Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Reduce floating phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

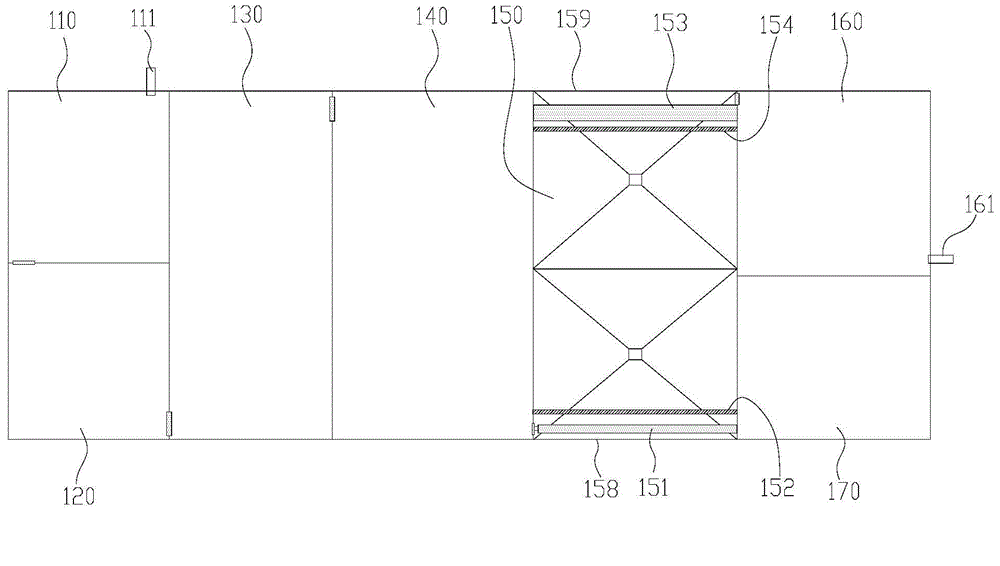

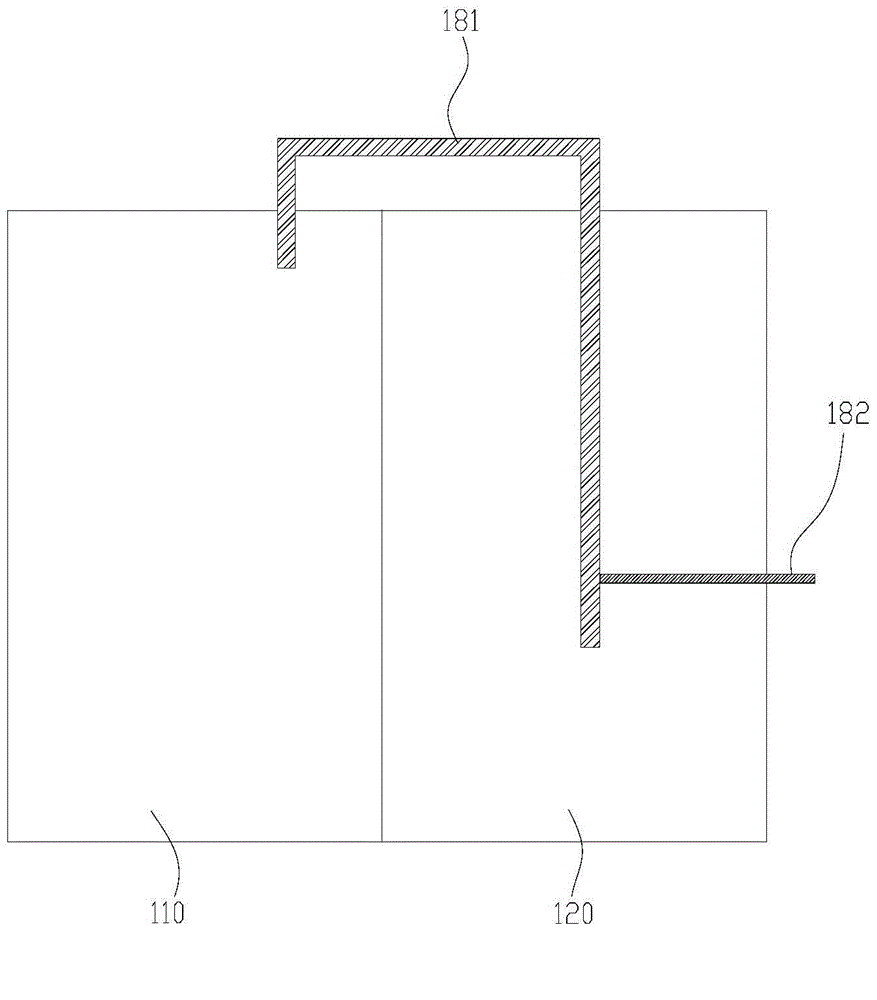

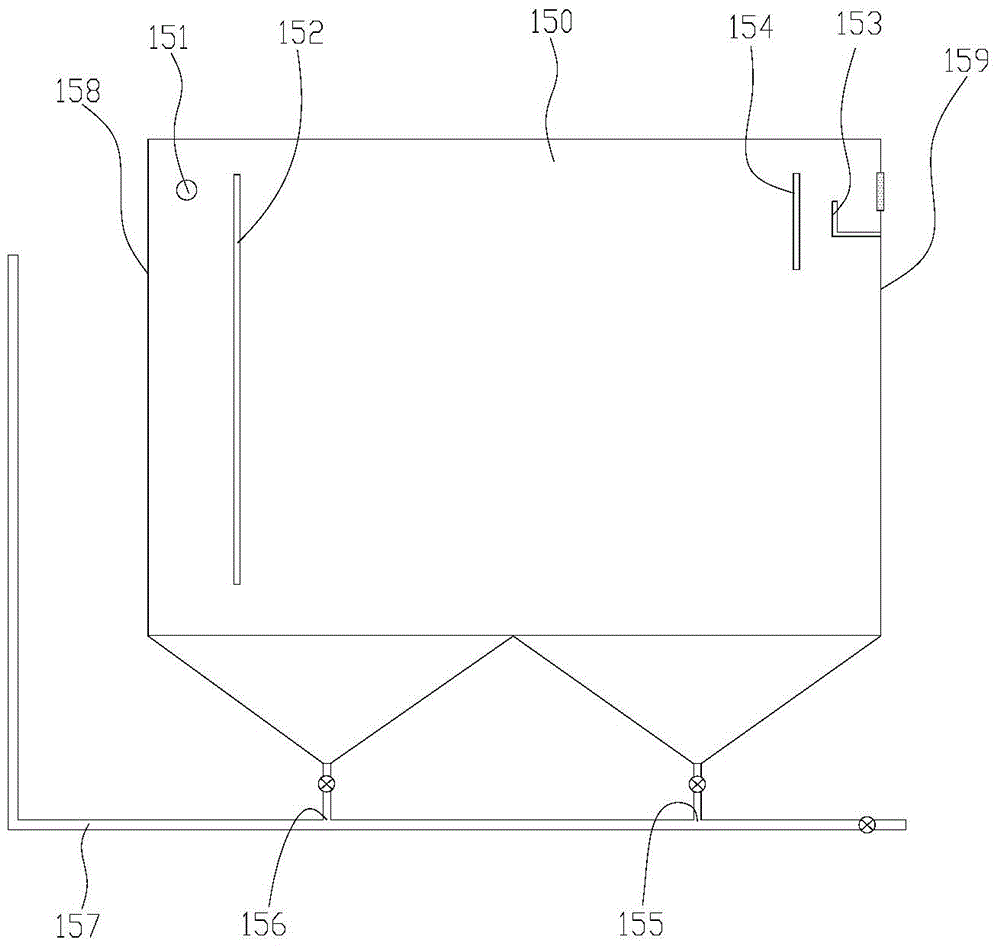

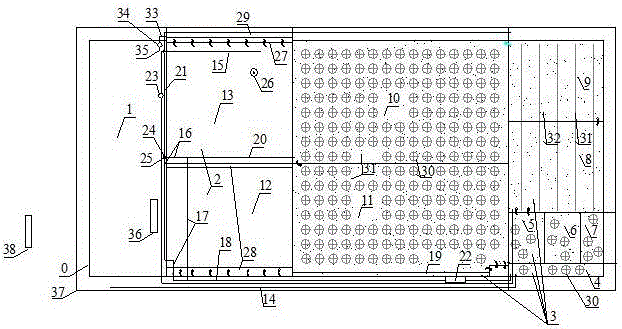

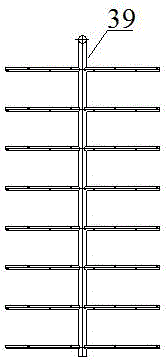

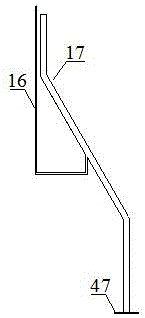

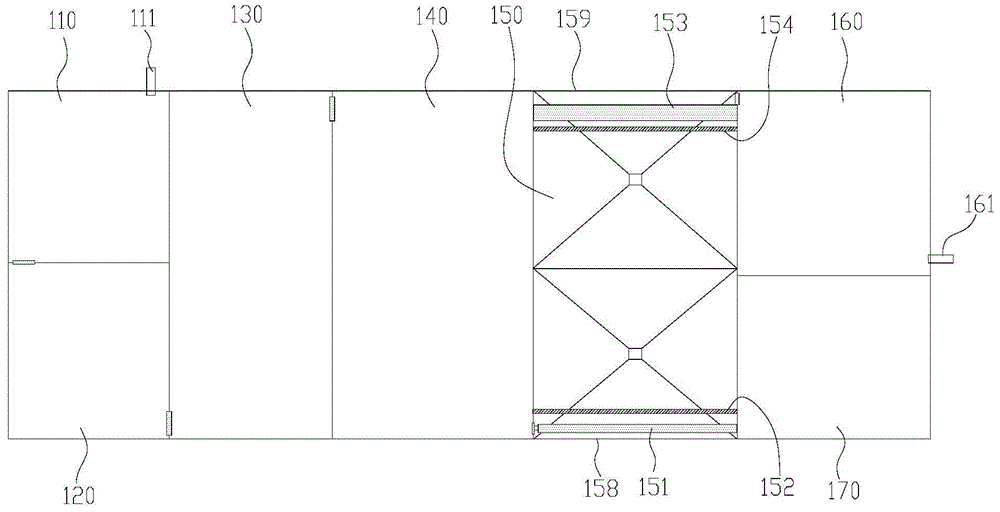

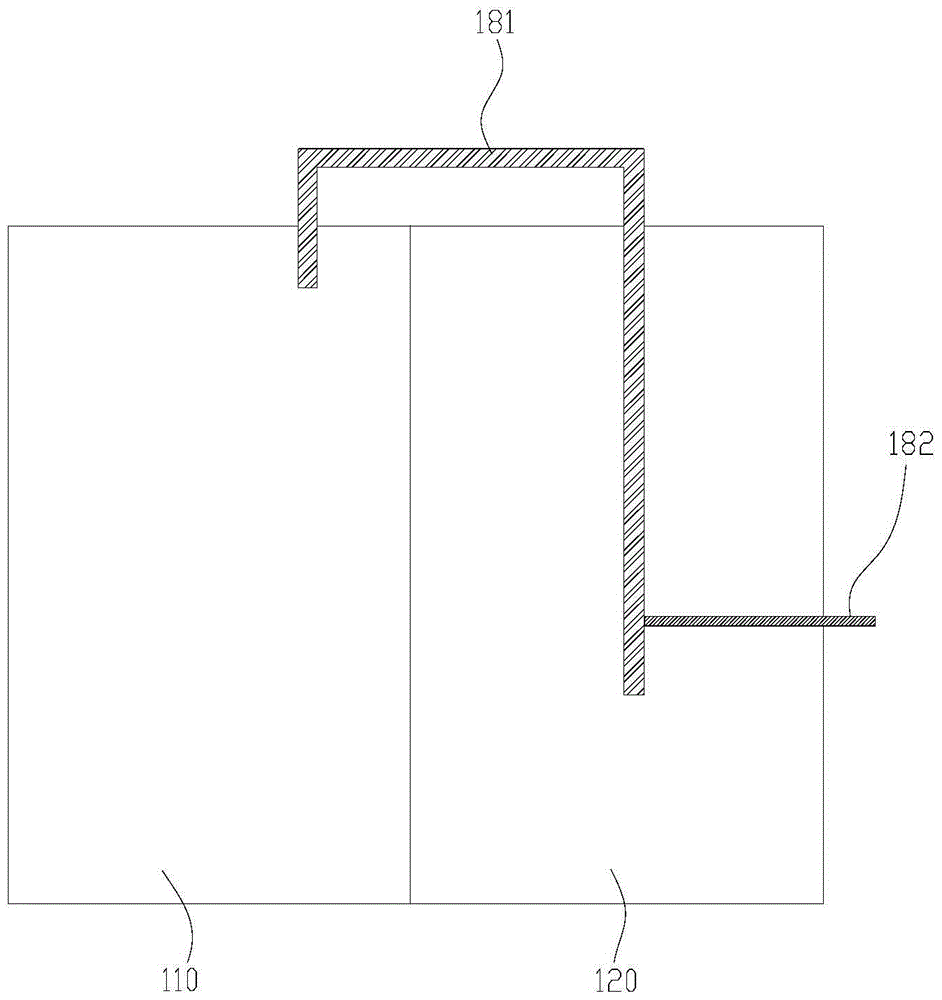

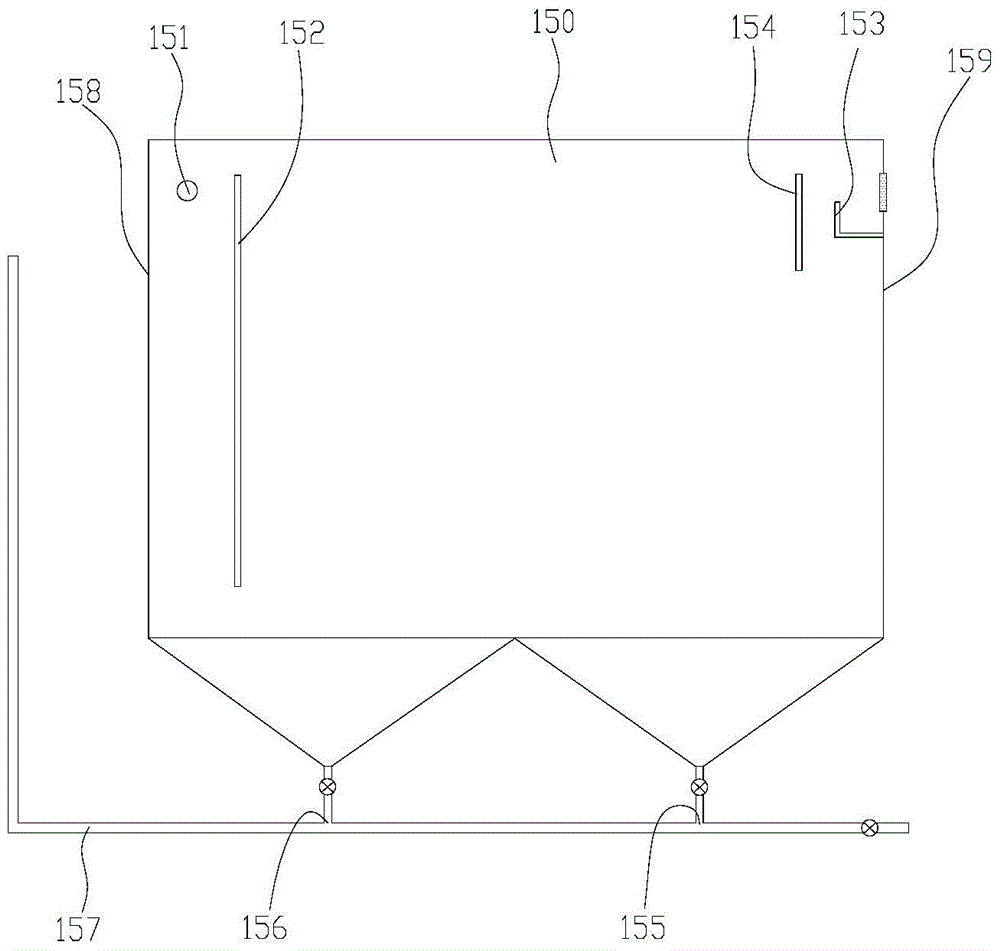

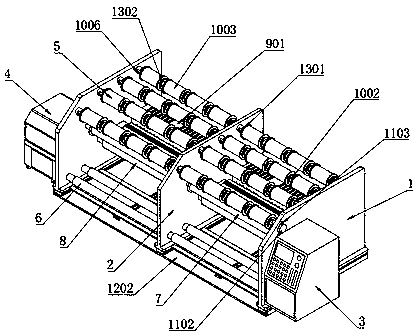

A3/O-MBBR (Moving Bed Biofilm Reactor) integrated sewage treatment device and A3/O-MBBR integrated sewage treatment method

ActiveCN104445830AReduce floating phenomenonImprove precipitation effectTreatment using aerobic processesTreatment with anaerobic digestion processesMoving bed biofilm reactorSmall footprint

