Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

254 results about "Contact spot" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

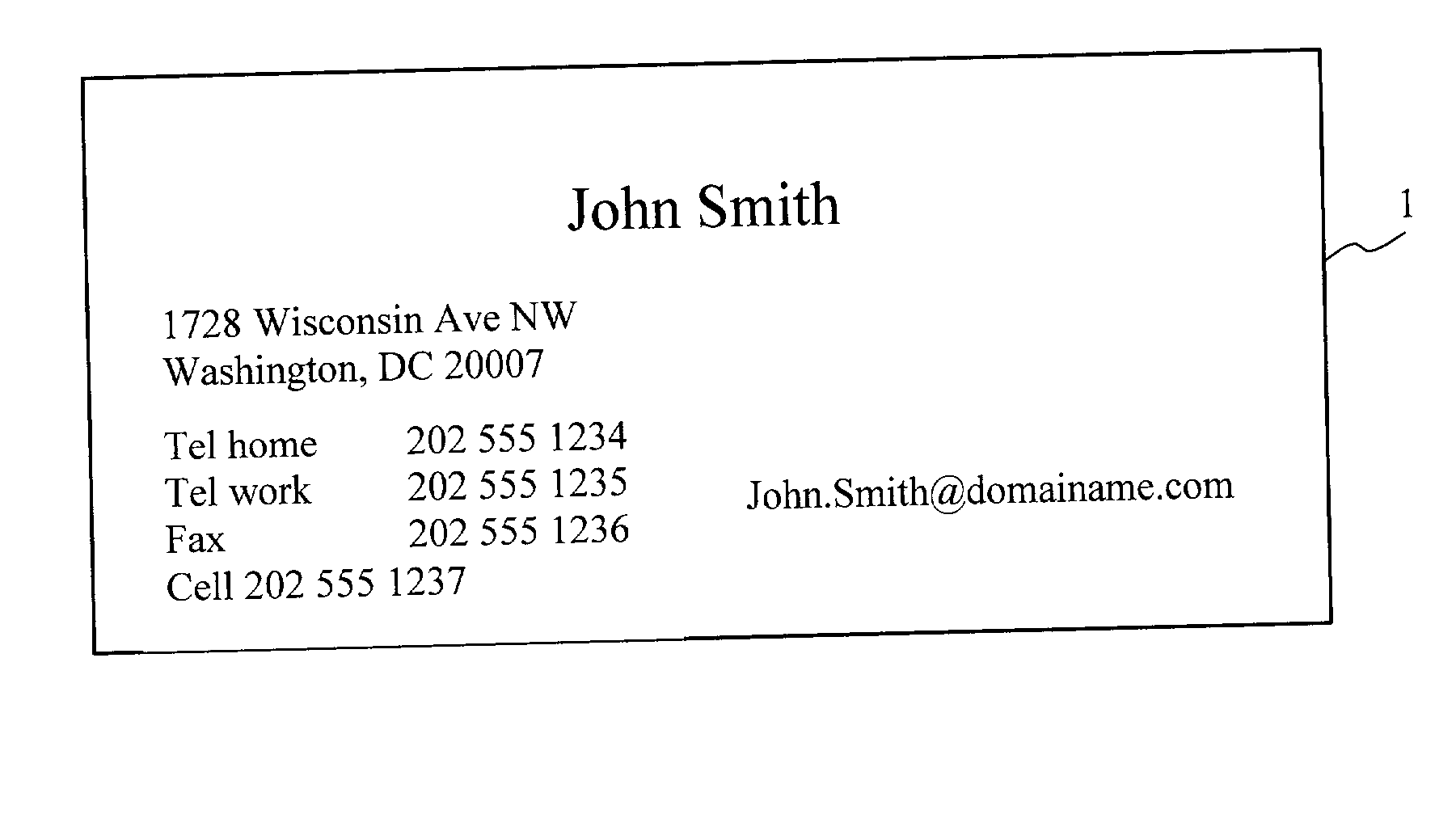

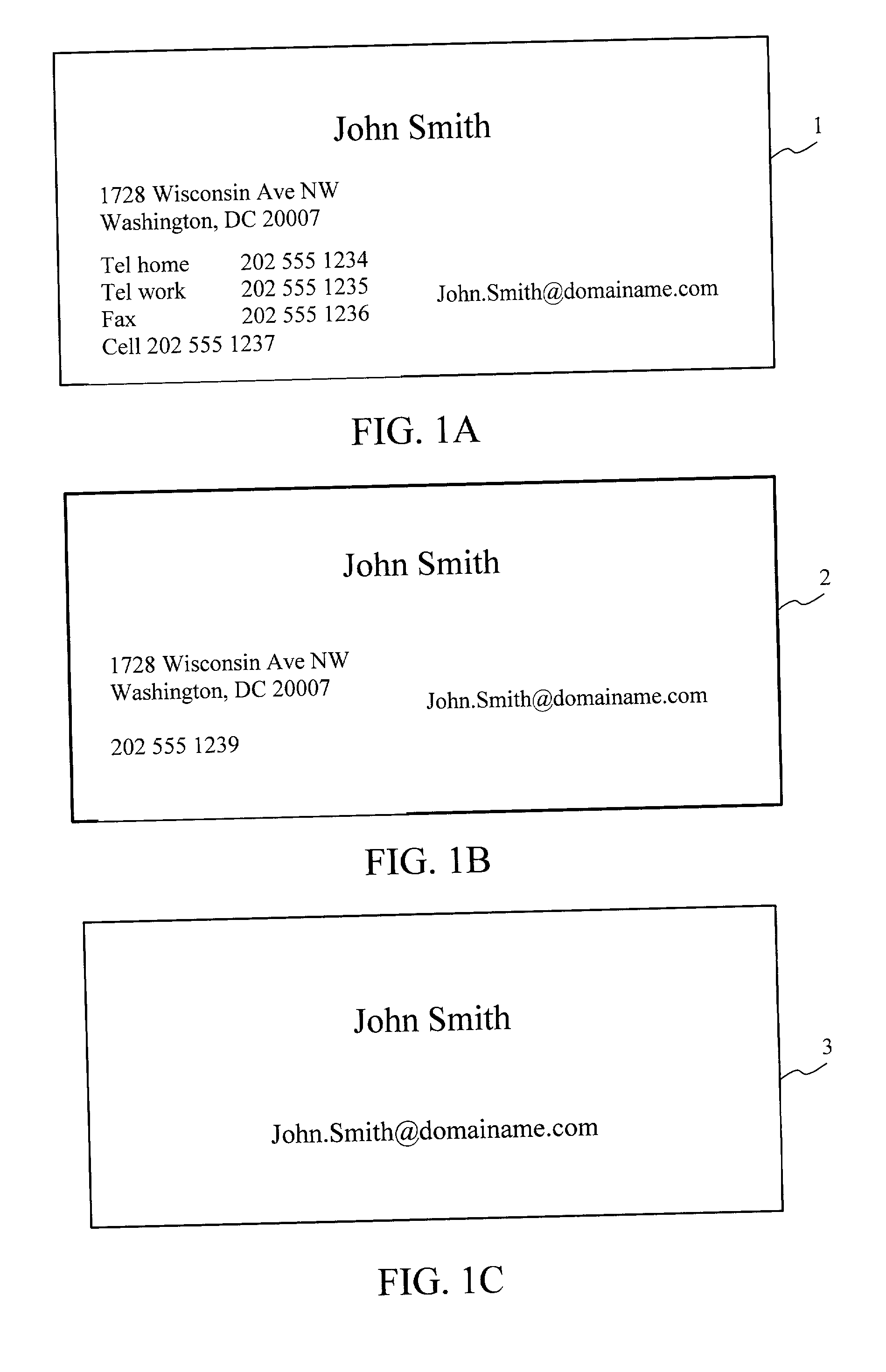

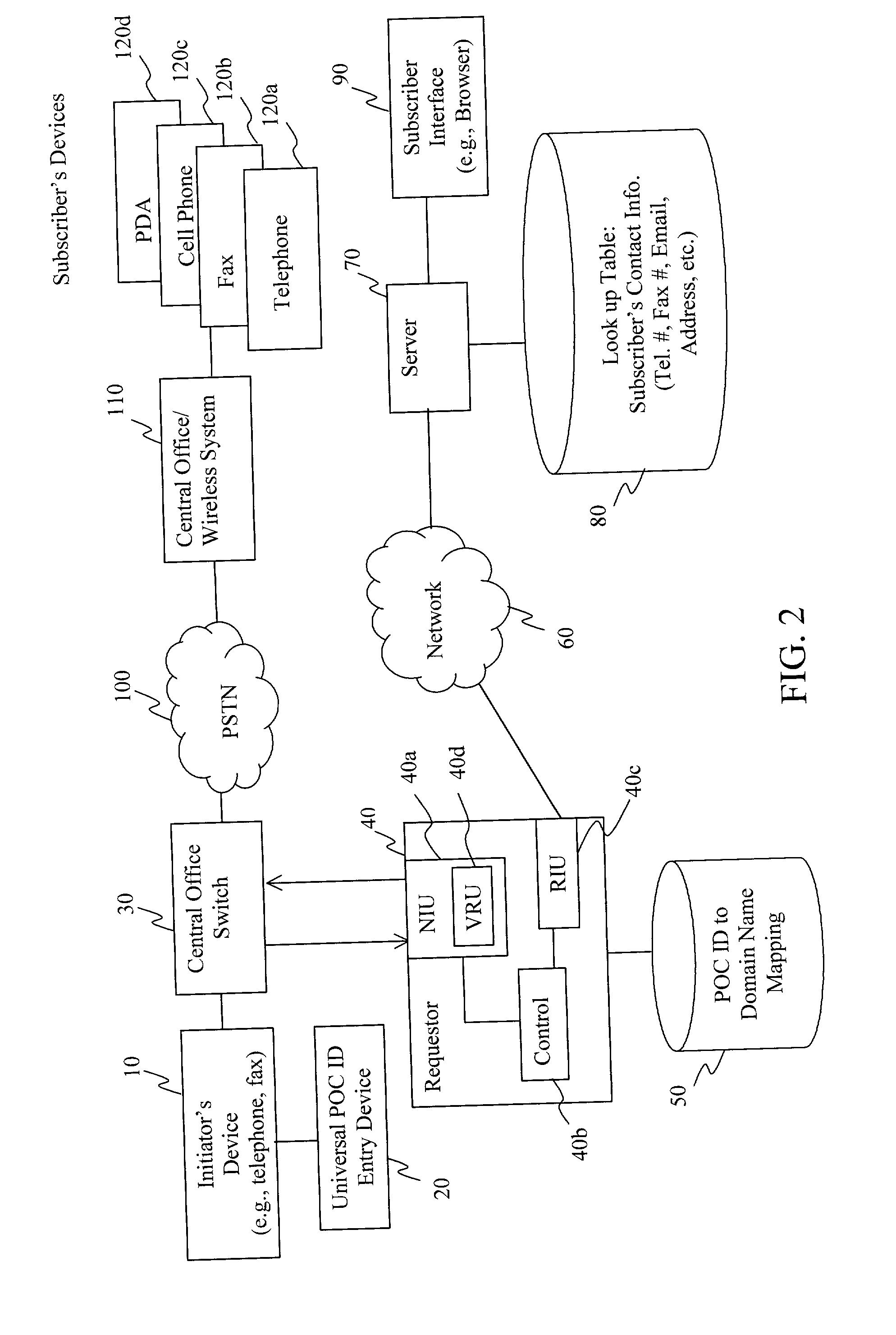

Universal point of contact identifier system and method

ActiveUS20020126817A1Telephone data network interconnectionsSpecial service for subscribersEmail addressElectronic mail

A subscriber to a universal point of contact service designates a preferred point of contact at which a communication initiator, such as a telephone caller, can contact the subscriber. Such an initiator desiring to contact the subscriber uses the subscriber's email address to establish a communication session with a device associated with the subscriber's preferred point of contact. The subscriber's email address is input to an initiating device, preferably a telephone or facsimile machine, using an entry device capable of entering an email address. A requestor unit, receiving the email address, locates a repository of the subscriber's point of contact information, and requests that information. The repository sends the point of contact information the subscriber has designated as preferred, and the requester unit uses that information to control a telephone switch to establish a communication session between the initiating device and the subscriber's preferred point of contact device.

Owner:AYMAN

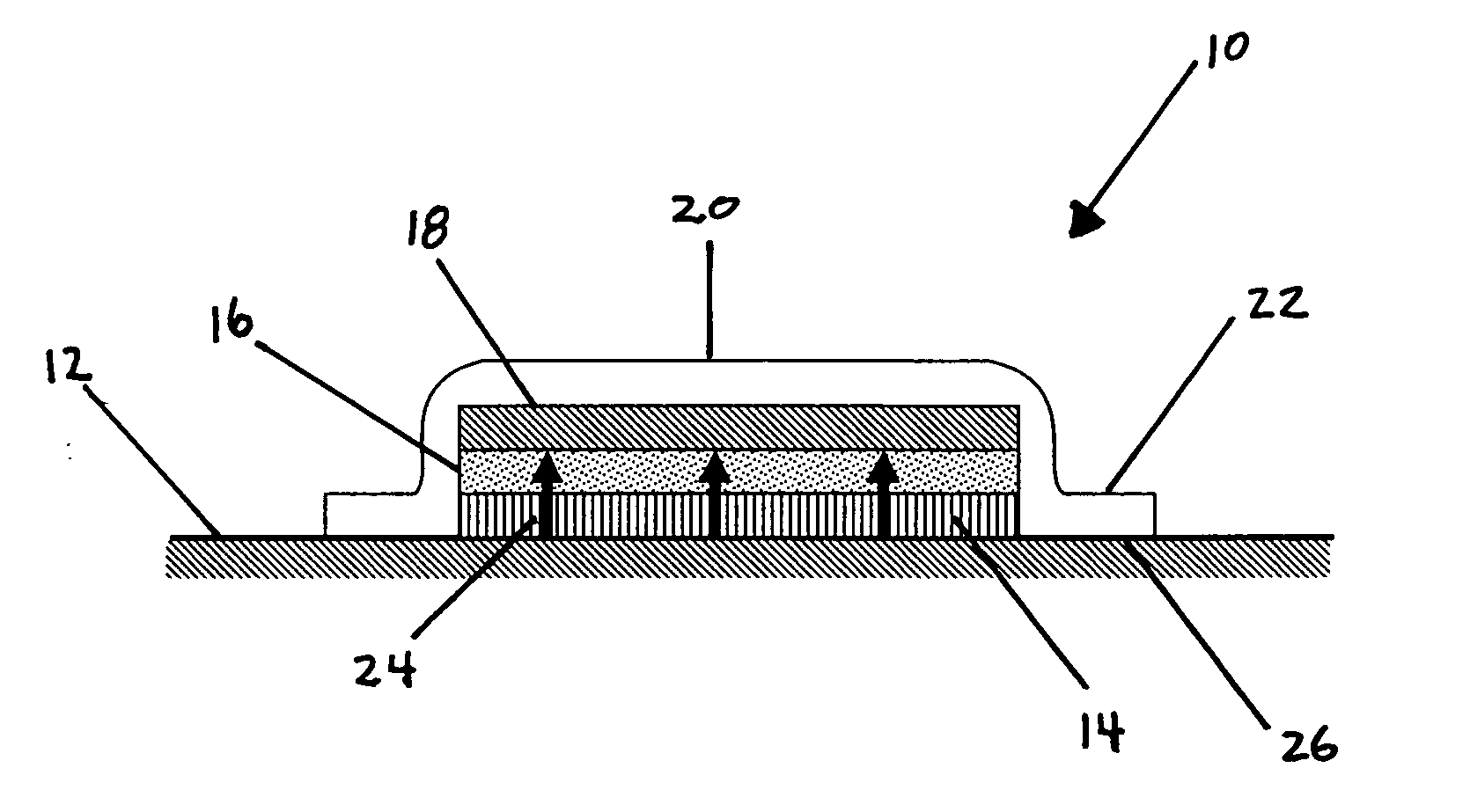

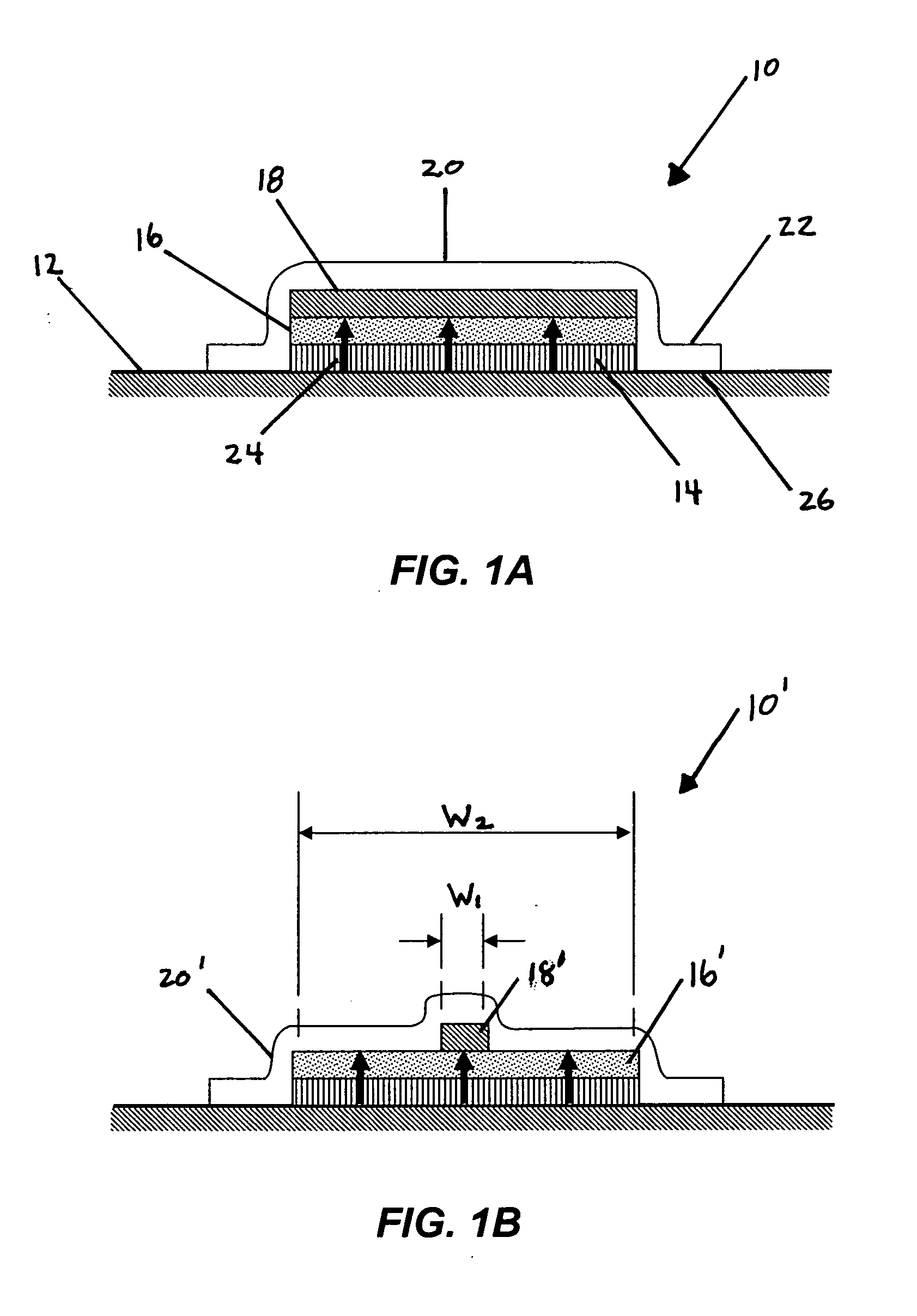

Integrated patch and assay device with visual detection means

InactiveUS20070179373A1Rapid analyte detection processQuick checkAnalysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorVisual perceptionTest set

Methods and apparatus for collecting a fluid sample using an integrated collection device are disclosed. The integrated collection device includes an analyte detector and a gradient means to actively and rapidly drive the transport of a sample fluid from the point of contact to the point of detection and reading. The analyte detector can include a visually-read colorimetric detector using a chemical or enzymatic detection process. The gradient means can include physical and / or chemical processes as described in more detail herein. In some embodiments, the device is provided as an occlusive patch. Preferably, the test device provides a reading immediately upon fluid contact with the analyte detector. Consequently, the time-to-result is sample volume and transport time dependent. By providing immediate or nearly immediate reading of results, the device is particularly useful in those applications in which immediate results are advantageous.

