Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "No reduction in mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-glare flame-retardant polycarbonate material, and preparation method and application thereof

The invention discloses an anti-glare flame-retardant polycarbonate material which comprises the following components by weight percent: 85-95 percent of polycarbonate, 2-12 percent of flame retardant, 0.1-1 percent of flame-retardant synergist, 0.1-5 percent of anti-glare agent, 0.3-2 percent of anti-ultraviolet agent, 0.05-3 percent of blue light absorbent, 0.2-3 percent of antioxidant and 0.2-2 percent of lubricating agent. The anti-glare flame-retardant polycarbonate material not only has an excellent anti-glare function, but also has higher light transmittance, and is capable of absorbing the blue wave band of the LED lighting spectrum at the same time. The invention further discloses a preparation method of the anti-glare flame-retardant polycarbonate material, which comprises the following steps: firstly preparing flame-retardant masterbatches, organic silicon microbead anti-glare masterbatches and blue light absorption masterbatches, and then preparing the anti-glare flame-retardant polycarbonate material, so that the performance anti-glare flame-retardant polycarbonate material is improved. The anti-glare flame-retardant polycarbonate material is particularly suitable for preparing an optical housing for LED lighting.

Owner:CGN JUNER NEW MATERIALS +1

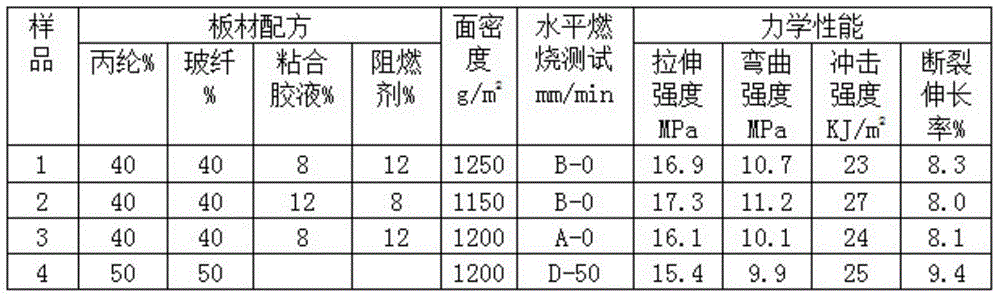

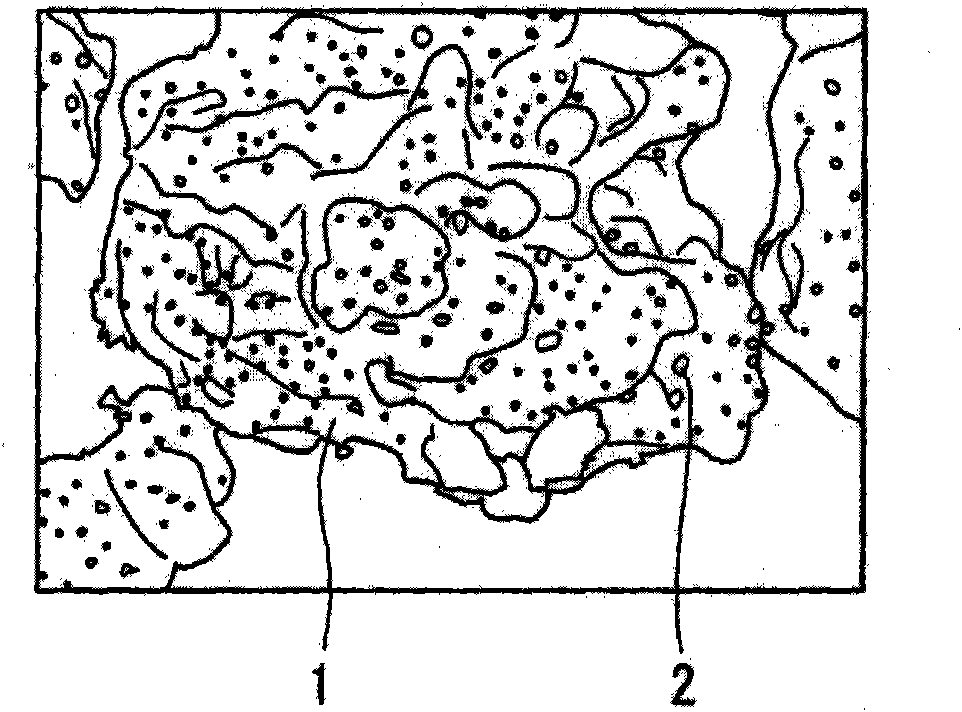

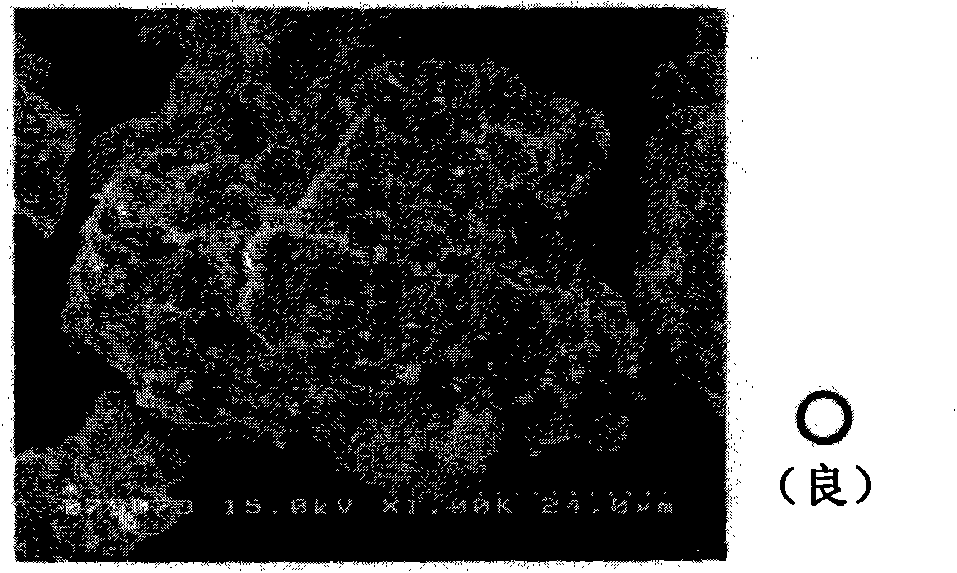

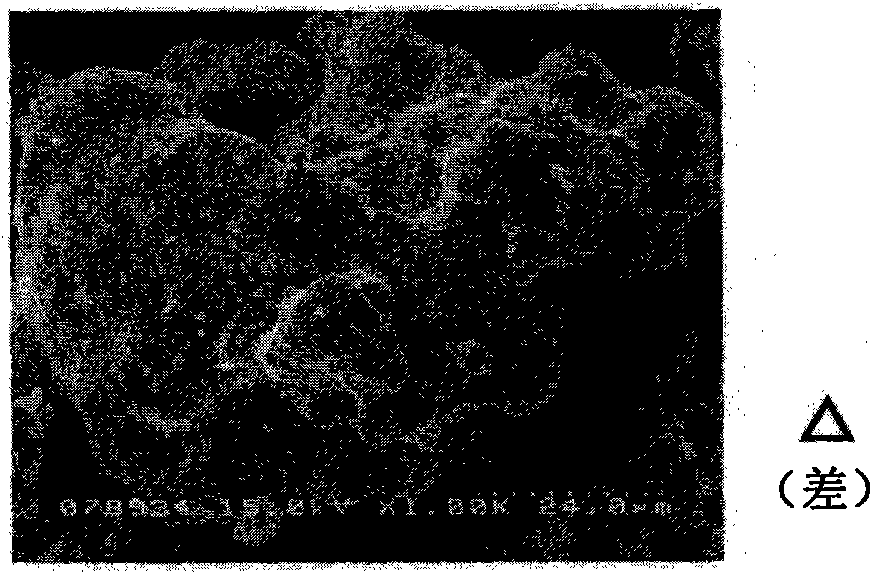

Formula and preparation technology of light fiber-reinforced thermoplastic resin composite sheet material with high flame resistance

ActiveCN103950251AImprove mechanical propertiesImprove flame retardant performanceSynthetic resin layered productsLaminationHigh resistanceFree falling

The invention discloses a formula and a preparation technology of a light fiber-reinforced thermoplastic resin composite sheet material with high flame resistance. The sheet material is composed of, 30-50% of reinforced fiber, 30-50% of thermoplastic resin fiber, 5-15% of halogen-free fire retardant powder and 5-15% of a bonding glue solution. The preparation technology comprises: weighing reinforced fiber and thermoplastic resin fiber according to the ratio, and performing preliminary mixing; utilizing a blower fan to convey reinforced fiber and thermoplastic fiber to a cotton storage bin; and utilizing the effect of free fall to enable fiber to be mixed fully, dispersed uniformly and the like. The light fiber-reinforced thermoplastic resin composite sheet material with high flame resistance has the advantages of simple production technology, low cost, excellent flame resistance and no obvious reduction on mechanical properties, is extremely applicable to fields of automotive trims, building decoration and the like, and has great practical value.

Owner:浙江华江科技股份有限公司

Method for differential arc oxidation treatment of Nickel-titanium alloy for medical purpose

InactiveCN101063221ANo reduction in mechanical propertiesSmall mechanical propertiesSurgerySurface reaction electrolytic coatingPlasma electrolytic oxidationMicro arc oxidation

The invention discloses a method of medical nickel titanium alloy differential arc oxidation treatment, which comprises the following steps: (1) pre-treating surface; (2) putting into hydraulic fluid; choosing NiTi ally as positive pole and loading trough as negative pole; treating; (3)washing; drying; getting the product. This invention possesses simple method, which can inhibit discharging of Ni ion in nickel titanium alloy and reinforce safety.

Owner:HARBIN INST OF TECH

Iron based powder for powder metallurgy

ActiveCN101896299AImprove liquidityNo reduction in mechanical propertiesMetal-working apparatusThin material handlingIron powderIron based

An iron based powder for powder metallurgy that can be molded while ensuring high fluidity, uniform filling in thin cavity and high withdrawal force can be provided by adhering fluidity improving particles via a binder onto the surface of iron powder.

Owner:JFE STEEL CORP

PC/ABS material composition for relieving yellow discoloration

ActiveCN101759979AReduce color differenceMeet the requirements of color differenceYELLOW DYEPolycarbonate

The invention discloses a PC / ABS material composition for relieving the yellow discoloration, which is prepared from the following ingredients in percentage by weight: 10 to 60 parts of acrylonitrile-butadiene-styrene graft copolymers, 30 to 85 parts of polycarbonate, 0 to 10 parts of acrylics graft rubber, 0.25 to 0.88 parts of coloring agents, 0 to 1 part of antioxidizers and 0 to 1 part of light stabilizers. Yellow dyes without light illumination resistance performance exist in a dye system, and the dyes can not influence the whole coloring process of plastics in the plastic coloring process, but in the light illumination process, the dyes gradually fade, the PC / ABS materials carry out yellow discoloration in the light illumination process, so the two mutually inconsistent processes have the mutual counteraction effect, and the color aberration of the whole PC / ABS composition is reduced after the light illumination. At the same time, the mechanical property of the composition material is not obviously reduced.