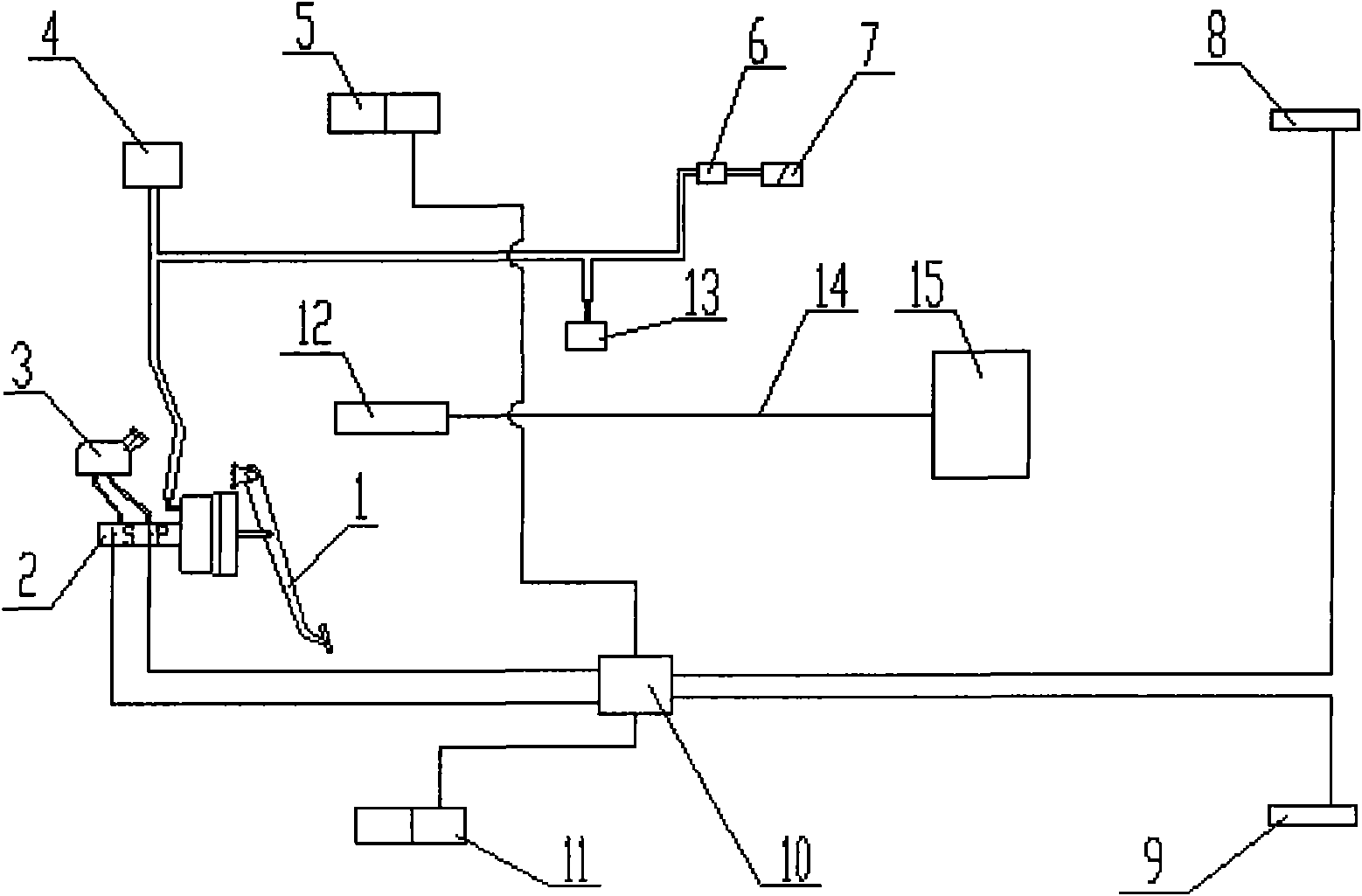

The invention relates to the technical field of sewage treatment and particularly relates to an A3 / O-MBBR (Moving Bed Biofilm Reactor) integrated sewage treatment device and an A3 / O-MBBR integrated sewage treatment method. According to the device provided by the invention, a sewage backflow mechanism, a nitrification liquor backflow mechanism and an anaerobic liquor backflow mechanism are arranged and suspended filler is filled in an aerobic tank, so that the integrated sewage treatment device has a good effect for treating nitrogen and phosphorus in sewage and is high in treatment efficiency, compact in structure and small in occupied area. In addition, by virtue of optimizing a settling pond structure in the integrated sewage treatment device, the settling effect of the settling pond is improved, and the sludge floatation phenomenon and the content of suspended solids in effluent can be remarkably reduced. After sewage is treated by the integrated sewage treatment device provided by the invention, the effluent can reach the level A of first class stand of pollution discharge standard for municipal sewage treatment plant (GB18918-2002).

Owner:YUNNAN HEXUN ENVIRONMENTAL TECH CO LTD

High-strength light-weight concrete and preparation method thereof

The invention relates to high-strength light-weight concrete and a preparation method thereof. The preparation method comprises the following steps: step 1, ceramsites and pottery sand which are included in the raw material formula of the high-strength light-weight concrete are soaked in water to fully absorb water; step 2, adding the ceramsites and pottery sand absorbed with water and the rest of materials to a stirring machine, stirring for 3 min to obtain a high-strength light-weight concrete mixture. The high-strength light-weight concrete in the raw material formula comprises the following raw materials in percentage by weight: 18-27% of portland cement, 6-10% of vitrified microspheres, 2-6% of silica fume, 20-30% of ceramsites, 25-35% of pottery sand, 0.2-0.8% of a high-performance water reducing agent, 0.05-0.3% of molecular sieves, 0.05-0.8% of an air entraining agent and 8-12% of water. According to the high-strength light-weight concrete and the preparation method thereof, provided by the invention, through the combined action of the adopted molecular sieves and the air entraining agent, a large number of air holes causing little influence on the strength is introduced into the concrete, the unit weight of the high-strength light-weight concrete is reduced, the application range of the high-strength light-weight concrete is expanded, the possibility that aggregate in the concrete tends to float upwards due to density variation can be greatly reduced under the existence of the air holes.

Owner:JIANGSU MINGHE GRP

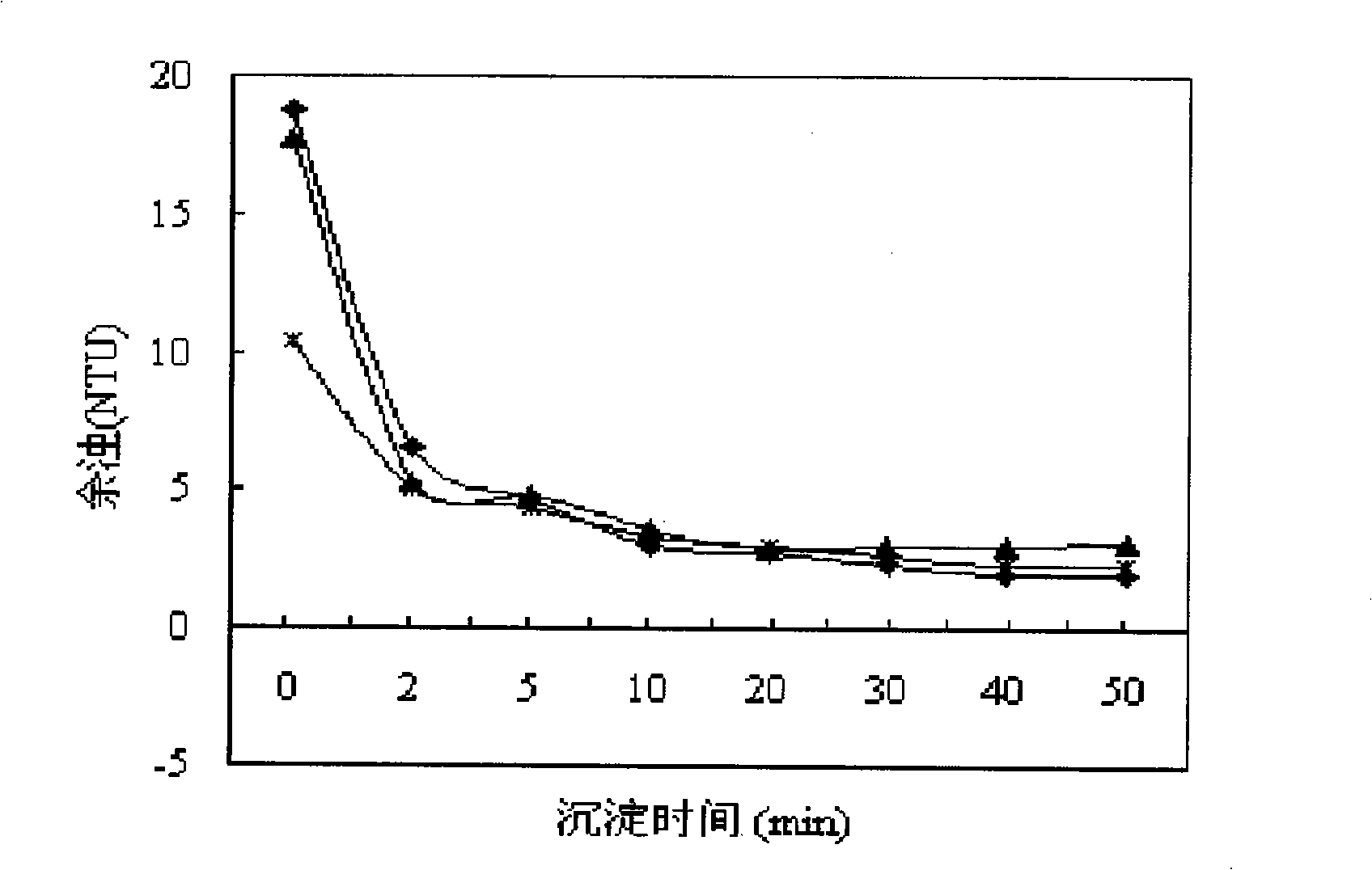

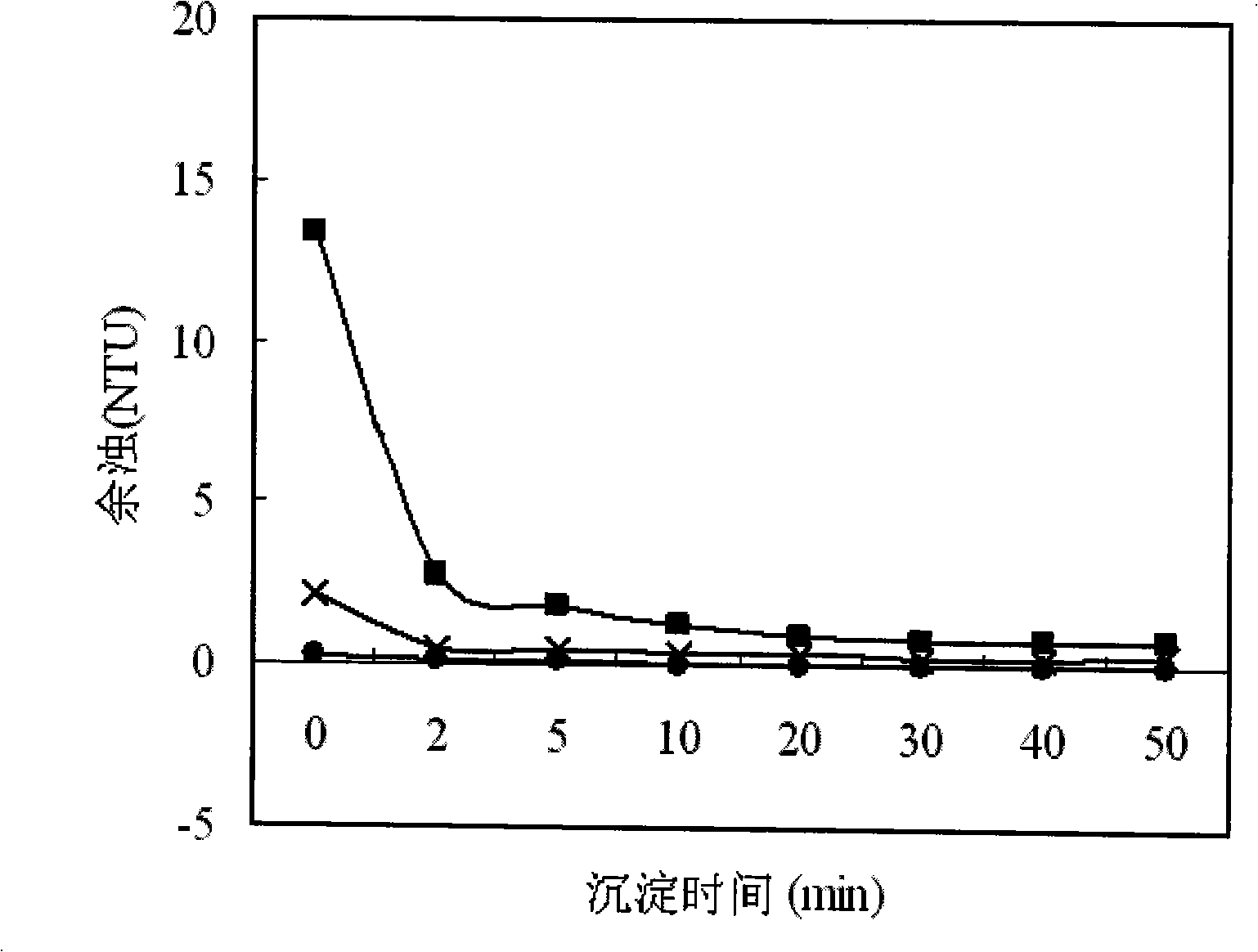

Polysilicic iron-zinc coagulant and preparation thereof

ActiveCN101407352AReduce floating phenomenonReduce residual chromaWater/sewage treatment by flocculation/precipitationSodium bicarbonateAntioxidant

The invention relates to a silicone iron zinc coagulant and a preparation method thereof, relating to an inorganic polymer coagulant and a preparation method thereof. The invention solves the affection of weak adaptability to low temperature and low turbidity water quality, low turbidity removal rate, residual chroma and fast hydrolysis of the existing molysite coagulant, and the problems of complicated preparation process, high cost of raw materials and long time consuming, and production of second pollution to environment. The silicone iron zinc coagulant is prepared by sodium silicate, dilute sulphuric acid solution, sodium bicarbonate, ferrous sulfate, zinc sulfate and an antioxidant. The preparation method comprises the following steps of: 1. weighing raw materials; 2. preparing clustering silicic acid solution; 3. preparing the clustering ferrosilicon zinc solution and 4. adopting a reverse contact type spray drying method or cocurrent flow contact type spray drying method to dry the clustering ferrosilicon zinc solution, thus obtaining the clustering ferrosilicon zinc coagulant. The product has the advantages of being suitable for low temperature and low turbidity water quality, more than 99 percent of the turbidity removal rate, no residual chroma and being not easy to be hydrolyzed, low preparation cost, simple method and no pollution in preparing process.

Owner:HARBIN INST OF TECH

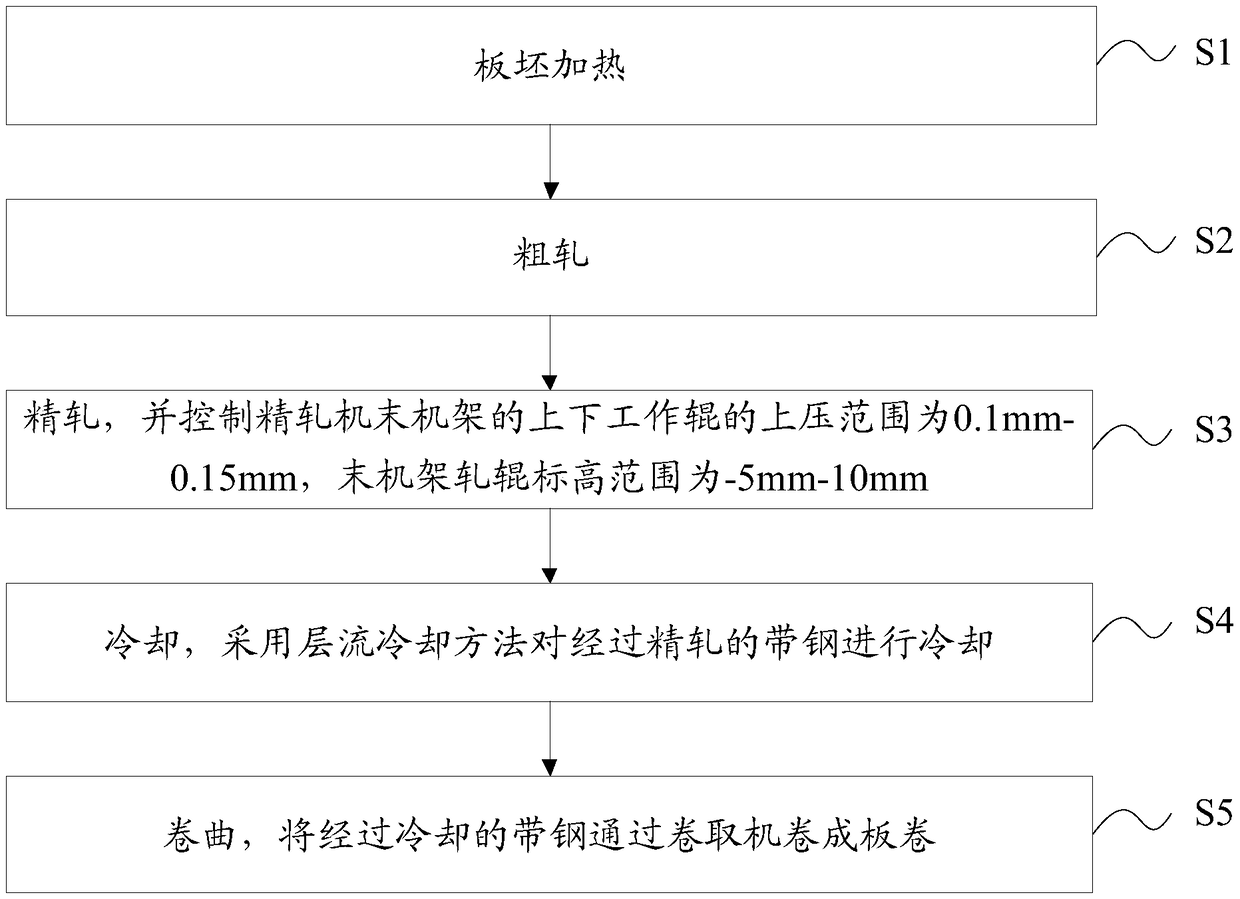

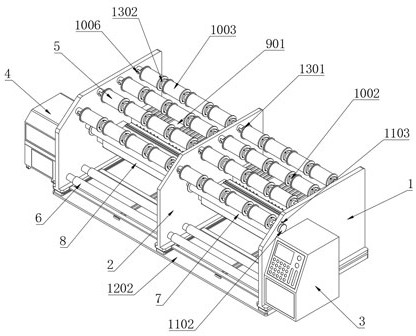

Ultrathin steel strip hot rolling process

ActiveCN108637014AMake sure the shape of the headReduce floating phenomenonTemperature control deviceProfile control deviceWinding machineStrip steel

