Gear oil special for reduction gearbox of pumping unit

A reduction box and gear oil technology, applied in the field of lubrication, can solve the problems that industrial gear oil can not fully meet the requirements of oil pumping unit reduction box oil, can not fully apply to the pumping unit reduction box and other problems, achieve excellent shear stability, The effect of reducing surface pitting and improving anti-emulsification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

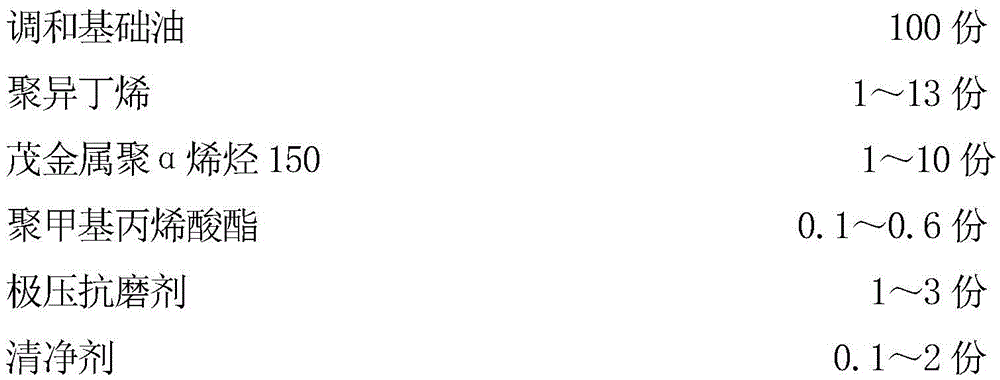

[0027] Taking the used blending base oil 1000g as an example for preparing the special gear oil for pumping unit reduction box of the present invention, its raw material composition is as follows:

[0028]

[0029] The preparation method is as follows: mix 900g of paraffinic base oil 600SN, 80g of residual oil 150BS, and 20g of hydrogenated refined oil 250N to prepare 1000g of blended base oil, and then add 90g of polyisobutylene PB2400 and 50g of metallocene to 1000g of blended base oil Polyalphaolefin 150, 4g polymethacrylate with an average molecular weight of 70,000, 5g ammonium thiophosphate, 5g zinc dioctyl dithiophosphate, 3g oil-soluble molybdenum, 10g T154A polyisobutylene succinimide, 30g T106D High base value synthetic calcium sulfonate, 0.01g methyl silicone oil T901, T1001 anti-emulsifier, stir evenly, heat up to 70°C, then add 0.5g benzotriazole completely dissolved in ethanol, stir at constant temperature until ethanol is completely volatilized, Obtain specia...

Embodiment 2

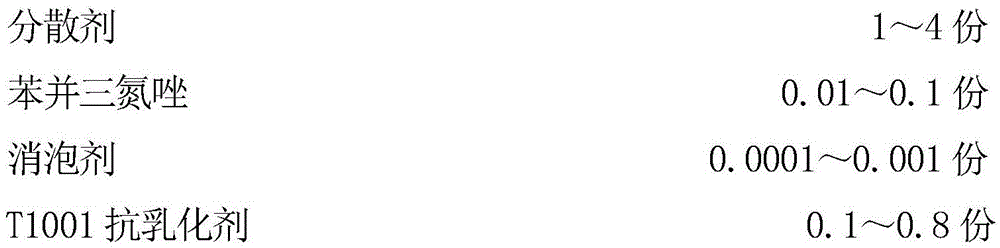

[0031] Taking the used blending base oil 1000g as an example for preparing the special gear oil for pumping unit reduction box of the present invention, its raw material composition is as follows:

[0032]

[0033]

[0034] Its preparation method is identical with embodiment 1.

Embodiment 3

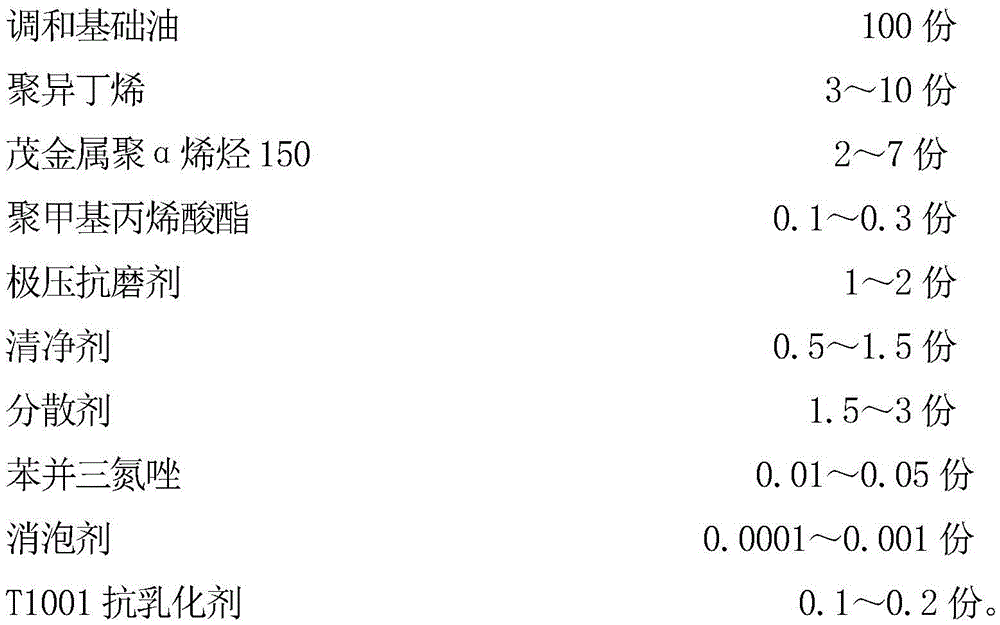

[0036] Taking the used blending base oil 1000g as an example for preparing the special gear oil for pumping unit reduction box of the present invention, its raw material composition is as follows:

[0037]

[0038] Its preparation method is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com