In-wheel motor drive device

A technology of driving device and in-wheel motor, applied in the direction of gear transmission, power device, transmission, etc., can solve the problems of reducing the efficiency of electric motor, adverse effects of electric motor, etc., and achieve the effect of reducing torque loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

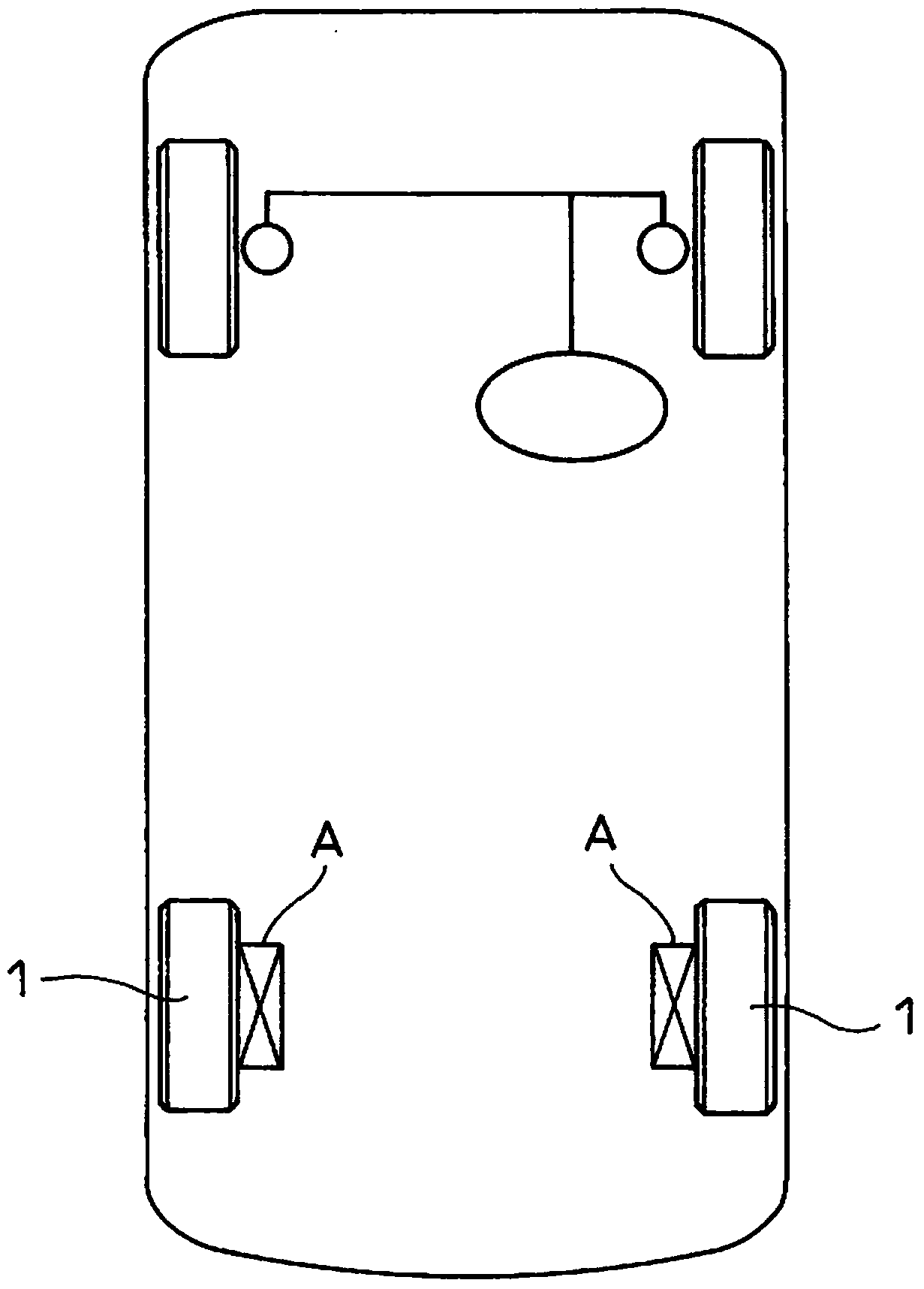

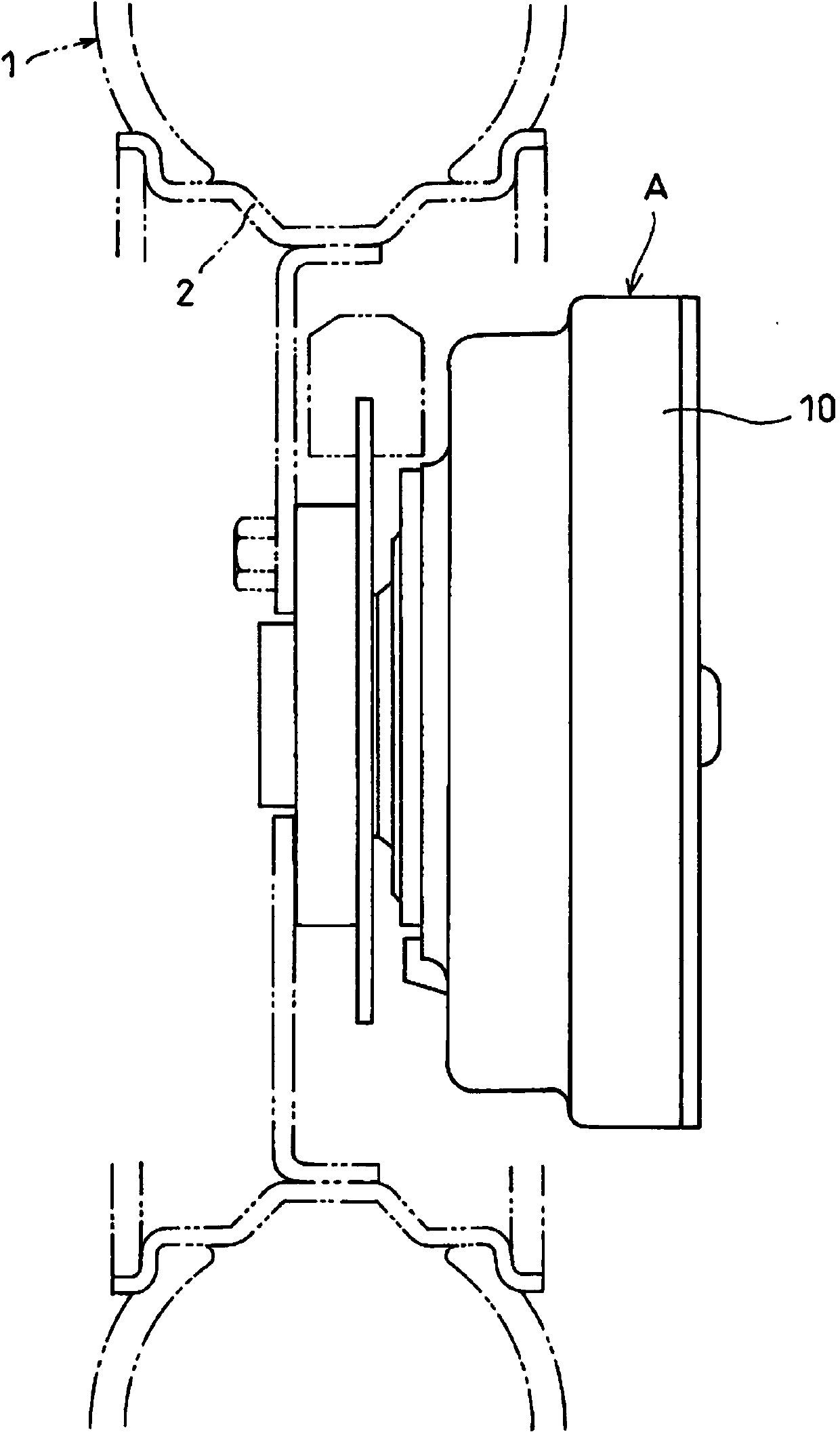

[0039] Embodiments of the present invention will be described below based on the drawings. Such as figure 2 As shown, the in-wheel motor driving device A according to the present invention is provided inside the wheel 2 among the driving wheels 1 .

