Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

693results about How to "Effective lubrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

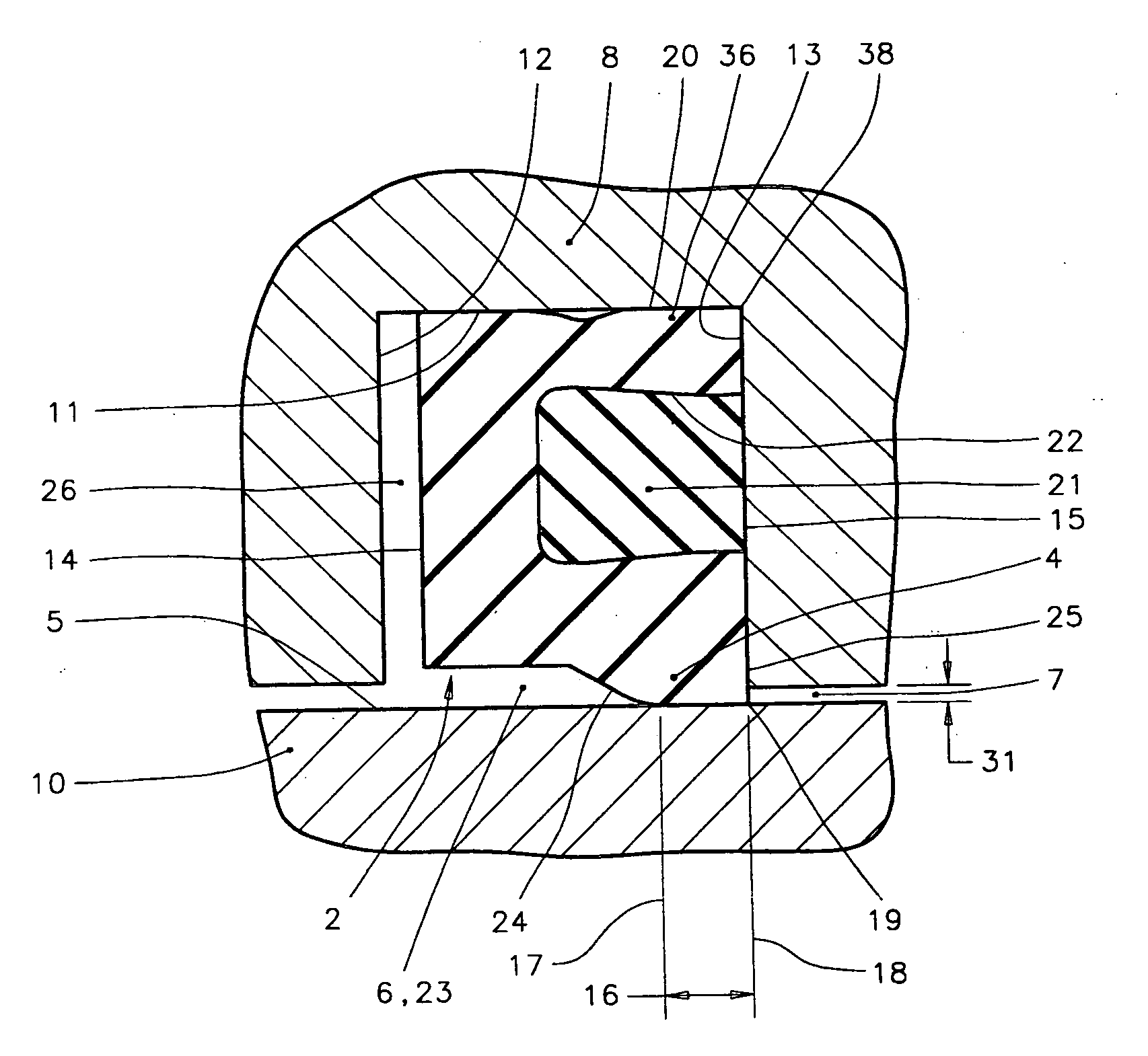

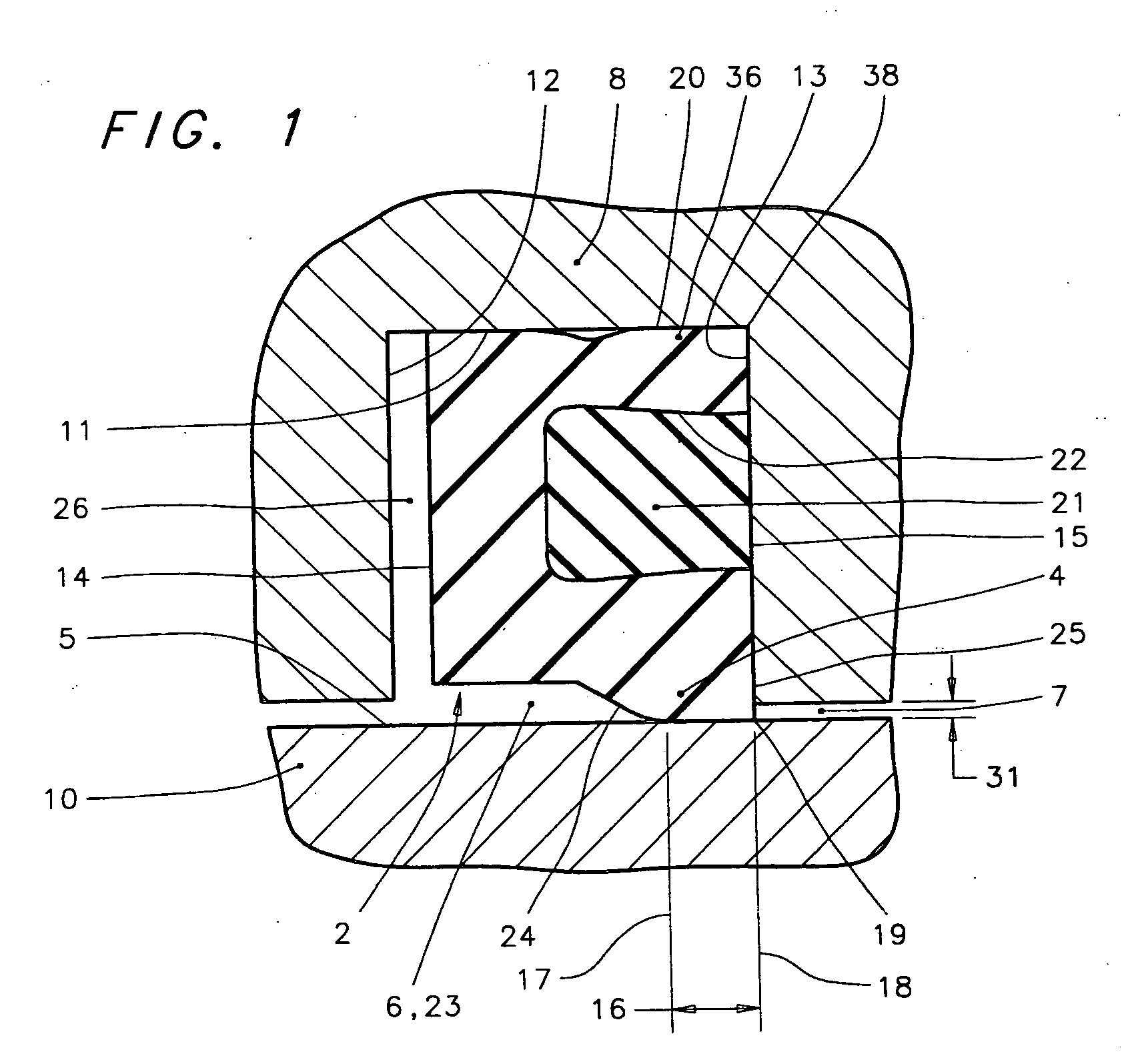

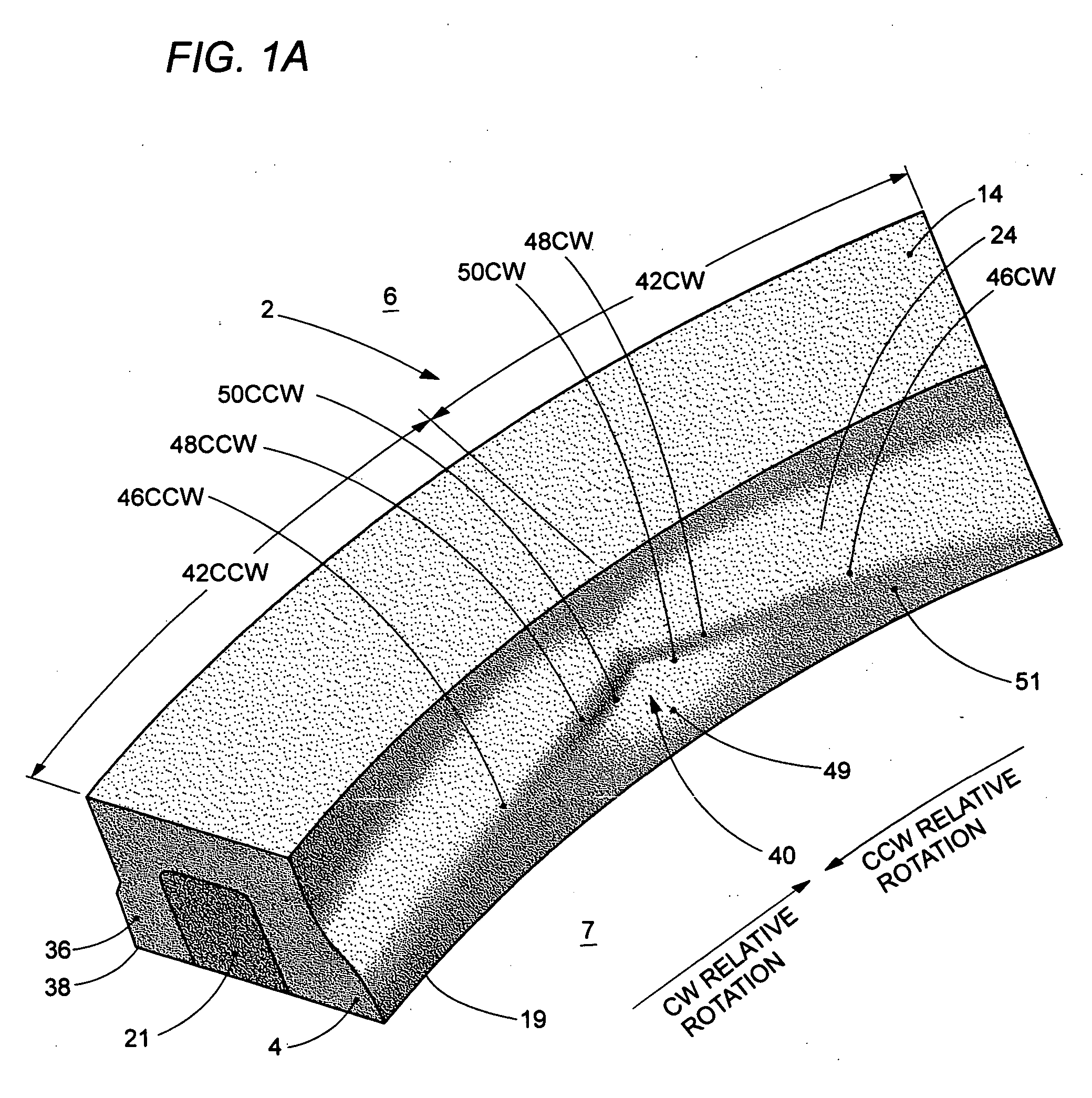

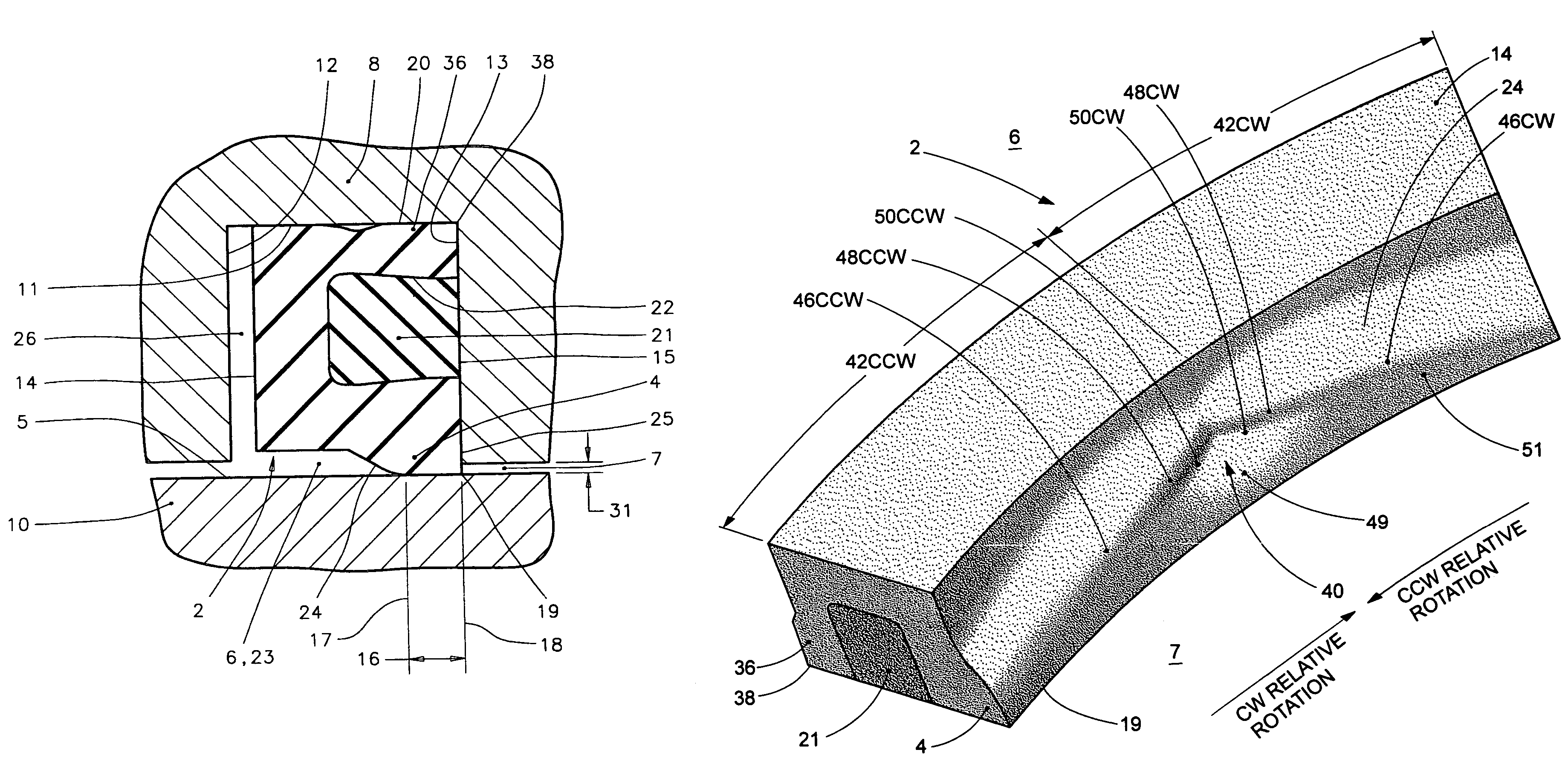

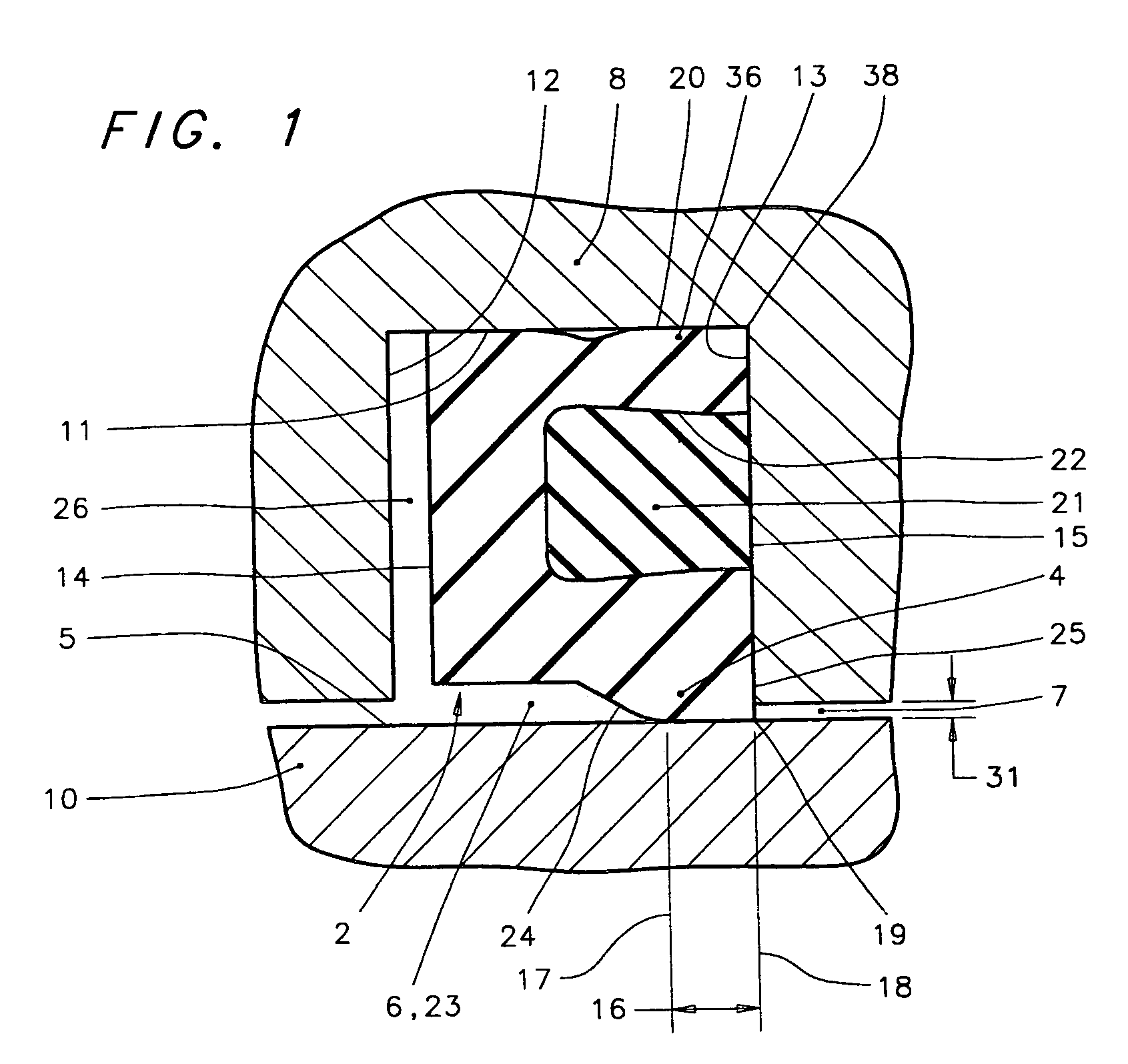

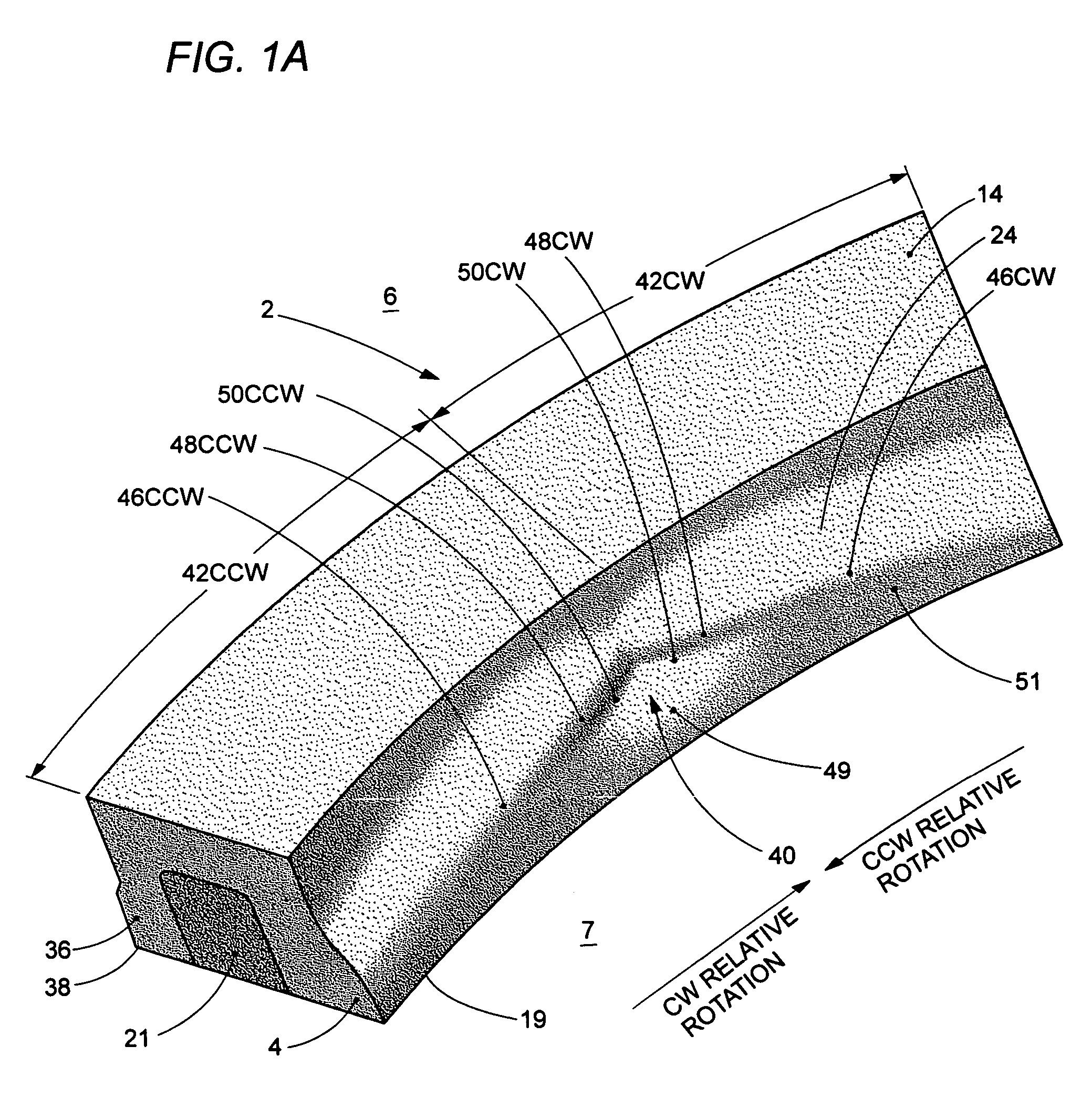

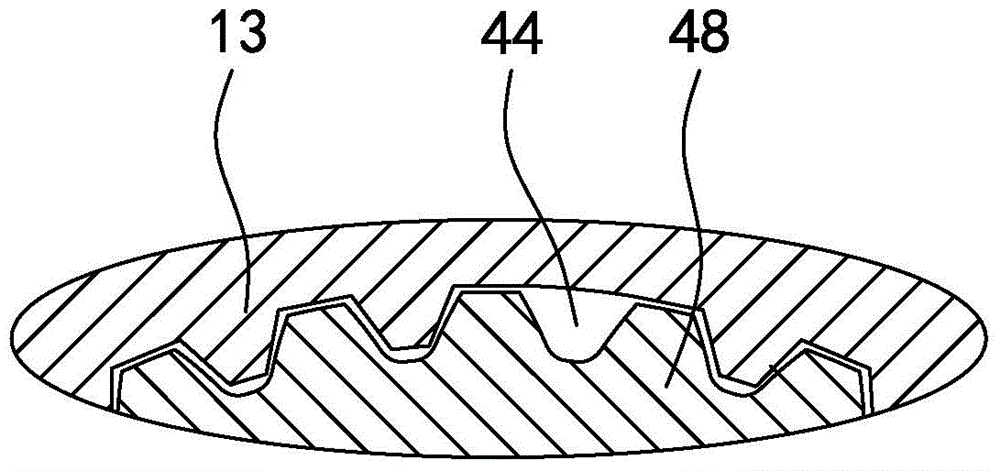

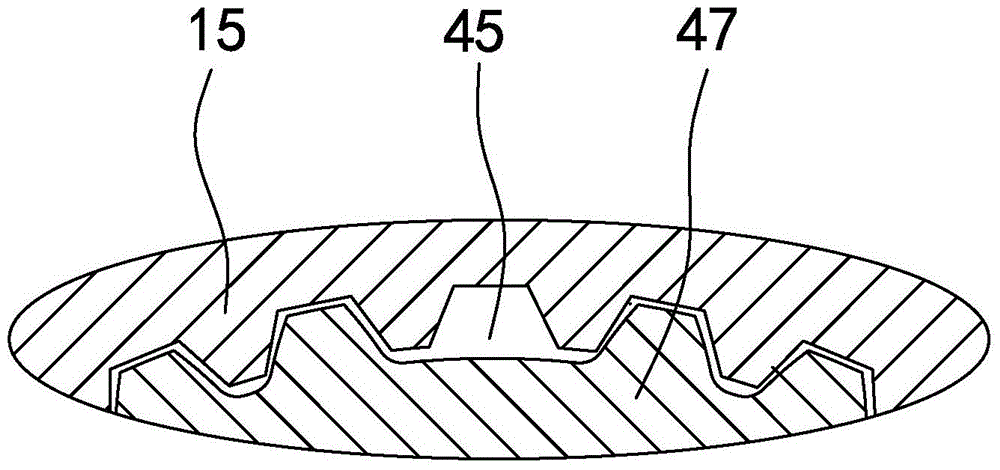

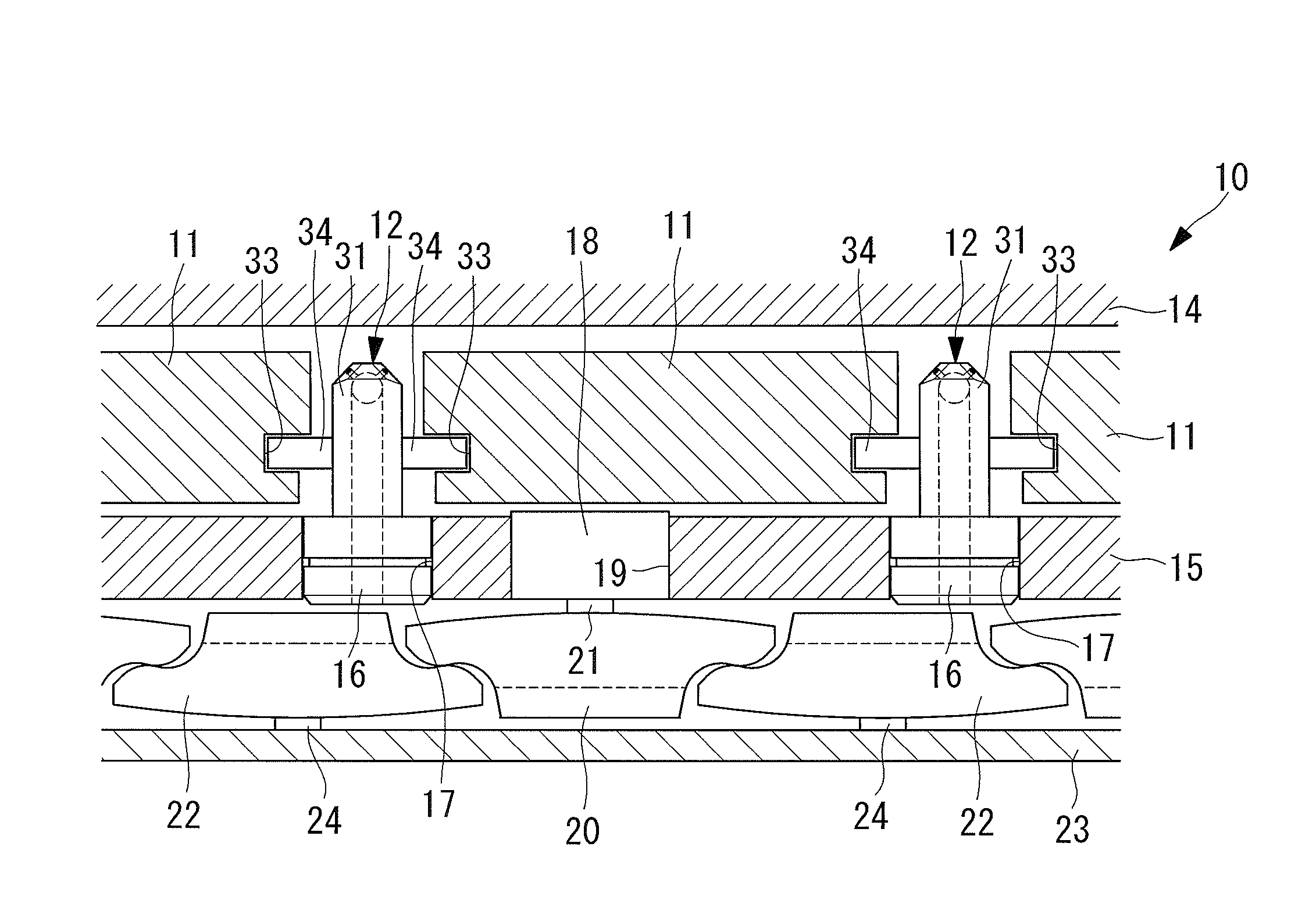

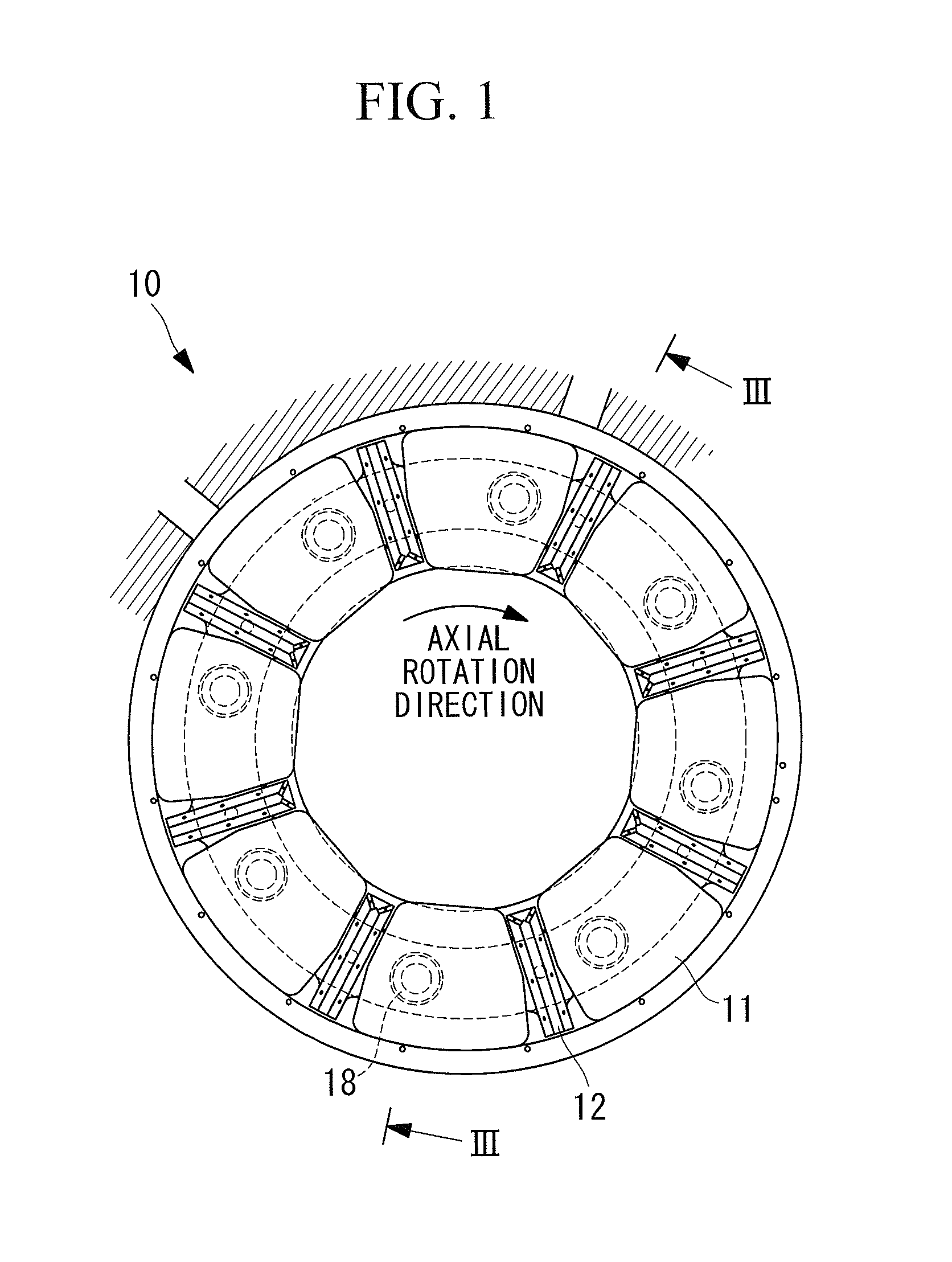

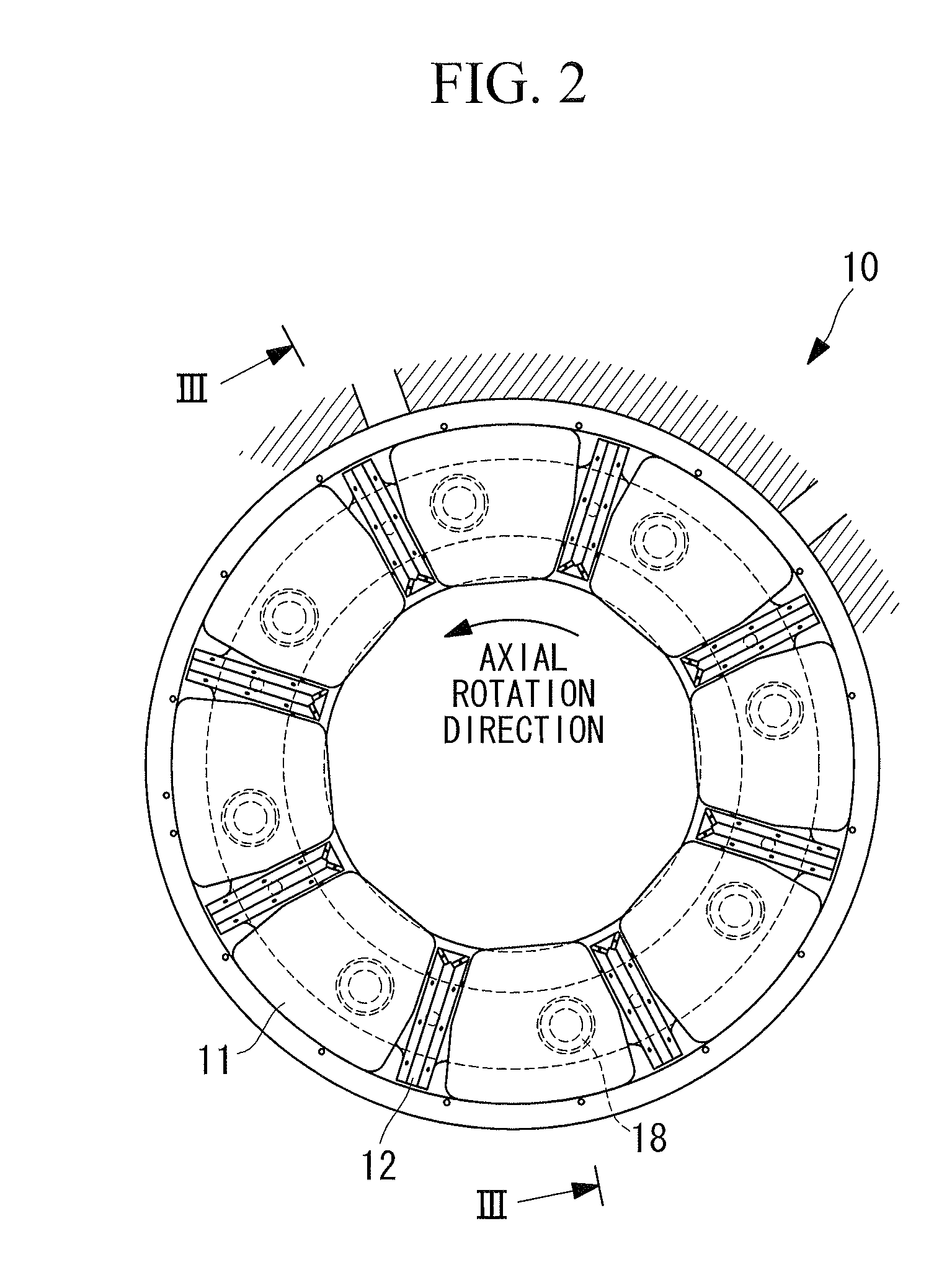

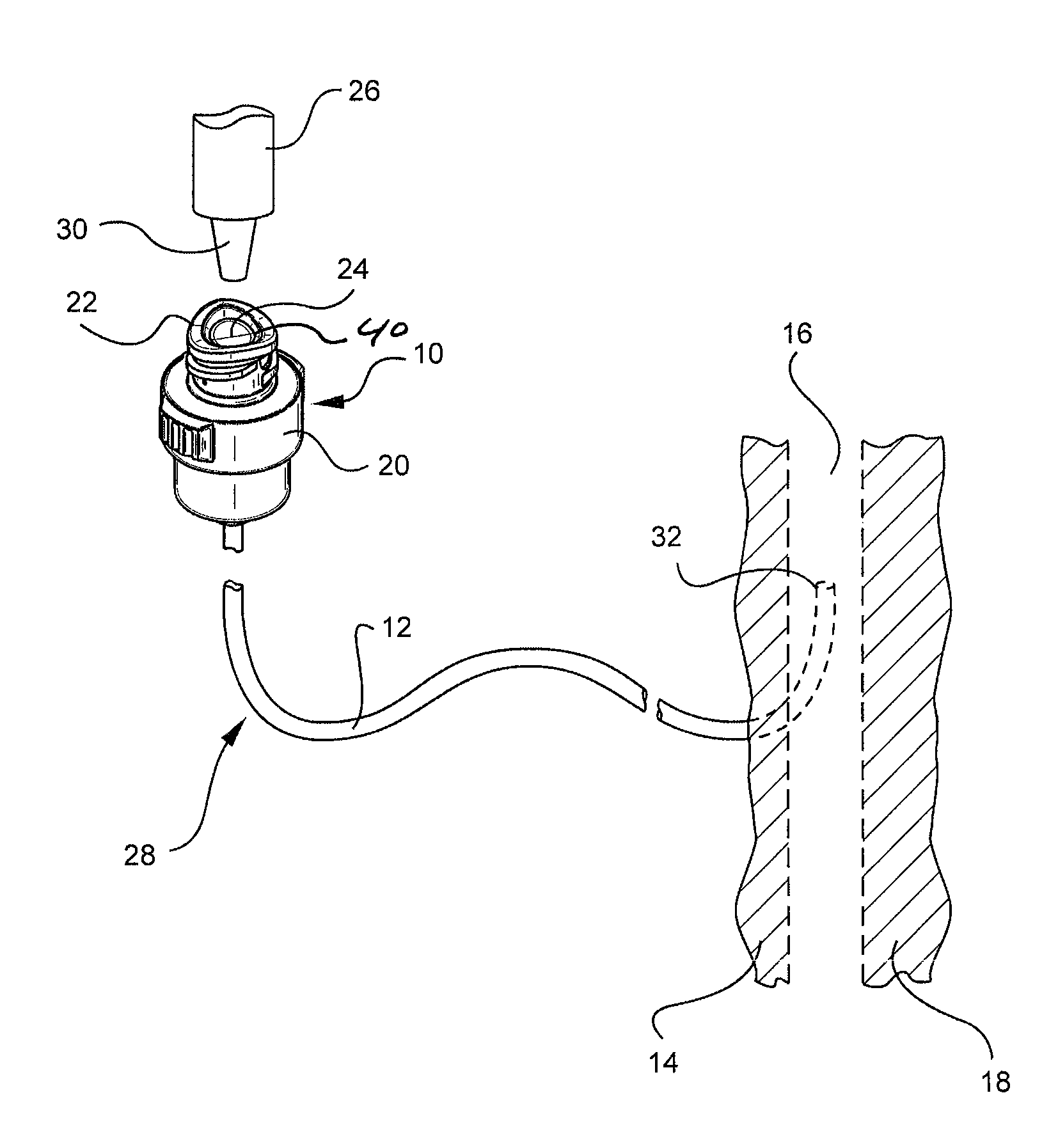

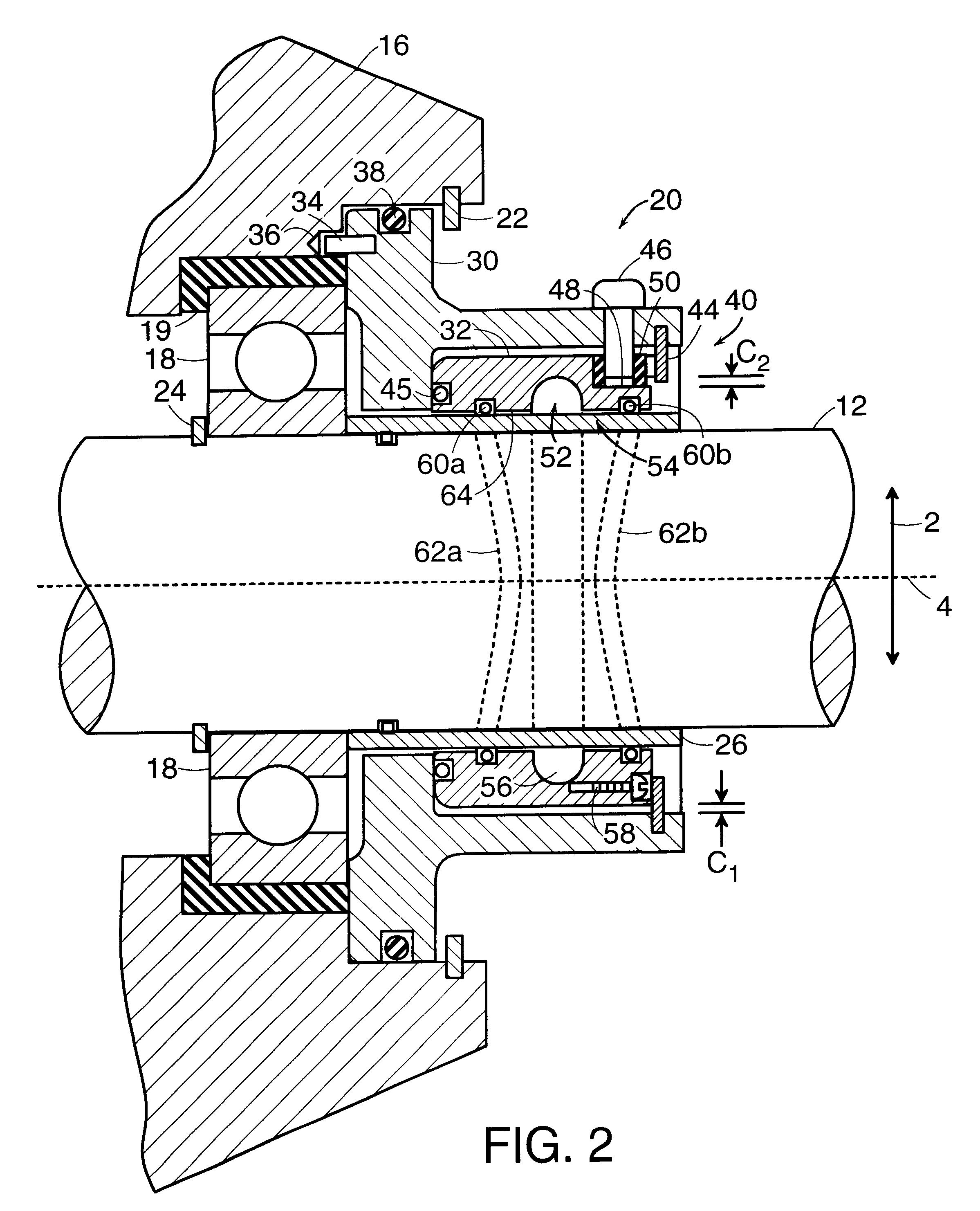

Low torque hydrodynamic lip geometry for bi-directional rotation seals

ActiveUS20060214380A1Extended seal lifeEffective lubricationEngine sealsContact pressureEdge effects

A hydrodynamically lubricating geometry for the generally circular dynamic sealing lip of rotary seals that are employed to partition a lubricant from an environment. The dynamic sealing lip is provided for establishing compressed sealing engagement with a relatively rotatable surface, and for wedging a film of lubricating fluid into the interface between the dynamic sealing lip and the relatively rotatable surface in response to relative rotation that may occur in the clockwise or the counter-clockwise direction. A wave form incorporating an elongated dimple provides the gradual convergence, efficient impingement angle, and gradual interfacial contact pressure rise that are conducive to efficient hydrodynamic wedging. Skewed elevated contact pressure zones produced by compression edge effects provide for controlled lubricant movement within the dynamic sealing interface between the seal and the relatively rotatable surface, producing enhanced lubrication and low running torque.

Owner:KALSI ENG

Antimicrobial lubricant compositions

ActiveUS20100137379A1Reduce complicationsFacilitate smooth and reliable actuationBiocidePretreated surfacesAmmonium compoundsChlorhexidine Acetate

Antimicrobial lubricant compositions are disclosed. The antimicrobial lubricant compositions are particularly useful in providing antimicrobial capability to a wide-range of medical devices. The compositions include an oil lubricant. Representative lubricants may include polydimethyl siloxane, trifluoropropyl copolymer polysiloxane, and a copolymer of dimethylsiloxane and trifluoropropylmethylsiloxane. The compositions include rheology modifiers as necessary. The compositions also include antimicrobial agents, which may be selected from a wide array of agents. Representative antimicrobial agents include of aldehydes, anilides, biguanides, bis-phenols, quaternary ammonium compounds, cetyl pyridium chloride, cetrimide, alexidine, chlorhexidine diacetate, benzalkonium chloride, and o-phthalaldehyde.

Owner:BECTON DICKINSON & CO

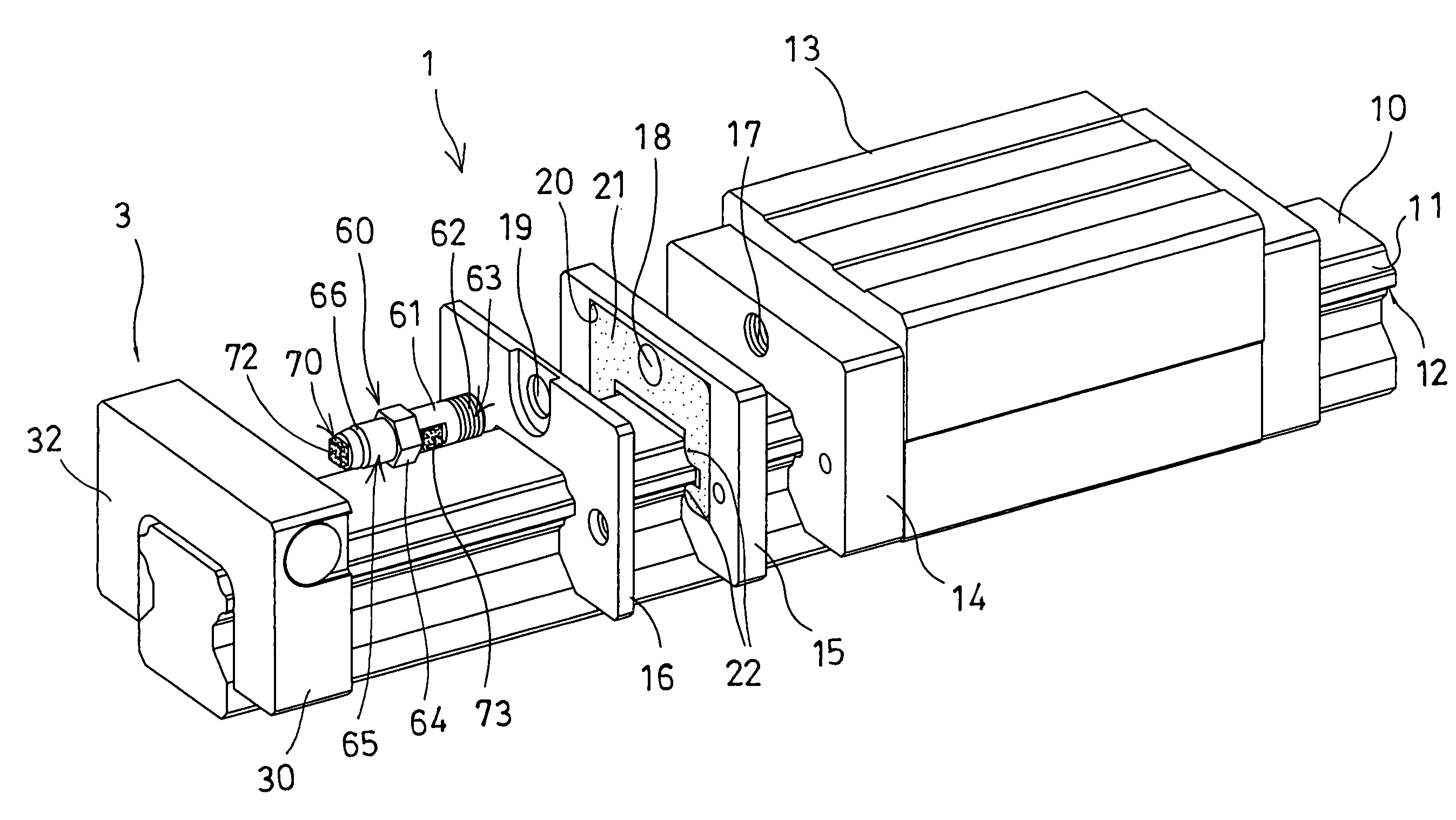

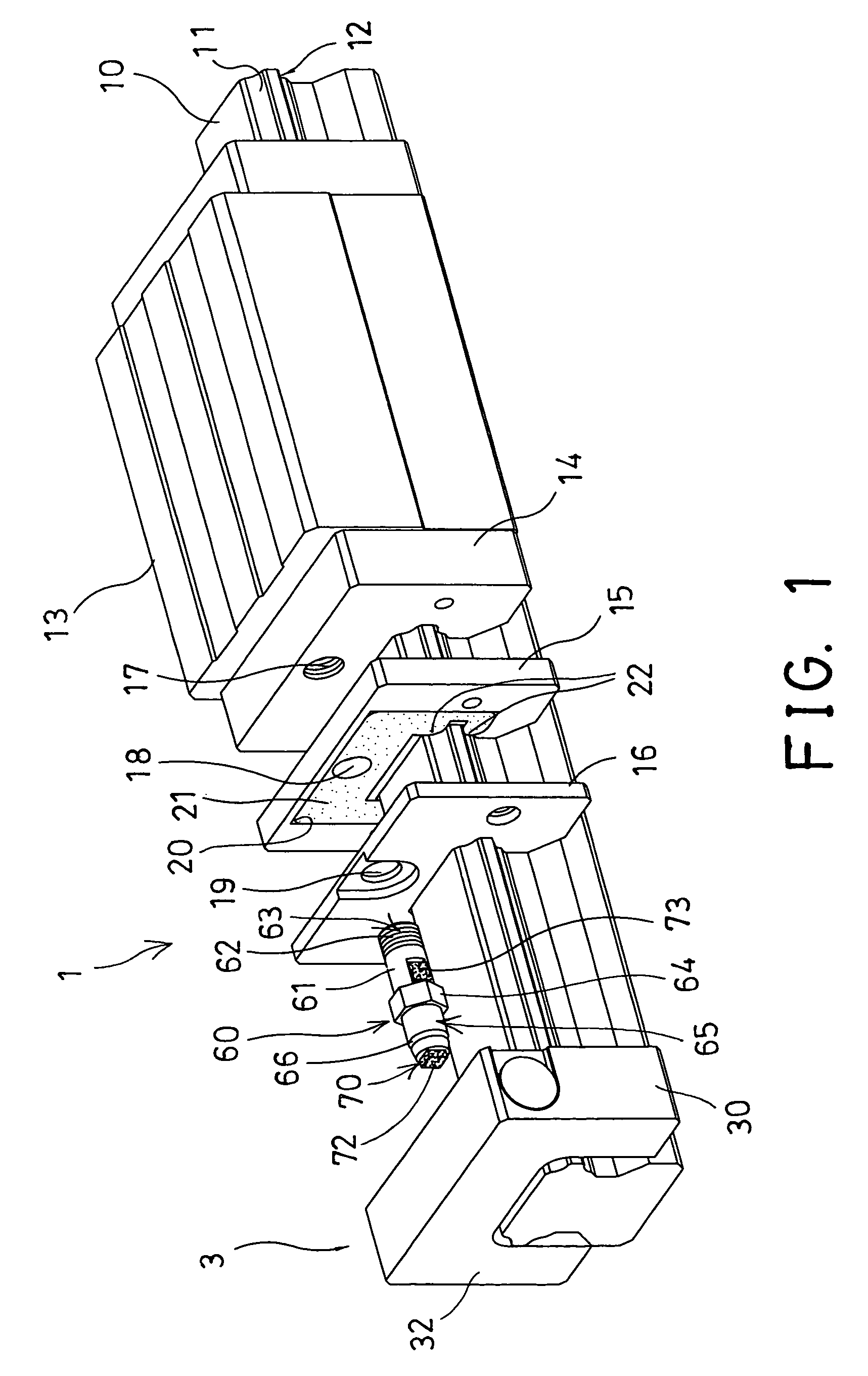

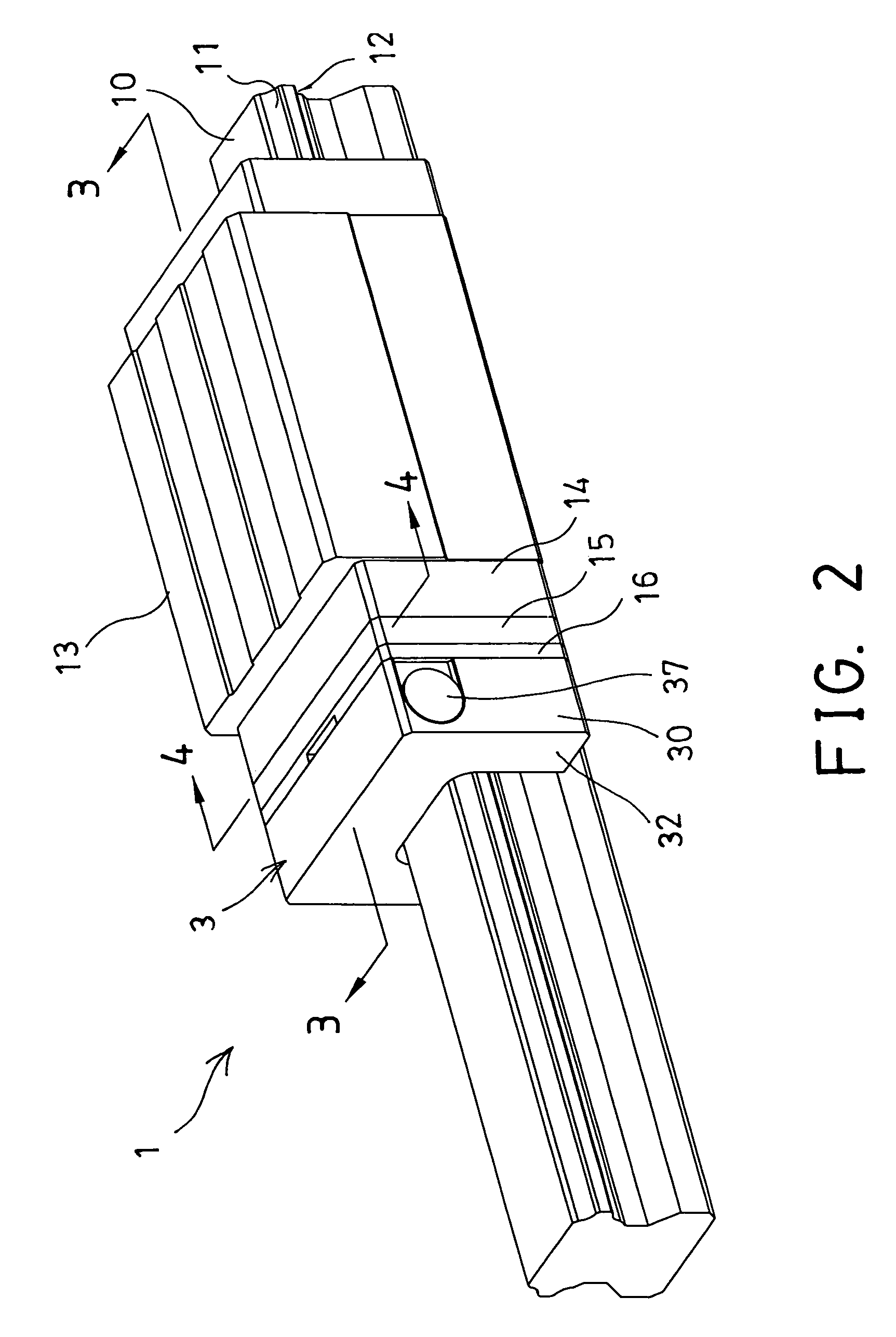

Linear motion guide apparatus having lubricating device