Owner:CHONGQNG PRET NEW MATERIAL +2

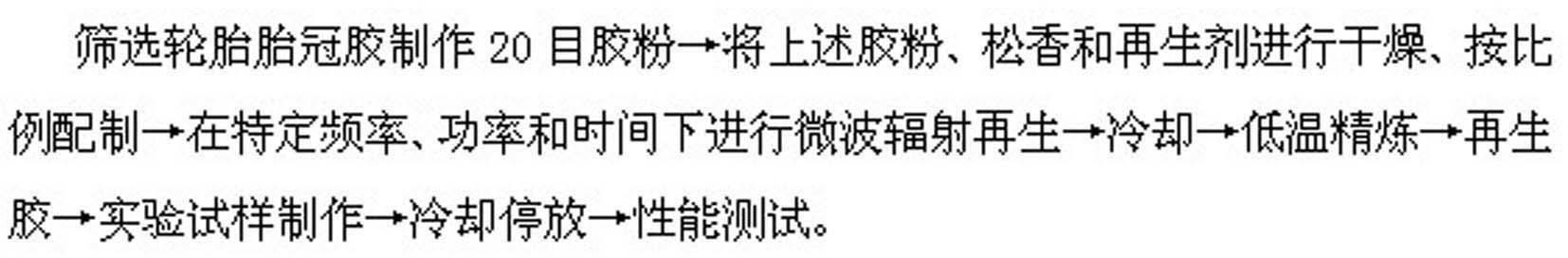

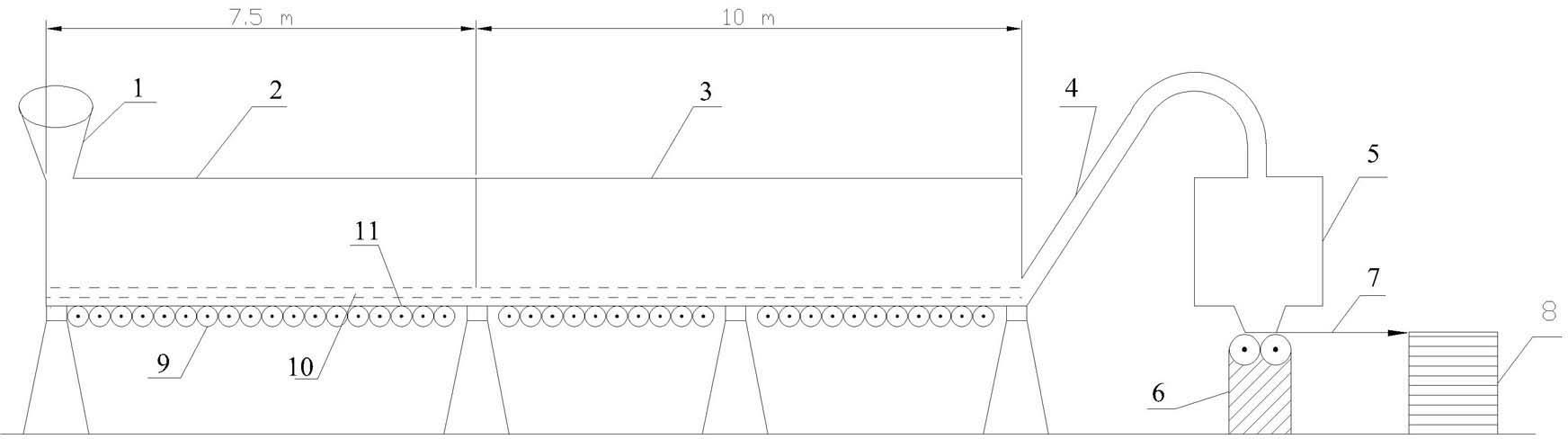

Microwave radiation reclaiming method for environment-friendly high-strength reclaimed rubber

InactiveCN102634056AProtection from destructionSure breakPlastic recyclingRubber materialWaste rubber

The invention discloses a microwave radiation reclaiming method for environment-friendly high-strength reclaimed rubber, and belongs to the technical field of waste rubber reclaiming. The method comprises the following steps of: mixing waste rubber outer tire crown powder with the particle size of 20 meshes, rosin and dipentene according to a certain proportion; uniformly feeding the materials with a certain thickness on a roller way conveying device; determining the length of a roller way according to microwave radiation time; arranging a high-frequency microwave radiation device on the roller way; conveying the materials on the roller way for reclaiming the materials by microwave radiation during conveying; continuously putting the reclaimed rubber materials into a cooling device through the roller way; directly discharging the cooled materials to an open mill for performing refining, wherein the refining temperature is controlled to be 35-50 DEG C; and refining at low temperature on the open mill for 20 minutes to obtain a refined rubber sheet with smooth surface and uniform texture. A test result shows that the tensile strength of the reclaimed rubber is more than 18MPa, the breaking elongation is over 400%, and the Weigert plasticity is 0.35-0.45. The microwave radiation reclaiming method has the advantages of environment friendliness, short reclaiming time, low reclaiming temperature, energy conservation and high production efficiency.

Owner:XUZHOU COLLEGE OF INDAL TECH

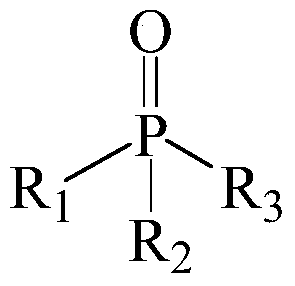

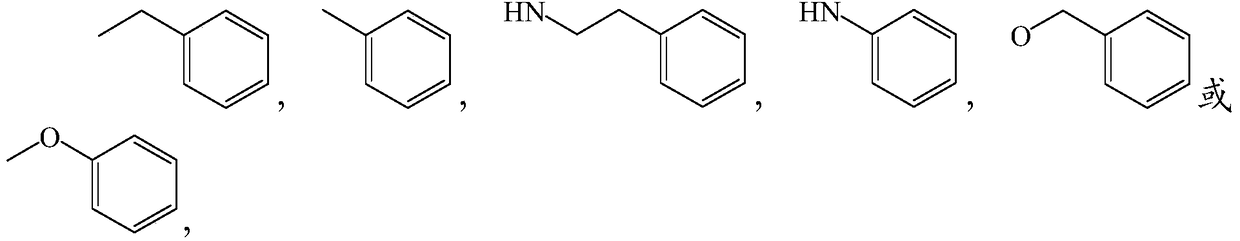

Low addition type halogen-free and flame-retardant polylactic acid composite and preparation method thereof

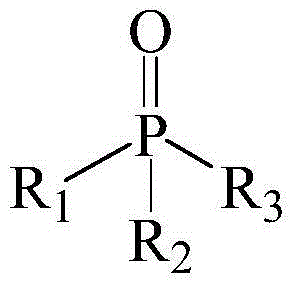

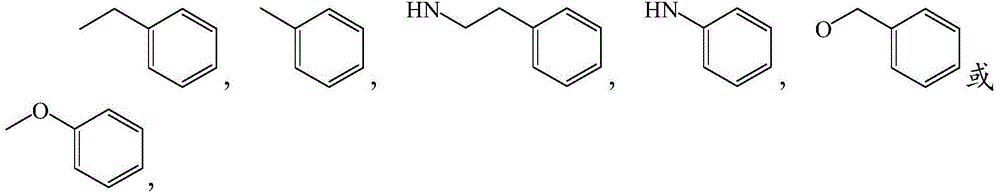

The invention discloses a low addition type halogen-free and flame-retardant polylactic acid composite and a preparation method thereof. The composite is prepared from polylactic acid, a flame retardant, an optional flame retardant additive, an optional antioxidant and an optional lubricant, wherein the flame retardant is a phosphate, phosphamide, phosphoryl ester or phosphoramidate compound; the flame retardant additive is inorganic filler or organically modified inorganic filler. The preparation method of the polylactic acid composite comprises the following steps: polylactic acid is dried under vacuum and uniformly mixed with the flame retardant, the optional flame retardant additive, the optional antioxidant and the optional lubricant, and the mixture is placed in a twin-screw extruder for melt blending and extrusion pelletizing. The low addition type halogen-free and flame-retardant polylactic acid composite is low in adding quantity of the flame retardant, good in flame retardance and environment-friendly, and the mechanical properties are not reduced but are even increased; the preparation method is simple, convenient, fast, low in cost and suitable for industrial production.

Owner:马德里高等材料研究院 +1

Fiber- reinforced polyphenylene sulfide/polyamide alloy material and preparation method thereof

InactiveCN103387746AImprove antistatic performanceImprove mechanical propertiesGlass fiberCarbon fibers

The invention belongs to the technical field of polymer materials, and relates to a fiber-reinforced polyphenylene sulfide / polyamide alloy material and a preparation method thereof. The material comprises the following components by weight: 25-56 parts of polyphenylene sulfide, 10-35 parts of polyamide 66, 15-25 parts of carbon fibers, 15-25 parts of glass fibers, 0.5-0.7 parts of an antioxidant, 0.7-1.2 parts of a lubricant and 1-1.5 parts of a coupling agent. In the PPS / PA66 alloy material provided by the invention, the carbon fibers are used for reinforcing conductivity of the material, without reducing the mechanical properties of the material. The material has excellent mechanical properties as well as antistatic properties. The cost of the material is relatively low due to the compound of the fibers and the addition of PA66.

Owner:HEFEI GENIUS NEW MATERIALS

Composite calcium carbonate modified PVC (polyvinyl chloride) rolling film and preparation method thereof

The invention relates to a composite calcium carbonate modified PVC (polyvinyl chloride) rolling film and a preparation method thereof. The preparation method comprises the preparation of composite calcium carbonate and the preparation of the composite calcium carbonate modified PVC rolling film. According to the composite calcium carbonate modified PVC (polyvinyl chloride) rolling film and the preparation method thereof, the composite calcium carbonate is formed by mixing active water-ground calcium carbonate and active nano-calcium carbonate, the production process is simple, the preparing costs are low, the prepared composite calcium carbonate is high in activating rate, and the needed coupling agents are small, can coat the surface thin layers of particles evenly and stably and well control the particle size of the processed particles. When the composite calcium carbonate which is prepared by mixing the active water-ground calcium carbonate and the active nano-calcium carbonate is used for preparing the PVC rolling film, the agglomeration of calcium carbonate particles is avoided, and the prepared rolling film has good mechanical properties.

