Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Meet lubrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rolling oil composition for 12-roller reversing mill

The invention relates to a rolling oil composition used for a twelve-high reversing cluster mill; the rolling oil composition belongs to the field of metallurgical steel rolling oil products, and comprises the components according to weight percent as follows: 60-70 percent of compound neopentyl polyol ester, 14-28 percent of mineral oil, 1-5 percent of phosphorus-containing extreme-pressure and anti-wear agent, 1-5 percent of sulfur-containing extreme-pressure and anti-wear agent, 2-12 percent of compound emulsifier, 1-3 percent of anti-rust agent, 1-3 percent of antioxidant and 0.01-0.5 percent of defoamer; the rolling oil composition takes the compound neopentyl polyol ester synthetic ester with excellent lubricating performance as the lubricating basic component; an oiliness agent main body with high lubricating performance and high extreme-pressure and anti-wear performance is composed by adding the scientific components of the phosphorus-containing and the sulfur-containing extreme-pressure and anti-wear agents; and the anti-rust performance and the emulsion stability are ensured by adopting the mineral oil, the anti-rust oil, the emulsifier and the antioxidant with the appropriate proportion for coordination, thereby creatively solving the contradiction between the lubricating performance and the detergence, ensuring the requirements on the lubricating performance of the quality when rolling steel plates with thin specifications, protecting the lubricating requirements of back-up bearings and ensuring the volatility and the annealing detergence under the cleaning-free condition.

Owner:WUHAN TONGSHENG FINE CHEM TECH DEV

Sedan hand gearshift case gear lubricating oil composition

ActiveCN101298578AMeet lubricationMeet lubrication requirementsAdditivesBase-materialsGear wheelBench test

The invention provides a gear lubricant composite for manual transmissions of the light cars, comprising (A) at least one type of refining mineral oil with high viscosity index, or polyolefin synthesis oil, or ester lubricants, or a free composite of the above components, (B) at least one type of viscosity index improver, (C) at least one type of pour point depressant, (D) at least one type of extreme pressure additive with sulfurs, (E) at least one type of anti-wear additive with phosphorus, (F) at least one type of wear, oxygen, and corrosion-preventing multifunctional additive with phosphorus, (G) at least one type of anti-rusting additive, and (H) at least one type of friction modifier. The lubricant composite has excellent performance of high and low temperature, which can meet the requirements of gear oil with a viscosity grade of 75W / 90. Moreover, passing the full-size gear bench tests as CRCL-42, L-37, L-33, L-60, and L-60-1 as well as cycle bench tests for the manual transmissions of the light cars, the gear lubricant composite can meet lubrication requirements of the manual transmissions of the light top-grade cars.

Owner:PETROCHINA CO LTD

Special gear lubricating oil composition for high speed train

ActiveCN103509636AExcellent high speed scratch resistanceExcellent high temperature detergencyLubricant compositionFriction reductionViscosity index

The present invention provides a special gear lubricating oil composition for a high speed train. The special gear lubricating oil composition comprises: (A) at least a high viscosity index hydrorefining III mineral oil, or polyolefin synthesis oil, or ester synthesis oil, or an any combination selected from the above components; (B) at least a viscosity index improver; (C) at least a pour point depressant; (D) at least a vehicle gear oil composite additive; (E) at least a phosphorus-containing anti-wear additive; (F) at least a metal deactivation additive; (G) at least an ash-free dispersion additive; and (H) at least an energy-saving friction-reduction agent. The lubricating oil composition has characteristics of excellent high speed anti-scratching performance, excellent high temperature detergency and excellent energy-saving friction-reduction performance, wherein the high speed anti-scratching performance of the lubricating oil composition can be increased by 33% and transmission efficiency can be increased by 15% compared with the commercially available API GL-5 vehicle gear oil.