ActiveUS7556430B2Effective lubricationSmooth movementRotary combination bearingsLinear bearingsLinear motionBall bearing

A linear motion guide device includes a slider slidably attached onto the guide rail, a ball bearing device disposed between the slider and the guide rail, and a lubricating device having a housing slidably attached onto the guide rail for receiving and for supplying a lubricant to lubricate the ball bearing device. A lubricant-conveying member is disposed in the housing and has an upper segment and one or more lower segments and one or more middle segments coupled between the upper segment and the lower segments for absorbing the lubricant even when the lubricant is below a lower level and even when the housing is tilted or turned up side down relative to the slider and the guide rail.

Owner:HIWIN TECH

Low torque hydrodynamic lip geometry for bi-directional rotation seals

A hydrodynamically lubricating geometry for the generally circular dynamic sealing lip of rotary seals that are employed to partition a lubricant from an environment. The dynamic sealing lip is provided for establishing compressed sealing engagement with a relatively rotatable surface, and for wedging a film of lubricating fluid into the interface between the dynamic sealing lip and the relatively rotatable surface in response to relative rotation that may occur in the clockwise or the counter-clockwise direction. A wave form incorporating an elongated dimple provides the gradual convergence, efficient impingement angle, and gradual interfacial contact pressure rise that are conducive to efficient hydrodynamic wedging. Skewed elevated contact pressure zones produced by compression edge effects provide for controlled lubricant movement within the dynamic sealing interface between the seal and the relatively rotatable surface, producing enhanced lubrication and low running torque.

Owner:KALSI ENG

Rotating filter cartridge type air dust remover

InactiveCN101264406AEfficient removalConstant dust removal effectDispersed particle filtrationHigh humidityChain type

The invention discloses a rotary drum type dust remover, comprising a housing, a plurality of filter cylinders arranged in the intracavity of the housing for isolating dust, a main motor for driving filter cylinders, an impulse sweep system for cleaning the deposit dust on the surface of the filter cylinder, a chain typed scraper chain conveyor for cleaning dust, a spiral ash transportor and a dust discharge valve. The dust remover has the advantages of low dust concentration requirement for the air to be purified, ability to remove dust in various environments, and stable dust removal efficiency; and high temperature resistance, high humidity resistance, acid and alkaline corrosion resistance, electrostatic prevention as the filtered cloth material is stainless steel material; and ability to be used independently, also to be used multi-parallelly, and to select the number of single machine in an unit according to different discharge standard.

