Phosphorus silicon type inflaming retarding and non-enhancing PA66 composite material and preparation method thereof

A technology of PA66 and composite materials, applied in the field of phosphor-silicon flame retardant non-reinforced PA66 composite materials and their preparation, can solve the problems of great influence on the mechanical properties of materials, unstable flame retardant effect, etc., to achieve improved temperature resistance, high relative Tracking index, the effect of enhancing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

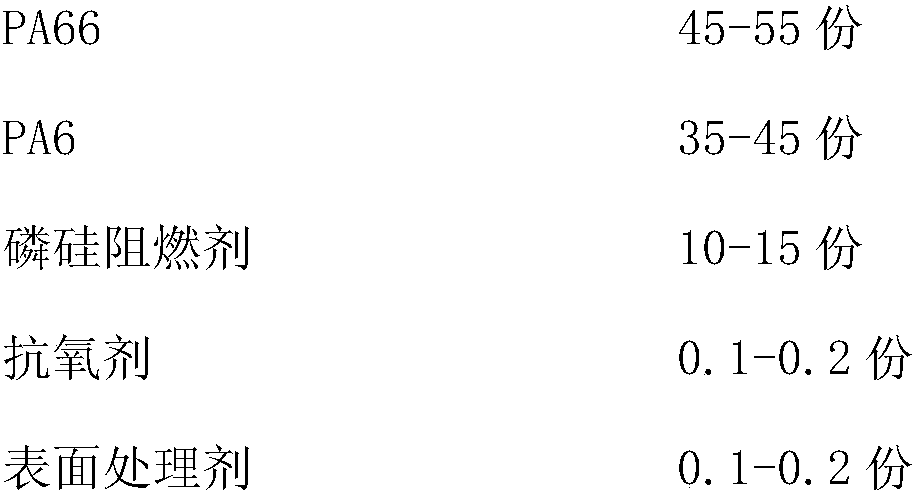

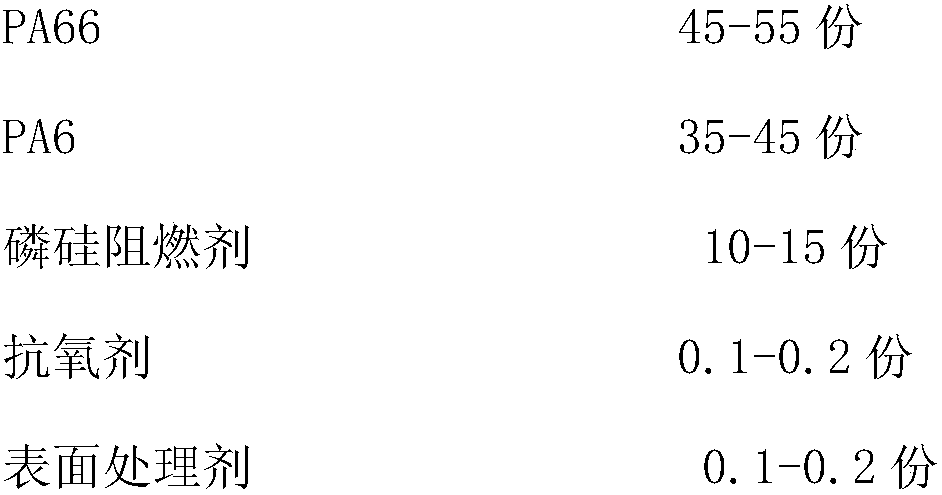

Method used

Image

Examples

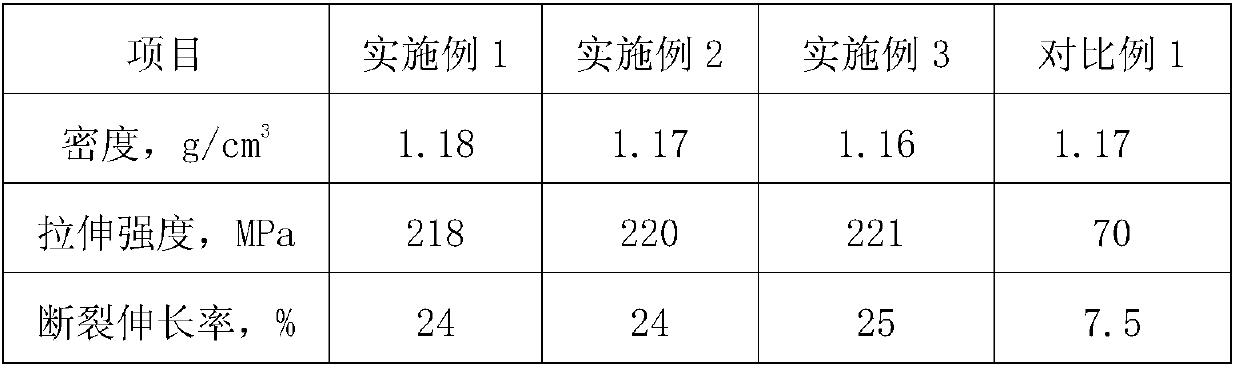

Embodiment 1

[0027] Take PA66 slices (Shenma EPR27) 55KG, PA6 slices (Polymer Shun J2500) 35KG, phosphorus silicon flame retardant 10KG, antioxidant 1010 (Abemarle) 180g and antioxidant 168 (Abemarle) 20g, surface treatment agent ( Silane coupling agent KH560) 200g.

[0028] The preparation method of phosphorus silicon flame retardant non-reinforced PA66 composite material is:

[0029] 1) First put PA66 in a drying oven to remove surface moisture. The oven temperature is 120°C for 4 hours.

[0030] 2) Mix the dried PA66 slices and the surface treatment agent with a high-speed mixer (mixing time 8 minutes, stirring speed 1500r / min).

[0031] 3) Premix the antioxidant and the flame retardant at 500r / min for 8 minutes, then add to the mixture, and stir evenly to obtain the premix.

[0032] 4) Add the above premixed material into a twin-screw extruder to melt and extrude to granulate, the extrusion temperature is 265°C, and the screw speed is 300r / min.

Embodiment 2

[0034] Take PA66 slices (Shenma EPR27) 45KG, PA6 slices (Polymer Shun J2500) 45KG, phosphorus silicon flame retardant 10KG, antioxidant 1010 (Abemarle) 180g and antioxidant 168 (Abemarle) 20g, surface treatment agent ( Silane coupling agent KH560) 200g.