Owner:PETROCHINA CO LTD

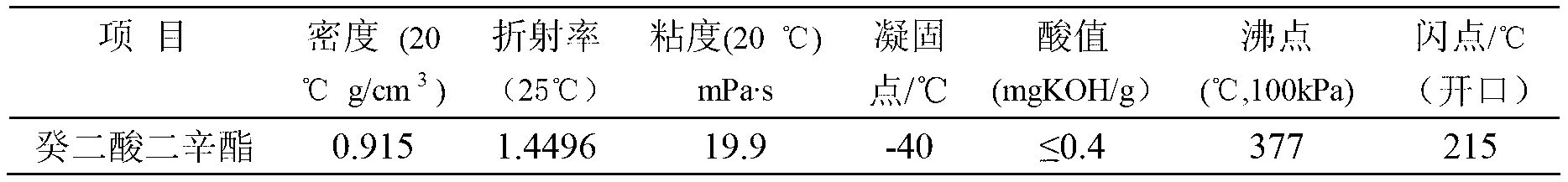

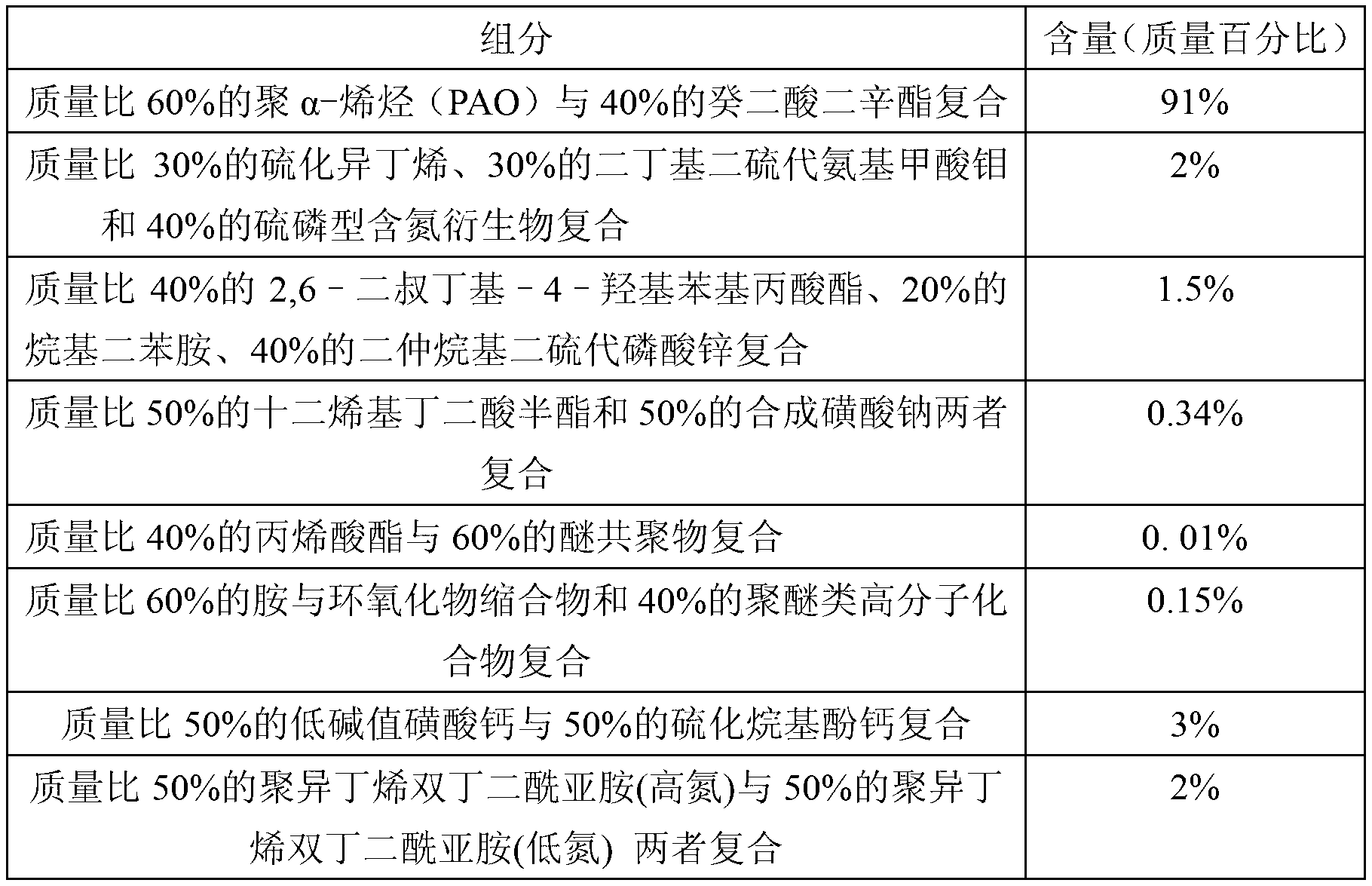

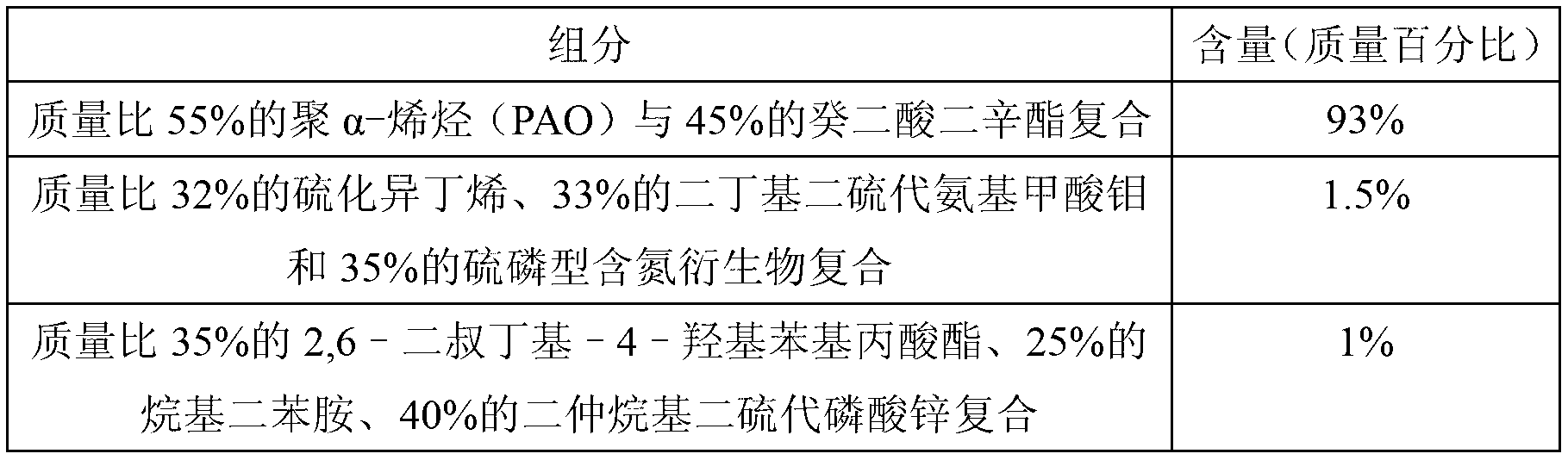

Environmentally-friendly energy-saving-type heavy loading screw compressor oil

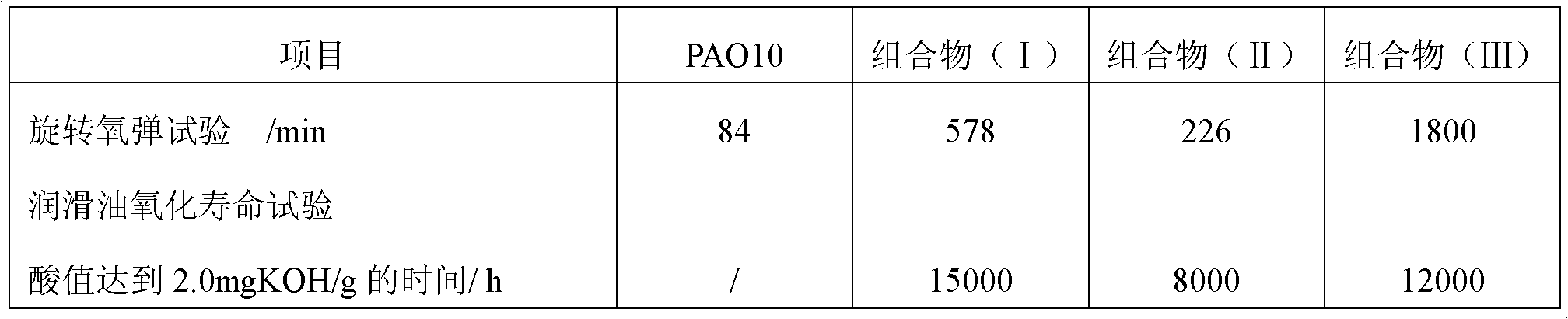

ActiveCN103194301AGood low viscosityLow volatilityLubricant compositionLubricationEnvironmentally friendly

The invention provides environmentally-friendly energy-saving-type heavy loading screw compressor oil. The environmentally-friendly energy-saving-type heavy loading screw compressor oil comprises 90-95% of composite base oil and 10%-5% of other additives in percentage by weight. Poly Alpha-Olefins (PAO) and dioctyl sebacate are compounded to serve as the base oil of the environmentally-friendly energy-saving-type heavy loading screw compressor oil. The environmentally-friendly energy-saving-type heavy loading screw compressor oil provided by the invention has the advantages of good operating characteristics, long service life and good biodegradability and also has effects of improving the efficiency of a screw compressor, reducing the abrasion and corrosion of a screw, effectively prolong the service life and the oil draining period of the screw compressor and meeting the requirements under special service conditions. The environmentally-friendly energy-saving-type heavy loading screw compressor oil provided by the invention is not only suitable for the requirements of various middle-heavy loading screw compressors under service conditions, and but also can meet the lubrication, cooling and sealing requirements of the middle-heavy loading sliding vane compressors.

Owner:GUANGXI UNIV

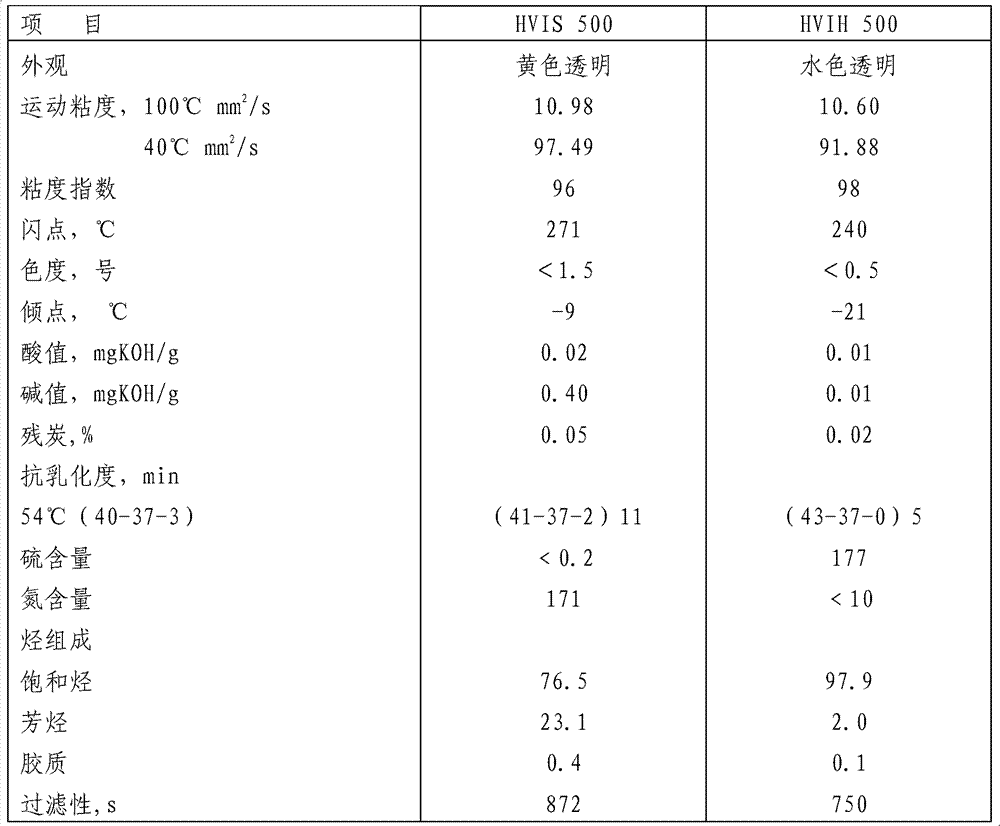

Ashless antiwear oil film bearing lubricant composition

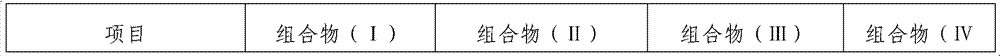

ActiveCN102766505AImprove filtering effectGood demulsibilityLubricant compositionWire rodFoaming agent

The invention provides an ashless antiwear oil film bearing lubricant composition, which comprises: (A) at least a highly refined mineral oil with high viscosity index; (B) at least an emulsifier; (C) at least an anti-foaming agent; (D) at least an ashless phosphorus-containing antiwear additive; (E) at least an anti-oxidant; and (F) at least a metal passivator. The above lubricant component has excellent demulsibility, filterability, anti-foaming property, air release property, abrasion resistance and oxidation resistance, passes through FAG FE-8 bearing wear experiments, SKFEMCOR bearing corrosion experiments and FLENDER anti-foaming experiments, and is suitable for lubricating various bearings and industrial gears, especially lubricating highspeed wire rod oil film bearings.

Owner:PETROCHINA CO LTD

Energy-efficient vehicle gear lubricating oil composition

InactiveCN102417848AImprove performanceEasy to deployLubricant compositionRandom combinationPolyolefin

The invention provides an energy-efficient vehicle gear lubricating oil composition, which contains (A) at least a highly refined mineral oil with high viscosity index, or polyolefin cogasin, or ester cogasin, or random combination of the above components; (B) at least a viscosity-index improver; (C) at least a pour-point depressant; (D) at least a sulfur-containing extreme pressure additive; (E) at least a phosphorus-containing antiwear additive; (F) at least a metal deactivation additive; (G) at least an antirust additive; and (H) at least an energy-saving friction-reducing agent. The above lubricating oil composition has excellent energy-saving antifriction performance. Through the test evaluation of FZG gear drive efficiency, the lubricating oil composition provided by the invention can be used to raise transmission efficiency by 5-15% in comparison with commercial vehicle gear oil.

Owner:PETROCHINA CO LTD

Preparation of high-speed bearing grease

The invention discloses preparation of high-speed bearing grease, and the grease is particularly applied for lubricating high-speed bearings in the industries of electronics, machine tool manufacturing, textile chemical fiber and the like. The grease consists of base oil and thickening agent, the penetration of the prepared grease is between 200 and 340 at the temperature of 25 DEG C, and the similar viscosity is smaller than 1400 at the temperature of minus 50 DEG C. The grease can meet the lubrication of the bearing the speed factor (DN value) of which is more than 2 million, can lubricate completely in a cold environment, and produces very small noise.