Owner:JIANGSU HUAZHENG ENVIRONMENTAL PROTECTION TECH CO LTD

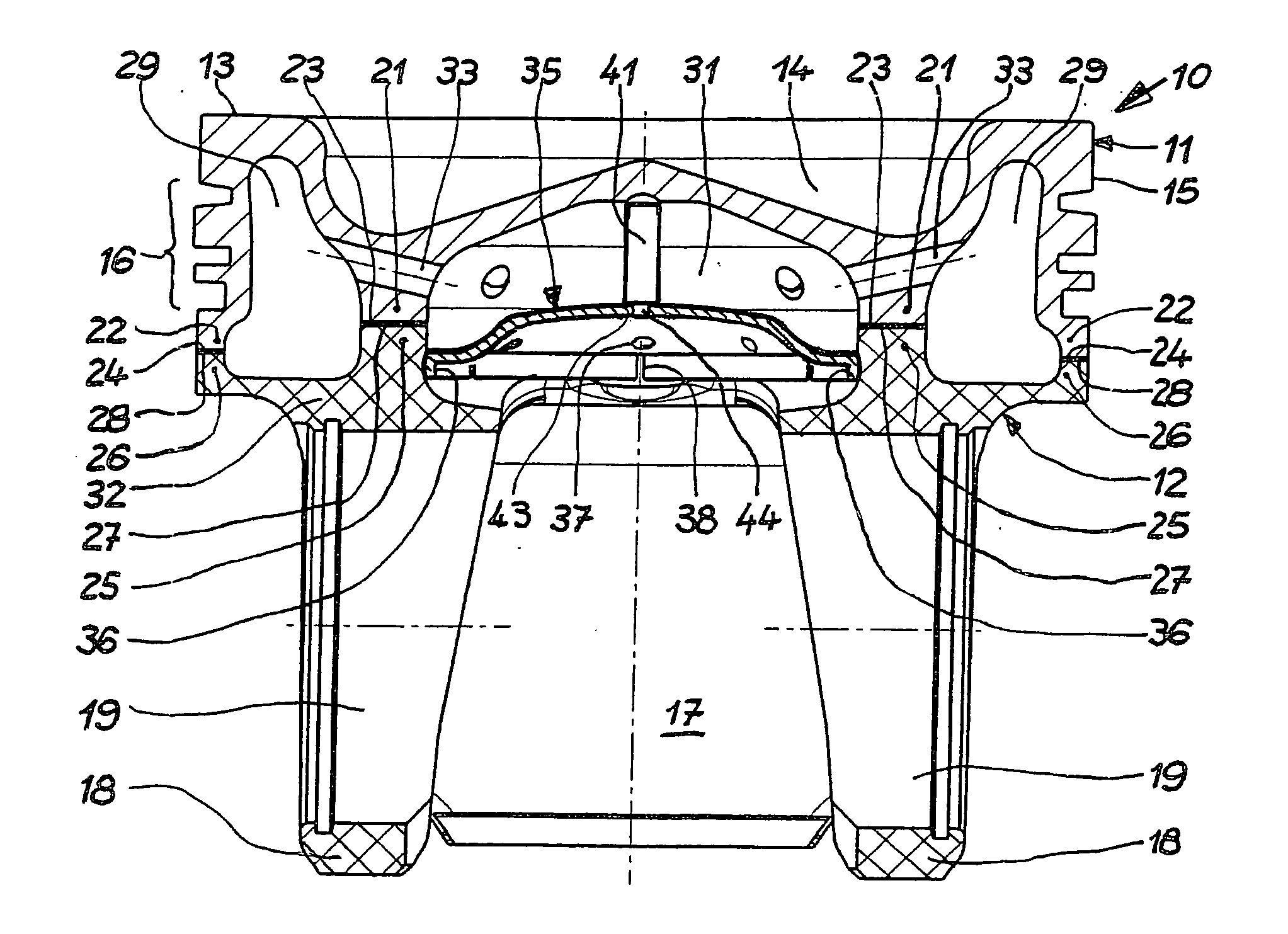

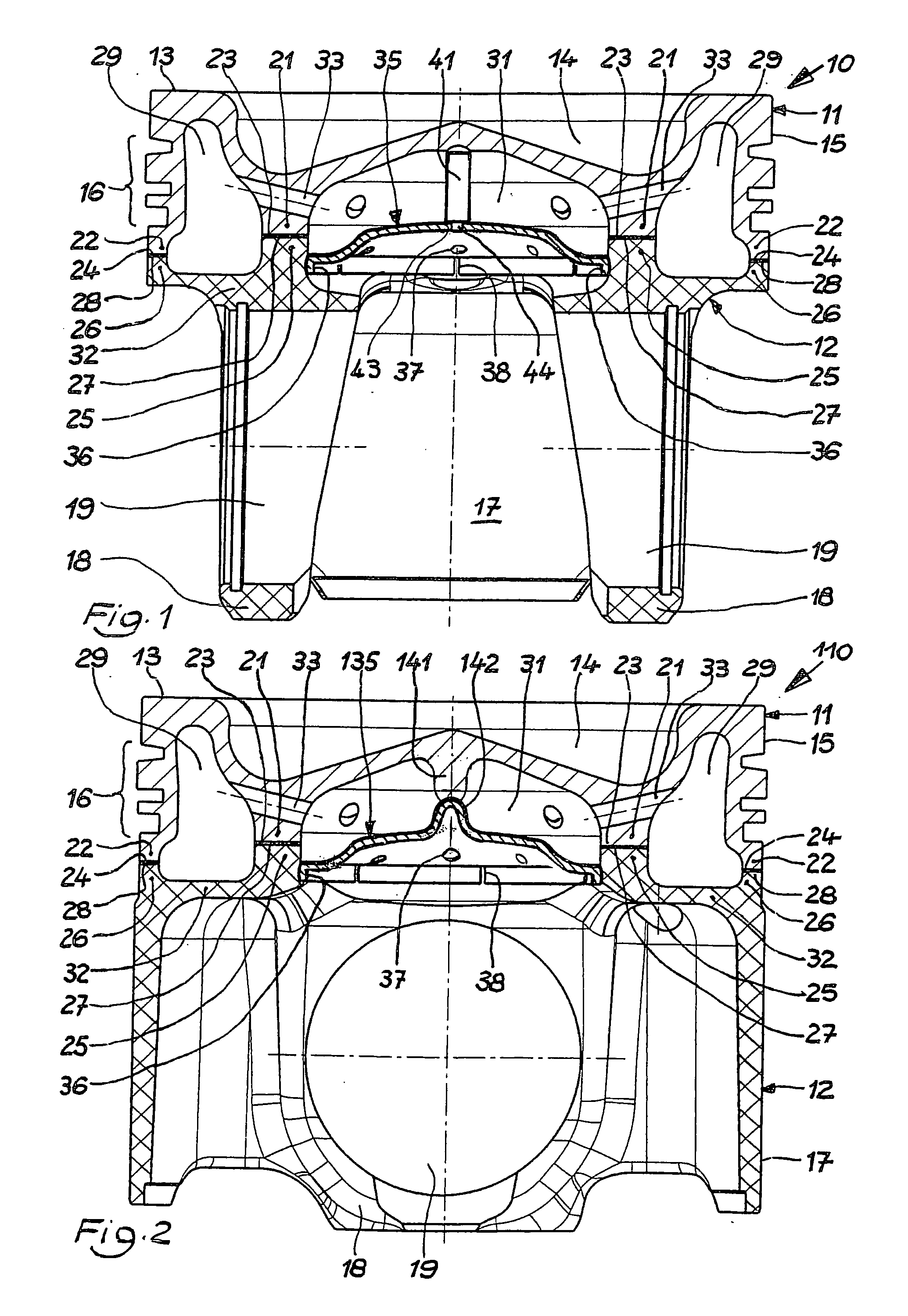

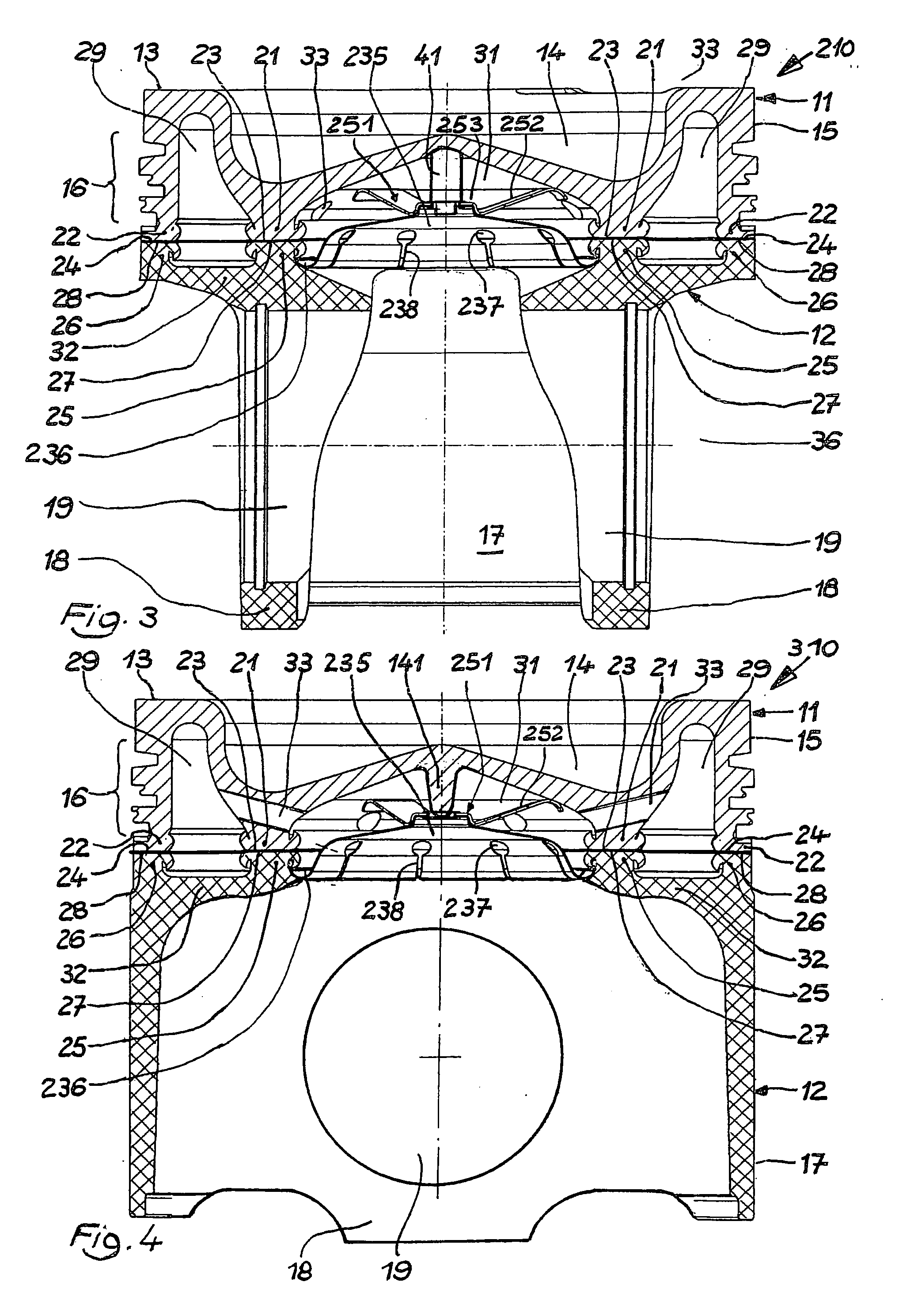

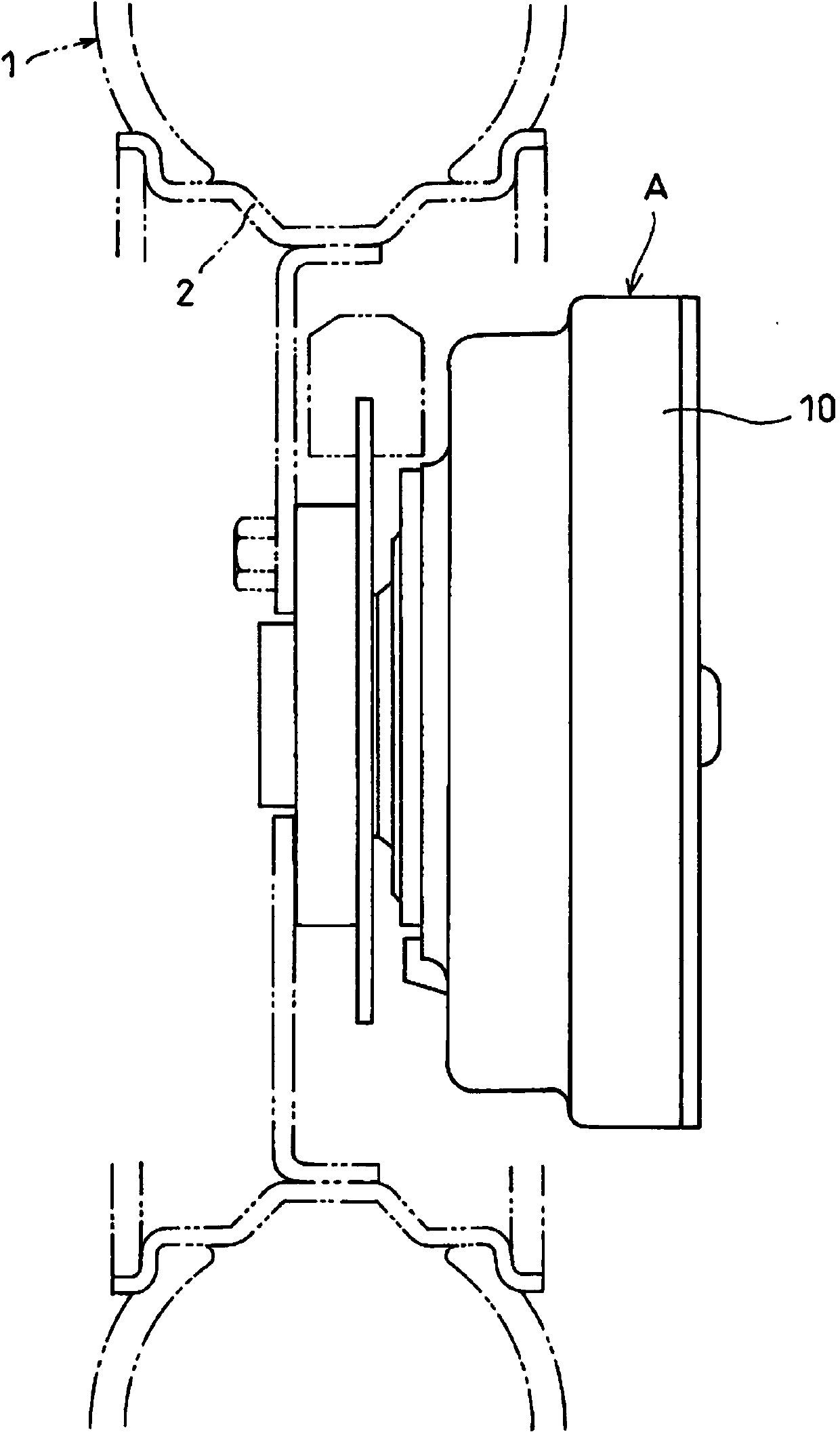

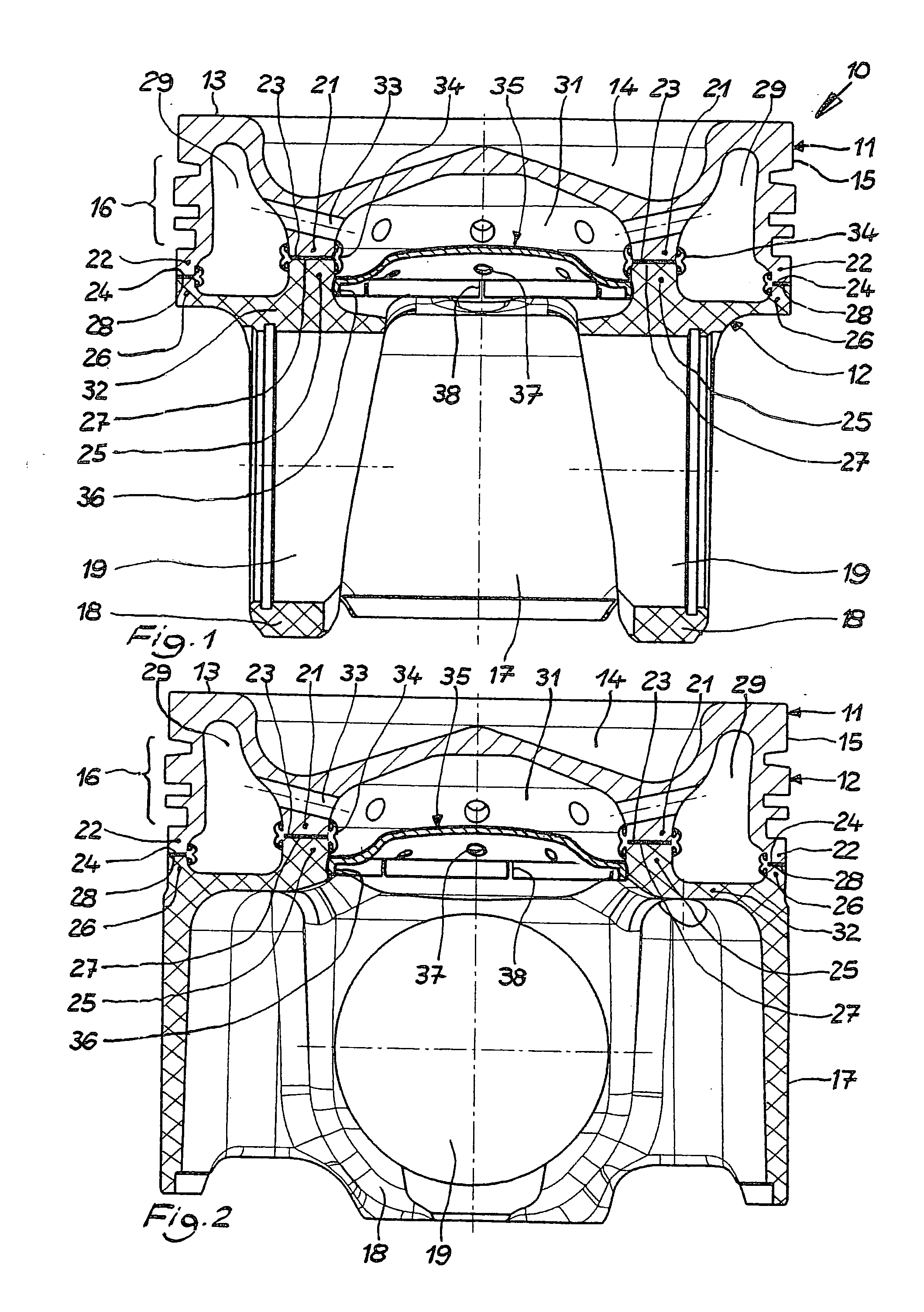

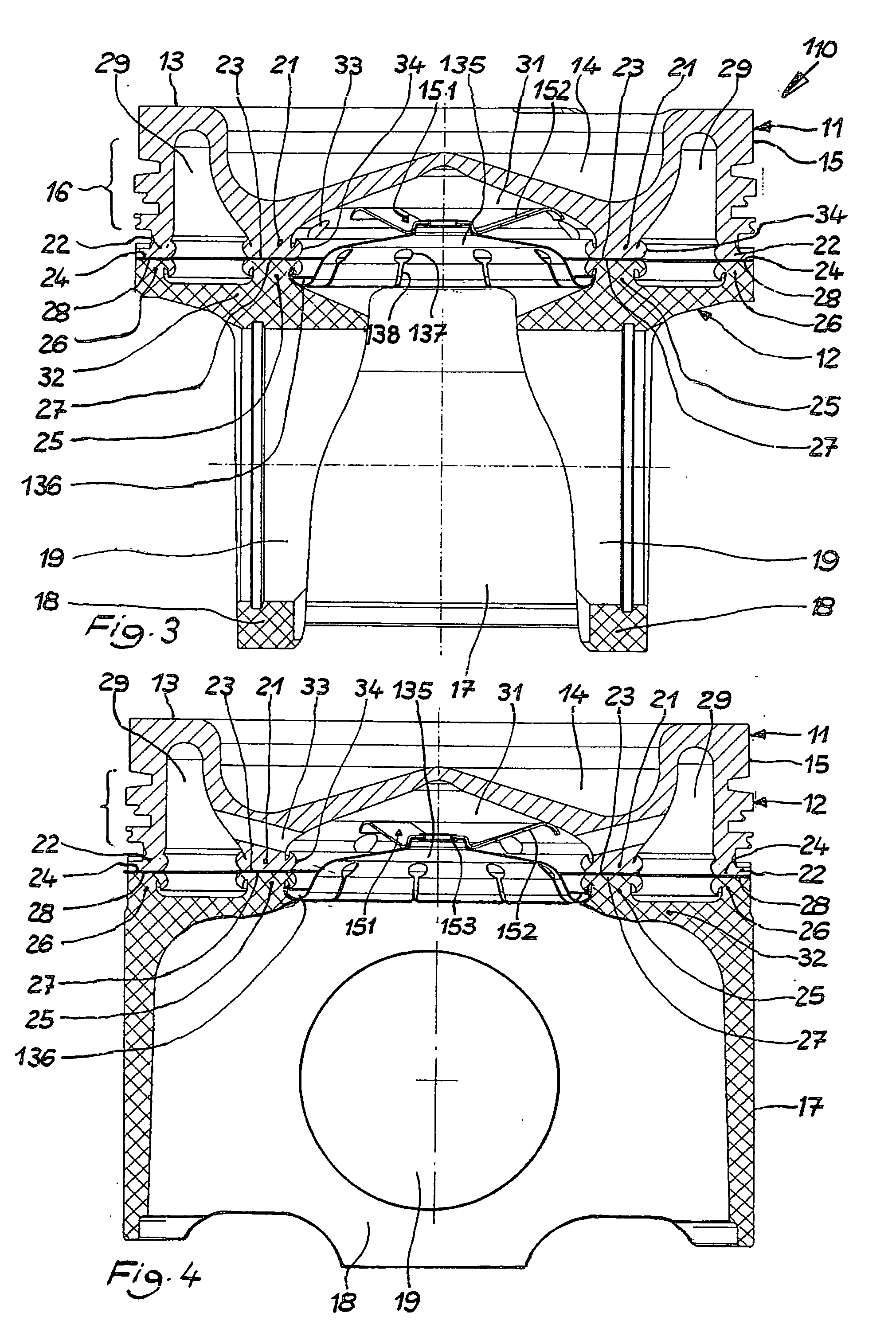

Multi-part piston for an internal combustion engine and method for its production

InactiveUS20100108001A1Easy to produceImprove cooling effectLiquid coolingAir coolingExternal combustion engineInternal combustion engine

A multi-part piston for an internal combustion engine has an upper piston part having a piston crown, and a lower piston part having pin boss supports and pin bosses connected with them. The upper piston part and lower piston part each have an inner and an outer support element, which delimit an outer circumferential cooling channel. The inner support elements delimit a cavity that is open toward the pin bosses, and the cavity is provided with a separate cooling oil collector that has at least one cooling oil opening. In a method for producing a piston, the upper and lower piston parts are manufactured, the cooling oil collector is inserted into one of the upper and lower piston parts in a region of the cavity, and the upper and lower piston parts are connected together at their support elements.

Owner:MAHLE INT GMBH

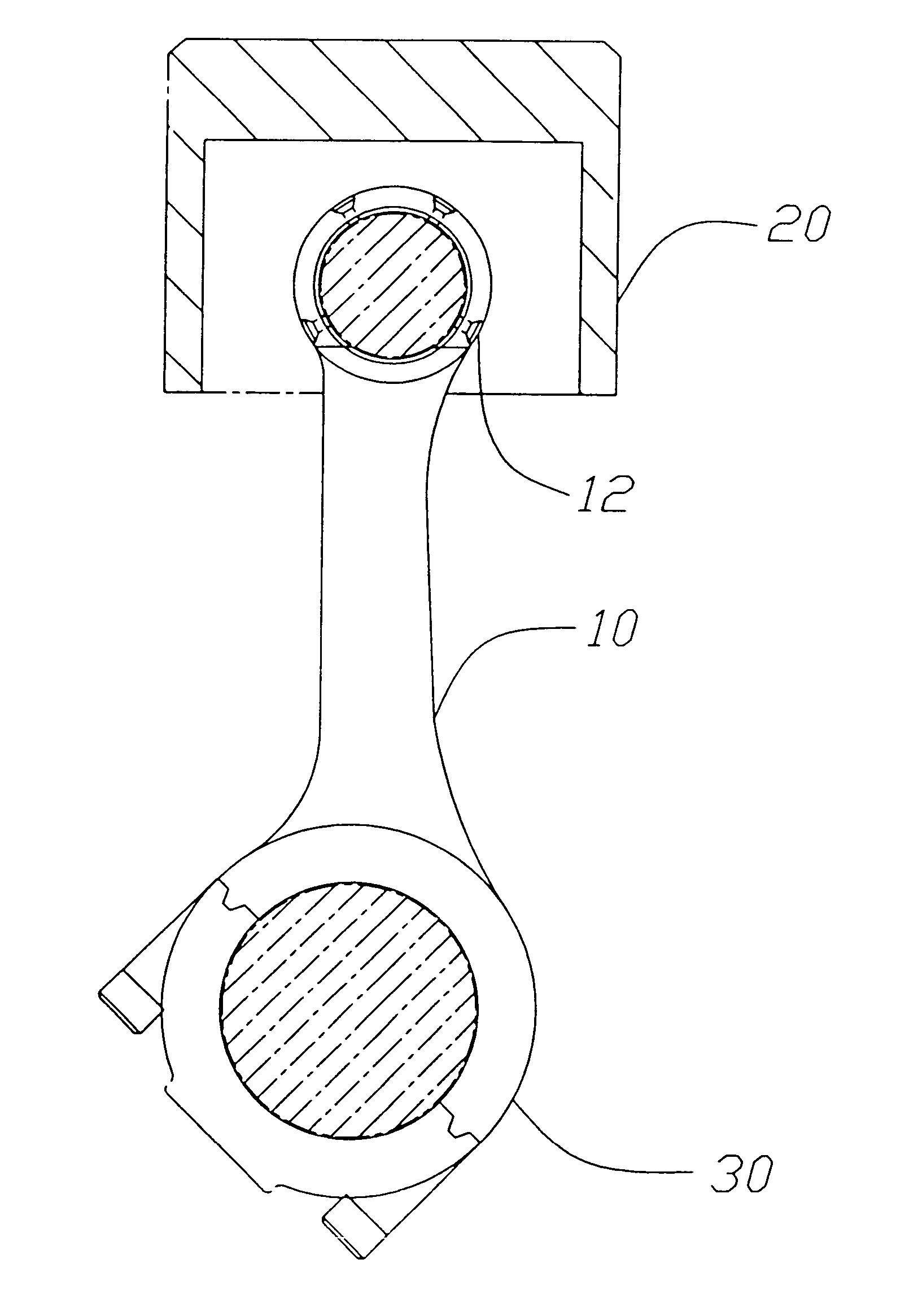

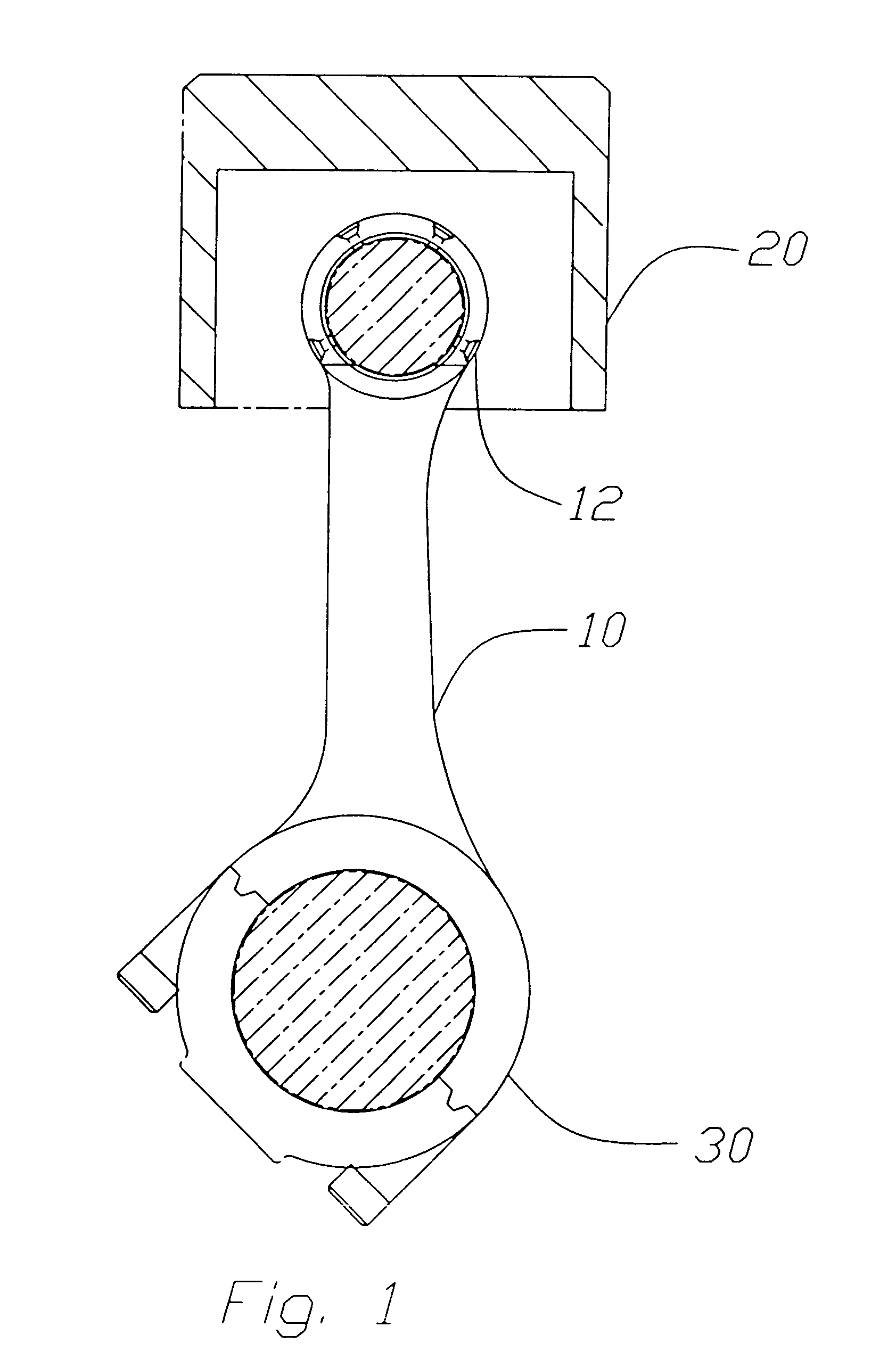

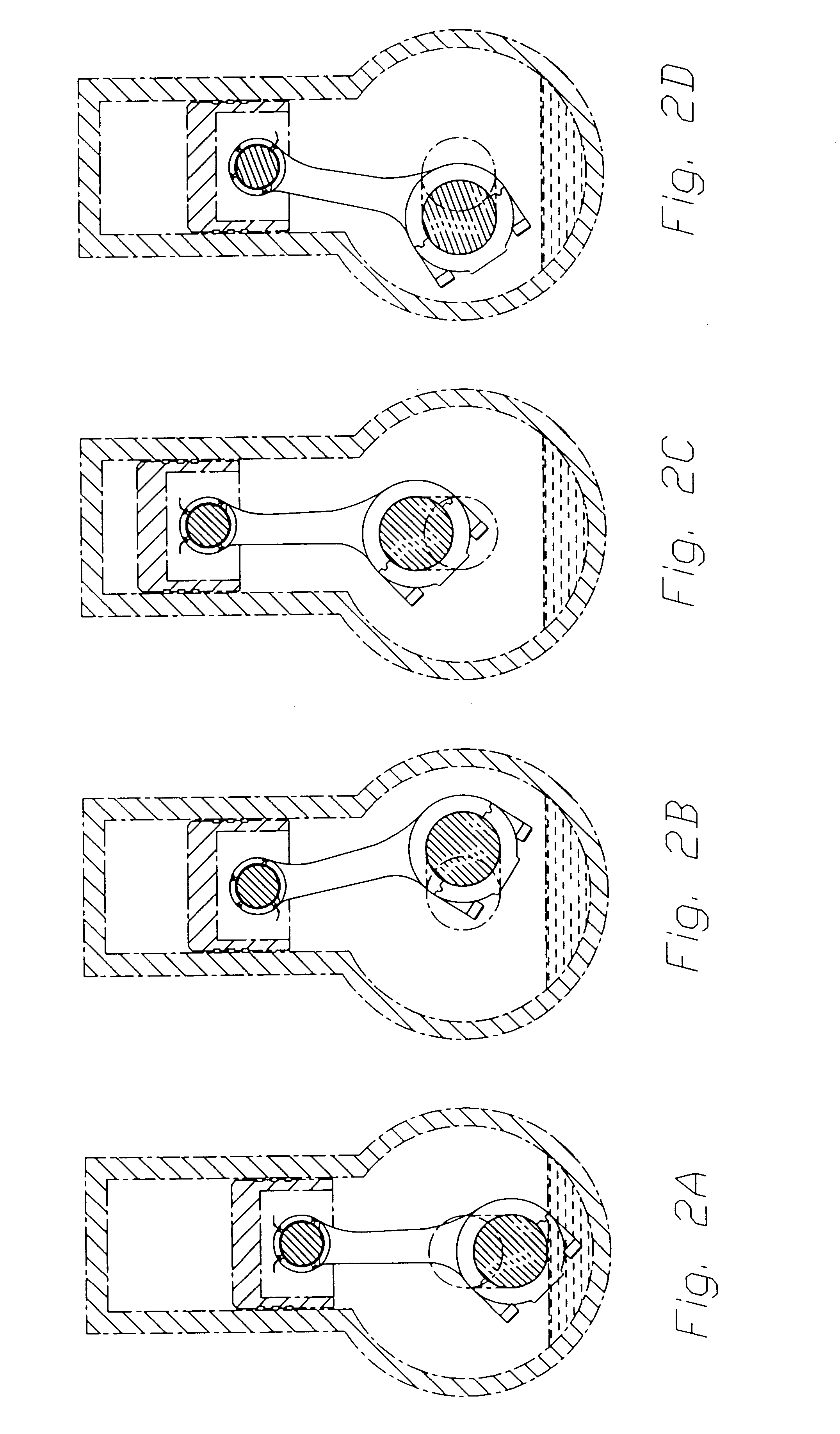

Connecting rod structure

InactiveUS6745742B2Effective lubricationSave energyConnecting rodsMachines/enginesMechanical engineeringLubrication

An engine having a connecting rod, a piston and a crankshaft is provided. The connecting rod extends between to connect the piston and the crankshaft. The connecting rod has formed therethrough at least one hole which provides a lubrication path to an interface between the connecting rod and piston conjunction point.

Owner:MEYER GMBH

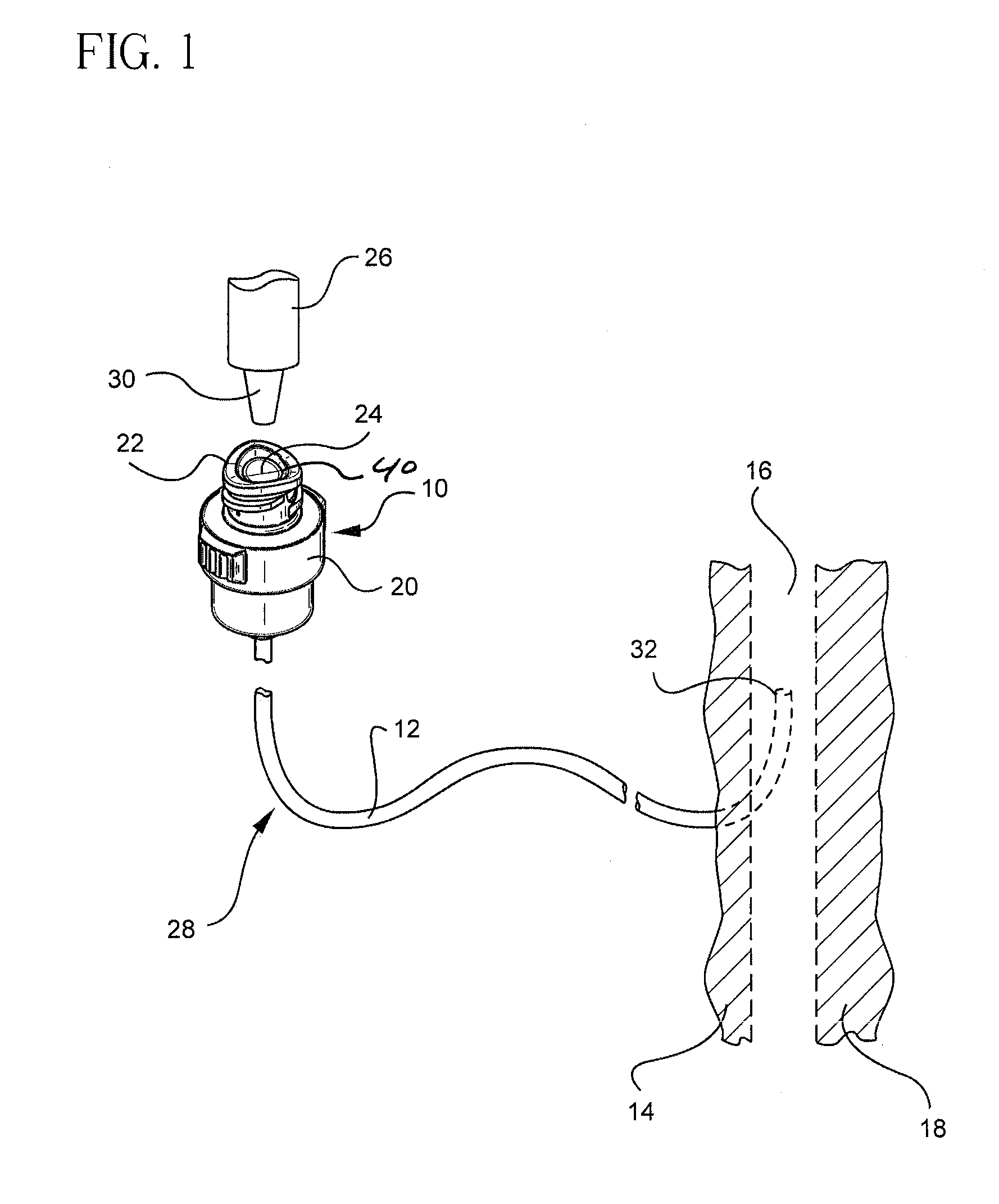

Ophthalmic compositions for lubricating eyes and methods for making and using same

InactiveUS7045121B2Easy and cost-effectiveClear visionBiocidePharmaceutical delivery mechanismLubricationOptometry

Ophthalmic compositions include an ophthalmically acceptable carrier component, for example, an aqueous-based carrier, and a plurality of polyanionic component portions having different molecular weights. In one embodiment, the polyanionic component includes a first polyanionic component portion having a first molecular weight; and a second polyanionic component portion having a different second molecular weight. Each of the first and second polyanionic component portions is present in an amount effective to provide lubrication to an eye when the composition is administered to an eye. Methods of making and using such compositions are also disclosed.

Owner:ALLERGAN INC

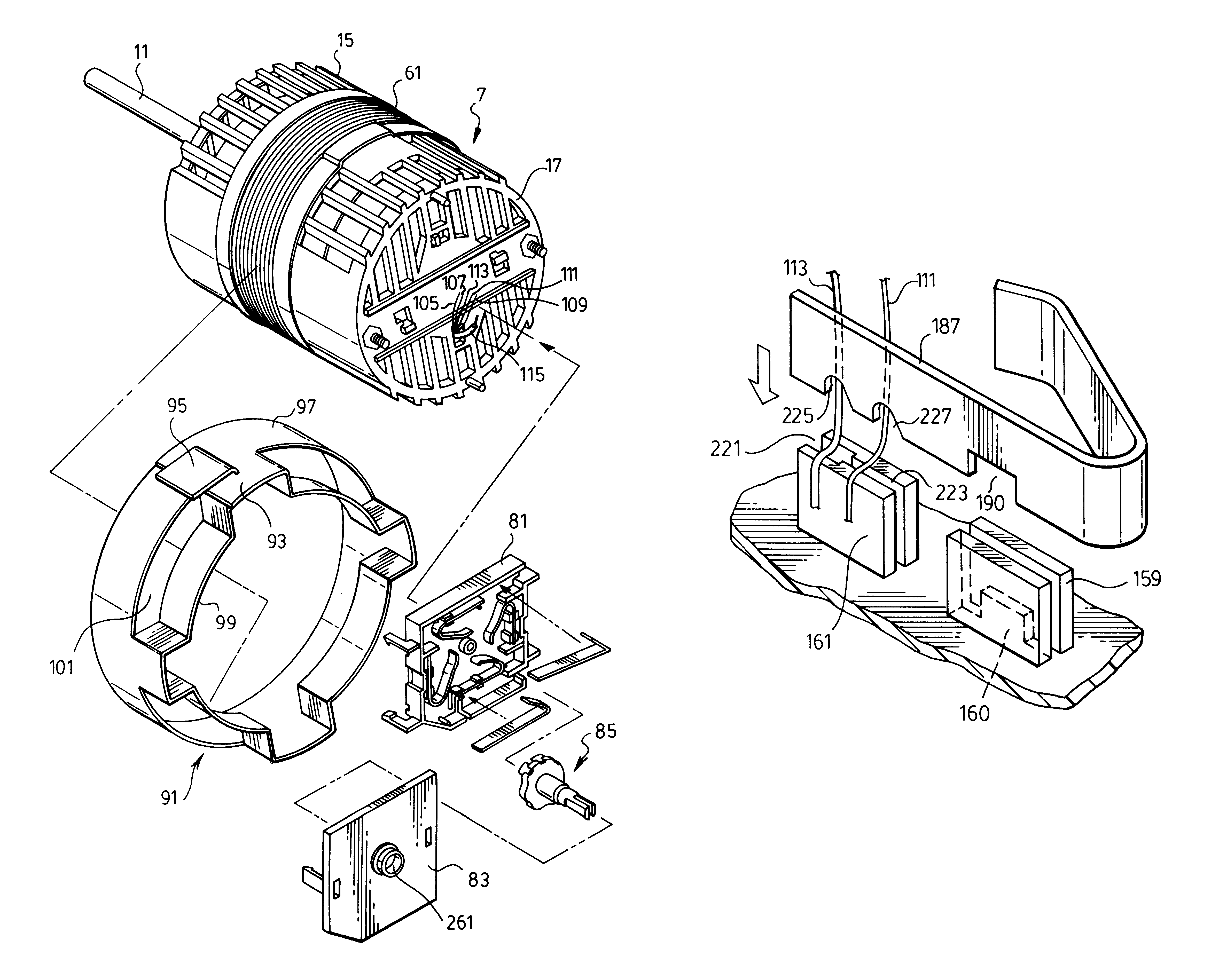

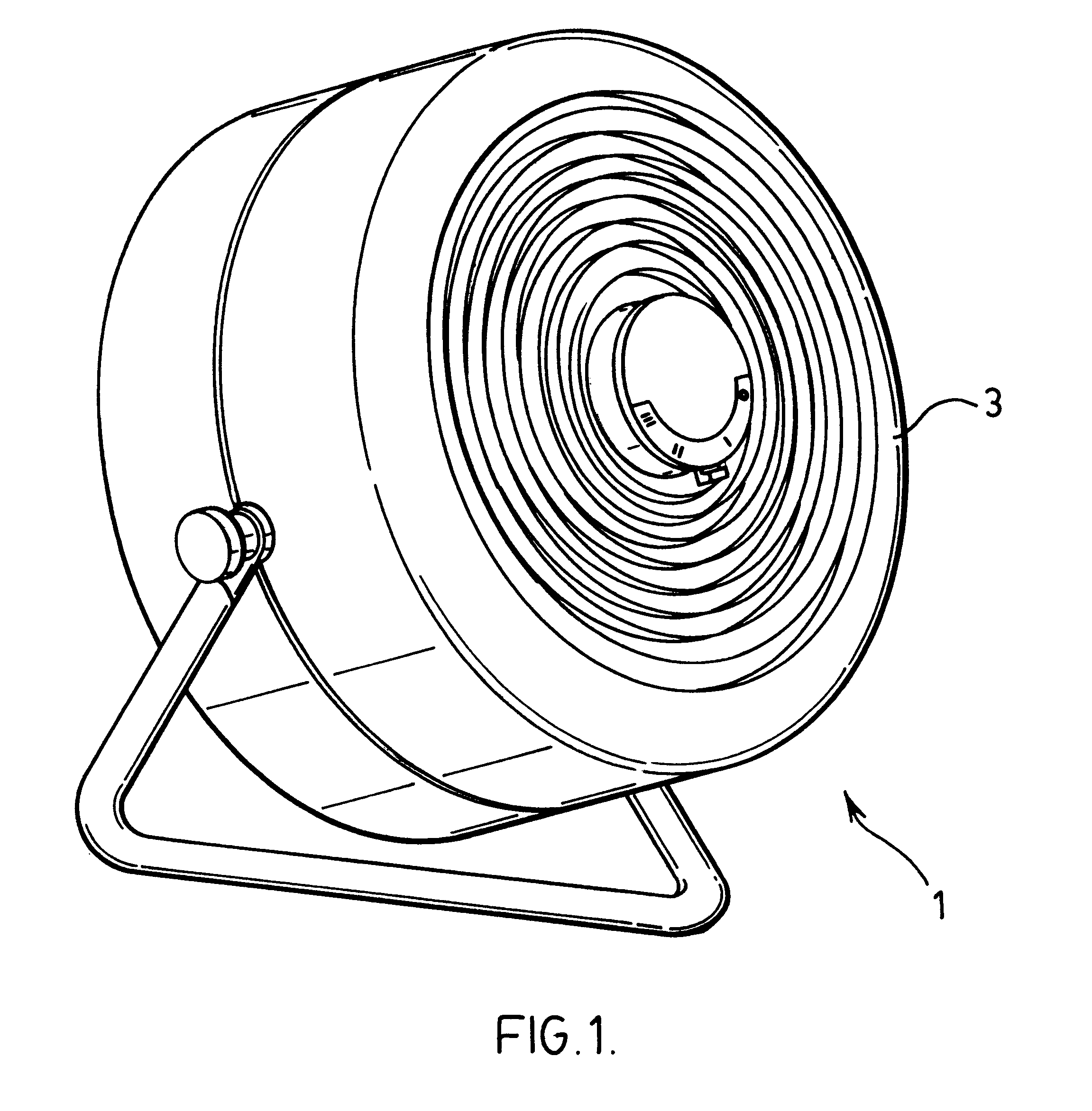

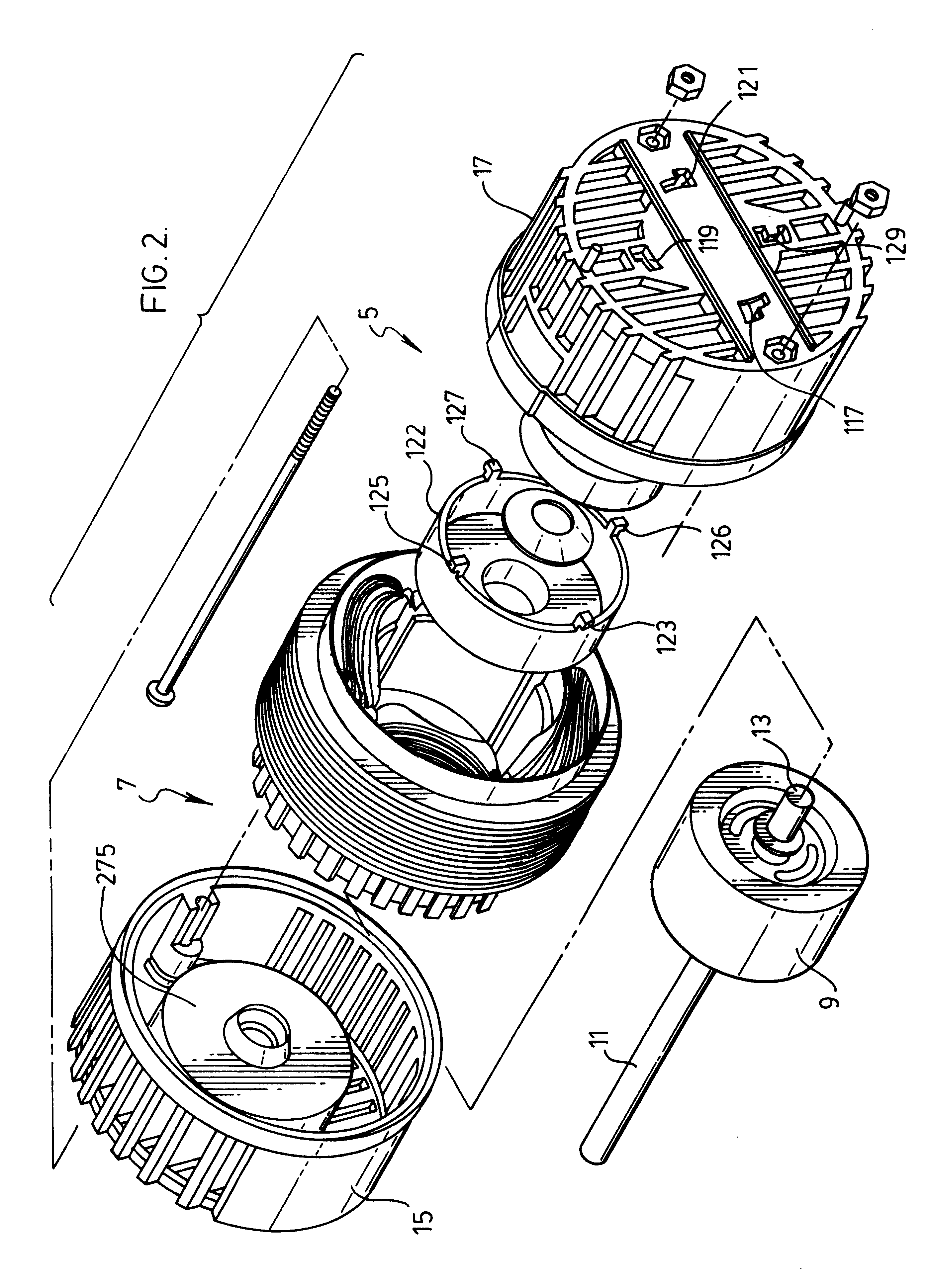

Motor mounted switch

InactiveUS6376947B1Avoid shortingPrecision injectionCoupling device connectionsWindingsMagnetic fluxElectric wire

An electrical appliance which operates at multiple speeds includes a motor construction having a stator and a rotor which rotates within the stator. The stator includes a plurality of magnetic flux inducing wires coiled on different poles of the stator. The stator and the rotor are contained within a motor housing with the appliance further including a switch housing mounted directly to the motor housing. The flux inducing wires have wire ends which extend out of the motor housing and into the switch housing which includes receptors to receive the ends of the flux inducing wires and which also receive electrical contact members which secure and electrically connect with the ends of the flux inducing wires within the receptors of the switch housing.