Owner:PROVEX TECH

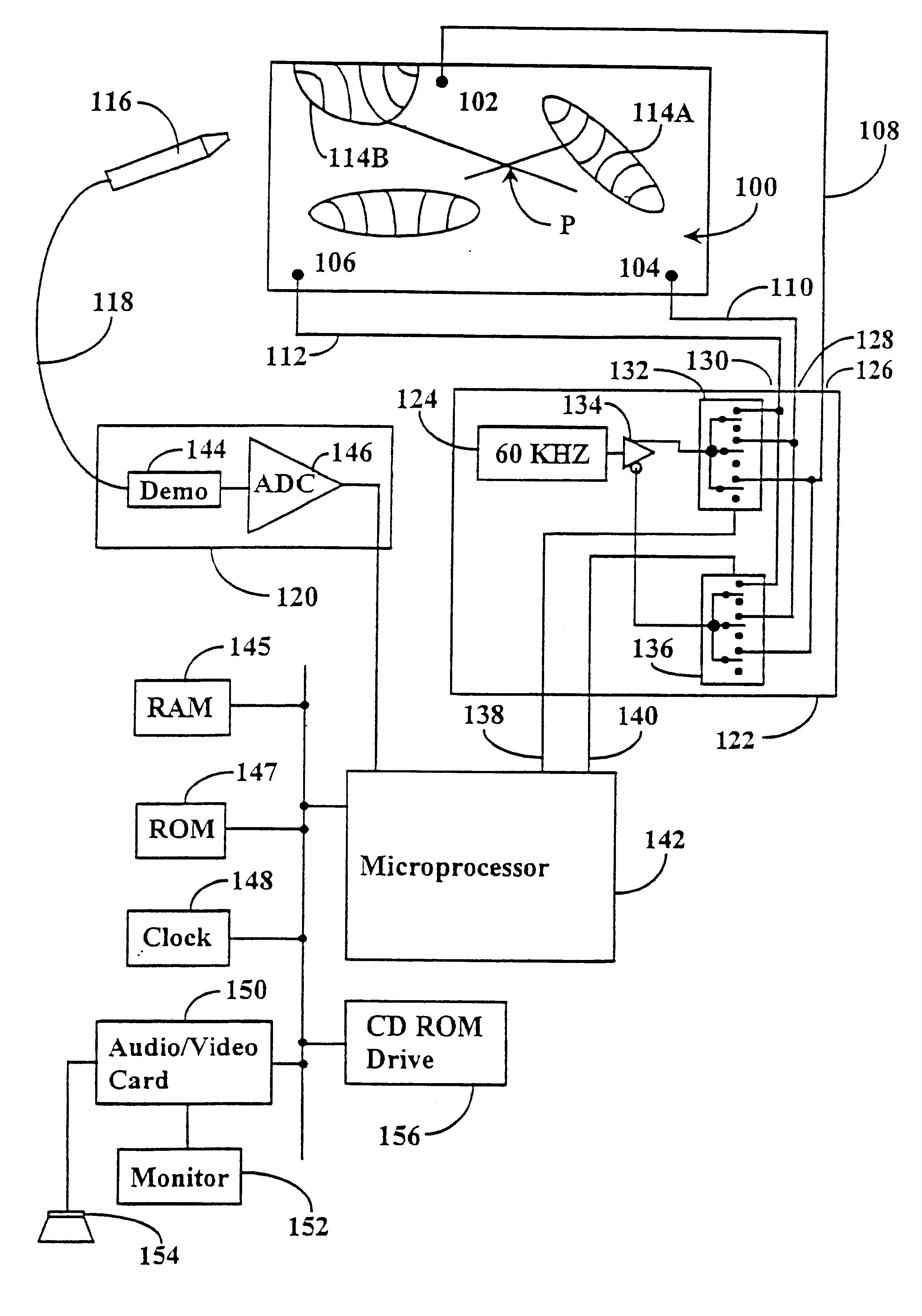

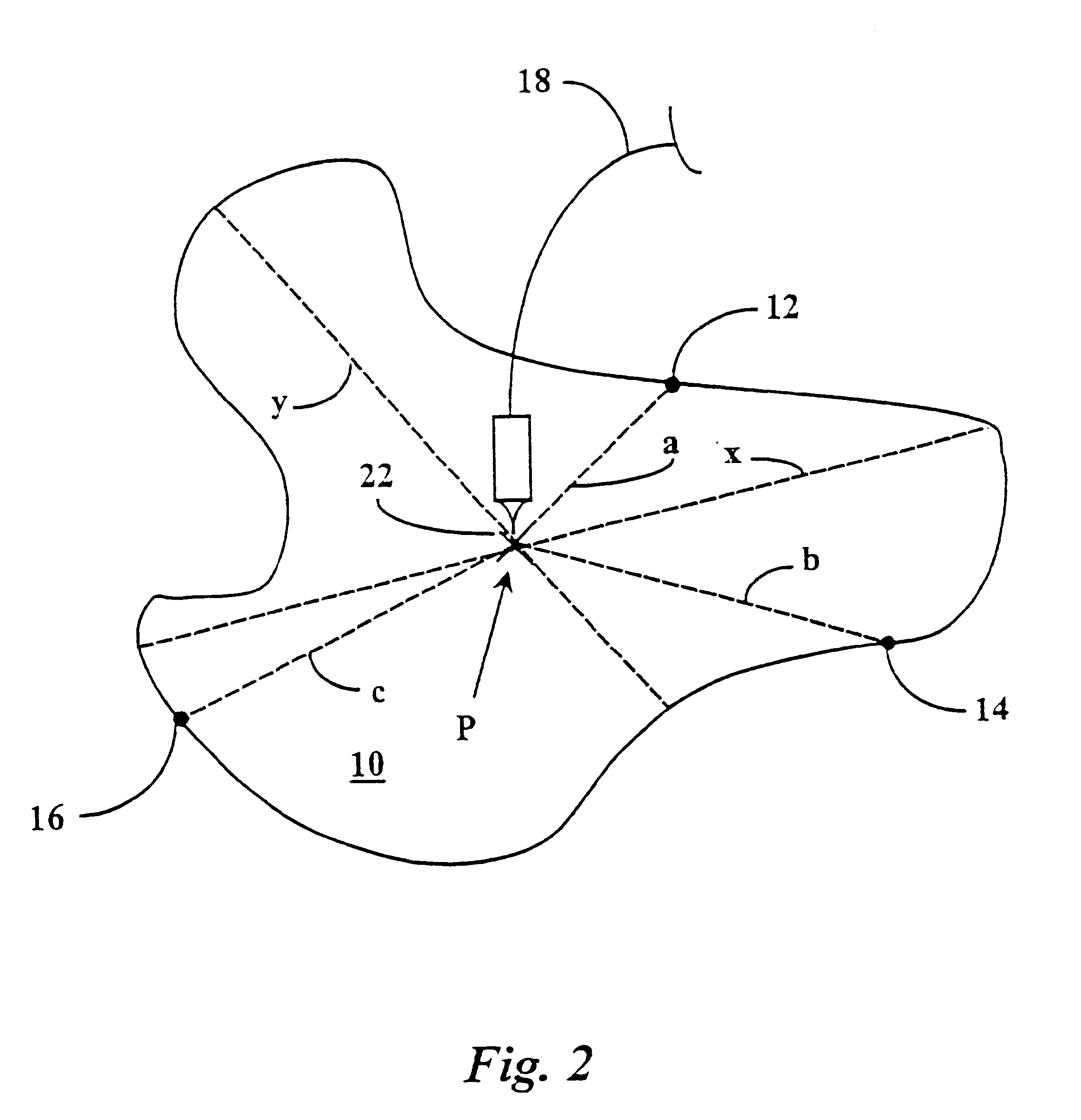

Surface position location system and method

InactiveUSRE38286E1Maximize probabilityImprove comfortTransmission systemsCathode-ray tube indicatorsEngineeringConductive materials

An electrographic sensor unit and method for determining the position of a user selected position thereon. The electrographic sensor unit includes a layer of a conductive material having an electrical resistivity and a surface, at least three spaced apart contact points electrically interconnected with a layer of conductive material, a processor connected to the spaced apart contacts and disposed to selectively apply a signal to each of the contact points, and a probe assembly, that includes either a stylus of a flexible conductive layer spaced apart from the layer, coupled to the processor with the stylus disposed to be positioned by a user in vicinity of a user selected position on the surface of the layer, or that position being selected with a user's finger on the flexible layer and to receive signals from the layer when the contact points have signals selectively applied thereto. The user selected position is determined by the processor from signals received from the stylus, or flexible layer, each in relation to a similar excitation of different pairs of the contact points under control of the processor. The conductive layer may be either two or three dimensional and may be a closed three dimensional shape. There may also be multiple layers with the processor being able to discern on which of those layers the user selected position is located. Further, provision is made to correct the calculated coordinates of the selected position for variations in contact resistance of each of the contact points individually. Additionally, a nonconductive skin having selected graphics printed thereon, such as a map, can be placed over the layer and the proces-sor further convert the calculated coordinates of the selected position to coordinates that relate to the graphical information printed in the skin, and even electro-nically (e.g., audio or visual) present information to the user relative to the graphical location selected as the selected position.

Owner:LEAPFROG ENTERPRISES

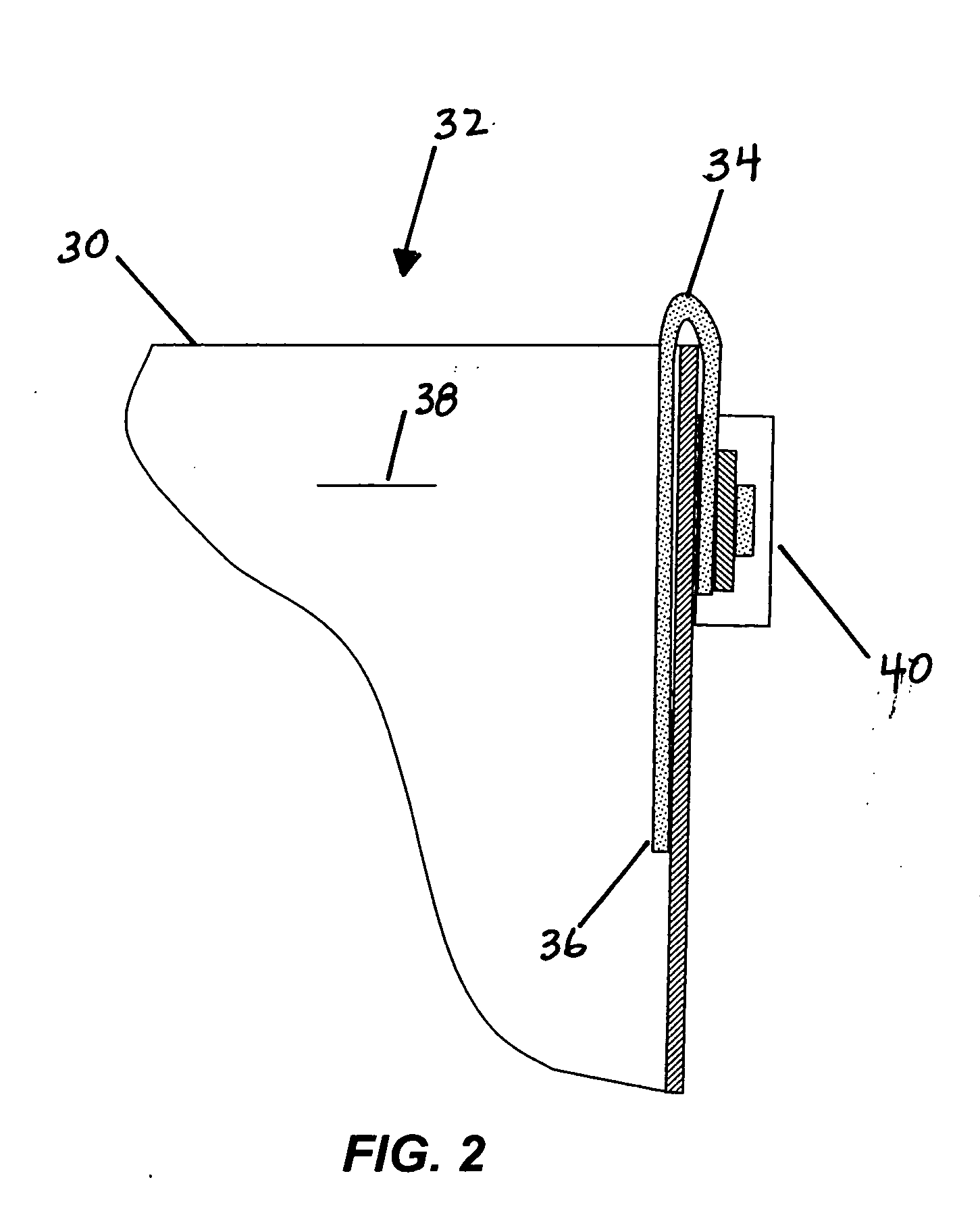

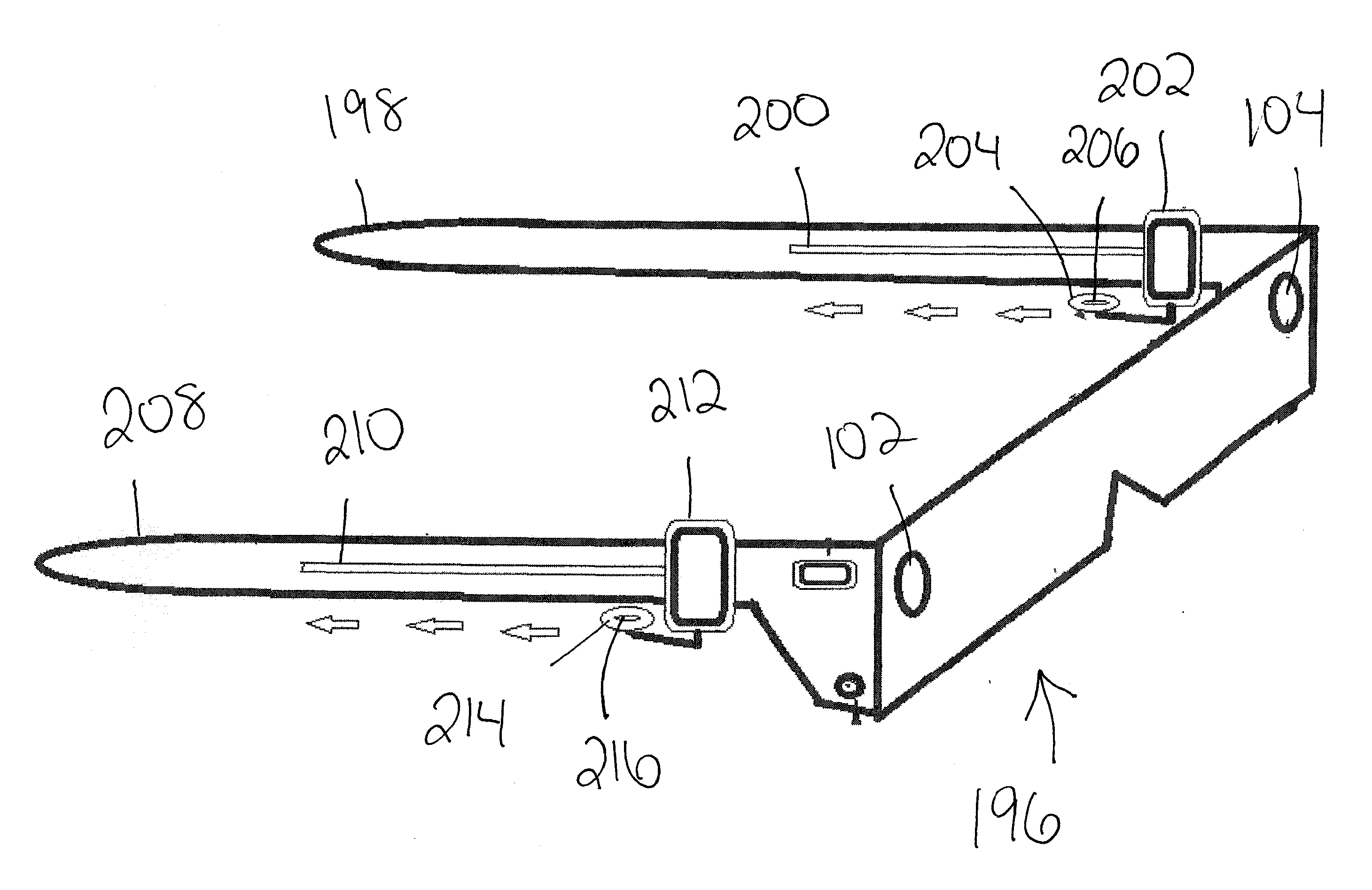

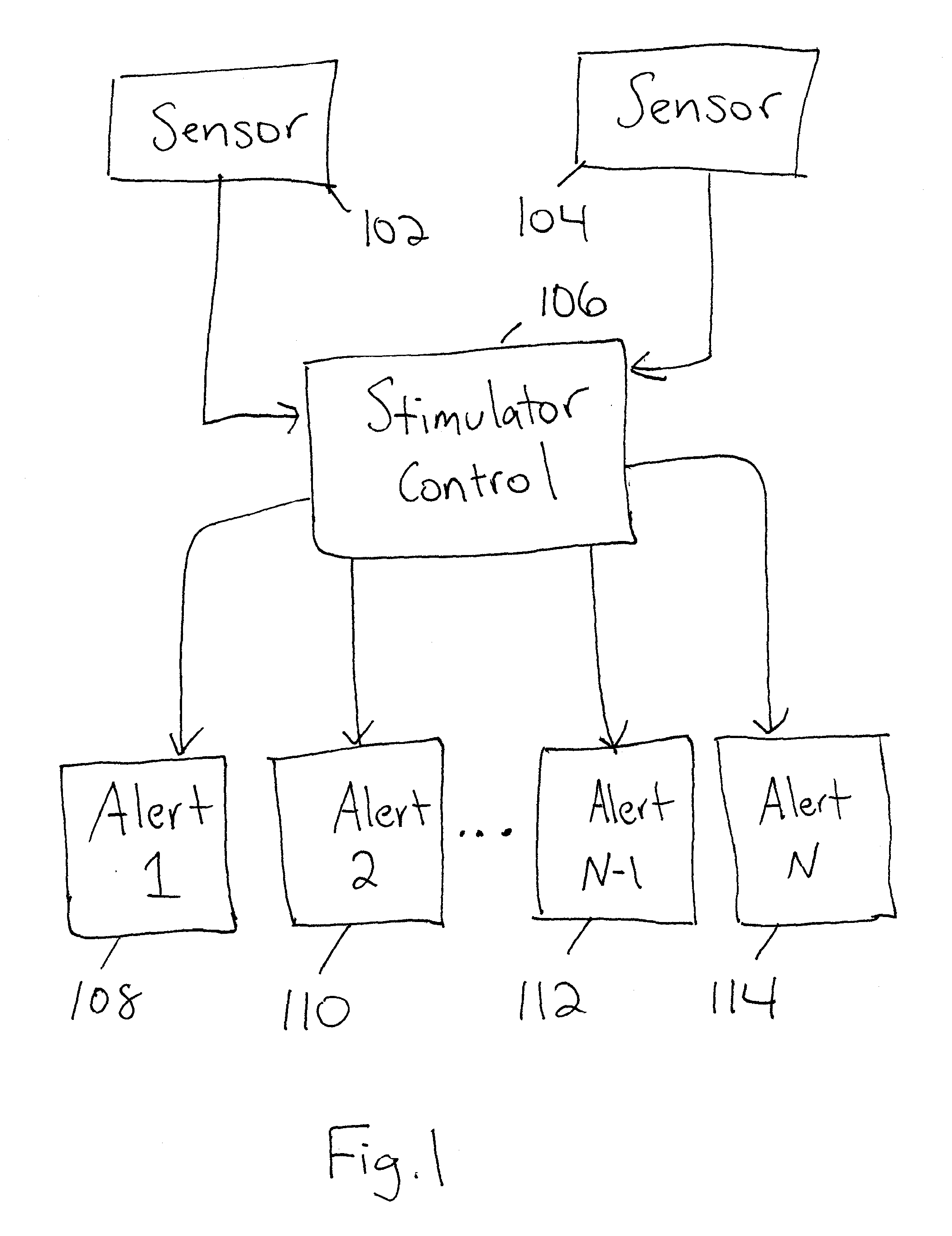

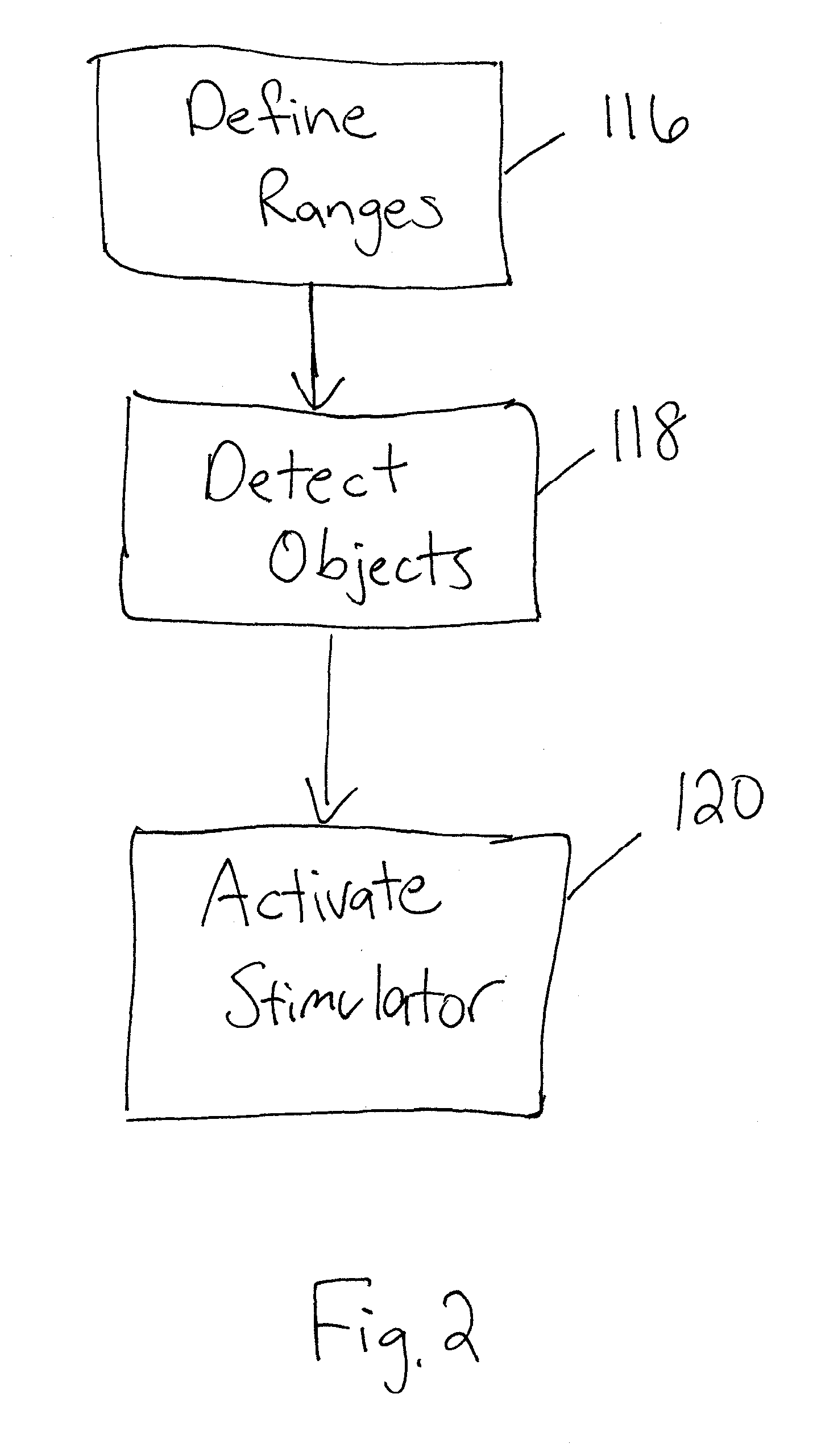

Object detection device

ActiveUS20130044005A1More experienceMore protective effectSignalling system detailsVisible signalling systemsProximity sensorHuman–computer interaction

When the sight impaired become mobile, they often bump their heads on unseen objects and / or hazards that could result in injury. The object detection device uses signal emitting proximity sensors that alert the user to unseen objects. The object detection device notifies the user of detected objects. Stimulators contact the user to warn the user that an object has been detected and the distance between the object and the user. Each stimulator contacts the user at a specific contact point. The stimulator finger contacting the user at a specific contact point informs the user of the distance between the user and the detected object.

