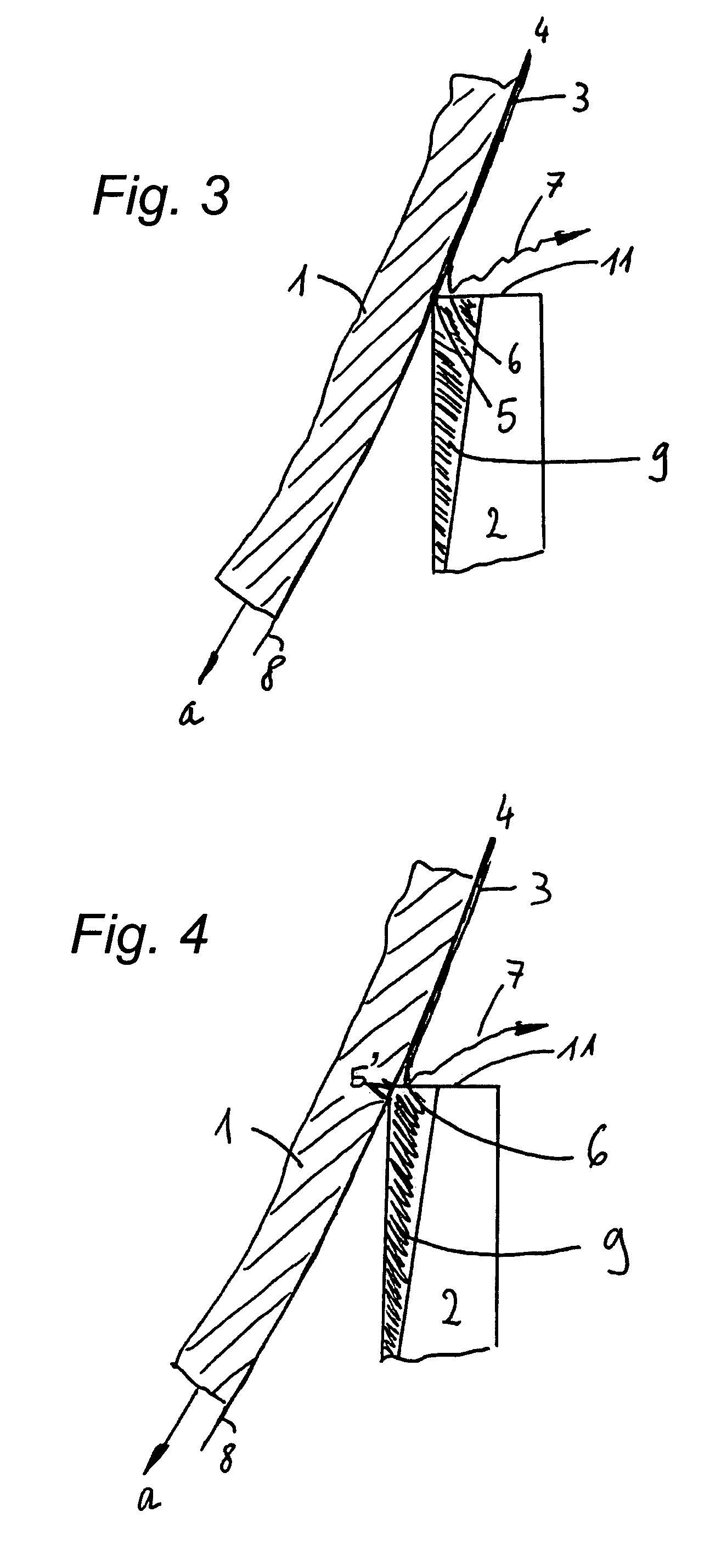

Creping blade

ActiveUS20050051292A1Improve toughnessEasy windingMechanical working/deformationBrushesMaterials scienceChromia

A blade for creping has been described. The blade according to the invention has a ceramic top layer covering the working edge of the blade, as well as the surface upon which the web impacts during creping. The ceramic top layer is a ceramic composition having a content of chromia. Preferably, the ceramic composition of the top layer comprises chromia-titania, with a titania content of up to 25% by weight, and preferably between 10% and 15% titania.

Owner:BTG ECLEPENS

Surface on a stainless steel matrix

InactiveUS20050257857A1Not to damage surfaceSolid state diffusion coatingSuperimposed coating processChemical reactionManganese

A stainless steel comprising at least 20 weight % of chromium and at least 1.0 weight % of manganese is adapted to support an overcoating having a thickness from 1 to 10 microns of a spinel of the formula MnxCr3-xO4 wherein x is from 0.5 to 2. Preferably the overcoating is on chromia and has stability against chemical reaction at temperatures at least 25° C. higher than the uncoated chromia.

Owner:NOVA CHEM (INT) SA

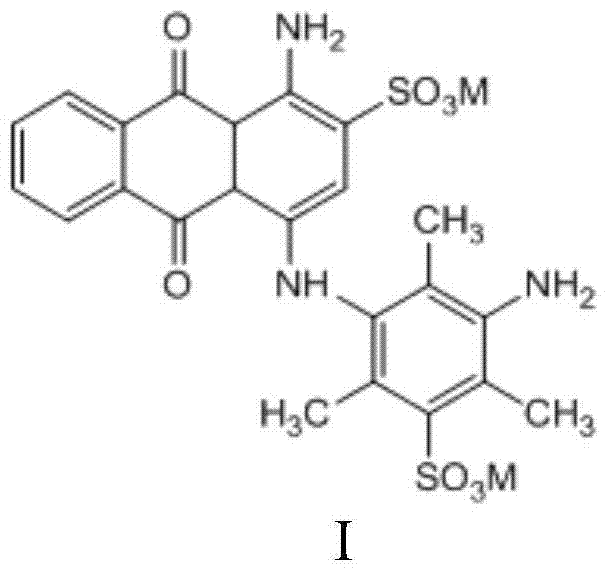

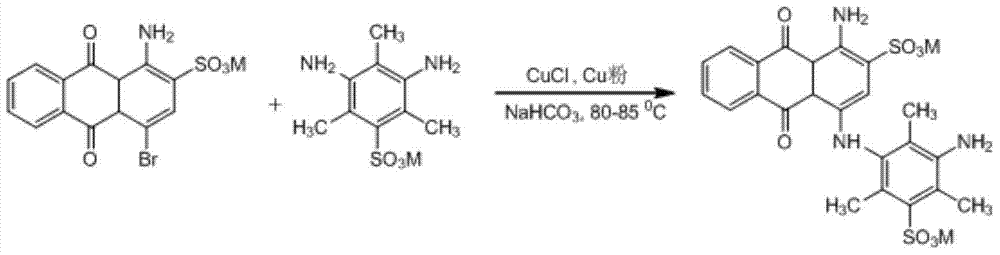

Preparation method of bromine ammonia blue

ActiveCN104327532AHigh yieldReduce generationOrganic-compounds/hydrides/coordination-complexes catalystsSulfonic acids salts preparationSolventCuprous chloride