Owner:TATEISHI ART

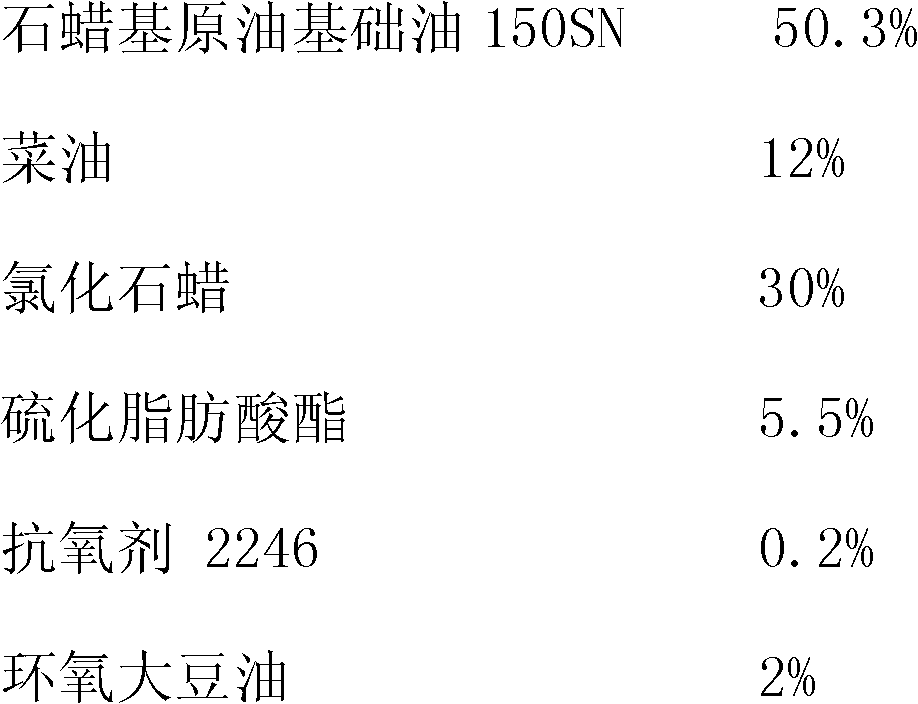

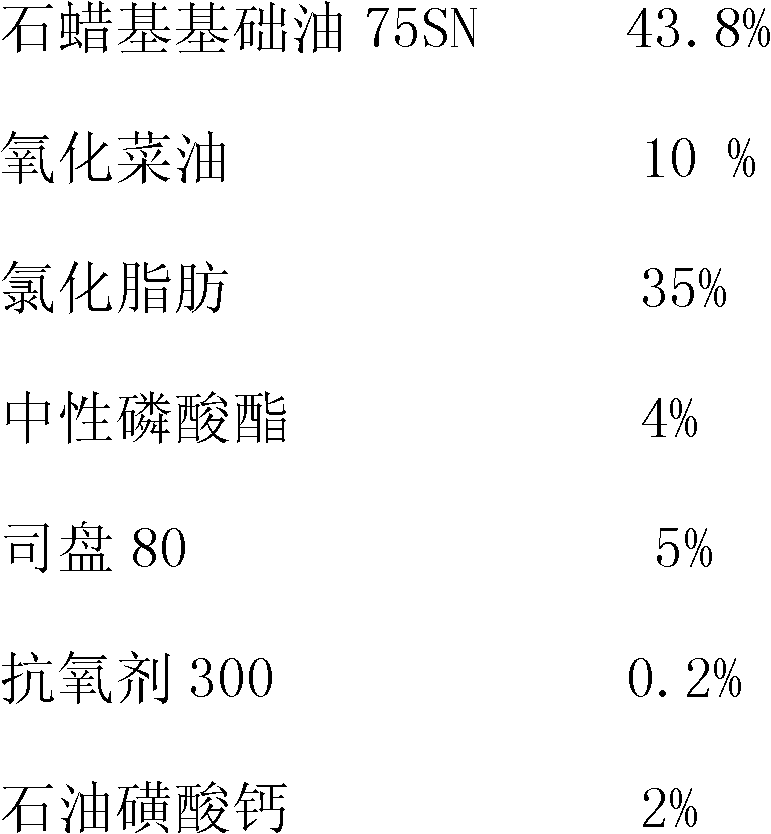

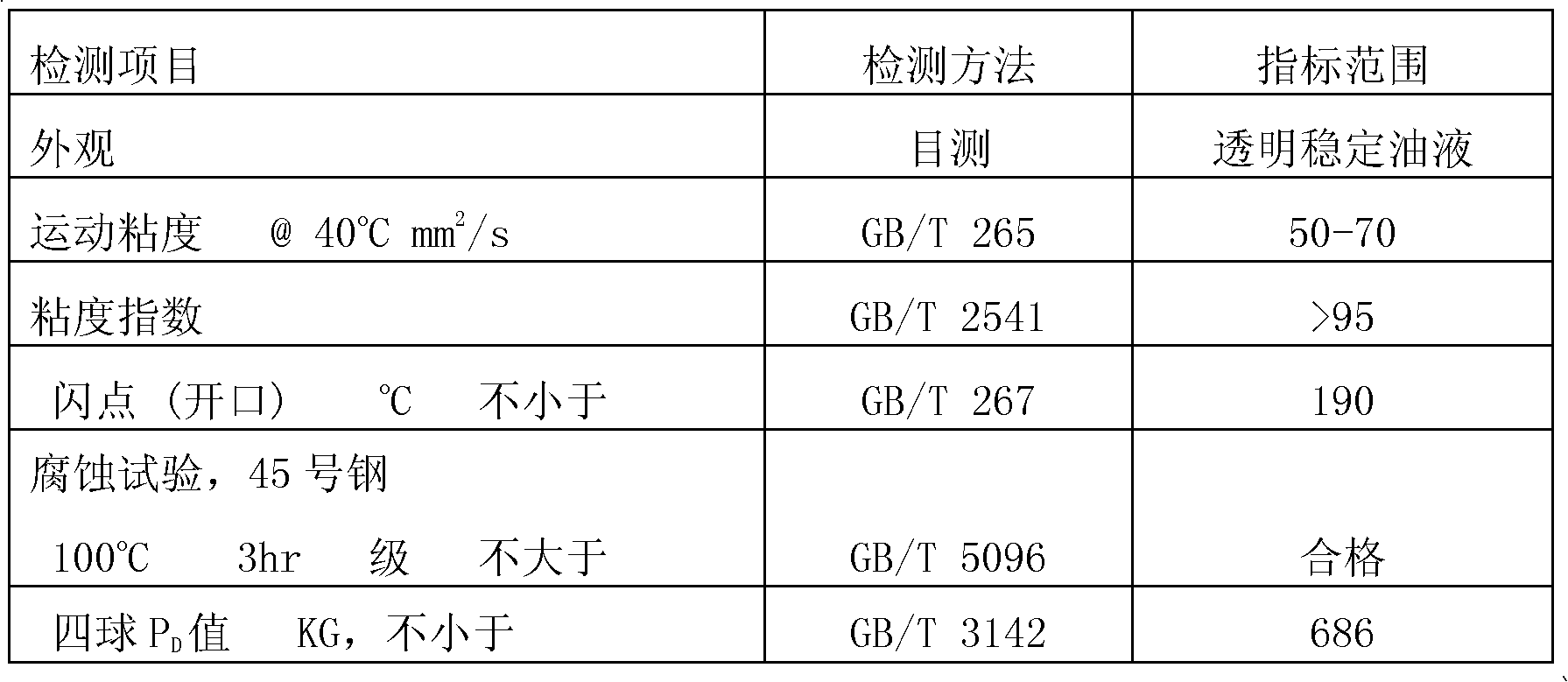

Metal drawing oil

The invention discloses metal drawing oil which is characterized by containing the following components in percentage by weight: 10-30% of oiliness agent, 20-40% of extreme pressure additive, 0-0.5% of antioxidant, 0-5% of corrosion inhibitor and the balance of base oil. The product disclosed by the invention contains a great deal of oiliness agent and extreme pressure additive, and can be used for providing favorable lubricating property and strong adhesive force, reducing the heat in a forming process, effectively lubricating a workpiece and a die, favorably protecting the die and prolonging the service life of the die. Due to the excellent extreme pressure property, the workpiece quality is effectively improved and the processing power is effectively increased under high, deep and difficult processing conditions; and the metal drawing oil is high in viscosity index, good in viscosity-temperature characteristics and high in temperature and weather adaptability.

Owner:LOCKS LUBE SHANGHAI

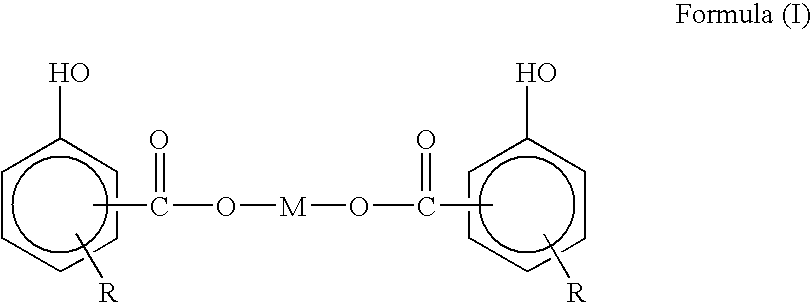

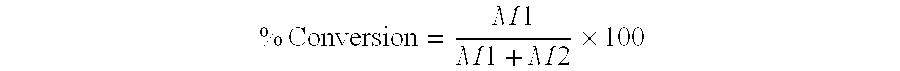

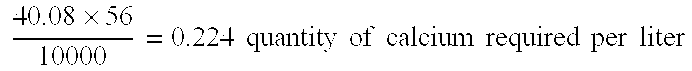

Overbased alkaline earth metal alkylhydroxybenzoates having low crude sediment

ActiveUS8030258B2Decrease in levelLow production costOrganic chemistryOrganic compound preparationAlkaline earth metalAliphatic hydrocarbon

A process for preparing an overbased alkaline earth metal alkylhydroxybenzoate, said process comprising overbasing an alkaline earth metal alkylhydroxybenzoate or a mixture of alkaline earth metal alkylhydroxybenzoate and up to 50 mole % of alkylphenol, based on the total mixture of alkylhydroxybenzoate and alkylphenol, with a molar excess of alkaline earth metal base and at least one acidic overbasing material in the presence of at least one carboxylic acid having from one to four carbon atoms and a solvent selected from the group consisting of aromatic hydrocarbons, aliphatic hydrocarbons, monoalcohols, and mixtures thereof.

Owner:CHEVRON ORONITE SA

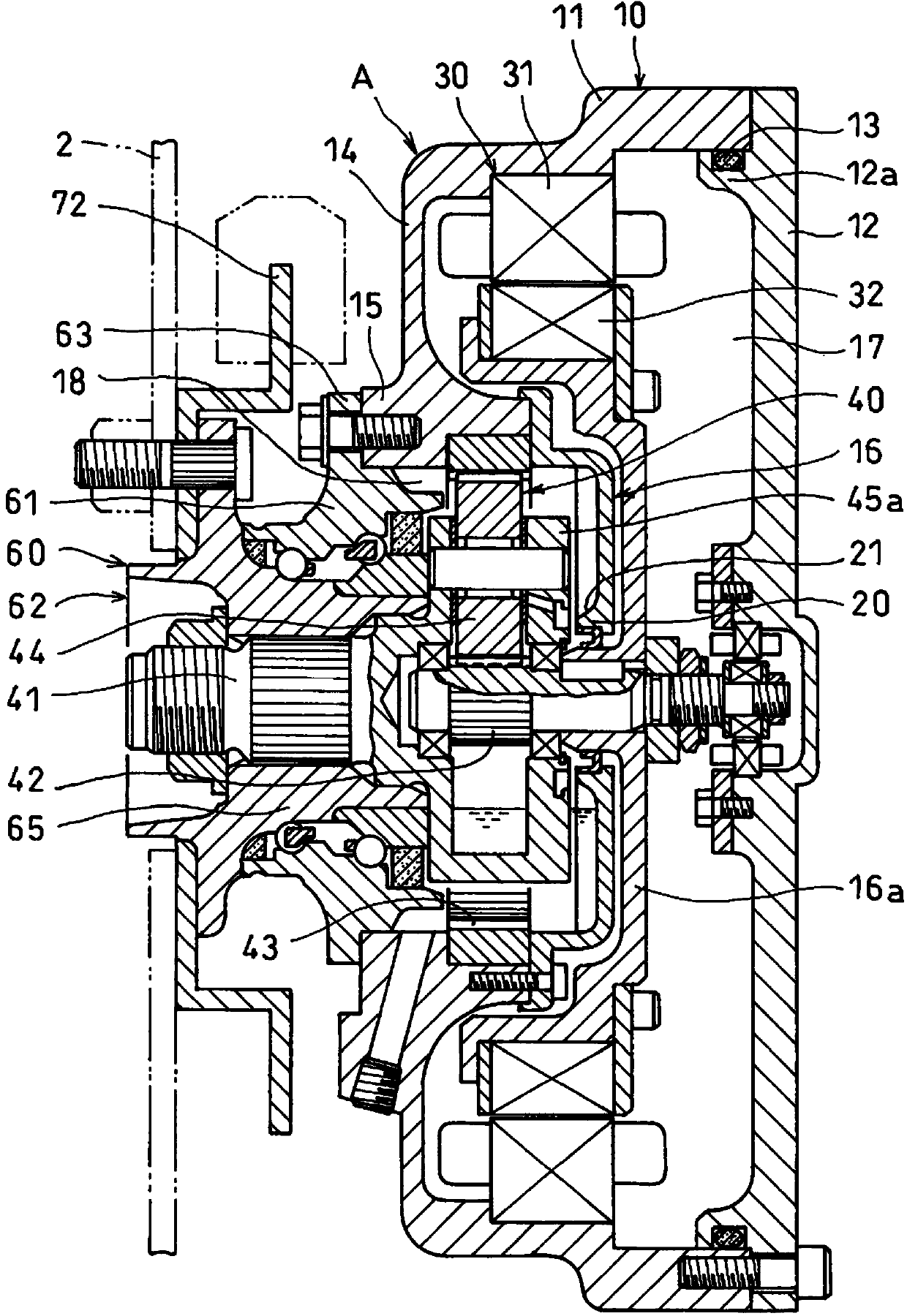

Automatic transmission

InactiveUS7021169B2Reduce gear shift shockSmooth gear shift qualityToothed gearingsControl devicesAutomatic transmissionEngineering

An automatic transmission with input shaft having drive gears and an output shaft with driven gears engaging with the drive gears are provided. A transmission gear for transmitting a power is selectively switched from transmission gear trains of the drive gears and driven gears, by a switching mechanism. An input clutch for switching engine power transmission and input shaft disconnect states is arranged between an engine crankshaft and the input shaft. Bypass clutches capable of transmitting the power to the respective transmission gear trains are provided at an end portion of the input shaft, and the engine power is transmitted to the output shaft via at least any one of the bypass clutches at a time of shifting gears. The input clutch and the plurality of bypass clutches are concentrically arranged in series between the engine and the input shaft providing size reduction.

Owner:SUBARU CORP

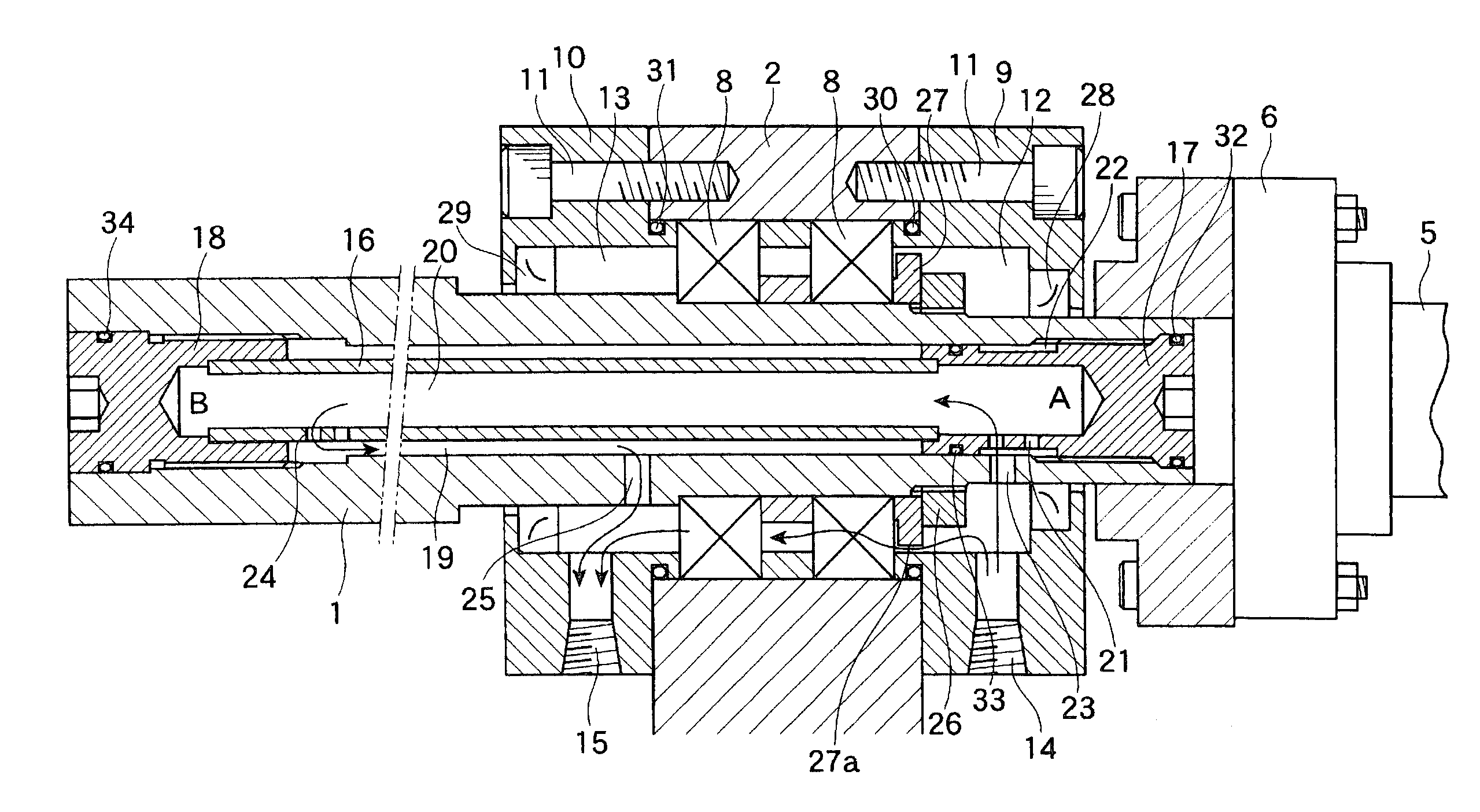

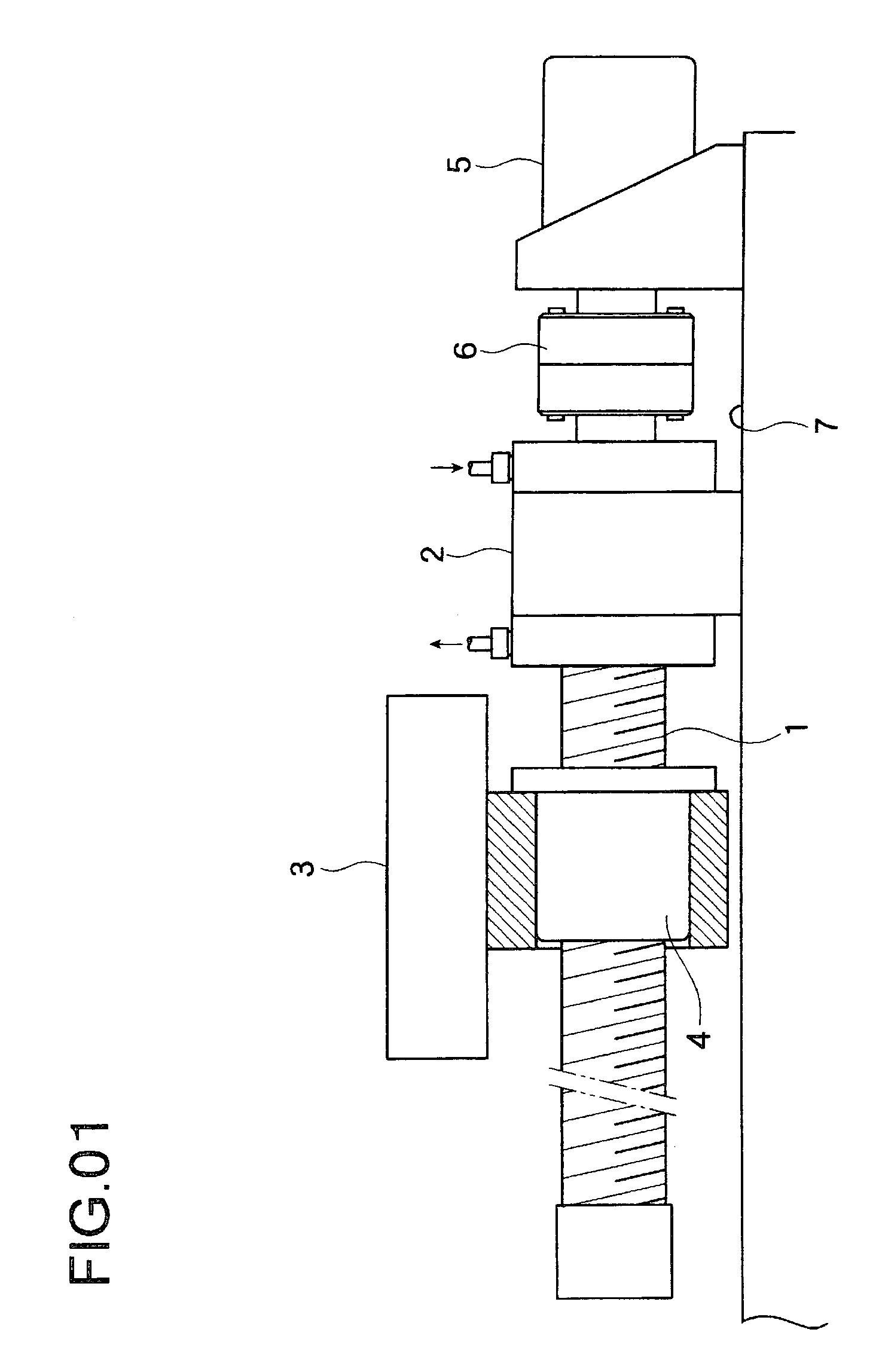

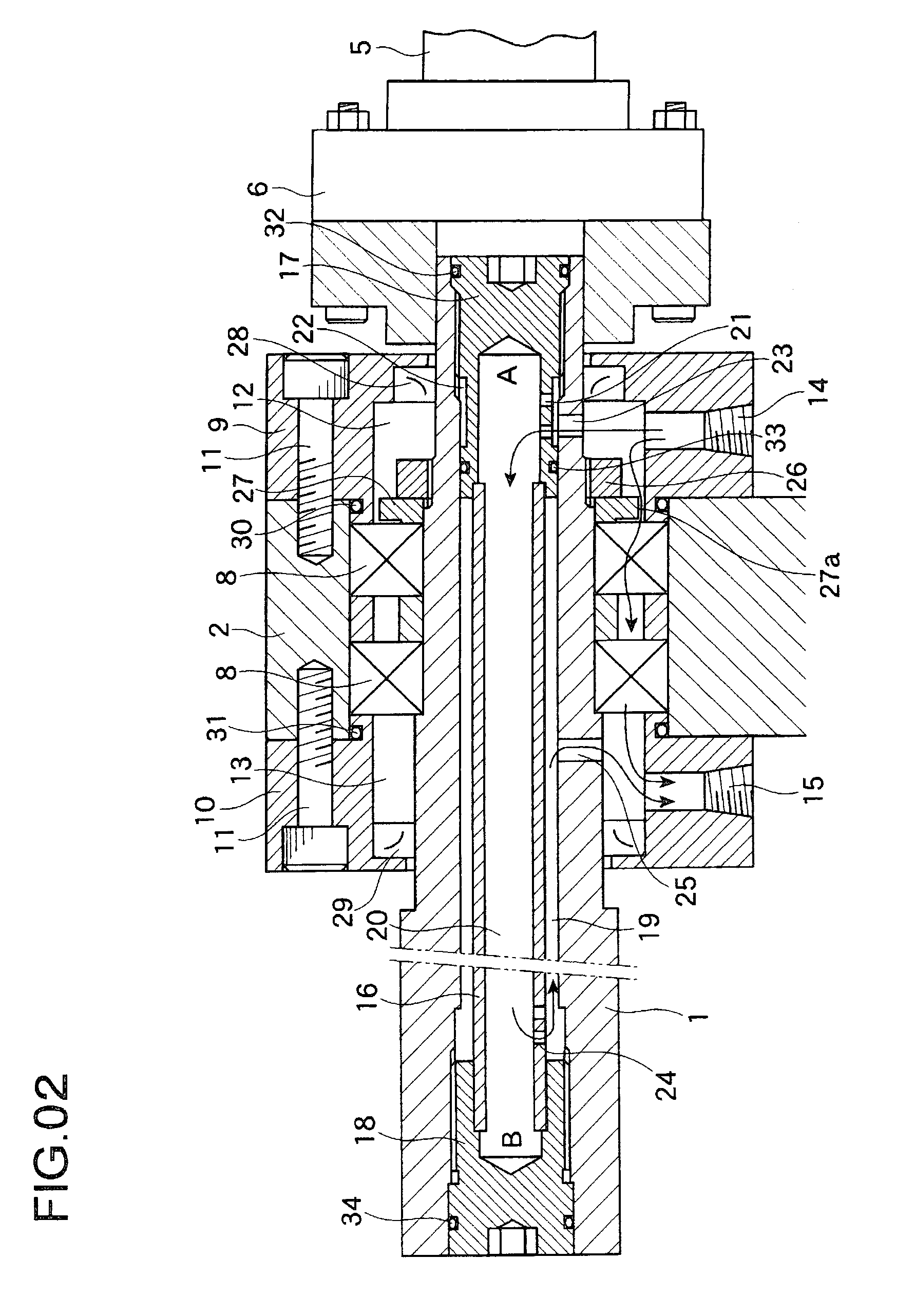

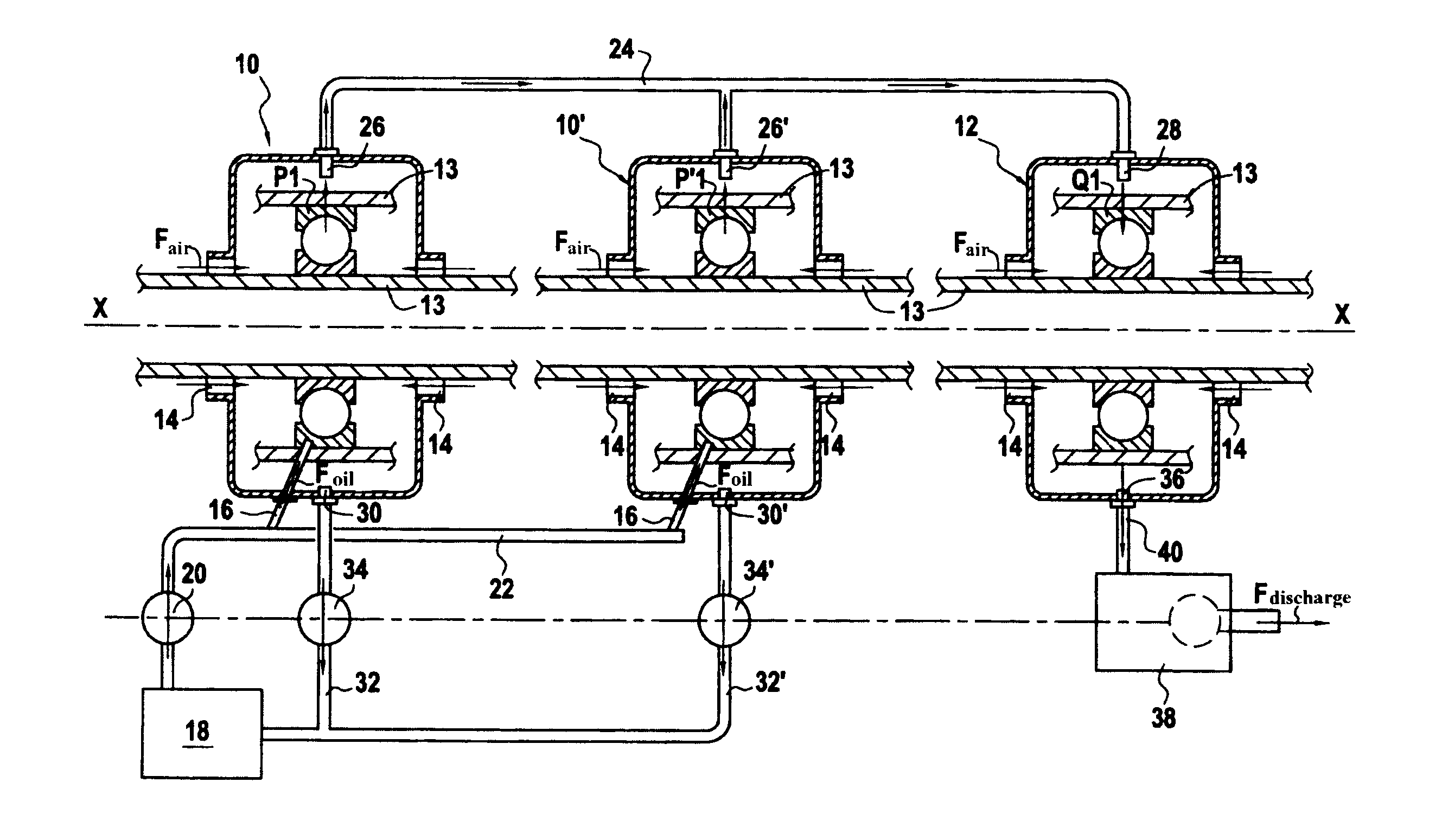

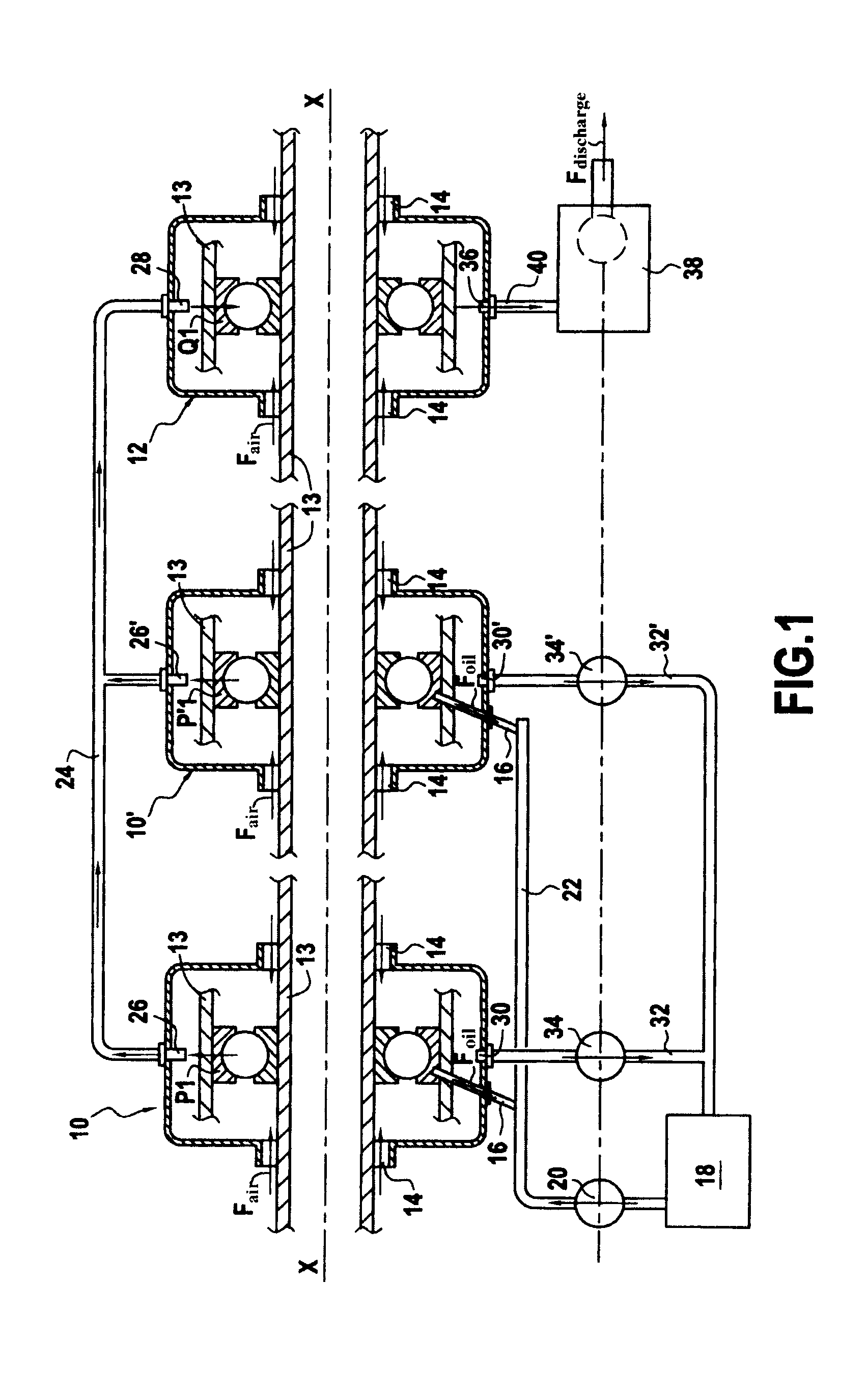

Cooling/lubricating device for machine tool feed shaft

ActiveUS20090229919A1Effective coolingEffective lubricationMachines/enginesPressure lubricationEngineeringMachine tool

By using the same liquid for cooling and lubricating a feed shaft, a simpler structure is obtained, thereby allowing easier maintenance. A feed shaft that is rotatably supported at one end thereof moves a slide of a machine tool. The feed shaft is supported by a support member via a bearing. A pipe is fitted to the feed shaft, and a pathway space is provided allowing the reciprocal flow of the cooling / lubricating liquid in the axial direction. Some of the cooling / lubricating liquid supplied via the support member to the feed space passes through the pathway space as cooling liquid, cools the feed shaft, and is held in a discharge space. At the same time, some of the cooling / lubricating liquid flows, as lubricating liquid, into the bearing, is discharged, and is held in a discharge space. The cooling / lubricating liquid in the discharge space that has absorbed the heat of the structure is immediately discharged out of the support member.