The invention discloses an ultrathin steel strip hot rolling process. The process comprises the following steps: plate blanks are heated, roughly rolled and finely rolled; the upper pressure range ofupper and lower working rollers of a final frame of a finish rolling mill is controlled within 0.1-0.15 mm, and the elevation range of rollers of the final frame is within -5-10 mm; cooling: the fine-rolled strip steel is cooled by a laminar cooling method; and winding: the cooled strip steel is wound as plate coils through a winding machine. In the ultrathin steel strip hot rolling process, as the upper pressure range of the upper and lower working rollers of the final frame of the finish rolling mill is controlled within 0.1-0.15 mm, and the elevation range of the rollers of the final frameis within -5-10 mm, the head shape of the strip steel discharged from the finish rolling mill is guaranteed, the head shape of the strip steel discharged from the finish rolling mill is not upwards turned and downwards buckled, the floating phenomenon of the strip steel is effectively reduced, and the caused material waste and product rolling mark defect are reduced.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

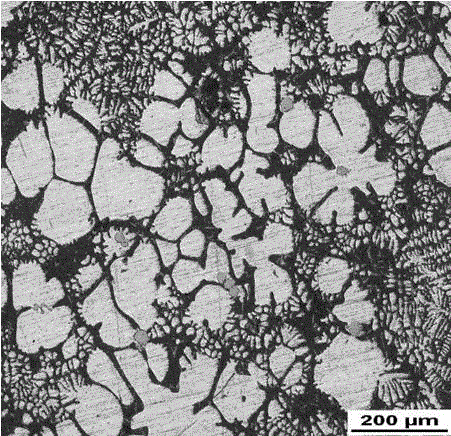

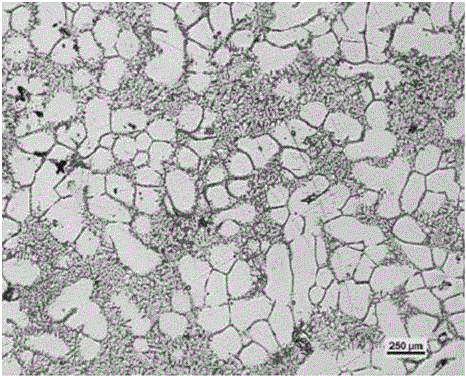

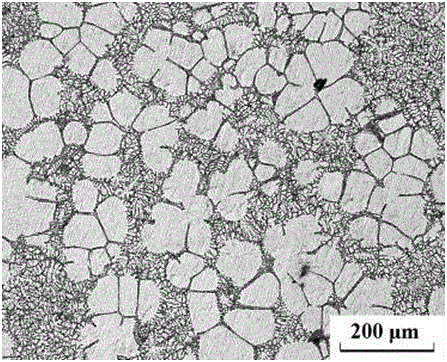

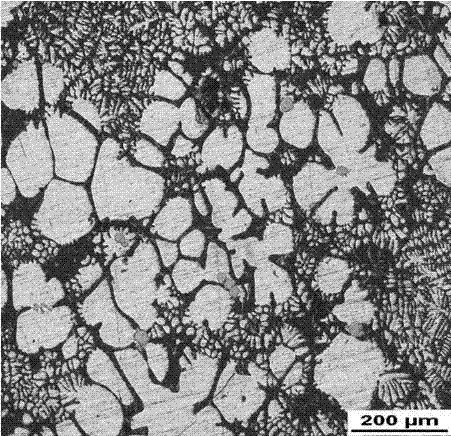

Preparation method of elemental-copper-coated multiwalled carbon nanotube/aluminum-based composite semisolid-state blank

A preparation method of an elemental-copper-coated multiwalled carbon nanotube / aluminum-based composite semisolid-state blank includes: preparing an elemental-copper-coated multiwalled carbon nanotube; guiding aluminum alloy powder and the elemental-copper-coated multiwalled carbon nanotube into a ball milling crucible, and performing ball milling treatment under protection of argon; putting mixed powder into the crucible, using a muffle furnace to heat to 20-40 DEG C below a solid-phase line, transferring into an ultrasonic magnetic stirring furnace, continuing heating, controlling solid-phase rate to a certain range, vibrating and stirring at a low speed, feeding argon for protection, and controlling stirring time; pouring obtained size into a corresponding die, and cooling to obtain the semisolid-state blank. The preparation method has the advantages of simplicity, safety, low cost, easiness in operation and controllability.

Owner:NANCHANG UNIV

Tubular welding wire for antiwear, heat resistant and antishock bead welding

InactiveCN1739906AUniform amount of powderImprove crack resistanceWelding/cutting media/materialsSoldering mediaChromium carbideNiobium

The tubular bead welding wire is made through rolling H08A steel belt into U shape and adding chromium carbide, molybdenum powder, niobium powder, graphite, WC and ferrovanadium in certain proportion. The present invention has proper amount of graphite and chromium carbide, homogeneous powder in the welding wire, greatly reduced floating, high welding seam wear resistance, high anticracking property of the bead welded layer, long service life of the welded part and other advantages.