The invention provides a preparation method of bromine ammonia blue. The preparation method comprises following steps: carrying out a condensation reaction between bromamine acid and 2,4,6-trimethyl-3,5-diaminobenzenesulfonic acid with a catalyst system containing a cuprous complex for catalyzing the reaction and then performing seperation to obtain the product bromine ammonia blue (sodium 1-amino-4-((3-amino-2,4,6-trimethyl-5-sulfonylphenyl)amino)-anthraquinone-2-sulfonate) after the reaction finished. By means of utilization of the catalyst system containing the cuprous complex, usage amounts of cuprous chloride and copper powder can be effectively reduced, thereby reducing the content of heavy metals in a dye product, reducing the content of heavy metals in waste water and reducing environmental pollution and production cost. In addition, the preparation method can avoid generation of a hydrolyzed by-product (a purple by-product) of the bromamine acid, can greatly reduce the generation of a debromination by-product, can significantly reduce the generation of a double-condensation substance, can increase yields of the condensation reaction and the dye product and can reduce discharge amount of waste water containing acids and being high in chroma.

Owner:DALIAN UNIV OF TECH

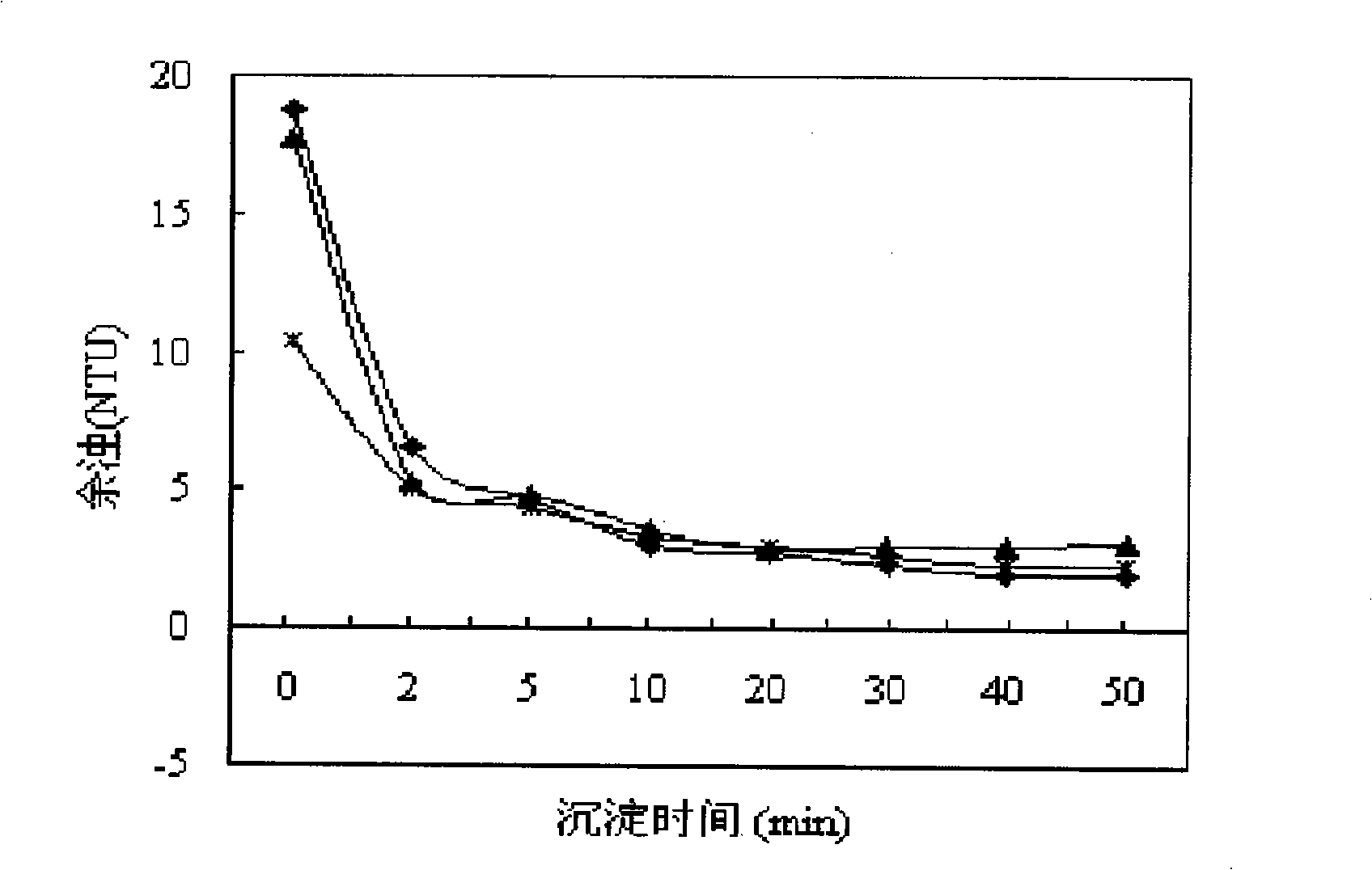

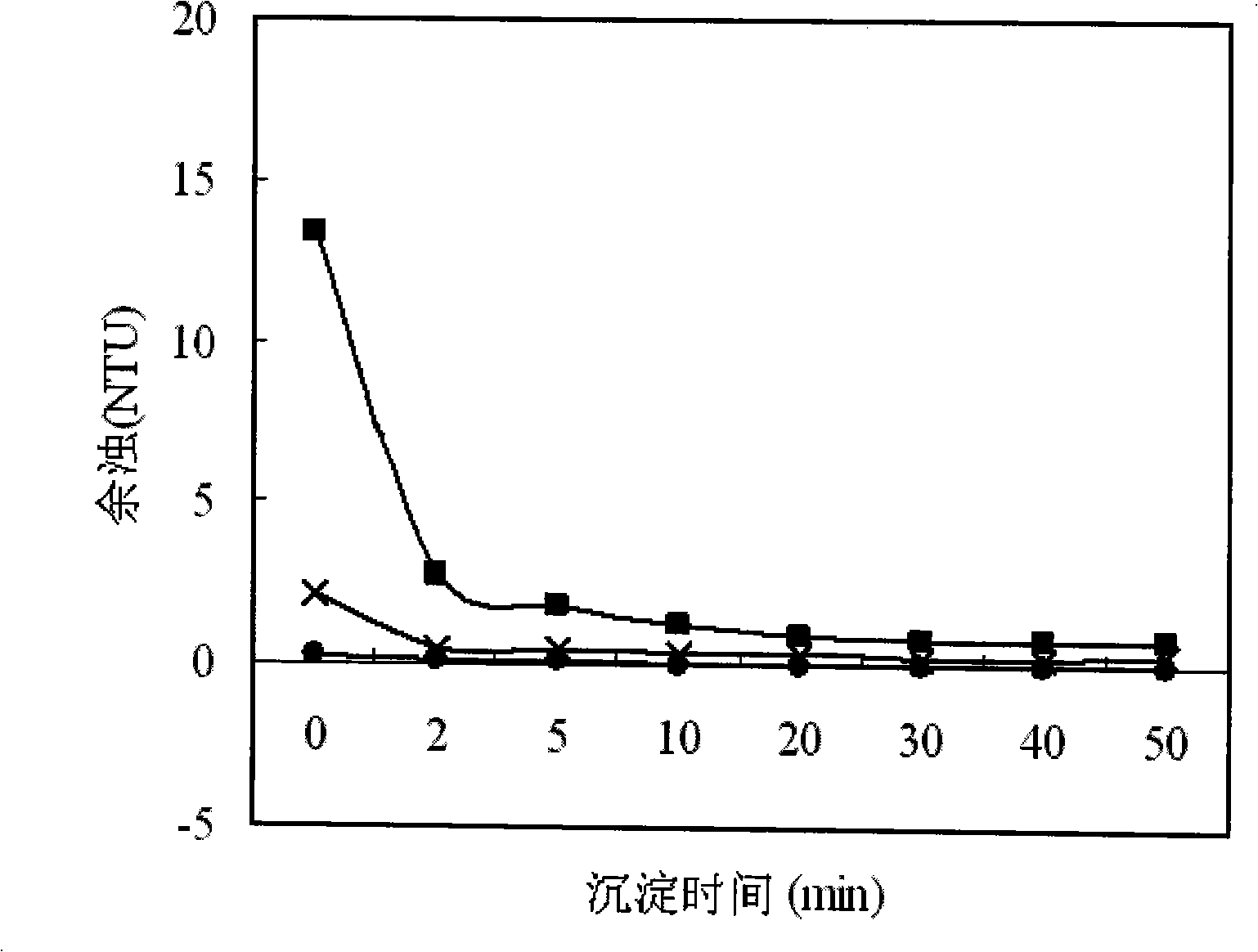

Polysilicic iron-zinc coagulant and preparation thereof

ActiveCN101407352AReduce floating phenomenonReduce residual chromaWater/sewage treatment by flocculation/precipitationSodium bicarbonateAntioxidant

The invention relates to a silicone iron zinc coagulant and a preparation method thereof, relating to an inorganic polymer coagulant and a preparation method thereof. The invention solves the affection of weak adaptability to low temperature and low turbidity water quality, low turbidity removal rate, residual