Owner:益田润石(北京)化工有限公司

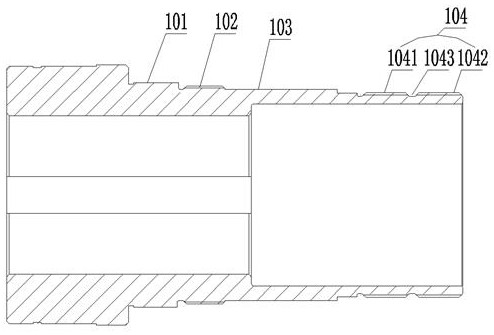

Bearing-lubricating device of turbojet engine

The invention discloses a bearing-lubricating device of a turbojet engine. The turbojet engine is provided with an oil inlet, and a lubricating oil tube is arranged from the oil inlet to the interior of the turbojet engine; a bushing is arranged in the turbojet engine, a spindle is arranged in the bushing, the front end of the spindle is provided with a front bearing pedestal and a front bearing, the rear end of the spindle is provided with a rear bearing pedestal and a rear bearing, the bushing is provided with a rear-bearing oil inlet close to the position of the rear bearing pedestal, and a front-bearing oil inlet is arranged at a position in the turbojet engine, which is close to the front bearing pedestal. A dedicated lubricating system or lubricating oil tank does not need to be arranged on the outside of the bearing-lubricating device, the bearings can be lubricated as long as lubricant is added in aviation kerosene according to an appropriate proportion, thereby, the bearing-lubricating device has convenient use and good lubricating effect.

Owner:SHENZHEN ANTUOSHAN TECH

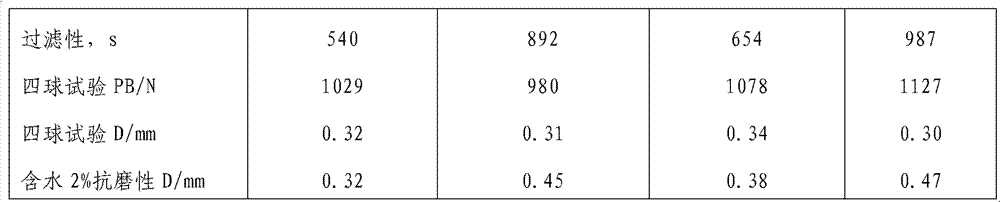

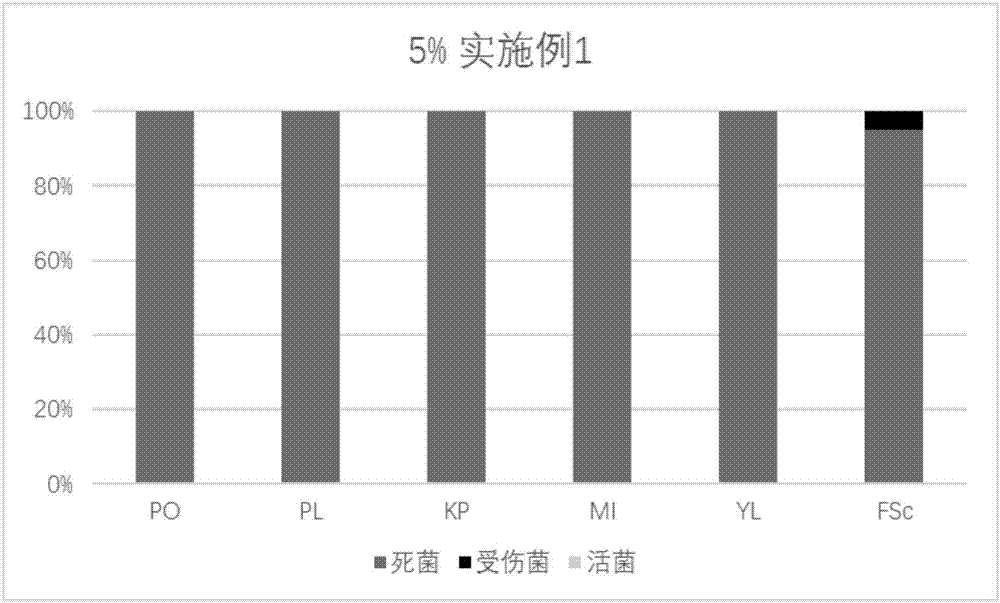

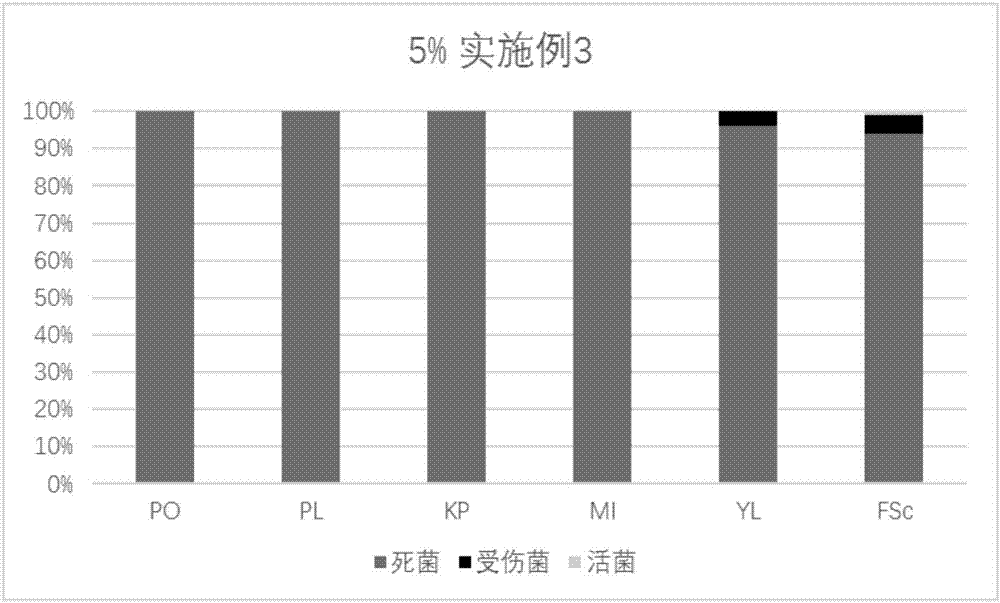

Composite fungicide and metal cutting fluid with same and preparation method of composite fungicide

ActiveCN107125249AImprove the bactericidal effectOvercoming the problem of poor sterilization effectBiocideDead animal preservationKetoneLubrication

The invention provides a composite fungicide and metal cutting fluid with the same and a preparation method of the composite fungicide. The composite fungicide comprises 1,2-benzisothiazole-3-ketone, epsilon-polylysine and water-soluble organic amino. In the composite fungicide provided by the invention, the three components, namely the 1,2-benzisothiazole-3-ketone, the epsilon-polylysine and the water-soluble organic amino are synergistic, so that the sterilization effect of the composite fungicide is improved; and the metal cutting fluid with the composite fungicide is good in sterilization effect, remarkable in biological stability, high in security and wide in application prospect, meets on-site process requirements such as lubrication, cooling, emulsion stability and corrosion resistance, and meets ideas of green chemicals.

Owner:QUAKER CHEM CHINA

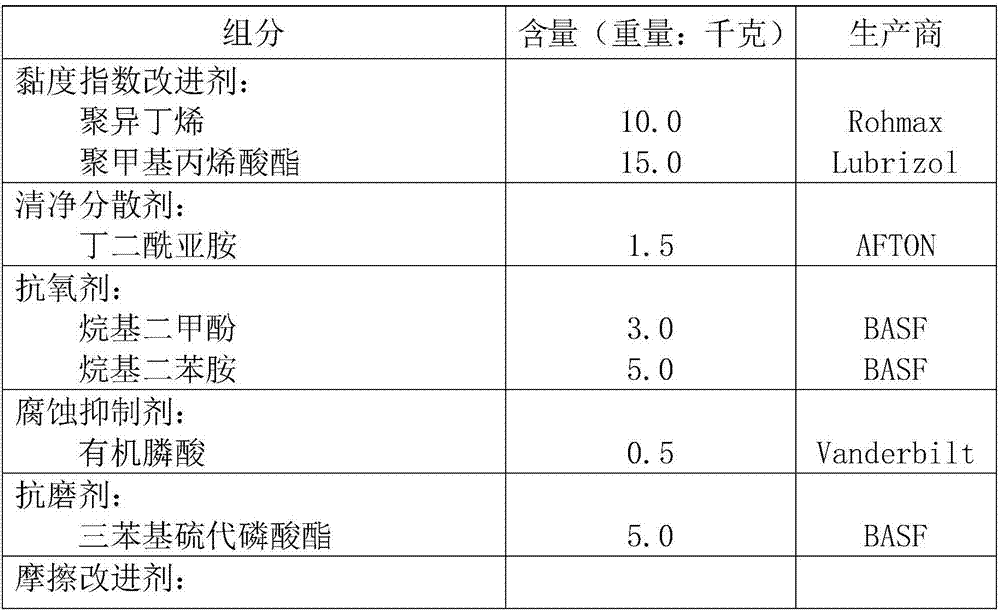

Composition used for pure electric vehicle transmission oil and preparation method thereof as well as transmission oil containing composition and preparation method thereof

ActiveCN106929129AStrong material adaptabilityMeet lubricationLubricant compositionAntioxidantHigh pressure

The invention relates to the field of lubricating oil and in particular discloses a composition used for pure electric vehicle transmission oil and a preparation method thereof as well as transmission oil containing the composition and a preparation method thereof. The composition used for the pure electric vehicle transmission oil is prepared from the following components in parts by weight: 5-25 parts of a viscosity index improver, 0.5-1.5 parts of a purification dispersant, 2-8 parts of an antioxidant, 0.05-0.5 part of a corrosion inhibitor, 1.5-5.0 parts of an antiwear agent, 0.5-3.0 parts of a friction modifier, 0.5-1.5 parts of an anti-aging agent, 0.01-0.1 part of an anti-foaming agent and the balance of base oil A, wherein the total parts by weight of the components is 100 parts. The composition used for the pure electric vehicle transmission oil and the transmission oil containing the composition can provide excellent oxidation stability, excellent antifoaming property, excellent antiwear corrosion-resistant property, good material adaptability with a pure electric vehicle transmission and copper protection performance under high voltage and high current conditions.