Owner:JIANDE QINTANG CALCIUM CARBONATE IND RES & DEV

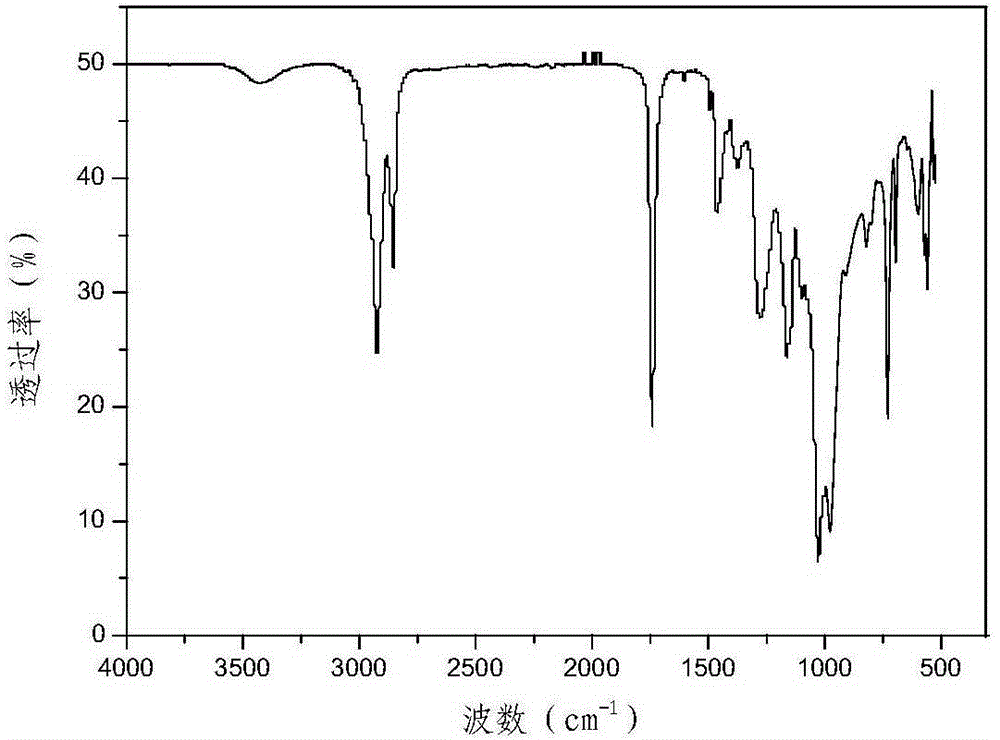

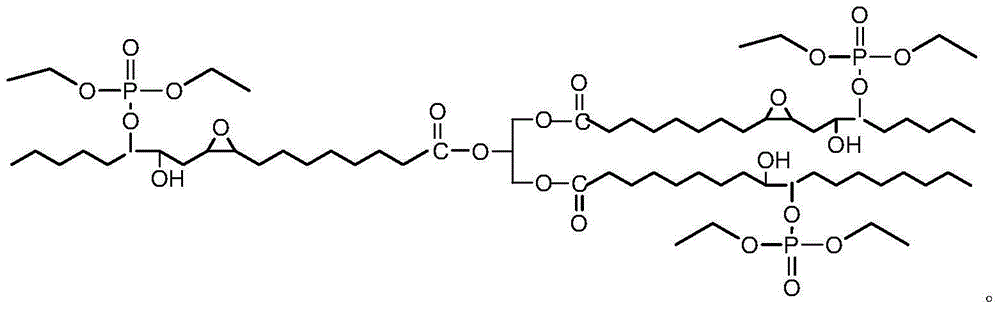

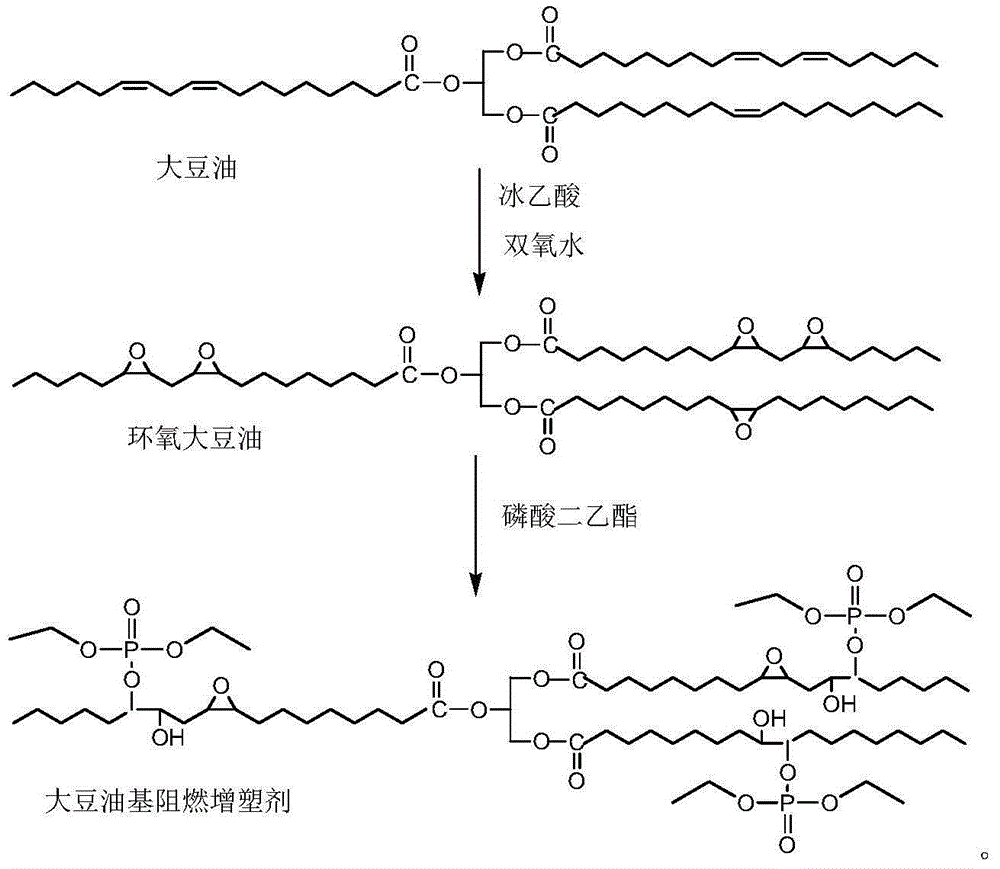

Soybean-oil-based flame-retardant plasticizer, and preparation method and application thereof

ActiveCN105153462AImprove flame retardant performanceNo reduction in mechanical propertiesGroup 5/15 element organic compoundsDiethyl phosphatePolymer science

The invention provides a soybean-oil-based flame-retardant plasticizer, and a preparation method and application thereof. The soybean-oil-based flame-retardant plasticizer is prepared from diethyl phosphate and epoxidized soybean oil by reaction. The soybean-oil-based flame-retardant plasticizer is prepared by adopting a structural modification method; diethyl phosphate containing a flame-retardant element P is added into the structure of soybean oil; the obtained soybean-oil-based flame-retardant plasticizer is applied in preparation of a flame-retardant type polyvinyl chloride product; and under the condition of no loss of mechanical performance, the plasticizer has higher flame-retardant property, and oxygen index can reach 24 to 33%. The soybean-oil-based flame-retardant plasticizer provided by the invention has extensive application prospects in the fields like plastics, rubbers, military products, textiles, conveyer belts and various building materials which have high requirements for flame-retardant performance.

Owner:徐州市洛克尔化工科技有限公司

Nanometer magnesium hydroxide flame retarding silicon rubber composite material and preparation method thereof

InactiveCN102964838AImprove flame retardant performanceNo reduction in mechanical propertiesNanometreMagnesium

The invention discloses a nanometer magnesium hydroxide flame retarding silicon rubber composite material and a preparation method thereof. The composite material comprises the following components in parts by weight: 100-120 parts of phenyl silicon rubber, 8-10 parts of diphenyldimethoxysilane, 10-20 parts of nanometer magnesium hydroxide, 5-30 parts of fumed silica, 2-4 parts of cyclotrisilazane, 3-6 parts of montmorillonite, 0.3-0.6 part of chloroform, 3-8 parts of surfactant and 1 part of vulcanizing agent. The composite material provided by the invention has excellent flame retarding property and the mechanical property of the composite material is not reduced at the same time; and the preparation method is simple and easy to operate.

Owner:高润宝

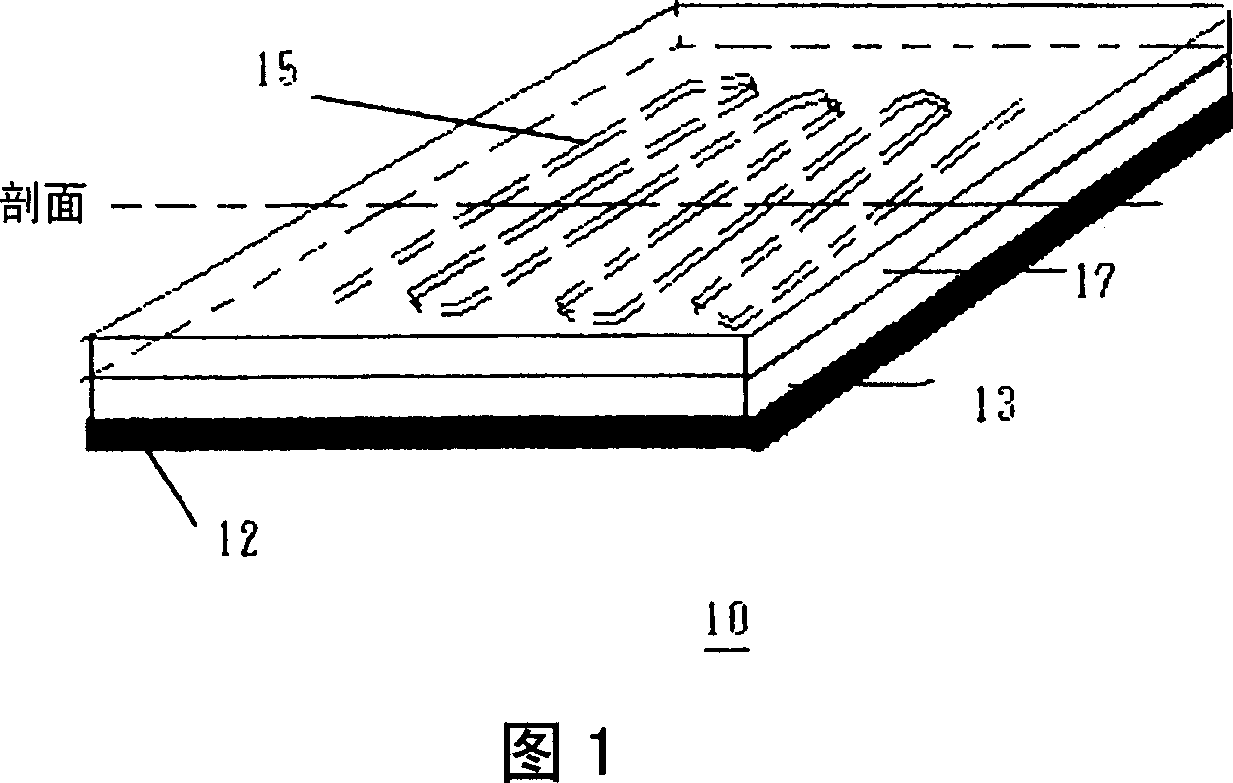

Curable resin composition for light guide, curable dry film for light guide

InactiveCN1922227AWorkability will not decreaseNo reduction in mechanical propertiesPhotomechanical apparatusOptical waveguide light guideLight guideOrganic chemistry

A curable resin composition for light guide characterized by containing as essential components copolymer (A) from radically polymerizable compound (a) having in its molecule an acid group of acid anhydride group and / or acid group blocked and a radically polymerizable unsaturated group and other radically polymerizable compound (b); polymerizable unsaturated compound (B); and polymerization initiator (C). There is further provided a curable dry film for light guide consisting of this composition; and provided a light guide having at least one of underpart clad layer (13), core portion (15) and upper part clad layer (17) formed therefrom.