Owner:FOSHEE GEORGE BRANDON +1

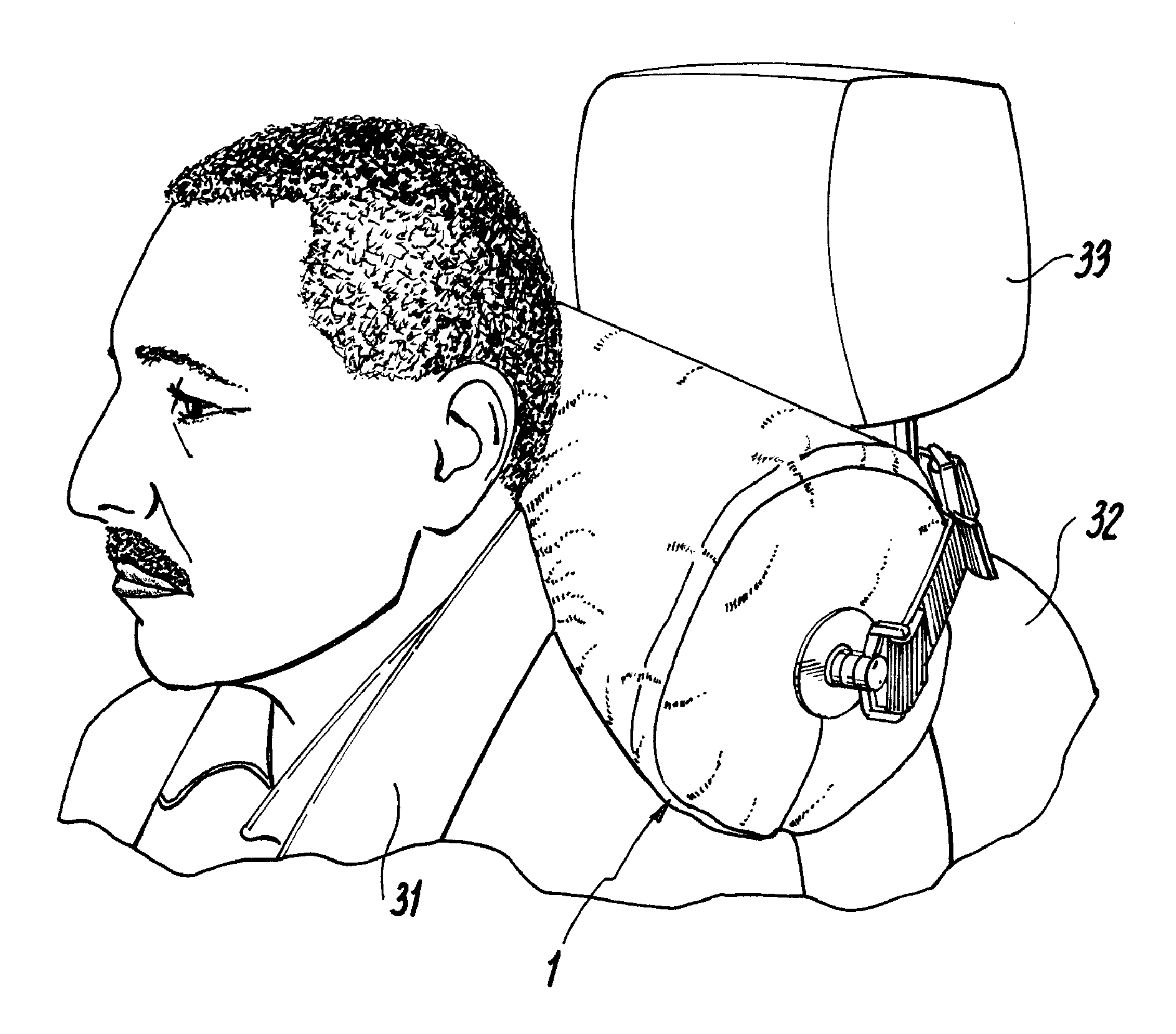

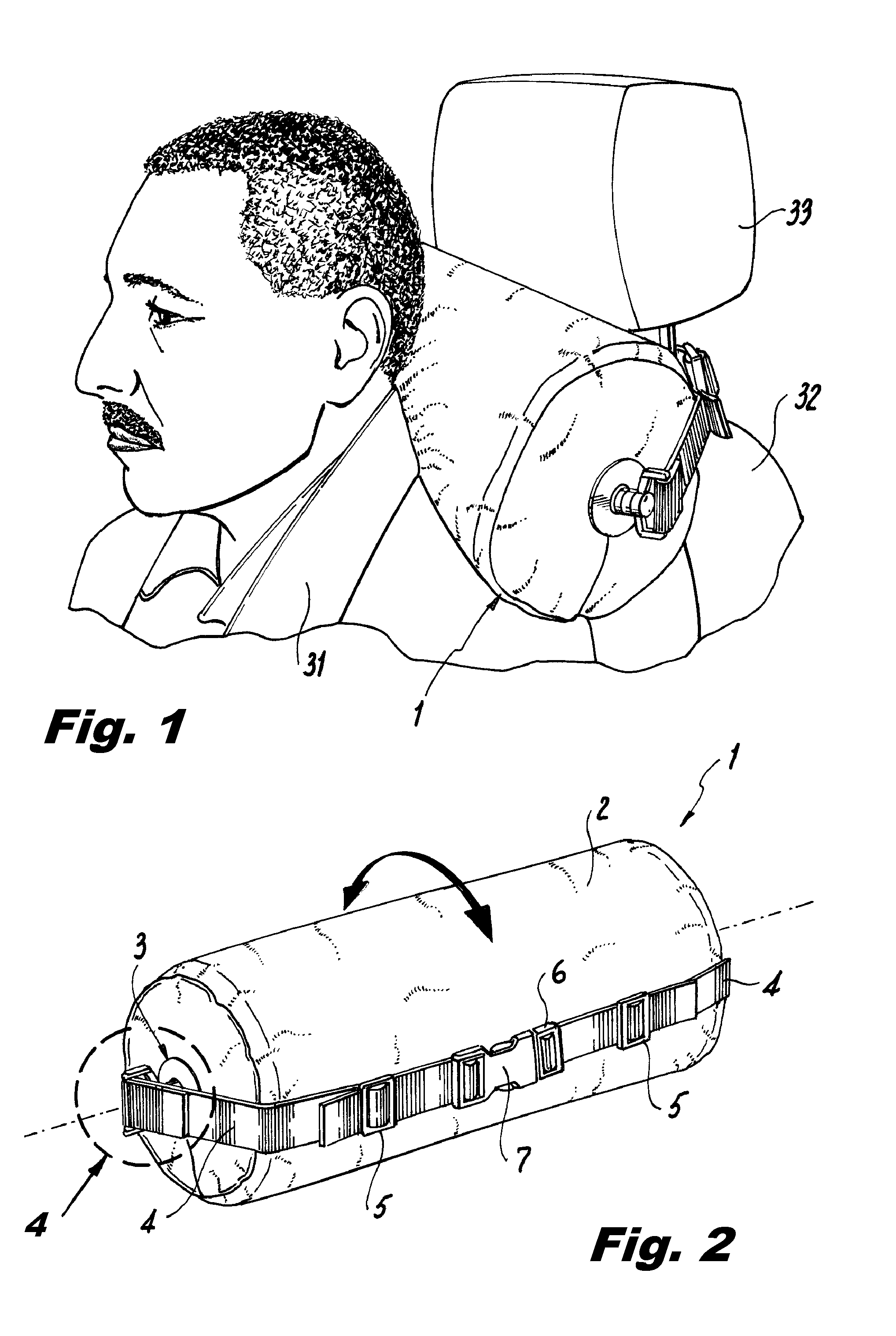

Rotatable cervical pillow for heavy equipment and other vehicles

InactiveUS20130119716A1Easy to disassembleSmooth rotationVehicle seatsOperating chairsHigh densityCervical pillows

A rotatable circular crossection cervical pillow is manually rotated in a continuous fashion as desired by a person whenever a fresh clean contact spot is sought, or a contact spot of variable support is sought, while the pillow is still attached to a seat back. The rotatable pillow is a cylinder of medium and / or firm high density polyurethane foam. An axial through-hole in the center permits the snug insertion of a rigid length of tubing to give the pillow axial rigidity. Swivel fixtures are attached at each end of the pillow by virtue of the central tube. A fabric cover with an opening closure covers the entire polyurethane cylinder snugly. Optionally the cover may carry therapeutic imparting elements therein. Straps with adjustable buckles are attached to each swivel fixture. Therefore, the cervical pillow rotates easily while still strap-attached to the seat back.

Owner:STRONCONI CHARLES J

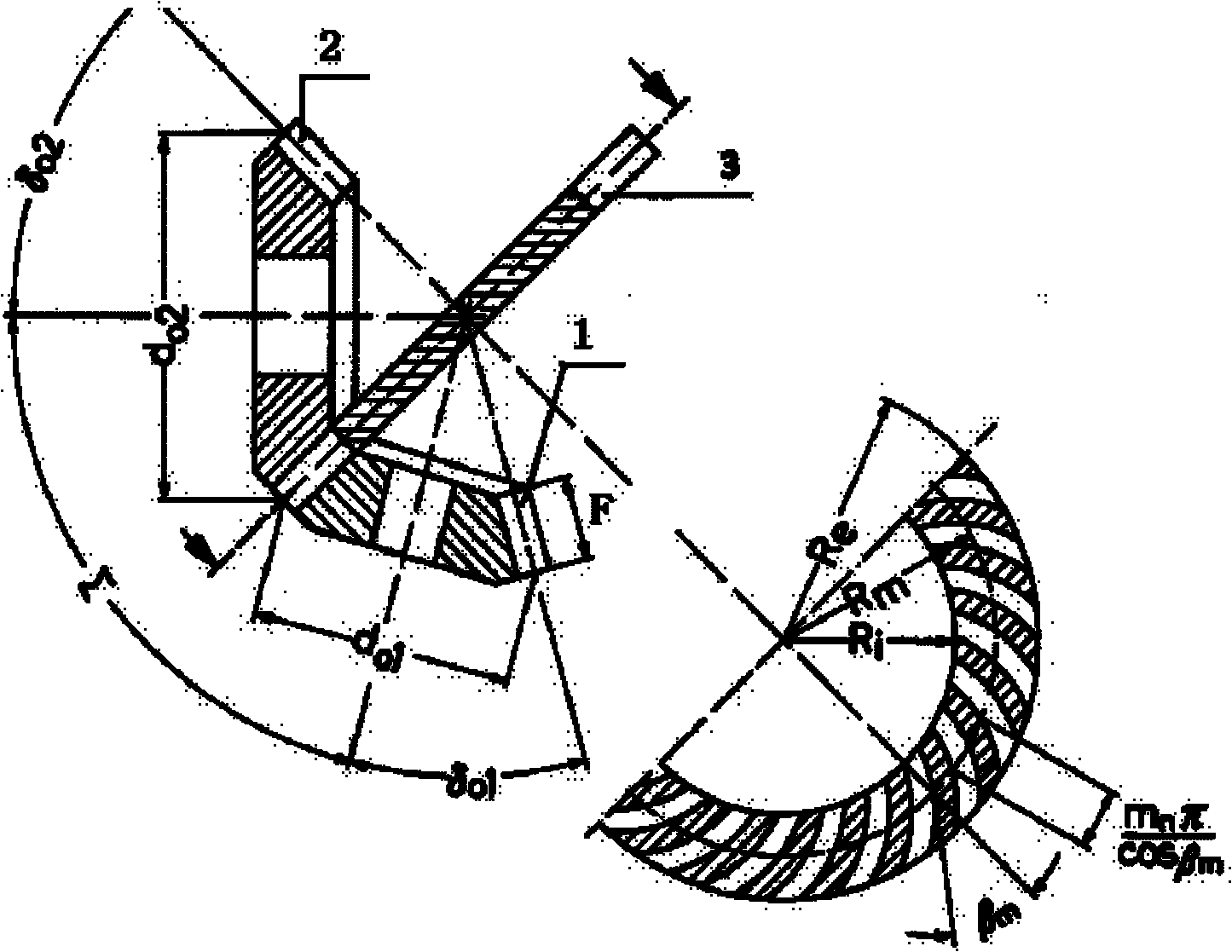

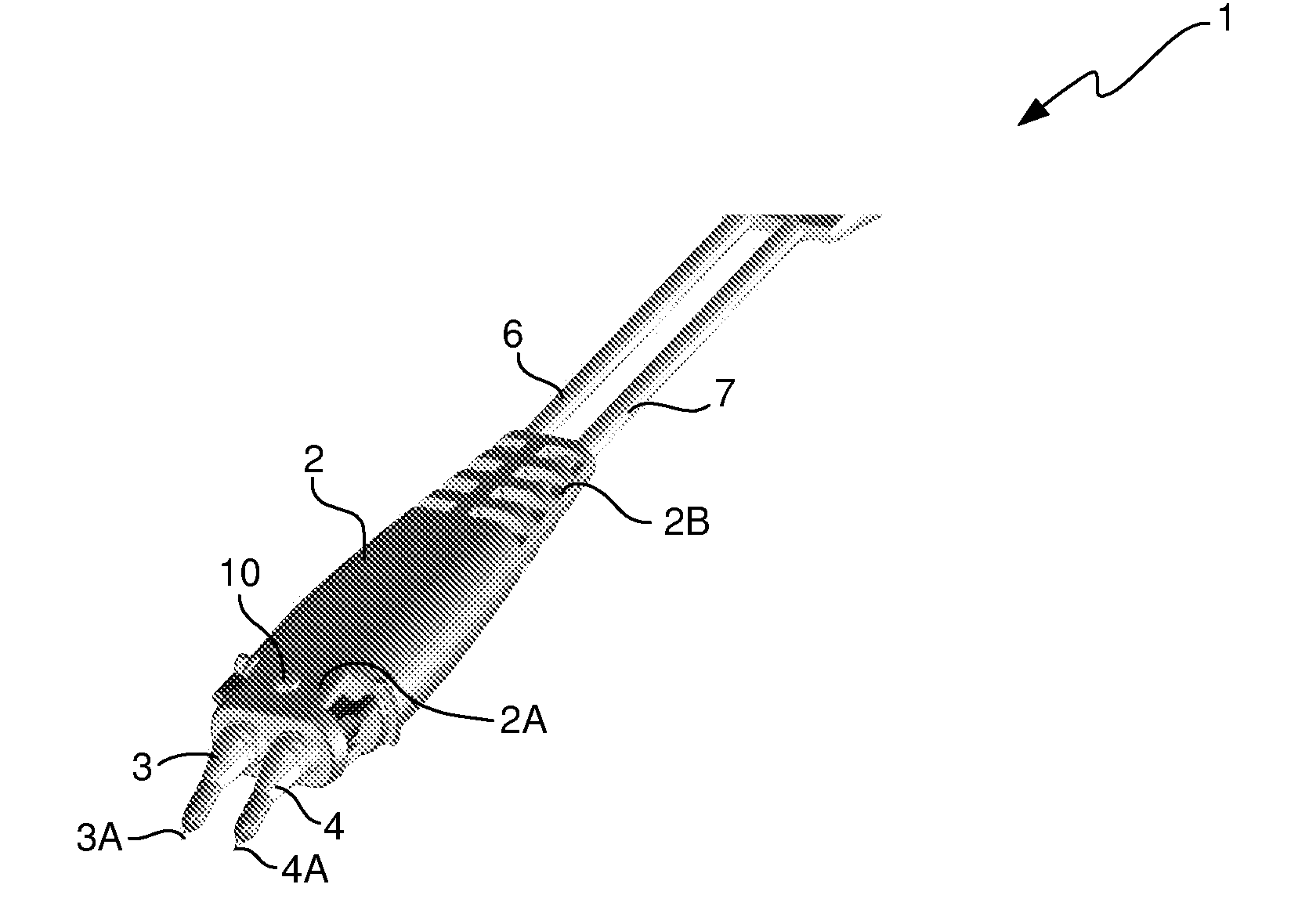

Bevel gear machining method

The invention discloses a bevel gear machining method. According to the geometric parameters and the required tooth system of a gear to be machined, the method comprises the following steps that: (1) the parameters of a shaping gear wheel are determined; (2) the tooth traces of the shaping gear wheel are determined; (3) the parameters of a cutter are determined; (4) the cutter movement on the tooth surface of the shaping gear wheel is determined; (5) the basic tooth surface modification of the shaping gear wheel is determined; (6) the movement of the shaping gear wheel generating the gear is determined; (7) the movement of the gear generated by the shaping gear wheel is corrected; and (8) the generation of the gear to be machined is completed. The invention has the advantages that: (1) the cutting and the grinding of bevel gears with straight teeth, curved teeth, cycloidal teeth, quasi-involute teeth and the like can be implemented on one machine tool; (2) the dimension of the cutter is determined only by the module of the gear to be machined and has nothing to do with the diameter of the gear to be machined and the tooth width; (3) the diameter of the cutter or the grinding wheel is small, the torque of the machine tool spindle is small, the force applied to the machine tool is small, the deformation of the machine tool is small and the machining accuracy is high; (4) the position, the dimension and the shape of the contact spots on the tooth surface can be conveniently controlled and all kinds of theoretically full-conjugated bevel gear pairs can be machined; and (5) the transmission ratio function required by the gear pairs to be machined can be accurately realized.

