Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Improve oil supply capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

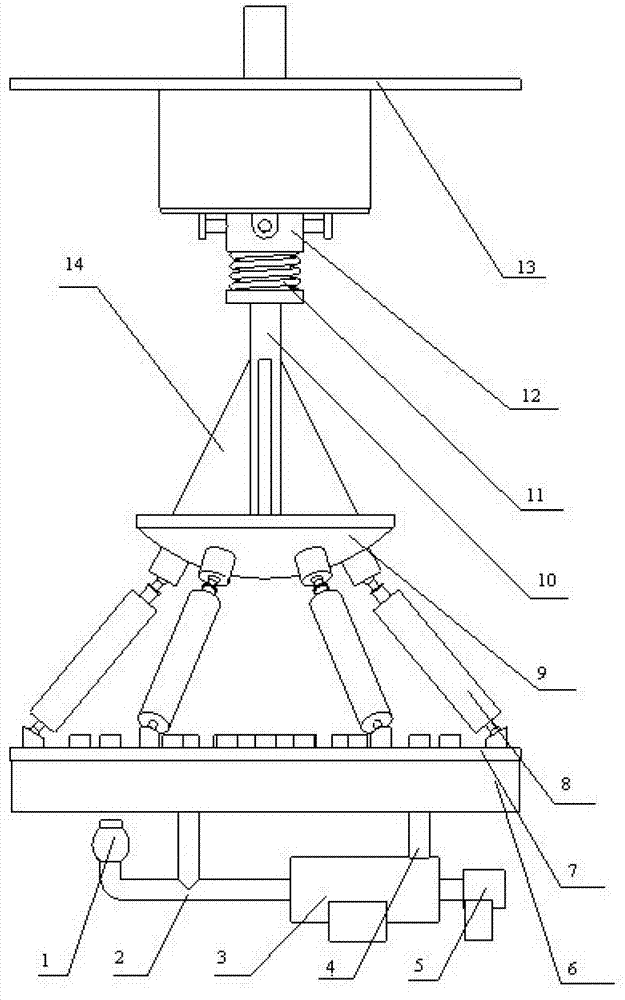

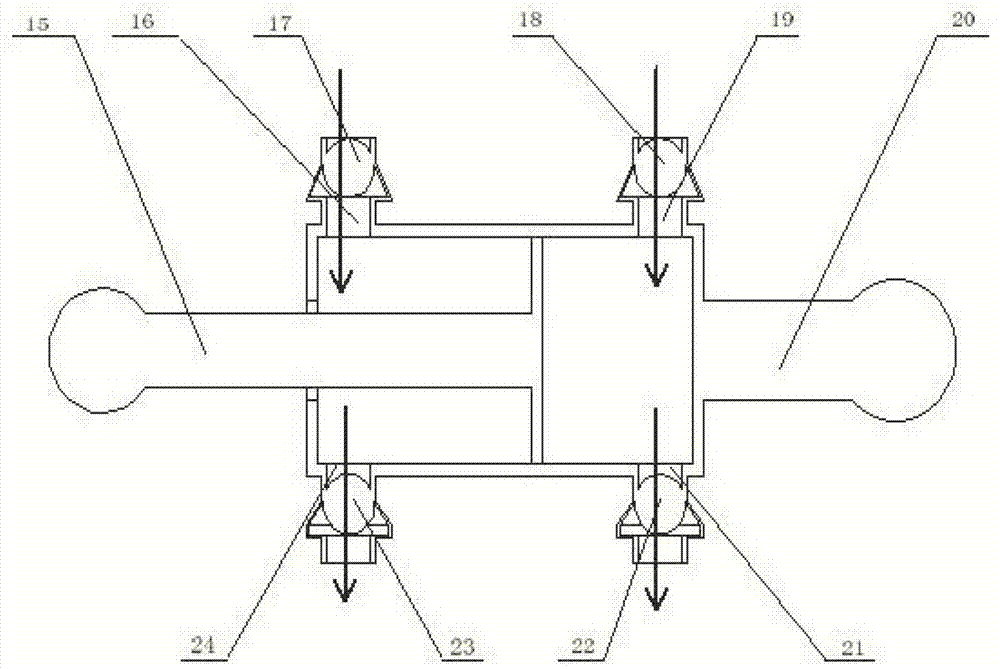

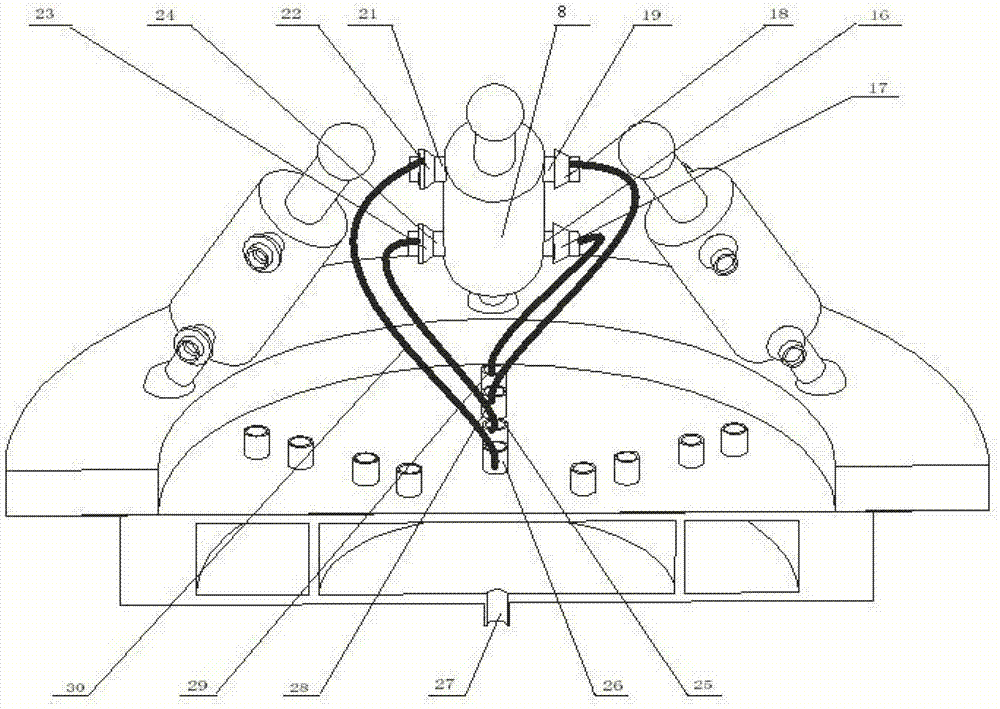

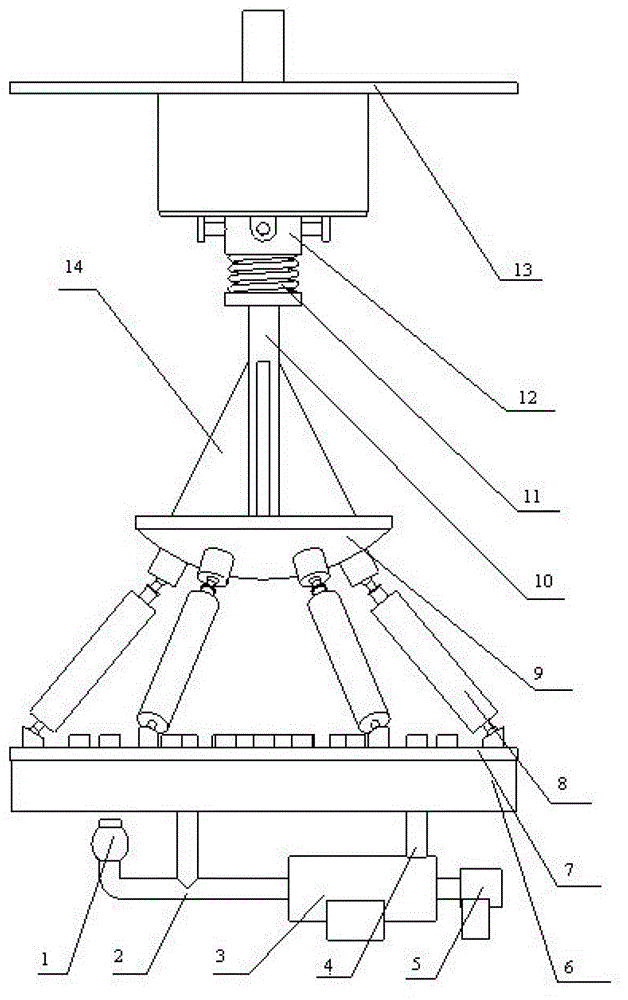

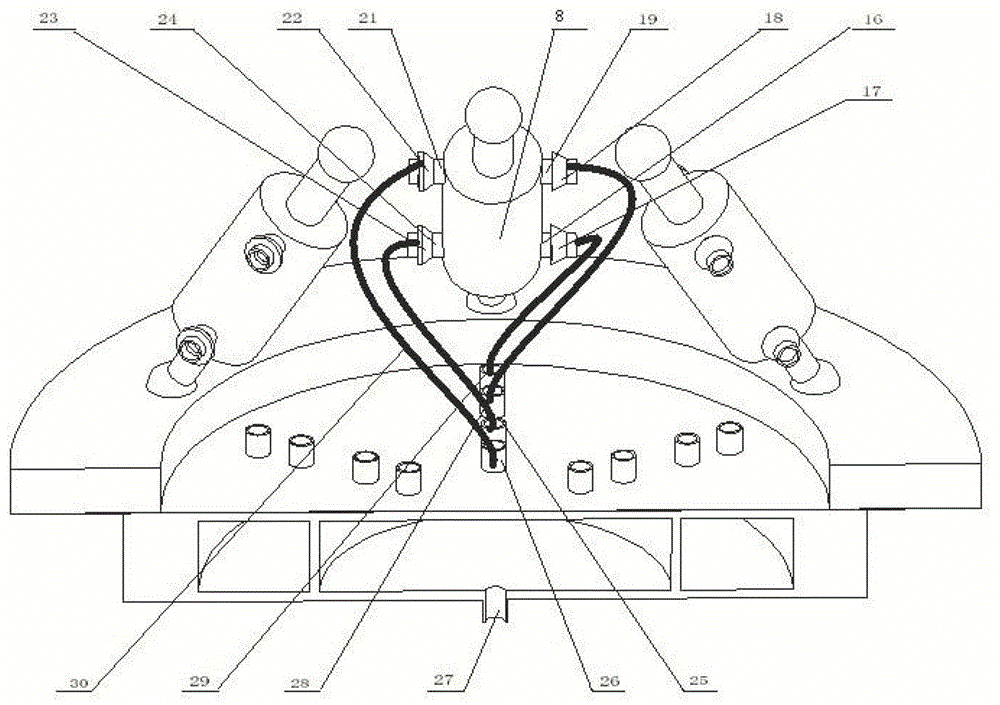

Multi-dimensional and parallel-swing sea wave power generation device

InactiveCN103306881AWon't be corrodedImprove sealingMachines/enginesEngine componentsHydraulic cylinderHydraulic motor

The invention discloses a multi-dimensional and parallel-swing sea wave power generation device. A top cover is fixedly connected with the top wall of a buoyancy box, one end of a three-degree-of-freedom movement pair is fixedly connected with the top cover, the other end of the three-degree-of-freedom movement pair is engaged with a swing rod, one end of the swing rod penetrates through the top wall of the buoyancy box and is fixedly connected with an outside device, the other end of the swing rod is fixedly arranged on an upper platform through the support of rib plates, a spring is fixedly connected with a shaft shoulder of the swing rod, six parallel hydraulic cylinders are arranged between the upper platform and a lower platform, piston rods of the six parallel hydraulic cylinders are hinged to the upper platform, cylinder bodies of the six parallel hydraulic cylinders are hinged to the lower platform, the lower platform is fixedly arranged on an oil mixture tank, the oil mixture tank is fixedly connected with the side wall of the buoyancy box, the oil mixture tank is connected with a hydraulic motor through a separating pipe and a return pipe, a generator is connected with the hydraulic motor, the generator and the hydraulic motor are arranged at the bottom of the buoyancy box, and an energy accumulator is connected with the hydraulic motor. The device has the characteristics that the service life is long, and the pollution is little; and while the energy of the sea wave in the transverse swinging is absorbed, the energy of the sea wave in the vertical direction can also be absorbed.