Owner:DMG MORI SEIKI CO LTD

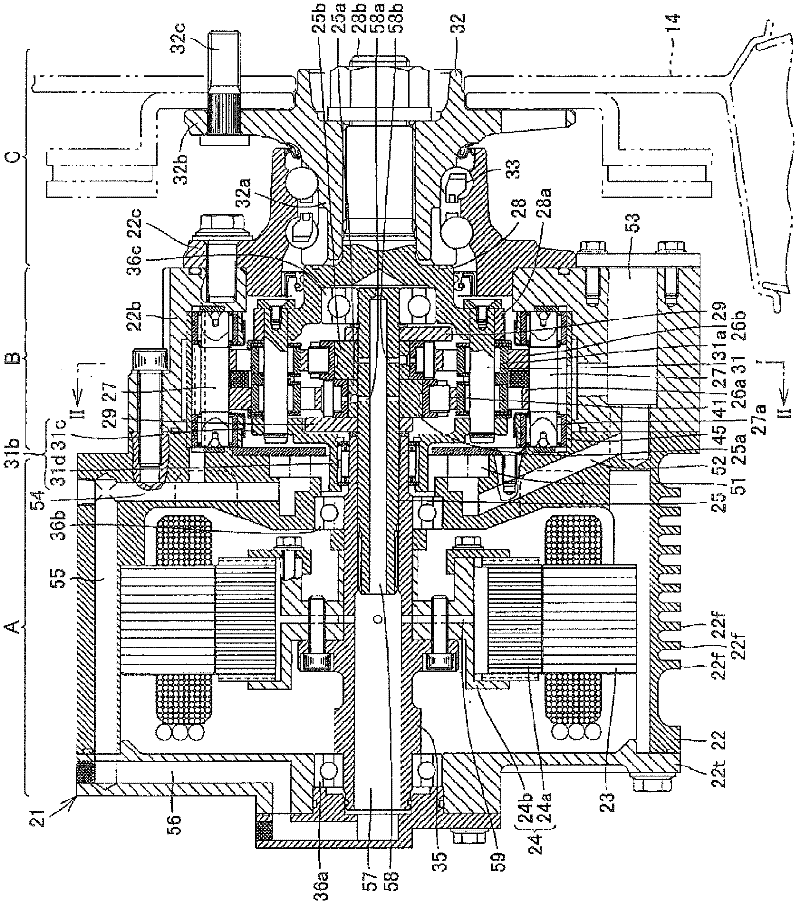

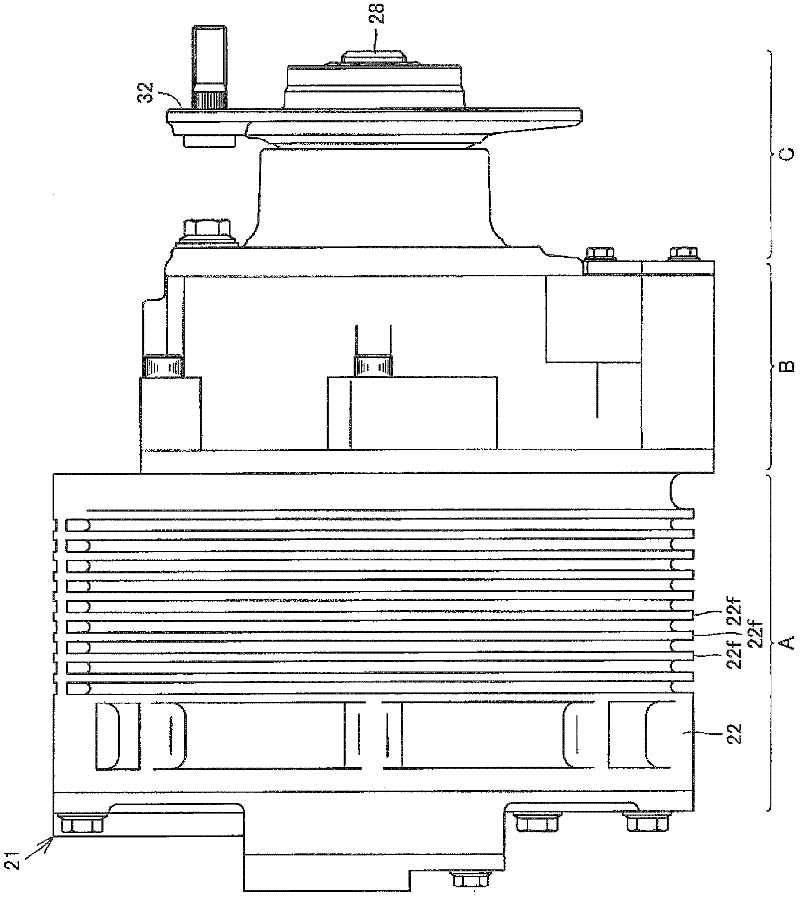

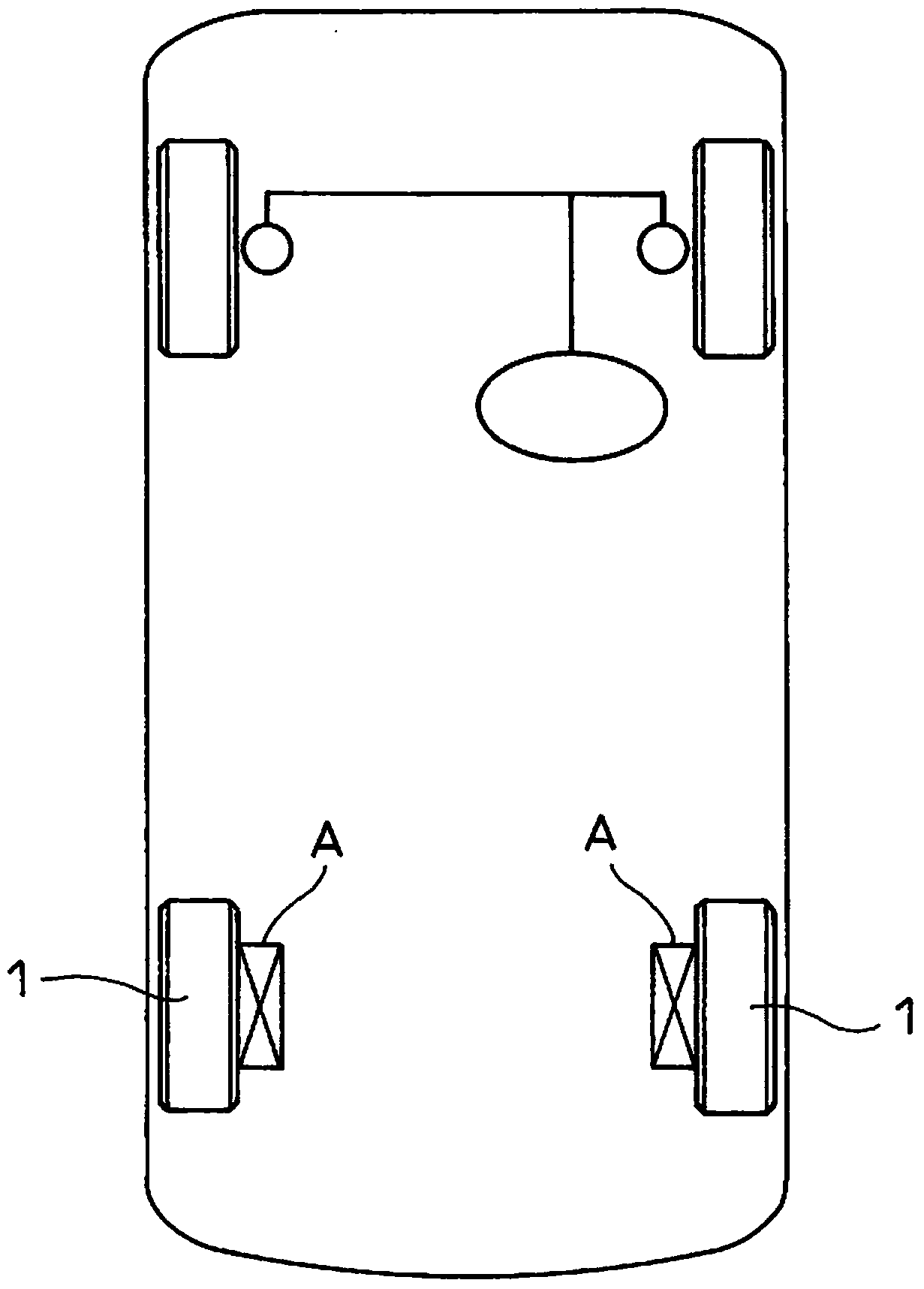

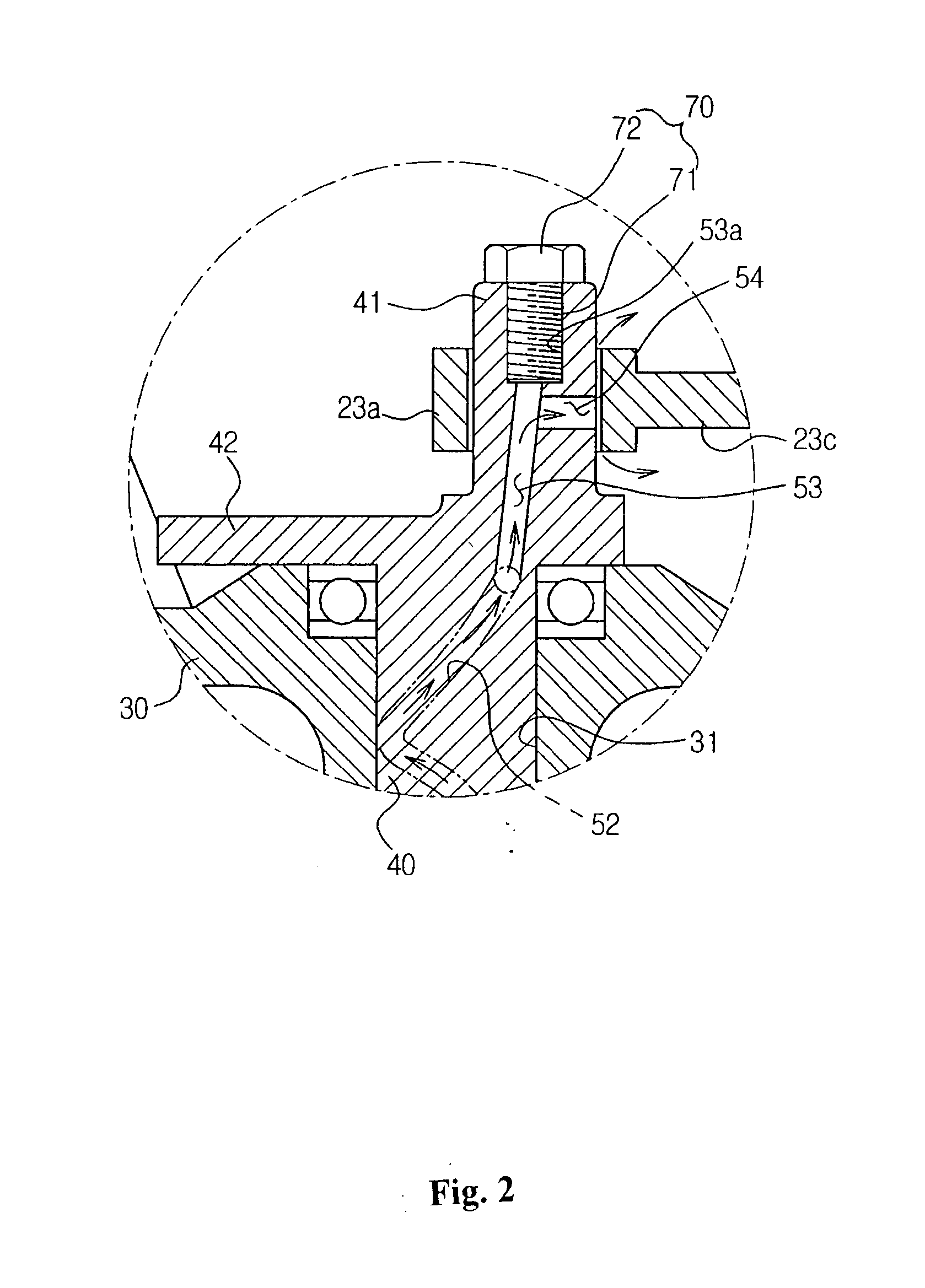

In-wheel motor drive device

ActiveCN102548783AAchieve lightweightEffective lubricationMagnetic circuit rotating partsElectric propulsion mountingMotor driveEngineering

An air-cooled, in-wheel motor drive device (21) is provided with a lubricating oil circuit which is configured in such a manner that a lubricating oil which is discharged from a lubricating oil pump (51) lubricates a reduction section (B) by flowing and circulating through oil paths (54, 55, 56) which are connected to each other and are provided in a casing (22), an oil path (57) which is provided in a motor's rotating shaft, an oil path (58) which is provided in the reduction section's input shaft, and the inside of the reduction section (B), and that the lubricating oil which flows through the oil paths (54, 55, 56), which are provided in the casing, and is cooled by outer peripheral fins (22f) cools a motor section (A) and the reduction section (B).

Owner:NTN CORP

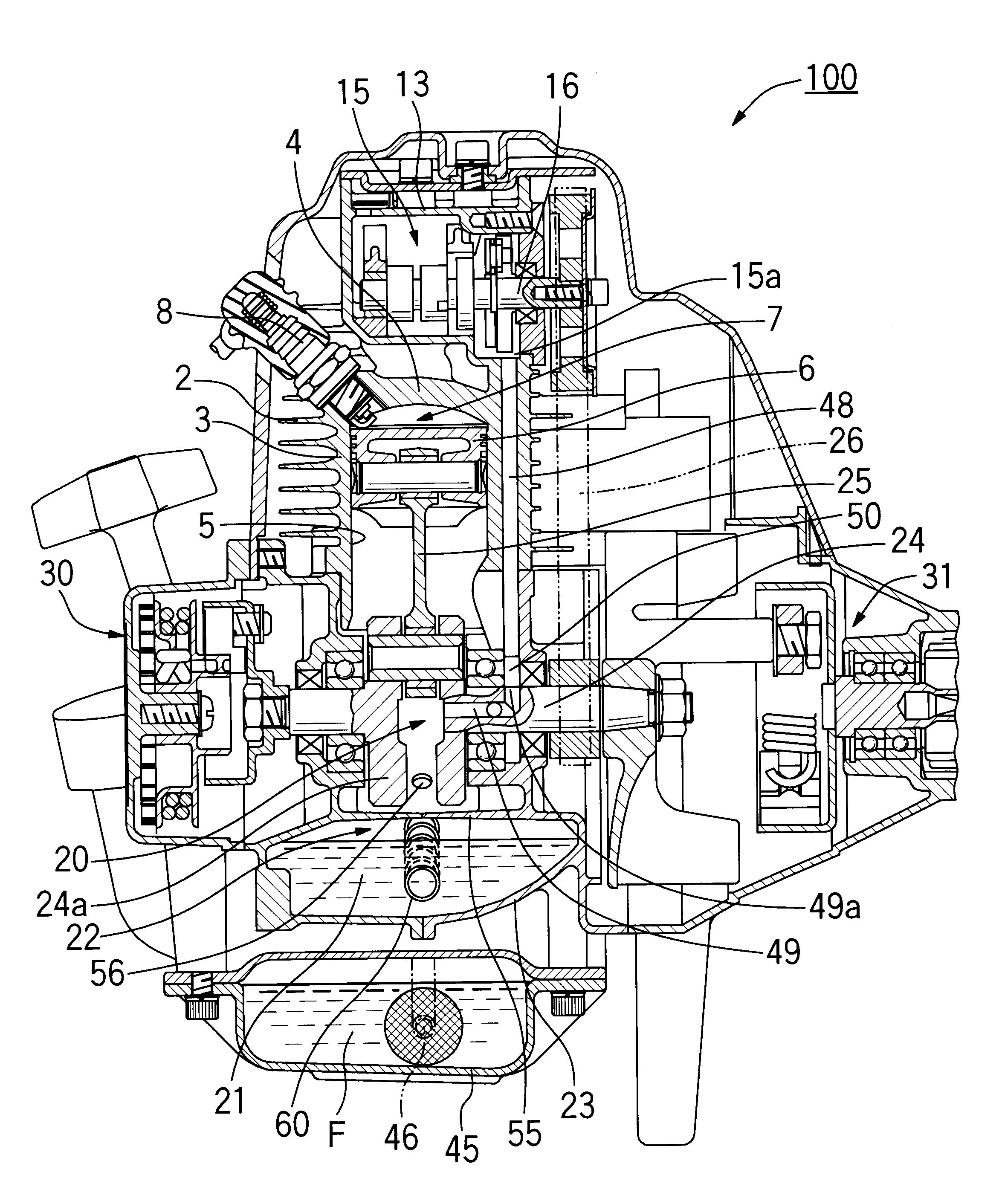

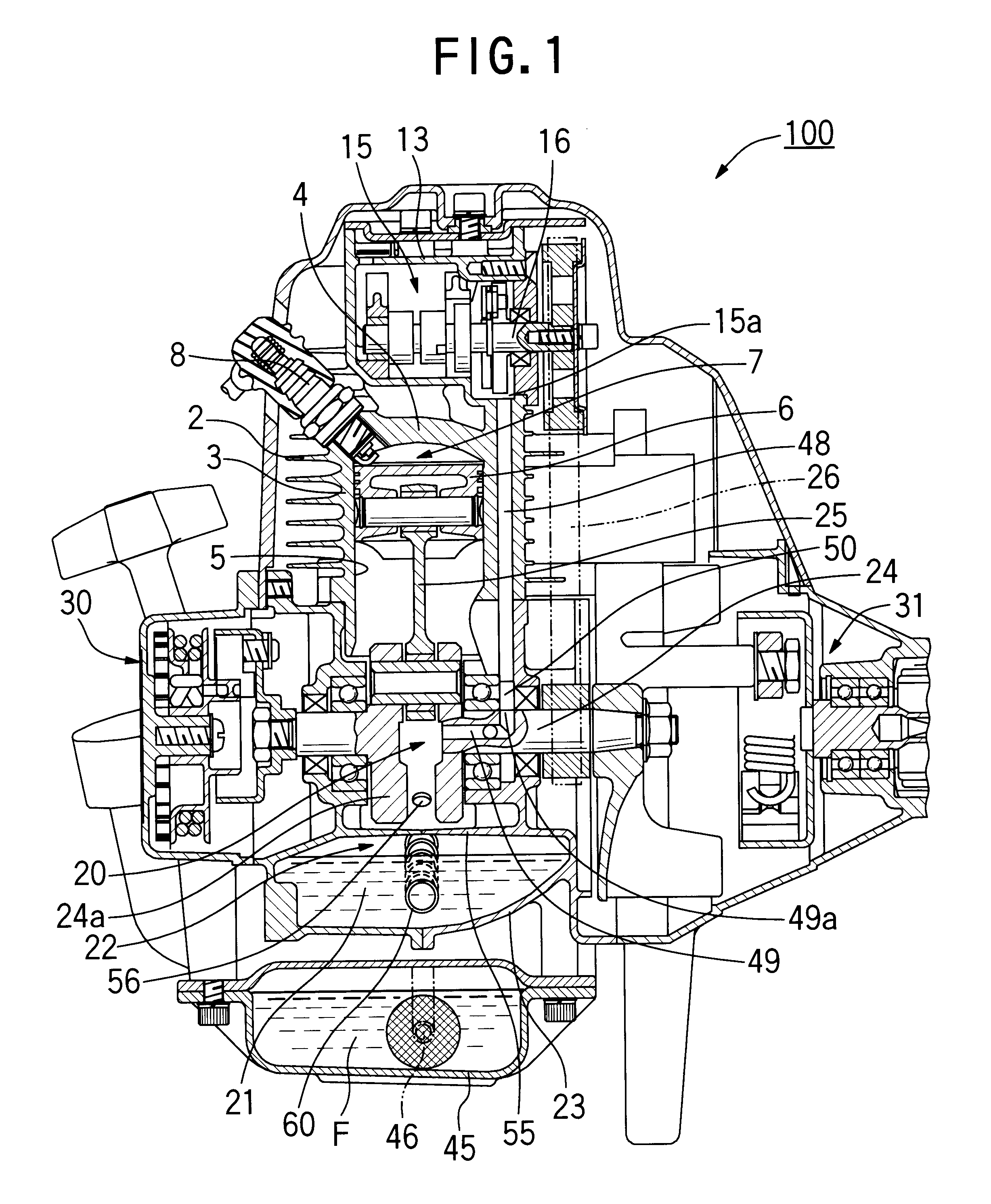

Internal combustion engine

InactiveUS6786187B2Amount of oil in can optimizedSimple structureCrankshaftsLubrication of auxillariesFuel tankEngineering

An internal combustion engine capable of optimizing the amount of oil in the crank chamber with a simplified structure of lubrication system, in which a U-shaped oil reservoir is formed surrounding and adjacent to a crank chamber. At least one small hole is formed on a partition wall which separates the oil reservoir and the crank chamber from each other so that the crank chamber may always communicate with the oil reservoir through the small hole. Due to a flow resistance in the small hole, a pressure Po in the oil reservoir changes following a change of pressure Pc in the crank chamber with some delay, and where the pressure difference between the oil reservoir and the crank chamber caused by a delay in the change of the pressure Po in the oil reservoir, results in the introduction of the oil in the oil reservoir into the crank chamber. It further allows excessive oil in the crank chamber to be circulated back into the oil reservoir.

Owner:KIORITZ

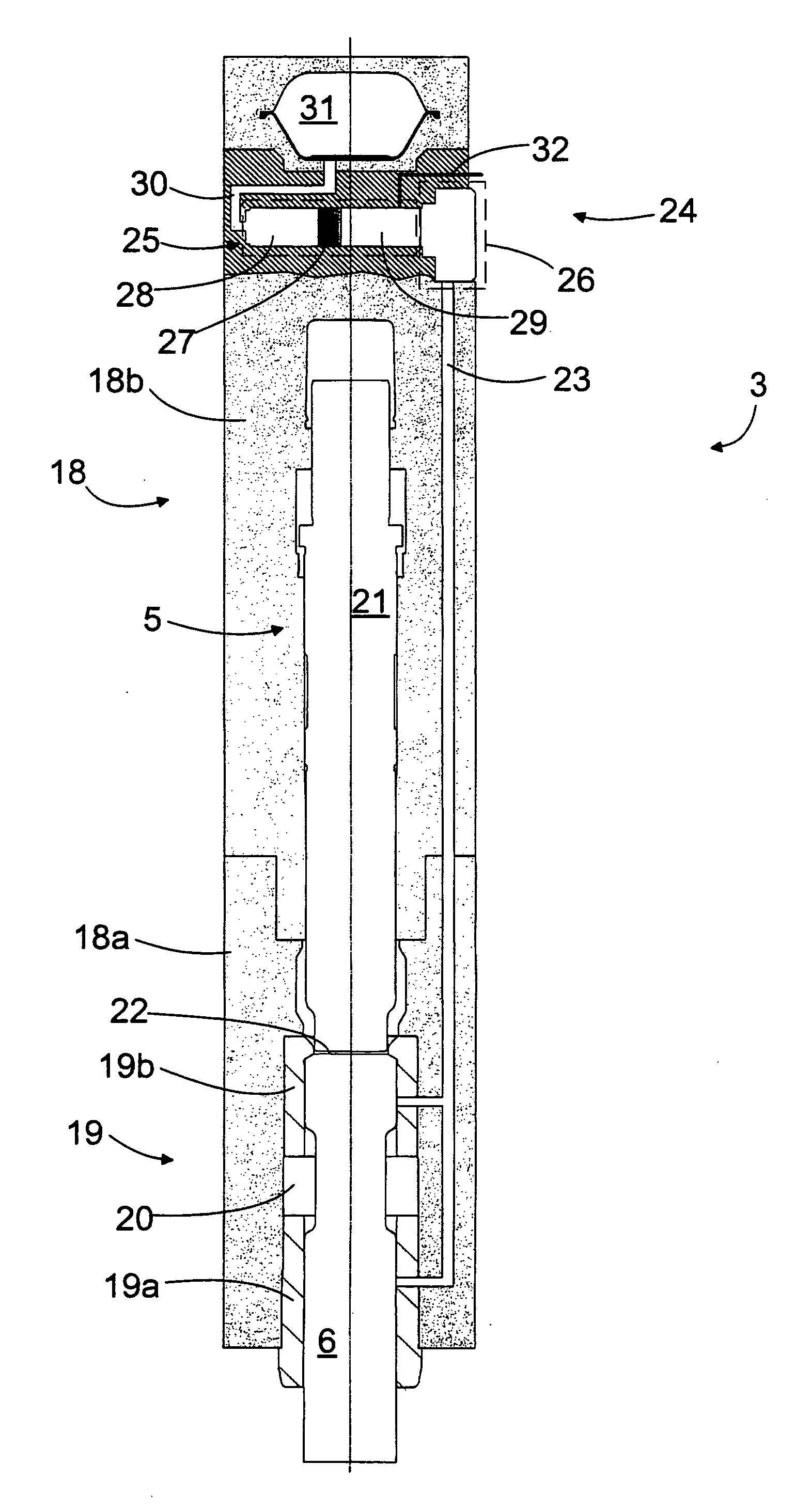

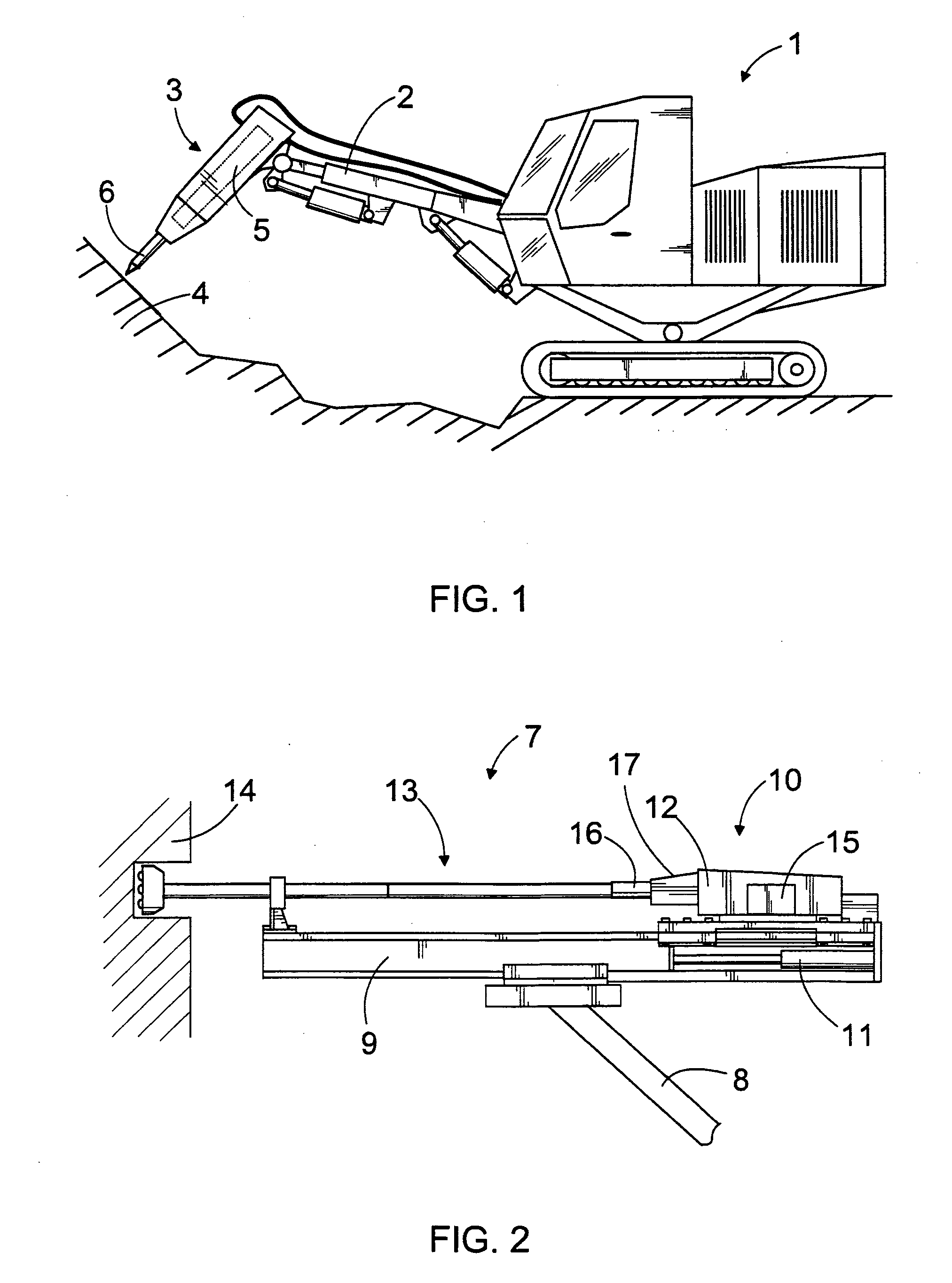

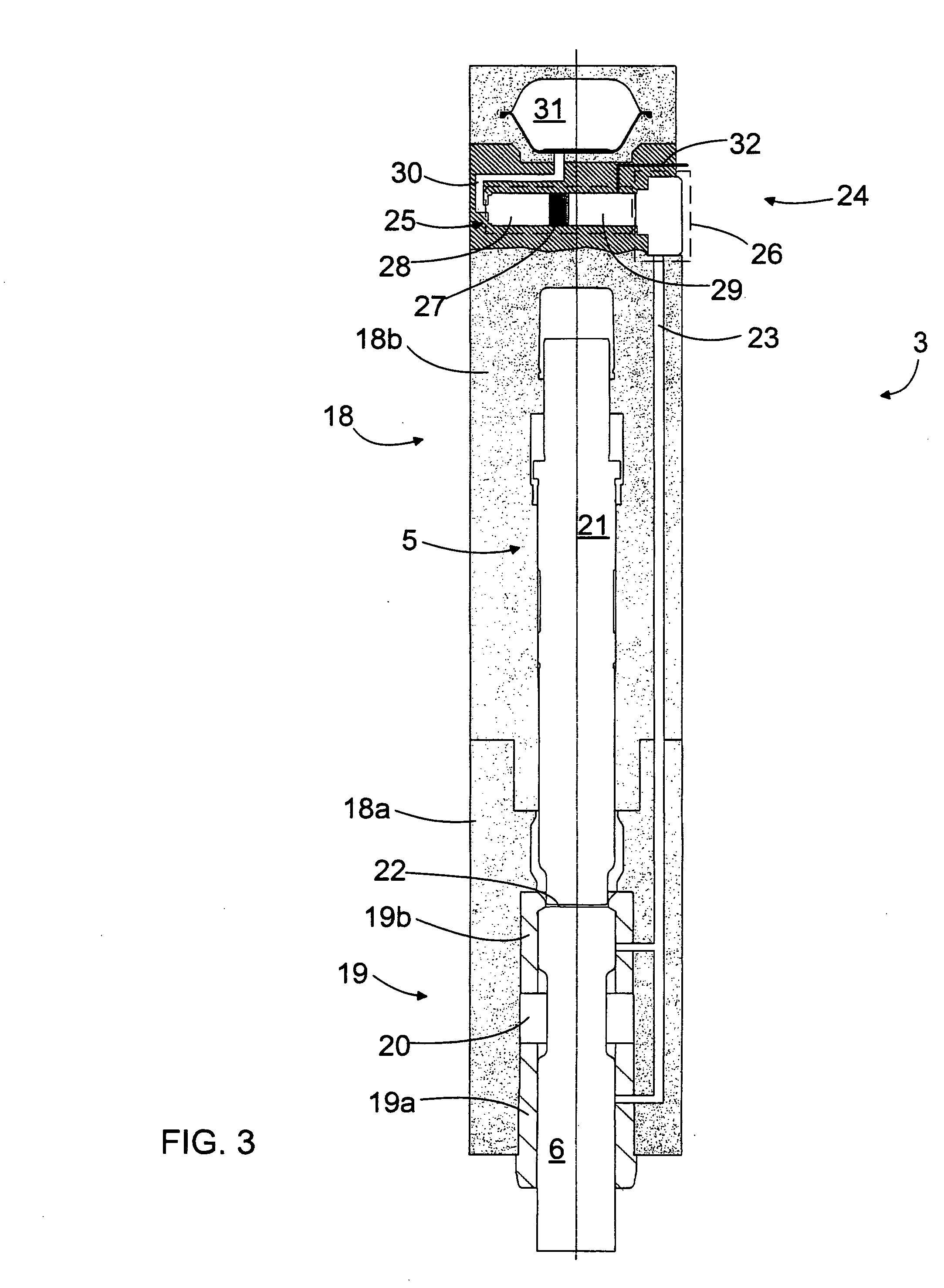

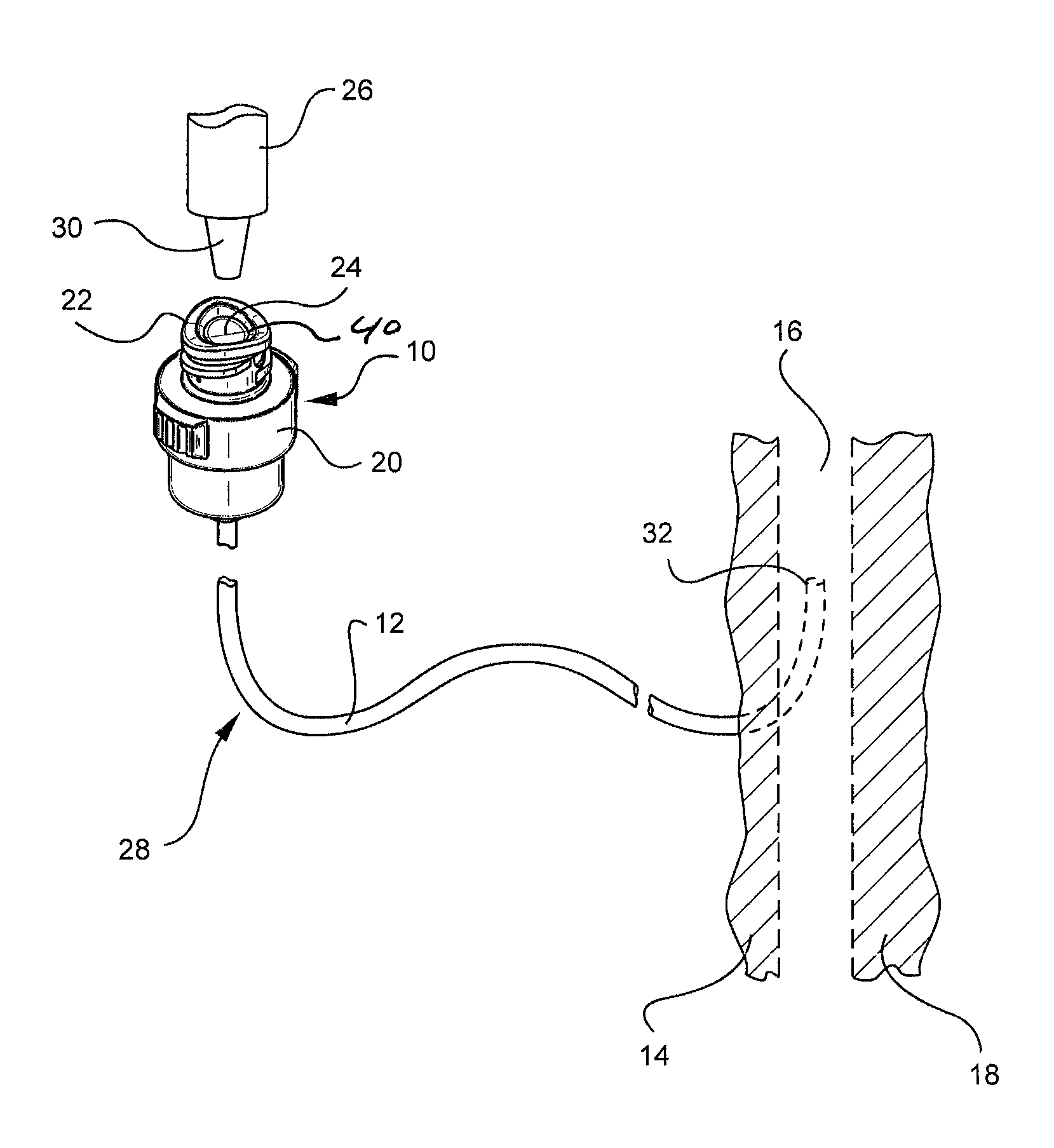

Rock breaking machine and lubricating method

InactiveUS20060048957A1Improve tool lifeEffective lubricationReciprocating drilling machinesSoil-shifting machines/dredgersEngineeringCrusher

A rock breaking machine and to a method of lubricating a tool of a rock breaking machine. The lubricating system comprises at least one lubricant channel (23) into which lubricant is fed by a lubricating device (24). Lubricant is supplied to the bearing members (19) of the tool (6, 13) of the rock breaking machine. The lubricating device comprises a lubricant container (25) and a transfer device (26). The transfer device (26) controls the feed of lubricant into the lubricant channel. The lubricant container (25) is integrated into the body (17, 18) of the rock breaking machine.