Owner:秦川机床工具集团股份公司 +1

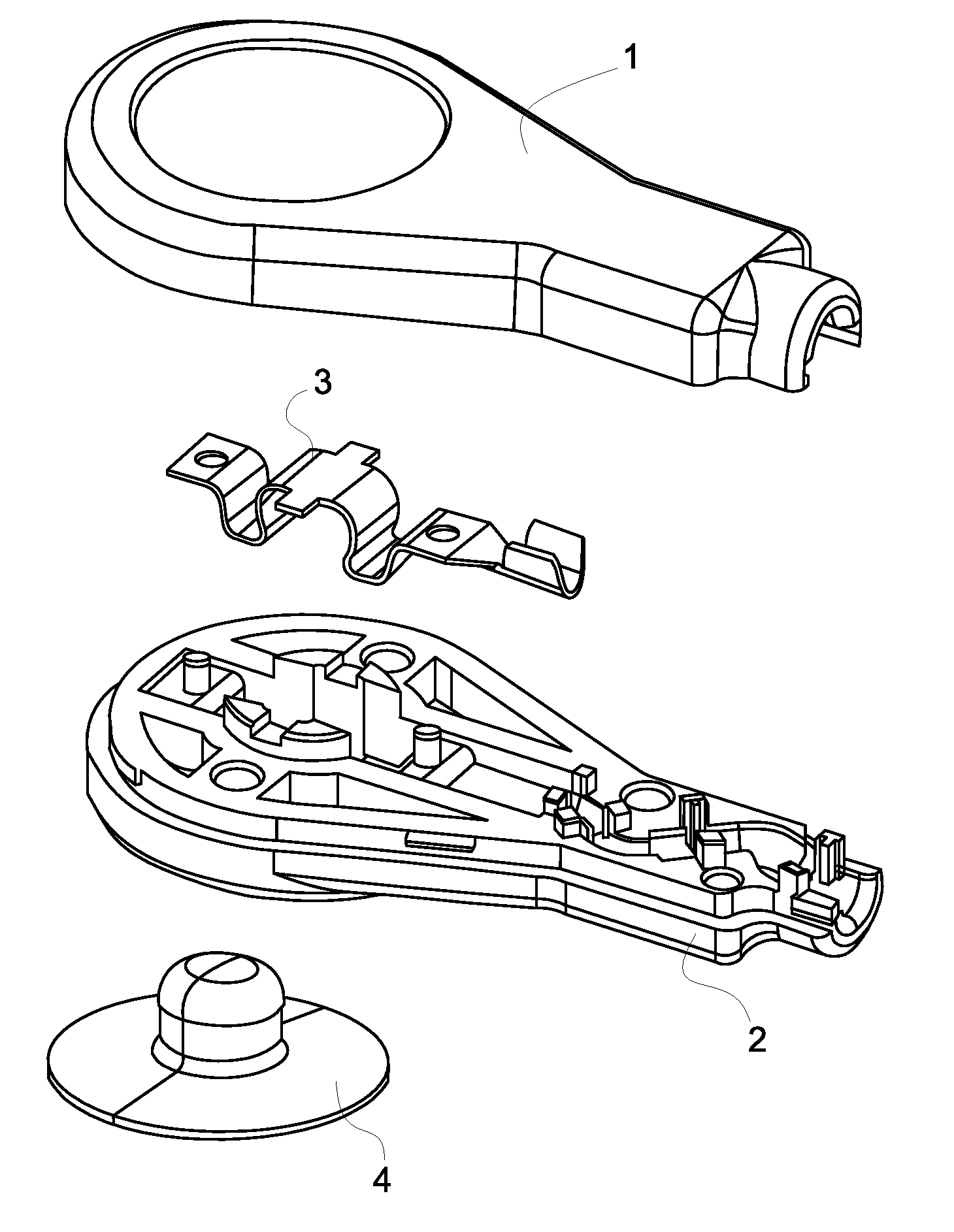

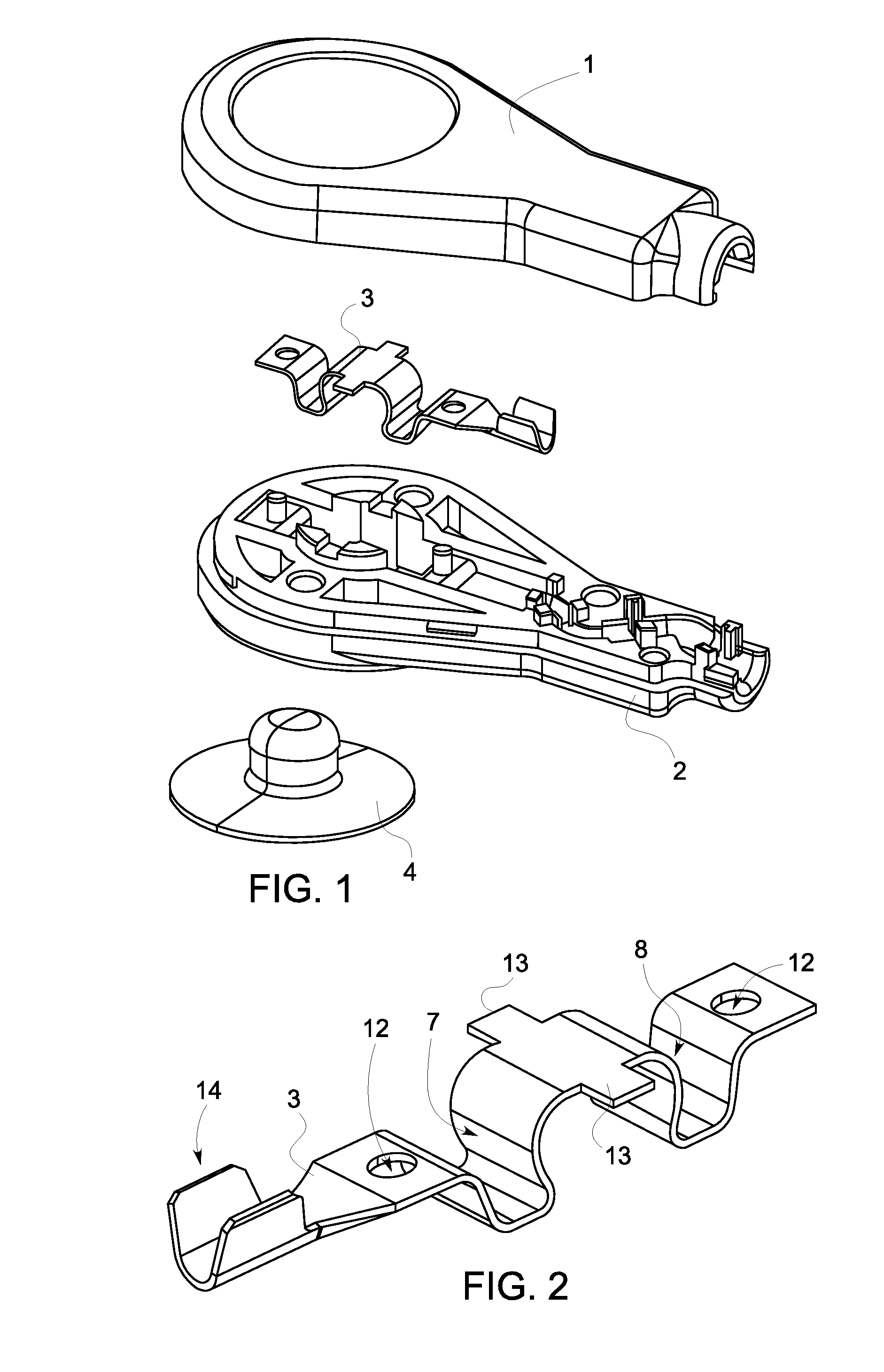

Electrical connector assembly

Electrical connector assembly comprising a cover part and a contact assembly for providing a mechanical and electrical contact to an electrode, and connecting arrangements for connecting lead wire to the contact component. The contact component is made of an elongated flat-formed strip forming at least two contact points for the electrode and between the contact points forming a recess having walls enlarging when drawing away from the contact points. The contact points are arranged to press against the electrode for detachable fastening.

Owner:GENERAL ELECTRIC CO

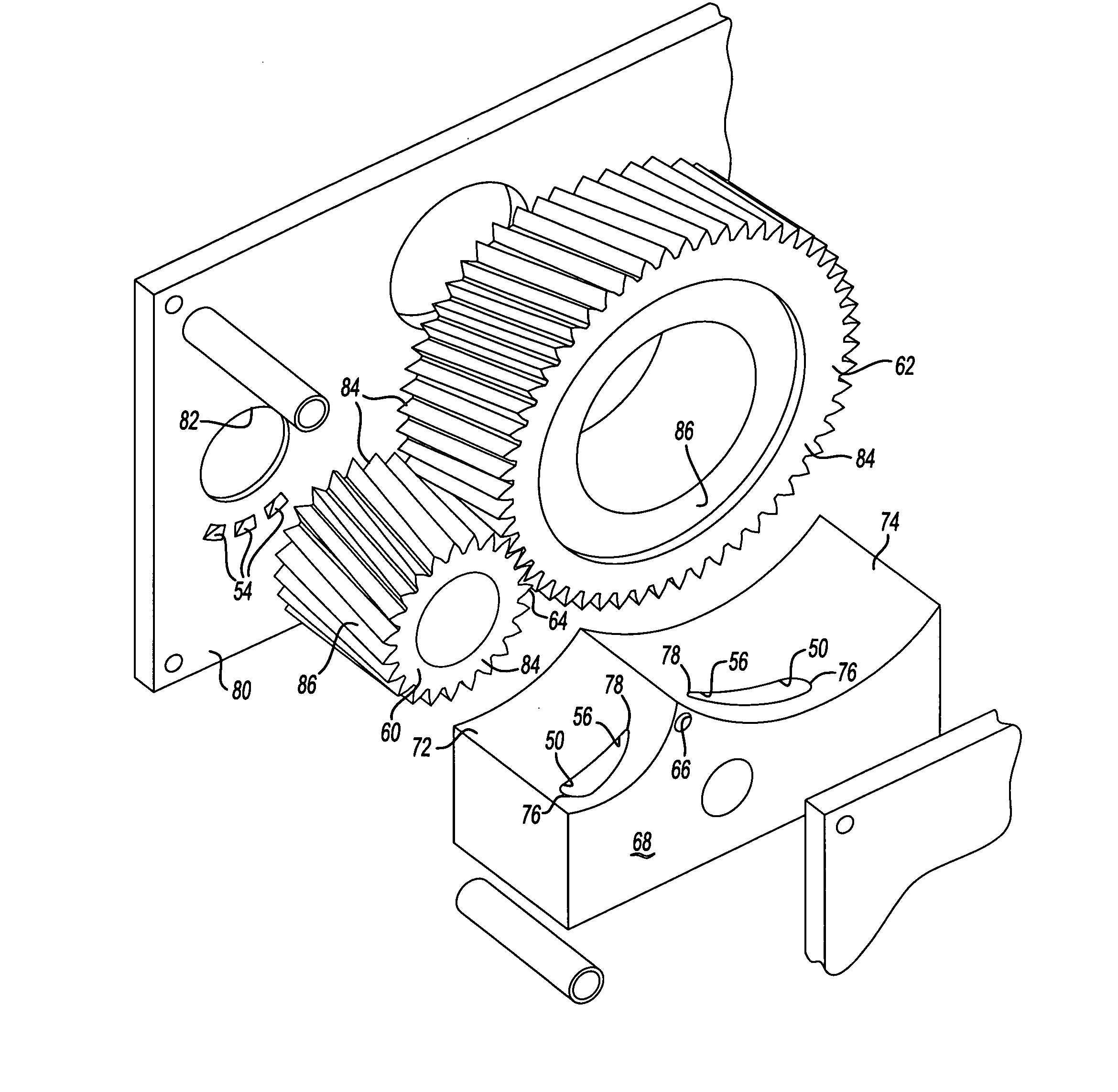

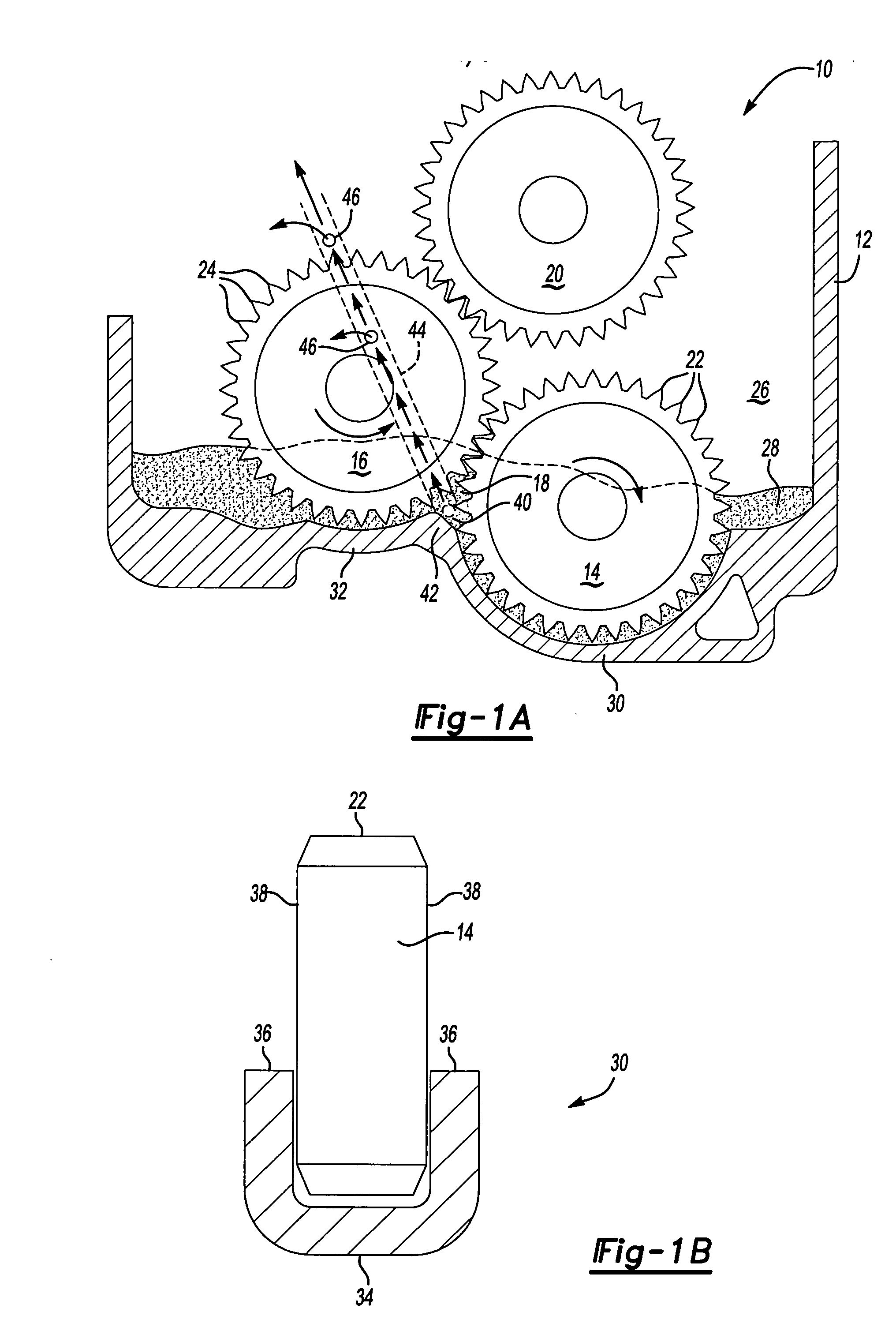

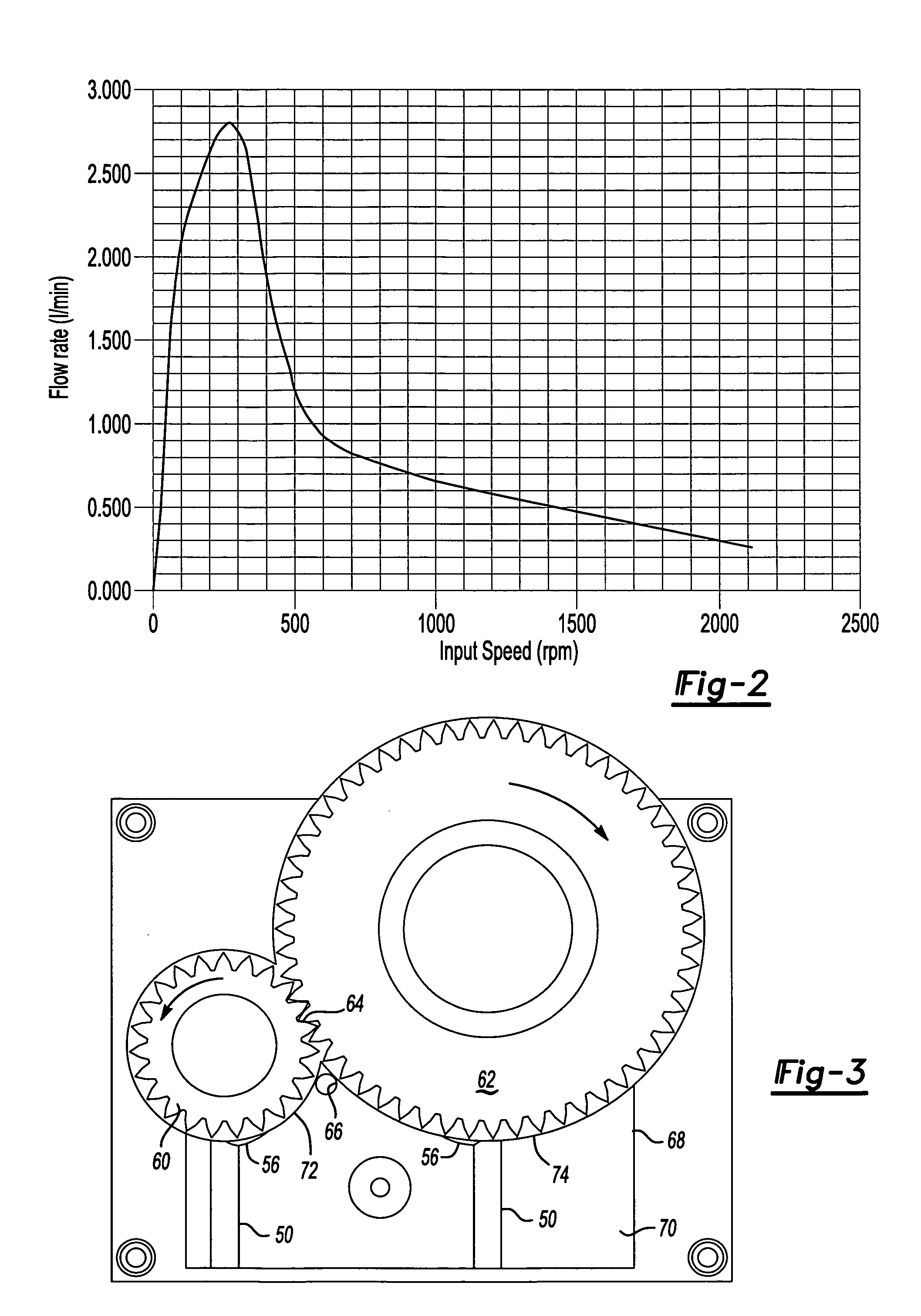

Ancillary oil pumping for gear box assembly

ActiveUS20070251348A1Effective lubricationSimple pumpingGearboxesOscillating piston enginesTransfer caseGear drive

A gear box assembly as used in an inverted portal axle or transfer case includes a drive gear and at least one driven gear in meshing engagement with the drive gear at a contact point. A gear housing closely surrounds portions of an outer circumference of the drive and driven gears to form a baffle area. The gear housing includes an discharge orifice that is located near the contact point and a fluid gallery that extends from the discharge orifice to other locations within the gear housing. As the drive gear drives the driven gear, fluid is pumped into the discharge orifice and through the fluid gallery to fluid outlets positioned at desired locations to lubricate other gear box components. Radial inlets with elongated chamfers and stator vanes can be formed within the gear housing to draw air ingested during pumping away from the discharge orifice. Additionally, a bypass loop can be used to scavenge unwanted air ingested into meshing gear teeth.

Owner:ARVINMERITOR TECH

Rotatable cervical pillow for heavy equipment and other vehicles

InactiveUS8708416B2Easy to disassembleSmooth rotationVehicle seatsOperating chairsHigh densityCervical pillows

A rotatable circular crossection cervical pillow is manually rotated in a continuous fashion as desired by a person whenever a fresh clean contact spot is sought, or a contact spot of variable support is sought, while the pillow is still attached to a seat back. The rotatable pillow is a cylinder of medium and / or firm high density polyurethane foam. An axial through-hole in the center permits the snug insertion of a rigid length of tubing to give the pillow axial rigidity. Swivel fixtures are attached at each end of the pillow by virtue of the central tube. A fabric cover with an opening closure covers the entire polyurethane cylinder snugly. Optionally the cover may carry therapeutic imparting elements therein. Straps with adjustable buckles are attached to each swivel fixture. Therefore, the cervical pillow rotates easily while still strap-attached to the seat back.