Owner:SHANGHAI JIAO TONG UNIV

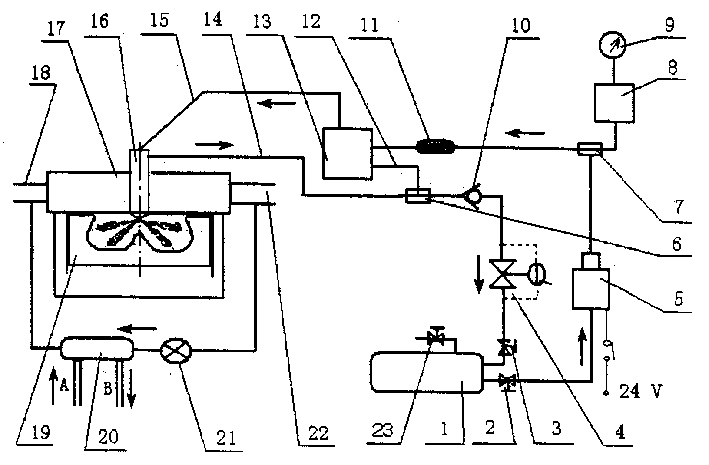

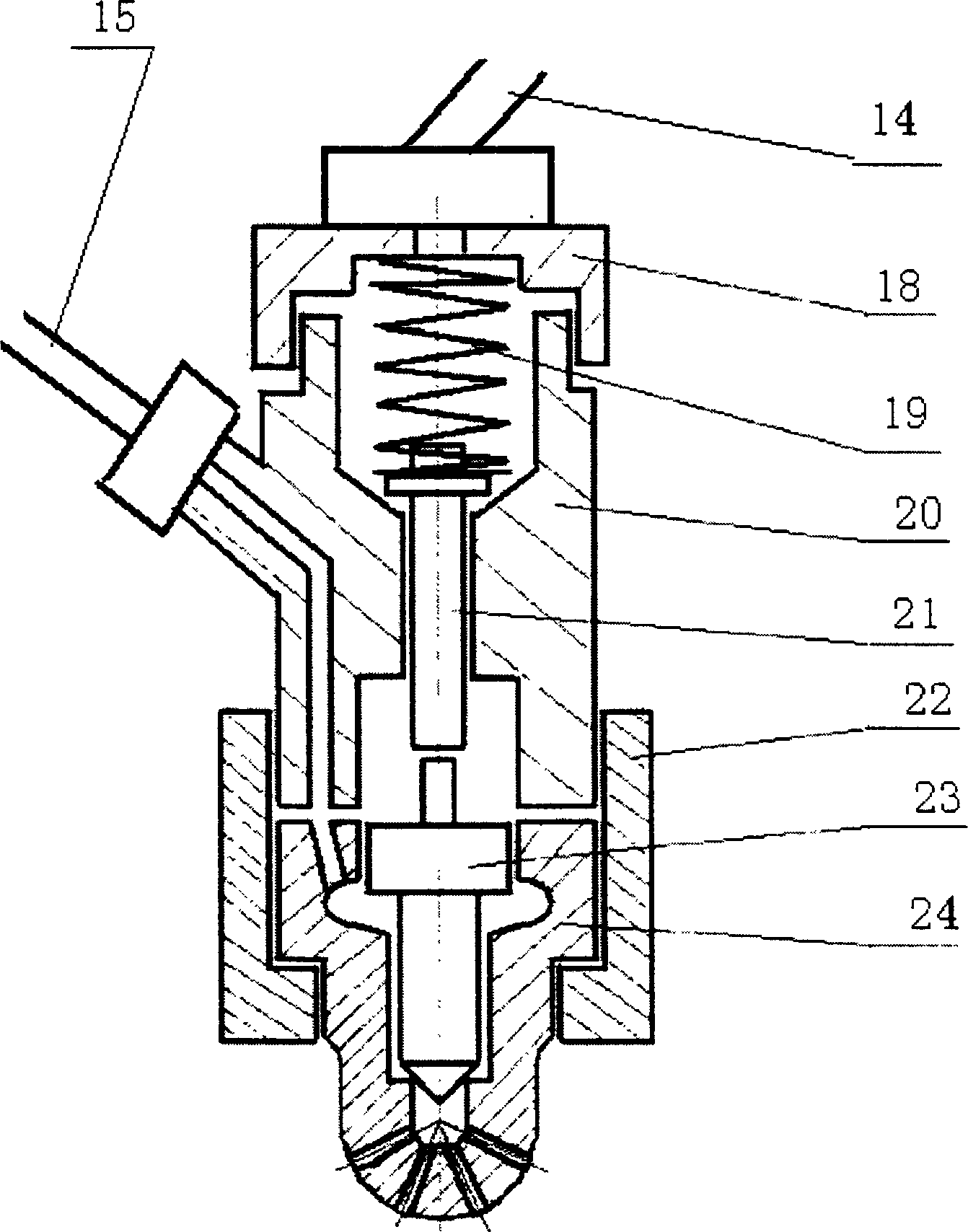

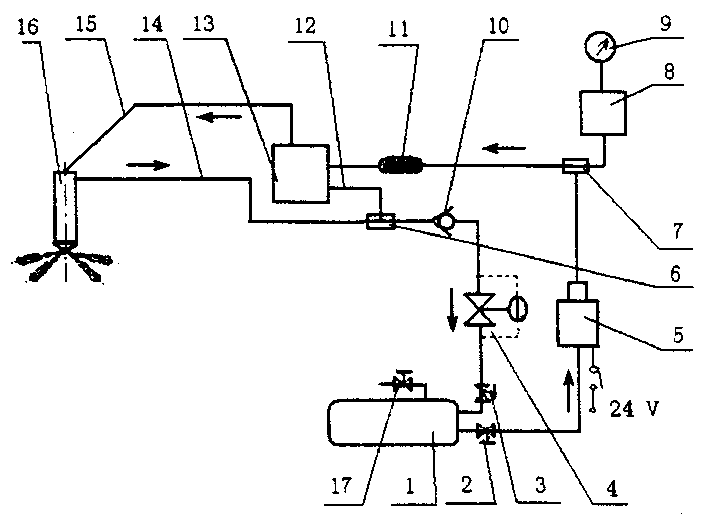

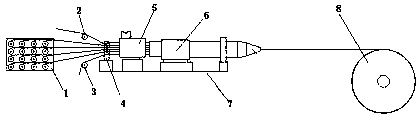

Dimethyl ether engine efficient, ultra-low emission combustion system

InactiveCN1470758AEasy to spreadWell formedInternal combustion piston enginesFuel supply apparatusExhaust fumesChiller

The dimethyl ether engine high-efficiency ultralow-discharge combustion system belongs to the field of internal combustion engine. The invented DME storage tank is connected with low-pressure fuel conveying pump by means of liquid outlet valve, the output of the low-pressure fuel conveying pump is connected with intensified fuel-spraying pump via one end of T-junctor and fuel filter, the outlet of intensified fuel-spraying pump is connected with ultramultinozzle fuel-spraying device via high-pressure fuel pipe, said ultramultinozzle fuel-spraying device is set on the cylinder cover of engine and is matched with combustion chamber, the outlet of waste gas recirculation control valve is connected with inlet of waste gas recirculation cooling device, and its inlet is connected with dischargetube.

