Iron based powder for powder metallurgy

An iron-based powder and powder metallurgy technology, which is applied in metal processing equipment, thin material handling, transportation and packaging, etc., can solve the problems of uniform and sufficient filling of iron-based powder and reduction of the yield of iron powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] Each binder shown in Table 1 and iron powder, graphite powder, Cu powder, etc. shown in Table 1 were heated and mixed using a Henschel type high-speed mixer, and cooled to 60°C. Then, various fluidity-improving particles and favorable lubricants shown in Table 2 and Table 1 were added and mixed. In addition, the physical properties of the fluidity-improving particles are shown in Table 3. In addition, some samples (No. 12, No. 13) used iron powder previously subjected to an overwetting improvement treatment with a silane coupling agent (phenyltrimethoxysilane) under the above-mentioned preferred conditions.

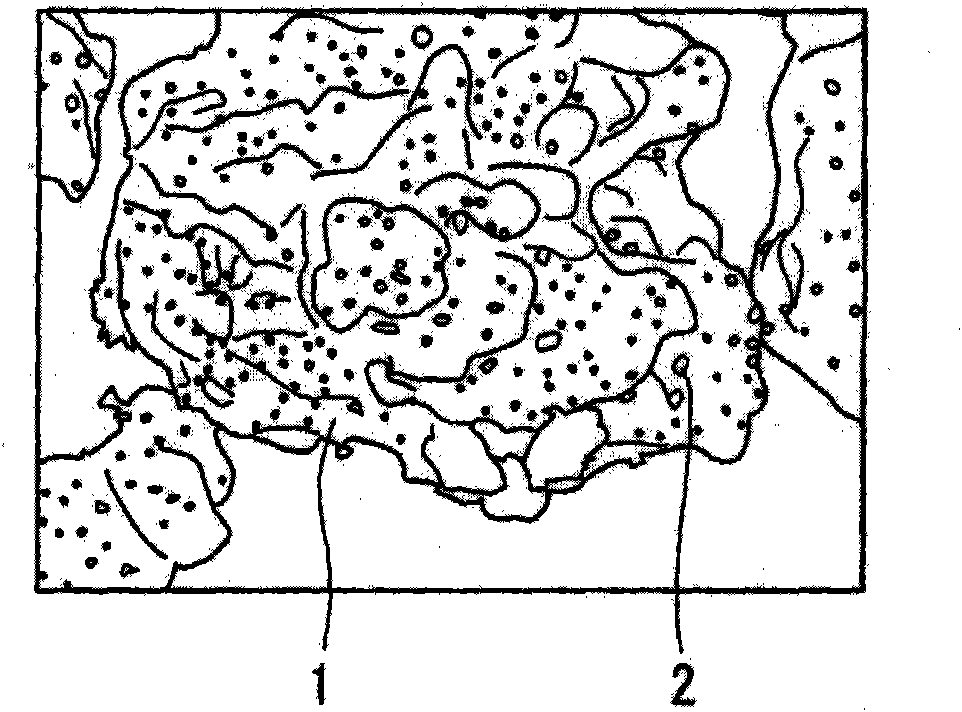

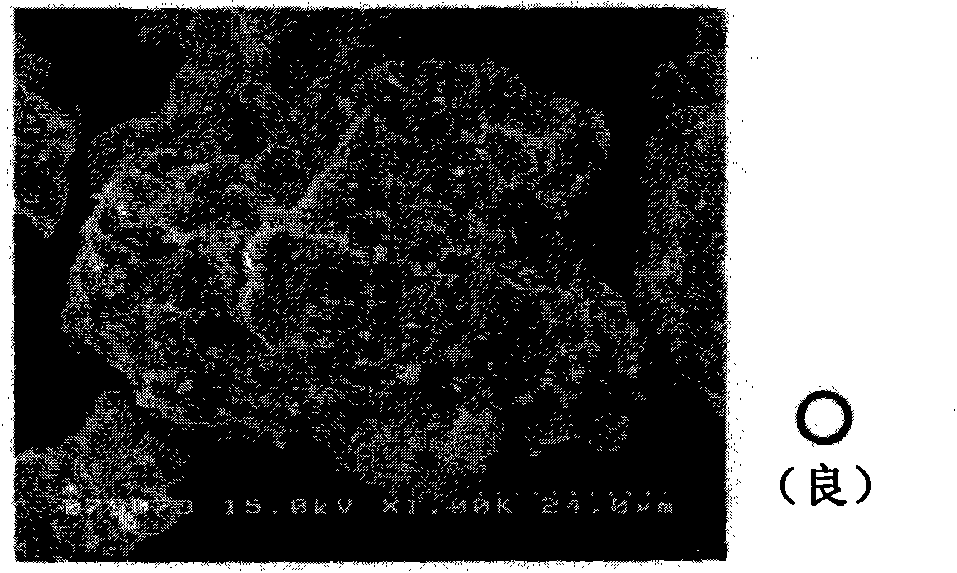

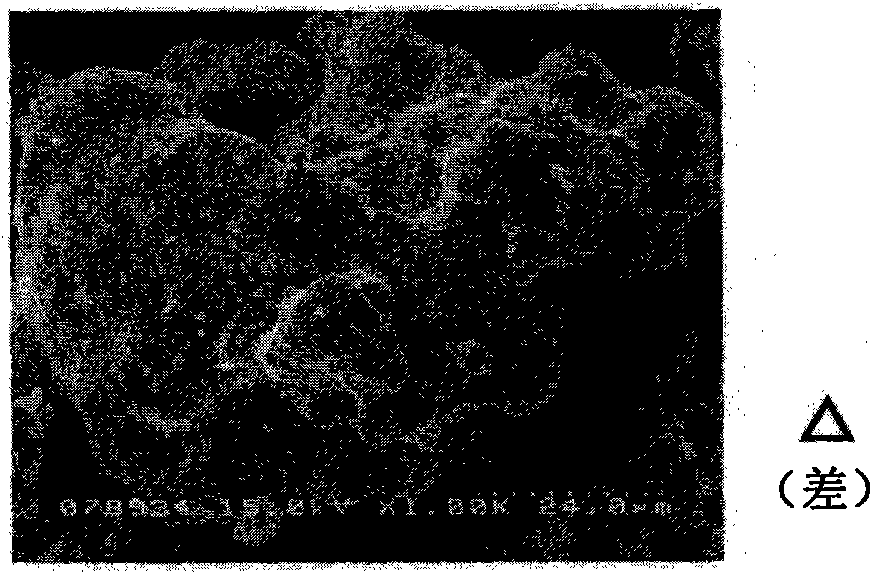

[0091] The surface of each of the obtained iron-based powders was observed using a scanning electron microscope (SEM), and the adhesion state of the fluidity-improving particles was evaluated. Examples of photographs taken of the iron-based powder surface are shown in Figure 2A ~ Figure 2C , and show the results of its evaluation together. Figure 2A ○ (良: Good...

Embodiment 2

[0116] Using a Henschel type high-speed mixer, heat and mix the binders shown in Table 4 and iron powder, graphite powder, Cu powder, etc. shown in Table 4, and cool to 60°C, and then put the Iron powder to which no binder was attached, free lubricant and fluidity-improving particles shown in Table 5. In No.31~33 and No.36~40, fluidity improving particles are pre-mixed with iron powder without binder, and then mixed with iron powder with binder attached (the above heating, mixing and cooling to 60 ℃ iron powder) mixing; in No.34 and No.35, the fluidity-improving particles and the iron powder without the binder were not previously mixed, but were mixed with the iron powder with the binder attached. In No. 40, the iron powder to which the binder was added was subjected to a wettability improvement treatment in the same manner as in Example 1.

[0117]Then, it examined similarly to Example 1. The results are shown in Table 5. In addition, all the determinations of the state of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com