Owner:李波 +1

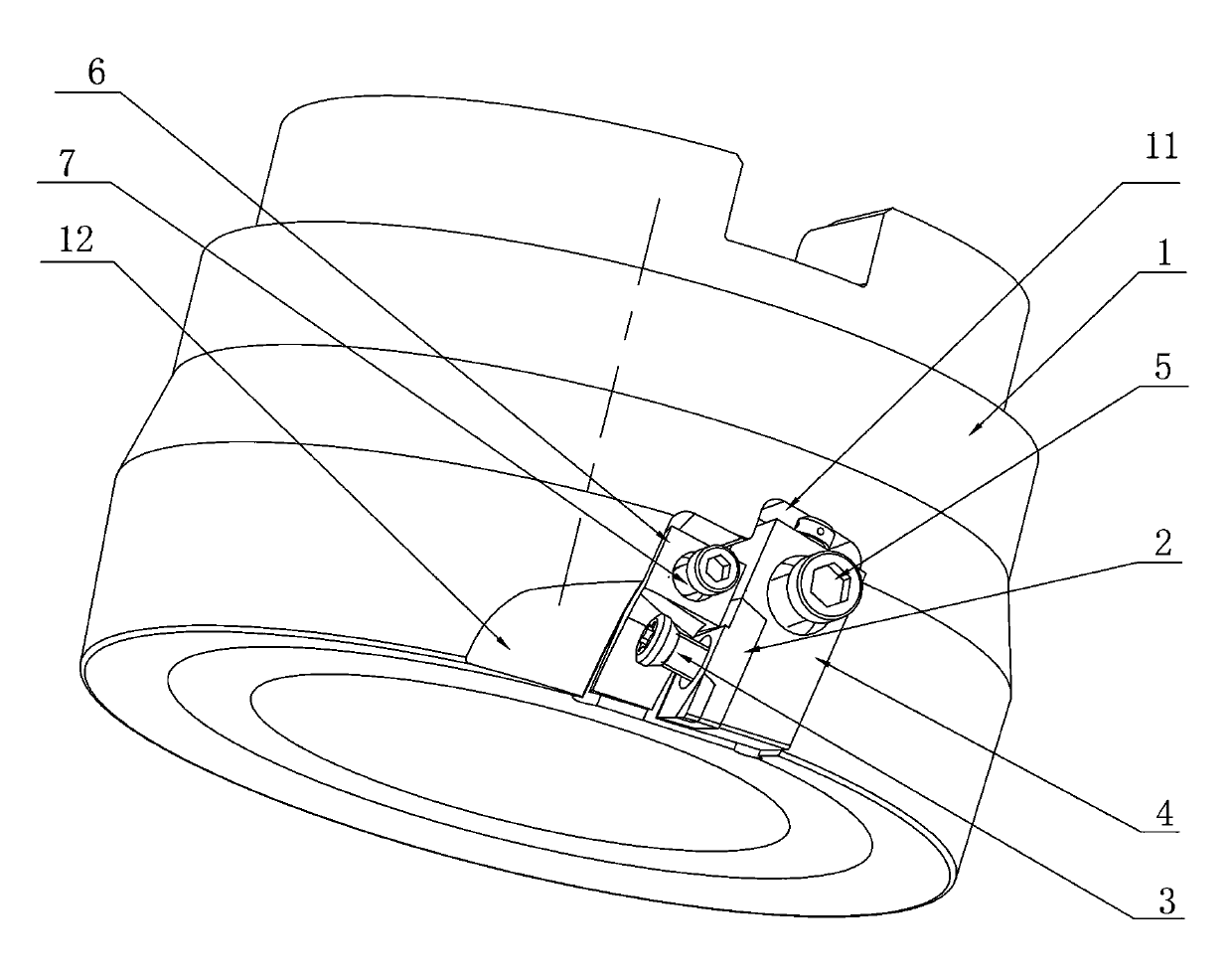

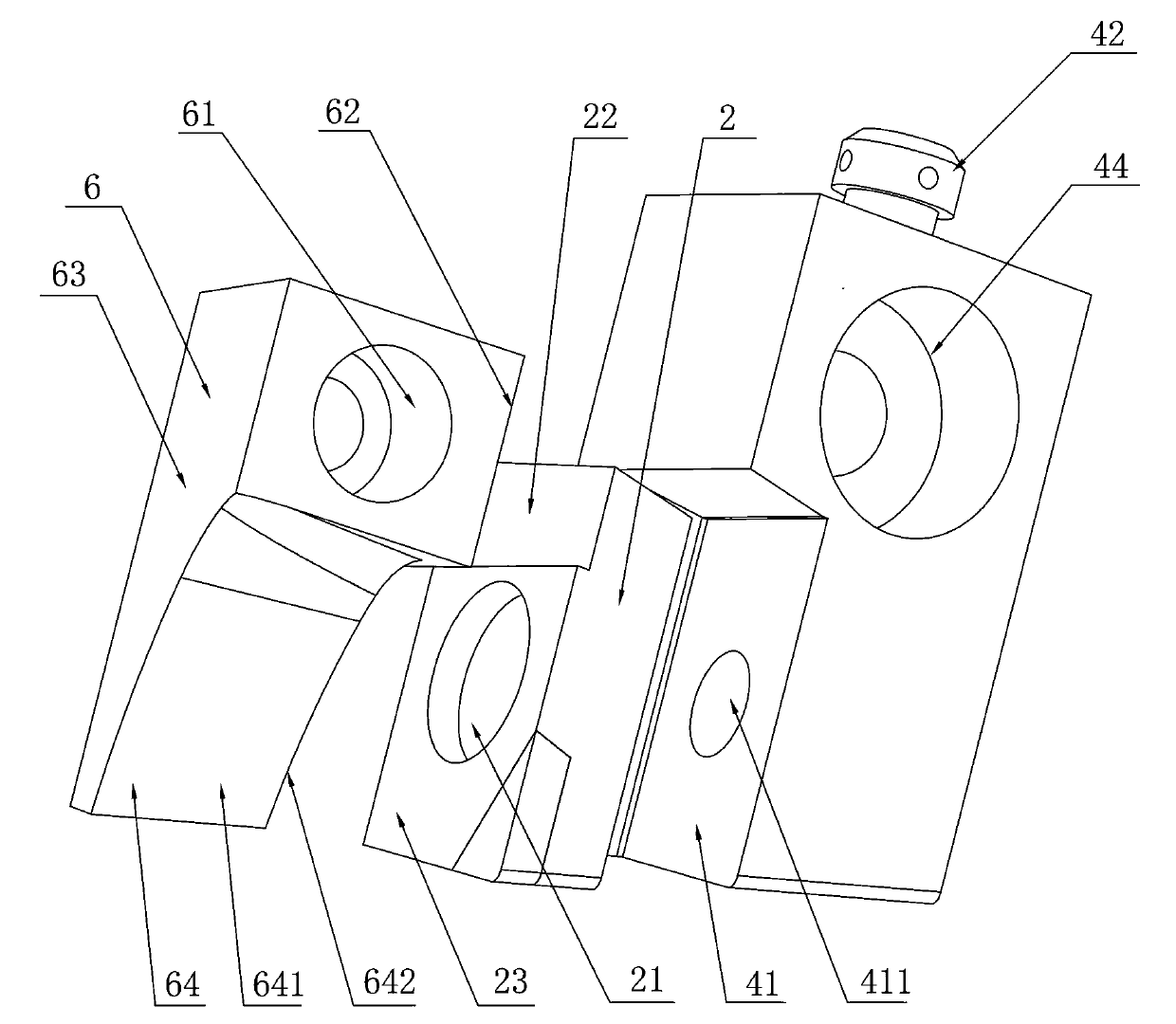

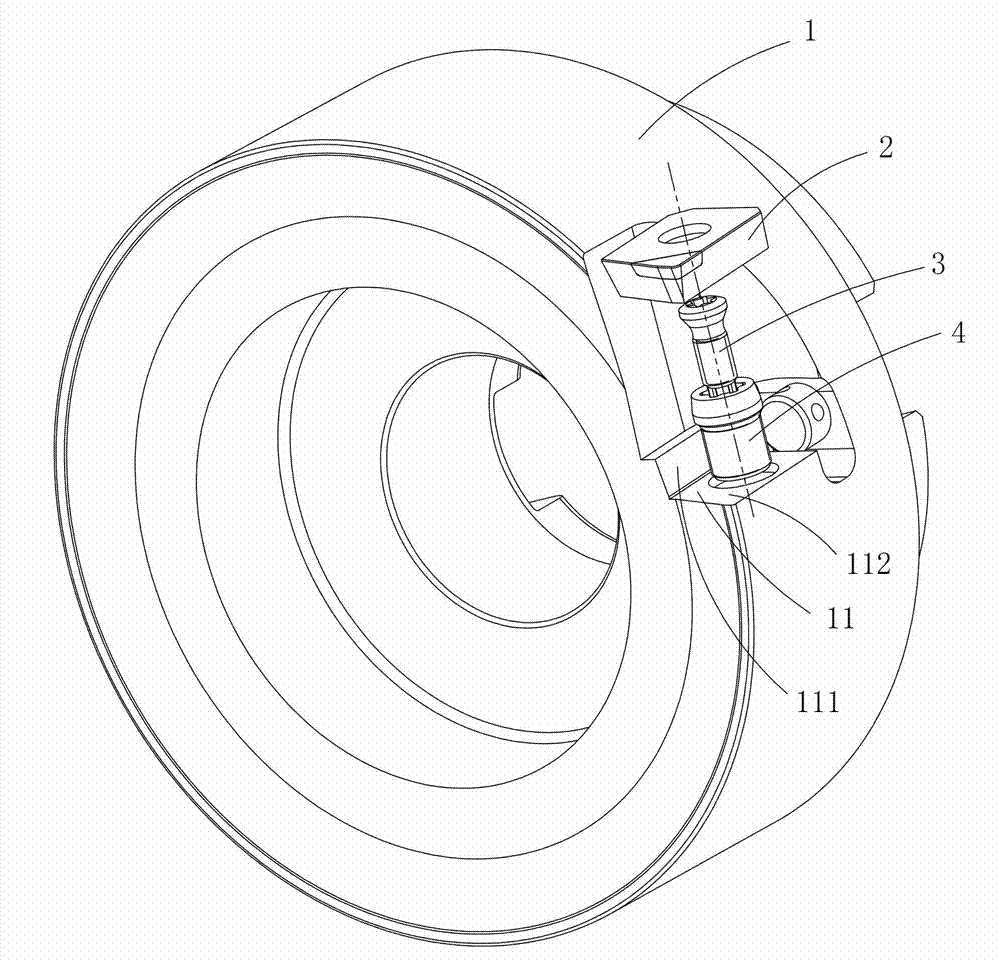

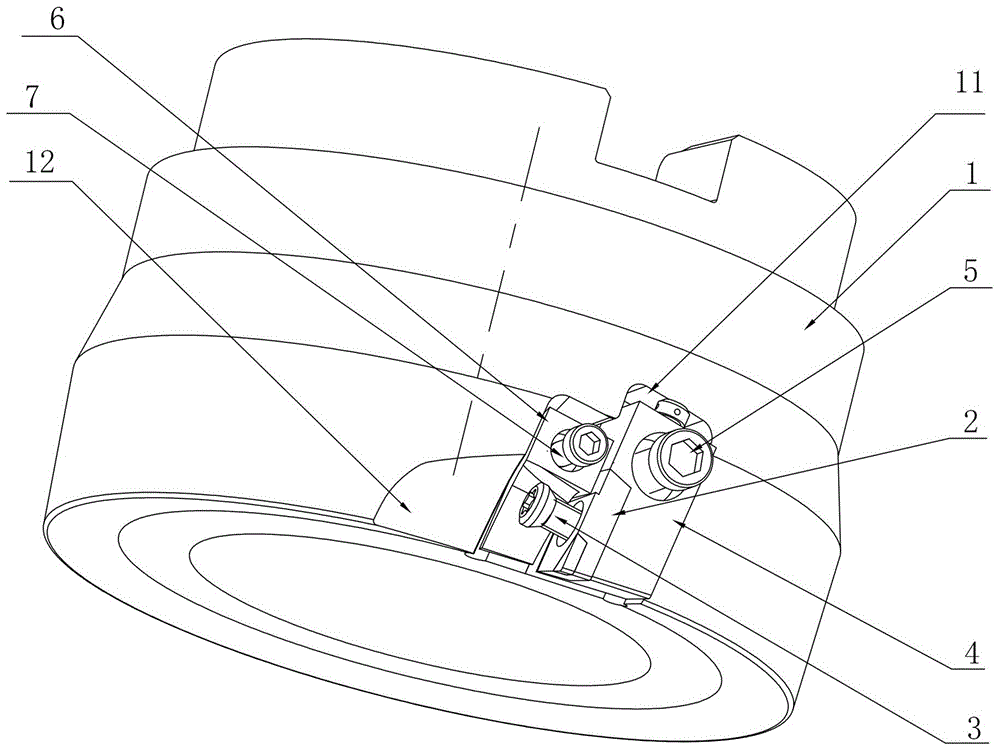

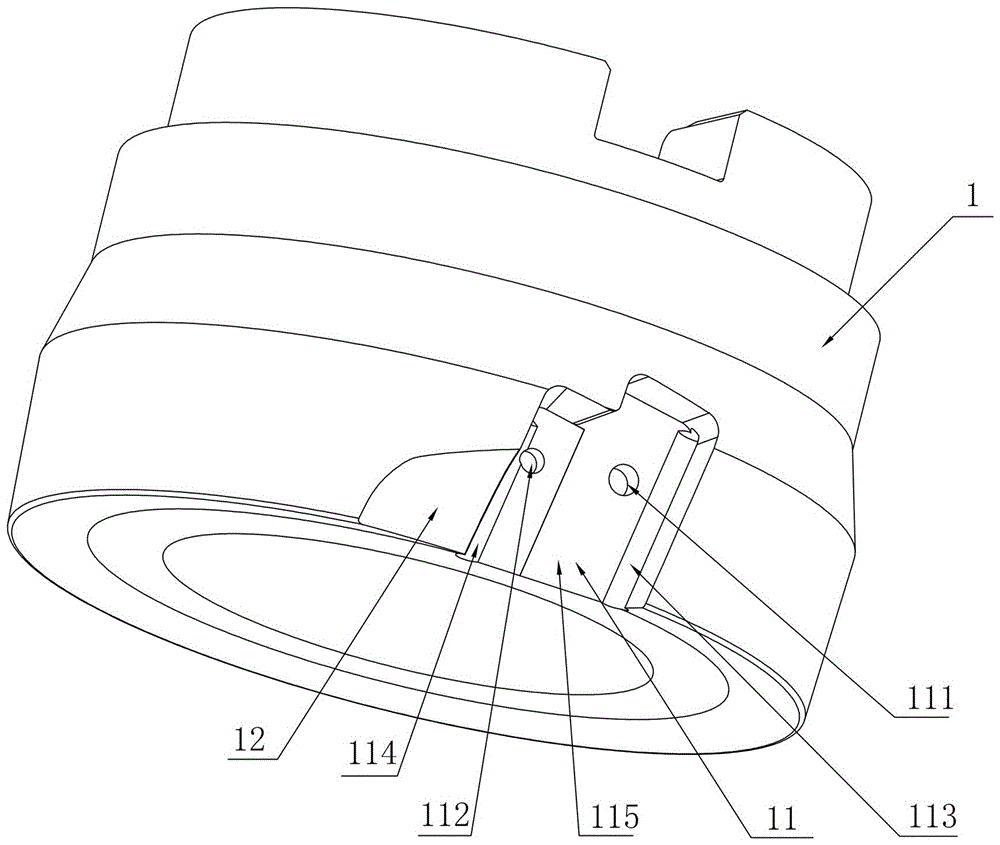

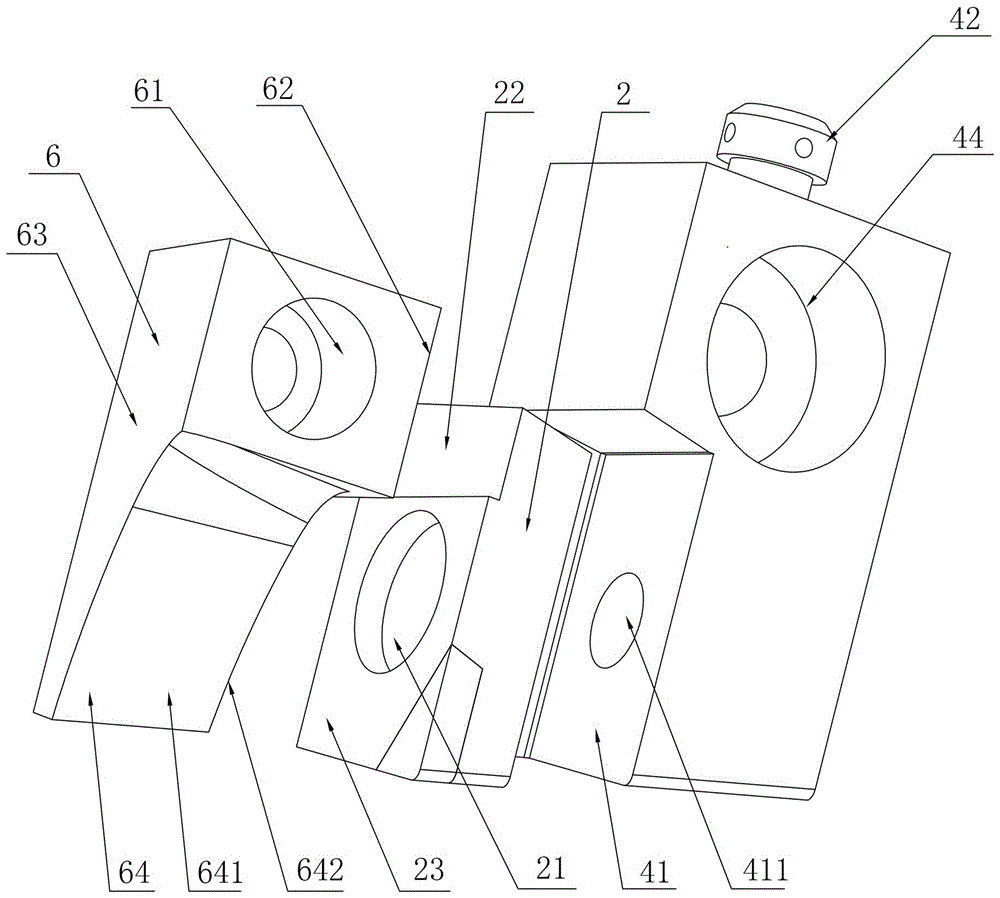

Cutting tool having fly-off prevention structure

The invention discloses a cutting tool having a fly-off prevention structure. The cutting tool having a tool body, a blade and a tool holder, the blade is installed on the tool holder, the tool body is provided with a tool slot, the tool holder is installed in the tool slot through a tool holder fastener, the front end of the tool slot is provided with a tool slot top surface along the cutting rotation direction of the cutting tool, one side of the blade facing the tool slot top surface is provided with a compaction inclined surface, a wedge is wedged between the tool slot top surface and the compaction inclined surface, and the wedge is connected with the tool slot through a wedge fastener. The cutting tool has the advantages of simple and compact structure, convenient processing and making, low production cost, convenient blade installing and dismounting, and good fly-off prevention effect.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

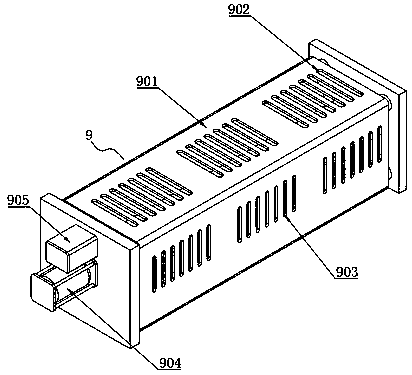

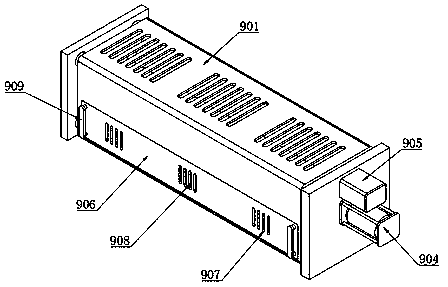

Efficient town sewage treatment and recycling device and process

PendingCN106116045AImprove mass transfer efficiencyEasy to handleWater treatment parameter controlWater/sewage treatment by irradiationSludgeSewage treatment

The invention discloses an efficient town sewage treatment and recycling device and process. The efficient town sewage treatment and recycling device comprises a device body and a remote environmental medicine expert diagnosis and control system, wherein the device body comprises three modules of a biochemical reaction module, a mud-water separation module and an equipment integration module; tank bodies of the biochemical reaction module and the mud-water separation module are communicated through partition water holes or overflow weir water holes; a water outlet pipe of a sedimentation tank is connected with an ultraviolet sterilizer in the equipment integration module; the biochemical reaction module comprises a pre-deoxidating mud film tank, a phosphorus-releasing mud film tank, a denitrifying phosphorus-accumulating mud film tank and an aerobiotic mud film tank which are communicated in sequence; a set of intermittent gas disturbance equipment is arranged at the bottom of the denitrifying phosphorus-accumulating mud film tank. According to the efficient town sewage treatment and recycling device and process, the short-flow phenomenon in the tanks is overcome, the microbial community structure distribution of the tanks is optimized, the function of the sedimentation tank is enhanced, the total nitrogen and total phosphorus treatment efficiency is higher, the gas-stripping energy consumption is low, the structure is compact, the occupied area is small, and the sludge floating phenomenon and the effluent suspended matter content can be significantly reduced.

Owner:HUAQI ENVIRONMENT PROTECTION SCI & TECH

Preparation method of elemental-copper-coated crystal whisker carbon nanotube/magnesium-based composite semisolid-state blank

ActiveCN106350753AReduce floating phenomenonReduce the chance of reunionLow speedMagnesium matrix composite

A preparation method of an elemental-copper-coated crystal whisker carbon nanotube / magnesium-based composite semisolid-state blank includes: preparing an elemental-copper-coated crystal whisker carbon nanotube; guiding aluminum alloy powder and the elemental-copper-coated crystal whisker carbon nanotube into a ball milling crucible, and performing ball milling treatment under protection of argon; putting mixed powder into the crucible, using a muffle furnace to heat to 20-40 DEG C below a solid-phase line, transferring into an ultrasonic magnetic stirring furnace, continuing heating, controlling solid-phase rate to a certain range, vibrating and stirring at a low speed, feeding argon for protection, and controlling stirring time; pouring obtained size into a corresponding die, and cooling to obtain the semisolid-state blank. The preparation method has the advantages of simplicity, safety, low cost, easiness in operation and controllability.

Owner:NANCHANG UNIV

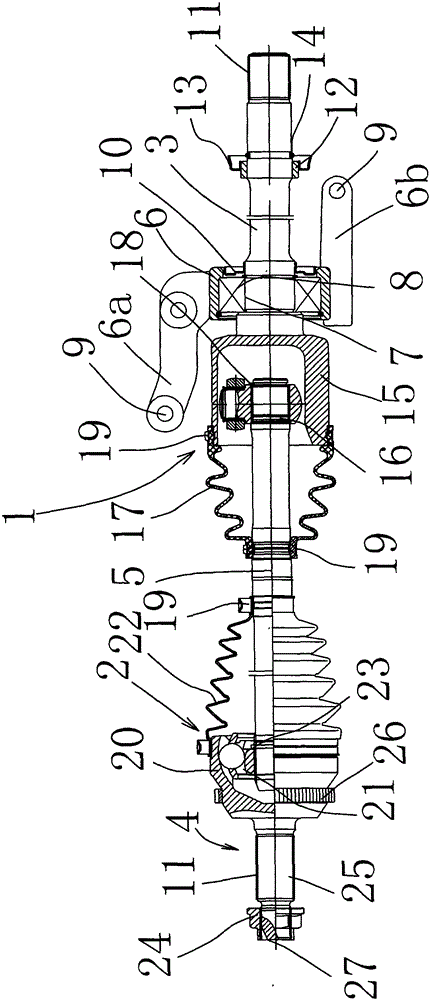

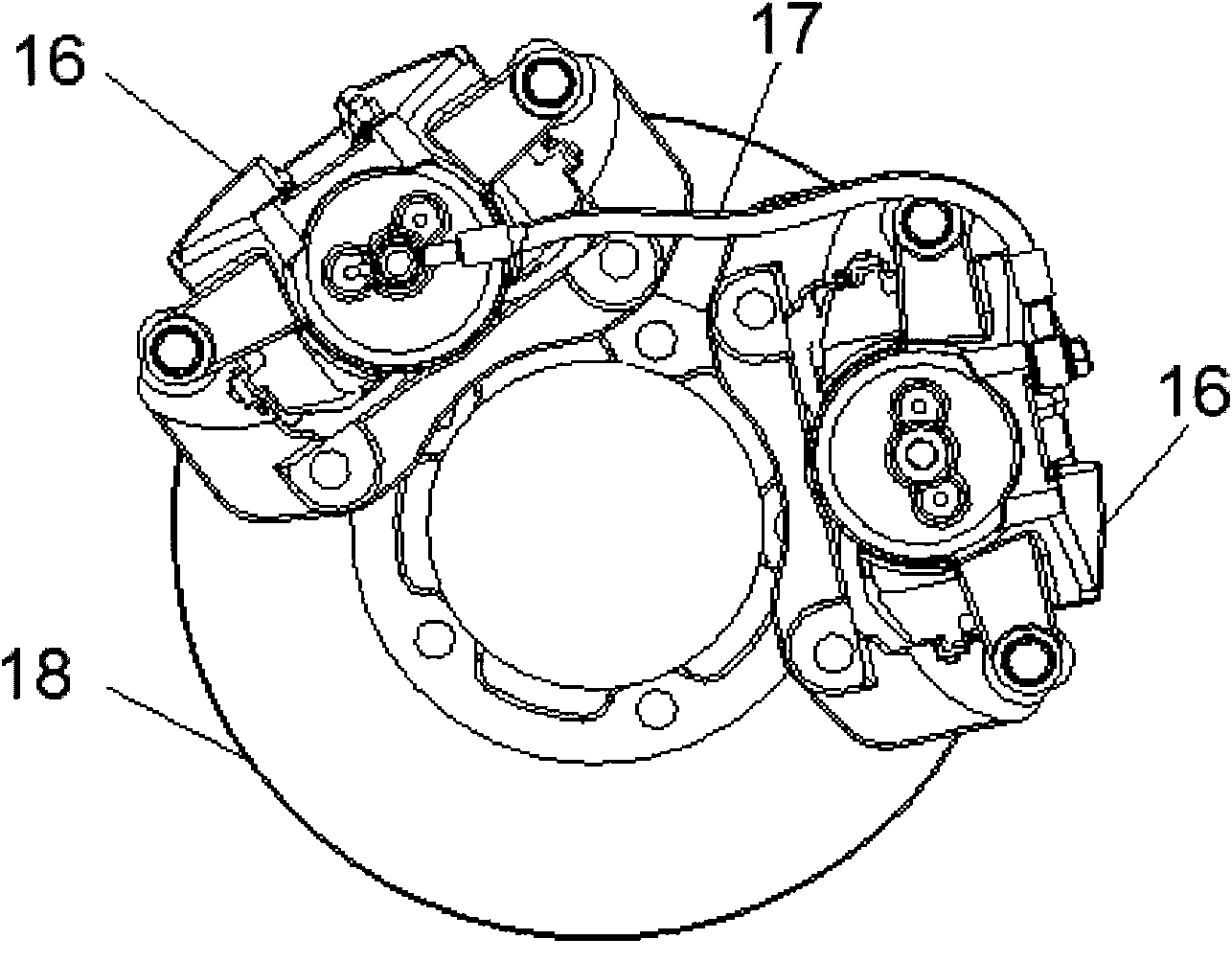

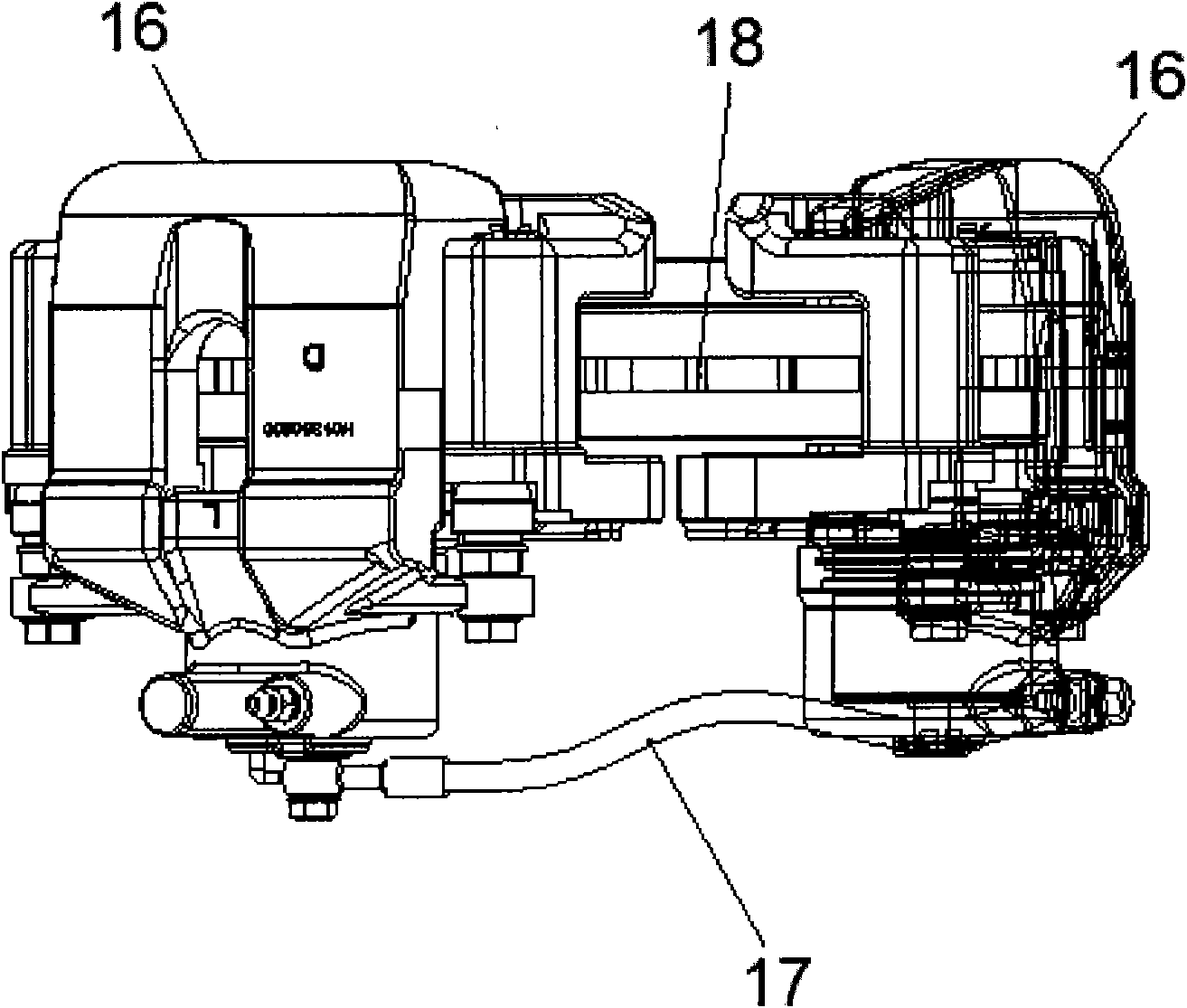

Drive axle assembly with fixed structure

InactiveCN103029575ASmooth rotationImprove stabilityYielding couplingControl devicesDrive shaftEngineering

The invention belongs to the technical field of vehicle drive accessories, and provides a drive axle assembly with a fixed structure, which comprises an inner constant velocity cardan joint, an outer constant velocity cardan joint, an input shaft, an output shaft and a transmission shaft, wherein the inner joint is mutually connected with the outer constant velocity cardan joint through the transmission shaft; the output shaft is connected onto the outer constant velocity cardan joint; the input shaft is connected onto the inner constant velocity cardan joint; a fixing connector is arranged on the input shaft; a holding hole is arranged between the fixing connector and the input shaft; a bearing is arranged in the holding hole; and a dust ring is arranged on an outer edge of a right end of the holding hole. The drive axle assembly with the fixed structure has the advantages that the fixing connector is added for being used on vehicle types with the requirements on high torsion and high strength, a lower part of the fixing connector is used as a bearing seat so as to protect the bearing in an installing hole, and the input shaft can be rotated conveniently; and simultaneously, a first extending part and a second extending part of the fixing connector can lock the input end, so that the shaking is reduced, and the stability of the input shaft during rotation is improved.