Owner:SHANGHAI JIAO TONG UNIV

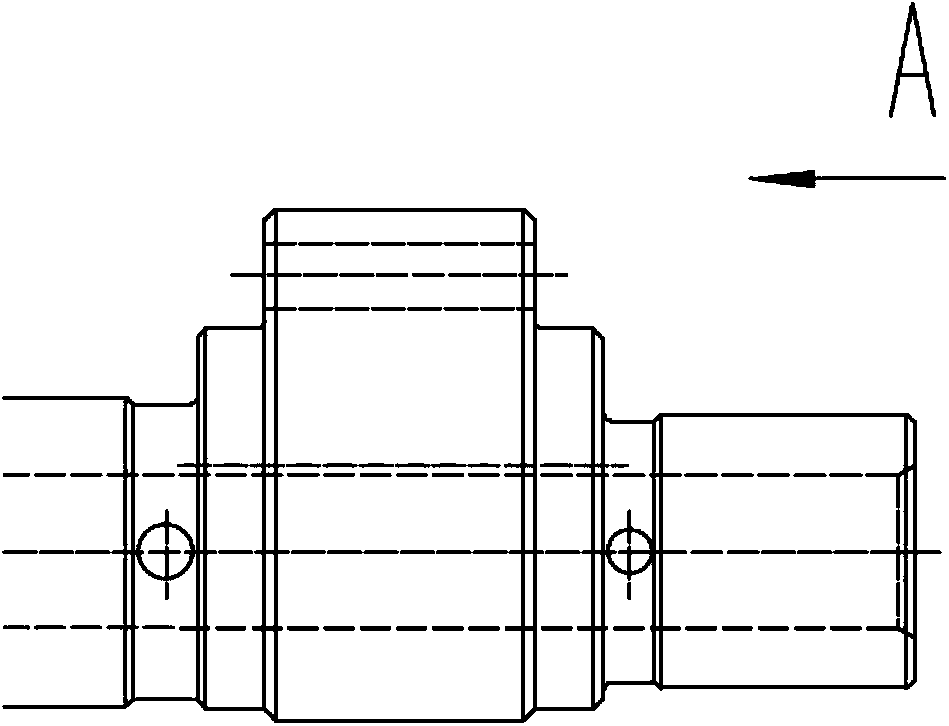

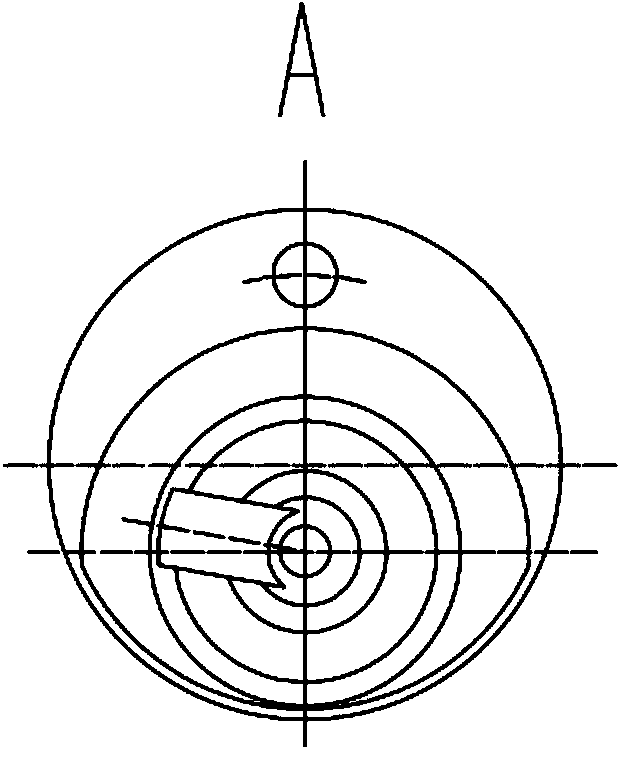

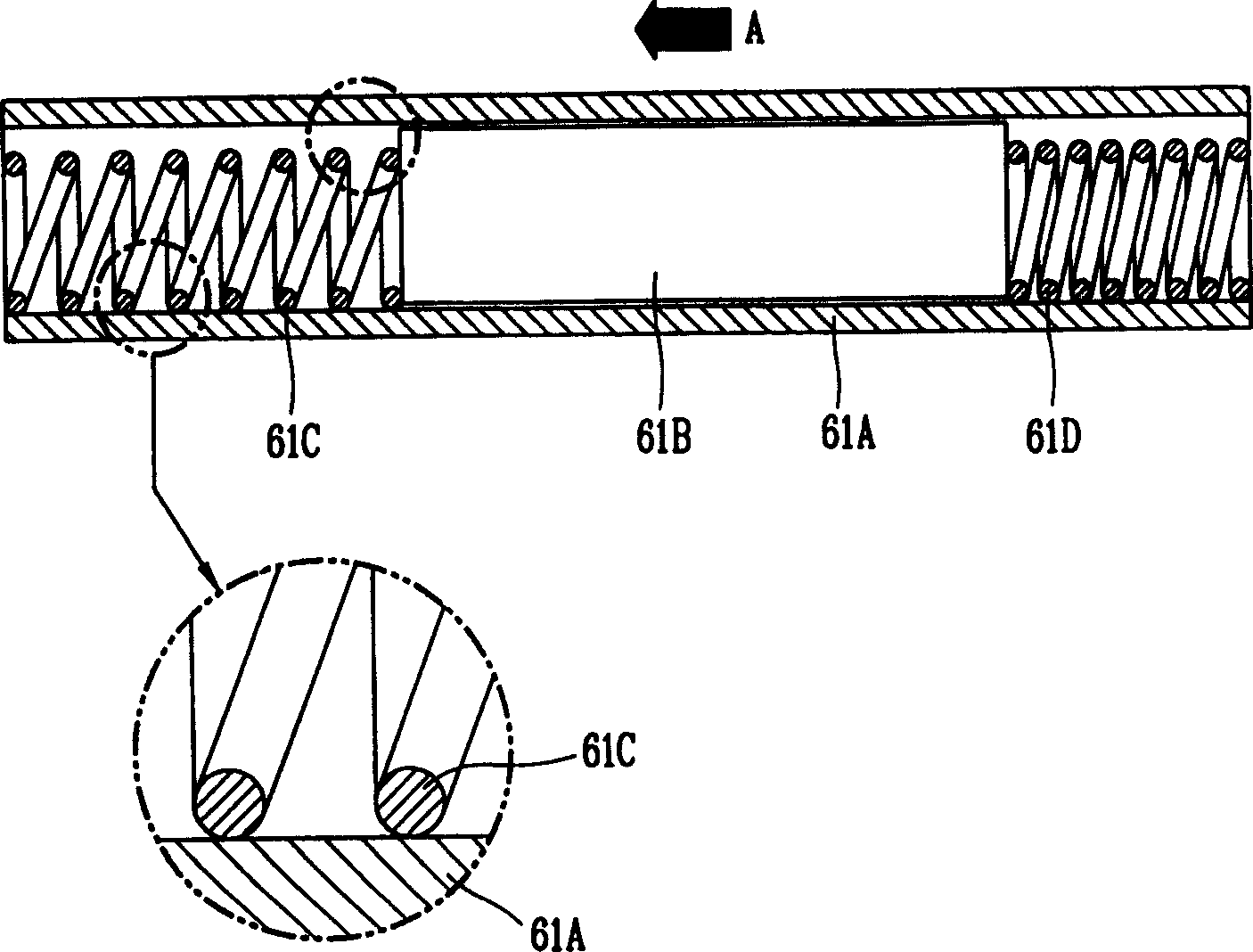

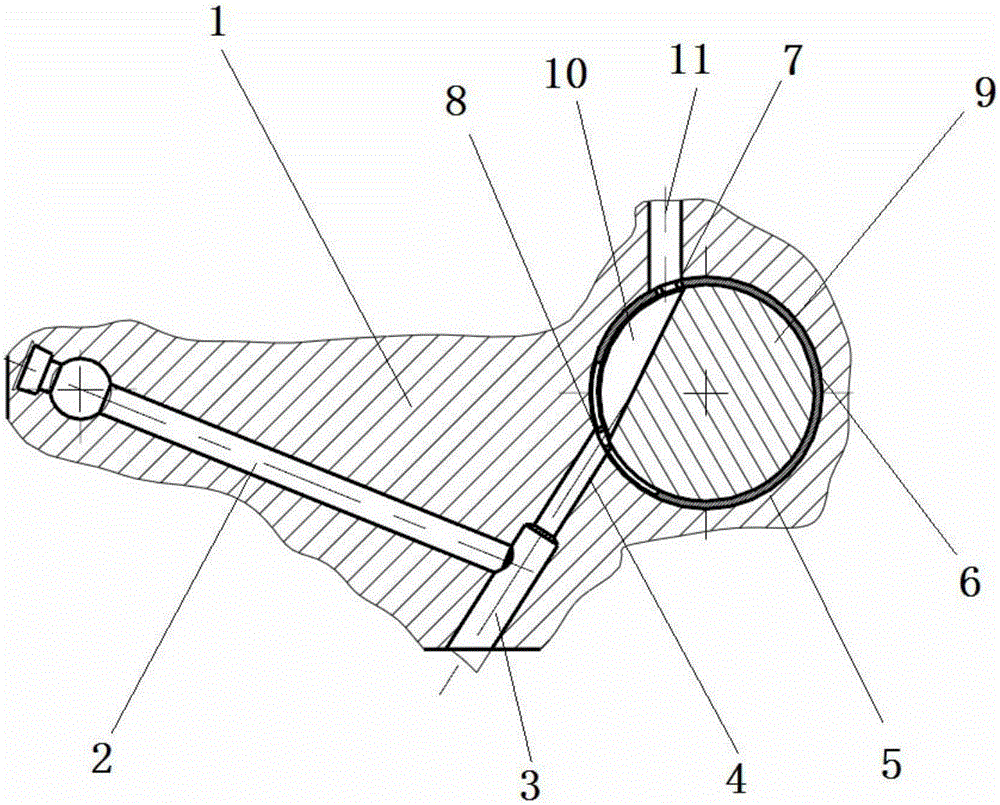

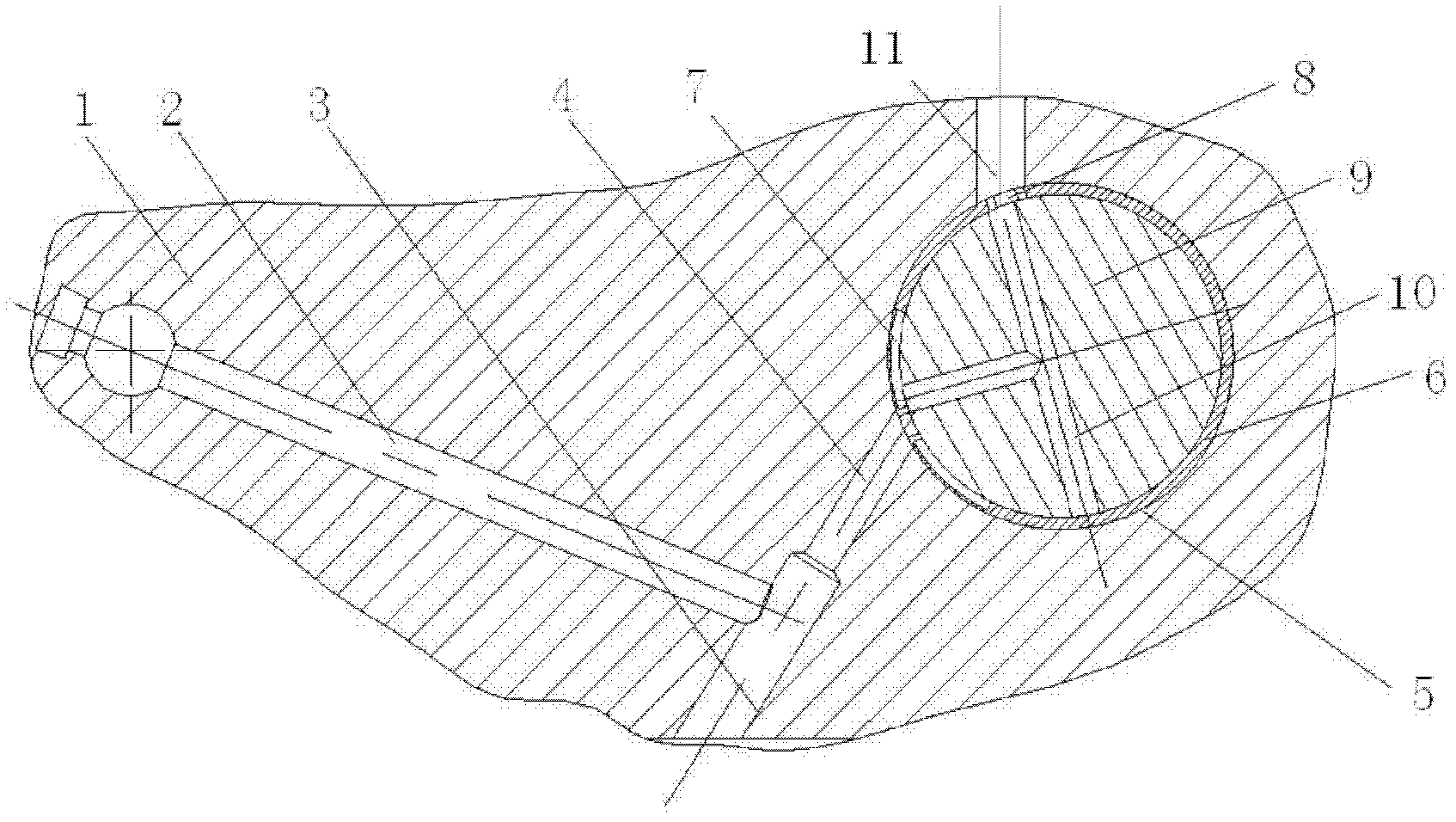

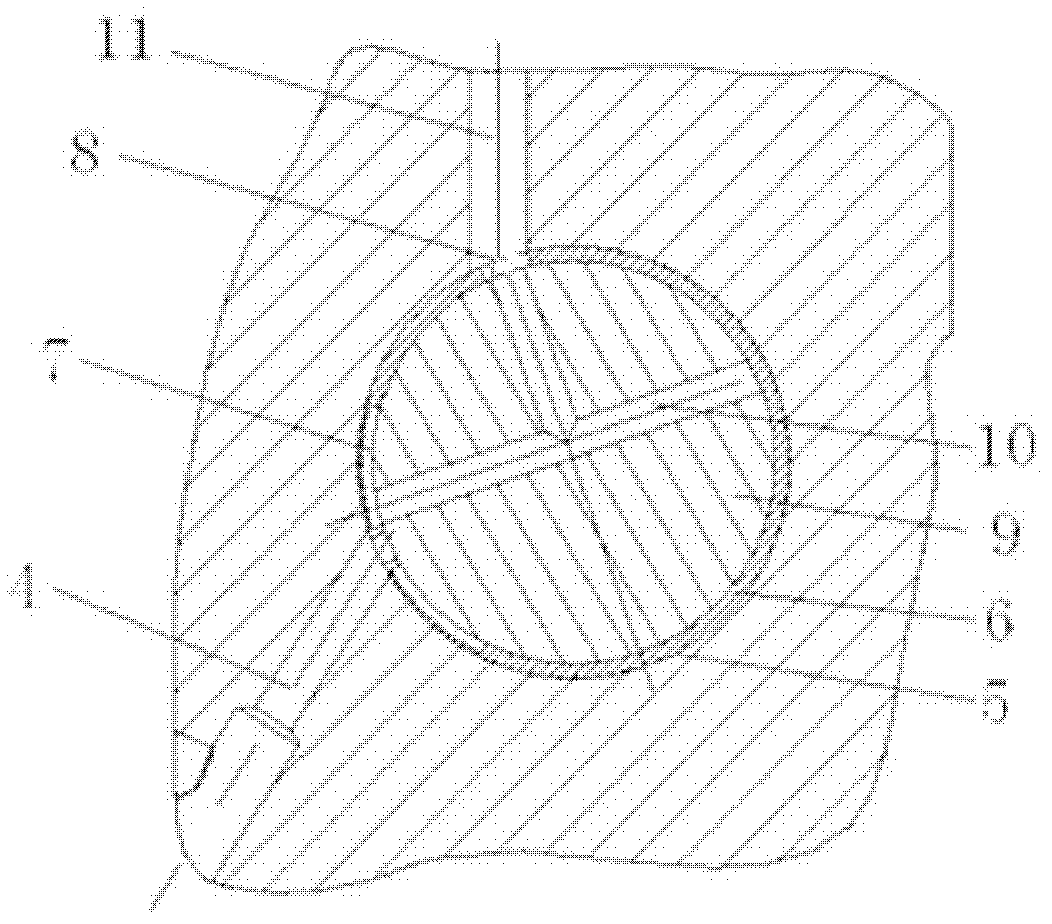

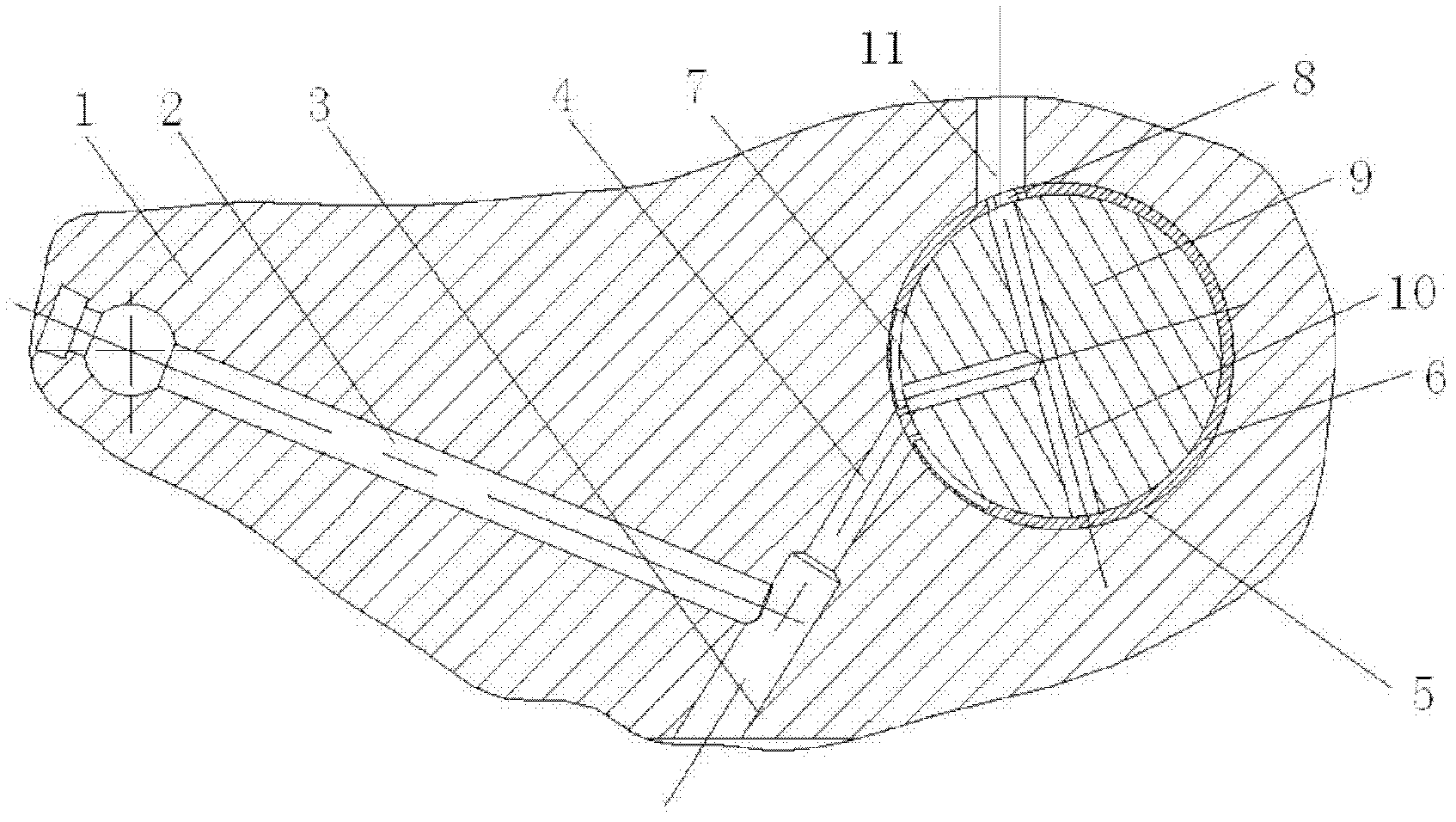

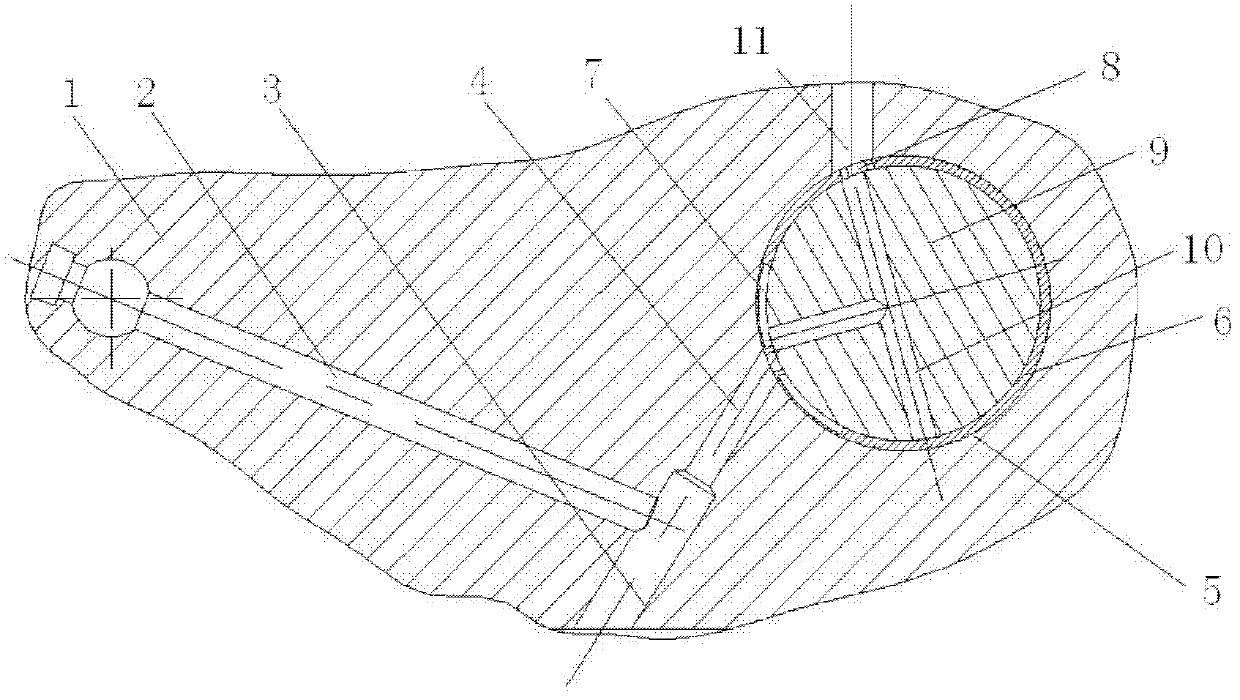

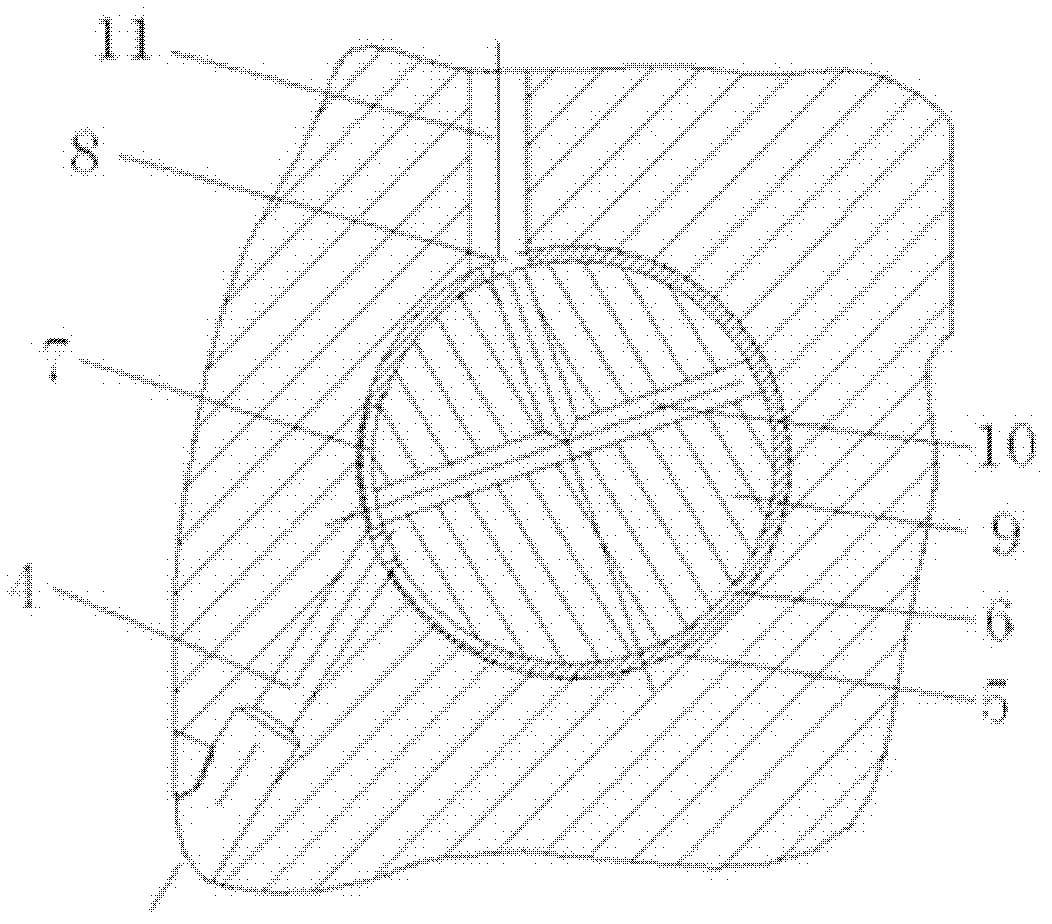

Self-lubricating crankshaft and rotary compressor, air conditioner and heat-pump water heater using same

ActiveCN103696966AImprove the lubrication effectIncreasing the thicknessCrankshaftsRotary/oscillating piston pump componentsEngineeringHelix angle

The invention discloses a self-lubricating crankshaft which comprises a major semi-axis, an eccentric circle and a minor semi-axis. The center of the crankshaft is provided with an axial through hole; the top and the bottom of the eccentric circle are respectively provided with a first radial oil guide hole and a second rail oil guide hole which are communicated with the through hole; the outer surface of the minor semi-axis is provided with at least one spiral oil guide slot which is slantingly formed along the axial direction and is communicated with the through hole; the rotating direction of the spiral oil guide slot is opposite to that of the crankshaft; the outer surface of the minor semi-axis is also provided with a spiral communication groove extending towards the bottom of the eccentric circle from the top end of the spiral oil guide slot; the spiral communication groove does not run through the lower end face of the minor semi-axis; the spiral oil guide slot is spirally formed by using the center line of the crankshaft as the center; a helix angle alpha of the spiral oil guide slot has an angle range of 5 degrees to 85 degrees; a concave included angle beta of two opposite lateral surfaces of the spiral oil guide slot in the process of ascending along the spiral direction has an angle range of 2 degrees to 80 degrees; and the rotating direction of the spiral communication groove is the same with that of the spiral oil guide slot. The invention also discloses a rotary compressor, an air conditioner and a heat-pump water heater which use the self-lubricating crankshaft.