Owner:KANSAI PAINT CO LTD

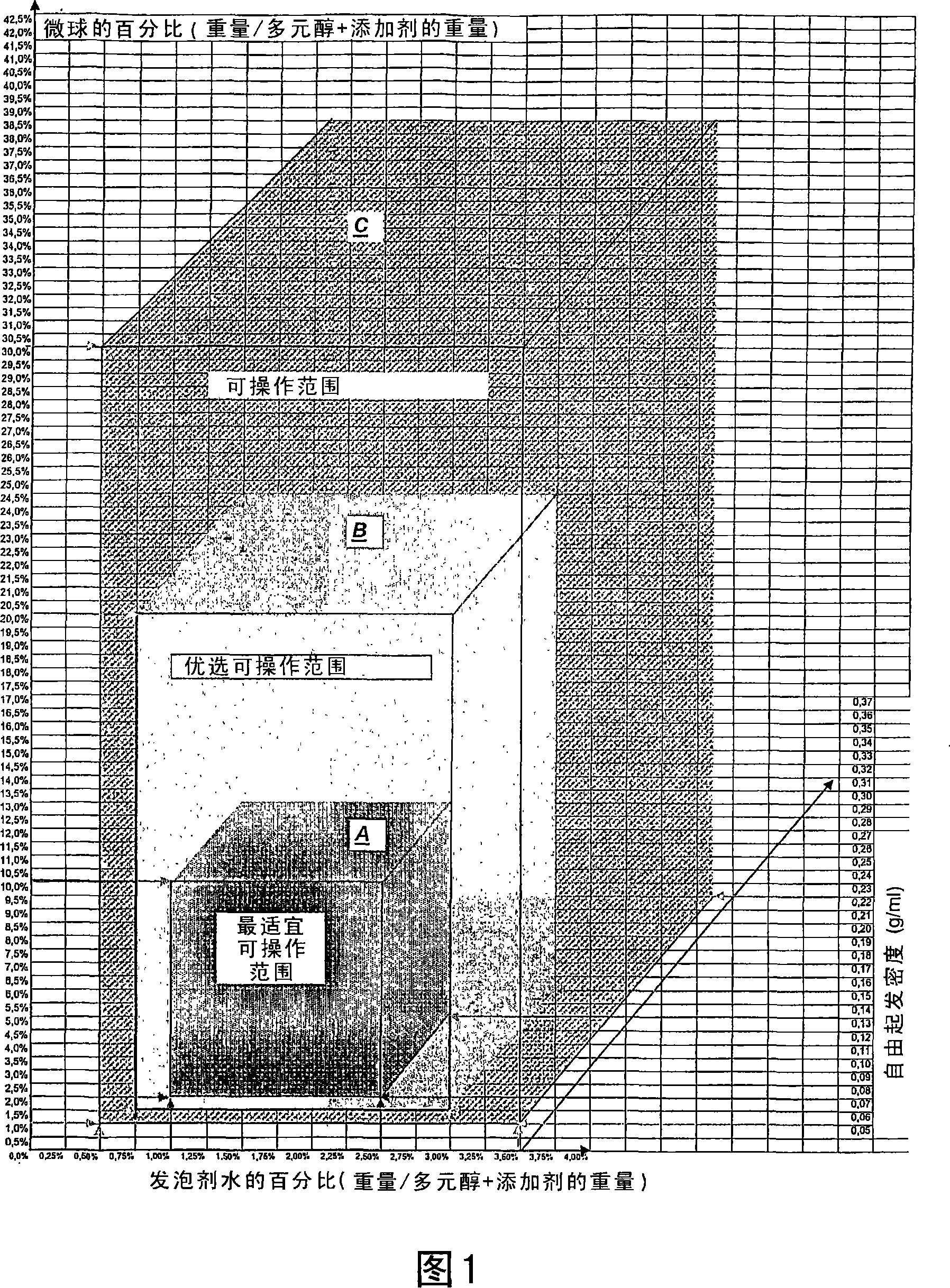

Use straddling microsphere and water as co-foaming agent to prepare low density polyurethane integral surface foam system

Foam products with densities between 0.10 and 0.28 are obtained by reacting at least one polyol with at least one isocyanate-prepolymer, in the presence of an amount of expandable microspheres within the range of 0.5 to 10% by weight on the weight of said polyol and an amount of expanding agent which is from 0.5 to 4,0 times the amount normally used for such polyol / isocyanate-prepolymer systems, and carrying out the polymer expansion step at a temperature which is sufficient to cause the substantially simultaneous expansion of the microspheres.

Owner:埃拉凯姆有限公司

A microcellular foamed fiber, and a process of preparing for the same

InactiveCN1304652CImprove lightnessImprove touch effectHollow filament manufactureFilament/thread formingSingle phaseSupercritical fluid

The present invention discloses microcellular fibers, in which microcells are formed with a density of more than 10<7>cells / cm<3> with a supercritical fluid introduced into fiber forming polymers and have a rate of volume expansion of 1.2 to 50, a ratio of microcell length to microcell diameter of more than 2 and a monofilament diameter of more than 5 m. The microcellular fibers provide high and uniform cell densities and are good in the rate of volume expansion and the ratio of cell length to cell diameter, thus they are very excellent in lightweight feeling and touch. The microcellular fibers are made by a method for making microcellular fibers, wherein a supercritical fluid is introduced into an extruder upon melting and mixing fiber forming polymers in the extruder, to thus prepare a single-phase solution of molten polymer and gas, then the single-phase solution of molten polymer and gas is extruded (spun) through spinneret of spinning pack by subjecting the single-phase solution to a rapid pressure drop, to thus make microcellular extrusion materials, the microcellular extrusion materials are rapidly cooled by a cooling medium, and then they are wound at a winding speed of 10 to 6,000m / min so that a spinning draft can be 2 to 300.

Owner:KOLON IND INC

Sprue device of magnesium alloy front-end support pressure castings

InactiveCN105880515AReduce weightNo reduction in mechanical propertiesPressure castingUltimate tensile strength

The invention relates to a sprue device of magnesium alloy front-end support pressure castings. The sprue device comprises a pressure chamber and is characterized in that the pressure chamber is divided into two paths; the two paths are each in a fan shape, one path is connected with a first casting body through a first straight pouring gate and a first transverse pouring gate, and the other path is connected with a second casting body through a second straight pouring gate and a second transverse pouring gate; the first transverse pouring gate is divided into five paths to enter a first sprue, a second sprue, a third sprue, a fourth sprue and a fifth sprue of the first casting body correspondingly; and the second transverse pouring gate is divided into five paths to enter a sixth sprue, a seventh sprue, an eighth sprue, a ninth sprue and a tenth sprue of the second casting body correspondingly. The sprue device has the beneficial effects that after the magnesium alloy pressure castings are used for replacing sheet iron stamping parts, the weight is reduced, mechanical performance is not reduced, oil consumption is reduced due to the fact that the weight is reduced, and strength is guaranteed; and production efficiency is improved due to the fact that two products are produced through one mold.

Owner:CHANGZHOU KAIFA GUANGMING CASTING FACTORY GENERAL PARTNERSHIP

Antistatic master batch and preparation method thereof

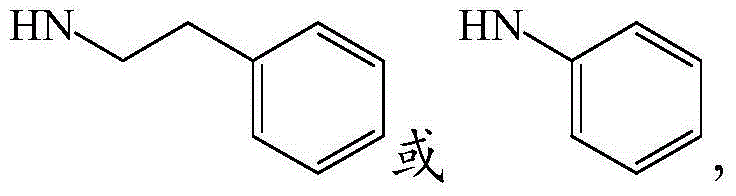

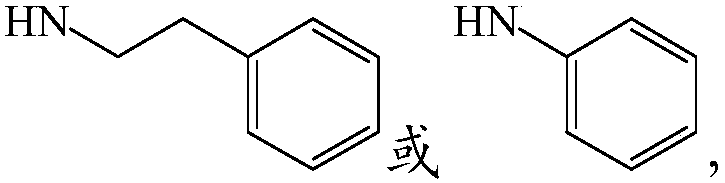

PendingCN114196094AGood dispersionNo reduction in mechanical propertiesPolymer sciencePerylene derivatives

The invention belongs to the technical field of plastics, and particularly discloses an antistatic plastic master batch which comprises 10-40 parts of carrier resin, 50-80 parts of functional filler, 0.5-1 part of flexibilizer, 1-5 parts of antistatic agent, 0.5-1.5 parts of coupling agent, 1-2 parts of dispersing agent and 2-5 parts of lubricant, and the antistatic agent is anionic antistatic agent. The melamine and the derivative release nitrogen during high-temperature combustion and are non-toxic and halogen-free antistatic agents, and due to the action of the coupling agent and the dispersing agent, the antistatic agent is easier to be uniformly dispersed in the carrier resin and plays a role of the antistatic agent, and meanwhile, the mechanical property of the master batch is not reduced.

Owner:HENAN JUNHUA DEV

Non-asphalt-based polymer self-adhesive waterproof coiled material and preparing method thereof

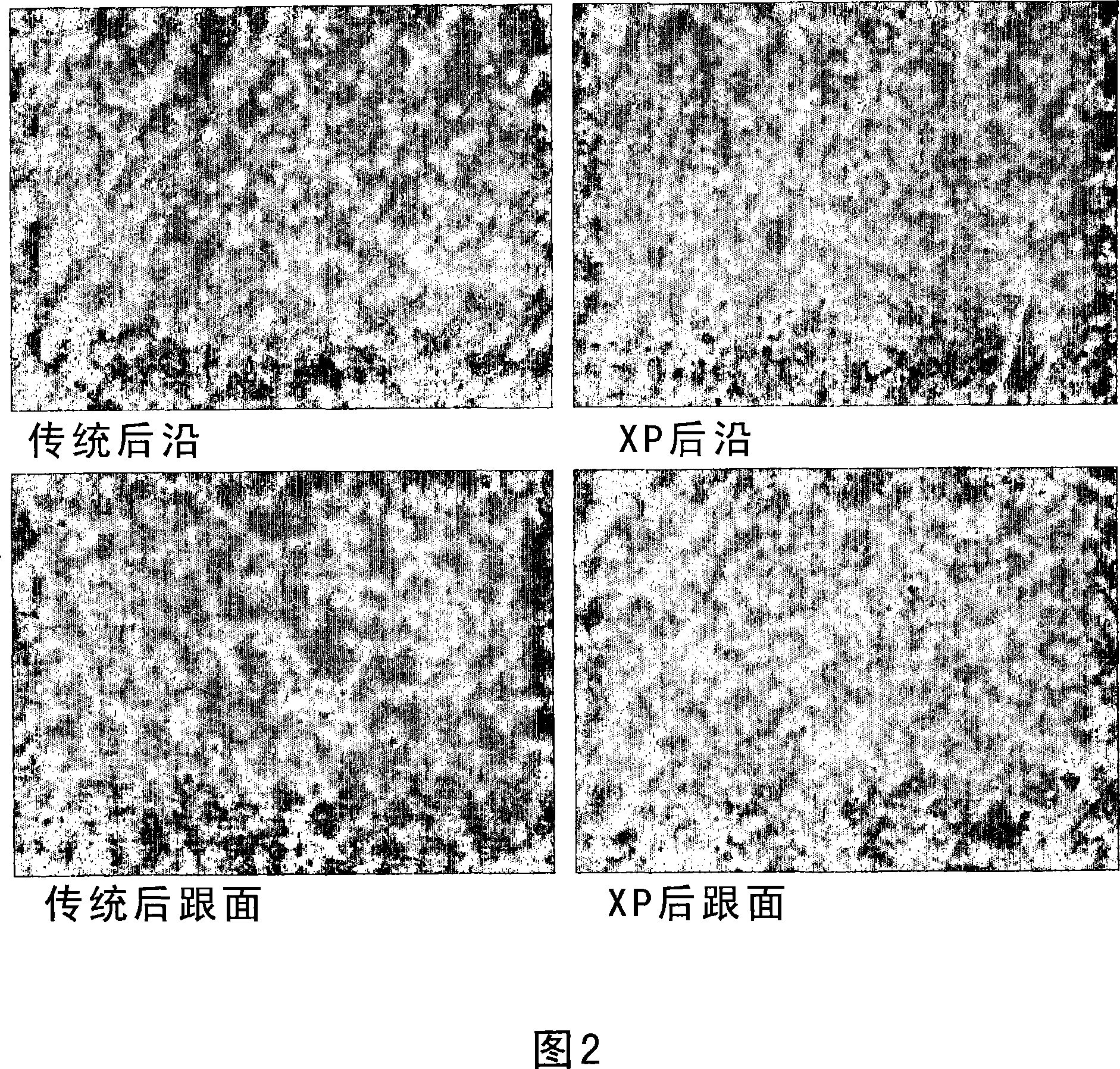

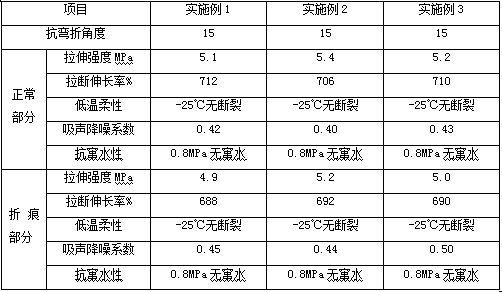

ActiveCN110117467AElasticGood sound absorption and noise reduction effectFilm/foil adhesivesPolymer scienceWater leakage

The invention provides a non-asphalt-based polymer self-adhesive waterproof coiled material. According to the non-asphalt-based polymer self-adhesive waterproof coiled material, the tensile strength is 5.1-5.4 MPa, the elongation at break is 706-716%, and when the material is folded by15 degrees 5 times, the tensile strength at the bent portion is 4.9-5.2 MPa, and the elongation at break is 688-692%; the waterproof coiled material comprises a polymer homogenizing sheet layer, wherein the polymer homogenizing sheet layer is prepared from LDPE, HDPP, melamine and salt thereof, waste reclaimed rubber powder, start-type SBS, rosin modified phenolic resin, polyacrylonitrile fibers, a heavy-polymer modifier and an accelerant. The non-asphalt-based polymer self-adhesive waterproof coiled materialhas high resilience and a significant sound absorption and noise reduction effect; the bending performance is excellent, water leakage does not occur even when the folding angle is 15 degrees, the mechanical performance of the bent portion is basically not lowered, and the non-asphalt-based polymer self-adhesive waterproof coiled material is particularly suitable for water proofing for pipelines,tunnels, bridge culverts and other curved-surface projects.