Owner:STRONCONI CHARLES J

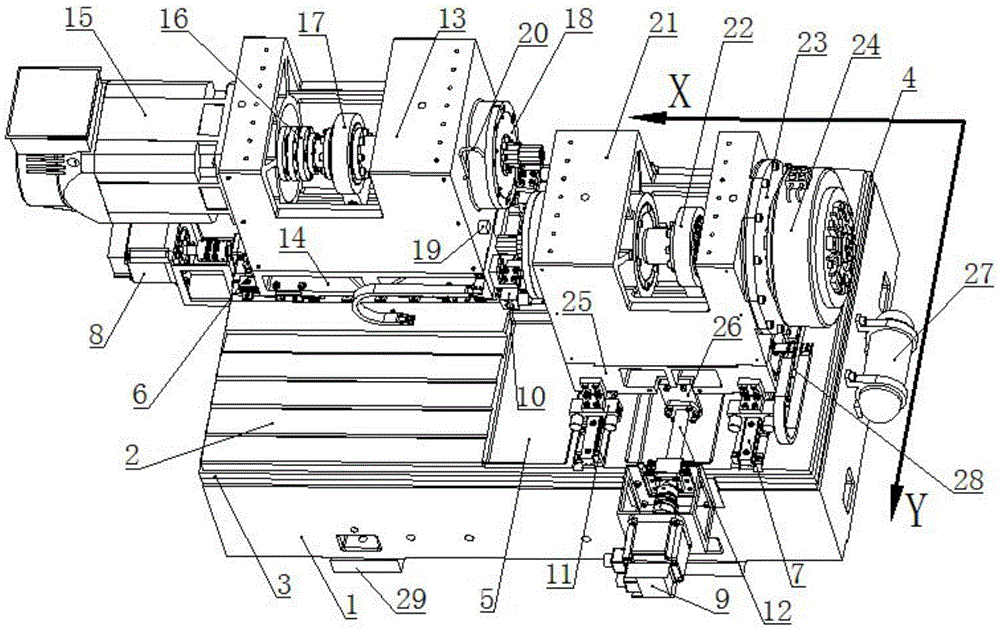

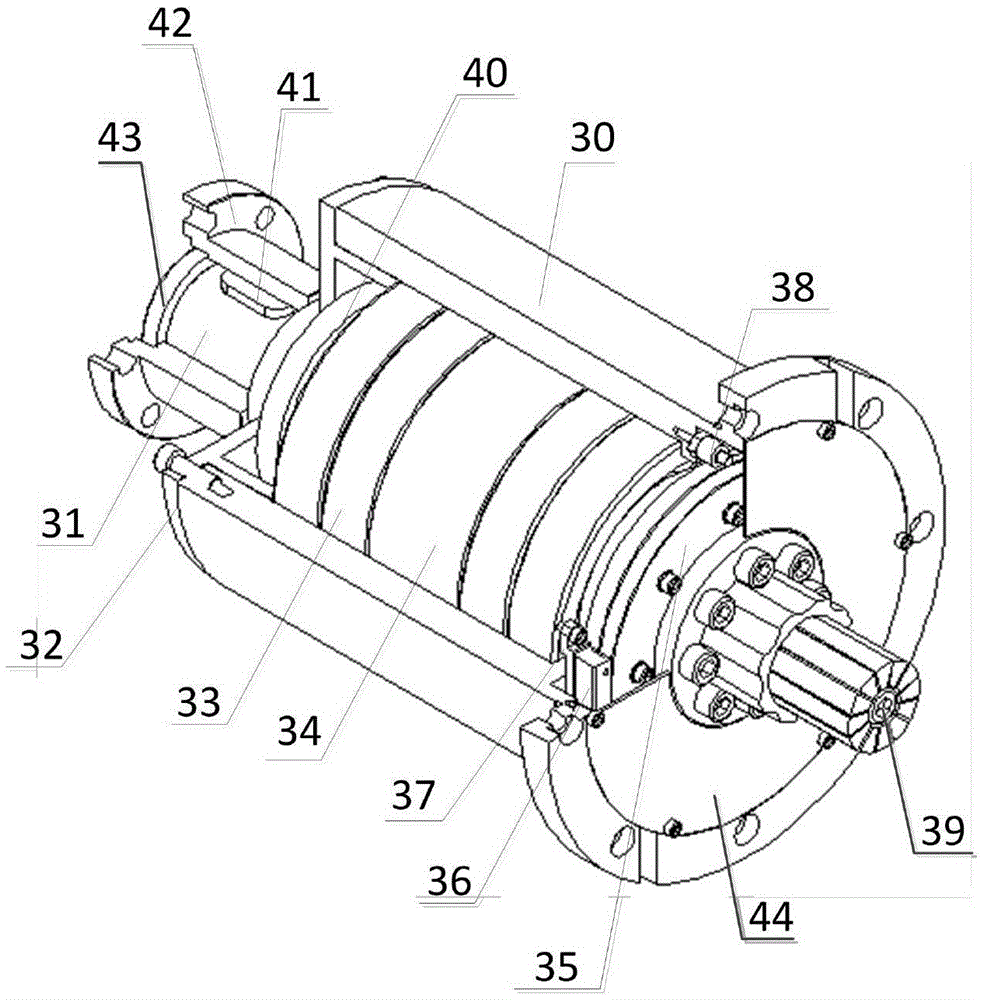

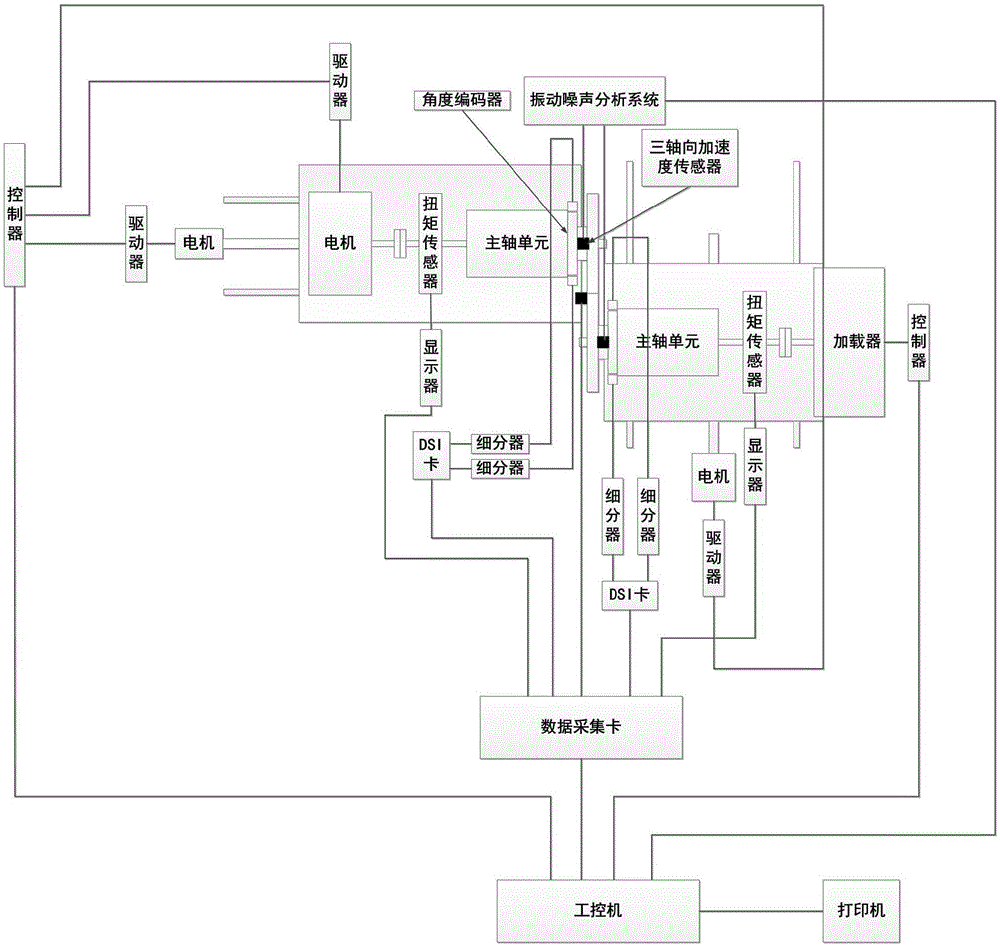

Experimental apparatus for dynamic performances of cylindrical gear

InactiveCN105651511AHigh degree of automationHigh precisionMachine gearing/transmission testingElectricityGear drive

The invention discloses an experimental apparatus for the dynamic performances of a cylindrical gear. The apparatus comprises a precision lathe bed and a precision spindle unit. A spindle unit, a torque sensor and a motor are fixed on a drive-end box body. A driven shaft spindle unit, a torque sensor and a loader are fixed on a load-end box body. A gear clamp and a spindle are connected via a lolley needle. In this way, the installation of gears is facilitated, and the gear clamp is ensured to be good in interchangeability. Meanwhile, the dimension range of experimental gears is enlarged. The experimental apparatus is provided with multiple sensors, thus integrating mechanical functions, optical functions and electrical functions as a whole. The experimental apparatus enables various common experiments on cylindrical gears, such as the measurement on the transmission error profiles of gears, the analysis on the meshing vibration noises of gears, the measurement on the contact spots of gears, the measurement on the transmission efficiencies of gears and the like. The experimental apparatus is high in precision, large in rigidity, extremely good in stability and high in degree of automation, which can meet the requirements of dynamic and static tests on gears.

Owner:BEIJING UNIV OF TECH

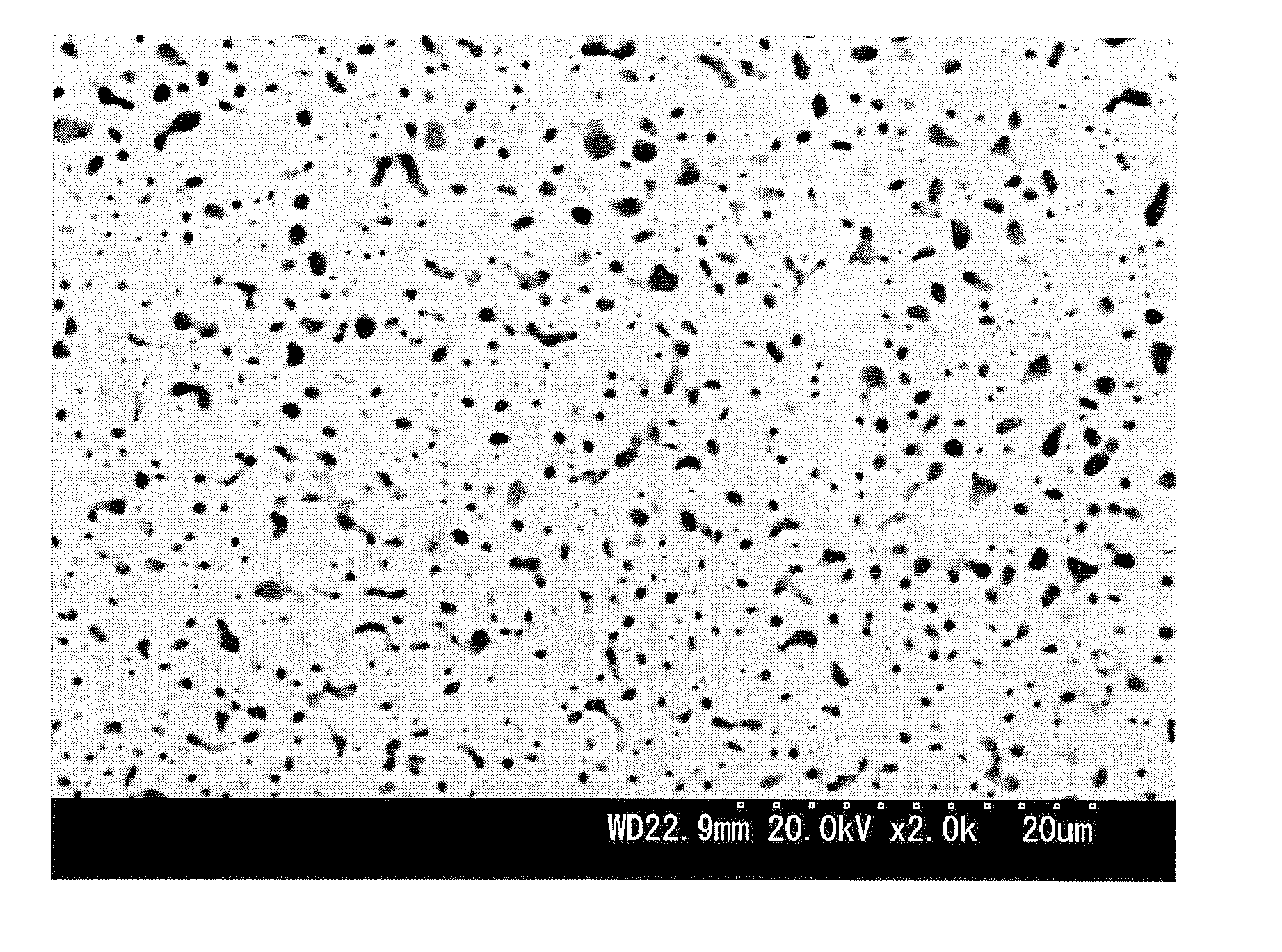

Sputtering Target of Nonmagnetic-Particle-Dispersed Ferromagnetic Material

ActiveUS20100320084A1Good effectDeposition speed is fastCellsConductive materialProduction rateSputtering

Provided is a sputtering target of nonmagnetic-particle-dispersed ferromagnetic material comprising a phase (A) such that nonmagnetic particles are dispersed in a ferromagnetic material formed from a Co—Cr alloy containing 5 at % or more and 20 at % or less of Cr and Co as the remainder thereof, and schistose textures (B) with a short side of 30 to 100 μm and a long side of 50 to 300 μm formed from a Co—Cr alloy phase in the phase (A); wherein each of the foregoing nonmagnetic particles has such a shape and size that the particle is smaller than all hypothetical circles with a radius of 1 μm around an arbitrary point within the nonmagnetic particle, or a shape and size with at least two contact points or intersection points between the respective hypothetical circles and the interface of the ferromagnetic material and the nonmagnetic material. Consequently, obtained is a high-density sputtering target of nonmagnetic-particle-dispersed ferromagnetic material whose crystal grains are fine, which realizes improvement of PTF (pass through flux) of the target, high-speed deposition with a magnetron DC sputtering system, reduction in the particles (dust) and nodules generated during the sputtering process, minimal variation in quality, and improvement of mass productivity.