Owner:TEXAS PETROCHEM YANTAI

Safe antibacterial cutting fluid

InactiveCN104059755AMeet lubricationMeet rustLubricant compositionPolyethylene glycolTricarboxylic acid

The invention relates to a safe antibacterial cutting fluid, which is prepared from the following raw materials in parts by weight: 14-27 parts of diethanol amine boric acid polycarboxylic acid composite ester, 16-23 parts of inositol hexaphosphate ester, 30-36 parts of petroleum sodium sulfonate, 3-6.5 parts of ethyl vanillin, 8-16 parts of polyethylene glycol, 1.6-3.3 parts of sodium benzoate, 4.5-8 parts of barium tricarboxylic acid, 3-7 parts of sodium gluconate, and 80 parts of water. The safe antibacterial cutting fluid can meet the functions of lubricating, antirust, cooling and washing, has strong antibacterial ability, does not give out odor in long time and is harmless to human bodies.

Owner:QINGDAO GUOQIANG ENVIRONMENTAL PROTECTION TECH

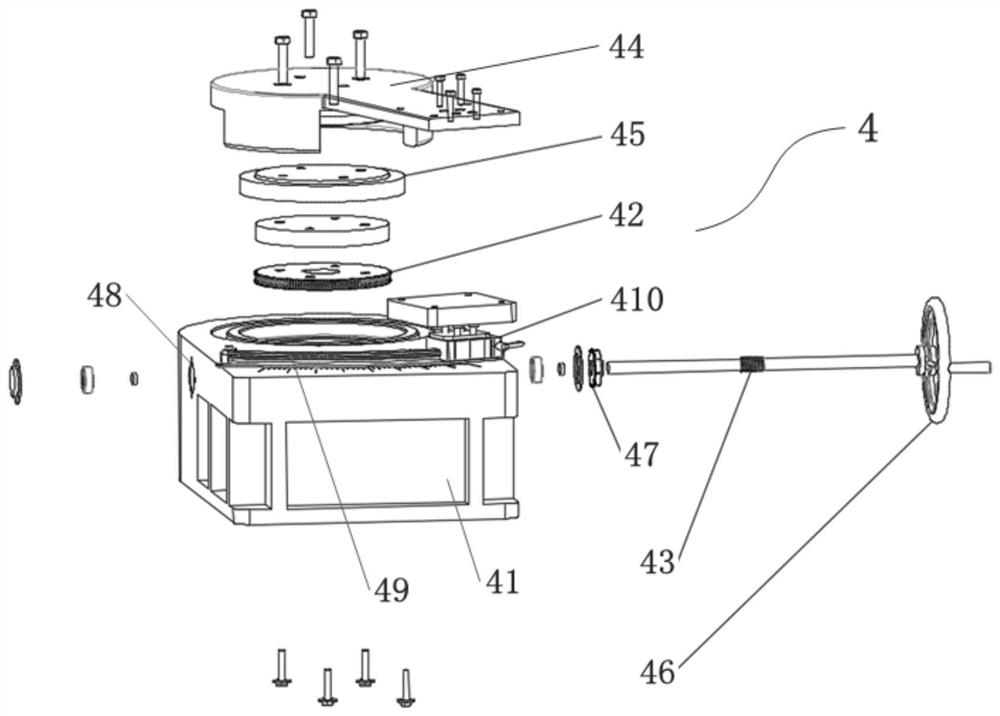

Power-closed small angle intersecting shaft gear test bench

ActiveCN109520730AMeet lubricationReasonable and reliable structural designMachine part testingAngular rotationHigh velocity

The invention discloses a power-closed small angle intersecting shaft gear test bench which comprises an electric motor, an auxiliary gear box, a moving platform, a rotating platform and intermeshingtest gear I and test gear II. Each part of the test bench constitutes a power-closed system to compensate for lost power. The movement of one test gear in directions of two degrees of freedom of X andY is achieved through the moving platform, the angular rotation of the other test gear is achieved through the rotating platform, the parallel shaft installation of a thickened gear and the intersection shaft installation in a certain angle range can be satisfied, and a shaft crossing angle error and a mounting distance error of the thickened gear are simulated. The contact spot, transmission error, transmission efficiency, vibration and the like of the high-speed thickening gear can be tested. At the same time, the test bench also be used for studying the influence of the shaft crossing angle error and the mounting distance error on the meshing performance of the thickened gear.

Owner:CHONGQING UNIV

Low-odor automobile switch lubricating grease composition and preparation method thereof

The invention provides a low-odor automobile switch lubricating grease composition. The low-odor automobile switch lubricating grease composition comprises the following components in parts by weight:62-93 parts of base oil, 5-20 parts of a thickening agent and 2-18 parts of a solid lubricant. The invention also discloses a preparation method of the low-odor automobile switch lubricating grease composition. The low-odor automobile switch lubricating grease composition prepared by adopting fumed silica to thicken poly-alpha olefin base oil and adding the solid lubricant has an extremely low odor grade. Through the test of VS-01.00-L-06005-A1-2018 Test Specification for Odor of Nonmetallic Materials in Vehicles, the odor grade is 1.0-1.5 grade, which is reduced by one grade or more than onegrade compared with the odor of the lubricating grease in the prior art. The automobile switch lubricating grease composition disclosed by the invention also has good colloid stability, wear resistance, friction reduction, shearing resistance and excellent high and low temperature performance, is suitable for lubricating and protecting various switches, and is also suitable for lubricating various parts of an automobile cockpit.

Owner:武汉博达特种润滑技术有限公司

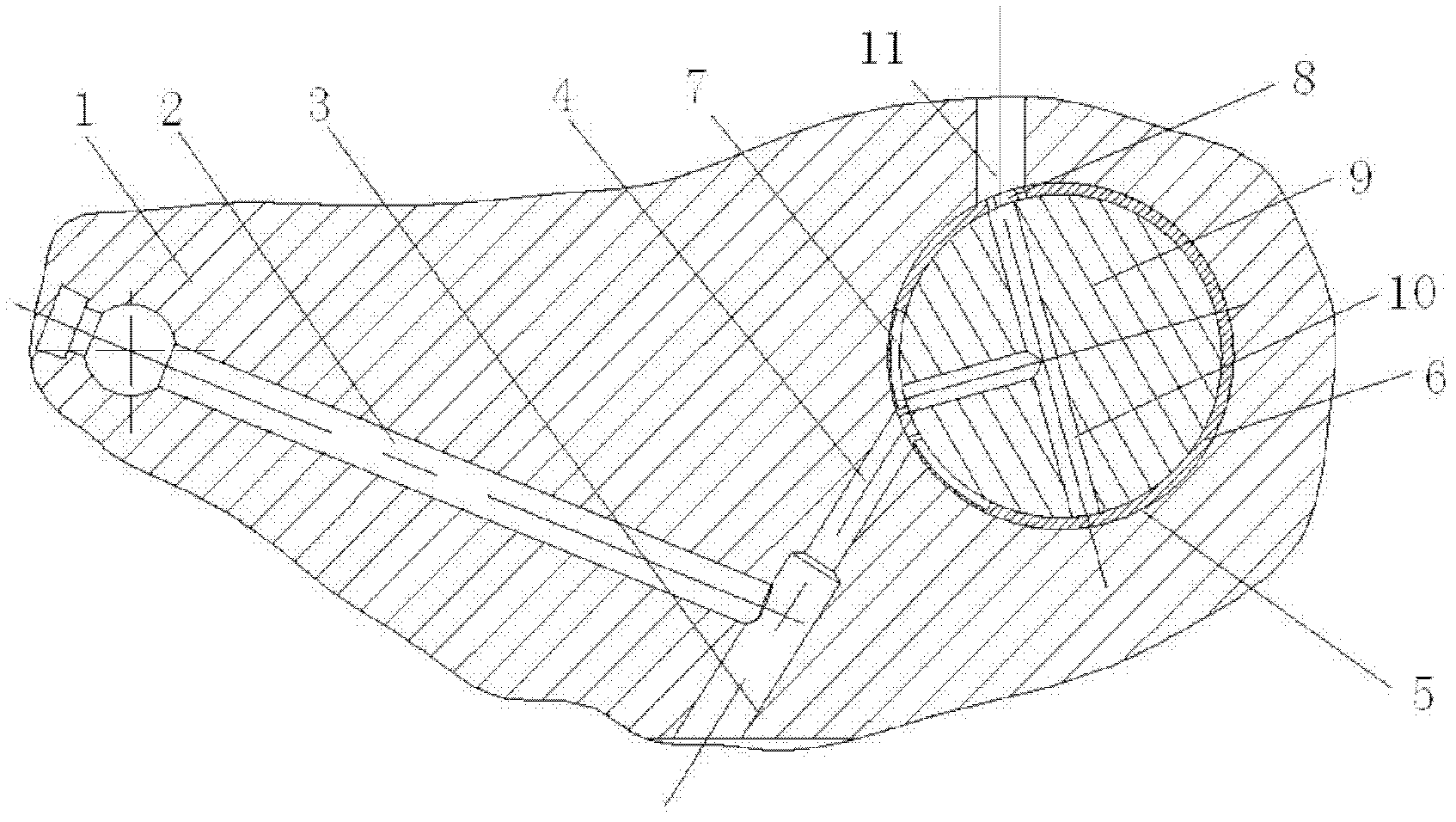

Pulse oil supply type engine air cylinder block oil passage

InactiveCN105756743AConstant pressureImprove oil supply capacityMachines/enginesPressure lubricationCylinder blockCam