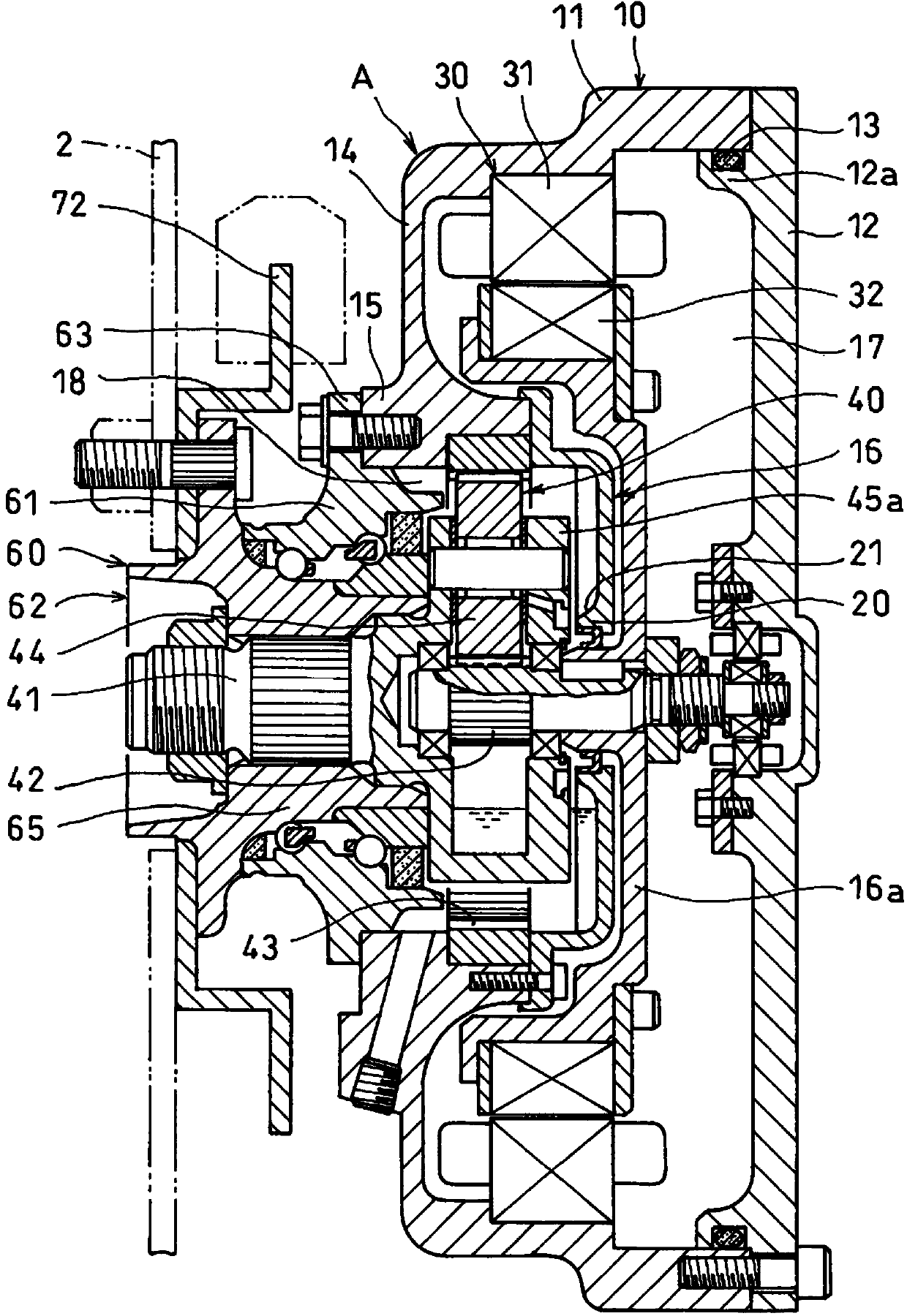

[0040] Such as image 3 As shown, the in-wheel motor driving device A has: a motor housing 10; an electric motor 30 accommodated in the motor housing 10; a speed reduction mechanism 40 for decelerating and outputting the rotation of the electric motor 30; The output shaft 41 of the mechanism 40 is supported by a rotatable wheel bearing 60 .

[0041] Such as image 3 as well as Figure 4 As shown, the motor housing 10 is composed of a cylindrical housing main body 11 and a cover 12 that closes the opening at one end of the housing main body 11 . The cylindrical portion 12 a is sealed by assembling a seal ring 13 between the fitting surfaces of the cylindrical portion 12 a and the housing main body 11 .

[0042] An annular en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com