Method and device for precision positioning and testing contact resistance

A technology of precise positioning and contact resistance, which is used in measuring devices, measuring resistance/reactance/impedance, measuring electrical variables, etc. It can solve the problem that the state of the contact area cannot be truly reflected, the resistance of the contact resistance is low, and the electronic connector cannot be accurately controlled, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

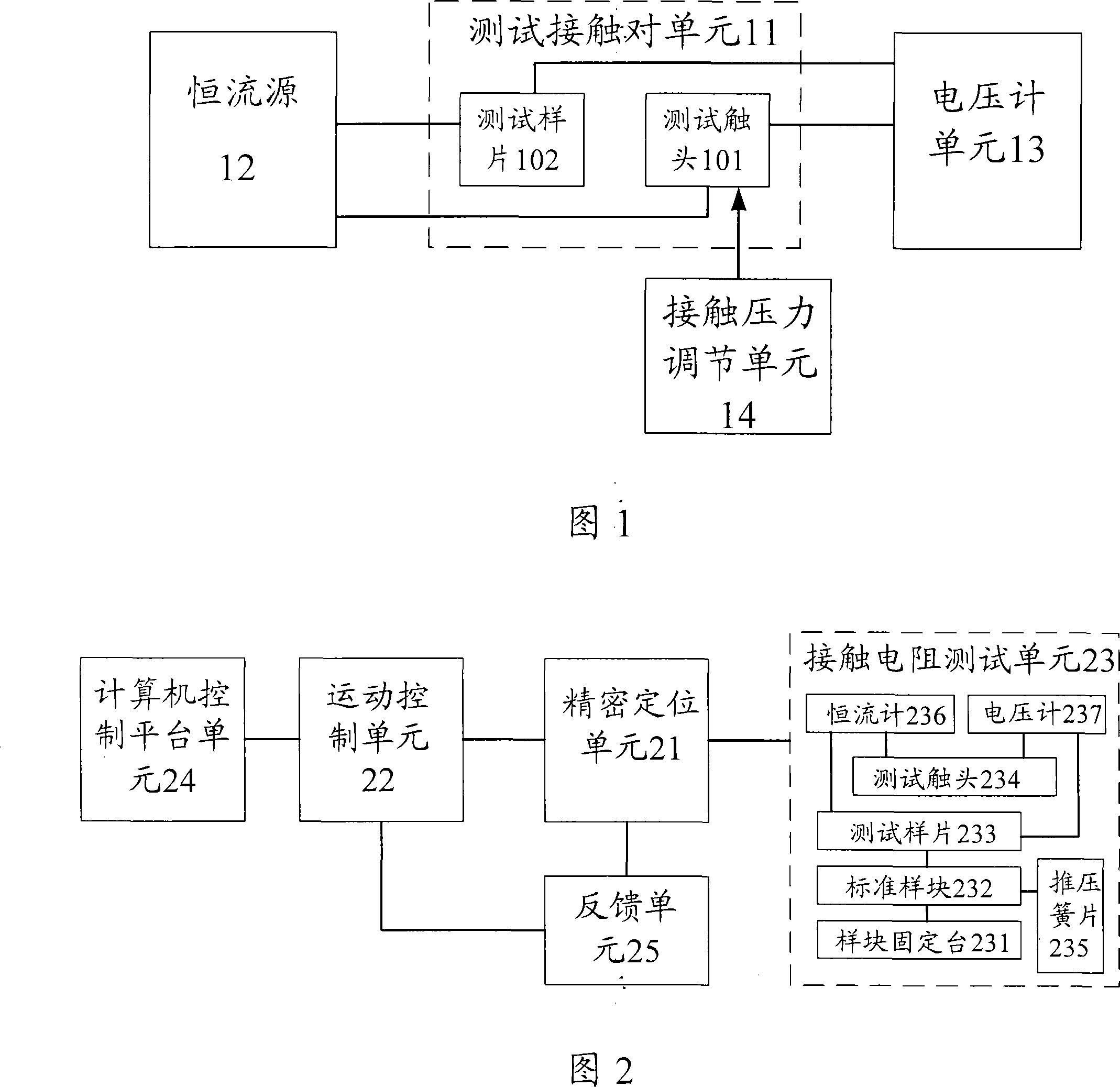

[0016] The core idea of the present invention is: predetermine the plane distance parameter from the intersection point on the surface of the standard sample block to the contact spot on the test sample, the computer control platform unit sends the positioning command to the motion control unit, and the motion control unit converts the command into a control voltage command and then outputs , the precision positioning unit performs precise positioning according to the control voltage command, and the feedback unit feeds back the distance information of the precision positioning unit to the motion control unit, and the motion control unit adjusts the output control voltage according to the positioning command and the feedback distance information, and controls the precision positioning unit to perform precise positioning Then, the computer control platform unit sends the contact pressure command and the test command, and the contact resistance test unit starts to test the conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com