The invention discloses a pulse oil supply type engine air cylinder block oil passage. According to the structure, the tail end of a main oil passage of an engine air cylinder block is divided into a crankshaft bearing oil supply branch passage and a cam shaft oil supply branch passage, and the cam shaft oil supply branch passage is communicated with a cam shaft bearing hole in the engine air cylinder block; the crankshaft bearing oil supply branch passage is communicated with a crankshaft bearing; a lining is inlaid in the cam shaft bearing hole and provided with oil inlet and outlet holes; a groove is formed in the large-head end of a cam shaft, when the cam shaft rotates to one certain position, the cam shaft oil supply branch passage is communicated with a rocker arm oil supply passage, and at the moment the main oil passage can supply oil to the crank shaft bearing, the cam shaft and a rocker arm at the same time. Oil supply time periods are different through the cam shaft large-head end structure, intermittent oil supply is carried out, and therefore reduction of oil pressure is relieved. While high oil pressure is ensured, enough lubrication oil is supplied to other parts. Due to the fact that the rotating speed of the cam shaft is relatively high, oil can be supplied to the rocker arm one time when the cam shaft rotates a circle, and the pressure of the main oil passage can be kept basically stable.

Owner:DONGFENG CHAOYANG CHAOCHAI DIESEL ENVIRONMENTAL PROTECTION TECH CO LTD

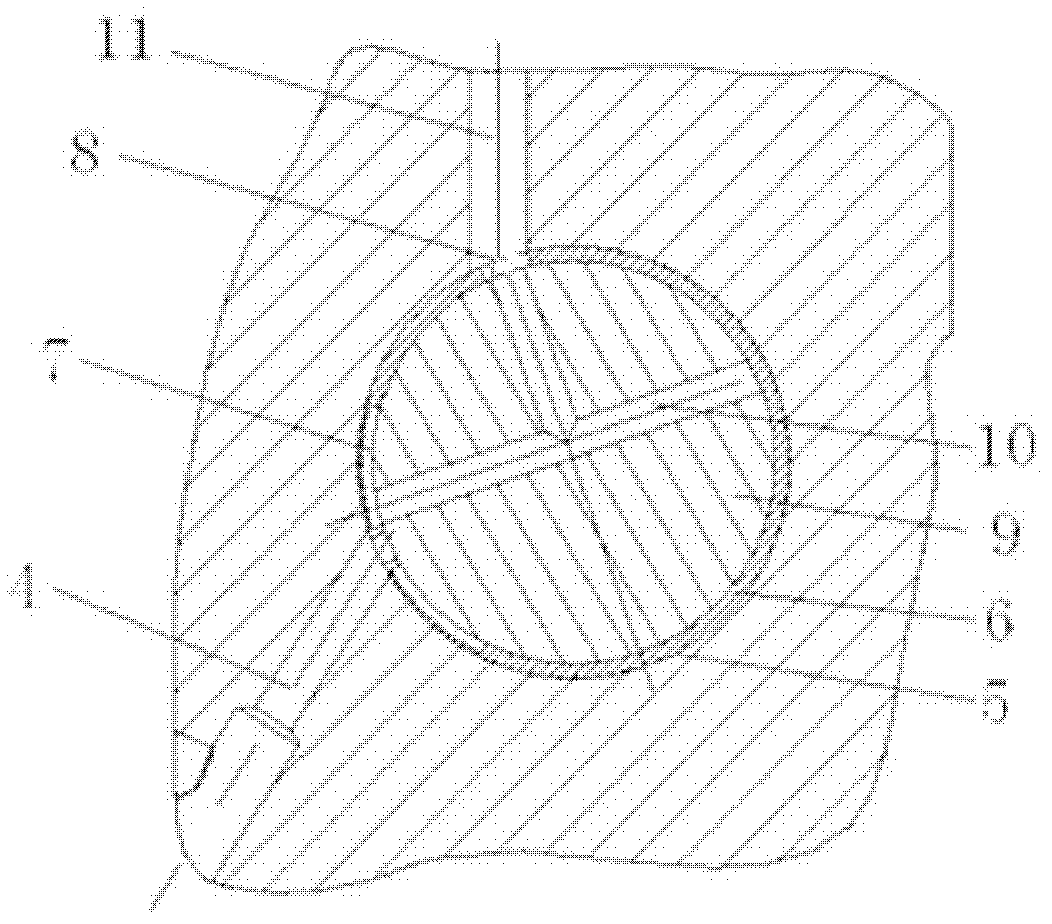

Pulse oil-supply type oil duct of engine cylinder body

InactiveCN102588137AImprove oil supply capacityMeet lubricationLubrication of auxillariesCylinder headsCamLubrication

The invention discloses a pulse oil-supply type oil duct of an engine cylinder body. The structure of the pulse oil-supply type oil duct of the engine cylinder body is as follows: a cam shaft bushing is arranged inside a cam shaft bearing hole on the engine cylinder body; a section of an oil tank and an oil outlet are arranged on the cam shaft bushing; and a T-shaped oil hole is processed on the cam shaft. The oil tank and the oil outlet on the cam shaft bushing are respectively communicated with the cam shaft and a rocker arm oil supply channel when the cam shaft rotates to a certain position; a main oil duct can supply oil to a crank bearing, the cam shaft and a rocker arm at the same time. The oil tank on the cam shaft bushing is communicated with an oil supply branch channel of the cam shaft, but the oil outlet on the cam shaft bushing cannot be communicated with the oil supply channel of the rocker arm when the cam shaft rotates to deviate from the position. By ingenious designs of the cam shaft bushing and the cam shaft, the cam shaft can finish twice and two paths of oil supply with different oil supply quantities after rotating a circle. Lubrication of the rocker arm can be achieved, at the same time the pressure of the main oil duct is basically constant, and parts such as a crank, the cam shaft and the like are guaranteed to be fully lubricated.

Owner:合肥云内动力有限公司

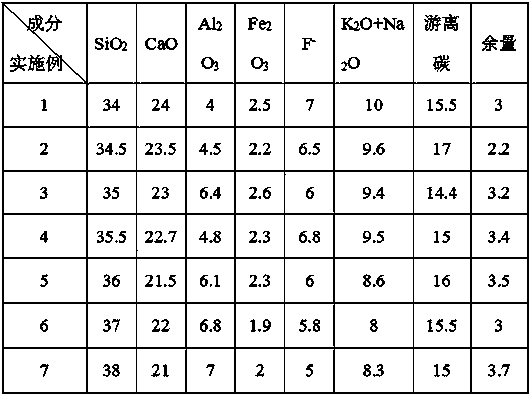

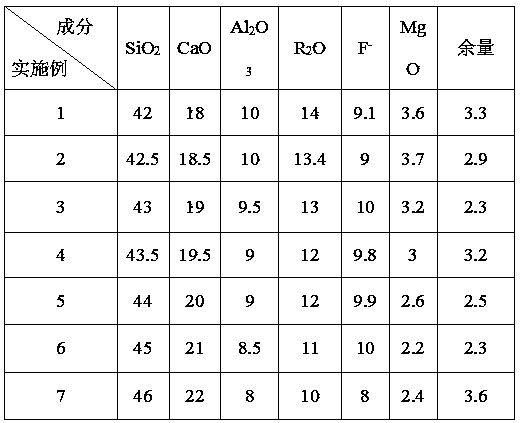

Valve steel continuous casting crystallizer functional protection material

The invention discloses a valve steel continuous casting crystallizer functional protection material. The material comprises the following raw material components including, by weight, 36.0-42.0% of pre-melt materials, 14.0-17.0% of wollastonite, 9.0-11.0% of fine glass powder, 3.0-5.0% of lithium carbonate, 7.0-9.0% of fluorite, 2.0-4.0% of sodium fluoride, 3.0-5.0% of cryolite, 10.0-12.0% of graphite carbon, 2.0-3.5% of carbon black and 2.0-3.5% of a binder. According to the valve steel continuous casting crystallizer functional protection material, the thermal insulation effect and the melting effect are guaranteed, furthermore, pulling break, slag inclusion and depression of casting blanks are effectively prevented, and the non-cleaning rate of the surfaces of the obtained casting blanks reaches up above 98%.

