Double-clutch lubricating structure for double-clutch gear box

A double-clutch, lubricating structure technology, applied in the direction of clutches, friction clutches, fluid-driven clutches, etc., can solve the problems of potential safety hazards, complex pipeline structure, low reliability, etc., and achieve high practical value, good safety, The effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

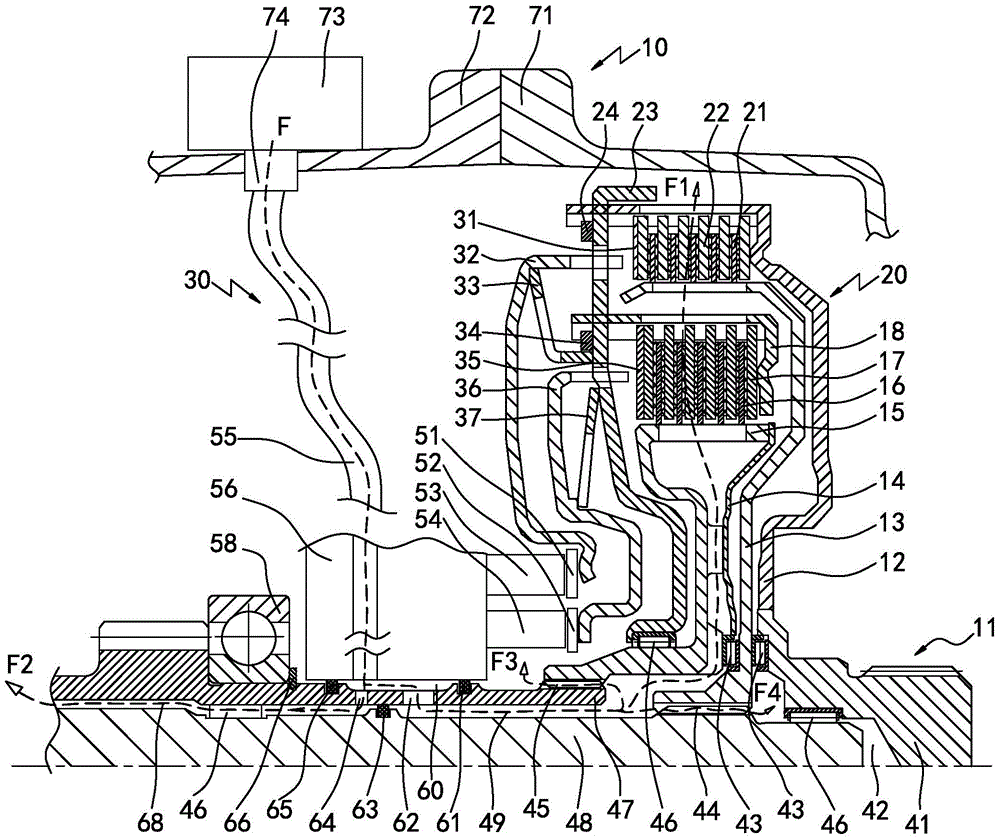

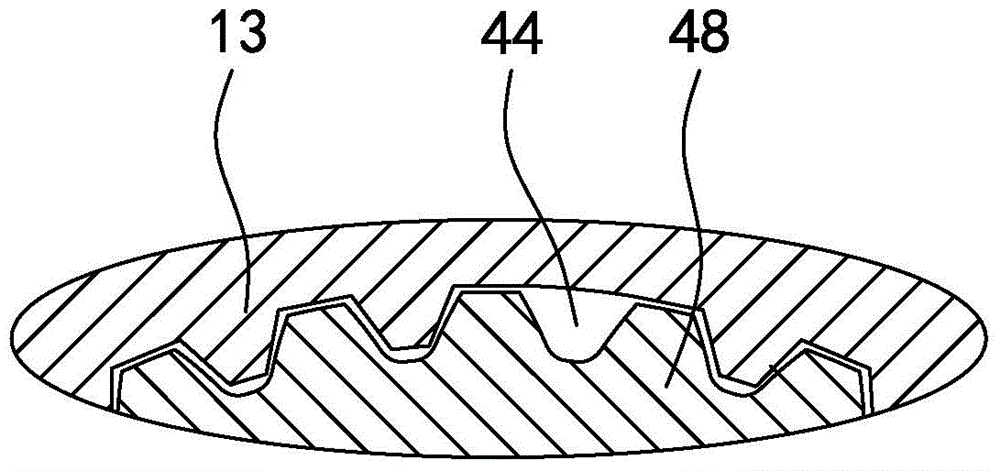

[0025] in such as figure 1 In the shown embodiment 1, a dual-clutch lubrication structure for a dual-clutch transmission is provided on a dual-clutch transmission 10, the dual-clutch transmission includes a dual-clutch 20 and an oil supply device 30, and the dual-clutch includes a The driving disc 12 connected to the driving device 11 is connected to the first input shaft 48 and the second input shaft 47 of the transmission. The first input shaft is connected, and the driving disc is connected with the second input shaft through the second clutch and the second clutch spline hub 15. It is characterized in that: the oil supply device includes an electronic oil pump 73, and the electronic oil pump is connected to the clutch through a lubricating oil pipe 55. Separation device 56, a closed oil storage chamber 60 is provided between the clutch separation device and the second input shaft, a lubricating oil passage is provided between the second input shaft and the first input shaf...

Embodiment 2

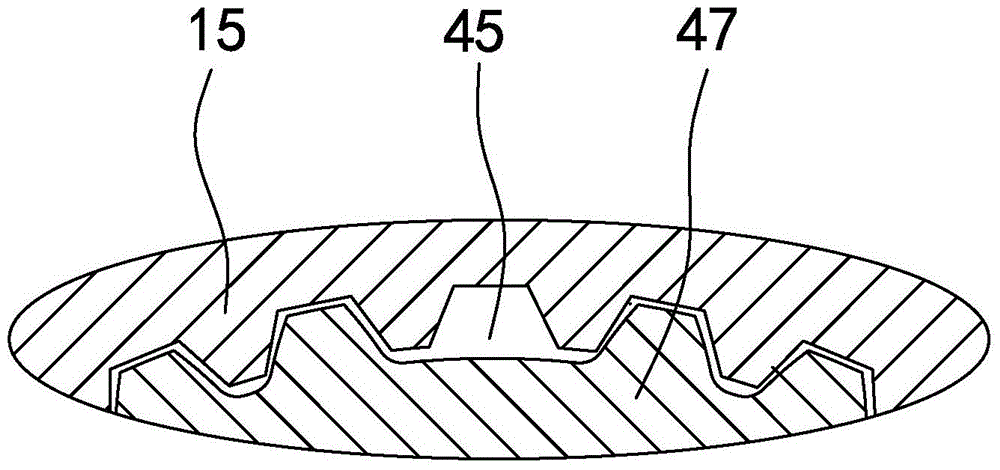

[0036] The front lubricating oil groove provided at the meshing place between the spline hub of the first clutch and the first input shaft in embodiment 2 is an axial groove between the two spline teeth on the outer spline of the first input shaft; the spline hub of the second clutch The rear lubricating oil groove set at the meshing place between the key hub and the second input shaft is an axial groove between two key teeth set on the external spline of the second input shaft (see image 3 ), and the rest are the same as in Example 1.

[0037]When the lubricating structure of the present invention works, the lubricating oil enters the oil storage chamber between the clutch separation device and the second input shaft from the electronic oil pump through the lubricating oil pipe, and the oil storage chamber passes through the front and rear oil holes on the second input shaft and four lubricating and cooling passages Connection, the lubricating oil in the first lubricating ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com