Owner:SANDVIK MINING & CONSTR OY

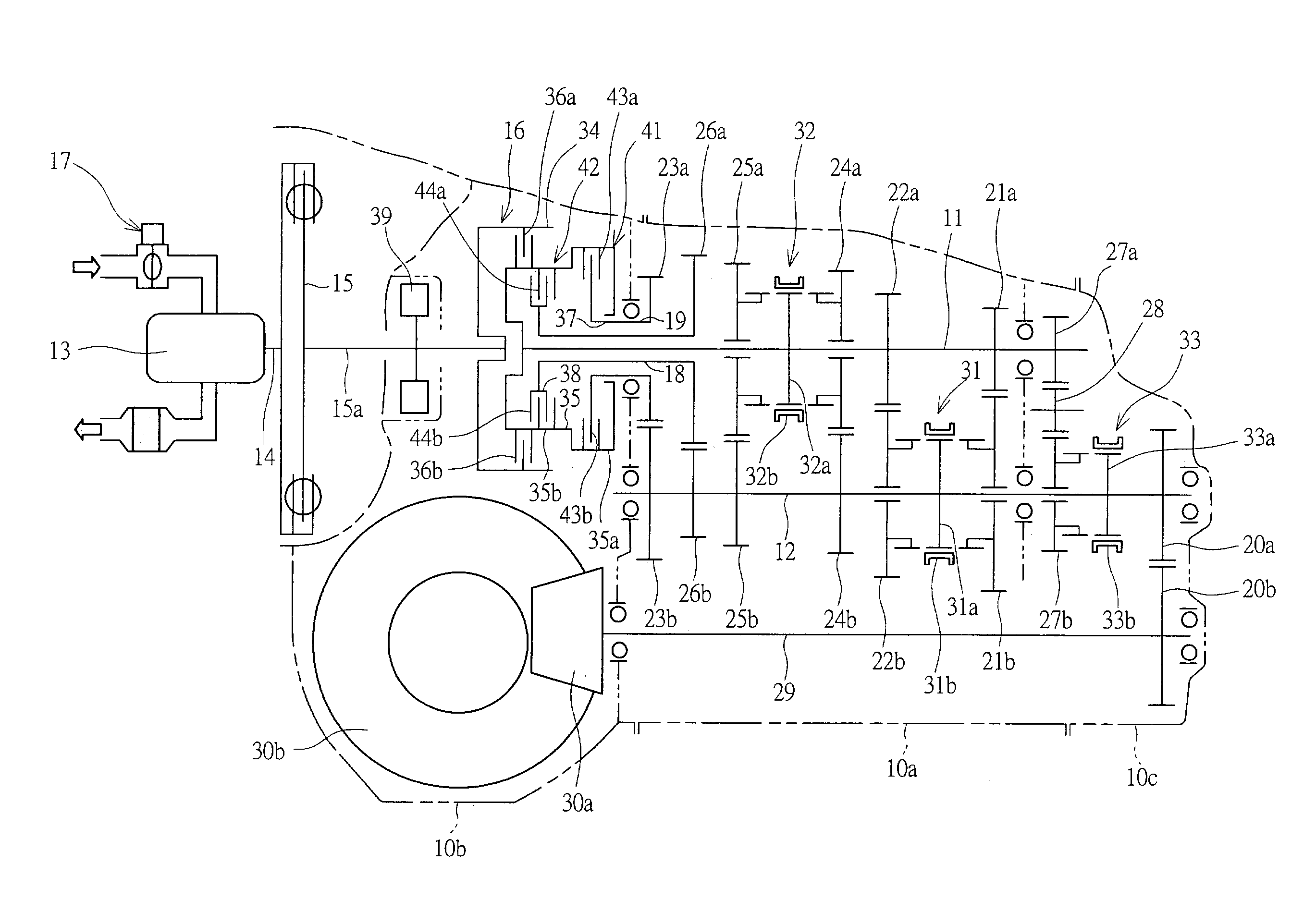

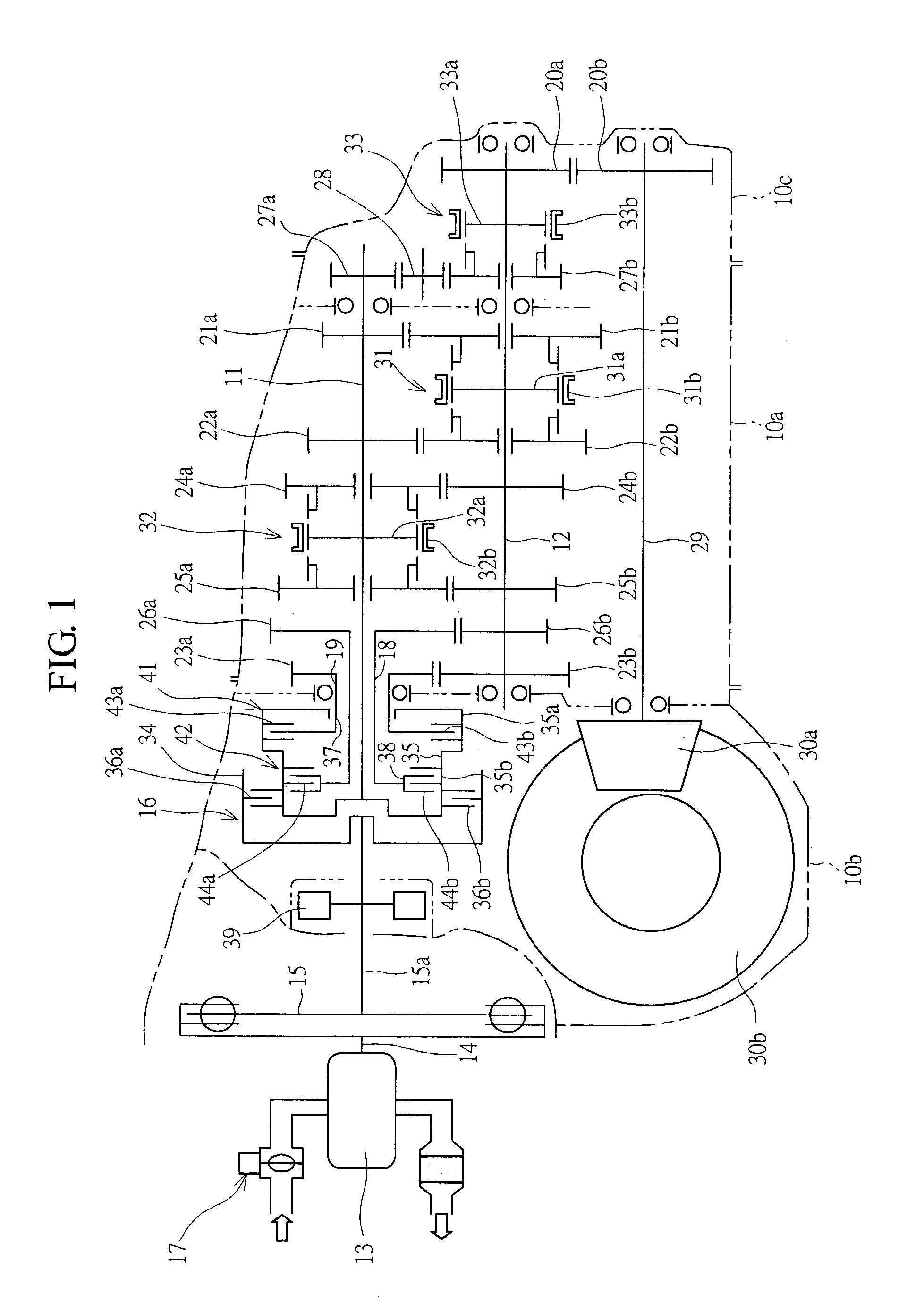

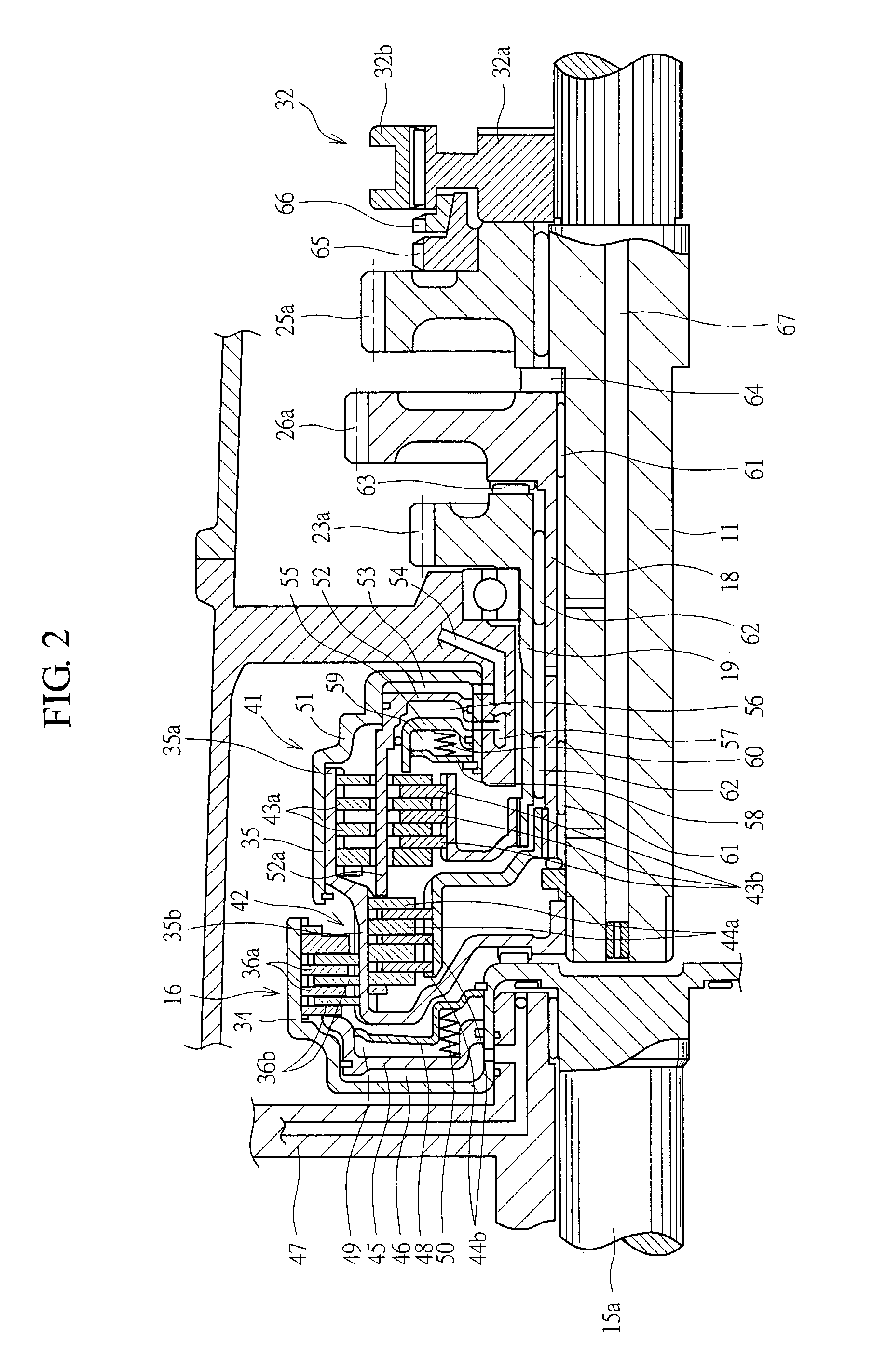

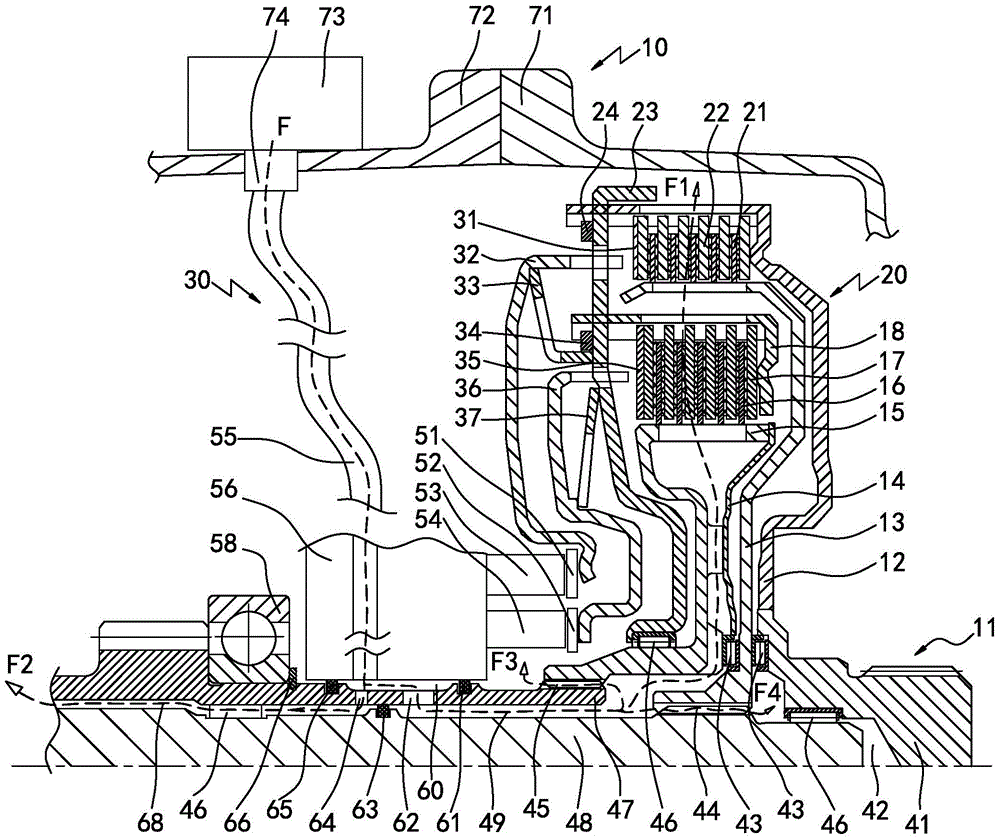

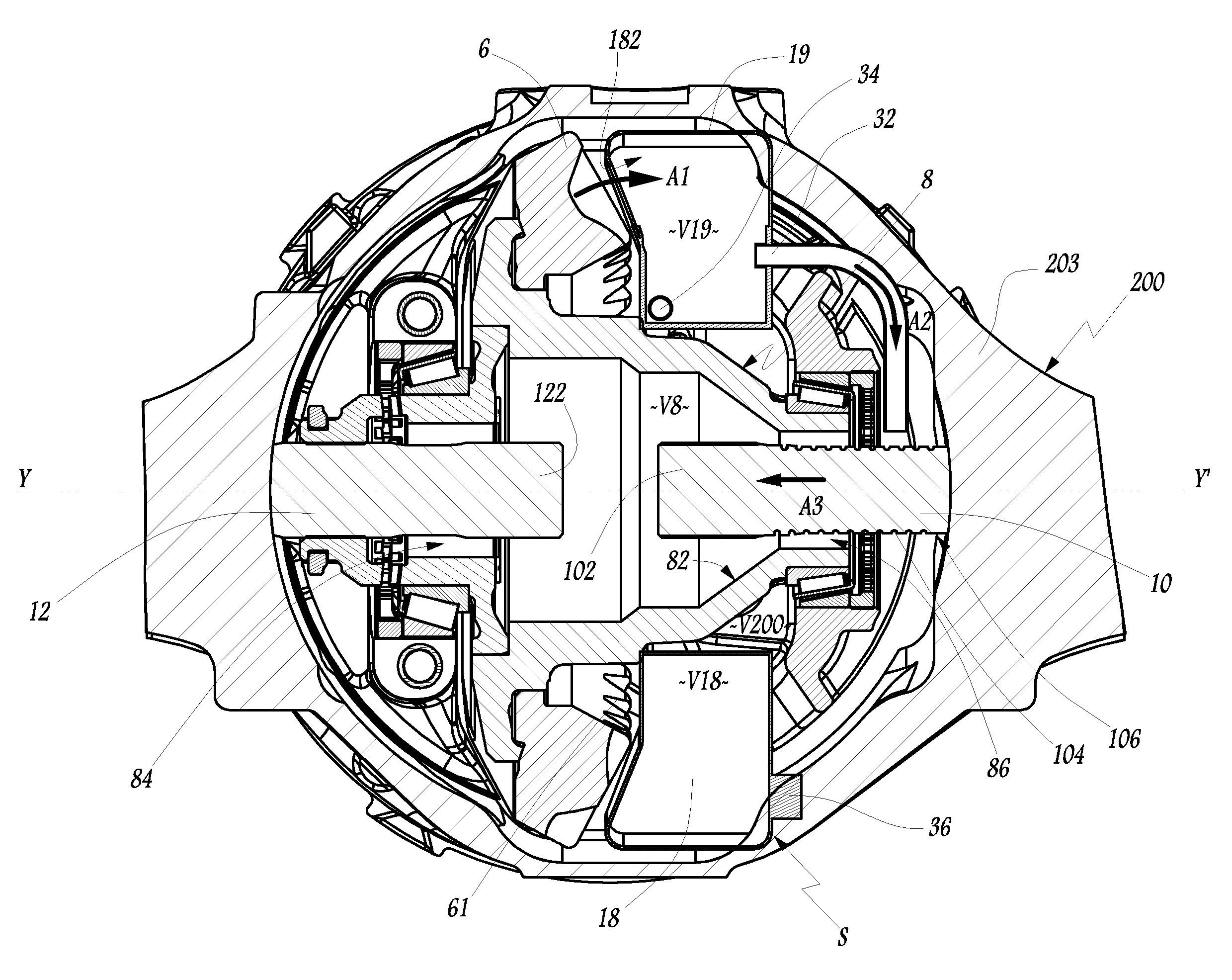

Double-clutch lubricating structure for double-clutch gear box

ActiveCN104061319AImprove securityEffective lubricationFluid actuated clutchesGear lubrication/coolingEngineeringClutch

The invention discloses a double-clutch lubricating structure for a double-clutch gear box. An electronic oil pump is connected with four lubricating channels through lubricating oil pipes and an oil storage cavity respectively, wherein the main components of the double-clutch, namely a first clutch and a second clutch, are lubricated and cooled by the lubricant liquid of the first lubricating channel; a first input shaft and a second input shaft of the double-clutch gear box are lubricated and cooled by the lubricant liquid of the second lubricating channel; a clutch separation device is lubricated and cooled by the lubricant liquid of the third lubricating channel; a bearing between the first input shaft and a driving device is lubricated and cooled by the lubricant liquid of the fourth lubricating channel. The double-clutch lubricating structure excellently solves the problem that a conventional cooling and lubricating system in a double-clutch gear box is complex in structure, high in cost and low in reliability, and is susceptible to potential safety hazard; the double-clutch lubricating structure provided by the invention is simple in structure, high in reliability and good in safety, and has very high practical value.

Owner:NINGBO SHANGZHONGXIA AUTOMATIC TRANSMISSION

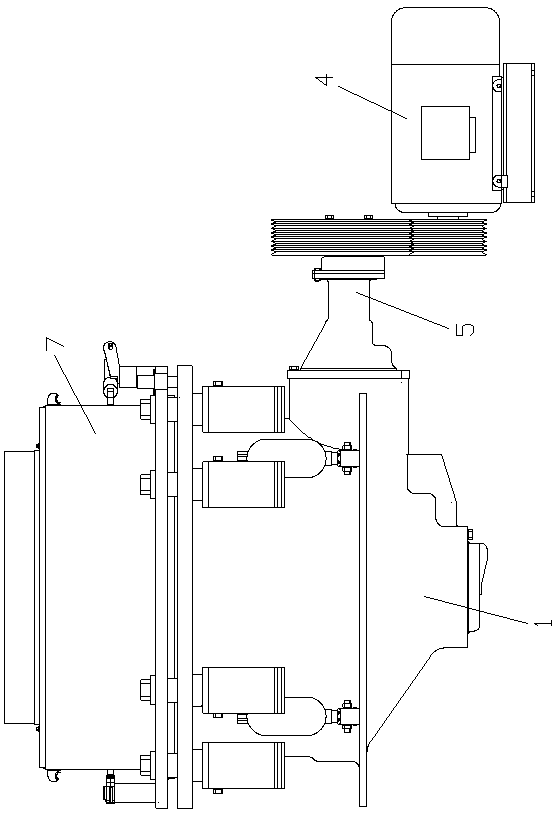

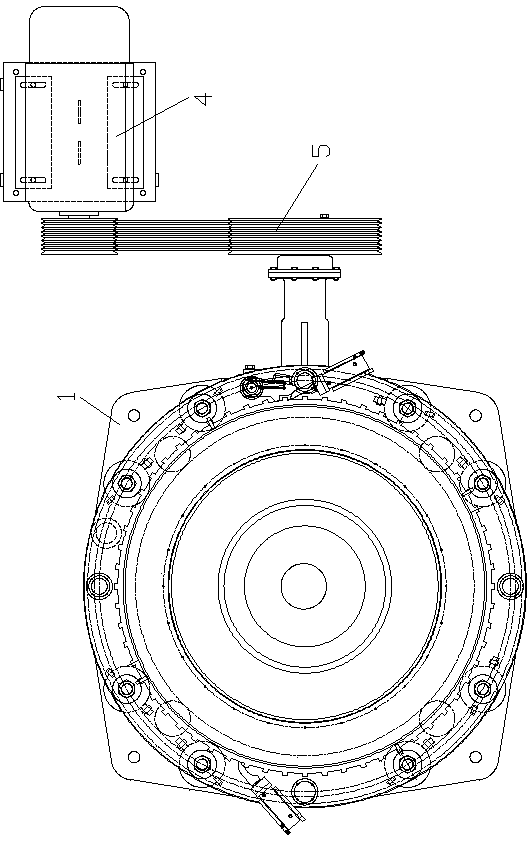

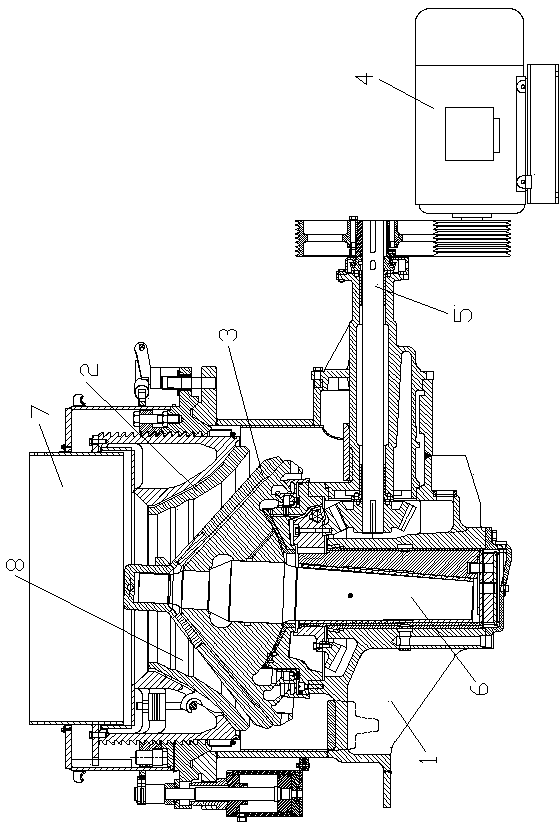

Oiling nozzle for thrust bearing

ActiveUS20100215299A1Efficiently supplySuppress increase in metal temperatureEngine manufactureBearing assemblyNozzleGasket

Provided is an oiling nozzle for a thrust bearing, capable of improving the following capability of pads, and achieving a higher bearing pressure of the thrust bearing. An oiling nozzle which is for use in a thrust bearing and is respectively arranged between pads disposed in positions facing the thrust surface of a thrust collar that protrudes radially outward from a rotor shaft, along the circumferential direction, wherein the oiling nozzle comprises: a cylindrical stem; and a rectangular-shaped mainframe whose heightwise middle portions of opposite lateral sides are provided with convex parts each presenting a semicircular disk shape in a plane view, to be fitted into concave parts that are formed in lateral sides of the pads, and whose top portion located on the side opposite to the stem is formed with a plurality of nozzle holes for ejecting lubricating oil that has been supplied from the bottom of the stem toward a space between the thrust collar and the pads.

Owner:MITSUBISHI HEAVY IND LTD

Large-scale energy-efficient high-efficiency cone crusher

The invention relates to a large-scale energy-efficient high-efficiency cone crusher, which comprises a rack, an upper lining plate, a lower lining plate, an electromotor, a transmission device, a crushing cone mechanism and a crushing cavity control mechanism, and is characterized in that the crushing cavity control mechanism consists of a feed hopper, a supporting sleeve, an adjusting sleeve, an outer gear ring, a push cylinder, a locking ring, 16 locking cylinders, 8 hydraulic cylinders and 4 jacks, wherein the supporting sleeve is movably connected to the rack, the adjusting sleeve is in threaded connection into the locking ring and the supporting sleeve, the 16 locking cylinders are all arranged on the supporting sleeve, the feed hopper is fixedly arranged on the adjusting sleeve, the outer gear ring is fixedly arranged on the feed hopper, and the push cylinder and the outer gear ring are matched; lifting ends of the 4 jacks are all supported against the bottom surface of a flange ring of the supporting sleeve; the crushing cone mechanism consists of an eccentric sleeve, a cone gear, an eccentric shaft, a crushing cone, a bowl-shaped bearing and a bowl-shaped bearing sealing ring. According to the large-scale energy-efficient high-efficiency cone crusher, the size of a crushing cavity and the size of a throat can be adjusted, and the cavity cleaning operation is convenient.