Owner:JX NIPPON MINING& METALS CORP

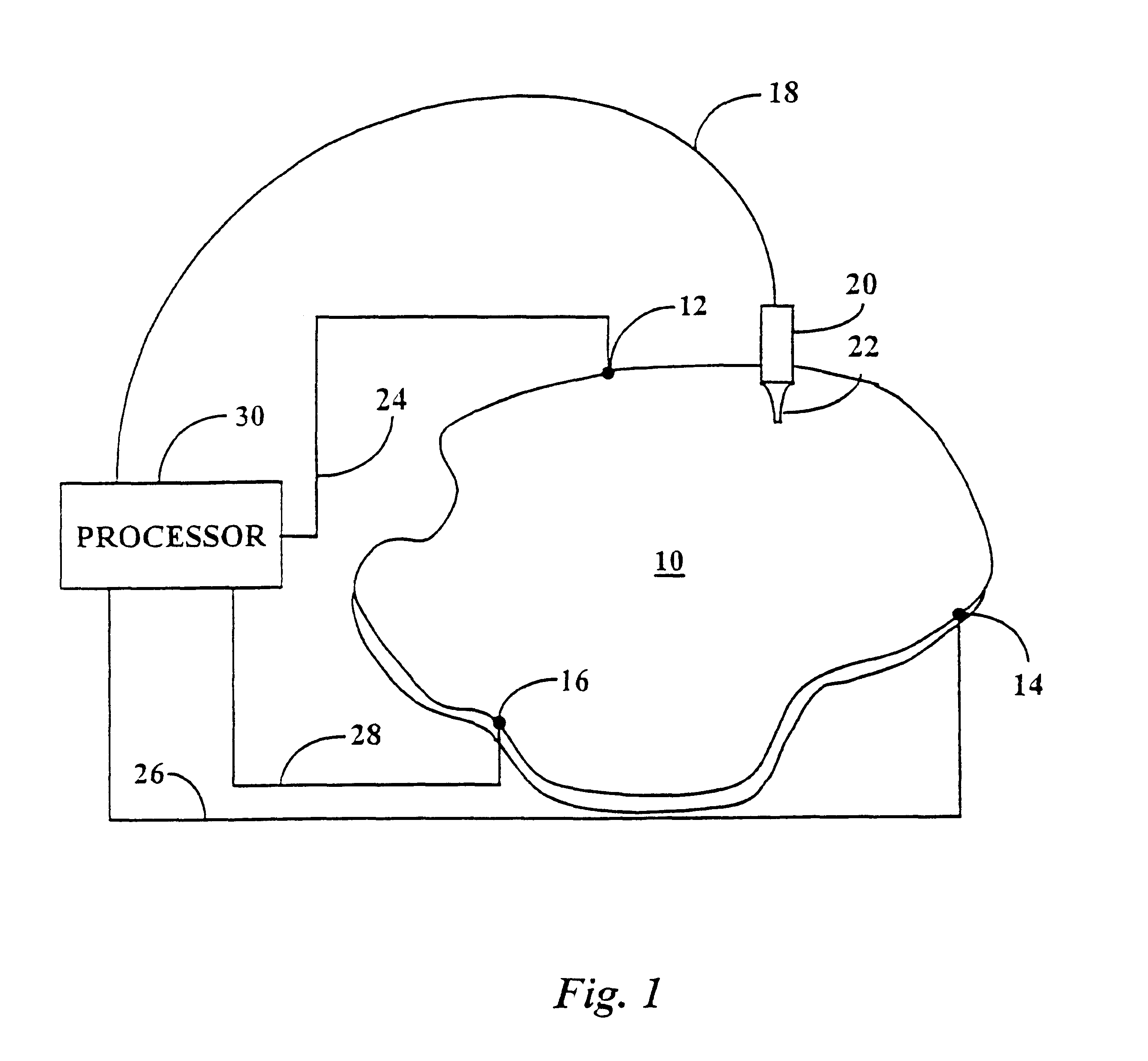

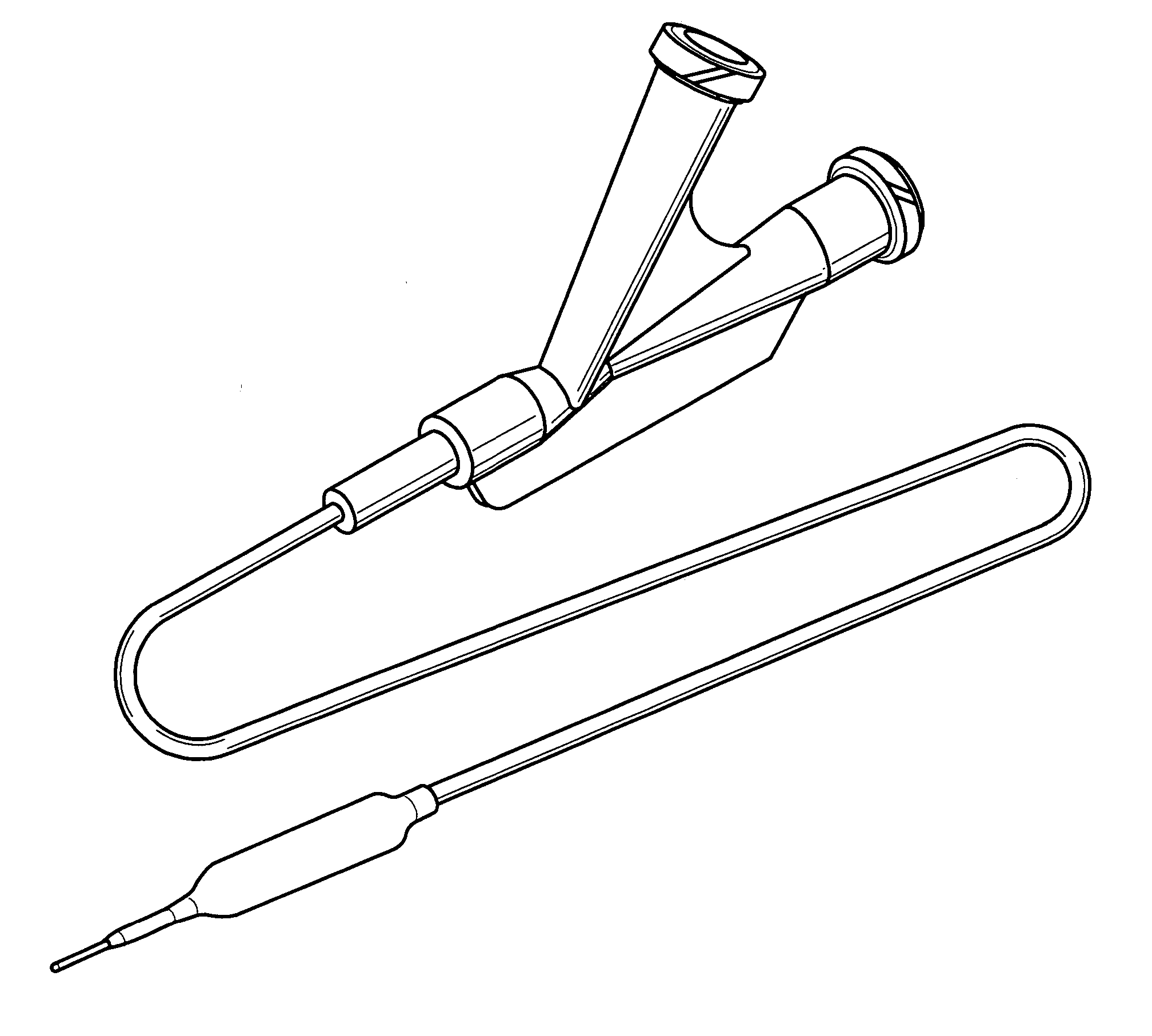

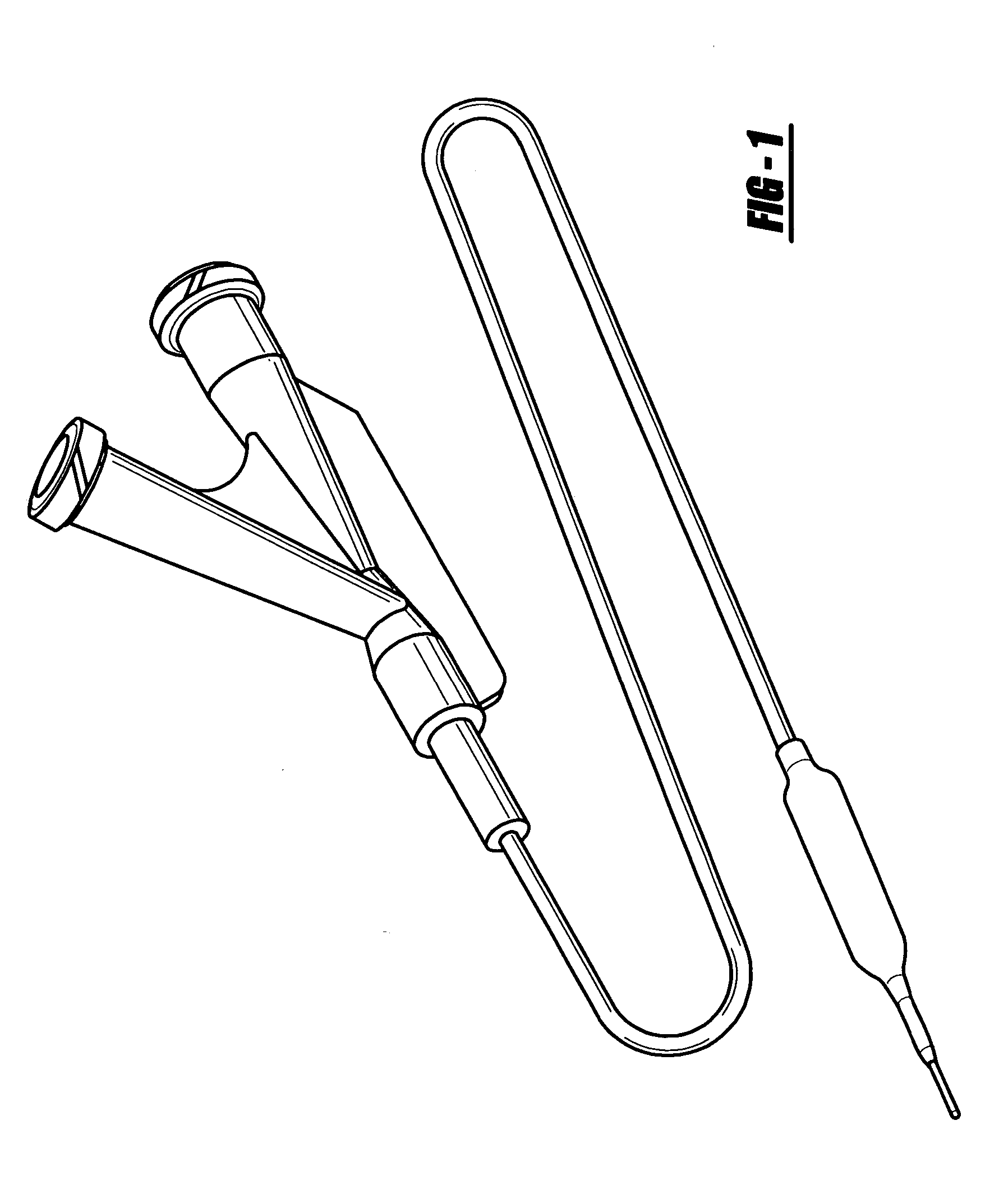

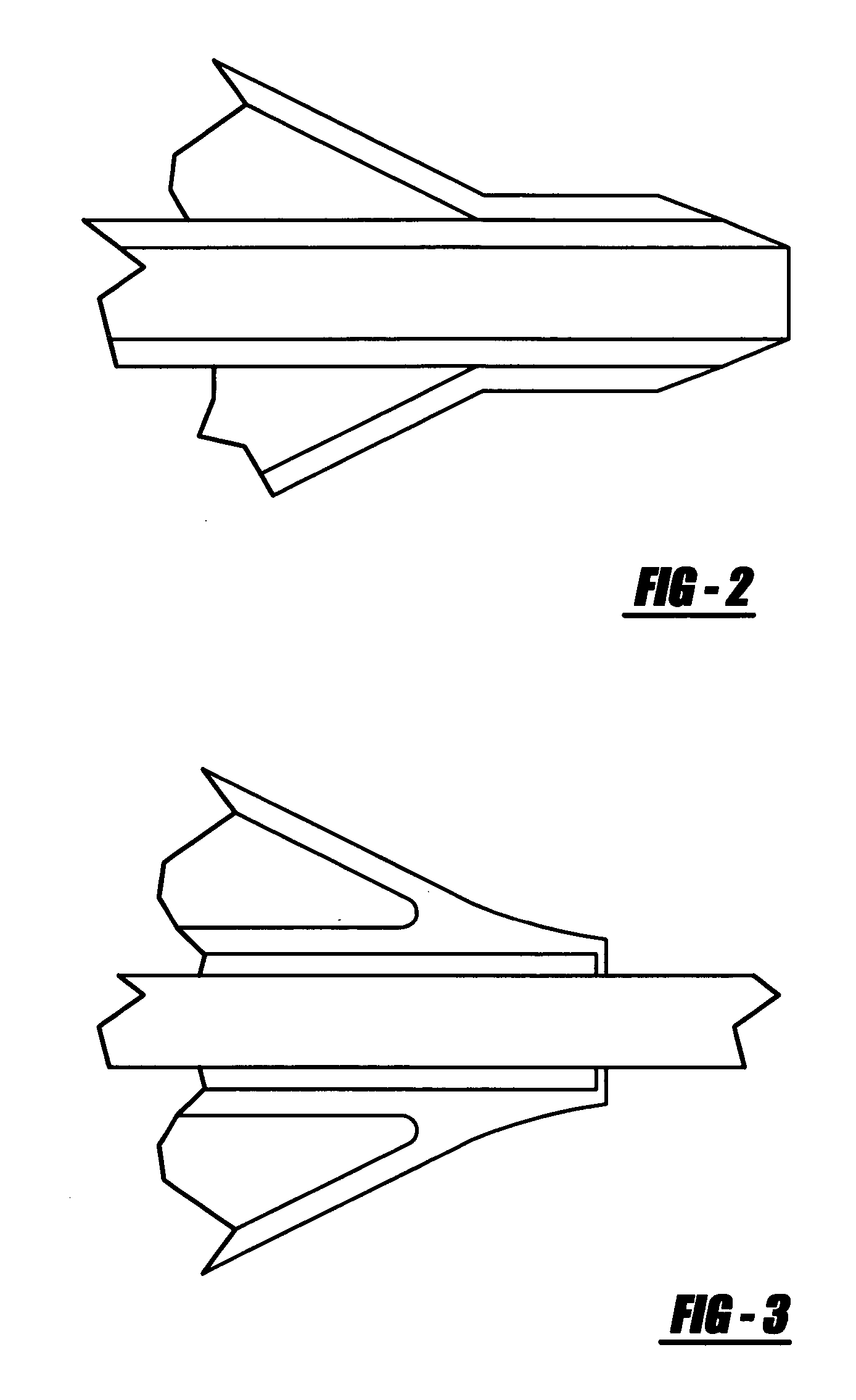

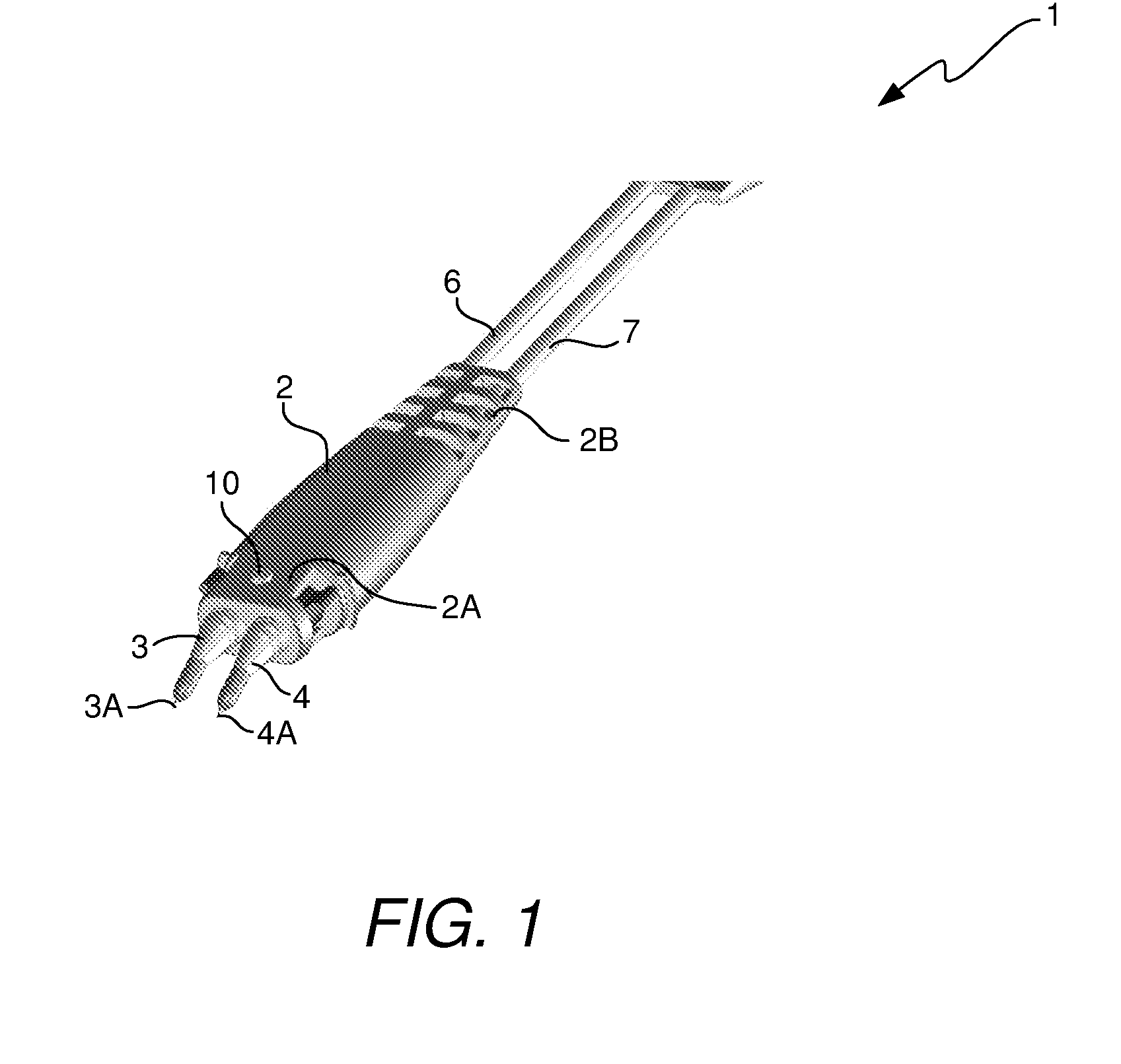

Methods of making balloon catheter tip

ActiveUS20060004399A1Increase inner diameter and cross-sectional areaPromote blood flowSurgeryDilatorsDistal portionBalloon catheter

A balloon catheter for medical treatment of a patient has an improved tip design and methods of making the tip. The balloon catheter has a flexible shaft with proximal and distal ends, a hub affixed to the proximal end, and a balloon affixed to the shaft near the distal end. At least a distal portion of the shaft includes a tubular inner body, and the balloon has a distal leg affixed to the inner body. A short, tubular tip member is placed in contact with the distal end of the inner body, and a shrink tube is placed around the point of contact. A wire mandrel is passed through a lumen defined by the inner body and tip member. While the shrink tube is heated, compressing the tip member and inner body, the mandrel is moved. This combination of heat, radial pressure, and mandrel movement causes a blending of the materials of the inner body and the tip member. The resulting joint of the tip member and inner body is both strong and flexible.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

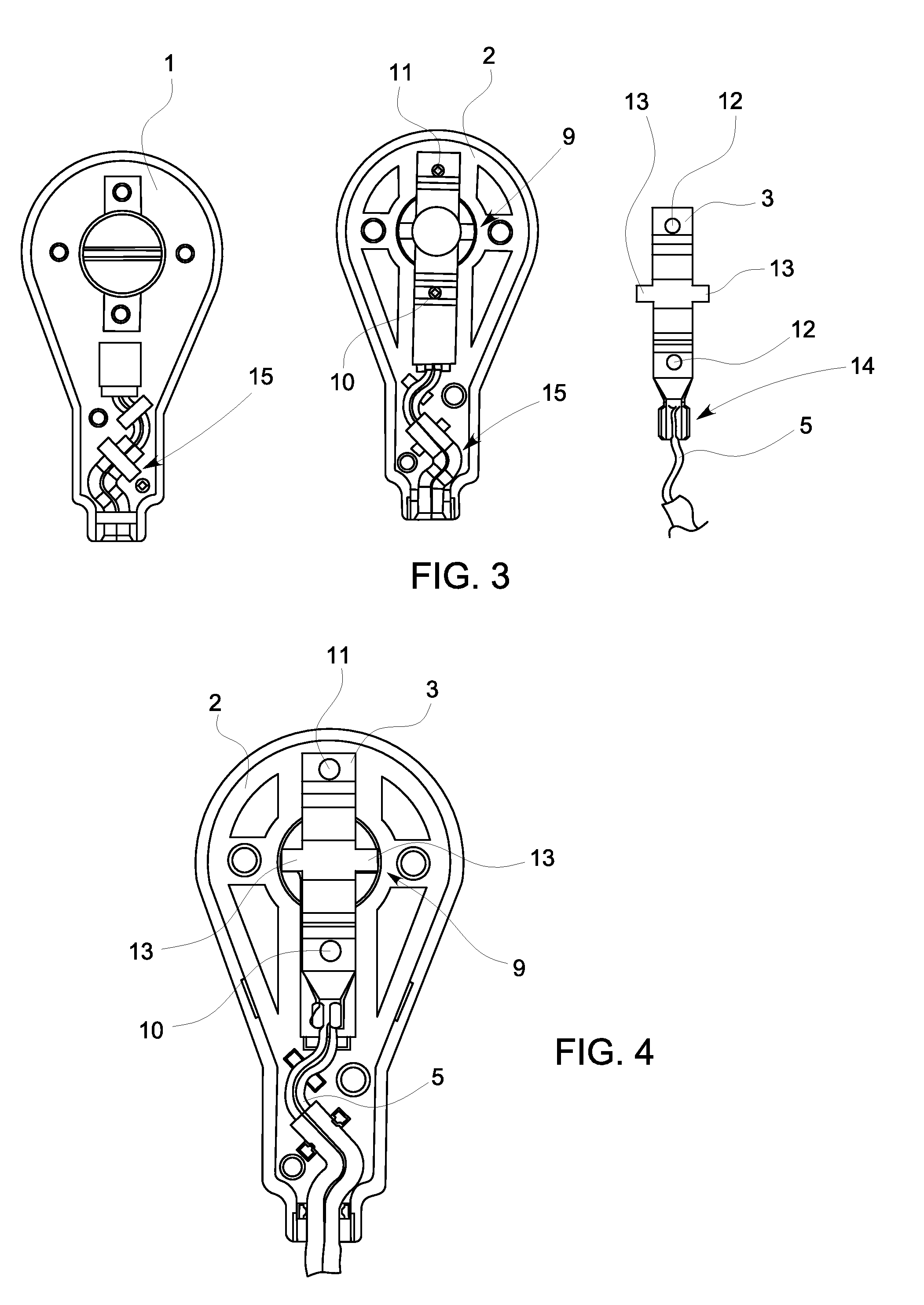

Electronic device test set and contact used therein

ActiveUS20070236236A1Semiconductor/solid-state device testing/measurementElectrical measurement instrument detailsEquipment under testClassical mechanics

A contact for use in a test set which can be mounted to a load board of a tester apparatus. The contact, which serves to electrically connect at least one lead of a device being tested with a corresponding metallic trace on the load board, has a first end defining multiple contact points. As the contact is rotated about an axis generally perpendicular to a plane defined by the contact, successive contact points are sequentially engaged by a lead of the device being tested.

Owner:JOHNSTECH INT

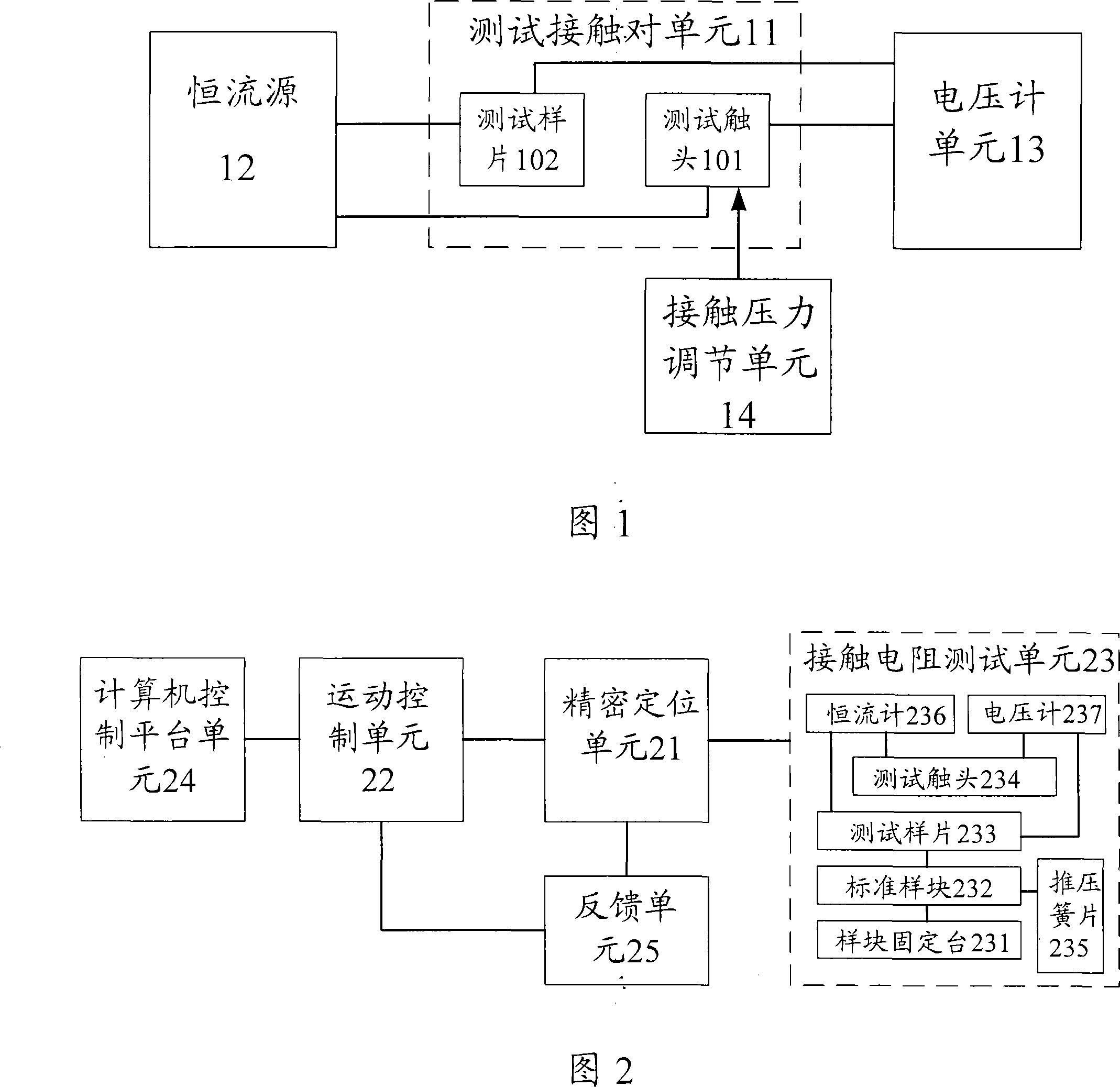

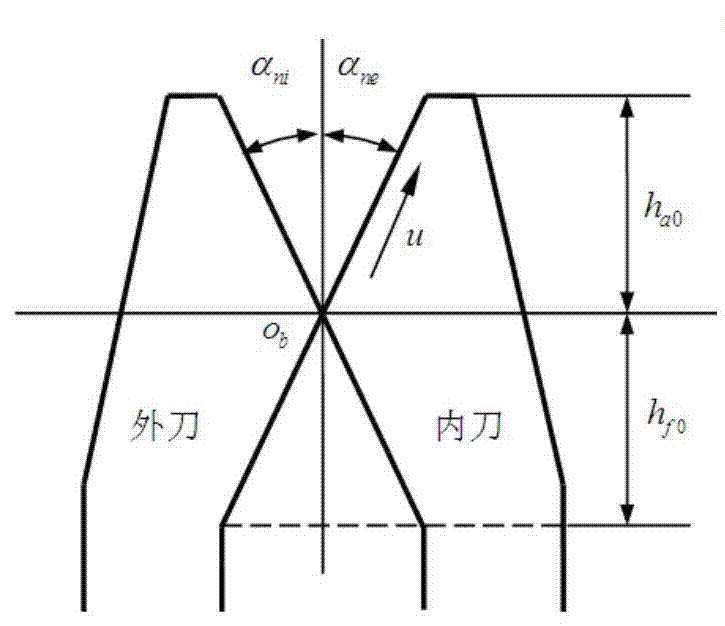

Method and device for precision positioning and testing contact resistance

InactiveCN101236221ARealize automatic collectionWith automatic collectionResistance/reactance/impedenceContact pressureTest sample

The invention discloses a precision positioning contact resistance testing method and a device. The device comprises a precision positioning unit, a motion control unit, a contact resistance test unit, a computer control platform unit and a feedback unit. The parameter of the plane distance between the surface intersection point of a standard sample block and the contact spot of a test sample wafer is determined in advance, the computer control platform sends a positioning command, the motion control unit receives and feeds back the positioning command and converts the command into a control voltage command output to control the precision positioning unit, and the feedback unit feeds back the distance information of the precision positioning unit to the motion control unit; then the computer control platform unit sends a contact pressure command and a test command, and the contact resistance test unit begins the contact resistance test, thereby realizing the precision positioning and repositioning of the contact spot in a contact area and also realizing automatic continuous test of the contact resistance under the multipoint and multi-contact-pressure condition.