[0035] The preparation method of phosphorus silicon flame retardant non-reinforced PA66 composite material is:

[0036] 1) First put PA66 in a drying oven to remove surface moisture. The oven temperature is 120°C for 4 hours.

[0037] 2) Mix the dried PA66 slices and the surface treatment agent with a high-speed mixer (mixing time 8 minutes, stirring speed 1500r / min).

[0038] 3) Premix the antioxidant and the flame retardant at 500r / min for 8 minutes, then add to the mixture, and stir evenly to obtain the premix.

[0039] 4) The above-mentioned premixed material was added into a twin-screw extruder for melt extrusion and granulation, the extrusion temperature was 265° C., and the screw speed was 300 rpm.

Embodiment 3

[0041] Take PA66 slices (Shenma EPR27) 45KG, PA6 slices (Polymer Shun J2500) 40KG, phosphorus silicon flame retardant 15KG, antioxidant 1010 (Abemarle) 180g and antioxidant 168 (Abemarle) 20g, surface treatment agent ( Silane coupling agent KH560) 200g.

[0042] The preparation method of phosphorus silicon flame retardant non-reinforced PA66 composite material is:

[0043] 1) First put PA66 in a drying oven to remove surface moisture. The oven temperature is 120°C for 4 hours.

[0044] 2) Mix the dried PA66 slices and the surface treatment agent with a high-speed mixer (mixing time 8 minutes, stirring speed 1500r / min).

[0045] 3) Premix the antioxidant and the flame retardant at 500r / min for 8 minutes, then add to the mixture, and stir evenly to obtain the premix.

[0046] 4) The above-mentioned premixed material was added into a twin-screw extruder for melt extrusion and granulation, the extrusion temperature was 265° C., and the screw speed was 300 rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com