Combination of general gear oil

A technology of composition and gear oil, which is applied in the direction of lubricating composition and petroleum industry, etc., can solve the problems of relatively little research on the effect of additive compounding, and achieve the effects of improving thermal oxidation stability, reducing total consumption, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

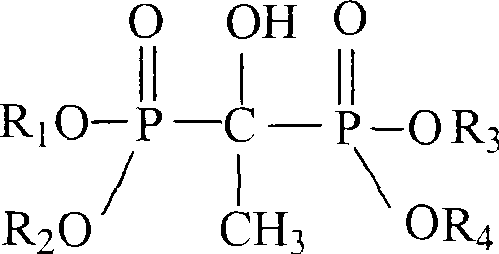

Method used

Image

Examples

example 1

[0020] First formulate the base oil of the general purpose gear oil composition of the present invention. In a mixing tank with agitator, add 25% by weight of HVI100SN mineral oil, 75% by weight of HVI 120BS mineral oil, and add 1.0% by weight of pour point depressant polyalpha-olefin and 0.6% by weight of viscosity index improver polymethacrylate , stirred at 70-80° C. for 1-3 h to obtain the 80 wt / 90 base oil of the composition of the present invention. Then add 3.0% by weight of sulfurized isobutylene, 1.0% by weight of triphenyl thiophosphate, 0.03% by weight of benzotriazole, 0.2% by weight of phosphonate, 0.05% by weight of synthetic calcium sulfonate, 0.5% by weight Isooctyl acid phosphate amine salt. Continue to heat and stir for 1-3h, thus obtaining the general gear oil composition of the present invention. The results are shown in Table 1.

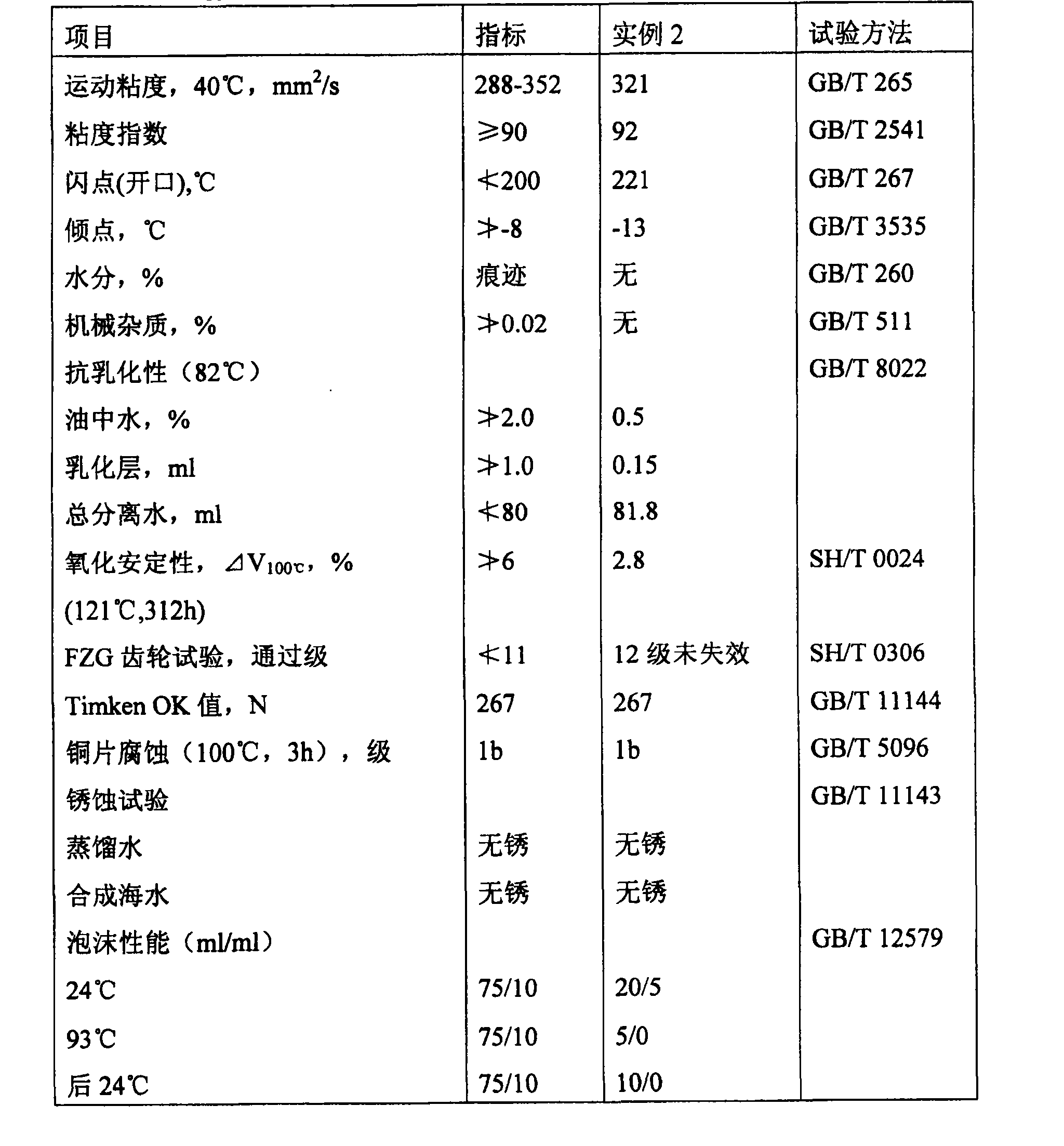

example 2

[0022] First formulate the base oil of the general purpose gear oil composition of the present invention. In the blending kettle with agitator, add polyalpha-olefin synthetic oil (40℃ kinematic viscosity 336mm 2 / s), and add 0.8% by weight viscosity index improver polymethacrylate, stir at 70-80°C for 1-3h, to obtain the N of the composition of the present invention 320 base oil. Then add 0.85% by weight of sulfurized isobutylene, 0.5% by weight of phosphorothioate double ester amine salt, 0.03% by weight of tolutriazole, 0.1% by weight of phosphonate, 0.03% by weight of petroleum calcium sulfonate, 0.1% by weight % isooctyl acid phosphate amine salt, and continue to heat and stir for 1-3h, thus obtaining the general gear oil composition of the present invention. The results are shown in Table 2.

example 3

[0024] First formulate the base oil of the general purpose gear oil composition of the present invention. In a mixing kettle with a stirrer, add 45% by weight of HVI350SN mineral oil, 55% by weight of poly-α-olefin synthetic oil (100°C kinematic viscosity 32.6mm 2 / s), and adding 0.8% by weight viscosity index improver polymethacrylate, stirring at 70-80°C for 1-3h, to obtain the 85% by weight / 90 base oil of the composition of the present invention. Then add 1.5% by weight of sulfurized isobutylene, 0.6% by weight of nitrogen-containing derivatives of sulfuric acid phosphoric acid, 0.04% by weight of thiadiazole polysulfide, 0.15% by weight of phosphonate, 0.13% by weight of isooctyl acid phosphate amine Salt. Continue to heat and stir for 1-3h, thus obtaining the general gear oil composition of the present invention. The results are shown in Table 3.

[0025] Table 1 Main properties of 80W / 90 GL-5 gear oil composition

[0026]

project

index

Example ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com