Owner:BEIJING UNIV OF POSTS & TELECOMM

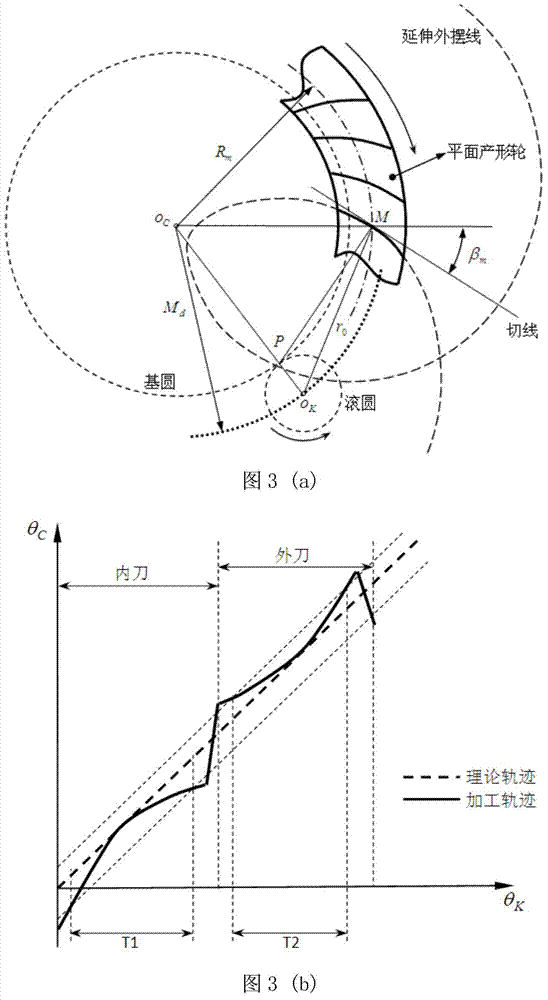

Machining method of cycloidal-tooth bevel gear

The invention discloses a machining method of a cycloidal-tooth bevel gear. The machining method comprises the following steps: (1) determining basic parameters of a generating wheel; (2) determining the movement for forming a tooth surface of the generating wheel; (3) determining the movement for expanding the generating wheel into the gear; (4) correcting the movement for expanding the generating wheel into the gear; and (5) finishing expansion of the machined gear. Compared with the Klingelnberg method, the machining method disclosed by the invention has the advantages that the structure of a tool disc is greatly simplified, a cross-shaped sliding block mechanism is not needed and the rigidity is improved; compared with the Oerlikon method, the machining method disclosed by the invention has the advantages that a tool inclining mechanism is not needed, so that the structure of a machine tool is greatly simplified and the rigidity is improved; the cycloidal-tooth bevel gear and a quasi-hyperbolic gear are processed on a bevel gear milling machine without a tool inclining and swinging disc; the correction of the tooth surface does not cause additional adjustment of the machine tool and the tool; second-order precontrol of the position, the size and the shape of contact spots of the tooth surface can be realized; second-order precontrol of required transfer errors can be realized; and a cycloidal-teeth bevel gear pair conjugate completely on theory also can be machined.

Owner:TIANJIN TEEK TRANSMISSION

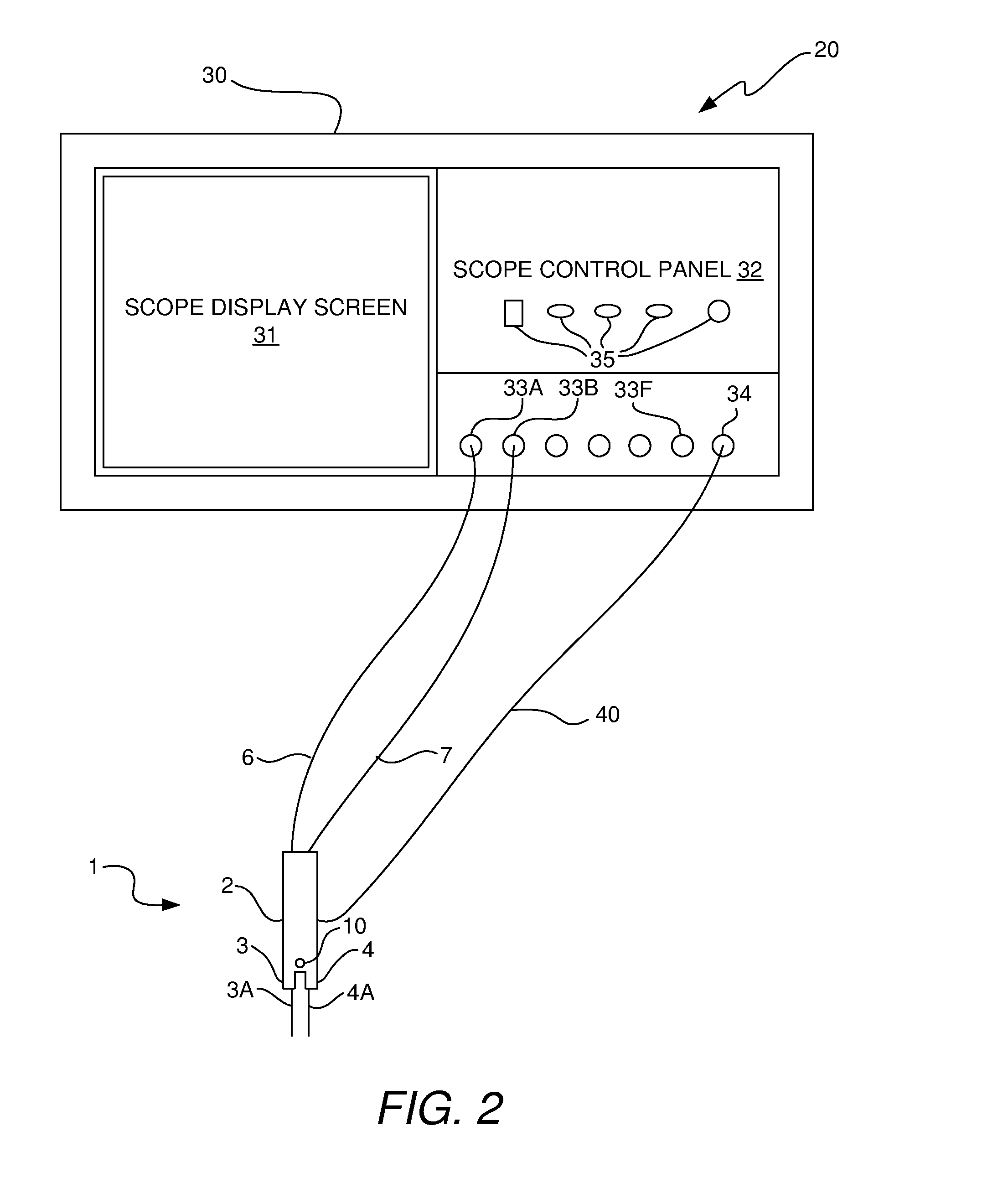

Probe device having a light source thereon

InactiveUS20090206859A1Electrical measurement instrument detailsElectrical testingDevice tipContact pad

A probe device is provided that has light source thereon that can be activated and deactivated. In accordance with an embodiment, the light source operates as a visual indicator to provide a visual indication of whether a good connection exists between the tips of the probe device and the intended contact points on the DUT. In accordance with another embodiment, the light source operates as a source of illumination to illuminate the probe tips and the contact pads on the DUT as the user is attempting to place the probe tips in contact with the contact pads on the DUT. In accordance with yet another embodiment, the light source performs the dual functions of providing a visual indication of connection status and of illuminating the probe device tips and the intended contact points on the DUT.

Owner:AGILENT TECH INC

Oil field pipeline leakage detection device in oil exploitation

InactiveCN108548095ATo achieve the alarm effectPrevent leakagePipeline systemsSurface mountingOil field

The invention discloses an oil field pipeline leakage detection device in oil exploitation. The oil field pipeline leakage detection device comprises conveying pipes, sealing shields, an exhaust pipe,fixed blocks and a movable block; one end of each conveying pipe is provided with the corresponding flange through welding; the outer wall of each conveying pipe is sleeved with the corresponding sealing shield; the outer wall of the opening of each sealing shield is provided with the corresponding fixed blocks through welding; the exhaust pipe is inserted in the upper surface of the sealing shield; the movable block is movably arranged in the exhaust pipe; the upper surface of the movable block is in elastic connection with the upper end inner wall of the exhaust pipe through a spring; the lower surface of the movable block is fixedly provided with a rubber block and contact spots; the lower end inner wall of the exhaust pipe is fixedly provided with a limiting block; a buzzer is arranged on the surface of one side of the sealing shield; and an indication lamp is arranged on the surface of the other side of the sealing shield. According to the oil field pipeline leakage detection device, the sealing shields are arranged at the connection parts of the conveying pipes, so that oil leakage is detected; besides, the buzzer gives alarms to remind working personnel to adopt effective measures in time; and therefore the phenomenon that a large amount of oil is leaked is avoided.

Owner:邢建

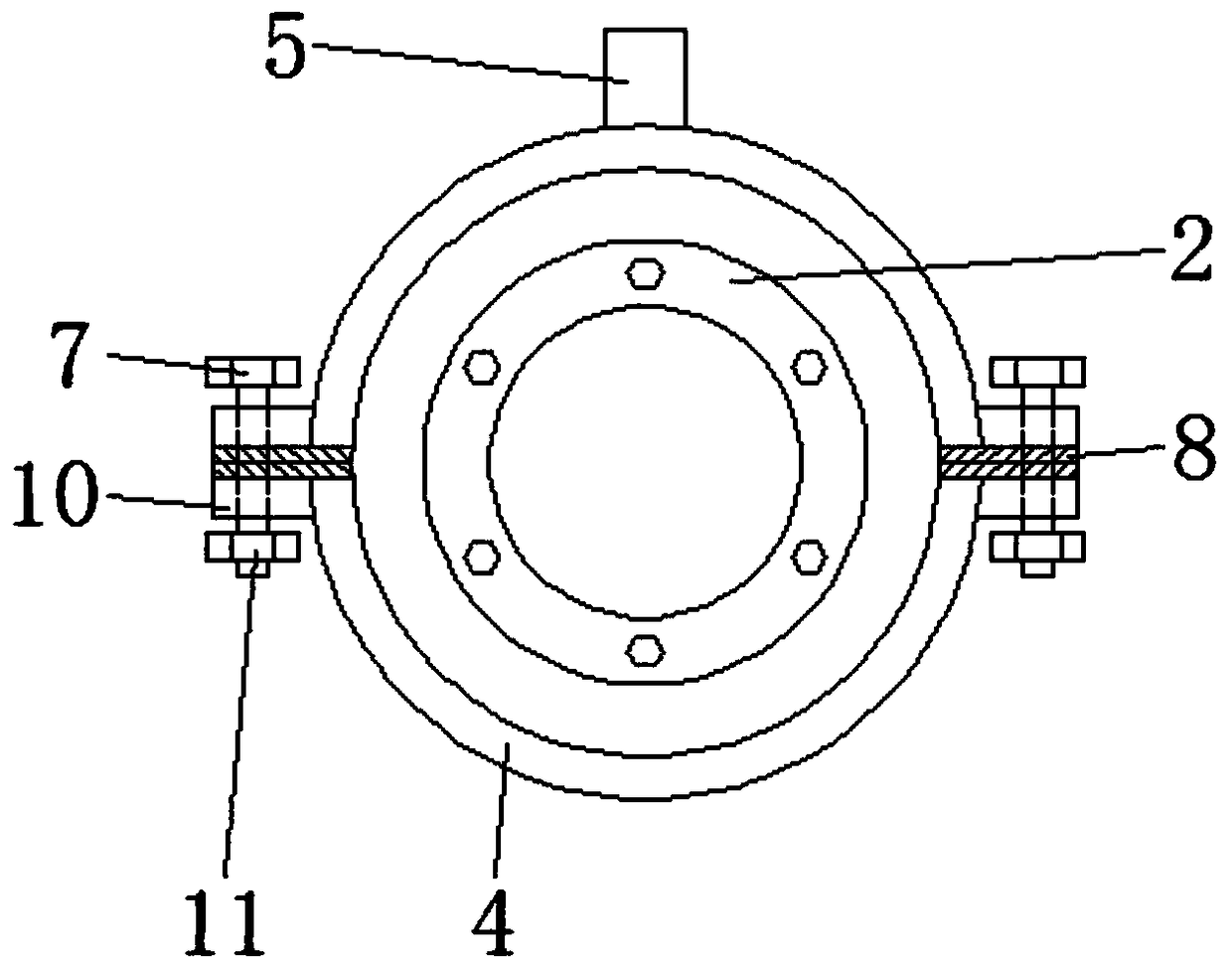

Regulating device and method for clearance and contact spot of thrust bearing

ActiveCN107717405ASolve the problem that the heavy weight cannot be pushed by manpowerControllable axial forceMechanical clearance measurementsMetal working apparatusDrive shaftThrust bearing

The invention discloses a regulating device and method for the clearance and the contact spot of a thrust bearing. The regulating device comprises a thrust collar, an ahead thrust device, an astern thrust device, a driving device and a measuring device, wherein the thrust collar is arranged inside the thrust bearing; colorant layers are arranged on the front surface and the back surface of the thrust collar; the ahead thrust device is arranged on a first surface in the thrust bearing; the astern thrust device is arranged on a second surface in the thrust bearing; the driving device is used fordriving a transmission shaft to move axially; when the transmission shaft moves forwards, the ahead thrust device is pressed on the front surface of the thrust collar, and when the transmission shaftmoves backwards, the astern thrust device is pressed on the back surface of the thrust collar; and the measuring device is capable of measuring the axial clearance value of the thrust bearing. The axial clearance check and the contact spot check are realized by one device, so that the efficiency is improved, and through grinding, the size of an adjusting pad can be successfully adjusted, so thatthe accuracy is improved.

Owner:CHONGQING GEARBOX

Touch control input device, touch positioning device and its method

InactiveCN101149659ASave resourcesPrecise positioningInput/output processes for data processingElectrical resistance and conductanceCarbon film

This invention discloses a touch-control input device, as well as the touching positioning device which uses the touch-control input device and its allocation method. This invention includes the first printed circuit level and the second printed circuit level: the first, second printed circuit level includes an insulation material base separately, in one side of this base, has many mutually parallel wires printed horizontally or vertically, many carbon film contact points lay down along each wire in order, then to form the carbon film contact point matrix; a resistance is separately between each neighboring wire bridge in bridge, forms the resistance network with a series connection; to fold opposite direction fixedly the first printing with the second printed circuit level which has wire, the corresponding carbon film contact point does not contact when does not have the pressure, and contacts when meets the pressure, to cause the corresponding horizontal wire and the vertical wire with connection. This localization of this invention is accurate, so saves the port, and the cost is low.

Owner:SUNPLUS TECH CO LTD +1

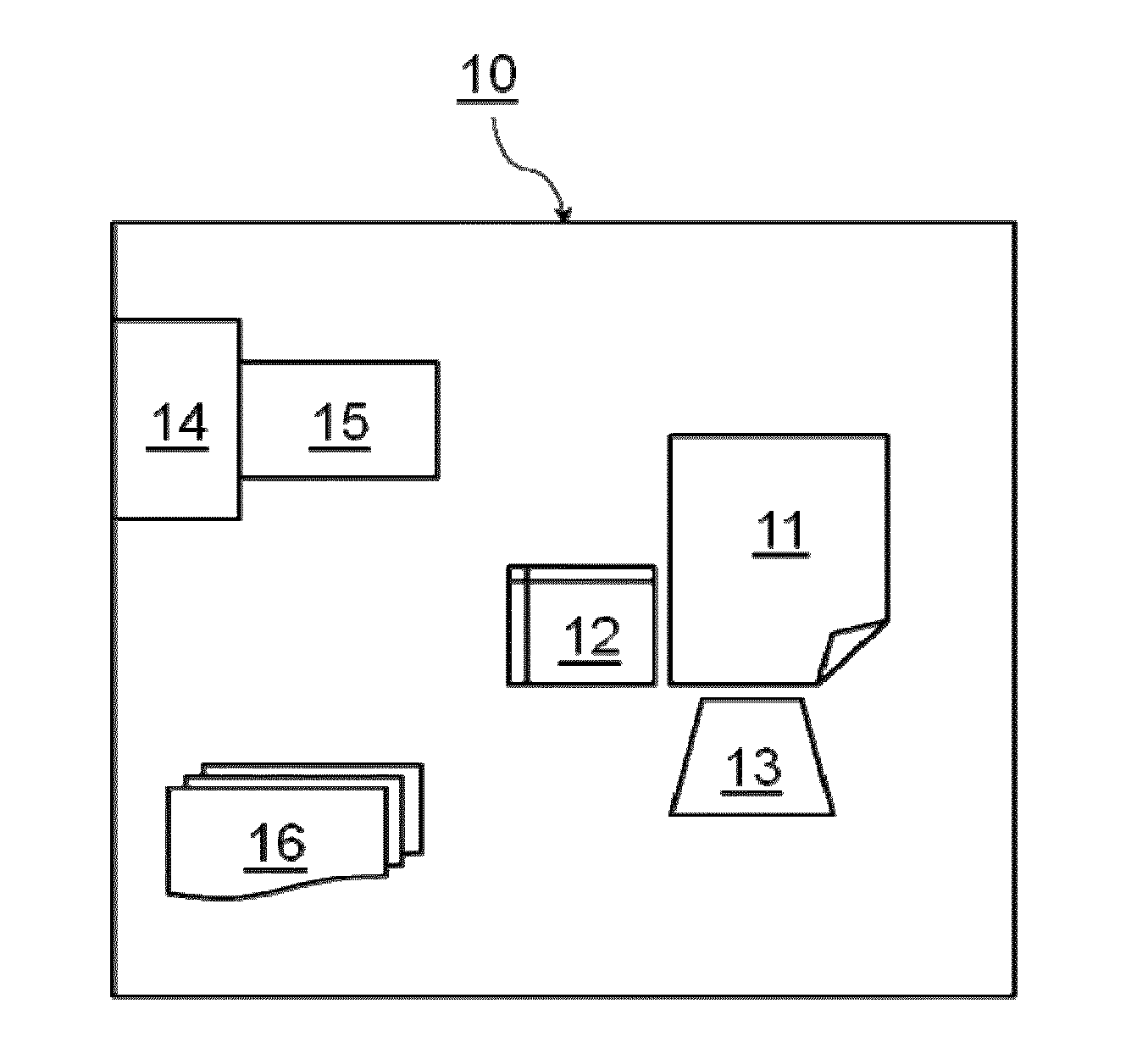

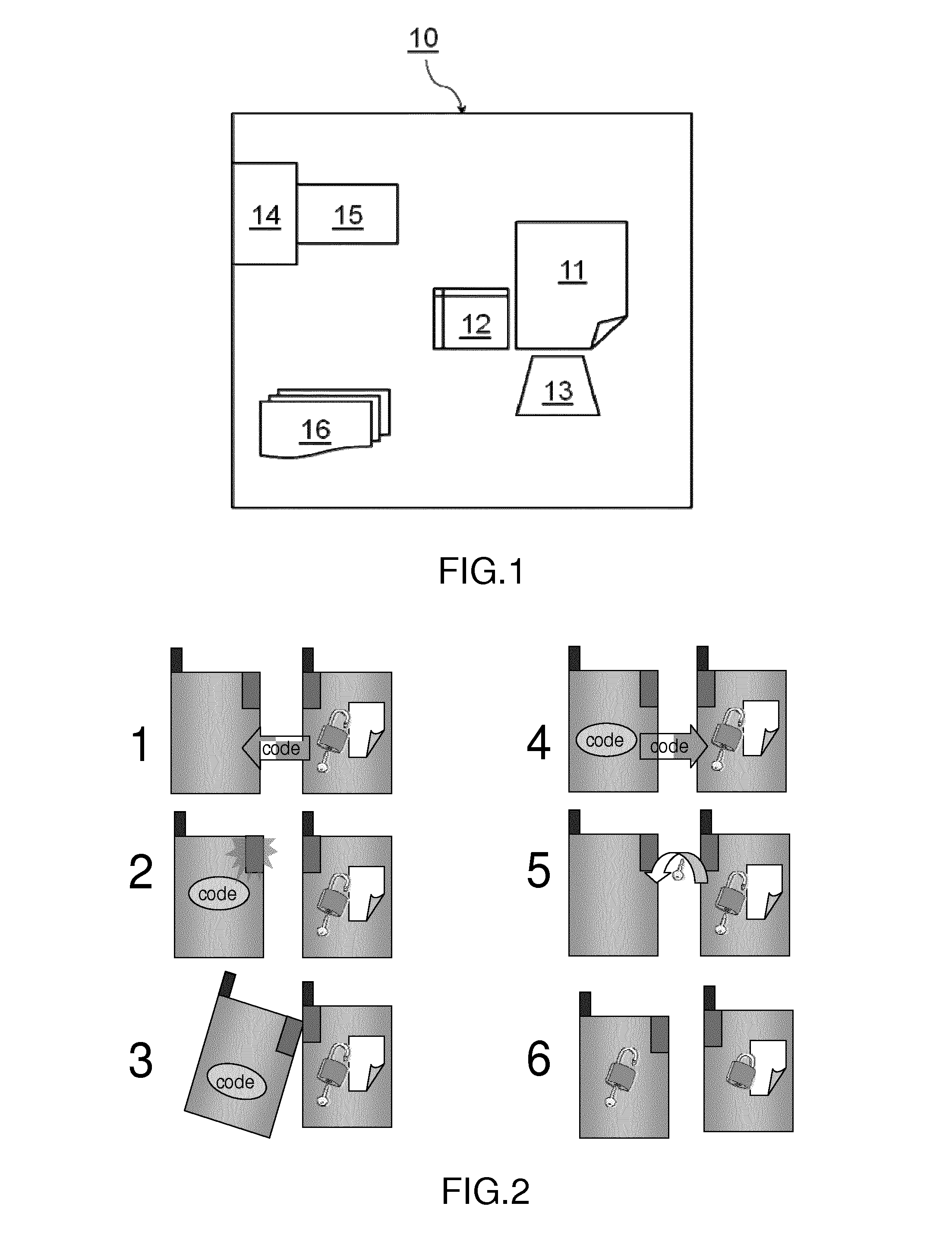

Method and system for digital contents lending

InactiveUS20140325676A1Well formedDigital data processing detailsAnalogue secracy/subscription systemsComputer hardwareCommunication unit

A method for transferring a digital right management-protected digital content from a first device (10) to a second device, said first and second devices respectively comprising a contact point (14), a contact communication unit (15) and a standard communication functionality (16), said digital content being protected by a digital right management module (12) and the digital right management license (13), said method comprising the following steps:—sending a code from the first device to the second device;—activating the contact point (1) and the contact communication unit (15) of the first device;—if there is a physical contact between the contact point (14) of the first device and the contact point of the second device within a predefined period of time, then sending the code from the second device to the first device for verification;—checking, by the first device, of the code received from the second device;—if the code received by the first device is correct, transmitting the digital right management license (13) of the first device to the second device and deactivating the digital right management license (13) of the first device.