chroma and fast hydrolysis of the existing molysite coagulant, and the problems of complicated preparation process, high cost of raw materials and long time consuming, and production of second pollution to environment. The silicone iron zinc coagulant is prepared by sodium silicate, dilute sulphuric acid solution, sodium bicarbonate, ferrous sulfate, zinc sulfate and an antioxidant. The preparation method comprises the following steps of: 1. weighing raw materials; 2. preparing clustering silicic acid solution; 3. preparing the clustering ferrosilicon zinc solution and 4. adopting a reverse contact type spray drying method or cocurrent flow contact type spray drying method to dry the clustering ferrosilicon zinc solution, thus obtaining the clustering ferrosilicon zinc coagulant. The product has the advantages of being suitable for low temperature and low turbidity water quality, more than 99 percent of the turbidity removal rate, no residual chroma and being not easy to be hydrolyzed, low preparation cost, simple method and no pollution in preparing process.

Owner:HARBIN INST OF TECH

Refractory metal core coatings

InactiveUS20090114797A1Trend downImprove the immunityFoundry mouldsFoundry coresTitanium nitrideDissolution

A refractory metal core for use in a casting system has a coating for providing oxidation resistance during shell fire and protection against reaction / dissolution during casting. In a first embodiment, the coating includes at least one oxide and a silicon containing material. In a second embodiment, the coating includes an oxide selected from the group of calcia, magnesia, alumina, zirconia, chromia, yttria, silica, hafnia, and mixtures thereof. In a third embodiment, the coating includes a nitride selected from the group of silicon nitride, sialon, titanium nitride, and mixtures thereof. Other coating embodiments are described in the disclosure.