Owner:富华防水科技股份有限公司

Preparation method of thermal expansion type polyurethane

ActiveCN111978704AHigh bonding strengthMechanical properties are not affectedThermal dilatationPolymer science

The invention discloses a preparation method of thermal expansion type polyurethane. The preparation method comprises the following steps: adding a raw material modified expanding agent, a halogen-containing flame retardant and a thermoplastic polyurethane elastomer into an internal mixer according to a weight ratio of (2-4): (1-2): (35-45), performing blending, and carrying out hot press moldingto obtain the thermal expansion type polyurethane. The defects in prior art are overcome. The flame retardant has relatively small influence on the mechanical properties of polyurethane, and has favorable flame-retardant effect.

Owner:安徽嘉明新材料科技有限公司

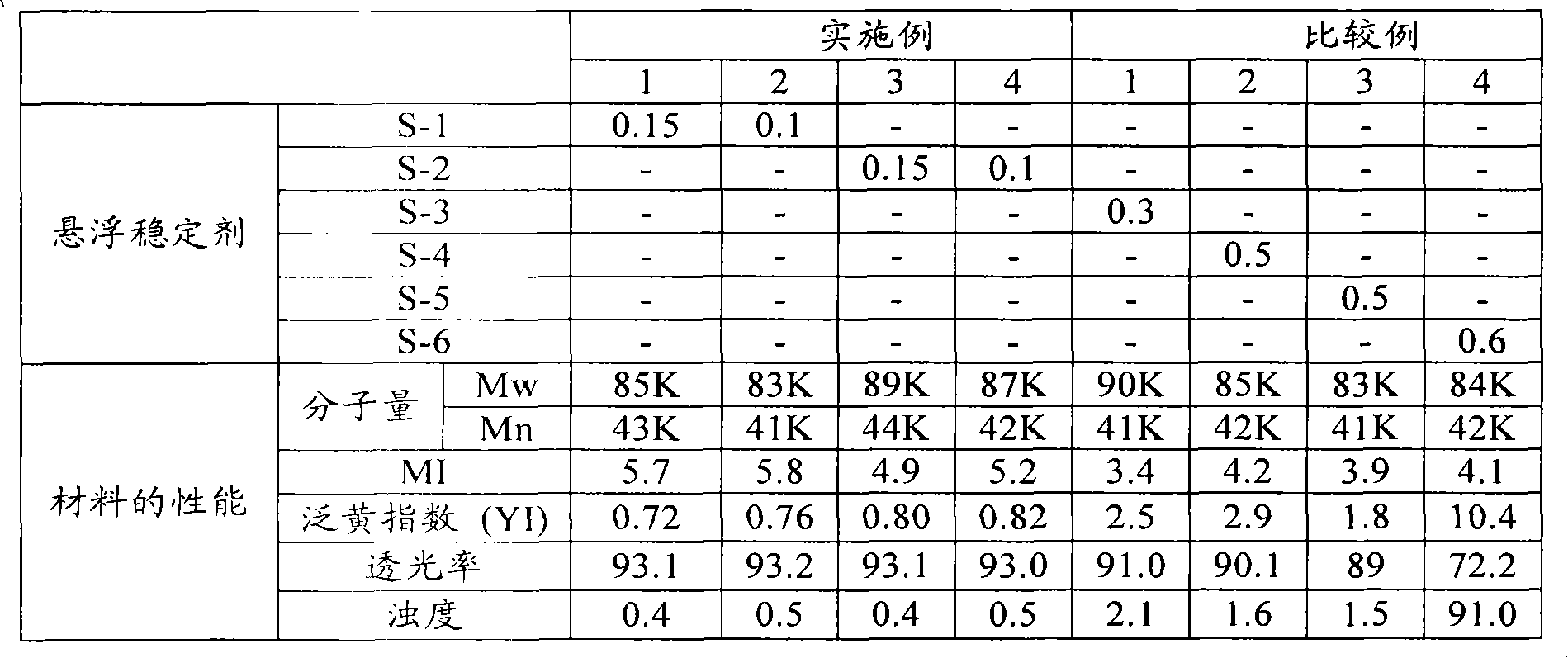

Methacrylate resin with excellent discoloration-resistance and transparency and method for preparing the same

ActiveCN101405309AExcellent resistance to discolorationNo reduction in mechanical propertiesAqueous solutionPolymer chemistry

Owner:LOTTE ADVANCED MATERIALS CO LTD

Method for differential arc oxidation treatment of Nickel-titanium alloy for medical purpose

InactiveCN100590234CNo reduction in mechanical propertiesSmall mechanical propertiesSurgerySurface reaction electrolytic coatingPlasma electrolytic oxidationMicro arc oxidation

Owner:HARBIN INST OF TECH

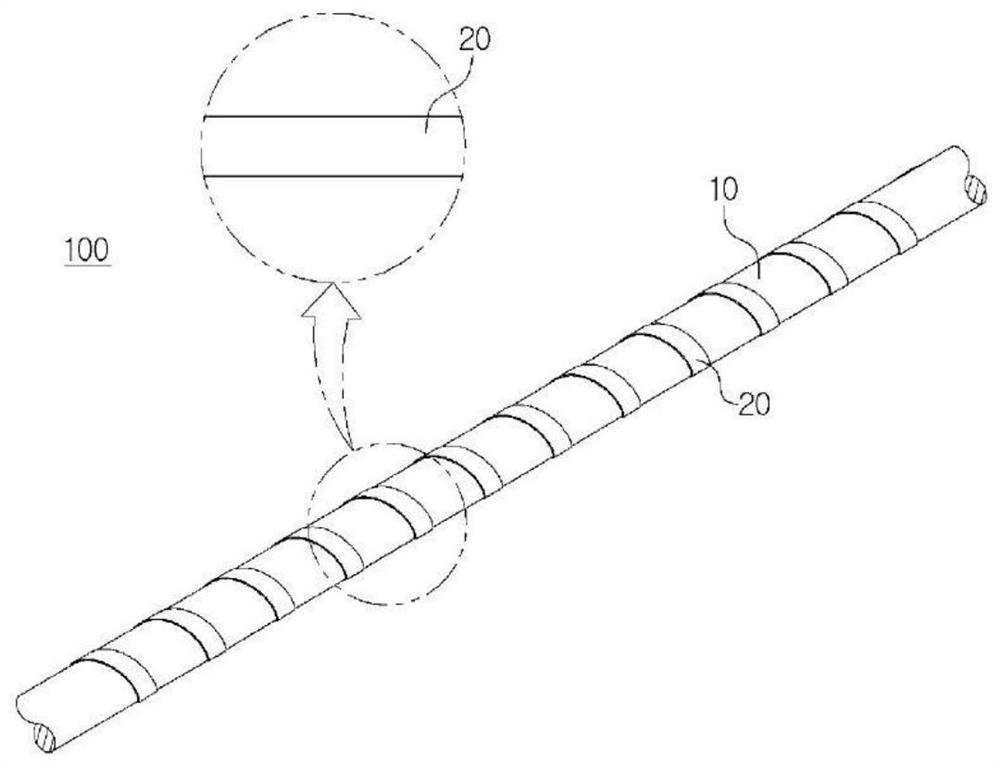

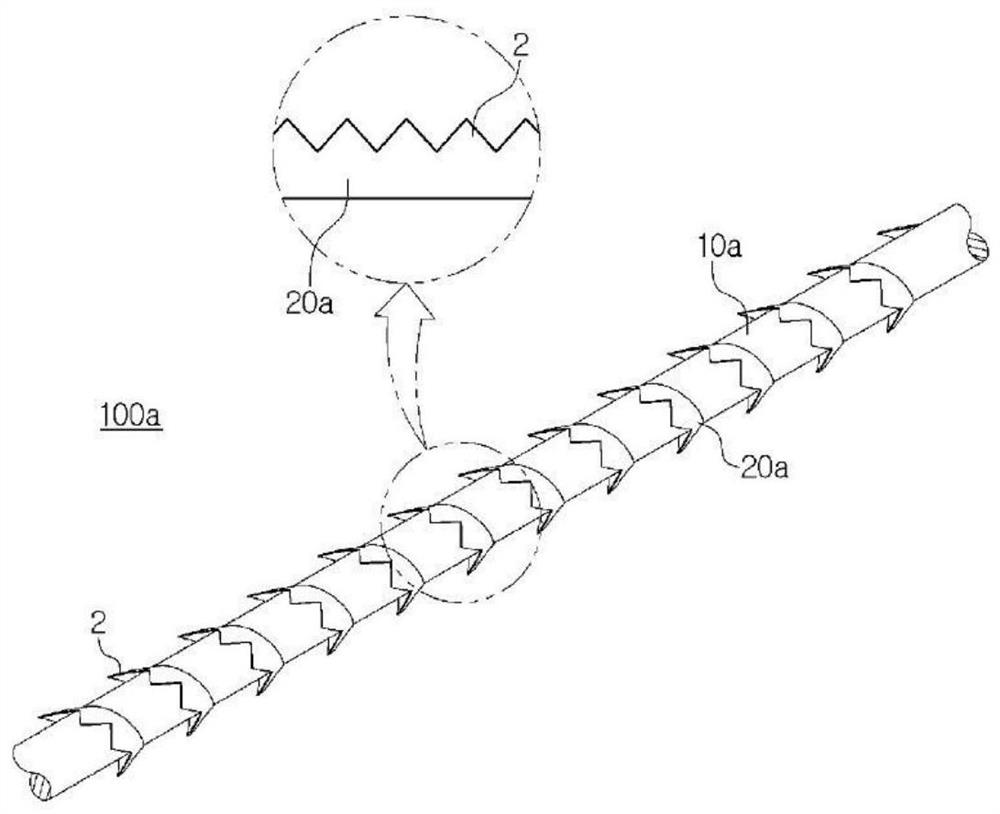

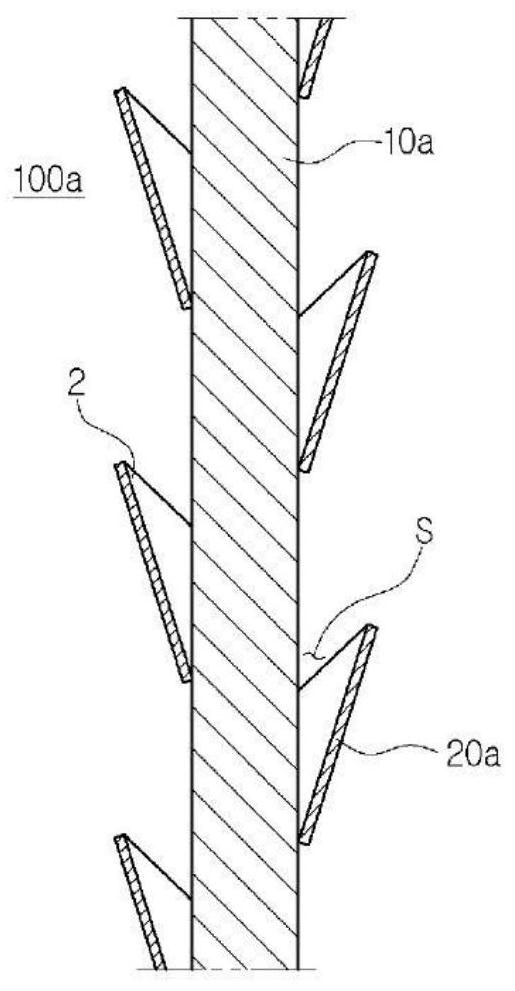

Thread embedding therapy rope and thread embedding therapy needle apparatus comprising same

PendingCN112672698AExtend your lifeReduce rigiditySuture equipmentsCosmetic implantsHuman bodyDrug carrier

The present invention relates to a thread embedding therapy rope and a thread embedding therapy needle apparatus comprising same, and disclosed are a thread embedding therapy rope and a needle apparatus comprising same, the rope comprising a linear core, which comprises a biodegradable polymer, and a metal wire, which is arranged to spirally encompass the outer circumferential surface of the linear core, wherein the metal wire comprises a biodegradable metal formed with magnesium or zinc as a main component, so as to have no side effects on biological tissue when applied to the human body by means of thread embedding therapy, pulling force on the tissue can be strengthened, lifespan can be extended over that of a conventional embedded thread of a biodegradable polymer, the drug loading capability of the embedded thread itself can be increased so as to allow for usefulness as a drug carrier, and a drug can be delivered through a simple method.