Owner:海盐机械厂 +1

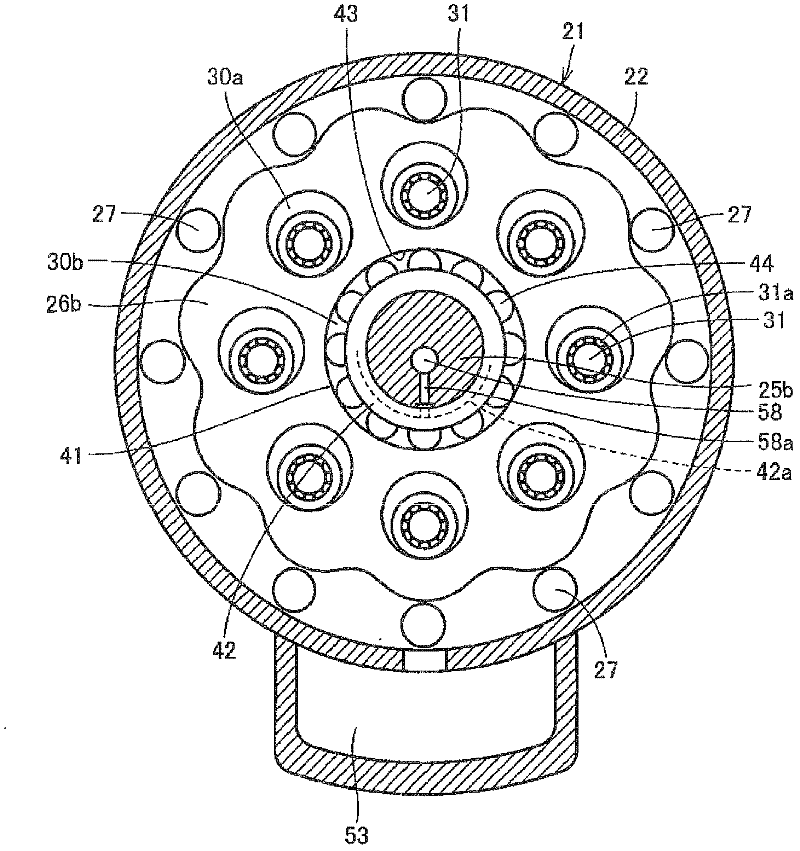

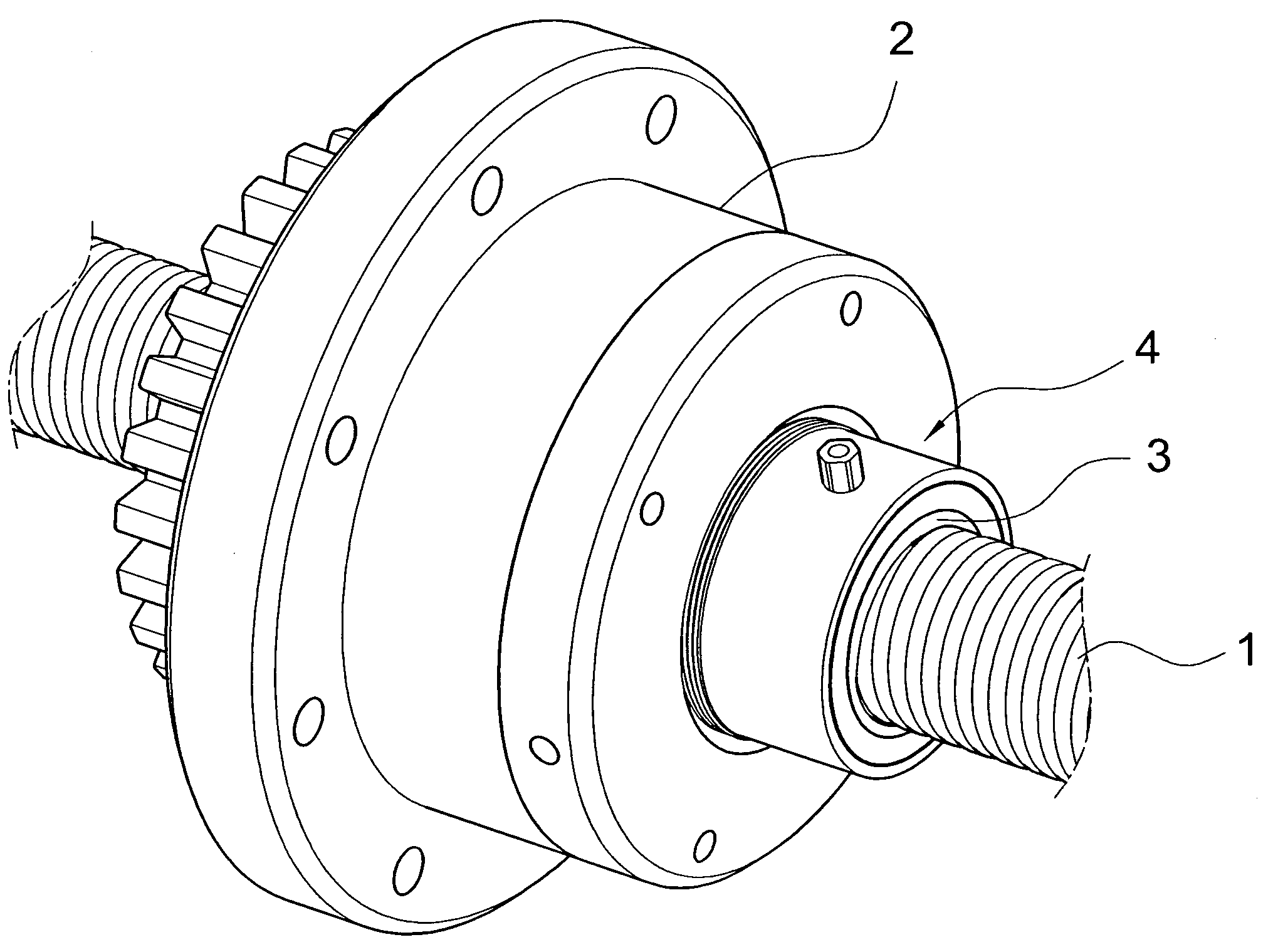

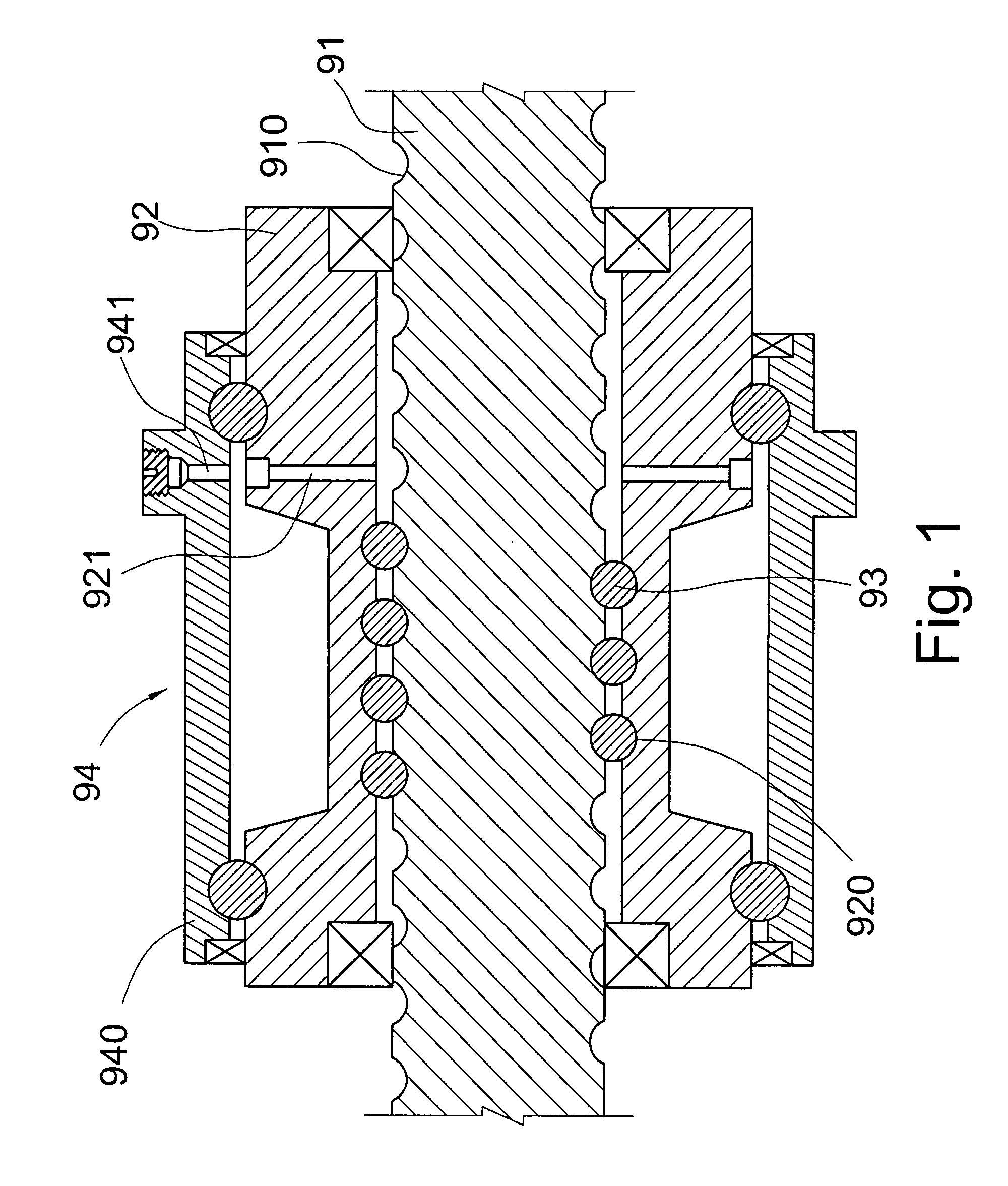

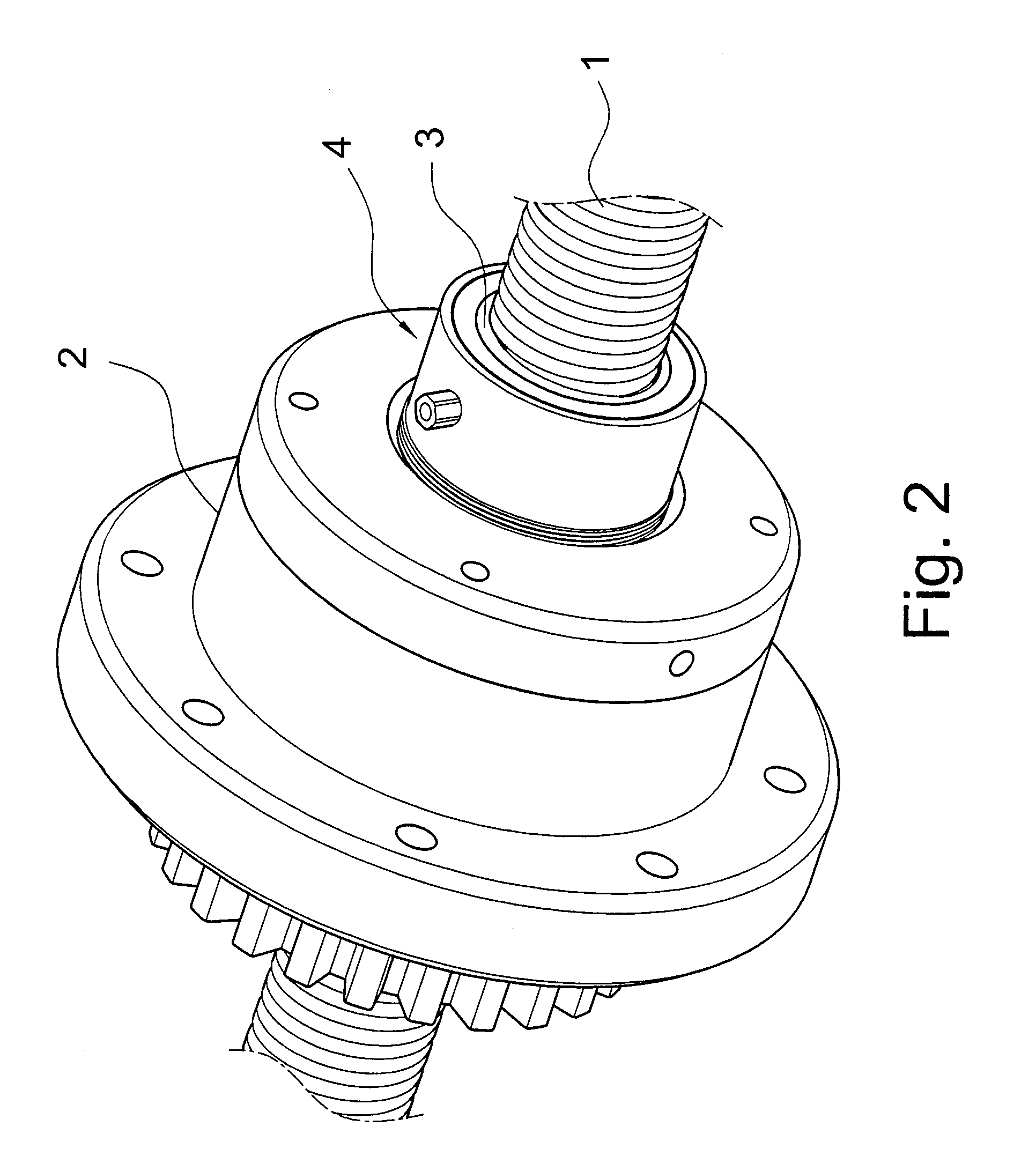

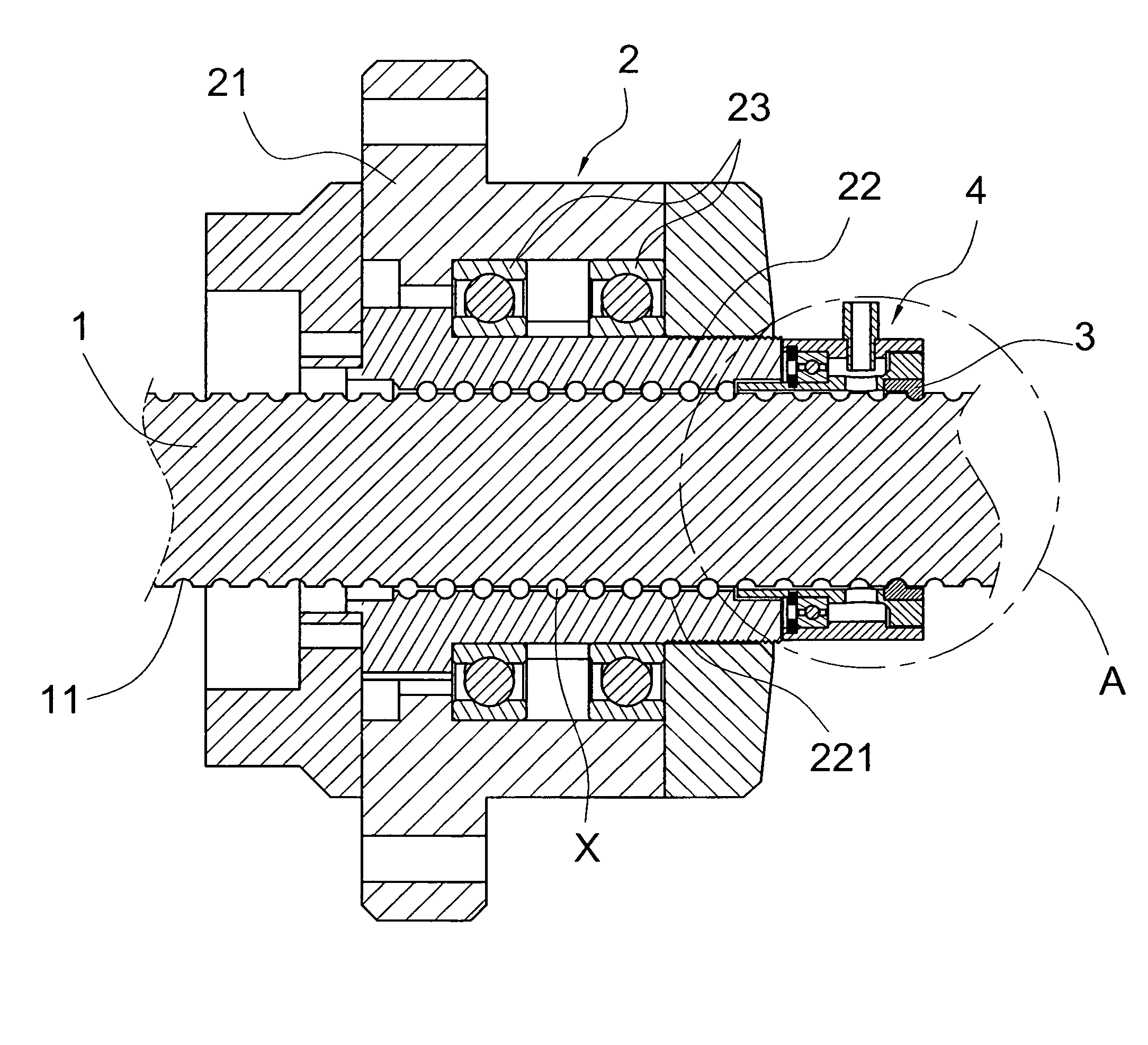

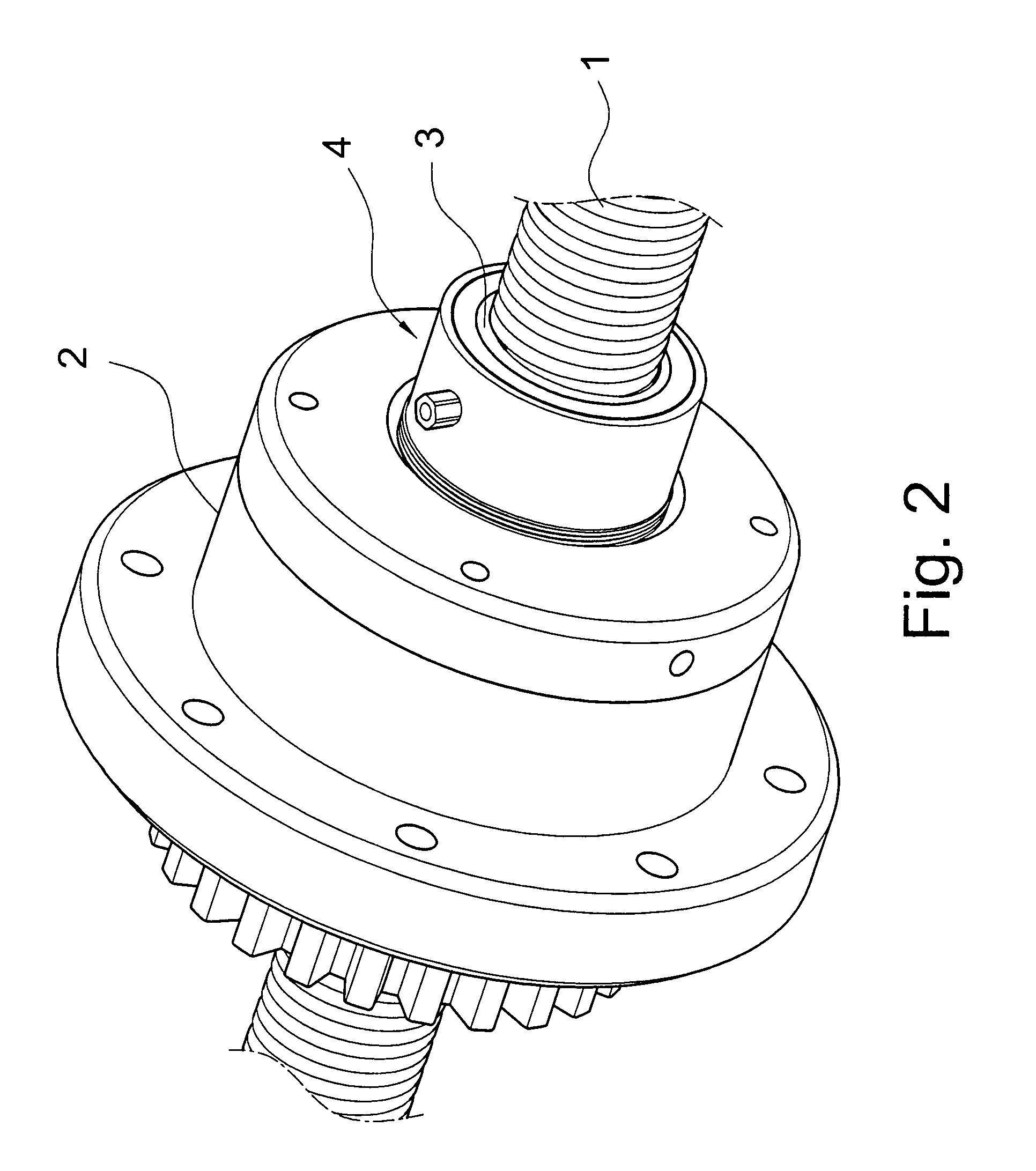

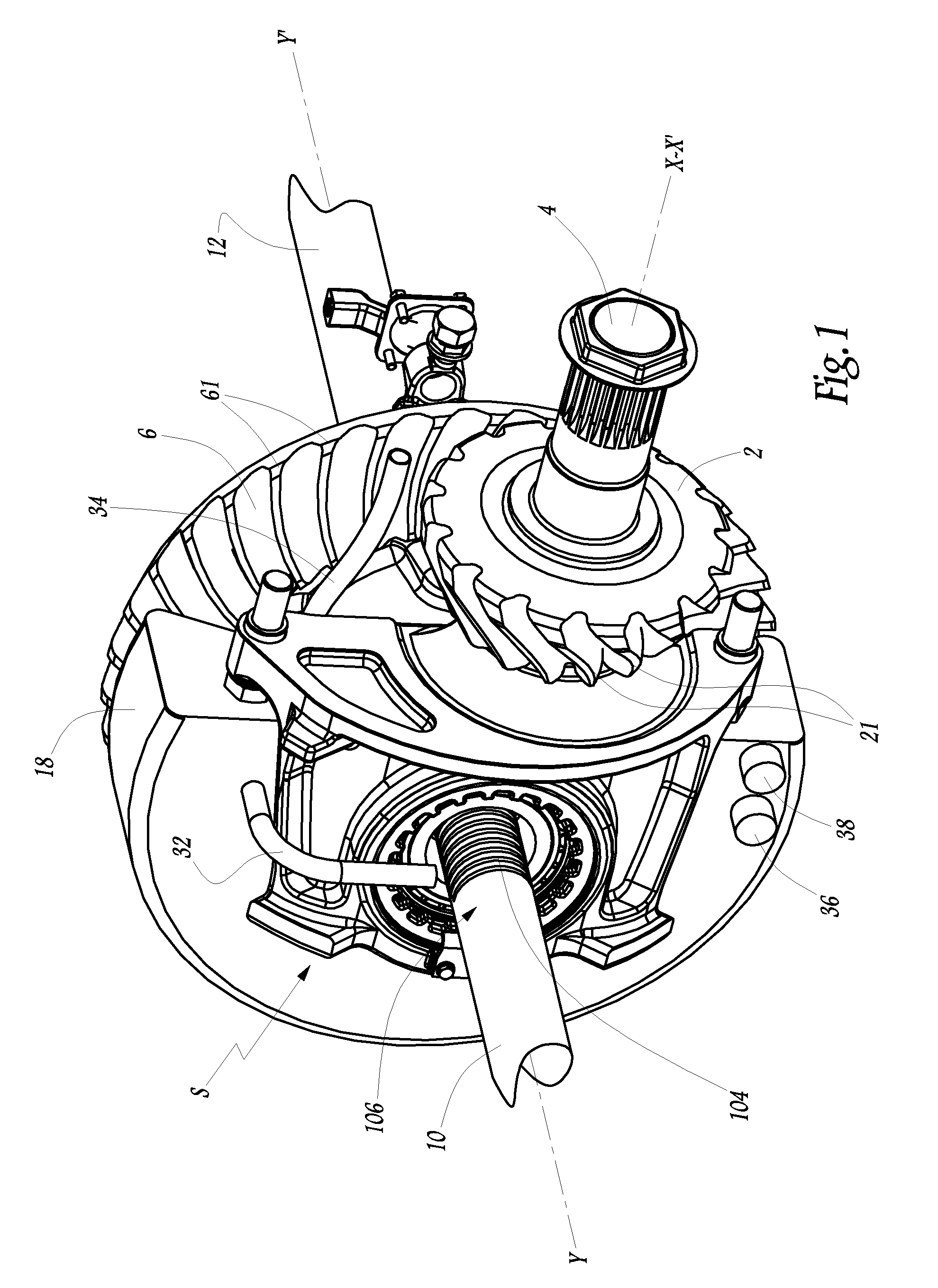

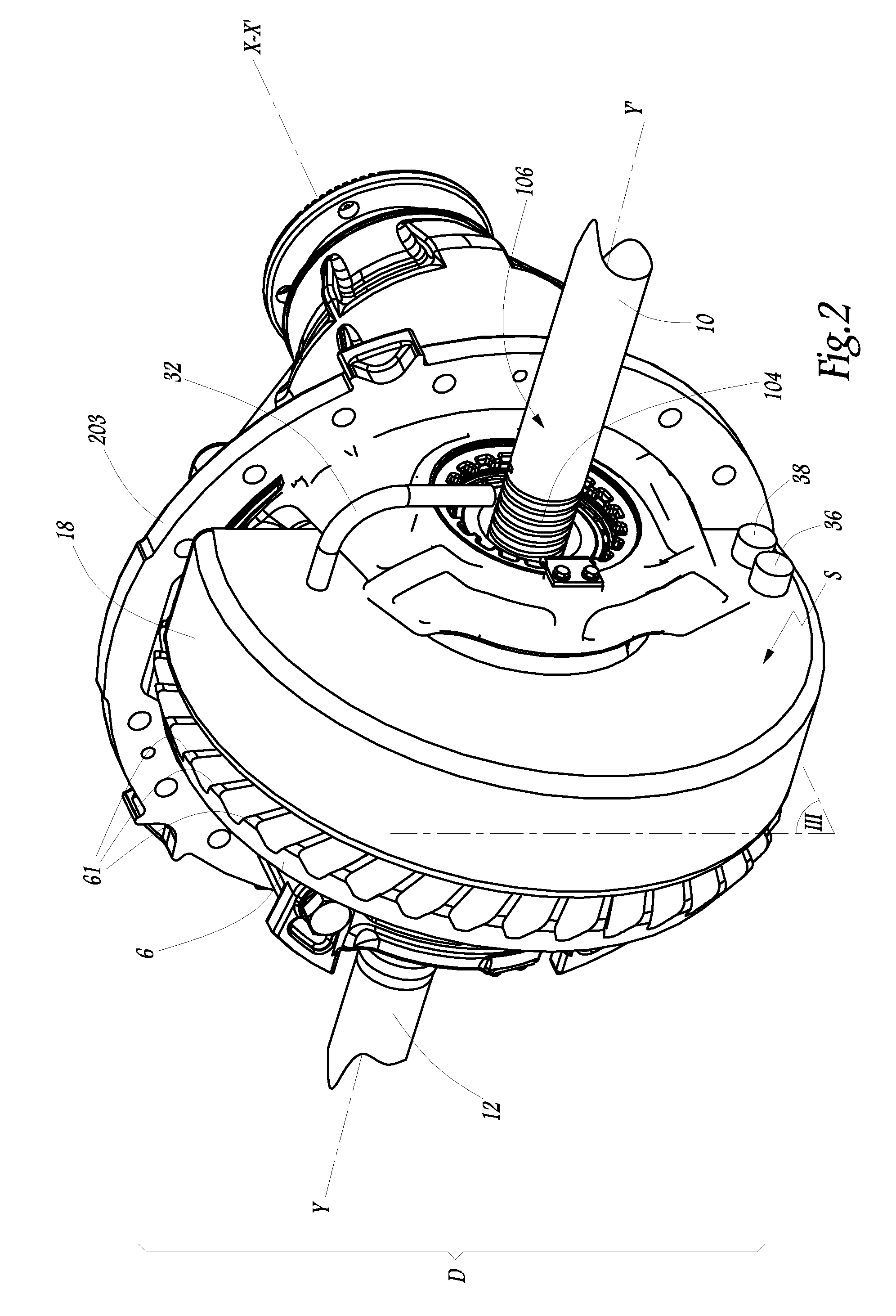

Rotating Nut Ball Screw Unit with Lubricating Arrangement

ActiveUS20090133520A1Effectively lubricateEffective lubricationToothed gearingsGear lubrication/coolingLubricationEngineering

The rotating nut ball screw unit with lubricating arrangement has a lubricating device composed of a main body, a collar and a bearing. The main body is provided with several oil holes and is attached to the end surface of the nut. The main body is relatively rotatable with respect to the collar intercalating the bearing therebetween. An oil storage forces the lubricant into an oil reserving space surrounded by the main body, the collar and the bearing. The oil reserving space is in communication with the oil holes and allows the lubricant to be forced into the main body and then to reach the surface of the screw bolt via oil holes. The forced lubrication arrangement of the present invention ensures a better lubricating effect.

Owner:HIWIN TECH

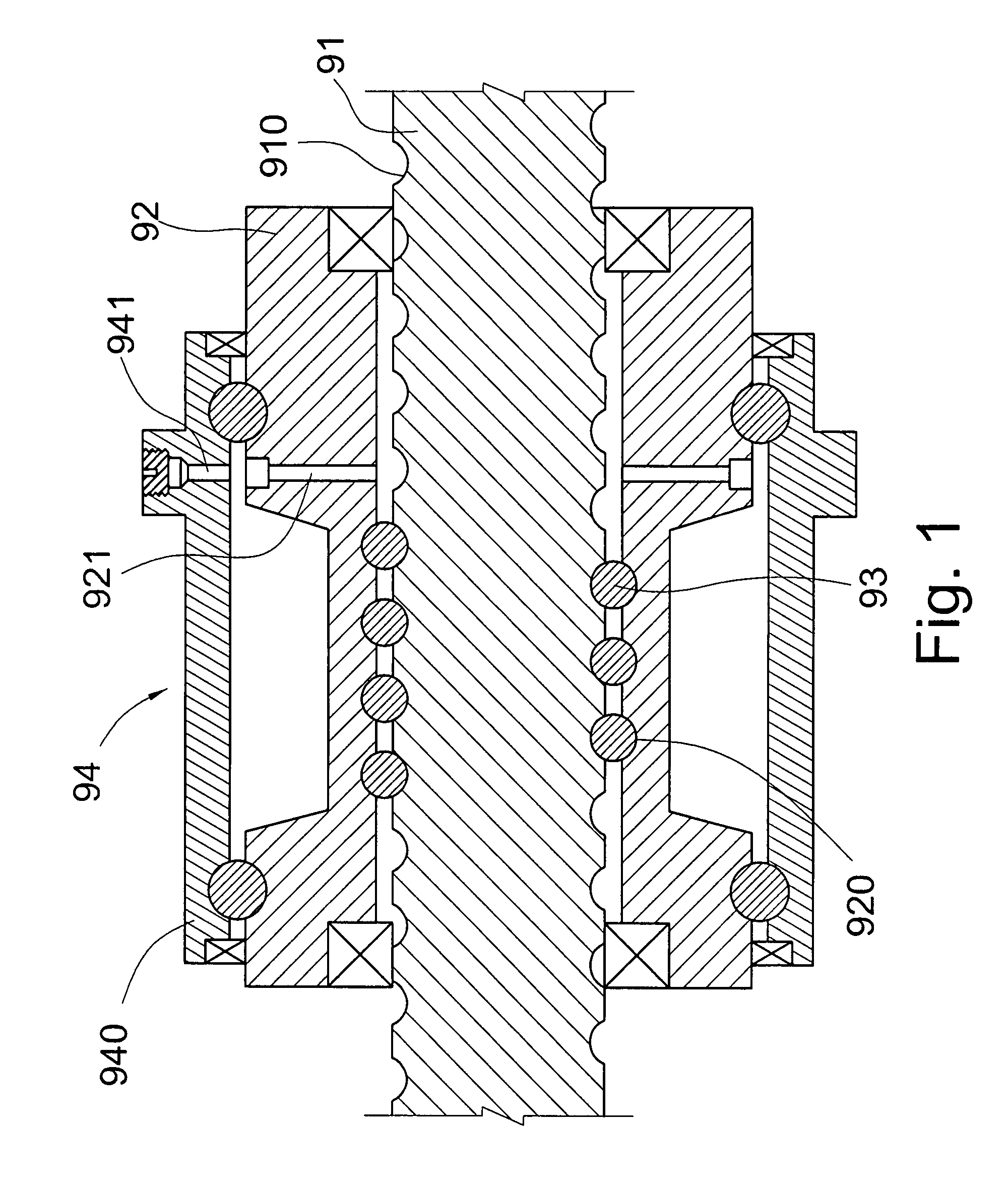

In-wheel motor drive device

InactiveCN103874871AEffective lubricationReliable bootSpeed controllerElectric devicesMotor driveElectric motor

An in-wheel motor drive assembly is provided of which a reduction mechanism and a bearing supporting a rotor shaft can be reliably lubricated with oil. The assembly includes a motor case (10) defining a motor chamber (17) and a reduction mechanism chamber (18) provided on one side of and isolated from the motor chamber by a partition wall (16). An electric motor (30) is mounted in the motor chamber (17). A planetary gear type reduction mechanism (40) is mounted in the reduction mechanism chamber (18), and is adapted to reduce the rotation of the electric motor (30) and output the reduced rotation to a hub ring (65). The reduction mechanism (40) is lubricated by lubricating oil stored in the reduction mechanism chamber (18). A tapered oil guide surface (21) is formed at the center of the inner surface of the partition wall (16) facing the reduction mechanism chamber (18). The oil guide surface (21) guides lubricating oil splashed up by the rotating reduction mechanism and flowing down along the inner surface of the partition wall (16), onto the rotor shaft (34) of the electric motor (30), thereby lubricating bearings (47) mounted on the rotor shaft (34).

Owner:NTN CORP

Rotating nut ball screw unit with lubricating arrangement

The rotating nut ball screw unit with lubricating arrangement has a lubricating device composed of a main body, a collar and a bearing. The main body is provided with several oil holes and is attached to the end surface of the nut. The main body is relatively rotatable with respect to the collar intercalating the bearing therebetween. An oil storage forces the lubricant into an oil reserving space surrounded by the main body, the collar and the bearing. The oil reserving space is in communication with the oil holes and allows the lubricant to be forced into the main body and then to reach the surface of the screw bolt via oil holes. The forced lubrication arrangement of the present invention ensures a better lubricating effect.

Owner:HIWIN TECH

Multi-part piston for an internal combustion engine and method for its production

InactiveUS20100108000A1Easy to produceImprove cooling effectAir coolingMachines/enginesFriction weldingExternal combustion engine

A multi-part piston for an internal combustion engine has an upper piston part having a piston crown, and a lower piston part. The lower piston part has pin boss supports and pin bosses connected with them and the upper piston part and the lower piston part each have an inner and an outer support element, which elements delimit an outer circumferential cooling channel. The inner support elements delimit a cavity that is open toward the pin bosses. The cavity has a separate cooling oil collector that has at least one cooling oil opening. The piston is produced by manufacturing the upper piston part and lower piston part, inserting the cooling oil collector into the upper piston part or lower piston part, and joining the upper and lower piston parts together by friction welding.

Owner:MAHLE INT GMBH

Antimicrobial lubricant compositions

ActiveUS8426348B2Reduce complicationsFacilitate smooth and reliable actuationBiocidePretreated surfacesChlorhexidine AcetateAmmonium compounds