Owner:RAYTHEON TECH CORP

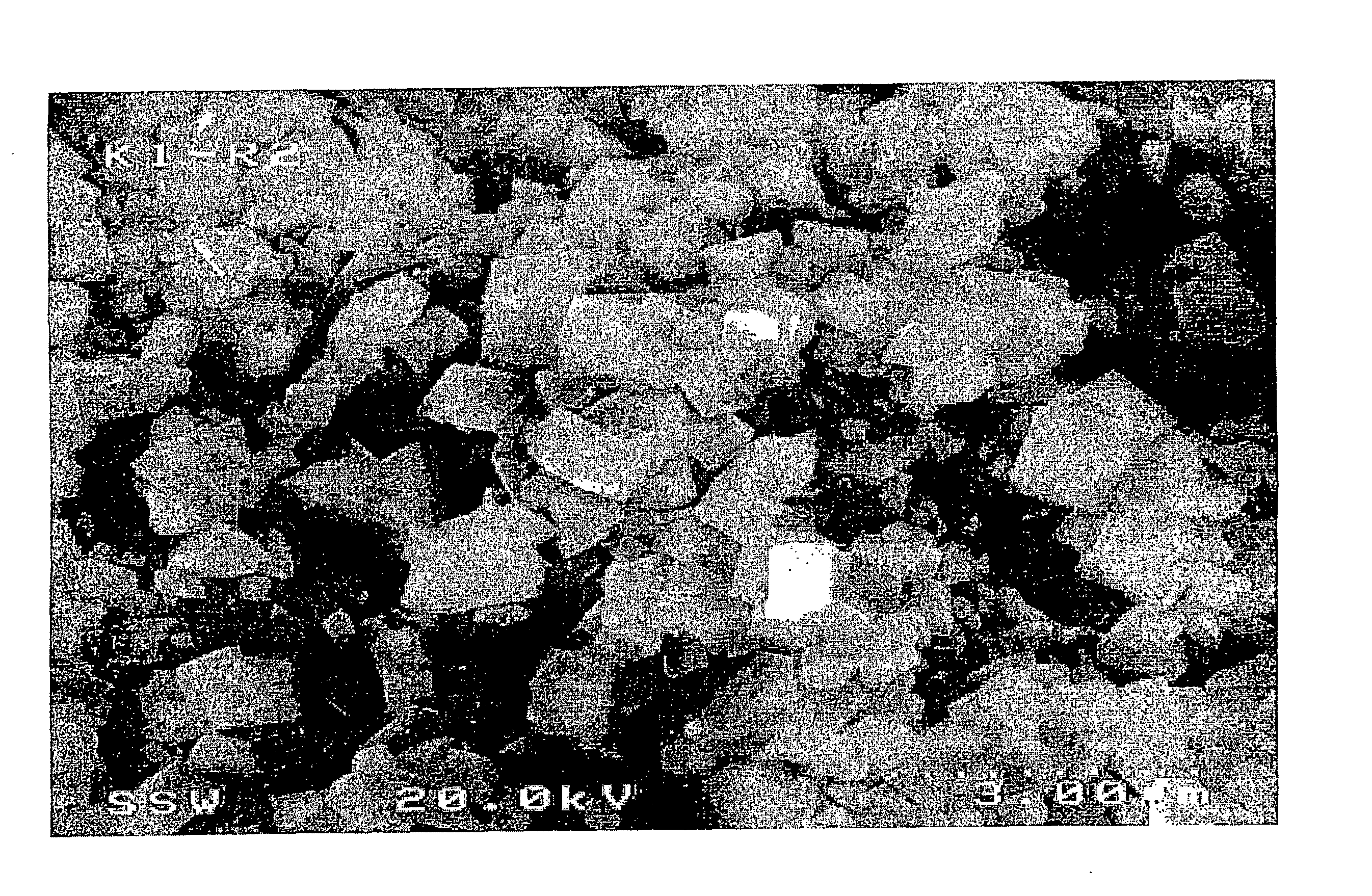

Creping blade

ActiveUS7244340B2Avoiding large fluctuation in lifetimeMore resistant to microchipsMechanical working/deformationBrushesChromiaTitanium dioxide

A blade for creping has been described. The blade according to the invention has a ceramic top layer covering the working edge of the blade, as well as the surface upon which the web impacts during creping. The ceramic top layer is a ceramic composition having a content of chromia. Preferably, the ceramic composition of the top layer comprises chromia-titania, with a titania content of up to 25% by weight, and preferably between 10% and 15% titania.

Owner:BTG ECLEPENS

Multi-layered dehydrogenation catalyst system and process of use

A system for dehydrogenating a C3 or C4 hydrocarbon feed stream containing a first and second layer of catalysts placed in the hydrocarbon feed stream, wherein the feed stream first passes through the first layer and then the second layer of catalysts and wherein the catalysts of the first layer contain from about 50 to about 90 percent by weight of an eta-alumina carrier, from about 10 to about 50 percent by weight of chromia and from about 0.1 to about 5 percent by weight of a zirconium compound and wherein the catalysts of the second layer of catalysts contain from about 50 to about 90 percent by weight of an eta-alumina carrier and from about 10 to about 50 percent by weight of chromia, without an added zirconium compound.