Owner:ZHUHAI LANDA COMPRESSOR +1

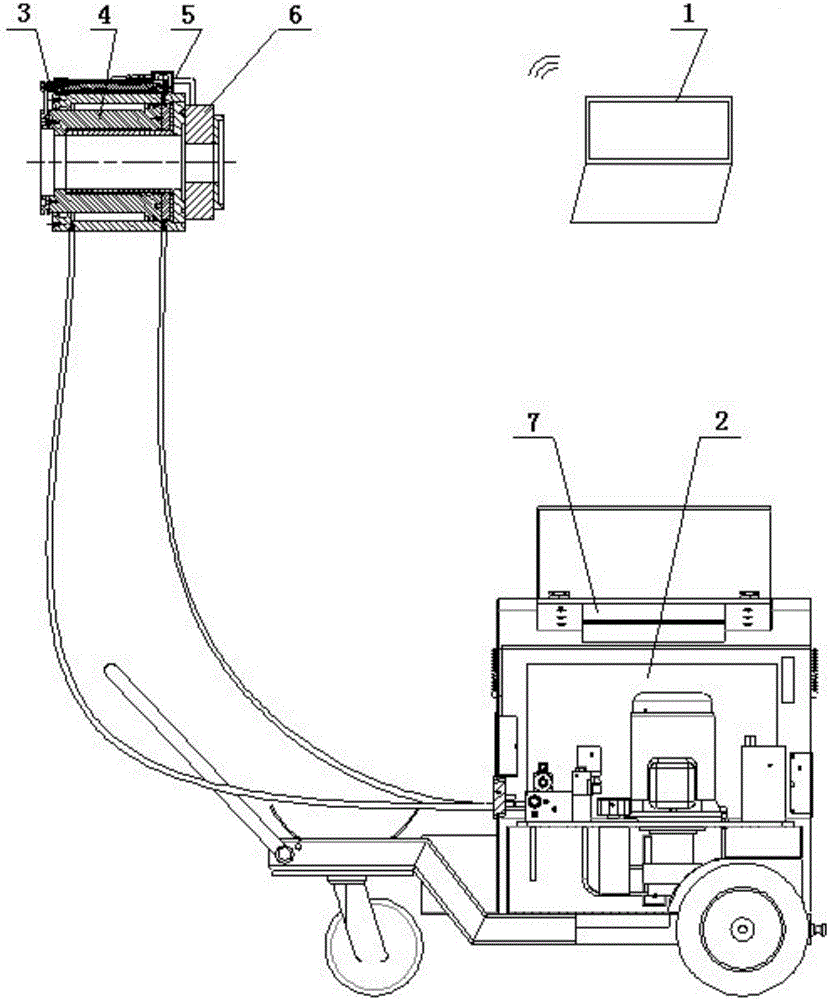

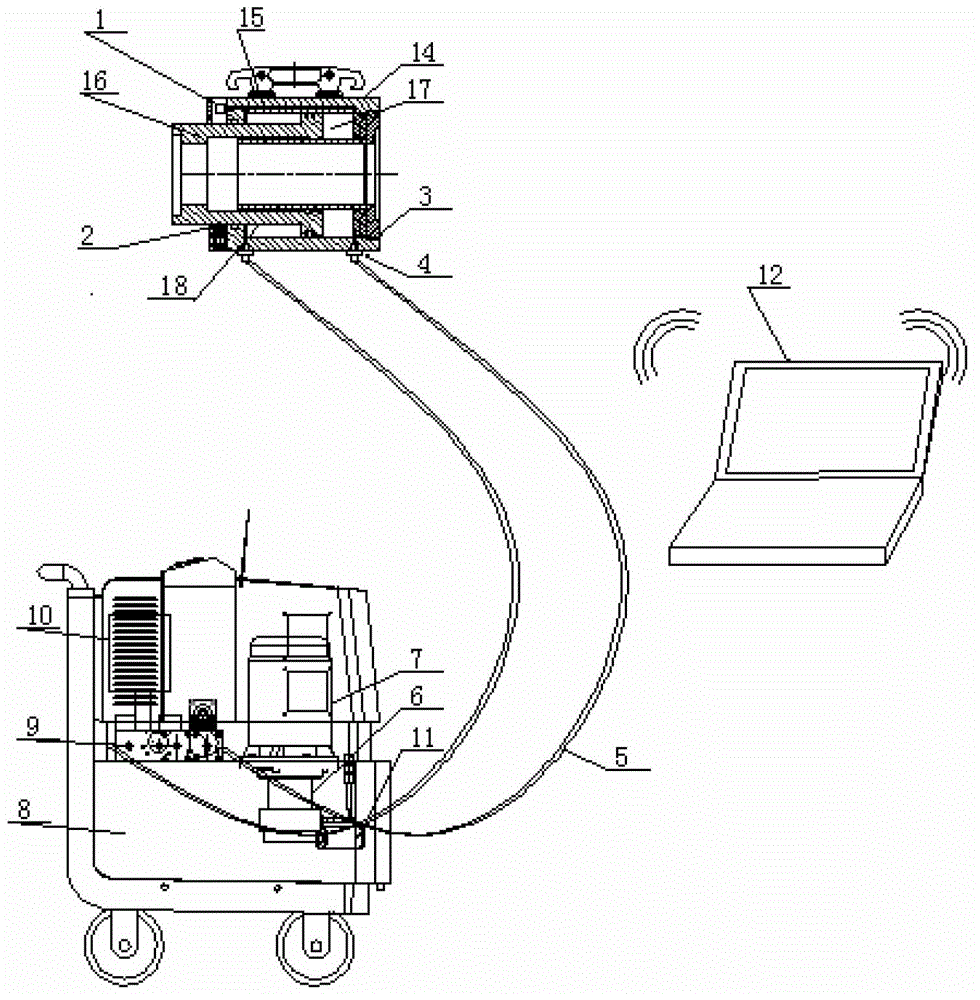

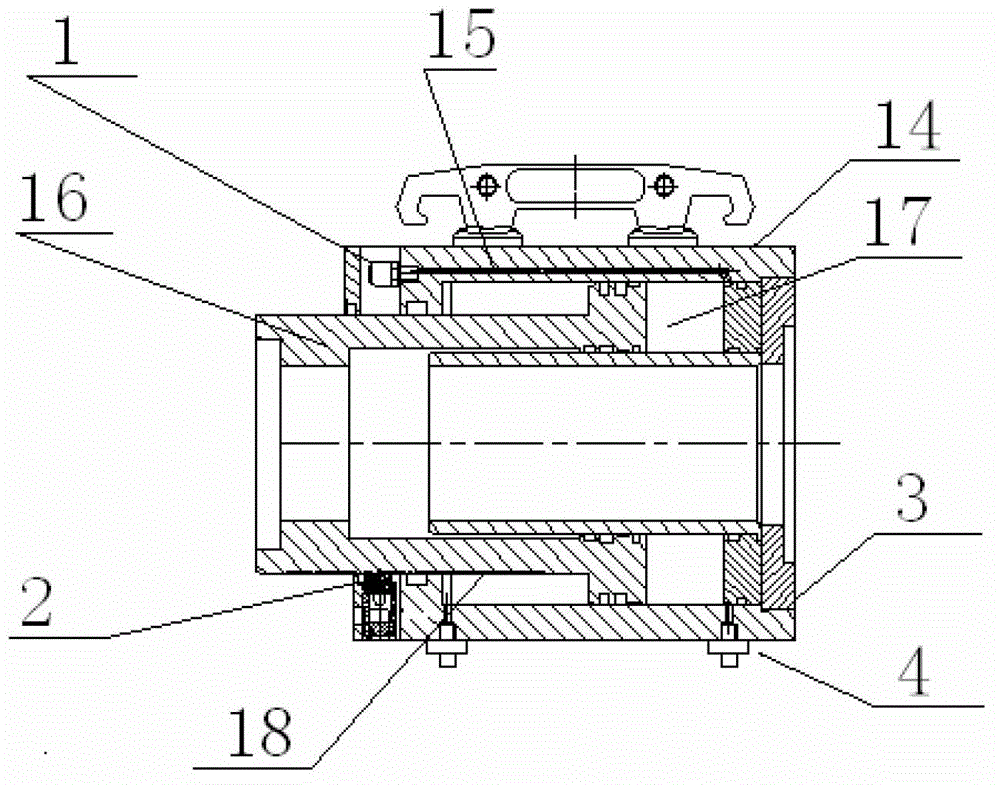

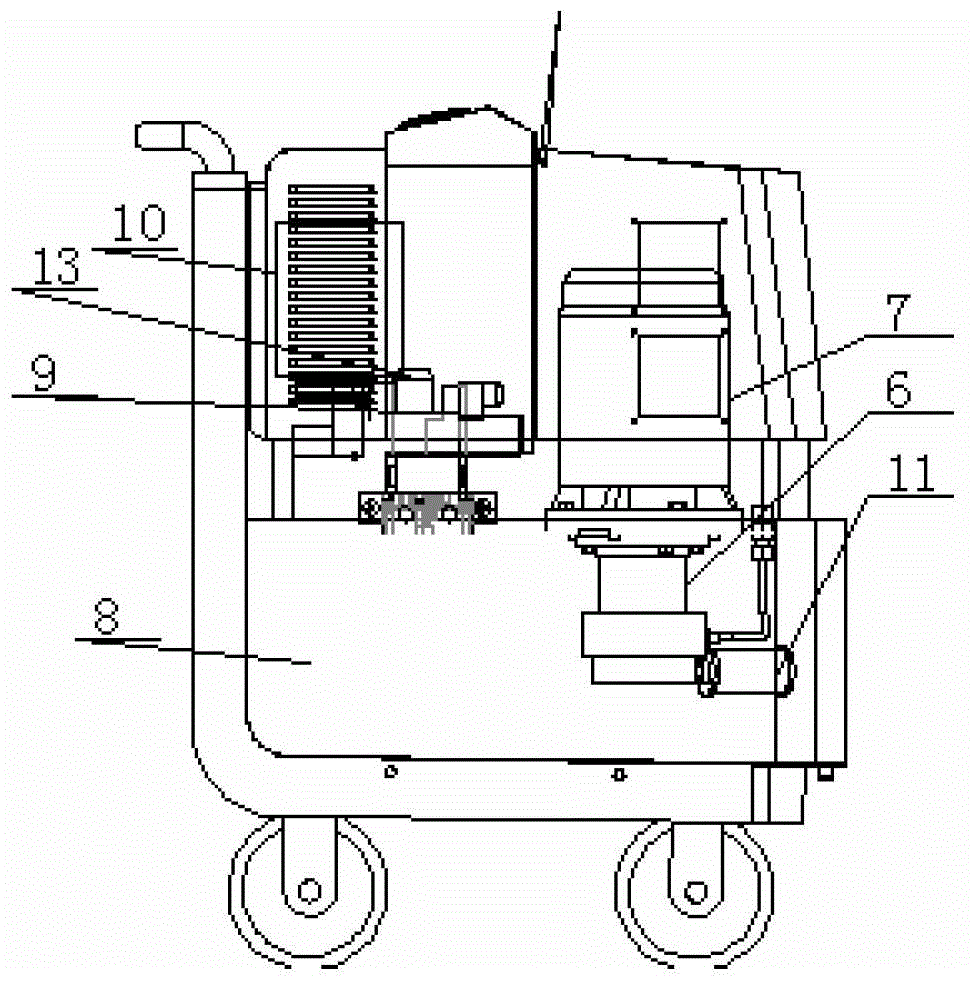

Bridge prestress tensioning system

InactiveCN105113417AReduce lossesSlow pressure releaseBridge erection/assemblyBuilding material handlingData informationFuel tank

A bridge prestress tensioning system comprises a computer unit, a tensioning instrument, a displacement sensor, a jack, a pressure sensor, a force sensor and a controller. The displacement sensor is arranged on the outer side of a cylinder barrel of the jack and connected with a piston rod, and the force sensor is arranged on a cylinder barrel base of the jack; the tensioning instrument comprises a temperature sensor arranged on the side wall of an oil tank, and the computer unit can send a signal and drives the jack to carry out tensioning operation through the controller; the controller is connected with the displacement sensor, the force sensor and the temperature sensor and transmits data information collected by the sensors to the computer unit to be further processed; and the force sensor, the displacement sensor and the temperature sensor are connected with the controller to achieve intelligence and standardization of bridge prestress tensioning work; and the system is scientific and reasonable in whole structure, convenient to install and operate, high in work automation degree, reliable in equipment running and capable of being widely suitable for being used in cooperation with various bridge prestress tensioning systems.