Owner:ALCATEL LUCENT SAS

High-uniformity ink-jet printing method of large-area films and printing system

ActiveCN107379804A"Coffee ring" effect inhibitionAids in shape controlDuplicating/marking methodsCoffee ring effectEngineering

The invention relates to a high-uniformity ink-jet printing method of large-area films. The method comprises the following steps: firstly washing and drying a substrate by putting the substrate in a washing solution, washing the substrate by using ultrasonic oscillation and drying the substrate after washing; secondly printing films by setting printing parameters and graphs, printing on the washed and dried substrate by using a non-contact spot-jetting printing system, heating the lower part of the substrate during printing, wherein printing ink adopts low-temperature gelatinization ink; and finally drying the films by continuously heating the lower part of the substrate and drying the films. Compared with the prior art, the problem of low uniformity during ink-jet printing of the large-area films is solved; a method of heating and printing the substrate is adopted on the basis of considering the coffee-ring effect of single liquid droplet; the printing liquid droplets are used for simultaneously printing and forming gelatinization edge areas; the flowing of a large amount of fluid between liquid droplets is avoided, so that the overall uniformity of printing of the films is achieved.

Owner:SOUTH CHINA UNIV OF TECH

Gear modification method

The invention provides a gear modification method. The gear modification method comprises the steps of material selection, rough machining, heat treatment normalizing treatment, semifinishing, gear hobbing, heat treatment carburizing and quenching, grinding machining, gear-grinding machining and the like. Modification is conducted through the gear modification method, the contact spot position is effectively controlled, bearing capacity is greatly improved, negative factors brought by external reasons are overcome, the service life of a gear is prolonged, and transmission performance is achieved.

Owner:常州市格里森前进齿轮有限公司

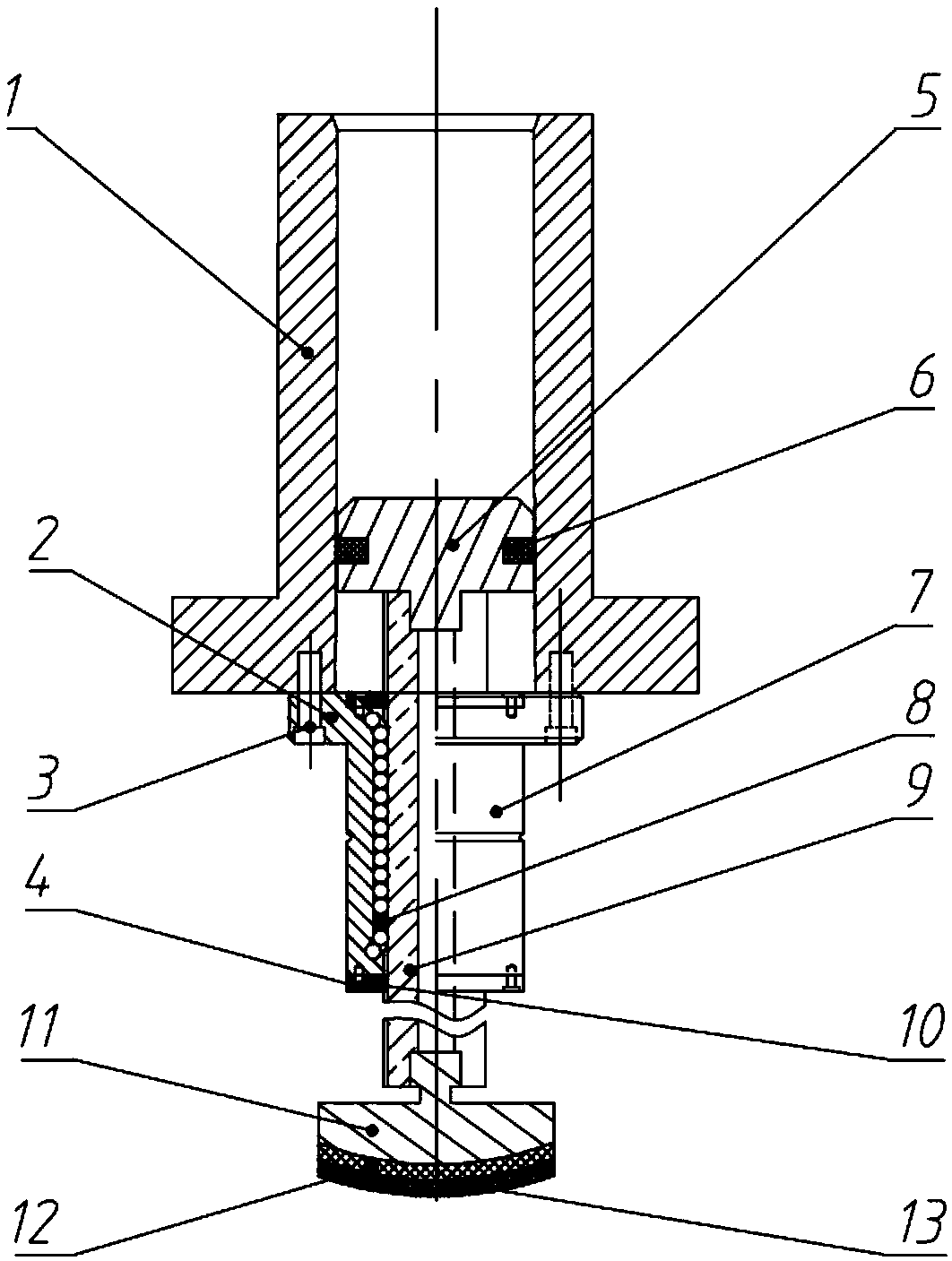

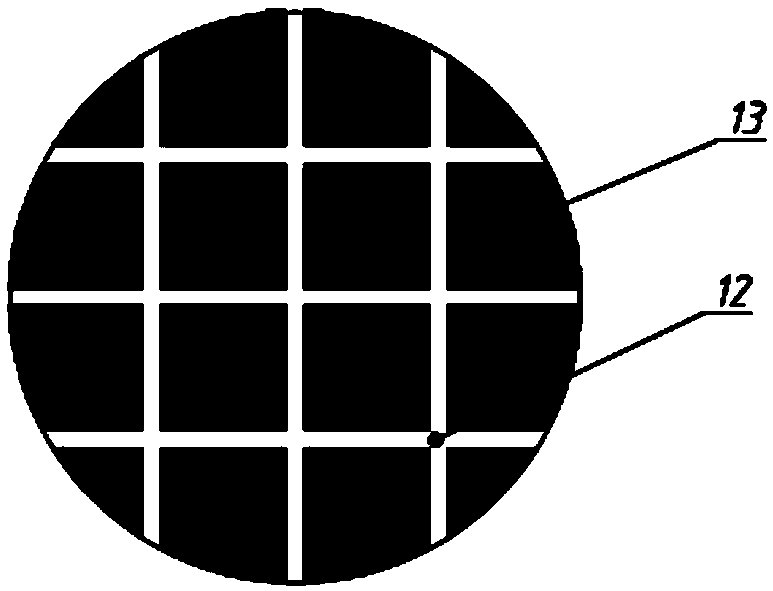

Pneumatic control constant pressure self-adaptive polishing grinding head

InactiveCN109202709AConstant pressureConstant modulus of elasticityGrinding machine componentsOptical surface grinding machinesAir springFree form

The invention relates to a pneumatic control pressure constant pressure self-adaptive polishing grinding head, comprising a spindle sleeve, a connecting flange, a fastening screw, a set screw, a piston, a sealing ring, a linear bearing, a roller, a tool spindle, a limiting flange, a grinding disc base, a flexible layer and a polishing layer; the piston and the tool spindle are coaxially and closely matched to realize sliding connection for ensuring airtightness; the air pressure enters the cylinder through the spindle sleeve to form an air spring to push the tool spindle, and the elastic coefficient of the air spring can be changed through adjusting the air pressure in the cylinder; the tool spindle is restricted in rotation and capable of freely sliding in an axial direction to compensatethe axial runout of the grinding head, and the polishing pressure is constant; the flexible layer and the polishing layer are arranged in sequence below the grinding disc base, and pressure distribution on the contact spot of the grinding head and a workpiece is uniform. The pneumatic control pressure constant pressure self-adaptive polishing grinding head has the characteristics of simple structure, constant and controllable pressure, and tight attachment to a surface to be machined, and is suitable for high-precision polishing of surfaces such as aspherical surfaces and free-form surfaces.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Electrical connector assembly

Electrical connector assembly comprising a cover part and a contact assembly for providing a mechanical and electrical contact to an electrode, and connecting arrangements for connecting lead wire to the contact component. The contact component is made of an elongated flat-formed strip forming at least two contact points for the electrode and between the contact points forming a recess having walls enlarging when drawing away from the contact points. The contact points are arranged to press against the electrode for detachable fastening.

Owner:GENERAL ELECTRIC CO

Machining method for epicycloid gear

ActiveCN103934513AHigh precisionSimple structureGear teeth manufacturing toolsGear teethGear wheelGear tooth

The invention discloses a machining method for an epicycloid gear. The machining method comprises the steps that (1) basic parameters of a generating gear are determined; (2) the motion mode forming the tooth surface of the generating gear is determined; (3) generating gear tooth surface shape correction is determined; (4) a tool path for forming the tooth surface of the generating gear is planned; (5) the motion through which the generating gear generates the gear is determined; (6) generation of the machined gear is completed. The machining method for the epicycloid gear has the advantages that compared with the Klingelnberg method, the structure of a cutterhead is greatly simplified, no crosshead shoe mechanisms are needed, and rigidity is improved; compared with the Oerlikon method, no knife tilt mechanisms are needed, the structure of a machine tool is greatly simplified, and rigidity is improved; an epicycloid gear and a hypoid gear can be machined on a knife-tilt-free rolled plate type bevel gear milling machine; tooth surface correction is achieved through software; second order precontrol over the positions, sizes and shapes of tooth surface contact spots can be achieved; required second order precontrol over transmission errors can be achieved; an epicycloid gear pair which is completely conjugated in theory can be machined.

Owner:TIANJIN TEEK TRANSMISSION

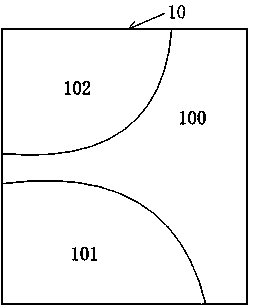

System and method for mapping blocked area

A system and method for mapping an occluded area. The invention solves the problem of finger occlusion of content displayed on a touch screen or of content depicted on a touch pad, as well as occlusion of the point at which the finger contacts the touch screen, when a user is manipulating a touch pad, touch screen, or other such device. The invention also solves the problem of some system-level virtual buttons occluding content of a window under said buttons. The invention mainly makes use of such means as creating mapping areas and mapping the contact point of a finger. Through the use of mapping areas to dynamically map and display content in an area covered by a finger or by a virtual button, the invention solves the occlusion problem currently present in the art.

Owner:顾红波

Method and apparatus for combining contact information, and terminal

InactiveCN104169861AReduce participationEasy to operateSubstation equipmentInput/output processes for data processingOutput deviceComputer science

The embodiment of the invention relates to the communication field, and provides a method and apparatus for combining contact information, and a terminal. The method comprises the steps of obtaining at least two contact coordinates, of detected gesture operation, in a display interface of a contact list when the detected operation in the display interface of the contact list is preset gesture operation; obtaining information about at least two contacts corresponding to the at least two contact coordinates in the contact list on the basis of the at least two contact coordinates; and combining the information about the at least two contacts into one piece of contact information. The apparatus comprises a first obtaining module, a second obtaining module and a combining module. The terminal includes an input device, an output device, a memory and a processor. The contact information can be combined as long as the gesture operation detected in the contact list is the preset gesture operation, so that the number of users for participation is reduced, and the efficiency for combination of contact information is improved.

Owner:HUAWEI TECH CO LTD

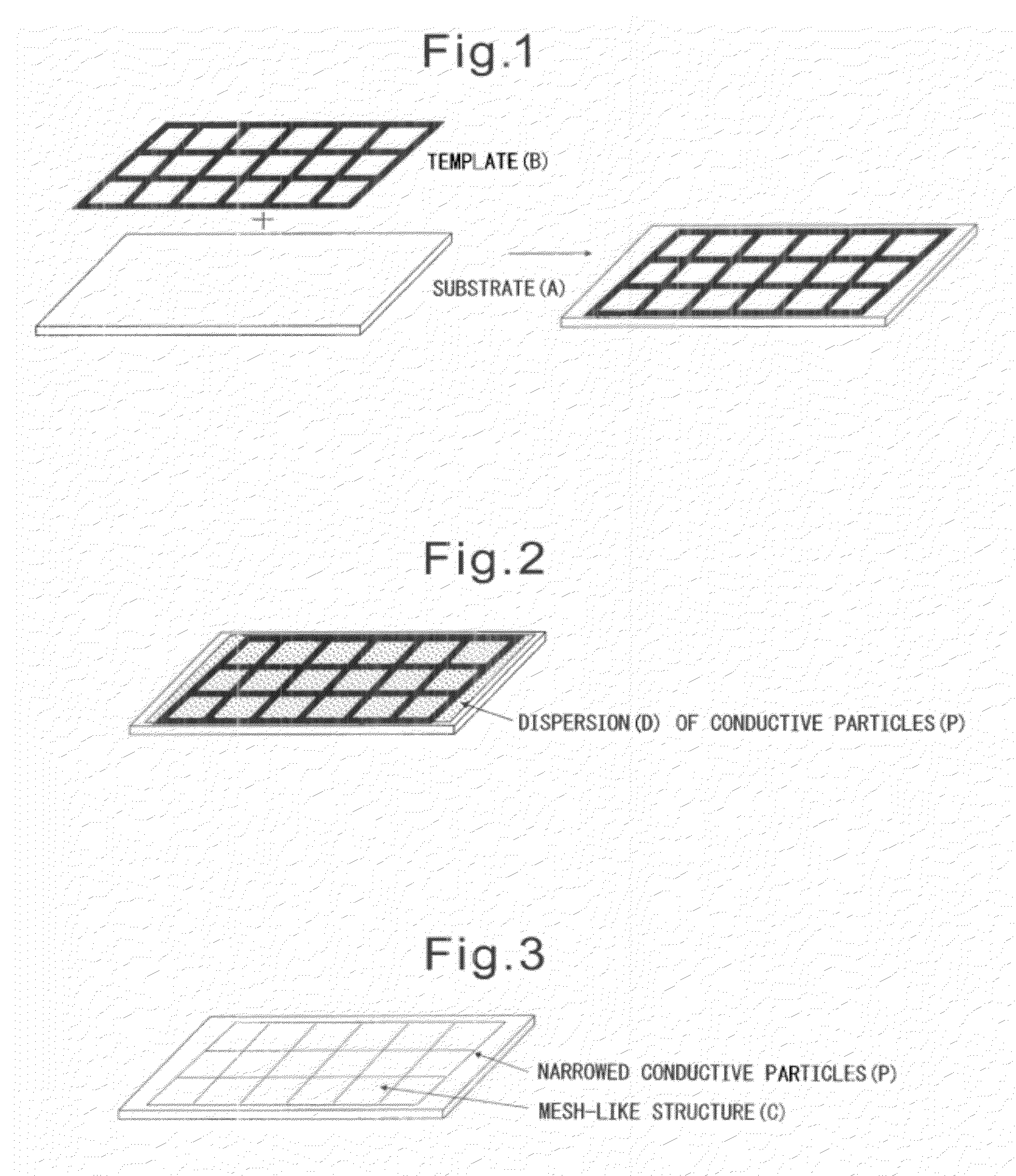

Conductive film and method for its production

InactiveUS20120325545A1Improve conductivityHigh transparencyConductive layers on insulating-supportsElectrolytic coatingsContact spotContact plane

To provide a method for producing a conductive film with excellent transparency and conductivity by a simple method suitable for large-area production.A method for producing a conductive film comprising a step of placing a template (B), having openings in a mesh structure running from the side that is to contact a substrate (A) through to the back side, on the surface of the substrate (A), and spreading a dispersion (D) of conductive particles (P) on the surface of the substrate (A) on which the template (B) has been placed, and drying it, thereby forming a mesh-like structure (C) of the conductive particles (P) near the points of contact between the substrate (A) and the template (B), and then removing the template (B) from the substrate (A) to form a mesh-like structure (C) of the conductive particles (P) on the surface of the substrate (A).

Owner:KYOTO UNIV +2

Plastic Embossed Carrier Tape Apparatus and Process

ActiveUS20090133367A1Precise positioningEliminate errorsCapsDecorative coversHeat shieldContact spot

An embossed carrier tape manufacturing apparatus includes features for integrating with other processing equipment so that other processes such as forming, filling, and sealing the tape can be performed sequentially in one integrated process. The apparatus includes retractable contact spot heaters for heating the tape prior to embossing, along with a unique heat shield arrangement that is interposable between the heaters and the tape so that the process may be paused. Also, a synchronizing apparatus is integrated so that the carrier tape embossing process may be automatically paused for adjusting to the input rate of other carrier tape processing apparatus.

Owner:ADAPTSYS

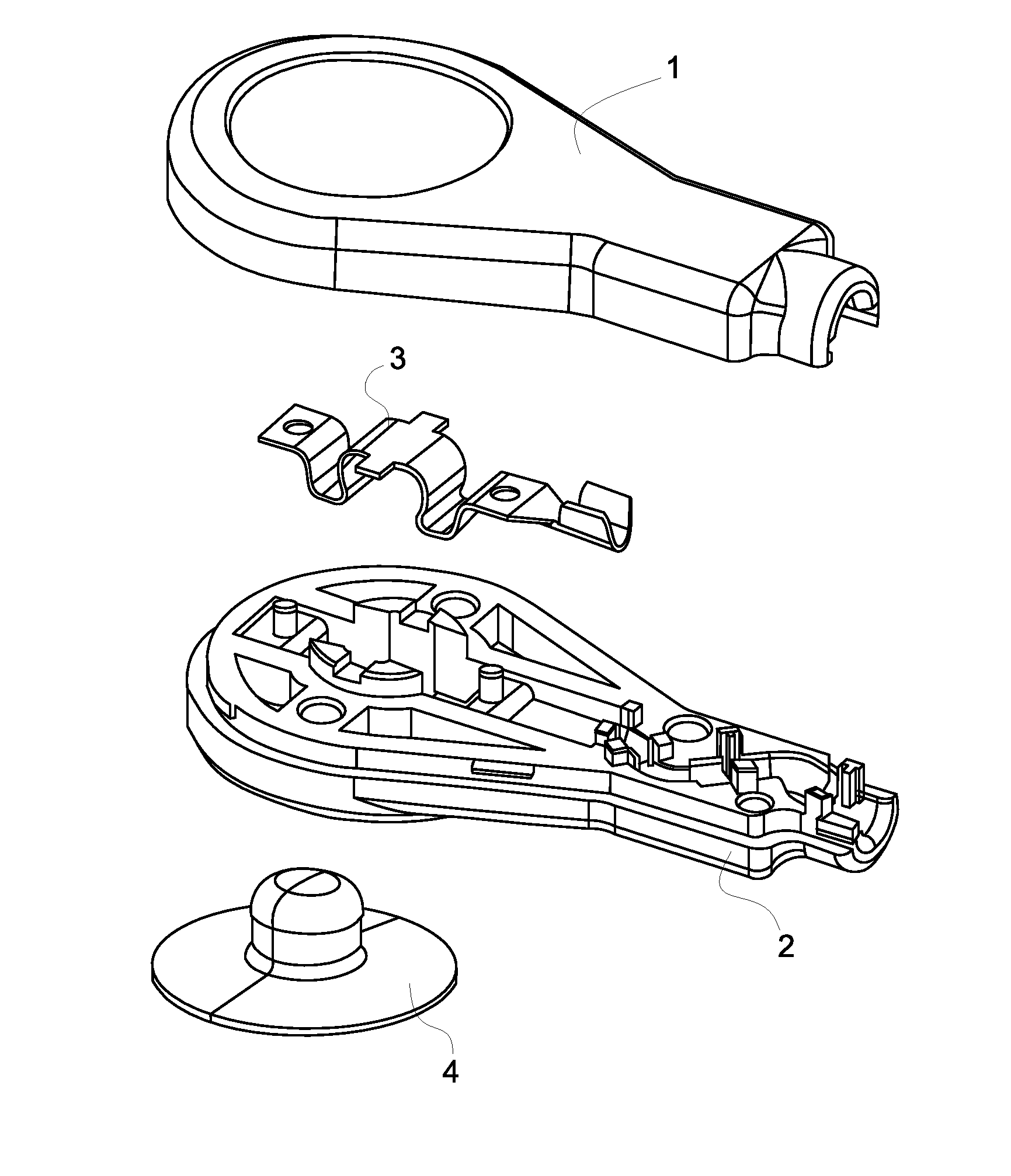

Mounting system for sealing and aligning the burner of the lamp at the centre of its base

InactiveUS20150028736A1Easy to insertAvoid possible electrical short circuits in the baseElectric discharge tubesDischarge tube main electrodesEngineeringLight head

A lamp having a longitudinal axis, comprising of a burner pinched at one end and a cement less base holding the contact points protruding from the burner. At least one end of the burner is sealed and aligned at the centre of the base in an upright direction following the lamp axis by means of a spring clip, which is mounted from the side of the pinch of the burner and does not interfere with the lead wires.

Owner:FLOWIL INT LIGHTING HLDG BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com