Methacrylate resin with excellent discoloration-resistance and transparency and method for preparing the same

一种甲基丙烯酸酯、甲基丙烯酸丁酯的技术,应用在甲基丙烯酸酯树脂领域,能够解决低耐热性和抗脱色性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

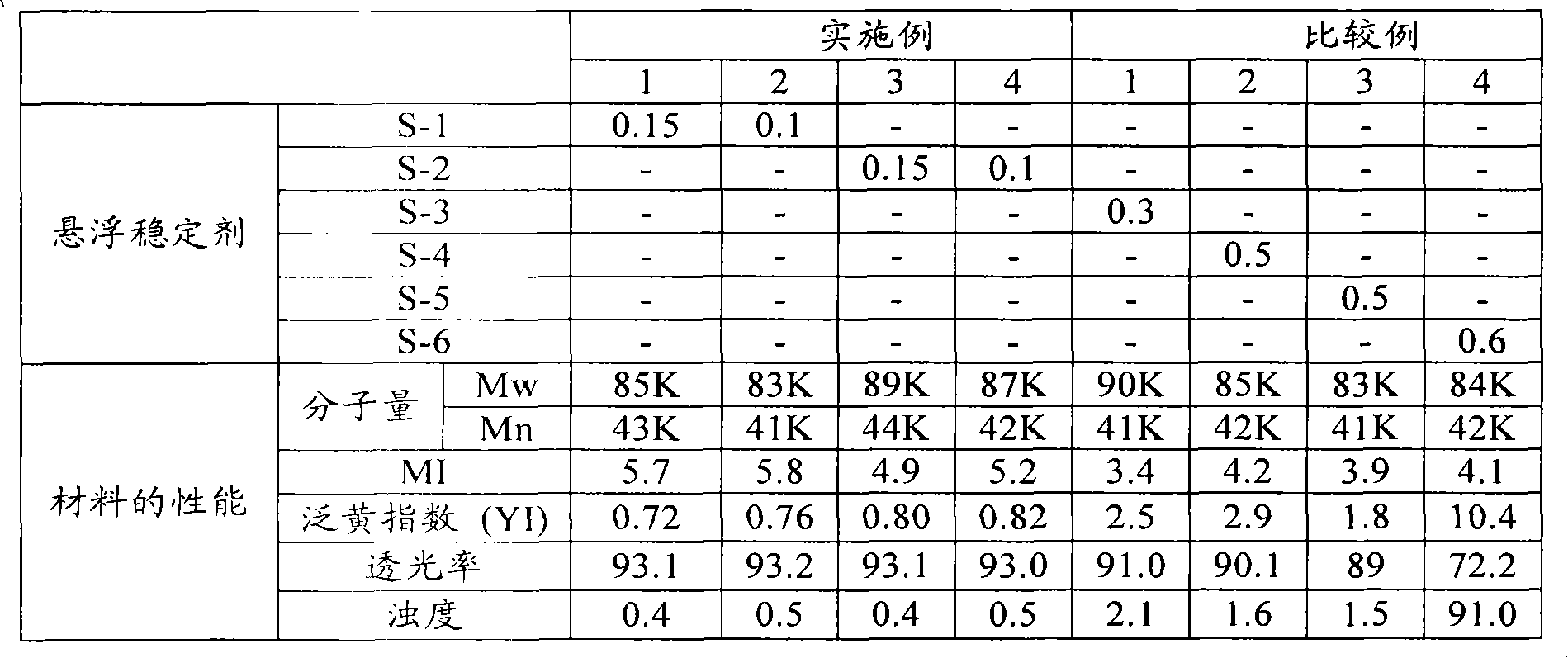

Embodiment 1

[0049] A monomer mixture including 97 parts by weight of methyl methacrylate and 3 parts by weight of methyl acrylate, 0.3 parts by weight of lauroyl peroxide, and 0.31 parts by weight of n-octyl mercaptan were mixed to form a homogeneous mixture.

[0050] Dissolve the trace suspension stabilization aids disodium hydrogen phosphate and sodium sulfate in 110 parts by weight of ion-exchanged water in a stainless steel high-pressure reactor with a stirring device, and add 0.15 parts by weight of poly(ethylene acrylate) as a suspension stabilizer to it ester - methacrylic acid (molecular weight of at least 1,000,000) and stir. To the aqueous solution of polyalkylacrylate-acrylic acid, the monomer mixture is added and vigorously stirred while purging the reactor with an inert gas such as nitrogen, argon, etc. and heating the reactor. The reaction was carried out at 72°C for 2 hours and then at 110°C for one hour to complete the polymerization. The product was washed, dehydrated an...

Embodiment 2

[0052] Example 2 was prepared in the same manner as Example 1 except that 0.1 parts by weight of polyethylacrylate-methacrylic acid was used.

Embodiment 3

[0054] Example 3 was prepared in the same manner as Example 1, except that 0.15 parts by weight of polyethylhexyl acrylate-acrylic acid was used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| visible light transmittance | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com