Owner:西峡县西保冶金材料有限公司

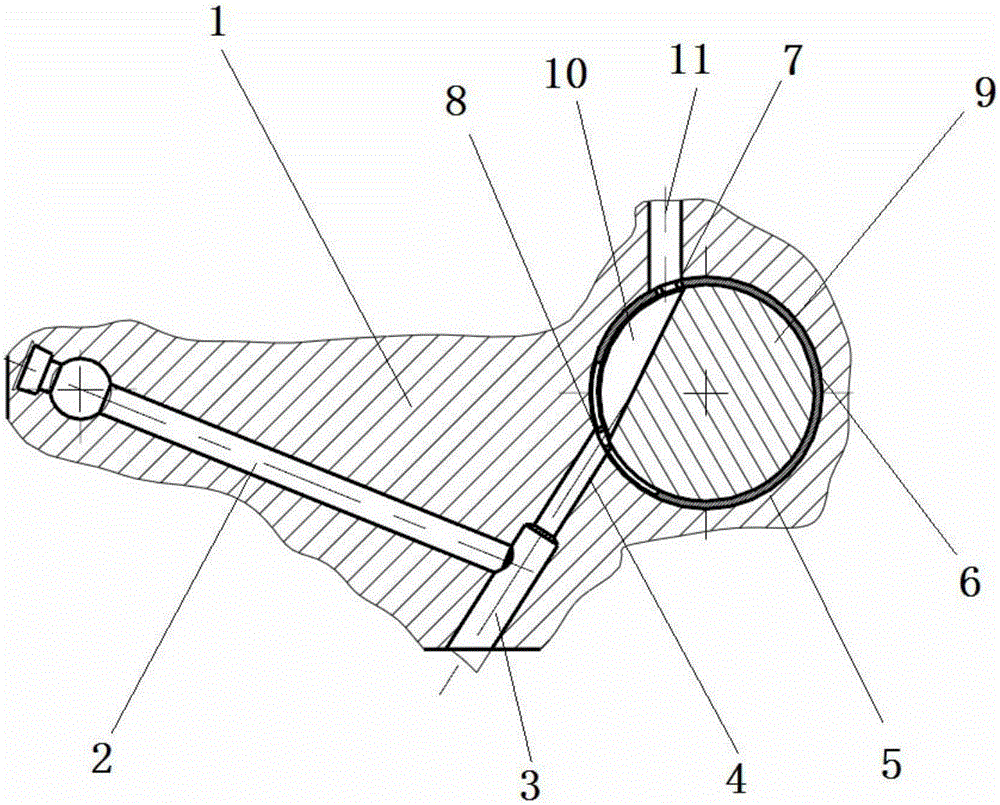

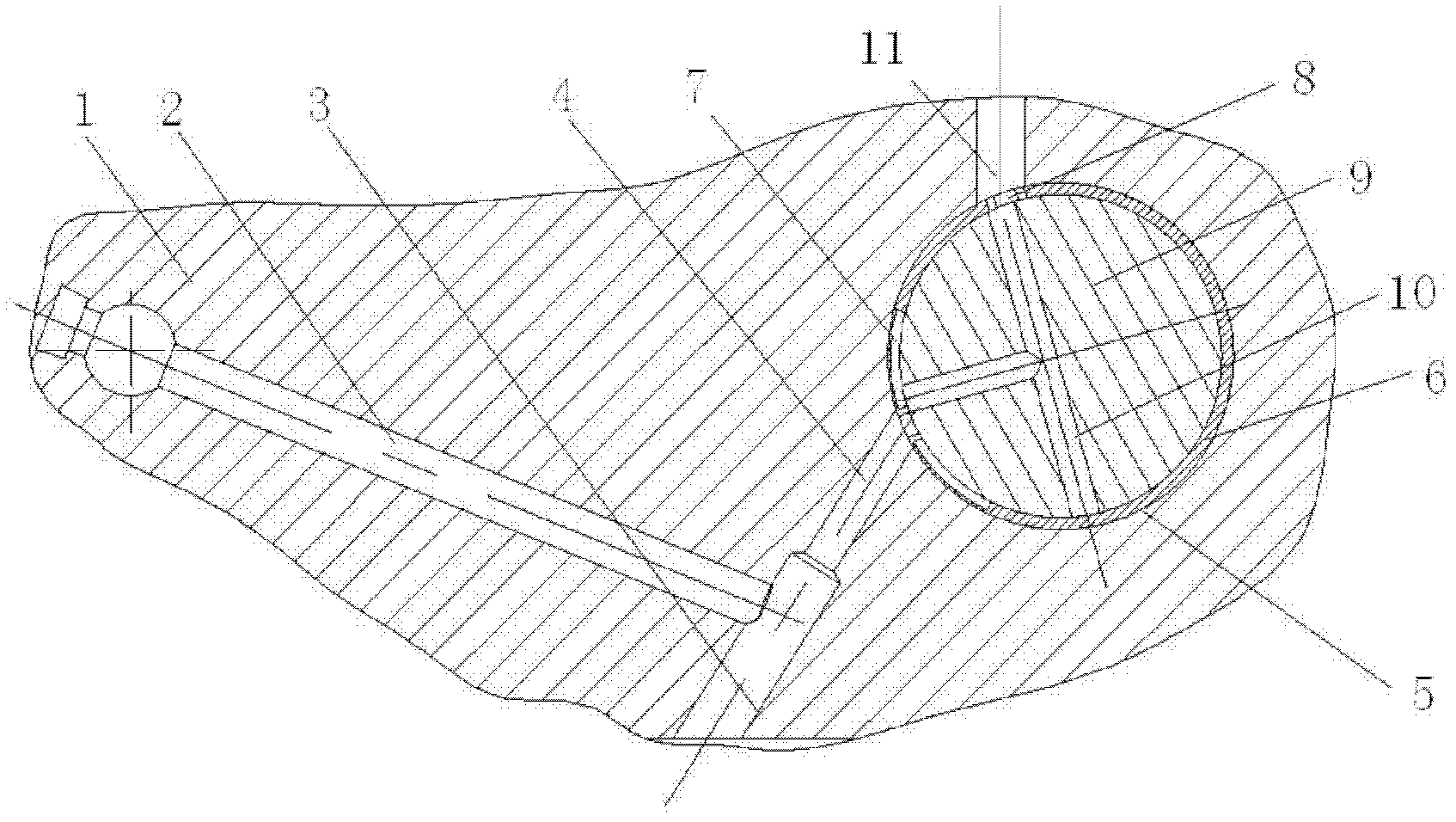

Novel rolling sliding bearing and friction-lubrication mechanism structure

InactiveCN104863959ALubrication of precipitated impuritiesMeet lubricationRotary combination bearingsBearing componentsLubricationEngineering

The invention relates to a novel rolling sliding bearing and friction-lubrication mechanism structure. According to the novel rolling sliding bearing and friction-lubrication mechanism structure, increasing rate of total hydrocarbon value is measured based on changing rate of total hydrocarbon data; the changing rate of total hydrocarbon data comprises total hydrocarbon data range changing rate and total hydrocarbon data depth changing rate; and total hydrocarbon value increasing rate is calculated via comparison of the total hydrocarbon data range changing rate with the total hydrocarbon data depth changing rate. The calculation method of the total hydrocarbon value increasing rate disclosed above is capable of providing oil gas layer evaluation with convenience.

Owner:ZHEJIANG WANLI UNIV +4

Diamond-like in-situ self-reaction graphitized lubricating coating cutter and preparation method thereof

InactiveCN109371375AGuaranteed original hardnessReduce the proportionVacuum evaporation coatingSputtering coatingCobaltReactive magnetron

The invention belongs to the technical field of metal cutting tool manufacturing, and relates to a diamond-like in-situ self-reaction graphitized lubricating coating cutter and a preparation method thereof. The base body surface of the cutter is provided with a diamond-like coating thin film, and the outer layer of the diamond-like thin film contains transition metal element components doped withiron, cobalt and the like. The diamond-like thin film of the cutter is prepared by using a reactive magnetron sputtering method, wherein the coating principal process is divided into two steps that adiamond-like inner layer is prepared through non-doping reaction magnetron sputtering, and a diamond-like outer layer is prepared through transition metal element doped reaction magnetron sputtering.The outer layer of the thin film of the diamond-like coating cutter contains a small amount of transition metal element impurities, and under the action of cutting high temperature, the transition metal elements can induce sigma bonds to be switched to pi bonds between carbon atoms in diamond-like coating, so that part of the diamond-like coating of the cutting friction interface is promoted to undergo the in-situ reaction to be converted into graphite, and then the metal cutting process is effectively lubricated.

Owner:SOUTHEAST UNIV

Vertical pump bearing lubrication cooling device

PendingCN112066234AReduce the temperatureGuaranteed safe operationPump componentsBearing componentsPhysicsLubrication

The invention relates to the technical field of lubrication of vertical pump bearings, in particular to a vertical pump bearing lubrication cooling device. The vertical pump bearing lubrication cooling device comprises a shaft, a bearing frame, an outer sleeve, a bearing gland, an upper bearing, a shaft sleeve, a lower bearing and a spiral sleeve. The spiral sleeve is connected to the shaft. The upper bearing, the shaft sleeve and the lower bearing are connected to the spiral sleeve. The spiral sleeve is provided with an oil rotating section. The oil rotating section is provided with trapezoidal threads I and trapezoidal threads II. An oil collecting groove is formed between the trapezoidal threads I and the trapezoidal threads II. The thread rotating direction of the trapezoidal threads Iis opposite to that of the trapezoidal threads II. An oil outlet pipe connecting pipe is provided with an oil outlet hole. A gland connecting pipe is provided with an oil inlet hole. An oil outlet pipe is connected between the oil outlet hole and the oil inlet hole. The vertical pump bearing lubrication cooling device solves the problem that a bearing on a vertical pump is hard to lubricate, meanwhile, the requirement for bearing lubrication at the low rotating speed can be met, the air cooling and heat dissipation functions are achieved, the temperature of the outer sleeve and the temperature of the bearings are effectively reduced, a good environment is provided for bearing running, and safe running of the vertical pump is guaranteed.