Owner:NINGBO V SHINE AUTO PARTS

Preparation method for crystal whisker carbon nano tubes coated with aluminum oxide/magnesium matrix composite semi-solid billets

The invention discloses a preparation method for crystal whisker carbon nano tubes coated with aluminum oxide / magnesium matrix composite semi-solid billets. The method includes the steps that the crystal whisker carbon nano tubes coated with magnesium oxide are prepared firstly, magnesium alloy powder and crystal whisker carbon nano tube materials coated with the magnesium oxide are guided into a ball-milling crucible, and ball-milling is carried out on the condition of argon shielding; mixed powder is placed into the crucible and heated to be lower than the solid phase line by 10-20 DEG C through a muffle furnace, and the temperature is preserved for 1-2 hours; then the mixed powder is shifted into an ultrasonic magnetic stirring furnace for being continuously heated, the solid rate of the mixed powder is controlled to be within a certain range, the mixed powder is stirred and dispersed at low speed under the synergistic effect of ultrasound and magnetic equipment, argon gas is guided into the ultrasonic magnetic stirring furnace for shielding, and the stirring time is controlled; and obtained slurry is poured into corresponding dies for being cooled to obtain the semi-solid billets. The method has the advantages of being simple, safe, low in cost, easy to operate and controllable.

Owner:NANCHANG UNIV

Efficient solid screw cleaning agent and preparation method thereof

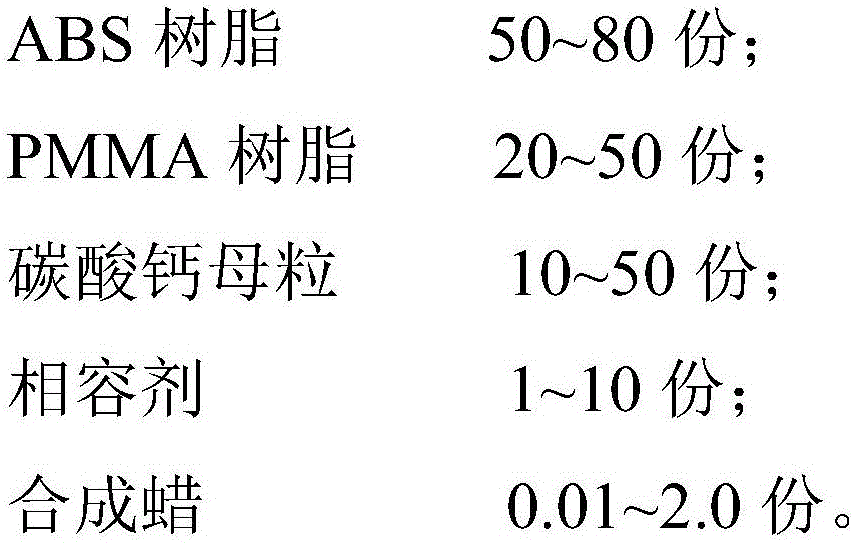

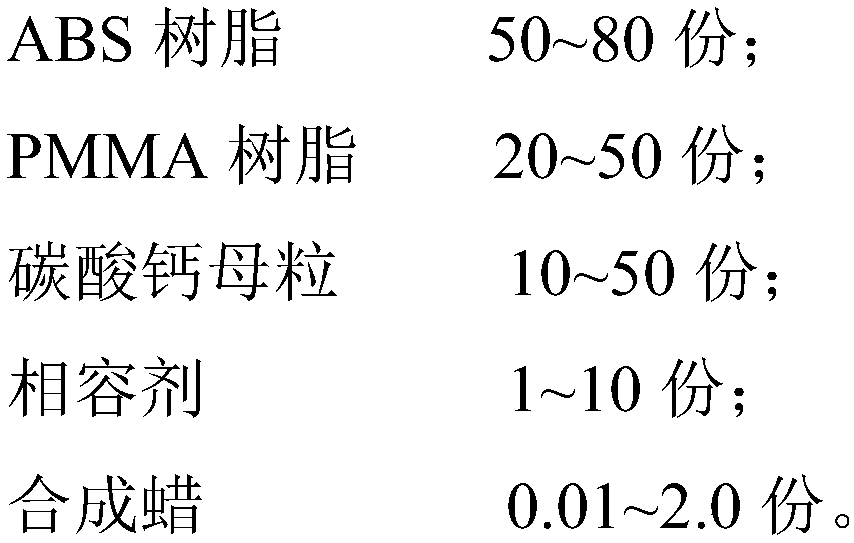

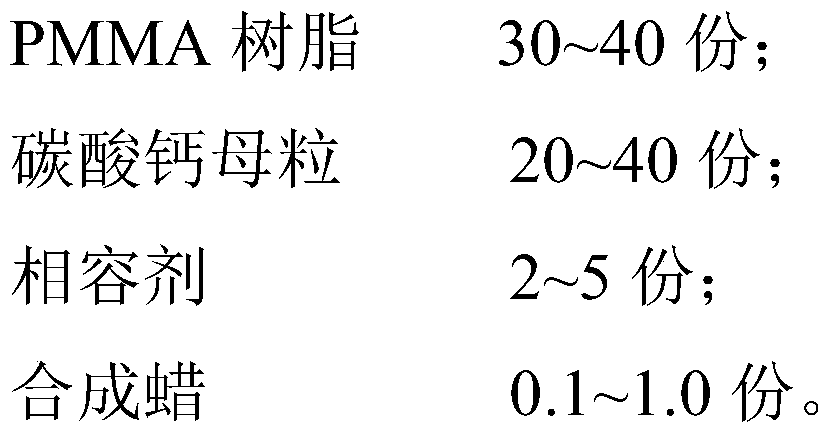

The invention discloses an efficient solid screw cleaning agent and a preparation method thereof. The efficient solid screw cleaning agent is prepared from ABS (acrylonitrile-butadiene-styrene) resin, PMMA (polymethyl methacrylate) resin, calcium carbonate masterbatch, a compatilizer and synthetic wax, wherein the cleaning capacity can be improved by means of the high-viscosity PMMA resin in the cleaning agent, compatibility between the ABS resin and the PMMA resin can be improved by means of the compatilizer, the abnormal phenomena of bar breakage and the like in an extruding granulation process are reduced, stabilization of production is facilitated, and the cleaning agent is discharged out of equipment by a follow-up material more easily during cleaning of the equipment; the capacity of the cleaning agent for cleaning residual substances can be improved by means of the synthetic wax; besides, inorganic powder is replaced with the calcium carbonate masterbatch, so that the phenomenon of powder floating is reduced, the production environment is improved, and harm of powder to the environment and the human body is reduced.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

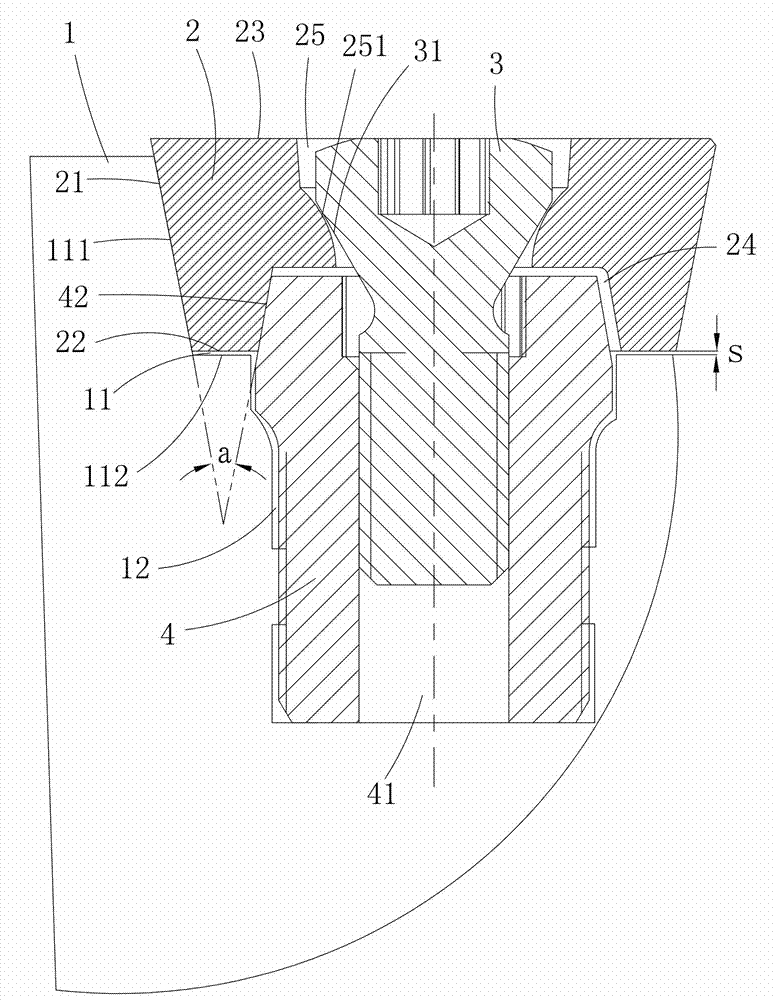

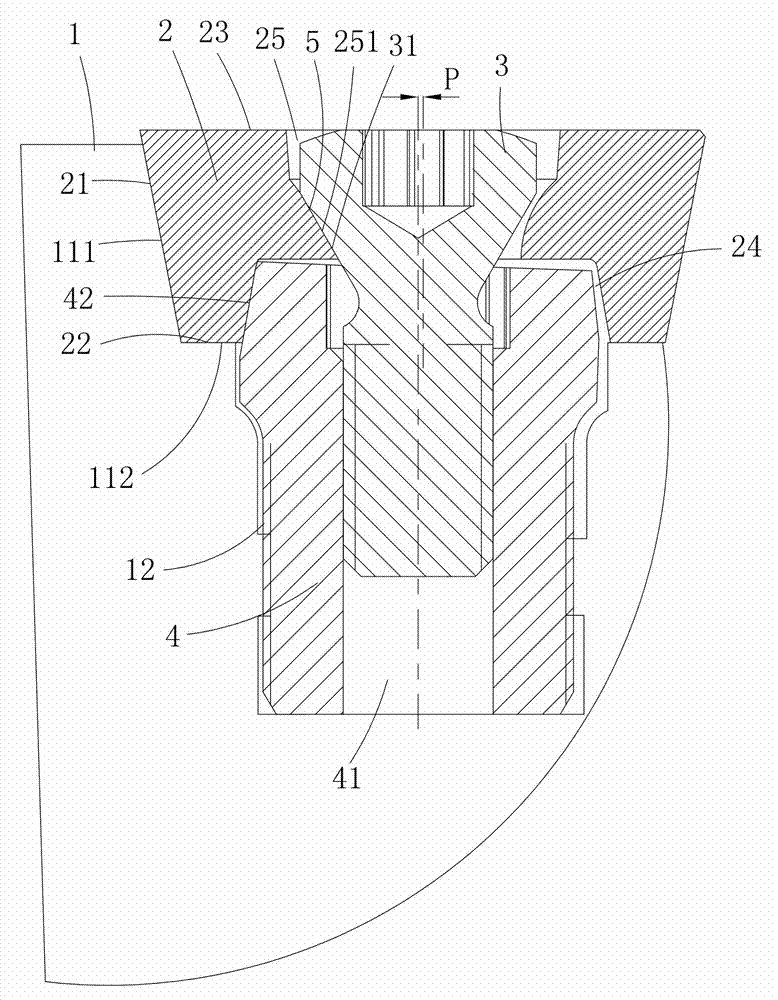

Cutting tool

ActiveCN102756137ASimple and compact anti-flying structureEasy to processTurning toolsTool holdersEngineeringMachining

The invention discloses a cutting tool, which comprises a body, a blade and a fastening screw, wherein the body is provided with at least one group of tool slots; each tool slot comprises a tool slot side face and a tool slot bottom surface; the tool slot bottom surface is provided with a positioning screw hole; an included angle between the tool slot side face and the tool slot bottom surface is an obtuse angle; a pin with an internal threaded hole is screwed in the positioning screw hole; the blade is sleeved on the head of the pin through a groove formed in a blade bottom surface and is connected with the pin through the fastening screw; when the fastening screw is not screwed up, the blade side face is contacted and matched with the tool slot side face; a pre-tightening gap S is remained between the blade bottom surface and the tool slot bottom surface; and when the fastening screw is screwed up, the blade slides to the blade bottom surface to be contacted and matched with the tool slot bottom surface along the tool slot side face, and the inner side wall of the groove is abutted against the head of the pin to produce elastic deformation so as to clamp the blade between the tool slot side face and the head of the pin. The cutting tool has the advantages of simple and compact structure, convenience in machining and manufacturing, low production cost, convenience in disassembly and the like.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

a kind of a 3 /o-mbbr integrated sewage treatment device and sewage treatment method

ActiveCN104445830BReduce floating phenomenonImprove precipitation effectTreatment using aerobic processesTreatment with anaerobic digestion processesMoving bed biofilm reactorSmall footprint

The invention relates to the technical field of sewage treatment and particularly relates to an A3 / O-MBBR (Moving Bed Biofilm Reactor) integrated sewage treatment device and an A3 / O-MBBR integrated sewage treatment method. According to the device provided by the invention, a sewage backflow mechanism, a nitrification liquor backflow mechanism and an anaerobic liquor backflow mechanism are arranged and suspended filler is filled in an aerobic tank, so that the integrated sewage treatment device has a good effect for treating nitrogen and phosphorus in sewage and is high in treatment efficiency, compact in structure and small in occupied area. In addition, by virtue of optimizing a settling pond structure in the integrated sewage treatment device, the settling effect of the settling pond is improved, and the sludge floatation phenomenon and the content of suspended solids in effluent can be remarkably reduced. After sewage is treated by the integrated sewage treatment device provided by the invention, the effluent can reach the level A of first class stand of pollution discharge standard for municipal sewage treatment plant (GB18918-2002).