Owner:SUD CHEM INC

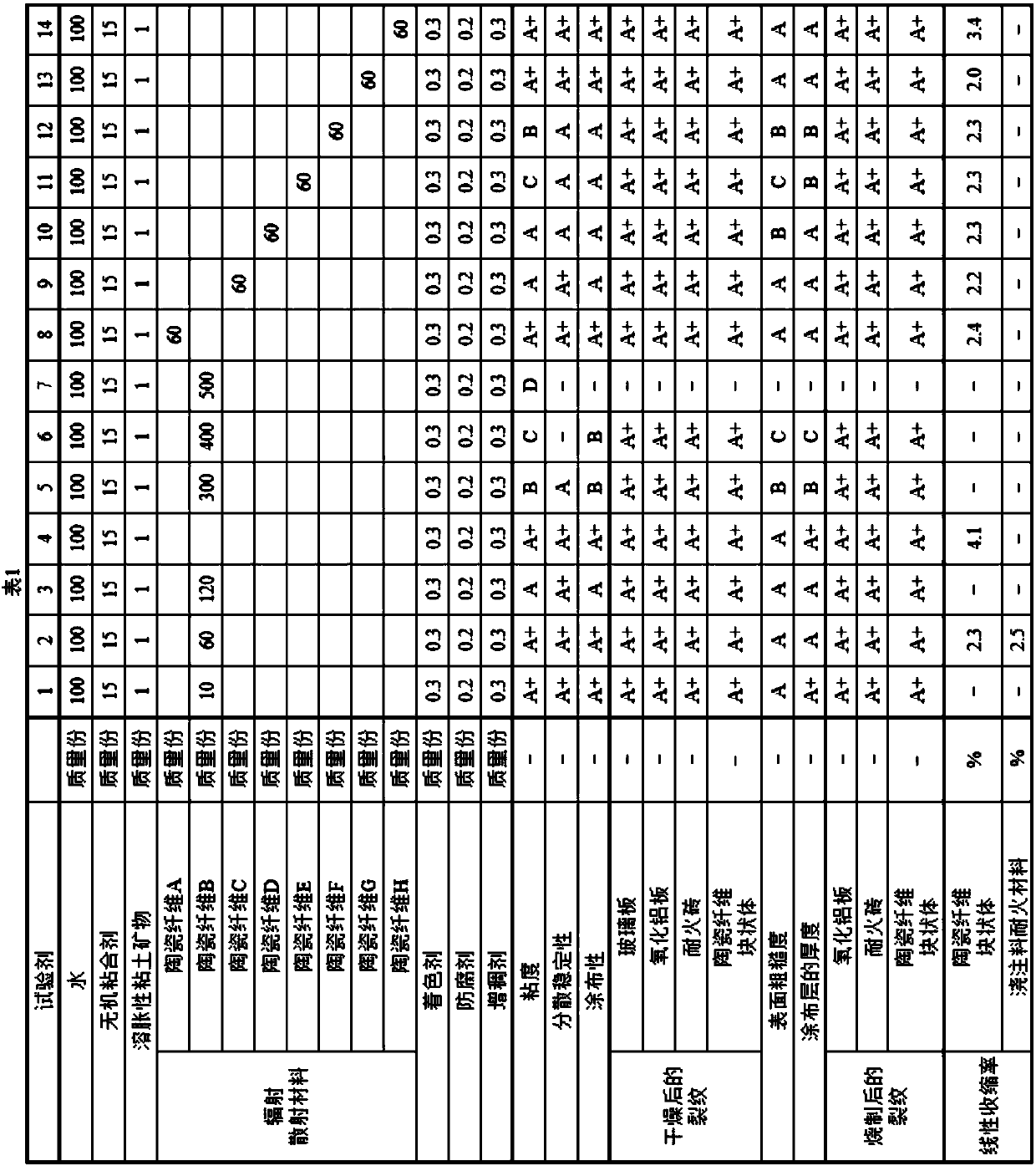

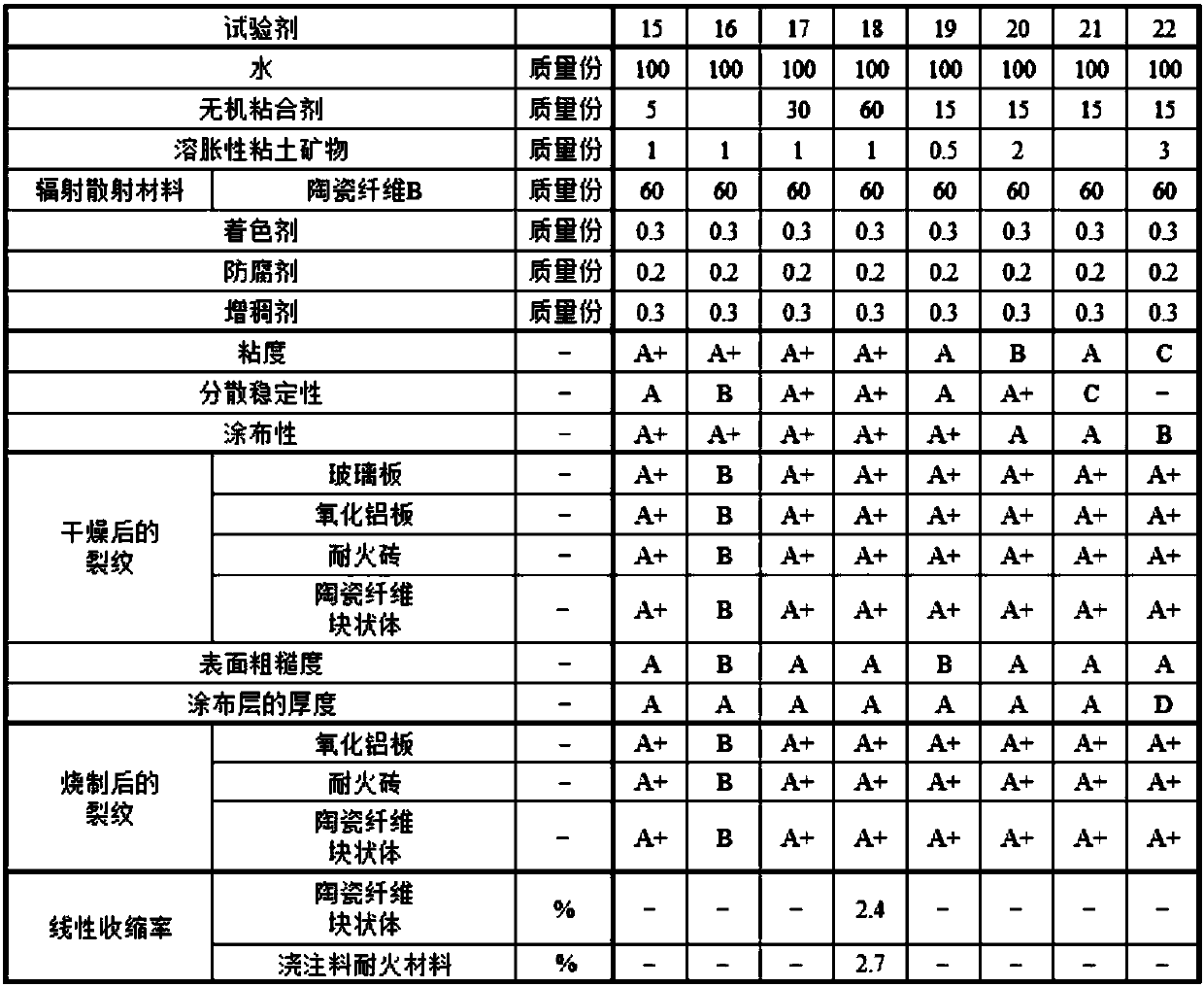

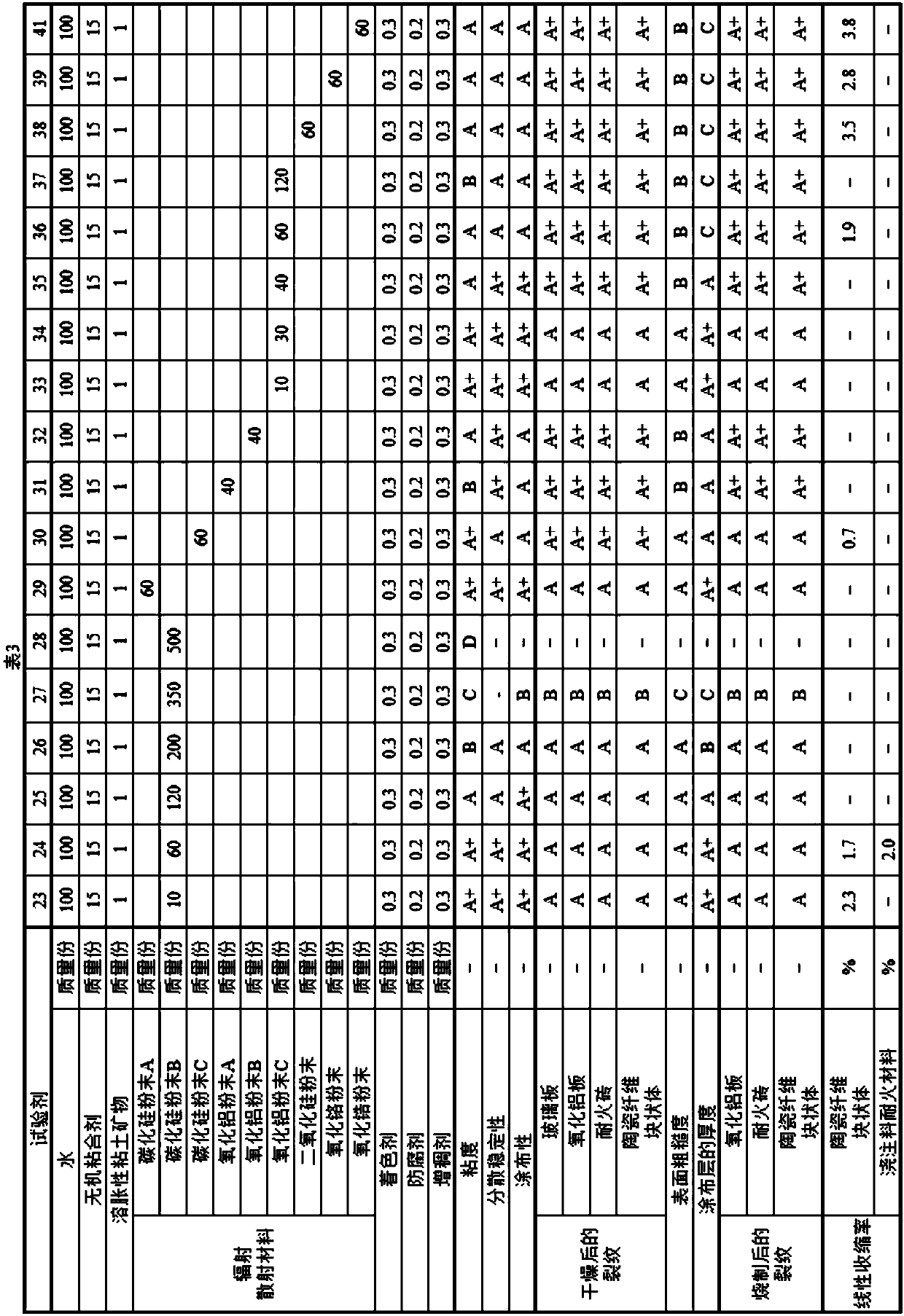

Coating liquid, composition for coating liquid, and refractory article having coating layer

Provided are: a coating liquid for refractory articles, which has excellent performance and which can be prepared through a simple operation; a composition for producing the coating liquid; and a refractory article with a coating layer having excellent thermal insulation performance and resistance against strong wind. The coating liquid contains 100 parts by mass of water, 10-20 parts by mass of an inorganic binder, 0.2-2 parts by mass of a swellable clay mineral, and 10-200 parts by mass of a radial-scattering material. The radial-scattering material contains: a ceramic fiber which comprisesfibrous particles containing Al2O3 and has an average fiber length of 100 [mu]m or less; and / or one or more ceramic powders which are selected from the group consisting of alumina powder, silica powder, titania powder, chromia powder, yttria powder, zirconia powder, lanthanum oxide powder, ceria powder, silicon carbide powder, silicon carbide aluminum powder, silicon nitride powder, and boron nitride powder, and have a median size of 60 [mu]m or less.

Owner:INUI CO LTD +1

Chromia-alumina refractory

A refractory composition comprising at least 50 weight percent chromic oxide (Cr2O3), as measured by chemical analysis. The composition includes fused chromia-containing grain, powdered chromic oxide and sintered chromia-containing grain. The fused chromia-containing grain and the sintered chromia-containing grain comprise at least 50 weight percent chromia oxide, as measured by chemical analysis.

Owner:A P GREEN REFRACTOR

Magnetoelectric chromia having increased critical temperature

ActiveUS20150243414A1Facilitates wide spread useIncrease flexibilityMagnetic paintsInorganic material magnetismMetallurgyPhysical chemistry

A magnetoelectric composition of boron and chromia is provided. The boron and chromia alloy can contain boron doping of 1%-10% in place of the oxygen in the chromia. The boron-doped chromia exhibits an increased critical temperature while maintaining magnetoelectric characteristics. The composition can be fabricated by depositing chromia in the presence of borane. The boron substitutes oxygen in the chromia, enhancing the exchange energy and thereby increasing Neel temperature.