Owner:兰州兰泵有限公司

Gearbox lubricating pump used for rail vehicle

PendingCN107013672AMeet lubricationImprove operational safetyGear lubrication/coolingLubricating pumpsGear wheelControl theory

The invention provides a gearbox lubricating pump used for a rail vehicle. The gearbox lubricating pump comprises a suction filter, an oil pump and an oil pump gear, wherein the oil pump comprises an oil pump shell; the suction filter is fixedly connected with the lower end surface of the oil pump shell; the oil pump shell comprises a ball valve chamber, a pump body and a gearbox; the ball valve chamber and the gearbox are separately arranged at the two sides of the pump body and are fixedly connected with the pump body; a gear pair is supported in the pump body through a gear shaft I and a gear shaft II; one end of the gear shaft I penetrates through the gearbox; and the oil pump gear is fixedly arranged on the gear shaft I. Driven by the oil pump gear, the clockwise and counterclockwise rotating of the gear pair can both produce forced lubrication, so that the lubricating pump rotates at different speeds when the vehicle is at different speeds, can perform a function of forced lubrication through both clockwise and counterclockwise rotating, can meet the lubrication of the axle gearbox no matter when the rail vehicle runs forwards, backwards or at different speeds and greatly improves the reliability of the axle gearbox and the running safety of the vehicle.

Owner:BAOJI CSR TIMES ENG MACHINERY

Improved gear oil composition

InactiveCN104673450AThe formula is scientific and reasonableExtended service lifeLubricant compositionParaffin waxLubrication

The invention discloses an improved gear oil composition which is prepared from the following raw materials in parts by weight: 36-44 parts of 38# cylinder oil, 0.5-0.9 part of BHT (butylated hydroxytoluene) antioxidant, 3-6 parts of di-n-butyl phosphite, 2-8 parts of sulfur-phosphorous butyl octanol zinc salt, 0.6-0.9 part of sodium petroleum sulfonate, 3-8 parts of chlorinated paraffin wax, 9-15 parts of dithiodipropionate, 5-15 parts of p-phenylenediamine, 5-15 parts of dibenzyl disulfur, 4-12 parts of polydimethylsiloxane, 9-16 parts of benzotriazole, 15-25 parts of synthetic oil and 3-12 parts of graphite. The improved gear oil composition can achieve maximum nonseizure load for lubrication and reduce the sintering load and comprehensive abrasion by reducing the abrasion loss of the automobile gear, and has the advantages of excellent abrasion resistance, excellent corrosion resistance and excellent rust resistance.

Owner:QINGDAO KERUN PLASTIC MACHINERY

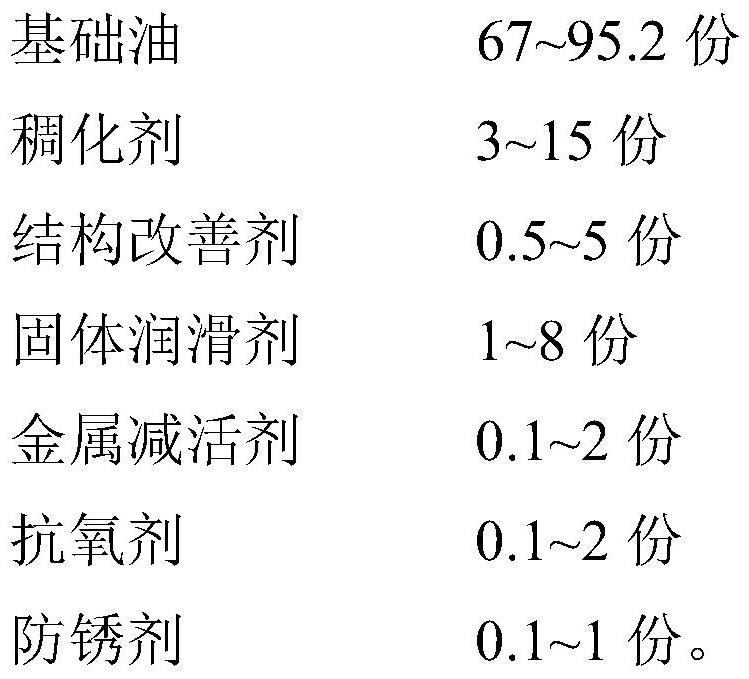

A dust-proof grease composition for optical instruments and its preparation method

ActiveCN108034480BPrevent intrusionExcellent anti-dust and anti-fog effectOther chemical processesLubricant compositionOptical instrumentationEngineering

The invention provides a dustproof grease composition used for an optical instrument and a preparation method of the composition. The dustproof grease composition comprises the following components inparts by weight: 67-95.2 parts of base oil, 3-15 parts of a thickening agent, 0.5-5 parts of a structure improving agent, 1-8 parts of a solid lubricant, 0.1-2 parts of a metal deactivator, 0.1-2 parts of an antioxidant, and 0.1-1 part of an antirust agent. The invention also provides a preparation method of the dustproof grease composition used for the optical instrument. The method provided bythe invention adopts fumed silica to thicken dimethyl silicone oil, and the structure improving agent, the solid lubricant, the metal deactivator, the antioxidant and the antirust agent are used to prepare the dustproof grease composition used for the optical instrument; and the prepared composition has excellent high and low temperature performance, colloidal stability, thermal oxidation stability, anti-wear and extreme pressure performance, sealing performance, adhesion performance and protection performance, and is suitable for long-term dust prevention and lubrication of rotating parts such as screw threads of various military and civilian optical instruments (sighting telescopes, periscopes and the like).

Owner:武汉博达特种润滑技术有限公司

Power enclosed small angle intersecting shaft gear test bench

ActiveCN109520730BMeet lubricationReasonable and reliable structural designMachine part testingGear wheelStructural engineering

The invention discloses a power-closed small angle intersecting shaft gear test bench which comprises an electric motor, an auxiliary gear box, a moving platform, a rotating platform and intermeshingtest gear I and test gear II. Each part of the test bench constitutes a power-closed system to compensate for lost power. The movement of one test gear in directions of two degrees of freedom of X andY is achieved through the moving platform, the angular rotation of the other test gear is achieved through the rotating platform, the parallel shaft installation of a thickened gear and the intersection shaft installation in a certain angle range can be satisfied, and a shaft crossing angle error and a mounting distance error of the thickened gear are simulated. The contact spot, transmission error, transmission efficiency, vibration and the like of the high-speed thickening gear can be tested. At the same time, the test bench also be used for studying the influence of the shaft crossing angle error and the mounting distance error on the meshing performance of the thickened gear.

Owner:CHONGQING UNIV

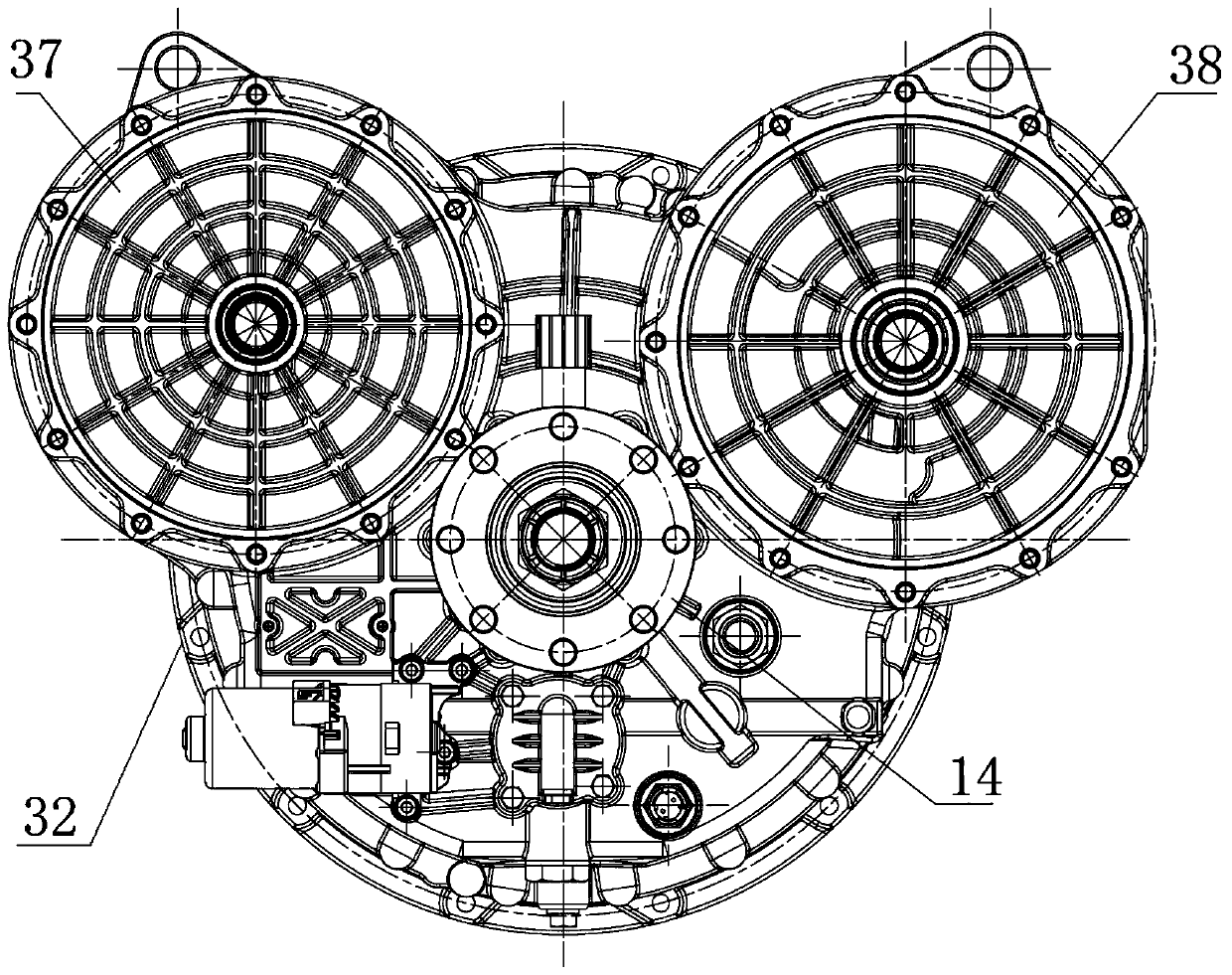

Hybrid transmission

InactiveCN111059230AWith drive functionIncrease useToothed gearingsGearing controlMaximum torqueGear drive