Owner:YUNNAN HEXUN ENVIRONMENTAL TECH CO LTD

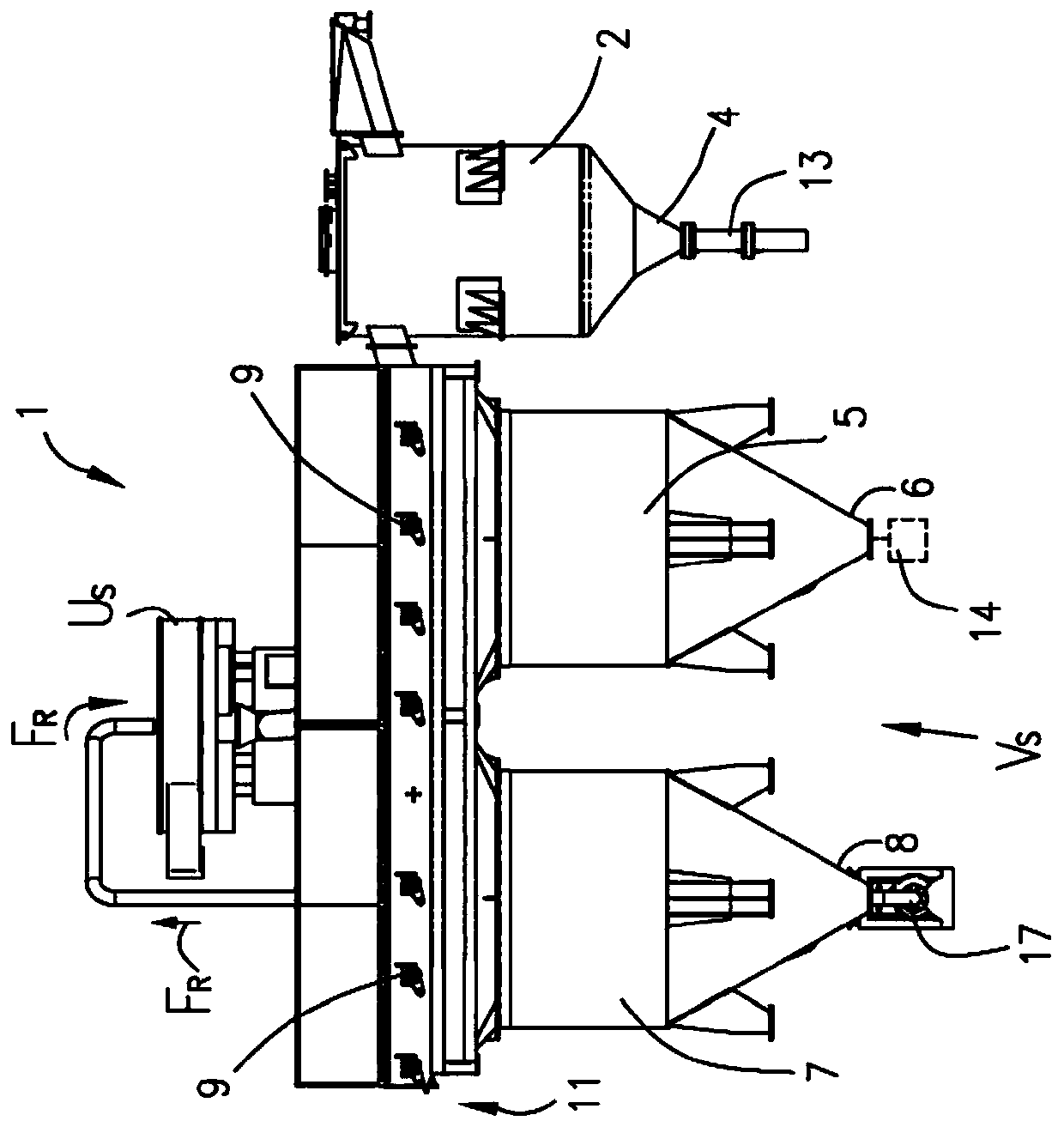

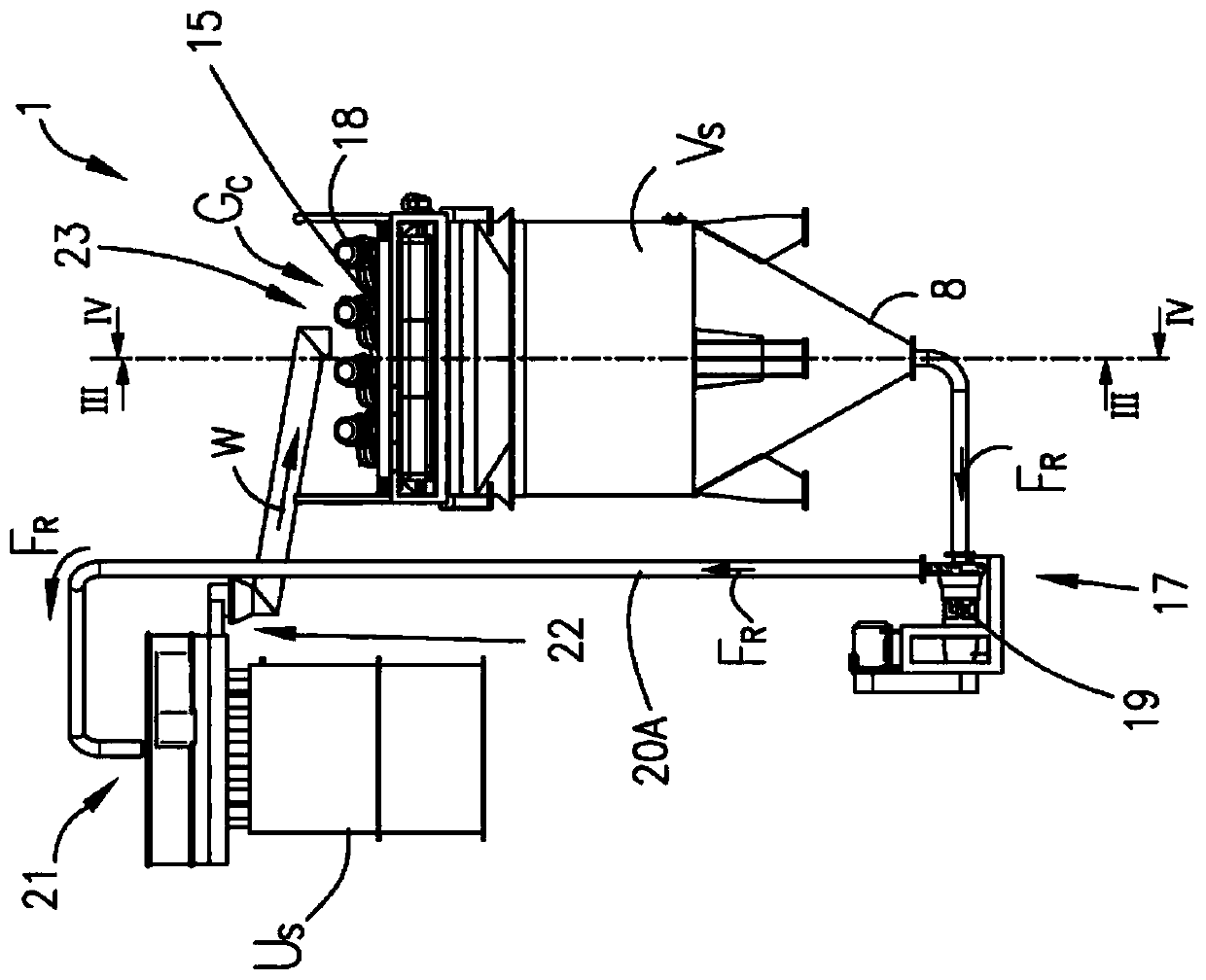

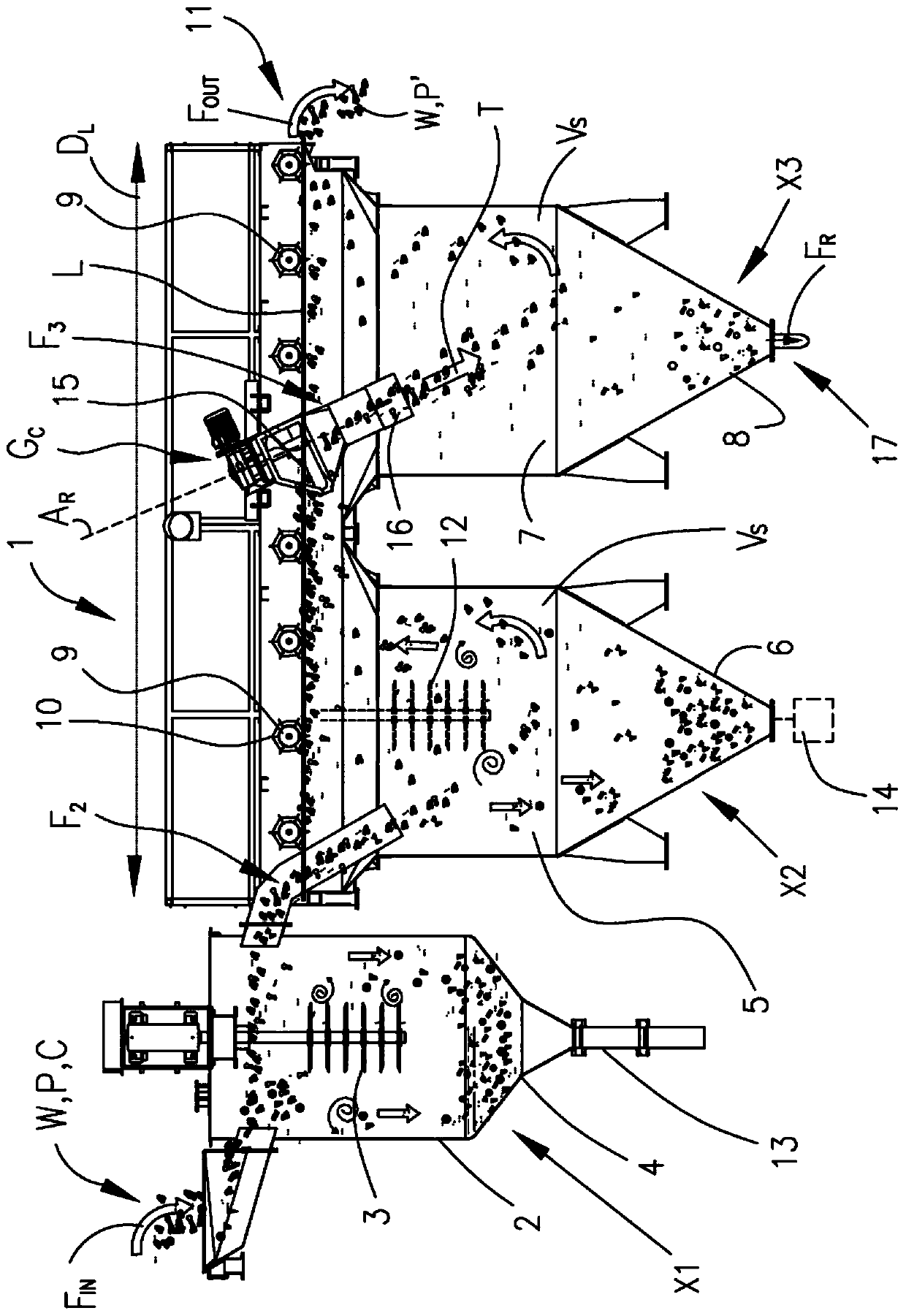

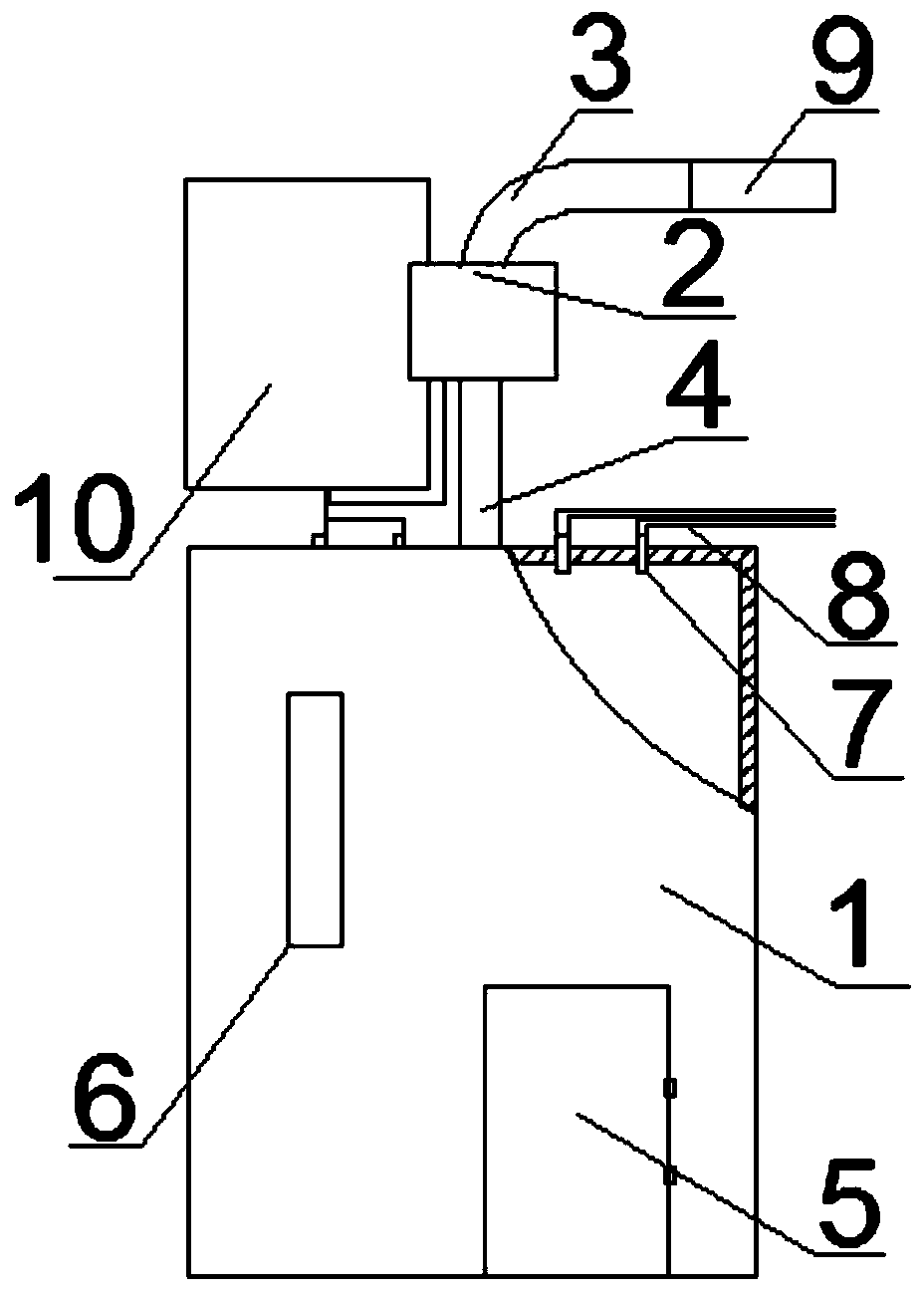

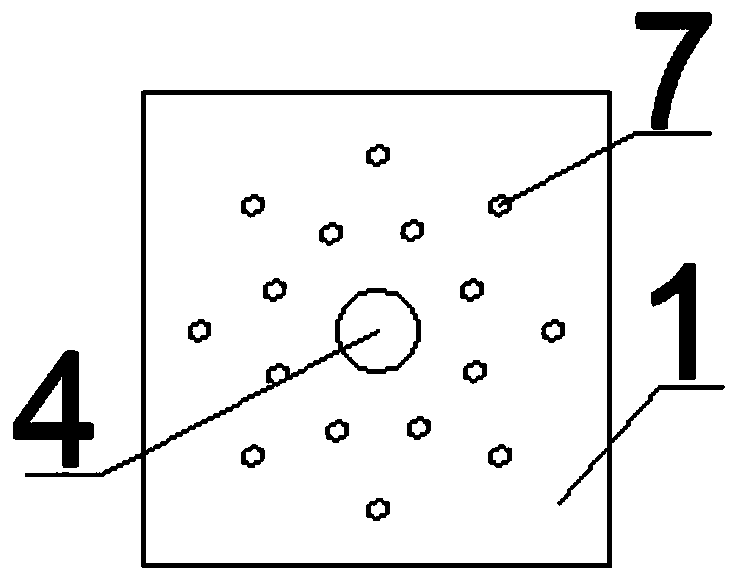

Method and apparatus for washing plastics materials

InactiveCN110114152ASolve the problem of floating conglomeratesEfficient separationPlastic recyclingFlat articlesEnvironmental engineeringPrecipitation

Method for washing a plastics material (P) and for separating contaminating substances (C) therefrom comprises the steps of: supplying a first flow (FIN) of a washing fluid (W) together with the plastics material (P) with contaminants (C) to a washing container (2) in which a stirrer (3) generates a turbulent action to detach mechanically the contaminants (C) adhering to the plastics material (P),enabling a first fraction (X1) of heavier contaminants (C) to precipitate onto a first bottom portion (4) of the container (2), thus performing a first action of separating contaminants (C); transferring a second flow (F2) of fluid (W) with floating plastics material (P) from the container (2) to a first separating chamber (5), in which a second separating action takes place with the precipitation of a second fraction (X2) of the contaminants (C) onto a second bottom portion (6) of the first chamber (5); conveying a third flow (F3) of fluid (W) with floating plastics material (P) from the first chamber (5) to a second separating chamber (7) and evacuating by overflowing an outgoing flow (Fout) of fluid (W) together with the processed plastics material (P'); in the transit from the first chamber (5) to the second chamber (7) the agglomerates of floating plastics (P) are disaggregated, and to the third flow (F3) and to the plastics material (P) a downward propelling action (T) inside the second chamber (7) is imparted to promote a third separating action with precipitation of a third fraction (X3) of the contaminants (C) onto a third bottom portion (8) of the second chamber (7); removing from the second chamber (7) a recirculation flow (FR) comprising precipitated fluid (W) and contaminants (C) and sending the recirculation flow (FR) to a screen unit (US) that retains the contaminants (C), returning the washing fluid (W) to the first (5) or second chamber (7). The apparatus for implementing the aforesaid method is also disclosed.

Owner:PREVIERO N

Tailing dust processing device and method for rice processing

InactiveCN110075952ASimple structureEasy to operateUsing liquid separation agentGrain treatmentsElectricityLivestock breeding

The invention discloses a tailing dust processing device for rice processing, comprising an electric cabinet, a bran discharging pipe, a collecting pipe, a collecting tank and a negative pressure pump; one end of the bran discharging pipe is connected with a bran outlet of a rice husking machine or a polishing machine, the other end of the bran discharging pipe is connected with the top end of thenegative pressure pump, the bottom end of the negative pressure pump is connected with the collecting pipe, the tail end of the collecting pipe is connected with the collecting tank, the collecting tank is of a cuboid structure, the top of the inner wall of the collecting tank is mounted with an atomizer, the front surface of the collecting tank is provided with a discharging hole and an observing hole, the negative pressure pump and the atomizer are both electrically connected with the electric cabinet. The invention further provides a tailing dust processing device for rice processing, wherein rice bran and dust generated through rice processing are collected into the collecting tank by the negative pressure pump and the collecting pipe, atomized water and fallen rice bran and dust arecombined through the atomizer, the rice bran and dust are quickly deposited, then are packaged and transported out of a workshop. The tailing dust processing device and method for rice processing aresimple in structure, convenient to operate, and can effectively reduce dust floating in the rice processing workshop; the rice bran and dust can be fully utilized for livestock breeding and farmland fertilization.

