Non-pneumatic tire with rigid and flexible structure

A kind of non-pneumatic tire, rigid-flexible technology, applied in non-pneumatic tires, special tires, tire parts and other directions, can solve the problems such as the lack of certain guarantee of tire safety performance, the complex manufacturing process of non-pneumatic tires, and the reduction of tire performance. , to achieve the effect of excellent comprehensive performance, outstanding mechanical strength and outstanding cold resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A rigid-flexible non-pneumatic tire of the present invention will be described below in conjunction with exemplary embodiments.

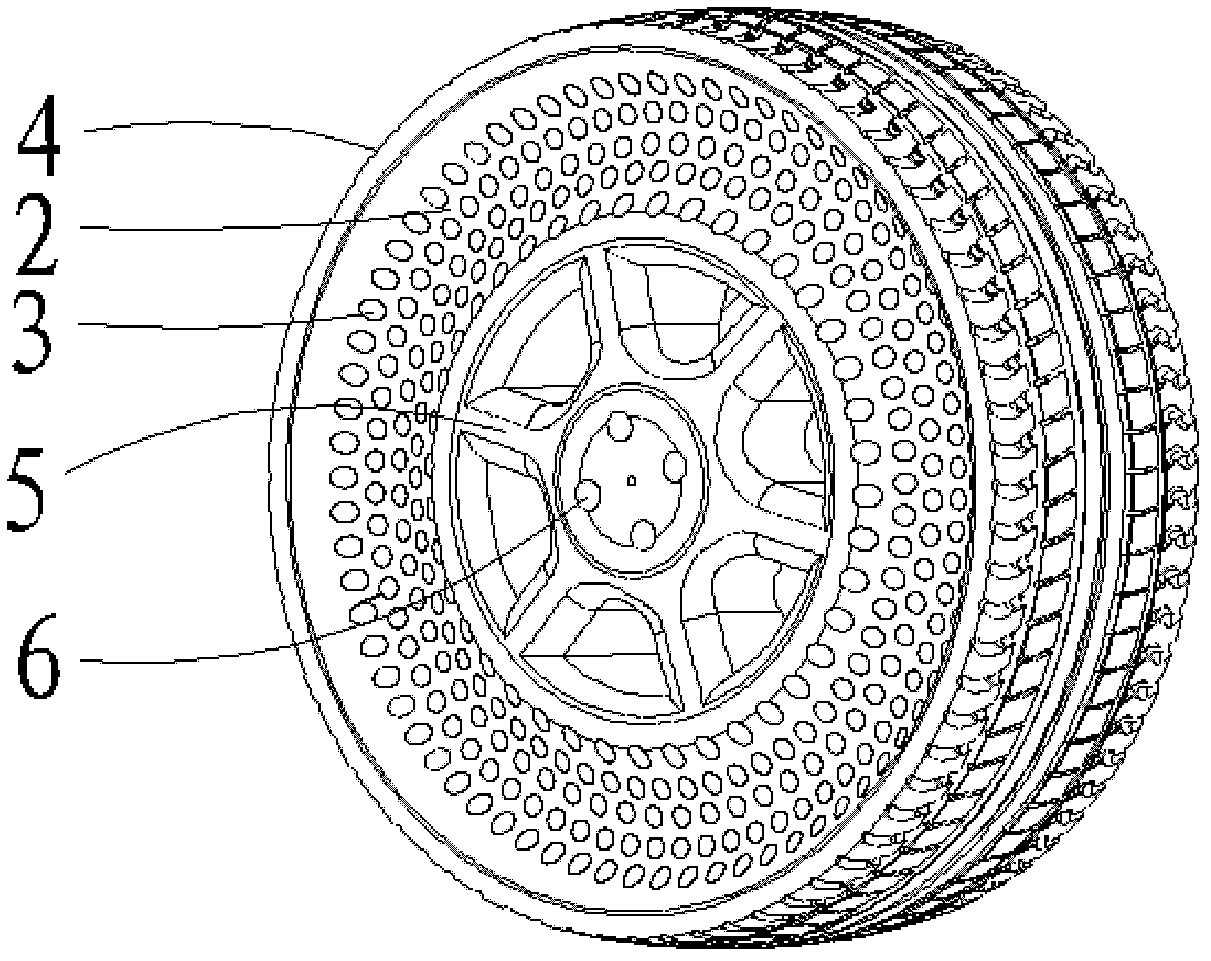

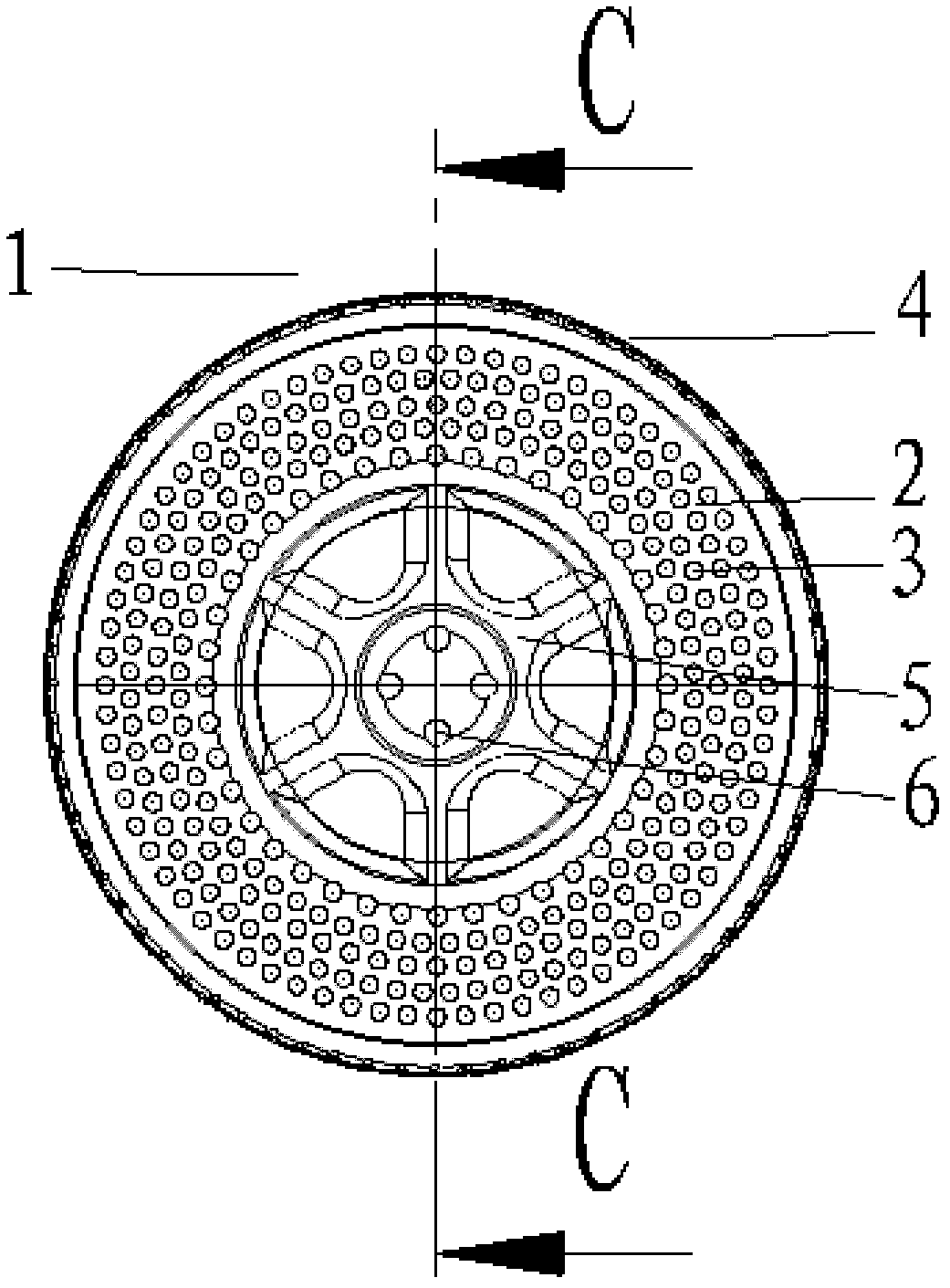

[0029] Such as figure 1 and figure 2 As shown, a rigid-flexible non-pneumatic tire 1 according to the present invention is mainly composed of two parts, the tread 4 and the carcass structure 2, and does not require other supporting elements for auxiliary installation. The hole 6 is used for the connection between the tire and the car, and the rim 5 and the carcass structure 2 belong to a complete integral structure.

[0030] The present invention is a rigid-flexible non-pneumatic tire 1 with a certain load-bearing capacity, which is comfortable and saves raw materials. Its tread 4 is mainly made of thermoplastic elastomers, such as polyurethane elastomer plastics, which not only have certain mechanical strength and It has outstanding flexibility and cold resistance, and has a wide range of hardness, which can well meet the basic physical a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com