Owner:BOARD OF RGT UNIV OF NEBRASKA

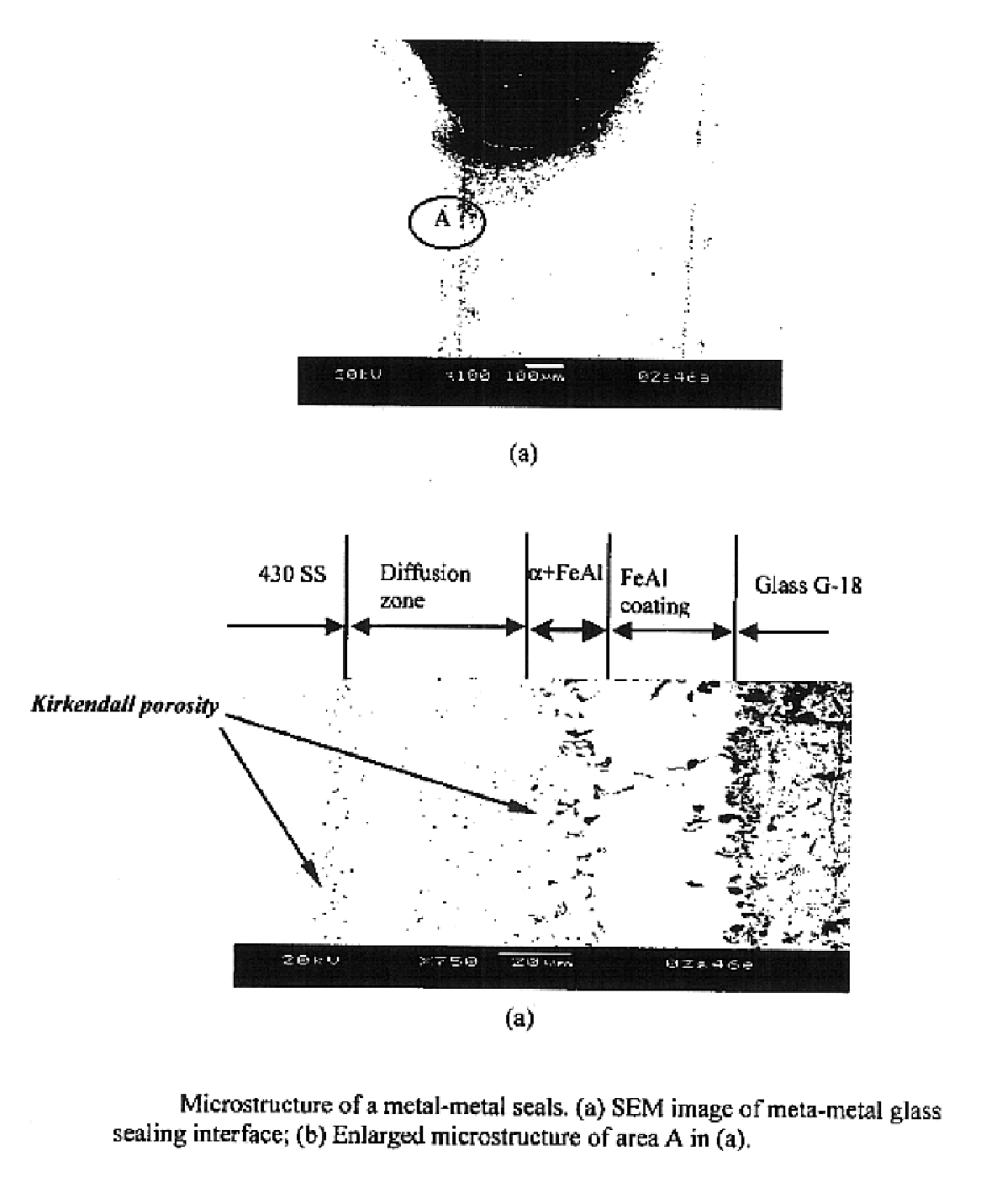

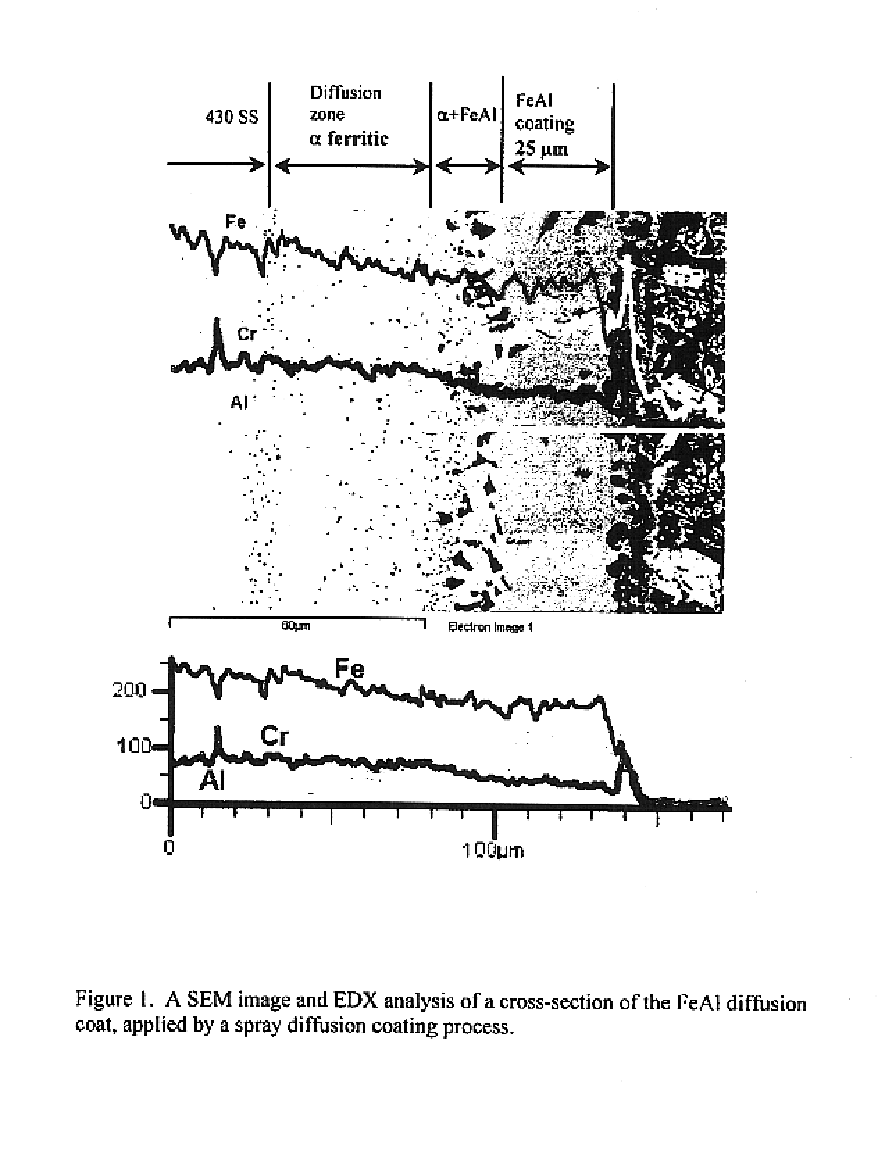

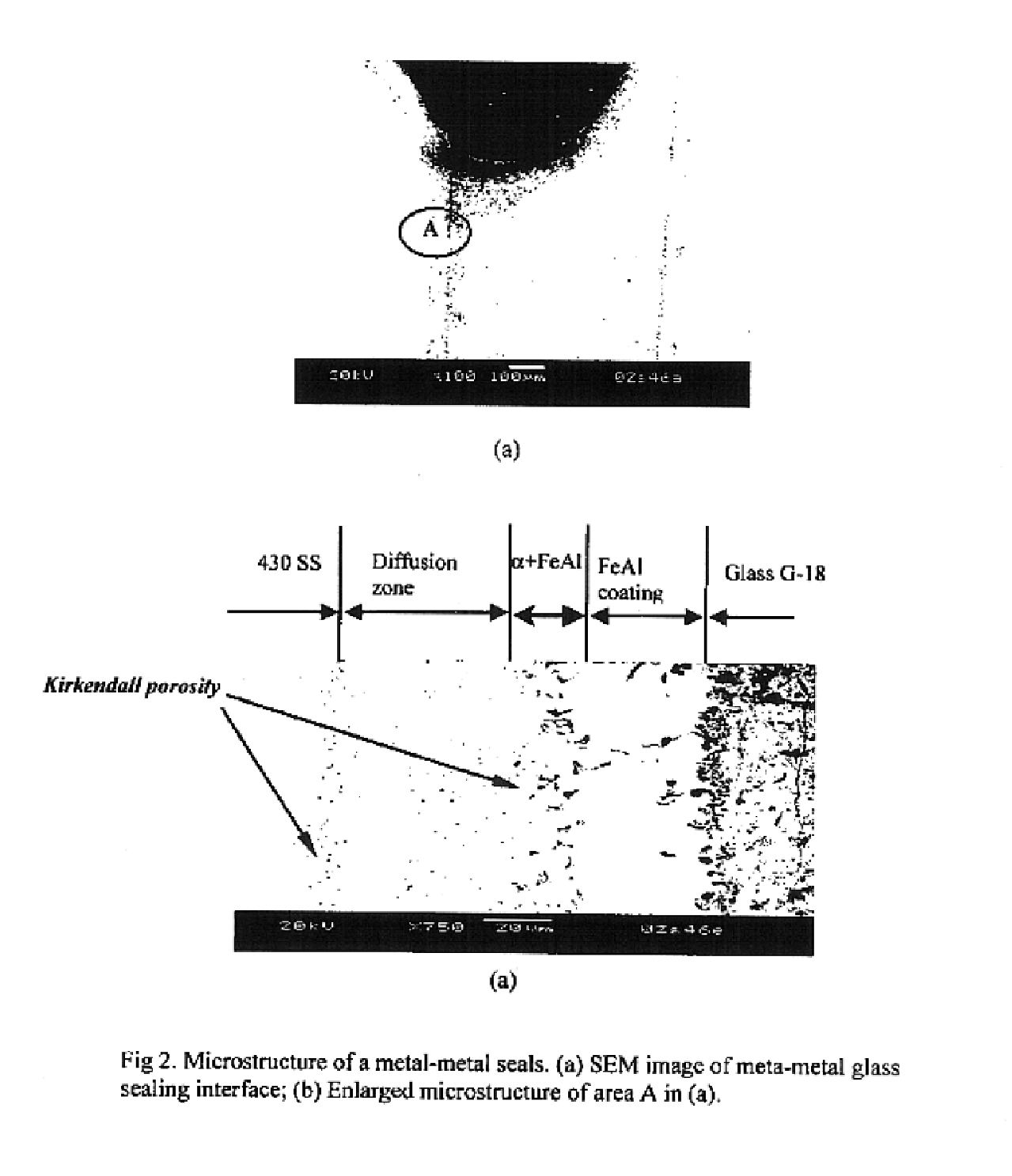

Gas-tight metal/ceramic or metal/metal seals for applications in high temperature electrochemical devices and method of making

InactiveUS6843406B2High bonding strengthImprove the bonding strength of the interfaceFuel cells groupingFinal product manufactureThin layerSuperalloy

A method of joining metal and metal, or metal and ceramic parts, wherein a first metal part is selected and then processed to form a bond coat that will effectively bond to a sealing material which in turn bonds to a second metal or ceramic part without degrading under the operating conditions of electrochemical devices. Preferred first metal parts include alumina forming alloys from the group consisting of ferritic stainless steels (such as Fecralloys), austinetic stainless steels, and superalloys, and chromia forming alloys formed of ferritic stainless steels. In the case of chromia forming ferritic stainless steels, this bond coat consists of a thin layer of alumina formed on the surface, with a diffusion layer between the first metal part and this thin layer. The bond coat provides a good bonding surface for a sealing layer of glass, braze or combinations thereof, while at the same time the diffusion layer provides a durable bond between the thin alumina layer and the first metal part. In the case of alumina forming alloys, the bond coat consists of cauliflower-like growths of an aluminum oxide nodules embedded in the surface of the alumina forming alloys.

Owner:BATTELLE MEMORIAL INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com