Owner:安徽晨阳粮油股份有限公司

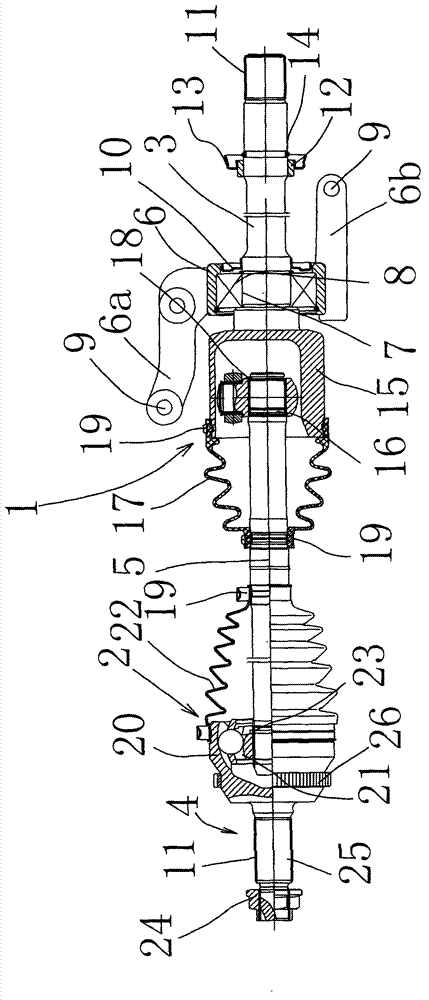

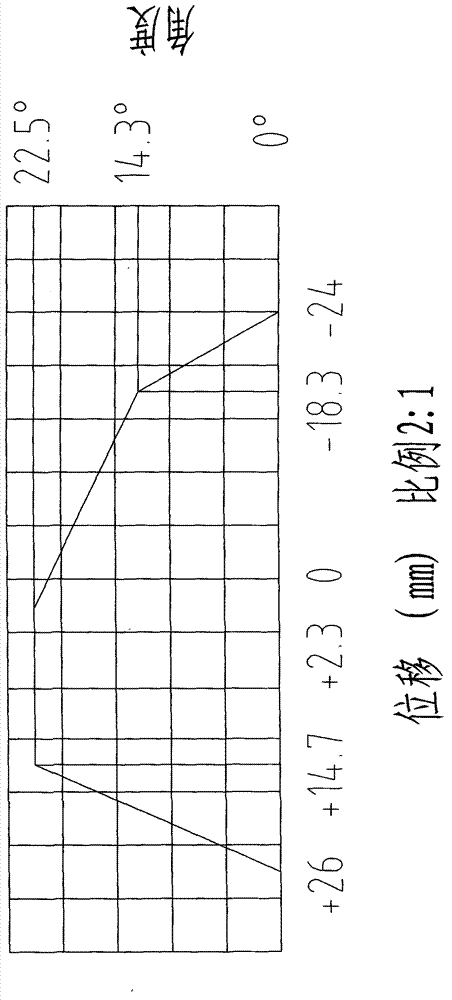

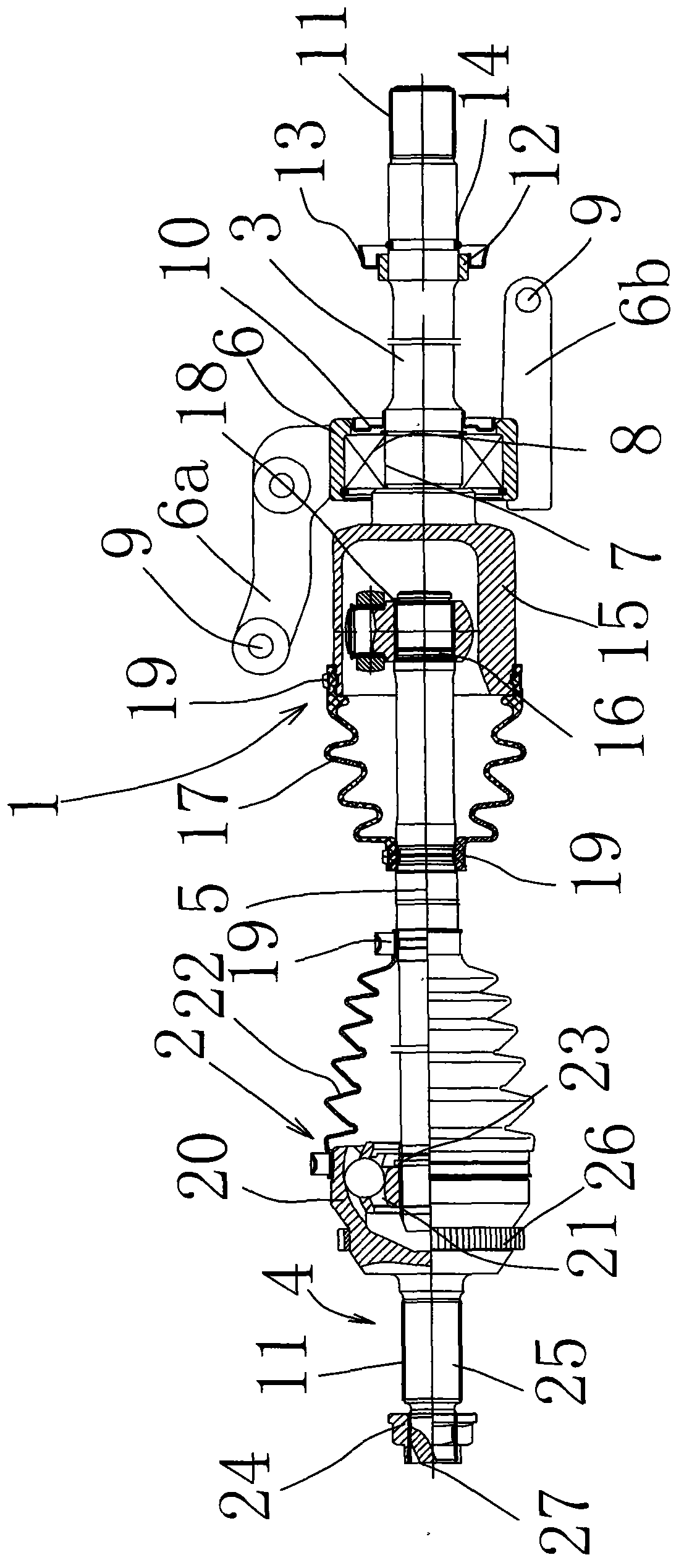

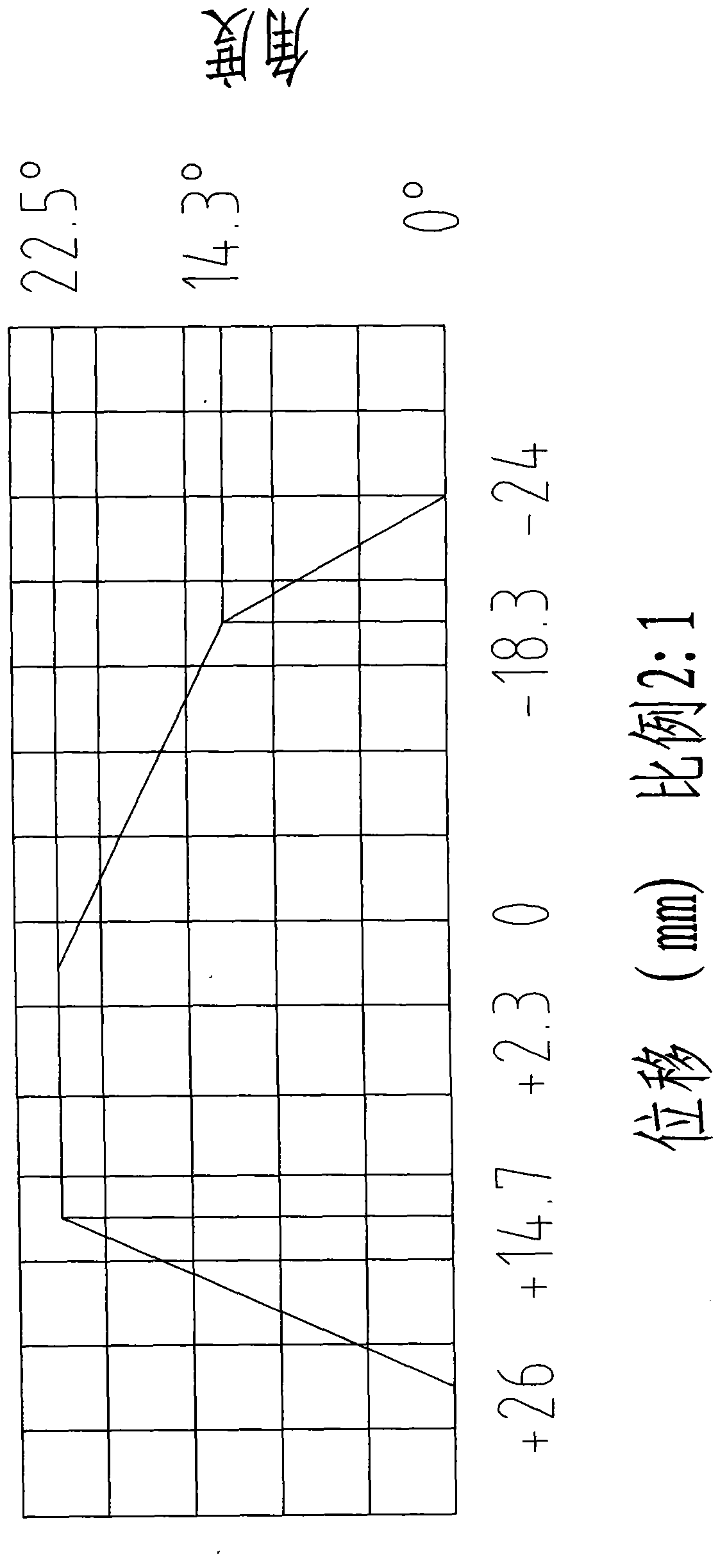

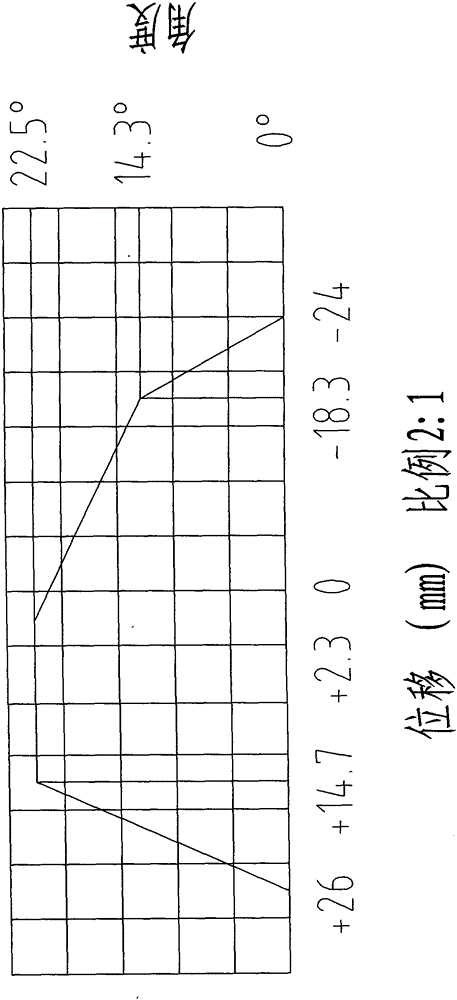

Input bending angle structure of driving axle assembly

The invention belongs to the technical field of automobile driving accessories, and provides an input bending angle structure of a driving axle assembly. The input bending angle structure comprises an inner ball cage, an outer ball cage, an input shaft, an output shaft and a transmission shaft, wherein the inner ball cage and the outer ball cage are connected with each other through the transmission shaft; the output shaft is connected to the outer ball cage; the input shaft is connected to the inner ball cage; a bending angle is formed along the connecting direction of the output shaft and a gear in an external gear-box; the angle control range of the bending angle is 14.3-22.5 degrees; and relative moving displacement is controlled between -18.3 millimeters and +14.7 millimeters. The invention has the advantages that the load carrying capability is improved through the bending angle, and the input bending angle structure is suitable for automobile types of high loads and high torques; moreover, the lower part of a fixed connecting frame is taken as a bearing base, so that a bearing in an installation hole is protected, and the input shaft can be rotated conveniently; and meanwhile, the fixed connecting frame can be used for locking the input end, so that shake is reduced, and the rotating stability of the input shaft is improved.

Owner:NINGBO V SHINE AUTO PARTS

Method for preparing high-strength anticorrosive plywood

InactiveCN111086068AImprove buffering effectImprove moisture resistancePlywood pressesWood treatment detailsCellulosePolymer science

The invention belongs to the technical field of plywood preparation, and particularly relates to a method for preparing a high-strength anticorrosive plywood. The method comprises the following stepsthat cellulose viscose and liquid paraffin are mixed, and then film-drawing is carried out to obtain a glue film; a composite fiber board and an anticorrosive wood board are bonded by using waterproofglue as an intermediate layer to prepare a unit board; then the waterproof glue is used for hot pressing; and then the surface is waxed to obtain the high-strength anticorrosive plywood. According tothe method for preparing the high-strength anticorrosive plywood, a sepiolite fiber sponge board is used as the composite fiber board, so that the adhesion performance of the plywood to the ground isimproved; a plastic EVA foam is used as a base material of the waterproof glue, so that the plywood has good buffering performance; methoxy is easy to hydrolyze, and is a mineral waterproof agent, sothat the moisture resistance of the plywood is improved; the EVA foam is soaked in lime water, so that the waterproof performance is improved; the liquid paraffin and the cellulose viscose are utilized to draw the film, so that the water absorption expansion and mildew of the plywood are avoided; and in addition, calcium carbonate can be formed by calcium oxide under the environment of water andcarbon dioxide, so that the strength of the plywood is improved, and the plywood has a wide application prospect.

Owner:杭州德问贸易有限公司

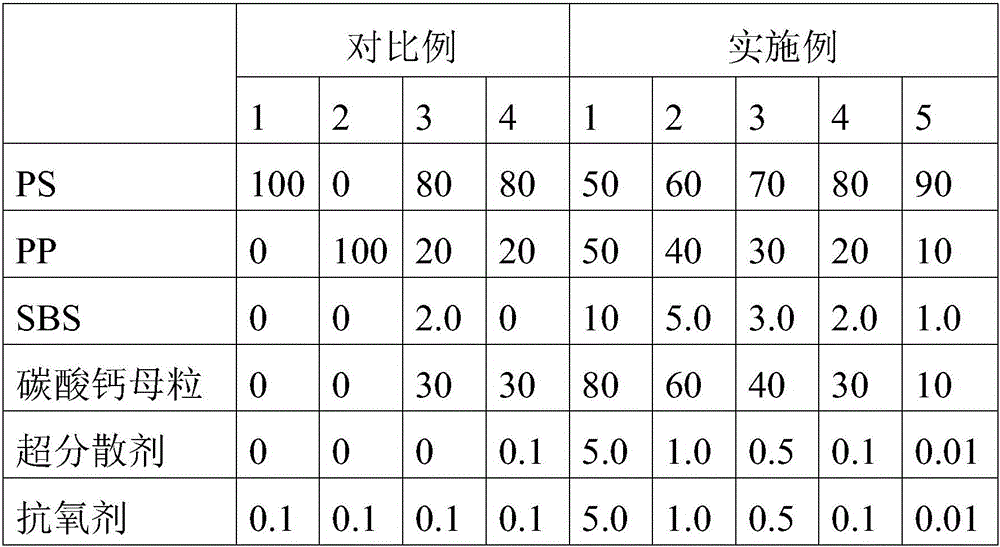

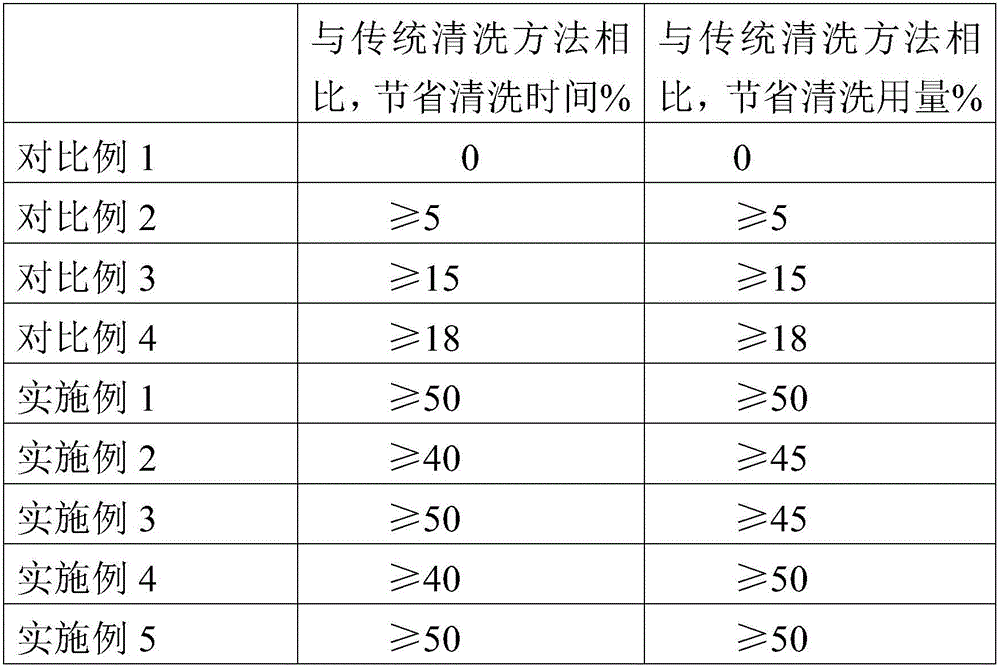

Cleanser for colored plastic processing equipment and preparation method for same

The invention discloses a cleanser for colored plastic processing equipment. The cleanser includes polystyrene resin, polypropylene resin, styrene-butadiene-styrene segmented copolymer resin, calcium carbonate master batches, a super-dispersant, and an antioxidant. In the invention, the calcium carbonate master batches are used instead of inorganic powder, so that powder floatation is reduced and production environment is improved, thereby reducing damage on environment and human body due to the powder. In addition, the styrene-butadiene-styrene segmented copolymer is used as a compatilizer for the polystyrene and the polypropylene, so that a problem of broken strips during extrusive granulation is reduced and production is easy to control. Finally, with addition of the super-dispersant, dispersion of pigment granules in residual batch products in the cleanser polymer is improved, so that emission speed of the residual pigment is increased. The cleanser is especially suitable for the colored plastic processing equipment.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

Efficient solid screw cleaning agent and preparation method thereof

The invention discloses an efficient solid screw cleaning agent and a preparation method thereof. The efficient solid screw cleaning agent is prepared from ABS (acrylonitrile-butadiene-styrene) resin, PMMA (polymethyl methacrylate) resin, calcium carbonate masterbatch, a compatilizer and synthetic wax, wherein the cleaning capacity can be improved by means of the high-viscosity PMMA resin in the cleaning agent, compatibility between the ABS resin and the PMMA resin can be improved by means of the compatilizer, the abnormal phenomena of bar breakage and the like in an extruding granulation process are reduced, stabilization of production is facilitated, and the cleaning agent is discharged out of equipment by a follow-up material more easily during cleaning of the equipment; the capacity of the cleaning agent for cleaning residual substances can be improved by means of the synthetic wax; besides, inorganic powder is replaced with the calcium carbonate masterbatch, so that the phenomenon of powder floating is reduced, the production environment is improved, and harm of powder to the environment and the human body is reduced.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

Sedimentation basin for mud-water separation and secondary sedimentation basin system

PendingCN109758796AAvoid enteringImprove mud discharge efficiencyTreatment using aerobic processesSettling tanks feed/dischargeDischarge efficiencyVertical projection

The invention provides a sedimentation basin for mud-water separation, and relates to the field of sewage treatment. The sedimentation basin comprises a basin body, which comprises an upper sedimentation area and a lower mud area, the lower mud area is arranged in a funnel shape, the bottom of the basin body is provided with a mud falling hole, an air-blocking plate is fixedly arranged on the lateral part of, below or above the mud falling hole, and the vertical projection of the mud falling hole falls on the air-blocking plate completely. The invention further relates to a secondary sedimentation basin system for the mud-water separation. The system comprises a sewage pool, an aeration device and the sedimentation basin for the mud-water separation. The sedimentation basin provided by theinvention can cause sludge to slide down automatically through the funnel-shaped lower mud area, the mud discharge efficiency is high, and a stable sedimentation area can form in the sedimentation basin through the air-blocking plate. The secondary sedimentation basin system provided by the invention can fully aerate the sludge at the bottom of the sewage pool, the sludge floating upward pheonomena are reduced, the water distribution requirement is low, the structure is simple, the use is convenient, and the operation is stable and reliable.

