Ashless antiwear oil film bearing lubricant composition

A technology of lubricating oil composition and oil film bearing, applied in the field of lubricating oil composition and oil film bearing system lubricating oil composition, can solve the problems of unpublished anti-wear oil film bearing oil and the like, achieve excellent filterability and low production cost , the effect of good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

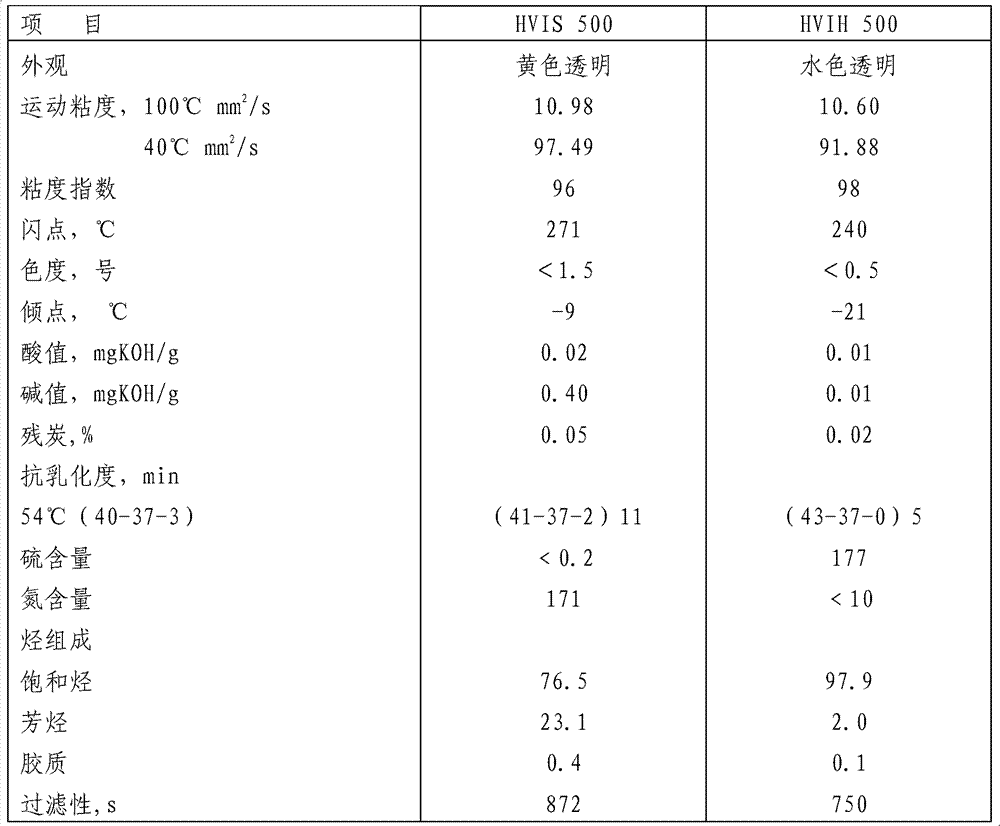

Embodiment 1

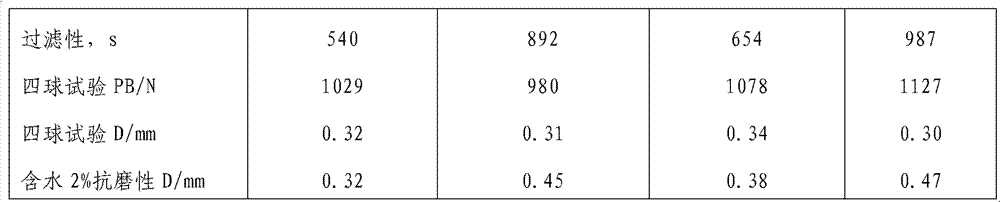

[0019] Lubricating oil composition (I), it comprises: 94.88wt% solvent deep refined mineral oil HVIS 500 (component A); 1.00wt% lauryl acrylate (component B); 0.10wt% polyethylene glycol Alcohol ether (component C); 1.0 wt% tricresyl phosphate, 1.0 wt% n-butyl phosphorothioate (component D); 0.50 wt% 2,6-di-tert-butyl p-cresol, 0.50 The N-phenyl-α-naphthylamine of wt%, the di-n-butyl dithiocarbamate of 0.50wt%, the dinonyl diphenylamine (component E) of 0.50wt%; The benzene triphenylamine of 0.02wt% Azole di-n-butylamine formaldehyde condensate (component F). Lubricating oil composition (II) is the same as composition (I) except that 1.00wt% of lauryl acrylate in component (B) is replaced by 1.00wt% of ethylene glycol oleate. Lubricating oil composition (III) is the same as composition (I) except that 1.00wt% of lauryl acrylate in component (B) is replaced by 1.00wt% of di(dodecyl)succinate. The lubricating oil composition (IV) is the same as the composition (I) except that ...

Embodiment 2

[0027]Lubricating oil composition (V), it comprises: 97.115wt% isomerization dewaxed hydrorefined mineral oil HVIH500 (component A); 0.10wt% lauryl acrylate (component B); 0.005wt% of Ethylene oxide propylene oxide copolyether (component C); 0.5 wt% diisooctyl phosphate stearylamine salt, 0.5 wt% lauryl thiophosphate, 0.2 wt% di-n-butyl Phosphorodithioate (component D); 1.00 wt% of 2,6-di-tert-butyl-p-cresol, 0.10 wt% of N-phenyl-α-naphthylamine, 0.20 wt% of diisooctyl Dithiocarbamate, 0.20% by weight of n-butyloctyldiphenylamine (component E); 0.08% by weight of benzotriazole di-n-octylamine formaldehyde condensate (component F). Lubricating oil composition (VI) is the same as composition (V) except that 0.10 wt% lauryl acrylate in component (B) is replaced by 0.50 wt% lauryl acrylate. Lubricating oil composition (VII) is the same as composition (V) except that 0.10 wt% lauryl acrylate in component (B) is replaced by 1.00 wt% lauryl acrylate. Compositions (V), (VI), (VII) i...

Embodiment 3

[0032] Lubricating oil composition (VIII), it comprises: 97.59wt% isomerism dewaxed hydrorefined mineral oil HVIH500 (component A); 0.30wt% diisooctyl adipate (component B); 0.01wt% % ethylene oxide propylene oxide copolyether (component C); 1.0 wt% tricresyl phosphate (component D); 0.50 wt% diisooctyl dithiocarbamate, 0.50 wt% Di-n-octyl diphenylamine (component E); 0.10 wt% benzotriazole di-n-octylamine formaldehyde condensate (component F). Lubricating oil composition (IX) is the same as composition (VIII) except that 0.01 wt% of ethylene oxide propylene oxide copolyether in component (C) is replaced by 0.01 wt% of polyethylene glycol ether. Lubricating oil composition (X) is the same as composition (VIII) except that 0.01 wt% of ethylene oxide propylene oxide copolyether in component (C) is replaced by 0.01 wt% of polyglycerol ether. Compositions (VIII), (IX), (X) in the main properties, performance list 4.

[0033] Table 4 composition main properties, performance

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com