Owner:BECTON DICKINSON & CO

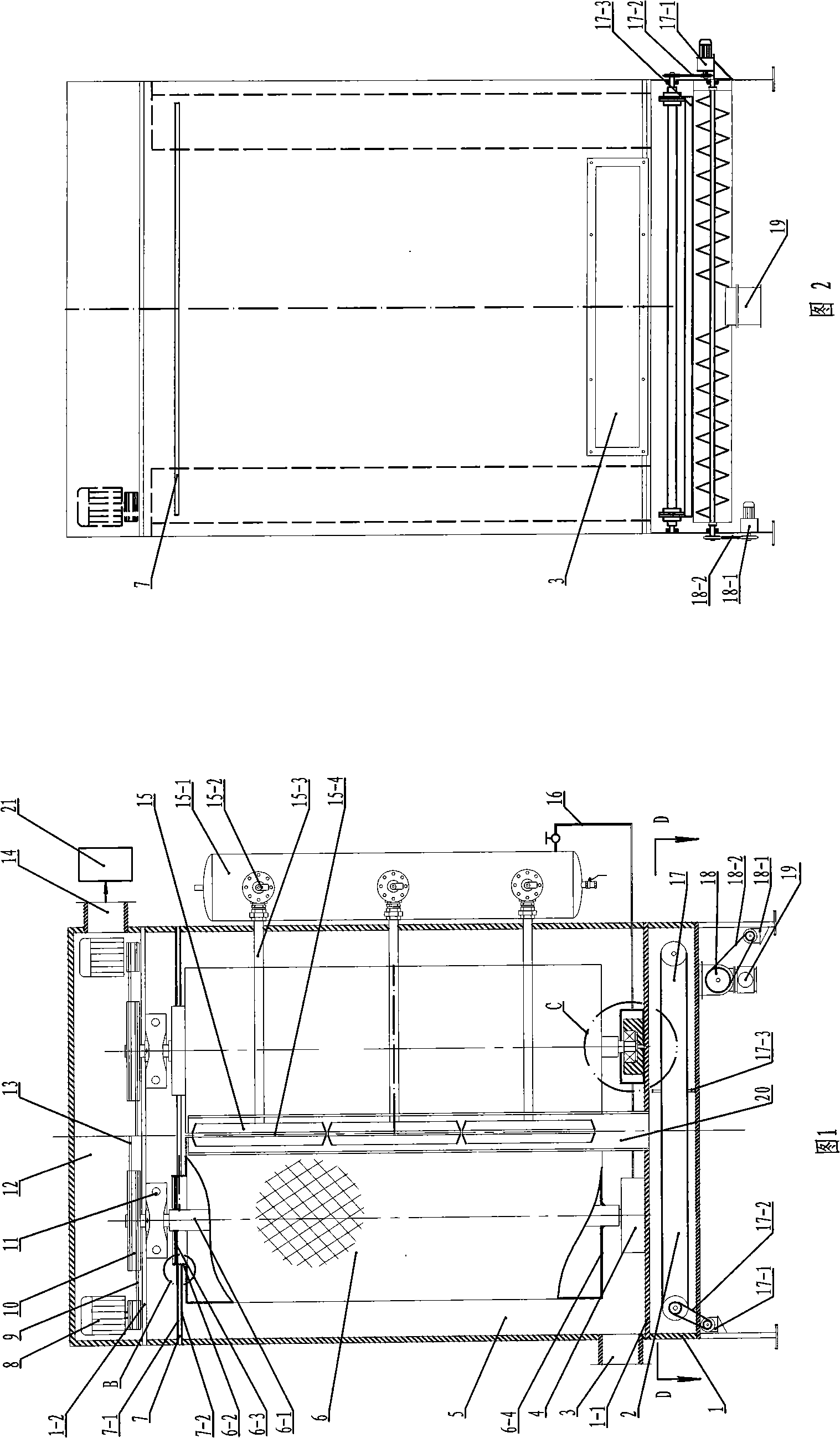

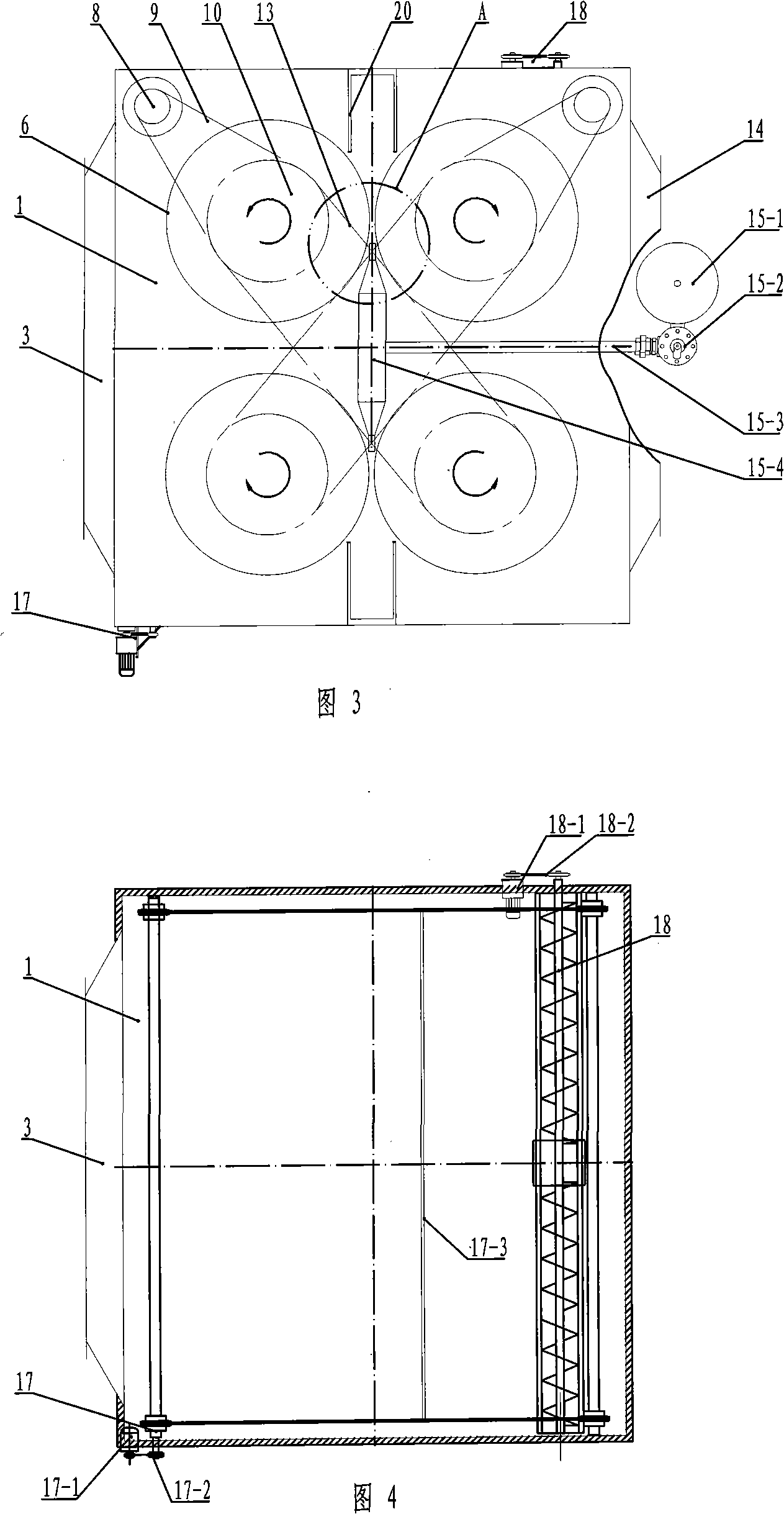

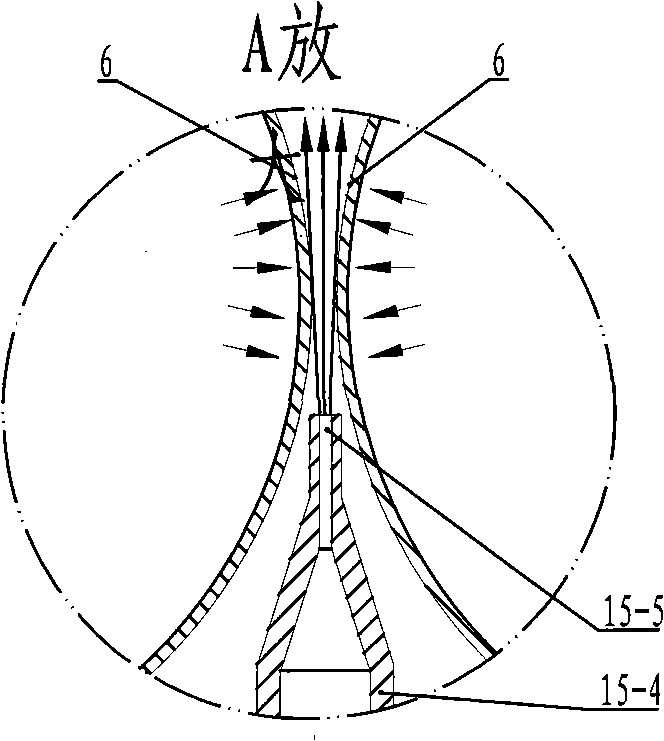

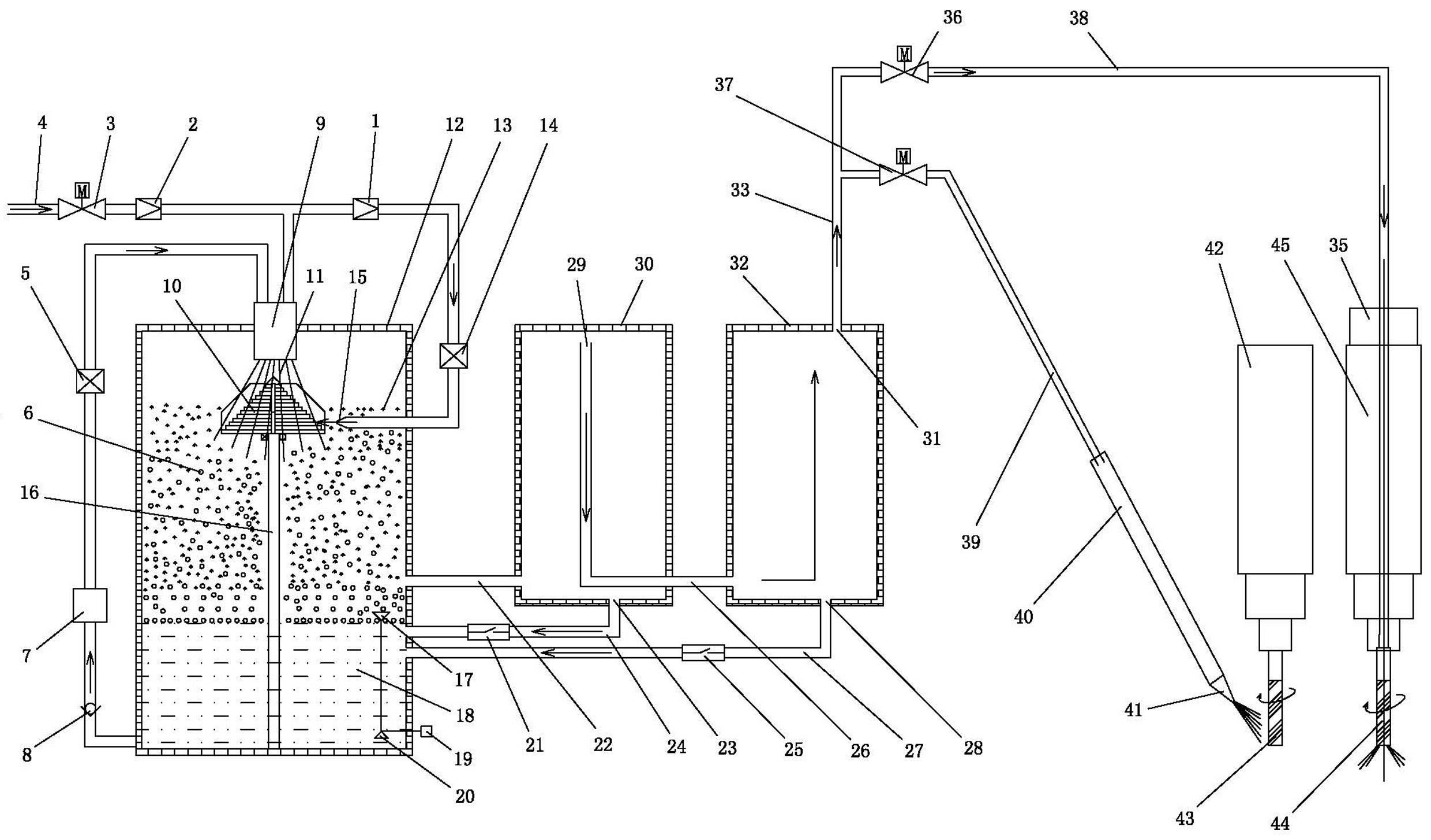

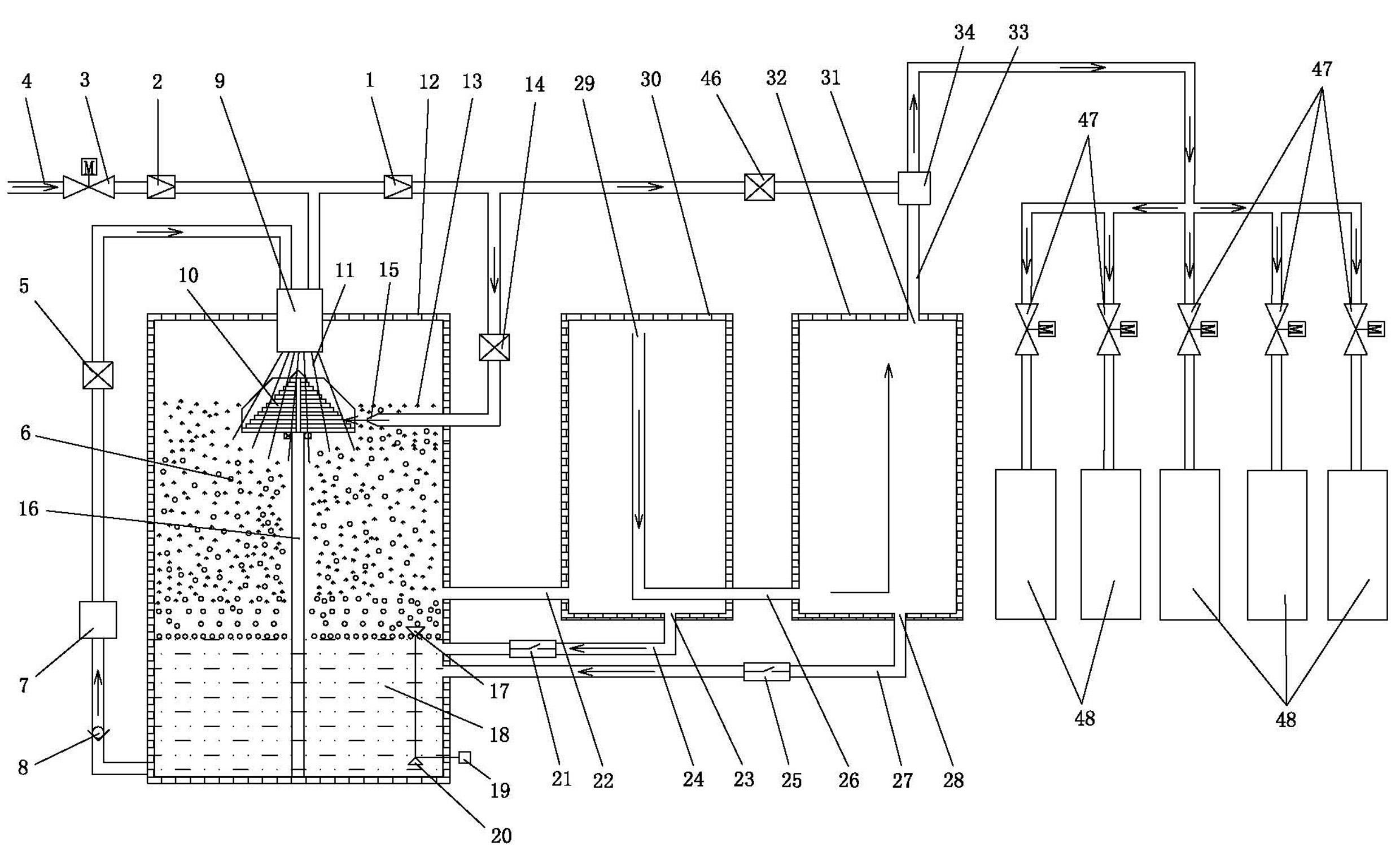

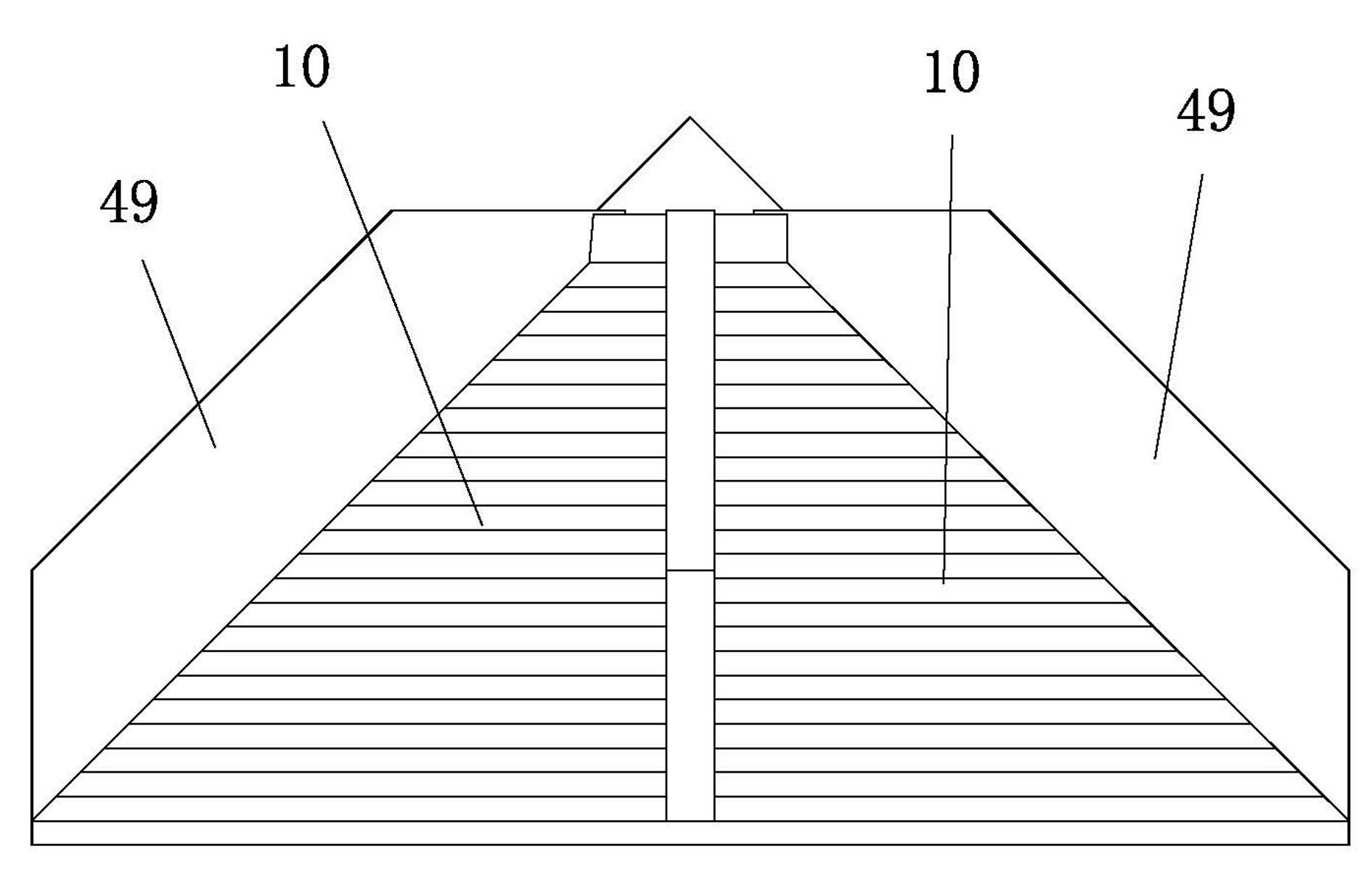

Minimal quantity lubrication (MQL) supply system for processing of outer-cooling type high-speed machine tool and inner-cooling type high-speed machine tool

InactiveCN102528550ALow costGood lubrication and cooling effectMaintainance and safety accessoriesLubricationProduct gas

The invention relates to a minimal quantity lubrication (MQL) supply system for processing of an outer-cooling type high-speed machine tool and an inner-cooling type high-speed machine tool, which mainly comprises a cutting oil atomizing chamber, a fine atomizing spray head, an electromagnetic valve A, a filtering pressure-reducing valve, a proportional pressure-reducing valve, a gas flow control valve A, a gas nozzle, an oil quantity control valve, a minitype oil pump, a one-way valve, a primary sedimentation chamber, a secondary sedimentation chamber and a cone-shaped body component, wherein the fine atomizing spray head is arranged at the upper part of an inner cavity of the atomizing chamber; the electromagnetic valve A, the filtering pressure-reducing valve and the fine atomizing spray head are sequentially connected together by gas delivery pipes; the filtering pressure-reducing valve, the proportional pressure-reducing valve, the gas flow control valve A and the gas nozzle are sequentially connected together by gas delivery pipes; the oil quantity control valve, the minitype oil pump and the one-way valve are sequentially connected together by oil pipes; the atomizing chamber is connected with the primary sedimentation chamber by an oil mist connecting pipe A; and the primary sedimentation chamber is connected with the secondary sedimentation chamber by an oil mist connecting pipe B. The MQL supply system is used for lubricating and cooling a processing area in mechanical processing.

Owner:DG ARMORINE ENERGY EFFICIENT & ECO FRIENDLY TECH

Lubrication system for a differential of a driven axle and automotive vehicle comprising such a lubrication system

ActiveUS9052009B2Effective lubricationImprove the level ofGear lubrication/coolingDifferential gearingsMobile vehicleGear wheel

Owner:VOLVO LASTVAGNAR AB

Radially pressure balanced floating seal system

InactiveUS6431553B1Minimize potentialEffective lubricationEngine sealsLeakage preventionDrive shaftAnnular aperture

A radially pressure balanced floating seal system is used to seal a rotating shaft, such as a drive shaft in a torpedo, or other type of vehicle or machinery. The radially pressure balanced floating seal includes an outer seal housing and an inner seal housing that floats with respect to the outer seal housing. The outer seal housing is secured proximate the shaft bearings, for example, in the tail cone of a torpedo. The inner seal housing is secured within an internal recessed region in the outer seal housing, and two or more discrete torque members or one distributed torque member extend from the outer seal housing to the inner seal housing to prevent rotation of the inner seal housing while allowing movement generally in a radial direction. The inner seal housing includes a lubricant recess formed within an internal annular aperture of the inner seal housing for containing lubricant. Double canted O-rings are disposed on each side of the lubricant recess in double canted O-ring grooves. The double canted grooves and O-rings prevent unbalanced radial forces that might cause rubbing of the shaft against the seal housing. In one embodiment, the lubricant recess is double canted to also minimize the sealing length.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

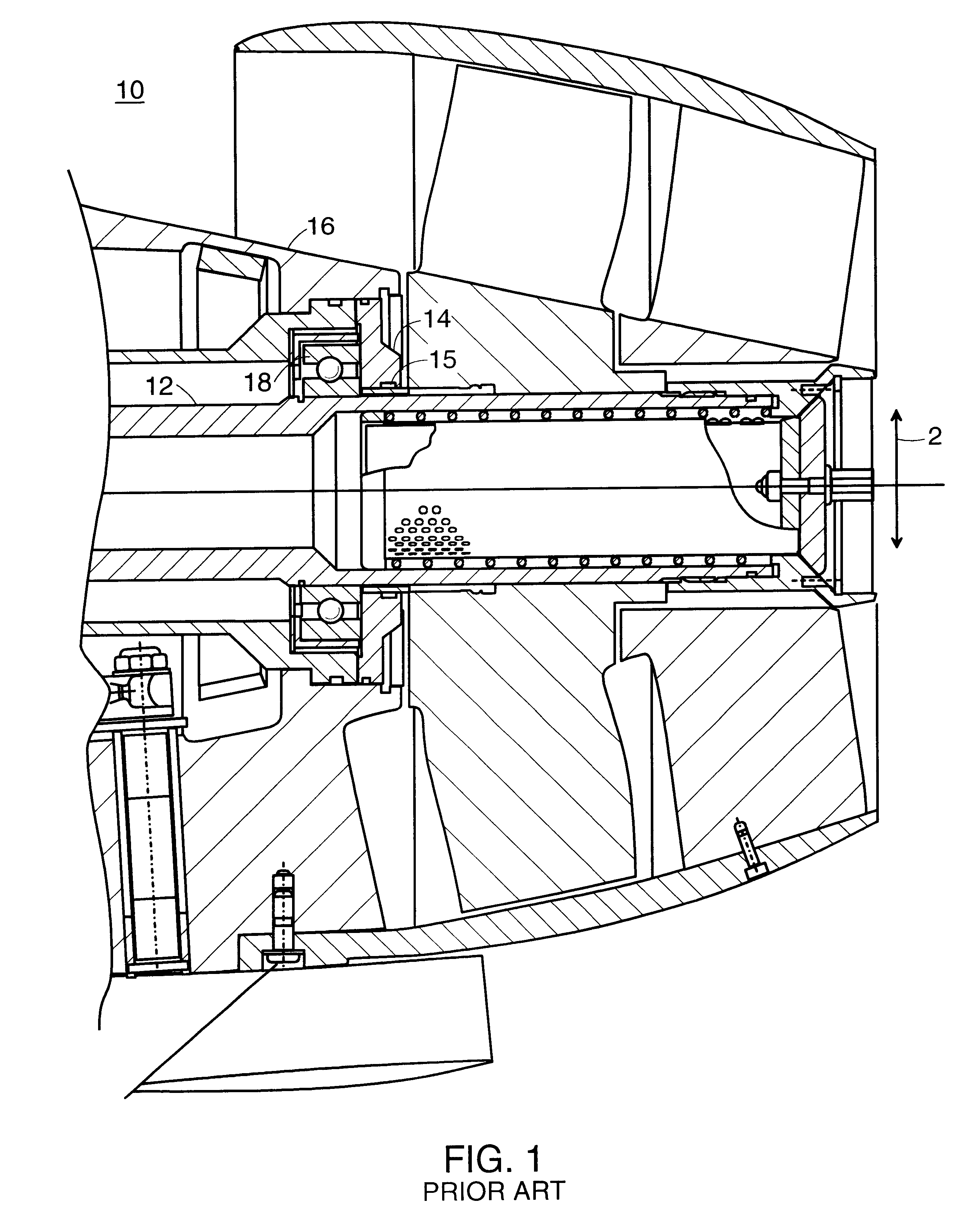

Method and system for lubricating a turbine engine

ActiveUS20110198155A1Mitigate such drawbackEffective lubricationEfficient propulsion technologiesMachines/enginesFuel tankPressure difference

A method and a system for lubricating a turbine engine including at least three separate housings each including at least one roller bearing. The method pressurizes the housings through seals, of which two main housings are pressurized at a pressure higher than that of a remaining secondary housing, lubricates a secondary roller bearing only by injecting an oil mist from at least one of the main housings, the oil mist being supplied by a pressure difference between the main housings and the secondary housing, recovers a remainder of the lubrication oil injected into the main housings to supply the same to an oil tank, and supplies the air / oil mixture from the secondary housing to an oil separator.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

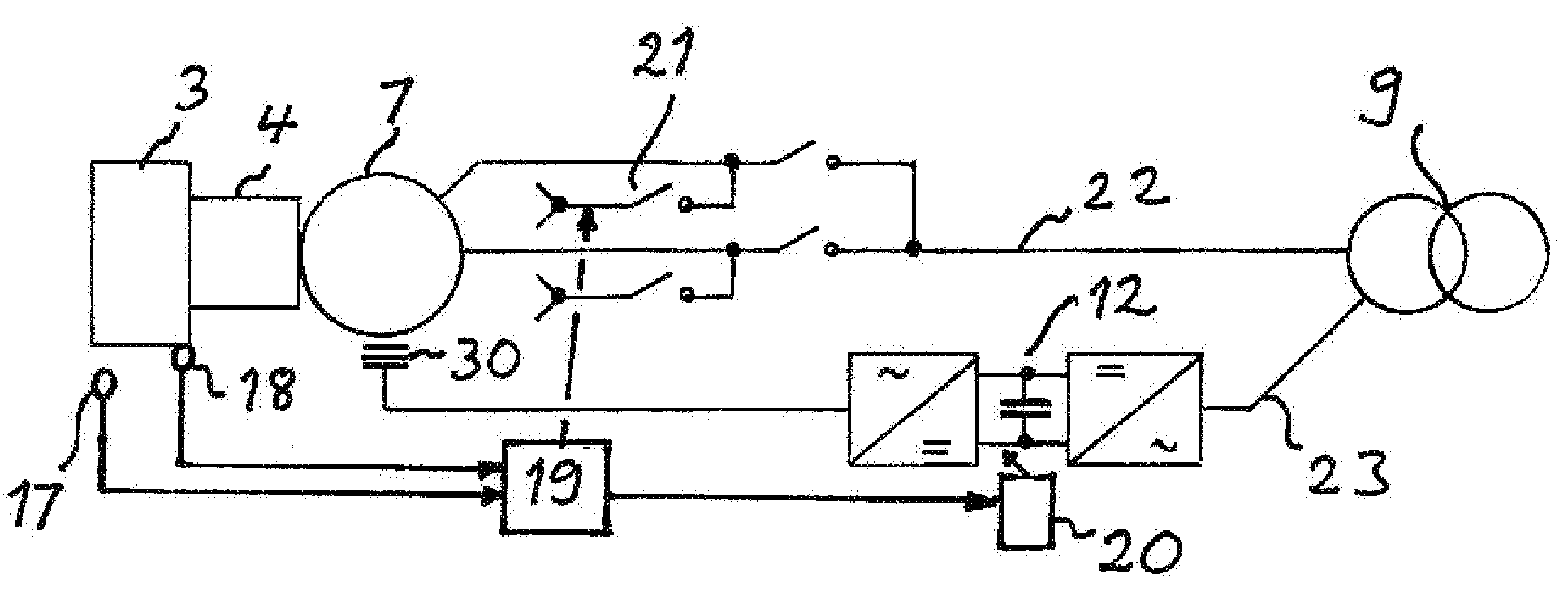

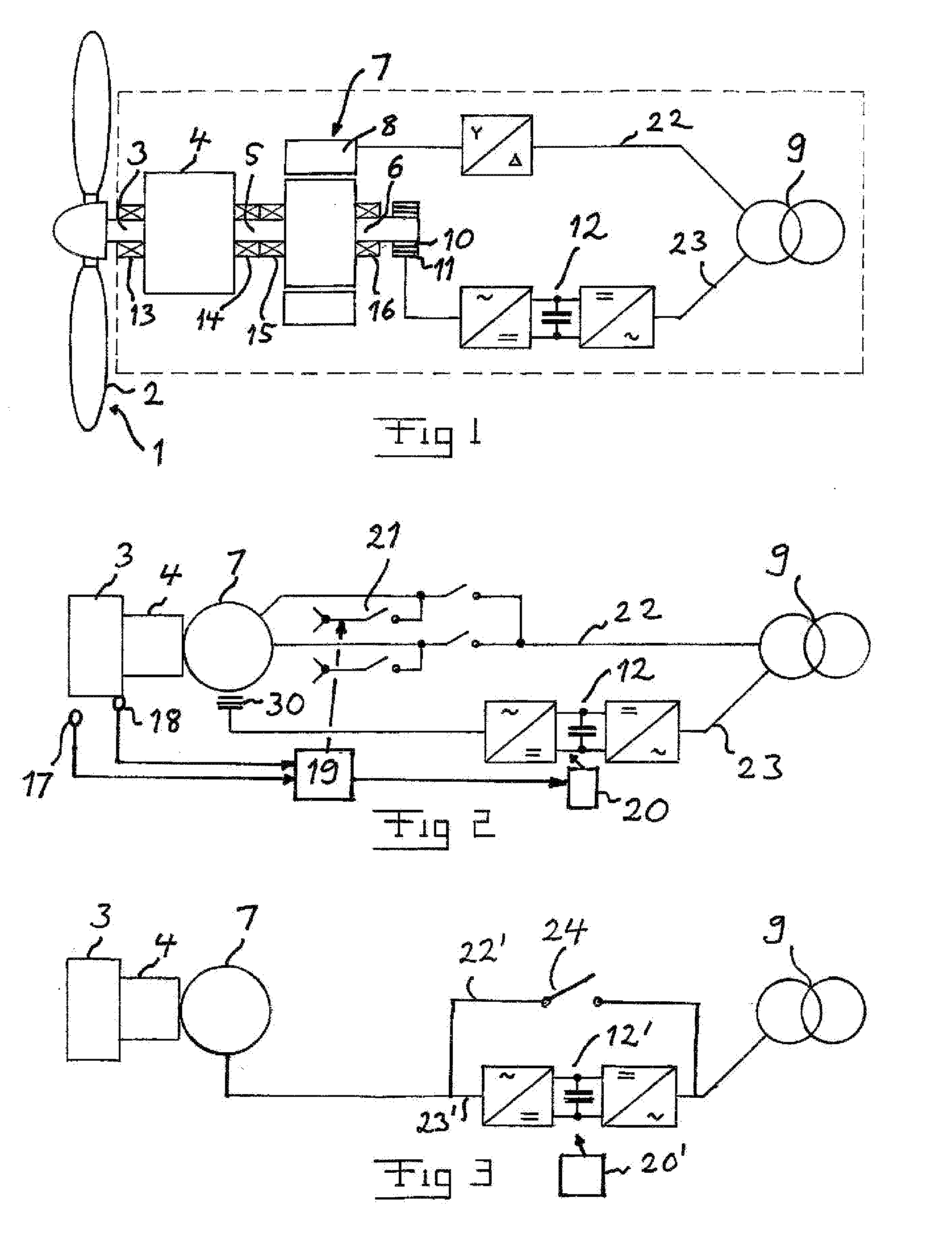

Control Method

InactiveUS20090273187A1Increase energy yieldHigh energyWind motor controlMachines/enginesElectric power transmissionAutomotive engineering

A generator of a wind turbine is at low power conditions operated as a motor by control of a frequency converter to feed electric power from an electric power transmission network to the generator for raising the speed of the wind rotor above a predetermined level for lubricating rotating parts of a drive train of the wind turbine.

Owner:ABB RES LTD

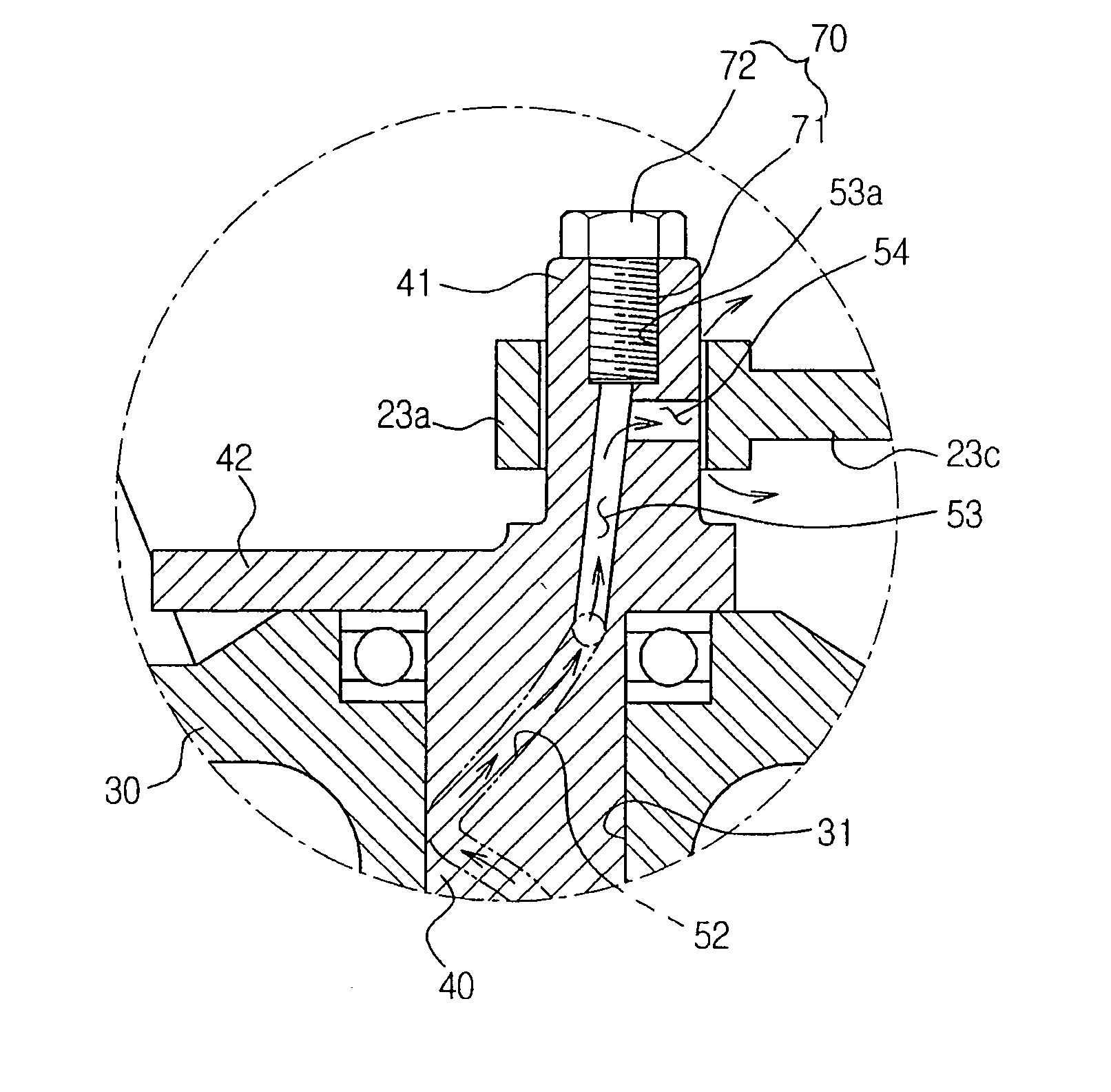

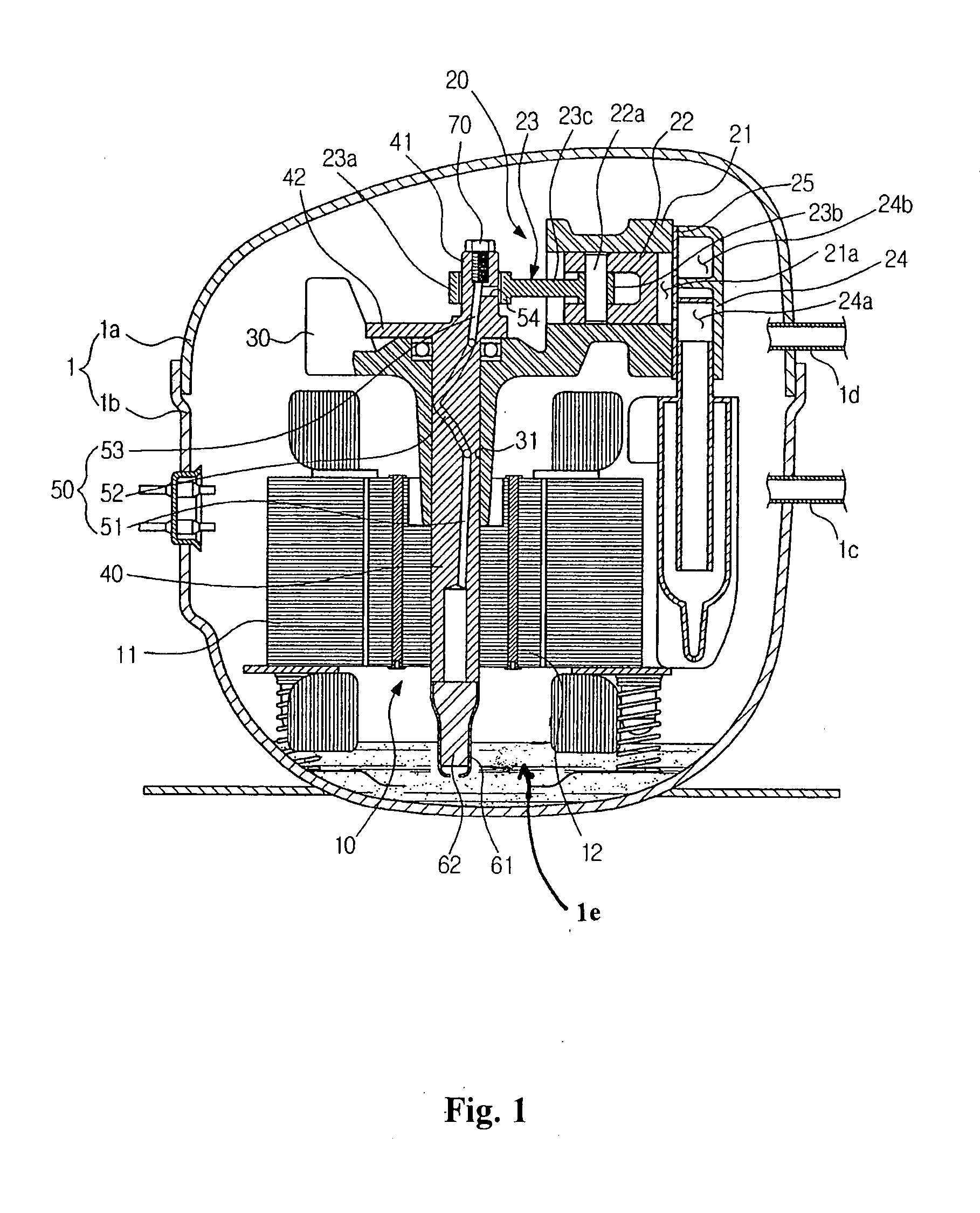

Hermetic compressor

InactiveUS20080145247A1Efficient oil lubricationEasy to installPositive displacement pump componentsPressure lubricationPistonPetroleum engineering

A hermetic compressor including a drive unit, a piston, a rotating shaft including an eccentric shaft portion and a weight balance portion located below the eccentric shaft portion, and an oil flow path having an upper oil hole formed in the rotating shaft and adapted to allow oil to be suctioned upward and dispersed to the upper side of the eccentric shaft portion and an auxiliary oil hole to allow a part of the oil being suctioned upward along the upper oil hole to be supplied into a gap between the eccentric shaft portion and the connecting rod. The eccentric shaft portion is installed with a plug member to close an upper end of the upper oil hole. The plug member is configured to selectively couple a weight balance member, which is separately fabricated from the rotating shaft, to an upper end of the eccentric shaft portion.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com