Owner:LIANYUNGANG DAYU WATER TREATMENT ENG CO LTD

A cutting tool with anti-flying structure

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

An input angle structure of drive axle assembly

The invention belongs to the technical field of automobile driving accessories, and provides an input bending angle structure of a driving axle assembly. The input bending angle structure comprises an inner ball cage, an outer ball cage, an input shaft, an output shaft and a transmission shaft, wherein the inner ball cage and the outer ball cage are connected with each other through the transmission shaft; the output shaft is connected to the outer ball cage; the input shaft is connected to the inner ball cage; a bending angle is formed along the connecting direction of the output shaft and a gear in an external gear-box; the angle control range of the bending angle is 14.3-22.5 degrees; and relative moving displacement is controlled between -18.3 millimeters and +14.7 millimeters. The invention has the advantages that the load carrying capability is improved through the bending angle, and the input bending angle structure is suitable for automobile types of high loads and high torques; moreover, the lower part of a fixed connecting frame is taken as a bearing base, so that a bearing in an installation hole is protected, and the input shaft can be rotated conveniently; and meanwhile, the fixed connecting frame can be used for locking the input end, so that shake is reduced, and the rotating stability of the input shaft is improved.

Owner:NINGBO V SHINE AUTO PARTS

Preparation method of elemental copper-clad multi-wall carbon nanotube/aluminum matrix composite semi-solid billet

A method for preparing a single-copper-coated multi-walled carbon nanotube / aluminum-based composite material semi-solid blank. Firstly, a multi-walled carbon nanotube coated with simple copper is prepared, and then aluminum alloy powder and simple copper-coated multi-walled carbon nanotubes are prepared. The tube was introduced into a ball milling crucible, and ball milled under the protection of argon. Finally, put the mixed powder into the crucible, heat it to 20-40°C below the solidus with a horse boiling furnace, then transfer it to an ultrasonic magnetic stirring furnace to continue heating and control its solid phase ratio within a certain range, oscillate and stir at a low speed and pass in argon protection And control the stirring time. The obtained slurry is poured into the corresponding mold to cool, and a semi-solid billet is obtained. The preparation technology disclosed in the invention has the advantages of simplicity, safety, low cost, easy operation, controllability and the like.

Owner:NANCHANG UNIV

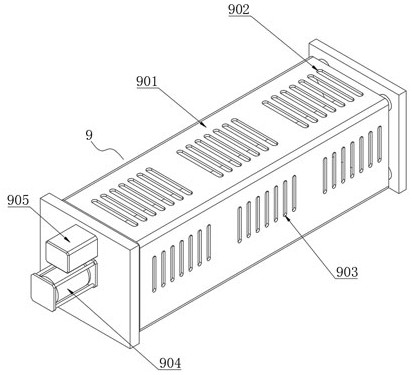

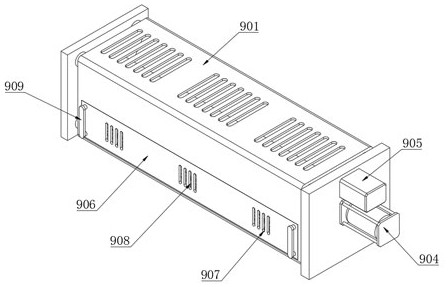

Floating fiber filtering mechanism and warp knitting machine using same

ActiveCN111118728AScientific and reasonable structureEasy to useWarp knittingFiberElectric machinery

The invention discloses a floating fiber filtering mechanism and a warp knitting machine using the same. The fiber filtering mechanism comprises a fiber filtering cabin mounted on the inner wall of one end of a warp knitting machine frame; top air inlet holes are uniformly formed in the top end of the fiber filtering cabin; side air inlet holes are uniformly formed in one end of the fiber filtering cabin; one end of the fiber filtering cabin is connected with a driving motor; an electrostatic generator is connected to a position, corresponding to the upper side of the driving motor, of one endof the fiber filtering cabin; a disassembling cover is mounted in the other end of the fiber filtering bin in an embedding mode; air outlet holes are uniformly formed in one end of the disassemblingcover; exhaust fans are uniformly connected to positions, corresponding to the air outlet holes, of the inner wall of one end of the disassembling cover; and disassembling handles are symmetrically mounted at one end of the disassembling cover. By virtue of the fiber filtering mechanism, the problem of influence to health of a worker caused by that the worker inhales too much floating fibers easily due to the phenomenon of fiber floating easily generated in yarn warping in the background technology can be solved effectively.

Owner:FUJIAN XIN GANG TEXTILE MACHINERY

Braking system of light truck

InactiveCN102398584BReduce floating phenomenonReduce operating frequencyBraking element arrangementsFluid braking transmissionBrake torqueButterfly valve

The invention discloses a braking system of a light truck. The braking system comprises a service braking unit, a parking braking unit and an exhaust aid braking unit, wherein the exhaust aid braking unit comprises a vacuum pump, a vacuum electromagnetic valve and a vacuum tank which are connected with an outlet pipeline of the vacuum pump, and an exhaust butterfly valve connected with the vacuum electromagnetic valve; the vacuum pump is arranged on an engine; and the exhaust butterfly valve is arranged on an exhaust pipe. By applying the exhaust aid braking unit, when the truck runs in a long downgrade section, the working frequency of the service braking system can be reduced, abrasion and consumption of a service braking system material and abrasion of tyres due to braking are reduced, and braking deviation is reduced; by using an anti-skid brake system (ABS), the truck can effectively avoid the locked working conditions of the front and rear wheels under various working conditions; and by using front and rear bridge disc type brakes, the risk that the braking torque greatly declines can be avoided when the brake is overheated and soaked into water, so that the braking stability is effectively improved.

Owner:陈言平

Self-insulating wall ceramsite concrete and preparation method thereof

The invention discloses self-insulation-wall ceramsite concrete. The self-insulation-wall ceramsite concrete comprises, by weight, 300-750 parts of ceramsite, 250-500 parts of cement, 50-200 parts of coal ash, 400-800 parts of sand, 120-150 parts of water, 1-3 parts of a polycarboxylate superplasticizer and 1-3 parts of fiber; the ceramsite is treated with pretreatment pulp which is (4-7):4:(3-6) in mass ratio of cement to coal ash to water. The invention further discloses a preparation method of the self-insulation-wall ceramsite concrete. The preparation method mainly includes pretreatment of the ceramsite, mixing and dry stirring of the pretreated ceramsite, sand and fiber and mixing and stirring by adding residual cement, water, coal ash and polycarboxylate superplasticizer. Through pretreatment of the ceramsite, water absorption of the ceramsite is lowered, workability of the concrete is improved, strength of the ceramsite is improved, concrete strength of the creamsite is further improved, optional scope of the creamsite is enlarged, and the ceramsite with small bulk density and good insulation property can be selected.

Owner:NINGBO PRECA CONSTR TECH CO LTD

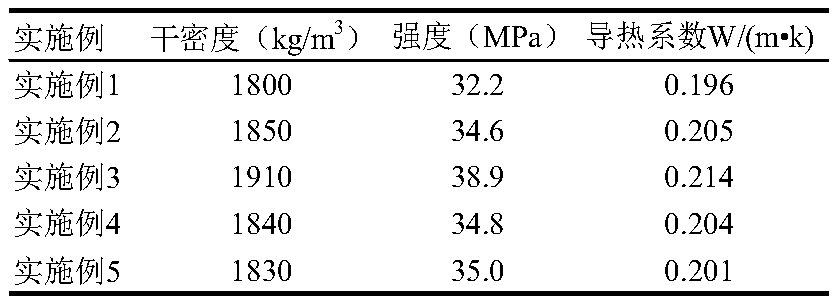

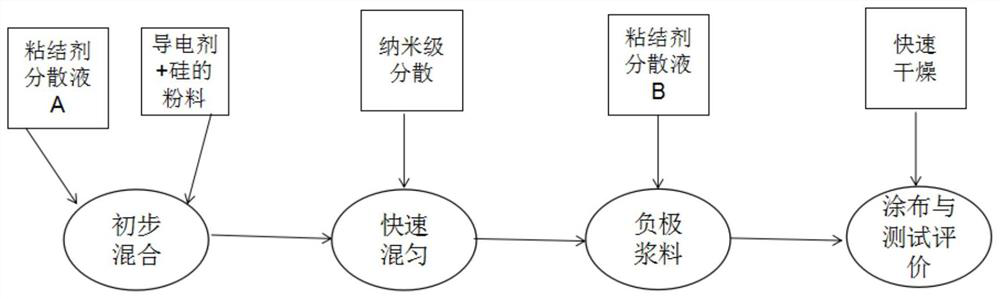

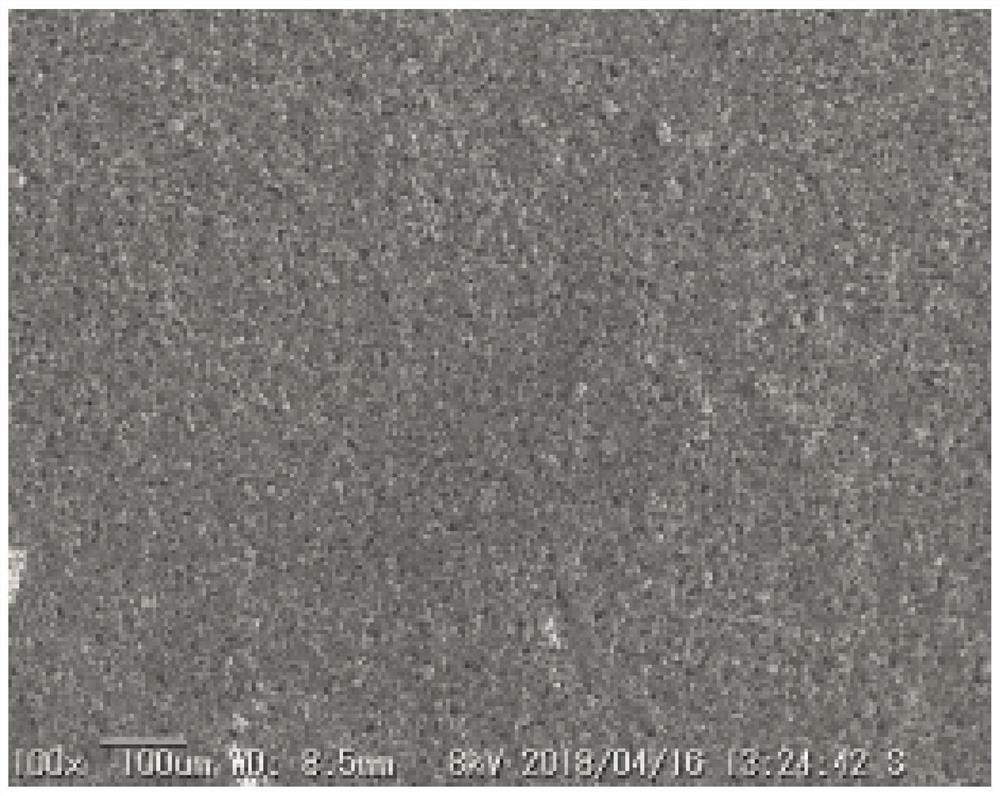

Rapid evaluation method for electrochemical performance of silicon negative electrode material

PendingCN111948542AFast analysis and evaluationAccurate and fast analytical evaluationMaterial nanotechnologyMaterial analysis using wave/particle radiationButton batteryPole piece

The invention discloses a method for quickly evaluating the electrochemical performance of a silicon negative electrode material, which comprises the following steps: adding silicon powder and a conductive agent into a binder A, and carrying out nanoscale dispersion to obtain slurry A; adding a surface functionalized binder B into the slurry A, and uniformly mixing to obtain slurry B; coating theslurry B on the surface of a copper current collector, performing drying, and performing punching to obtain a pole piece; and assembling the pole pieces into a CR series button cell, and carrying outevaluation test. Compared with the prior art, the method provided by the invention has the beneficial effects that the electrochemical performance of the silicon negative electrode material is accurately and quickly analyzed and evaluated mainly through the design of a nano-dispersion process of silicon particles, the matching of a surface functionalized binder, the quick drying of a pole piece and other process designs.

Owner:BAOSHAN IRON & STEEL CO LTD

A kind of warp knitting machine with floating fiber filter mechanism

The invention discloses a warp knitting machine with a floating fiber filter mechanism. The fiber filter mechanism includes a fiber filter bin installed on the inner wall of one end of the warp knitting frame. The top of the fiber filter bin is evenly opened with a top Air intake holes, one end of the fiber filter bin is uniformly provided with side air inlet holes, one end of the fiber filter bin is connected to a drive motor, and one end of the fiber filter bin is connected to an electrostatic generator at a position corresponding to the position above the drive motor, The other end of the fiber filter chamber is embedded with a dismounting cover, and one end of the dismounting cover is uniformly provided with an air outlet, and an exhaust fan is evenly connected to the inner wall of one end of the dismounting cover corresponding to the position of the air outlet. One end is symmetrically installed with a dismounting handle, which effectively solves the problem that the fibers are prone to float during warp knitting in the above-mentioned background technology, which may cause workers to inhale too much floating fibers and affect the health of the workers.

Owner:FUJIAN XIN GANG TEXTILE MACHINERY

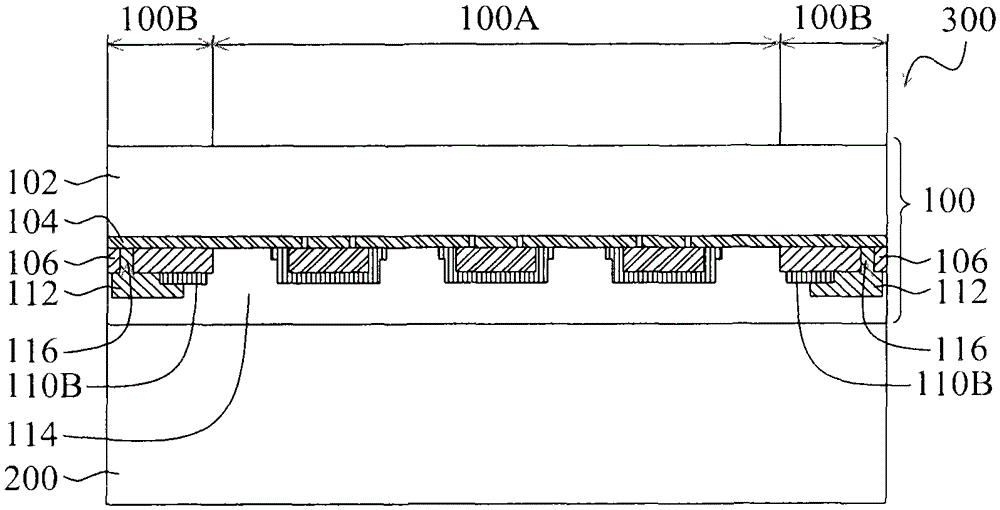

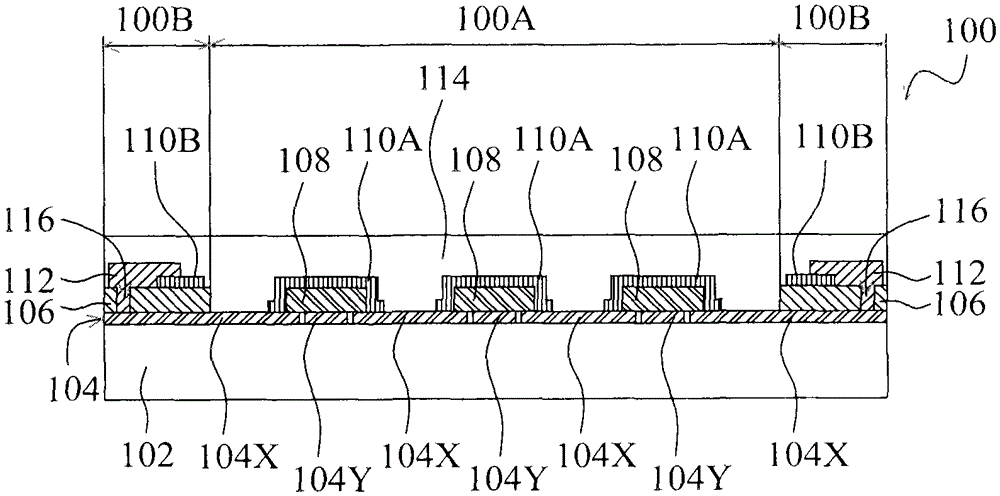

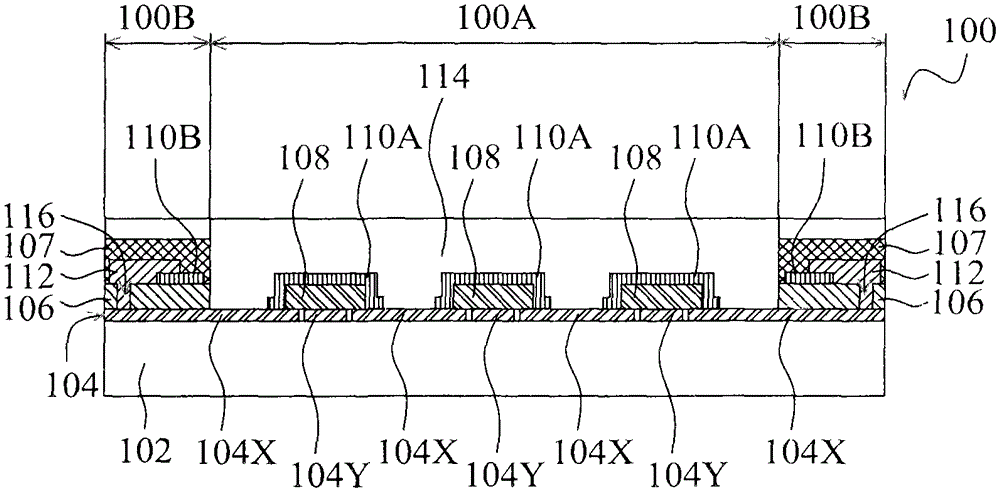

Touch device and manufacturing method thereof

ActiveCN103049121BReduce the floating phenomenon of resistance valueReduce floating phenomenonInput/output processes for data processingElectrodeTransmission line

The present disclosure relates to a touch technology, and more particularly to a touch device and a fabrication method thereof. The touch device comprises a sensing area and a peripheral area. The touch device further comprises a sensing electrode layer, a shading layer, a signal transmission line layer, and a conductive layer. The sensing electrode layer extends from the sensing area to the peripheral area. The shading layer is disposed on the peripheral area to overlay the sensing electrode layer and has a through hole to expose a portion of the sensing electrode layer. The signal transmission line layer is disposed on the shading layer and does not cover the through hole. The conductive layer fills the through hole and electrically connects the sensing electrode layer. In addition, a fabrication, method of a touch device is also provided.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com