Owner:实验室和人们有限公司

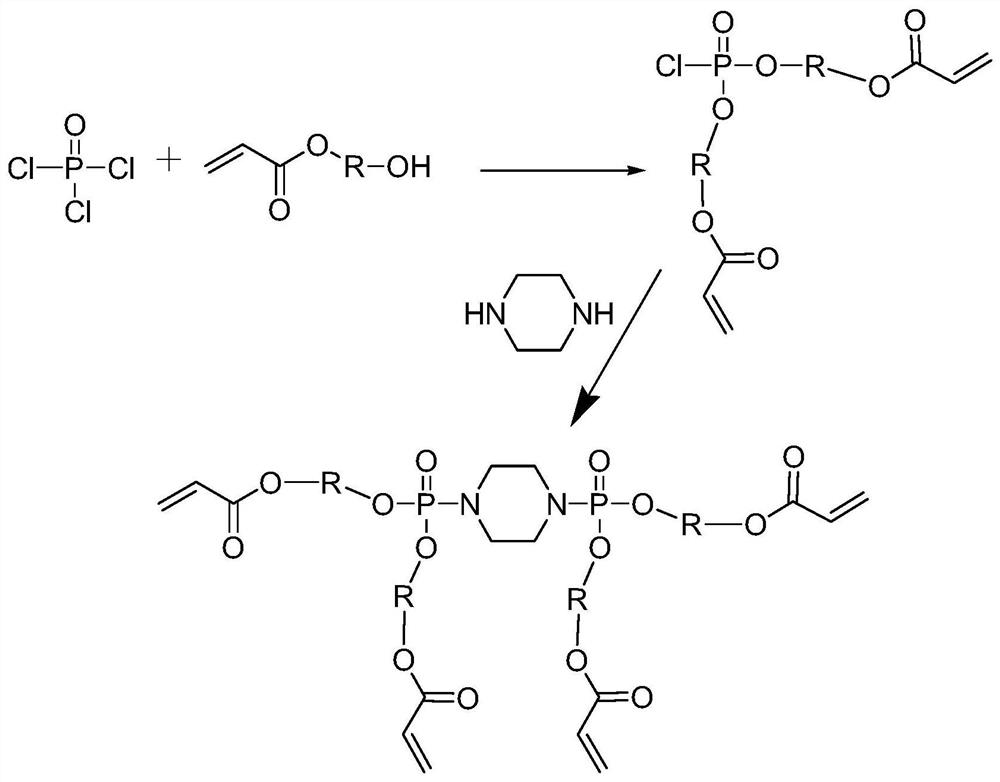

Nitrogen-phosphorus-silicon ternary halogen-free synergistic flame-retardant thermoplastic elastomer and preparation method thereof

PendingCN113956597AReduced mechanical propertiesNo reduction in mechanical propertiesPolymer sciencePolypropylene

The invention discloses a nitrogen-phosphorus-silicon ternary halogen-free synergistic flame-retardant thermoplastic elastomer and a preparation method thereof. The thermoplastic elastomer specifically comprises, by weight, 2-20 parts of phosphorus-nitrogen-containing tetrafunctional acrylate, 10-45 parts of a styrene block copolymer, 20-60 parts of filling oil, 5-20 parts of polypropylene, 5-10 parts of a maleic anhydride grafted styrene block copolymer, 0.1-2 parts of a stabilizer, 20-40 parts of thermoplastic polyurethane, 10-30 parts of an organic silicon and polyurethane segmented copolymer, and 1-5 parts of a silicone master batch. The preparation method comprises the following steps: weighing the raw materials in proportion, then mixing the raw materials in a high-speed stirrer, then putting the mixture into a double-screw extruder, performing melt extrusion, and after extrusion, cooling, drying and pelletizing to obtain the finished product. The thermoplastic elastomer with excellent flame retardance is prepared by adopting nitrogen-phosphorus-silicon ternary halogen-free synergistic flame retardance, and the mechanical property and smoothness of the material are not sacrificed while the flame retardance of the material is greatly improved. The flame-retardant thermoplastic elastomer is suitable for being applied to the fields of automobile parts, sealing strips, wires and cables, medical apparatuses and instruments and the like.