The invention discloses a hybrid transmission. The hybrid transmission is characterized in that a planetary gear transmission mechanism is connected with a power output mechanism, and the power outputmechanism is connected with a flange plate located at the other end of a transmission shell through an output shaft; a two-gear parallel shaft gear transmission mechanism is connected with the poweroutput mechanism; a generator transmission mechanism is connected with the planetary gear transmission mechanism; a locking mechanism is used for locking an engine input shaft; and after the engine input shaft is locked, a generator can sequentially output power through the generator transmission mechanism, the planetary gear transmission mechanism, the power output mechanism and the output shaft.According to the hybrid transmission, the hybrid drive of a drive motor and the generator can be realized, the double-motor drive is formed, the output torque of the two motors is coupled through a planetary differential mechanism, the maximum torque is output, and the power performance of the whole vehicle is greatly enhanced.

Owner:XIAN FASHITE AUTOMOBILE TRANSMISSION CO LTD

Long-life fully synthetic industrial gear lubricant composition

ActiveCN102766508BGood high and low temperature performanceImprove Oxidation StabilityLubricant compositionViscosity gradeOxidation resistant

The invention provides a long-life fully synthetic industrial gear lubricant composition, which comprises (A) at least one synthetic base oil; (B) at least one anti-oxidant; (C) at least one metal passivator; (D) at least one metal detergent; (E) at least one antiwear agent; (F) at least one antirust agent; and (G) at least one friction modifier. The above lubricant composition has characteristics of high viscosity index and low pour point and can satisfy needs of industrial gear oil of 68-680 viscosity grade. The above lubricant composition has excellent anticorrosive and antirust properties, anti-foaming property, demulsibility, oxidation resistance and abrasion resistance. The antioxidation performance of the lubricant composition is particularly prominent. In addition, the lubricant composition is applicable to industrial gear and bearing lubrication system under harsh conditions of high temperature, high pressure, heavy duty and the like, and especially has outstanding performance in equipment protection, oil life and failure-free operation.

Owner:PETROCHINA CO LTD

Rolling oil composition for 12-roller reversing mill

The invention relates to a rolling oil composition used for a twelve-high reversing cluster mill; the rolling oil composition belongs to the field of metallurgical steel rolling oil products, and comprises the components according to weight percent as follows: 60-70 percent of compound neopentyl polyol ester, 14-28 percent of mineral oil, 1-5 percent of phosphorus-containing extreme-pressure and anti-wear agent, 1-5 percent of sulfur-containing extreme-pressure and anti-wear agent, 2-12 percent of compound emulsifier, 1-3 percent of anti-rust agent, 1-3 percent of antioxidant and 0.01-0.5 percent of defoamer; the rolling oil composition takes the compound neopentyl polyol ester synthetic ester with excellent lubricating performance as the lubricating basic component; an oiliness agent main body with high lubricating performance and high extreme-pressure and anti-wear performance is composed by adding the scientific components of the phosphorus-containing and the sulfur-containing extreme-pressure and anti-wear agents; and the anti-rust performance and the emulsion stability are ensured by adopting the mineral oil, the anti-rust oil, the emulsifier and the antioxidant with the appropriate proportion for coordination, thereby creatively solving the contradiction between the lubricating performance and the detergence, ensuring the requirements on the lubricating performance of the quality when rolling steel plates with thin specifications, protecting the lubricating requirements of back-up bearings and ensuring the volatility and the annealing detergence under the cleaning-free condition.

Owner:WUHAN TONGSHENG FINE CHEM TECH DEV

Intermediate shaft structure of gearbox

ActiveCN112145658AImprove NHVReduce manufacturingGear lubrication/coolingAutomotive engineeringLubrication

The invention discloses an intermediate shaft structure of a gearbox, and relates to the technical field of gearboxes of motor vehicles. The structure solves the technical problem that an NHV index ofa vehicle is low due to unreasonable structural design of an intermediate shaft of a gearbox in the prior art. The structure comprises a shaft body, and an oil guide device, wherein the shaft body isconnected to a first bearing and a second bearing, and the shaft body is provided with an axially-through cavity; and the oil guide device is connected between the shaft body and a gearbox shell, andthe oil guide device is provided with a first oil guide channel and a second oil guide channel. According to the structure, the first oil guide channel in the oil guide device can enable oil to flowinto the first bearing through the cavity in the shaft body, so that lubrication of the first bearing is met, the oil liquid directly meets lubrication of the second bearing through the second oil guide channel, the simple oil guide device structure design meets sufficient lubrication of the first bearing and the second bearing, meanwhile, the problem that a complex oil guide pipeline is designedin an intermediate shaft or a bearing is solved, the NHV of the gearbox is improved, and the production and manufacturing of the intermediate shaft are facilitated, and the cost is reduced.

Owner:DONGFENG MOTOR CORP HUBEI

Method of gravity self-pressurization anti-segregation pumping high sand rate ready-mixed mortar

ActiveCN104631830BNot easy to segregateImprove suction capacityBuilding material handlingSuction stressDual action

A method for pumping high-sand-rate premixed mortar in a gravity self-pressure separation prevention mode comprises the steps that a mortar suction valve is arranged below a mortar suction hopper; mortar materials from the mortar suction hopper enter a cylinder tube of a conveying cylinder through the mortar suction valve under the mutual action of the gravity self-pressure and the suction force of a piston; the mortar materials in the cylinder tube are smoothly discharged through a mortar outlet valve in the mortar material flowing line direction, wherein the mortar outlet valve and the conveying cylinder are in the same direction, the discharging direction of the mortar materials is straight, and the flow direction is basically not changed. According to the method, the mortar suction valve is arranged below the mortar suction hopper, the mortar can be directly sucked from the bottom of the hopper, the mortar materials enter the cylinder tube under the double action of the gravity self-pressure and the suction force of the piston, the mortar suction resistance is greatly reduced, separation is not likely to happen in the mortar suction-in process, the mortal materials which are low in fluidity or include large aggregates can be sucked in, and the mortar suction capability is greatly improved.

Owner:WUHAN ORIENT CONSTR GROUP

Environmentally-friendly energy-saving-type heavy loading screw compressor oil

The invention provides environmentally-friendly energy-saving-type heavy loading screw compressor oil. The environmentally-friendly energy-saving-type heavy loading screw compressor oil comprises 90-95% of composite base oil and 10%-5% of other additives in percentage by weight. Poly Alpha-Olefins (PAO) and dioctyl sebacate are compounded to serve as the base oil of the environmentally-friendly energy-saving-type heavy loading screw compressor oil. The environmentally-friendly energy-saving-type heavy loading screw compressor oil provided by the invention has the advantages of good operating characteristics, long service life and good biodegradability and also has effects of improving the efficiency of a screw compressor, reducing the abrasion and corrosion of a screw, effectively prolong the service life and the oil draining period of the screw compressor and meeting the requirements under special service conditions. The environmentally-friendly energy-saving-type heavy loading screw compressor oil provided by the invention is not only suitable for the requirements of various middle-heavy loading screw compressors under service conditions, and but also can meet the lubrication, cooling and sealing requirements of the middle-heavy loading sliding vane compressors.

Owner:GUANGXI UNIV

Polyurea calcium acetate lubricating grease and preparation method thereof

InactiveCN102504920BImprove adsorption capacityOutstanding anti-wear extreme pressure performanceLubricant compositionEthylic acidPolyurea

The invention relates to polyurea calcium acetate lubricating grease and a preparation method thereof. The polyurea calcium acetate lubricating grease comprises the following components in percentage based on the total weight of the raw materials of the lubricating grease: 25-63% of base oil, 3-5% of 4,4'-methylene bis(phenyl isocyanate), 2-10% of organic amine, 20-55% of high-base-number calcium sulfonate, 10-15% of glacial acetic acid, 0.1-1% of antioxidant and 0.01-0.3% of corrosion inhibitor. Meanwhile, the invention also provides a preparation method realizing high yield and good quality. Compared with the common extreme pressure lithium-based lubricating grease and extreme pressure complex lithium-based lubricating grease, the polyurea calcium acetate lubricating grease provided by the invention has excellent anti-wear extreme pressure performance, antirust performance, colloid stability and water resistance without adding the additives such as extreme pressure anti-wear additives, antirust agents and the like.

Owner:无锡惠源高级润滑油有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com