Synthetic lubricating oil composition

A technology of lubricating oil composition and condensate, which is applied in the field of lubricating oil composition of oil and gas lubricating devices, can solve problems such as blockage of distributor conveying pipelines, poor lubrication of lubrication points, insufficient refining depth, etc., and achieves reduction of wear and high temperature. The effect of coking and technical difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The lubricating oil composition of this embodiment, it comprises: the EO / PO random water-insoluble polyether base oil (component A) of the butyl termination of 95.68wt%; The saturated dipentaerythritol ester of neopentyl decanoate of 3.0wt% (component B); 0.30wt% tricresyl phosphate and 0.2wt% diisooctyl phosphate stearylamine salt (component C); 0.02wt% benzotriazole dioctylamine formaldehyde condensate (component D ); 0.20wt% isopropyl isooctyl phosphate dodecylamine salt (component E); 0.40wt% 2,6-di-tert-butyl-p-cresol and 0.20wt% dialkyldiphenylamine (component Part F); 30 μg / g silicone antifoam (component G).

Embodiment 2

[0053] The lubricating oil composition of this embodiment, it comprises: the EO / PO random water-insoluble polyether base oil (component A) of the butyl termination of 93.68wt%; The saturated dipentaerythritol ester of neopentyl decanoate of 5.0wt% (Component B); 0.30 wt% tricresyl phosphate and 0.2 wt% butyl isooctyl phosphite-N,N-dibutylamine salt (component C); 0.02 wt% benzotriazole dioctylamine formaldehyde condensation 0.20 wt% dodecenylsuccinate half ester (component E); 0.40 wt% of 2,6-di-tert-butyl-p-cresol and 0.20 wt% of dialkyldiphenylamine (Component F); 30 μg / g silicone antifoam (component G).

Embodiment 3

[0055] The lubricating oil composition of this embodiment, it comprises: the EO / PO random water-insoluble polyether base oil (component A) of 93.68wt% butyl termination; 5.0wt% trimellitate (component B ); 0.30 wt% tricresyl phosphate and 0.2 wt% 2,5-dimercaptothiadiazole-N,N-dibutylamine salt derivative (component C); 0.02 wt% benzotriazole dioctylamine Formaldehyde condensate (component D); 0.20 wt% barium dinonylnaphthalene carboxylate (component E); 0.40 wt% of 2,6-di-tert-butyl-p-cresol and 0.20 wt% of dialkyldianiline (Component F); 30 μg / g silicone antifoam (component G).

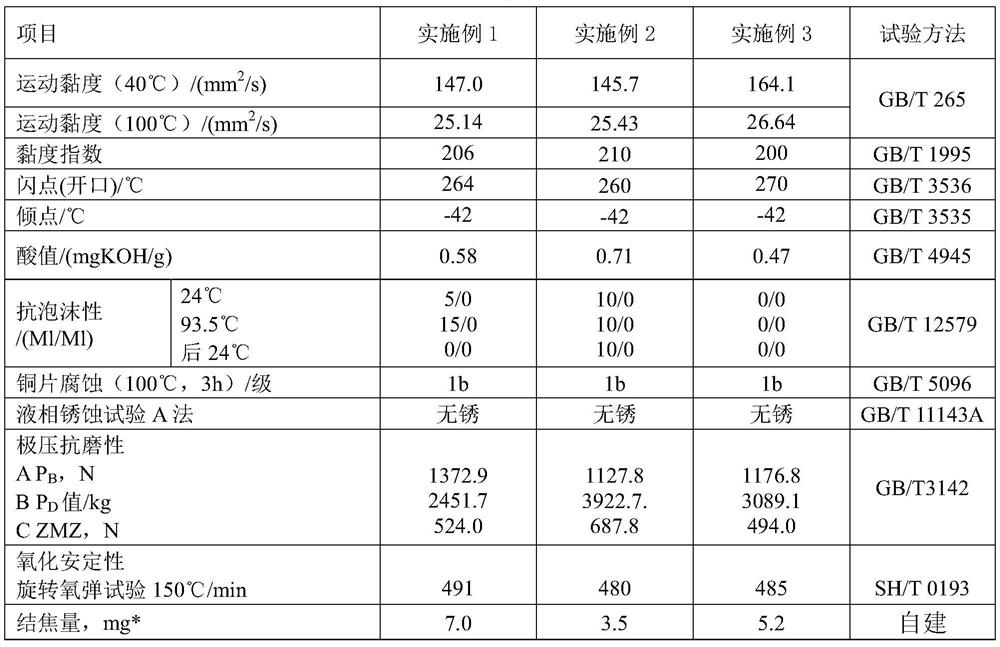

[0056] The main physical and chemical properties of the lubricating oil compositions of Example 1, Example 2, and Example 3 are shown in Table 1.

[0057] Table 1

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com