Owner:绍兴市聚成新材料科技股份有限公司 +1

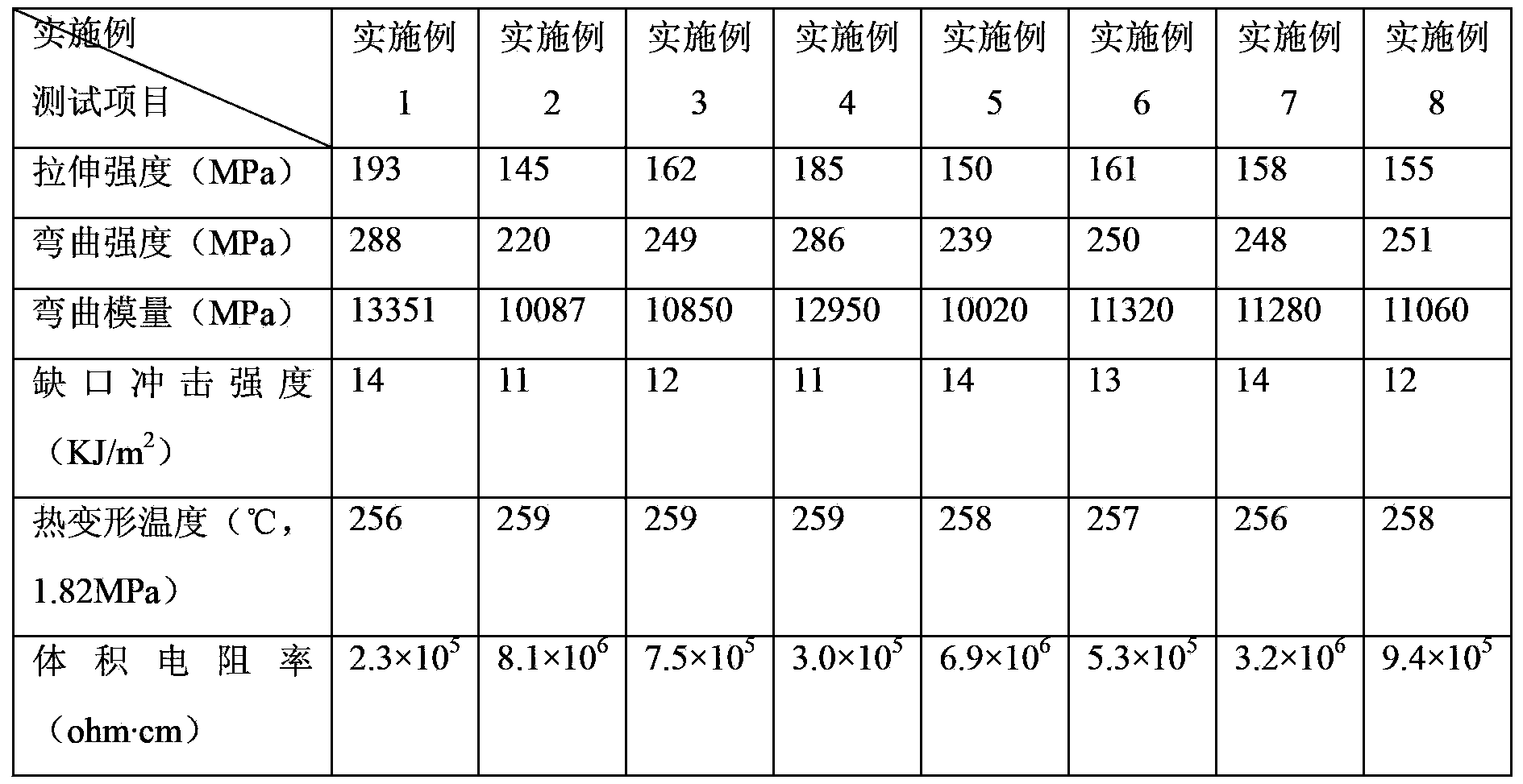

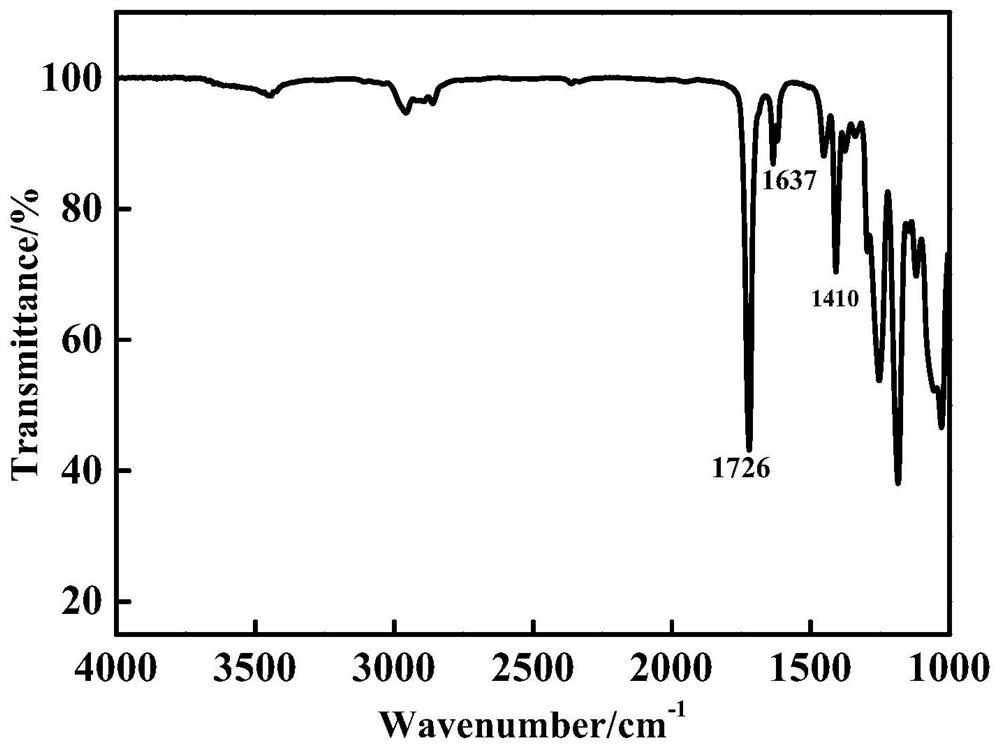

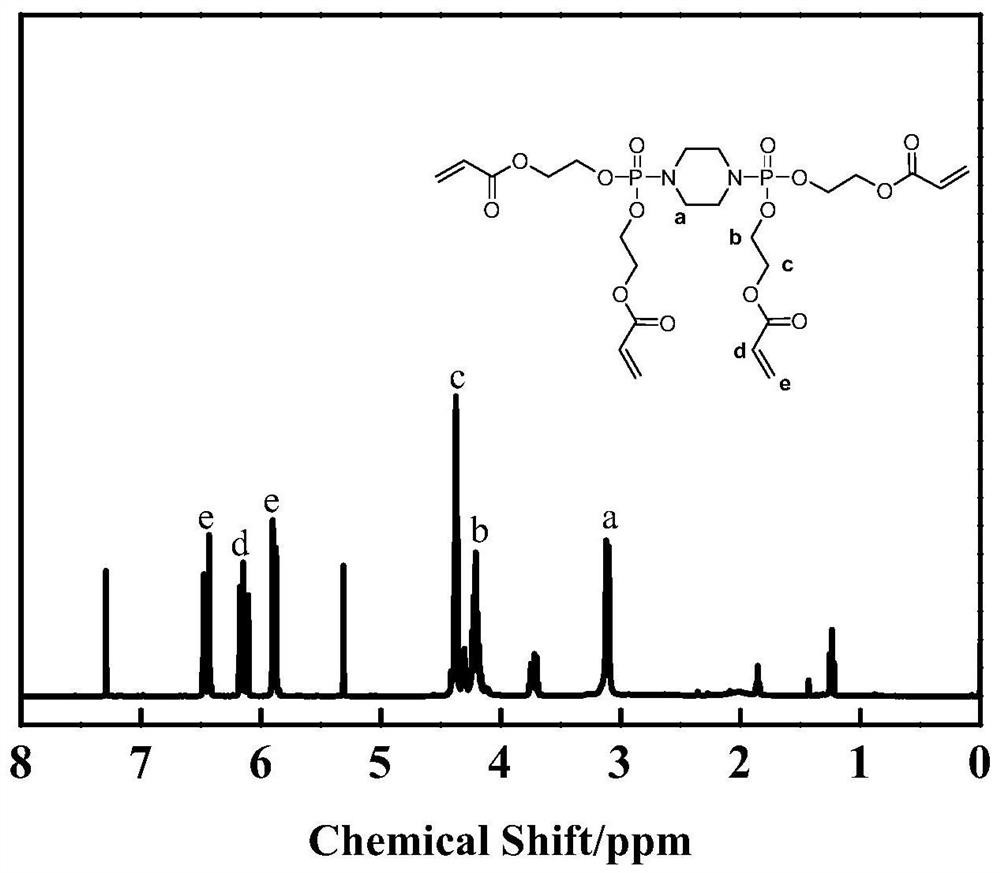

Phosphorus silicon type inflaming retarding and non-enhancing PA66 composite material and preparation method thereof

InactiveCN108034246AGood compatibilityNo reduction in mechanical propertiesAntioxidantSilsesquioxane

The invention discloses a phosphorus silicon type inflaming retarding and non-enhancing PA66 composite material and a preparation method thereof. The phosphorus silicon type inflaming retarding and non-enhancing PA66 composite material comprises the following raw materials in parts by mass: 45-55 parts of PA66, 35-45 parts of PA6, 10-15 parts of an inflaming retardant, 0.1-0.2 part of an antioxidant, and 0.1-0.2 part of a surface treating agent, wherein the phosphorus silicon inflaming retardant is the inflaming retardant with a cage type heptaphenyl trisilicate silsesquioxane structure. According to the phosphorus silicon type inflaming retarding and non-enhancing PA66 composite material, the inflaming retarding performance and relative tracking index of the material can be improved on the premise that the material remains the mechanical property.

Owner:NANJING HONGRUI PLASTIC PROD

Formaldehyde catalytic purification fibre and preparation method thereof

InactiveCN102127823BEase of industrial productionLow costFilament/thread formingMonocomponent polyolefin artificial filamentPlasticizerFiber

The invention relates to a formaldehyde catalytic purification fibre and a preparation method thereof. The catalytic fibre prepared according to the invention comprises the following required specific substance components in parts by mass: 100 parts of polymers, 20-50 parts of MnO2 catalytic particles, 0.2-1.5 parts of coupling agent, 0.1-0.5 part of antioxygen and 0-50 parts of plasticizer. The indoor formaldehyde catalytic fibre provided by the invention is not needed to be subjected to treatment on toxic organics, has no secondary pollution, is easy to industrially produce, is low in cost,is simple in preparation process, enables the utilization ratio of the catalyst to be increased, ensures high formaldehyde removal speed and removal ratio, is easy to weave and form, has high soapingdegree, and can be used for a long term; and abundant mineral products are used as the selected catalyst.

Owner:BEIJING UNIV OF CHEM TECH

Preparation of high-damping rubber containing hindered phenol terminated hyper branched polymer

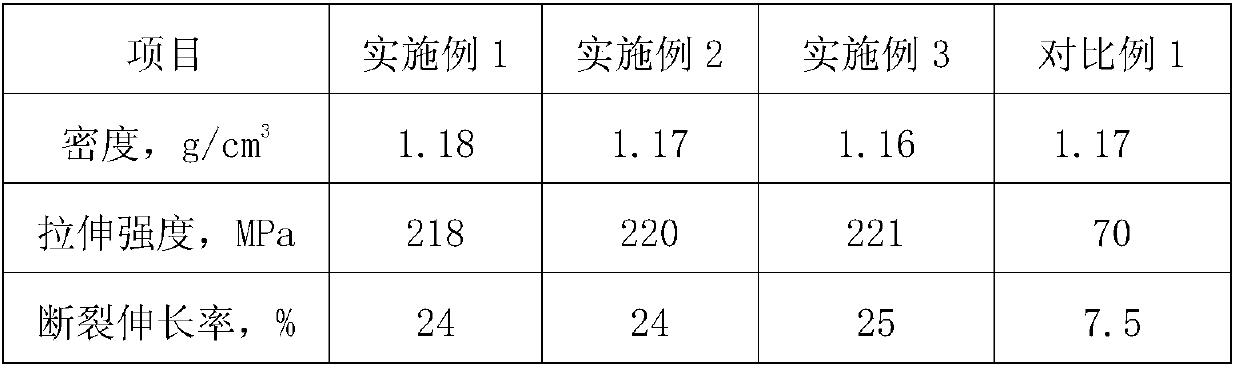

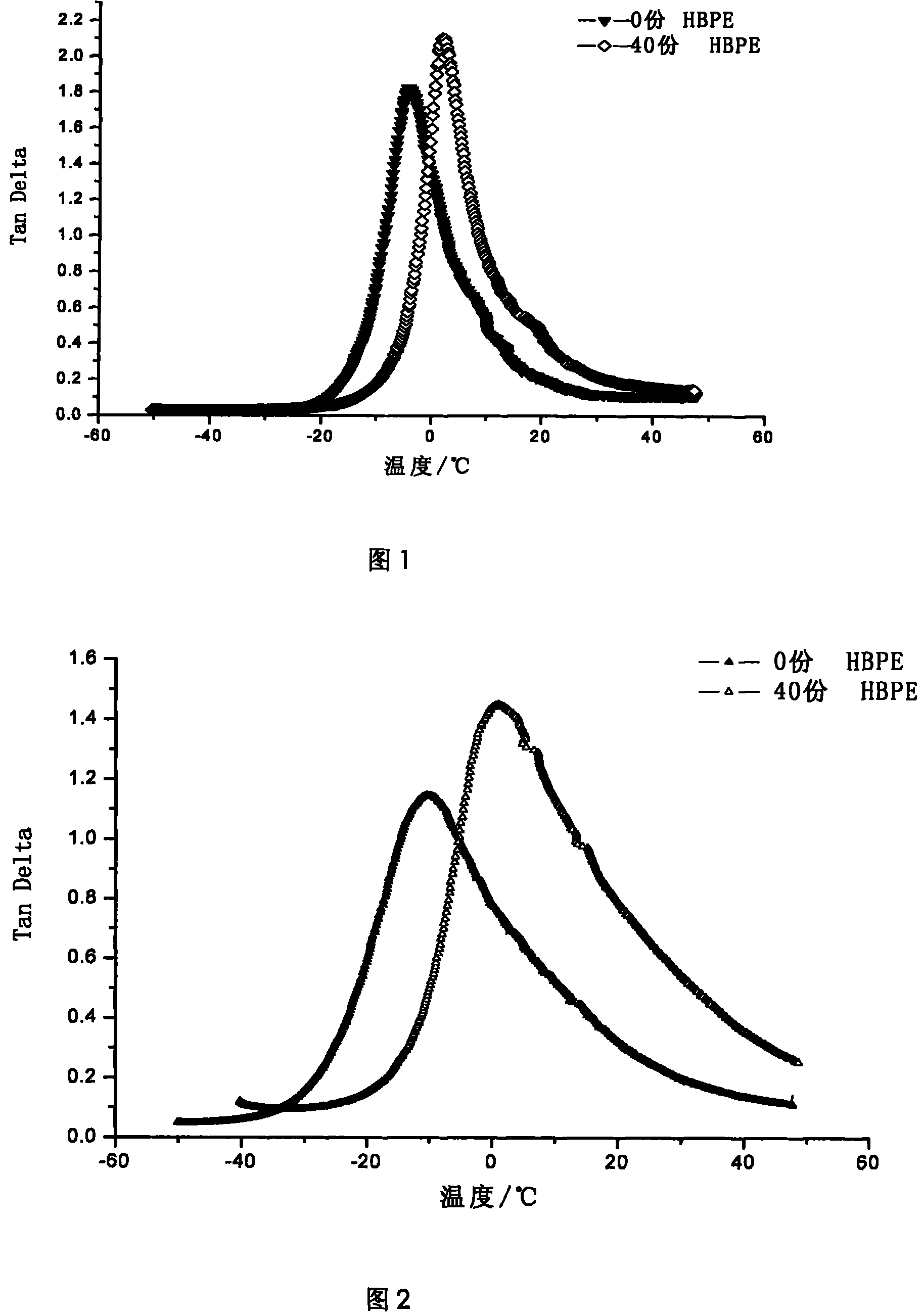

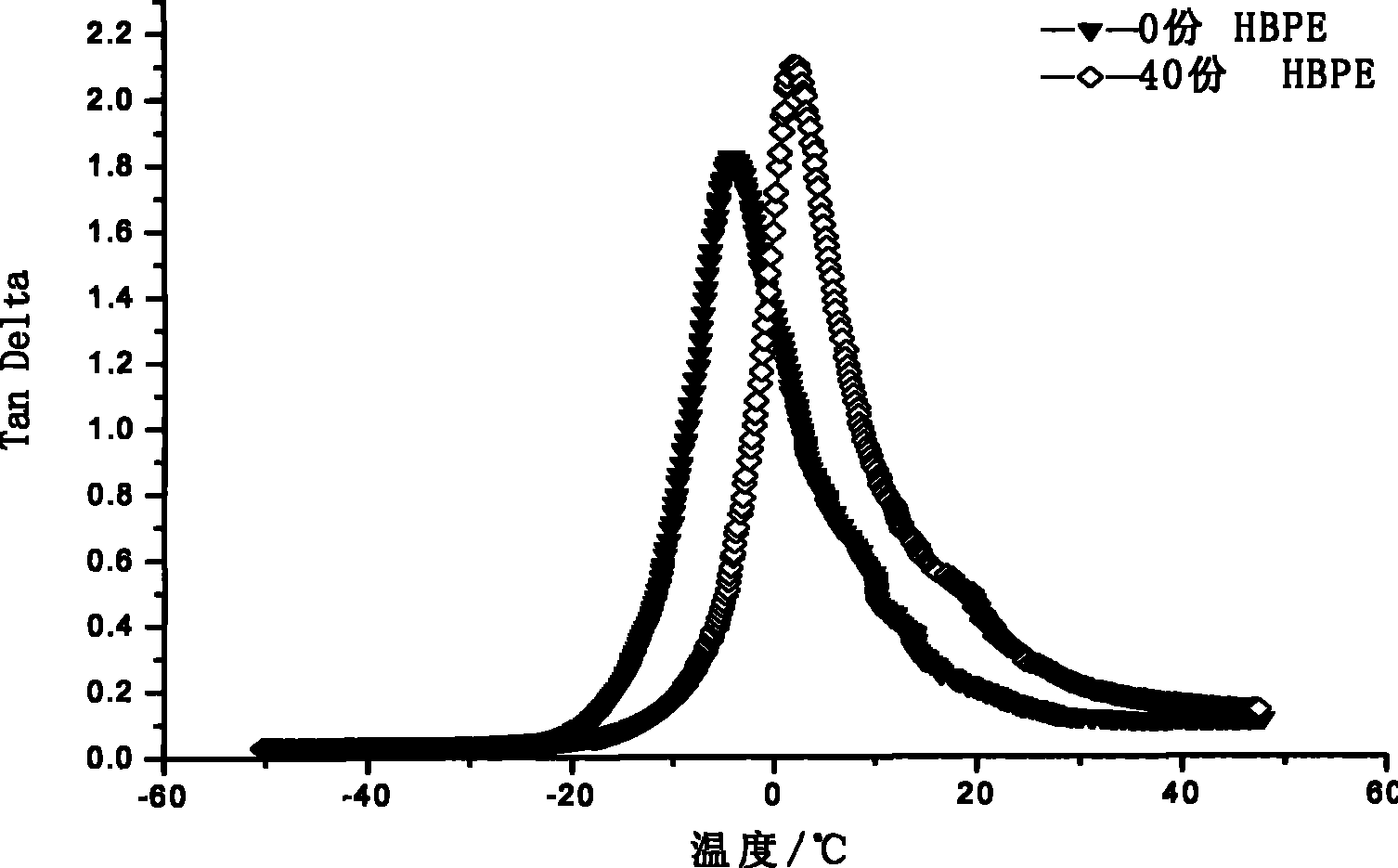

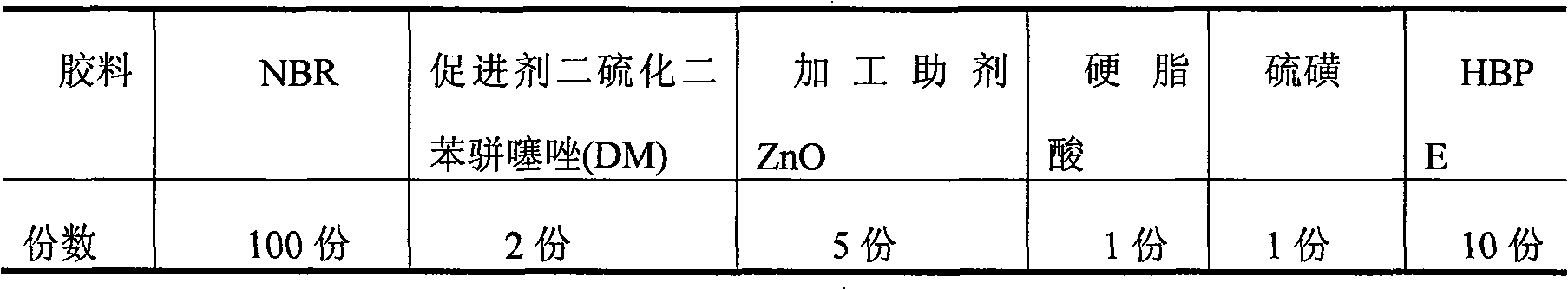

The invention belongs to the field of functional polymer materials. Aiming at the defect that the small organic molecules are easy to be moved and are easy to low the mechanical properties of a rubber, a hyperbranched polymer promoter capable of effectively enhancing the damping capacity of the rubber is designed. The invention is calcualted in mass percentage: 100 shares of raw rubbers, 10 to 40shares of terminated hyperbranched polymers of hindered phenol, 0.5 to 1 share of potassium stearates, 3 to 5 shares of stearic acids, 5 to 8 shares of zinc oxides, 1 to 2 shares of sulfurs and 20 to30 shares of carbon blacks are selected and the raw materials are mixed with each other uniformly on an open mill; the mixtures are subject to the packing mixing for 8 to 12 times; the mixtures are driven to rest for 10 to 16 hours with ventilation and the vulcanization time of the mixtures is tested on a rotor-free curometer at a temperature ranging from 150 DEG C to 170 DEG C; the curing time is recorded after the vulcanization curve flattens out; then the vulcanization is carried out utilizing a platten curometer, the temperature is set to range from 150 DEG C to 170 DEG C corresponding tothe rotor-free curometer and the pressure is 15MPa and the strips are taken out. The invention can enhance the damping capacity of the rubber, overcome the defect of a small organic molecular promoter without lowering the mechanical properties of the rubber and maintain the stable performances for a long time.

Owner:BEIJING UNIV OF CHEM TECH

PC/ABS material composition for relieving yellow discoloration

ActiveCN101759979BReduce color differenceMeet the requirements of color differenceYELLOW DYEPolycarbonate

The invention discloses a PC / ABS material composition for relieving the yellow discoloration, which is prepared from the following ingredients in percentage by weight: 10 to 60 parts of acrylonitrile-butadiene-styrene graft copolymers, 30 to 85 parts of polycarbonate, 0 to 10 parts of acrylics graft rubber, 0.25 to 0.88 parts of coloring agents, 0 to 1 part of antioxidizers and 0 to 1 part of light stabilizers. Yellow dyes without light illumination resistance performance exist in a dye system, and the dyes can not influence the whole coloring process of plastics in the plastic coloring process, but in the light illumination process, the dyes gradually fade, the PC / ABS materials carry out yellow discoloration in the light illumination process, so the two mutually inconsistent processes have the mutual counteraction effect, and the color aberration of the whole PC / ABS composition is reduced after the light illumination. At the same time, the mechanical property of the composition material is not obviously reduced.

Owner:CHONGQNG PRET NEW MATERIAL +2

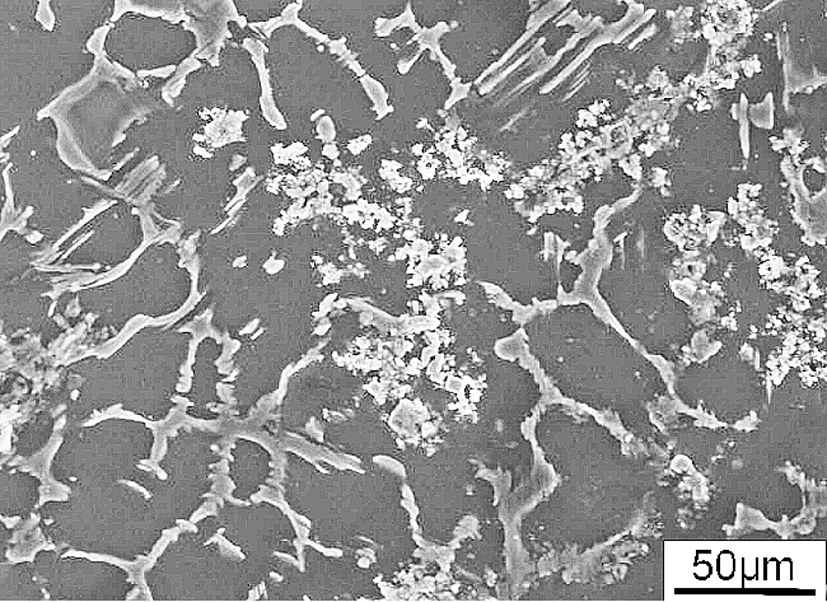

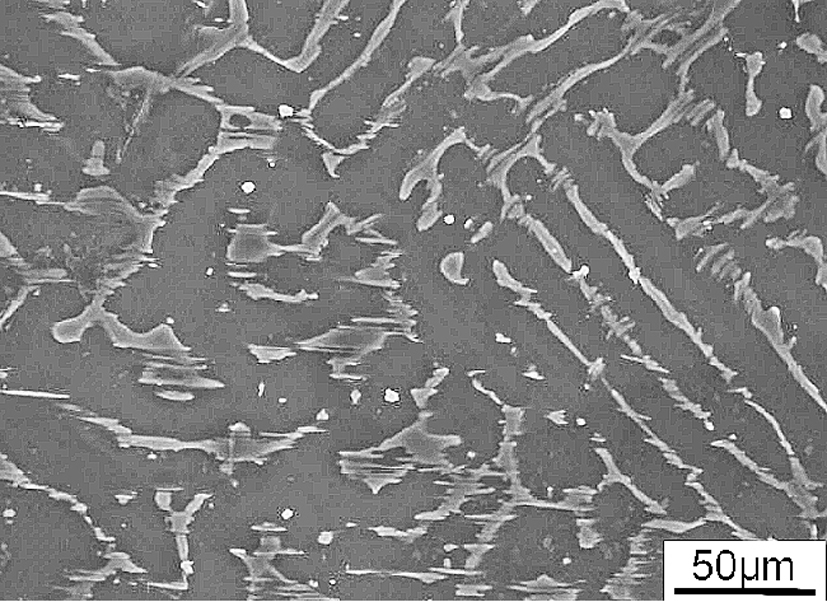

High-damping Mg-Zn-Ni-Y alloy and preparation process thereof

ActiveCN113913661AReduced dampingImprove mechanical propertiesUltimate tensile strengthMicrostructure morphology

The invention provides a high-damping Mg-Zn-Ni-Y alloy and a preparation process thereof, and belongs to the technical field of magnesium alloys and preparation thereof. The alloy comprises the following elements in percentage by mass: 1.28-3.5wt% of Zn, 1.16-3.2wt% of Ni, 4.68-12.8wt% of Y, and the balance of magnesium and inevitable impurities; and the microstructure morphology characteristics are as follows: a main phase consists of a magnesium phase and a long period phase; and a grain boundary is a parallel long period phase. The alloy is a two-phase alloy mainly consisting of the magnesium phase and the long period phase, wherein the long period phase is an effective reinforcing phase in the magnesium alloy, and facilitates the damping performance of the alloy. The alloy is simple in process, high in transportability, easy to operate, lower in cost and energy-saved; and through control of the alloy components and a heat treatment process, the LPSO phase morphology and solid solution atoms of the alloy are controlled, so that the damping performance of the alloy can be greatly improved, the strength of the alloy is guaranteed, and the balance optimization of damping and mechanics of the magnesium alloy is realized.

Owner:ZHONGBEI UNIV

A low-additive halogen-free flame-retardant polylactic acid composite material and preparation method thereof

Owner:马德里高等材料研究院 +1

Zinc alloy containing Te and Os for eliminating white spots and black spots by steel hot-dip galvanizing

InactiveCN108441677AImprove fatigue performanceLimit contactHot-dipping/immersion processesBlack spotZinc alloys

The invention discloses a zinc alloy containing Te and Os for eliminating white spots and black spots by steel hot-dip galvanizing and a processing technology thereof. The zinc alloy comprises, by weight, 0.8-1.0wt.% of Ba, 0.2-0.4wt.% of Te, 0.1-0.3wt.% of Os, 3.0-4.0wt.% of In, 0.5-0.8wt.% of W, 4.0-6.0wt.% of Sn, and the balance Zinc. According to the zinc alloy, a galvanizing layer without a phase S can be obtained, and the white spots and the black spots of a coating can be inhibited.

Owner:GUANGZHOU YUZHI TECH CO LTD

A kind of preparation method of heat-expandable polyurethane

ActiveCN111978704BHigh bonding strengthMechanical properties are not affectedThermal dilatationPolymer science

The invention discloses a preparation method of heat-expandable polyurethane, which comprises the following steps: adding raw material modified expansion agent, halogen-containing flame retardant, and thermoplastic polyurethane elastomer into a dense mixture at a weight ratio of 2-4:1-2:35-45 The heat-expandable polyurethane is obtained by blending in a mill, and then hot-pressing. The invention overcomes the shortcomings of the prior art, and the flame retardant has little influence on the mechanical properties of the polyurethane, and the flame-retardant effect is good.

Owner:安徽嘉明新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com