Owner:龙力群

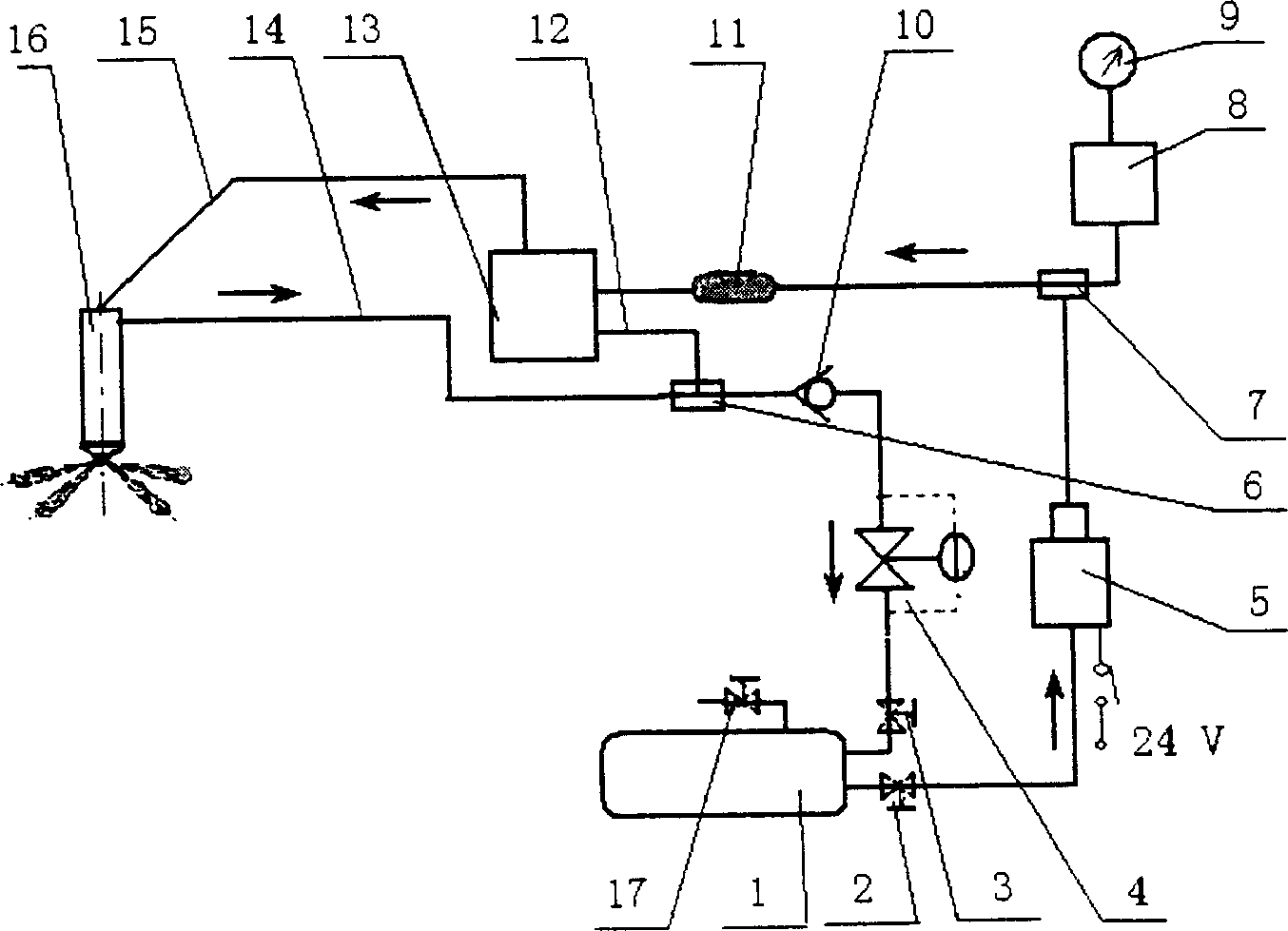

Dimethyl ether fuel hypermulti orifice forced injection system

InactiveCN1470757AEasy to spreadAccelerate emissionsInternal combustion piston enginesFuel supply apparatusReflux valveFuel filter

The present invention relates to a dimethylether fuel ultramultinozzle intensified spray system. The DME storage tank is connected with low-pressure fuel conveying pump via liquid outlet value, the outlet of the low-pressure fuel conveying pump is connected with intensified fuel-spraying pump through one end of T-junctor via fuel filter, an other end of T-junctor is connected with pressure-storing device on which the pressure gauge is mounted, the outlet of intensified fuel-spraying pump is connected with ultramultinozzle fuel-spraying device through high-pressure fuel pipe. Besides, said system also contains other several components of locking cap, needle valve, regulating nut, pressure-regulating spring, non-return valve and pressure control valve, etc. Said system can make engine obtain high efficiency and ultralow discharge.

Owner:SHANGHAI JIAO TONG UNIV

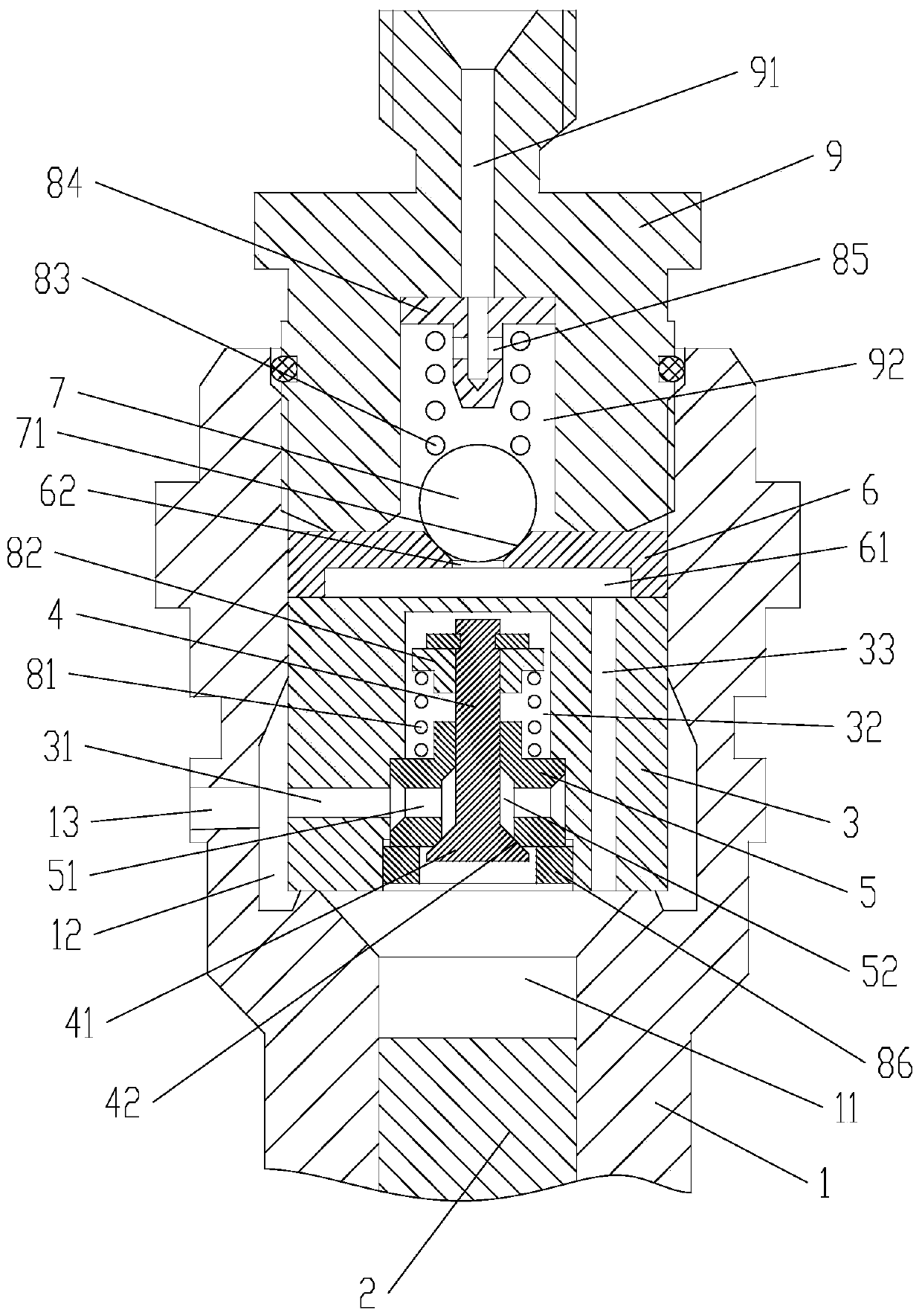

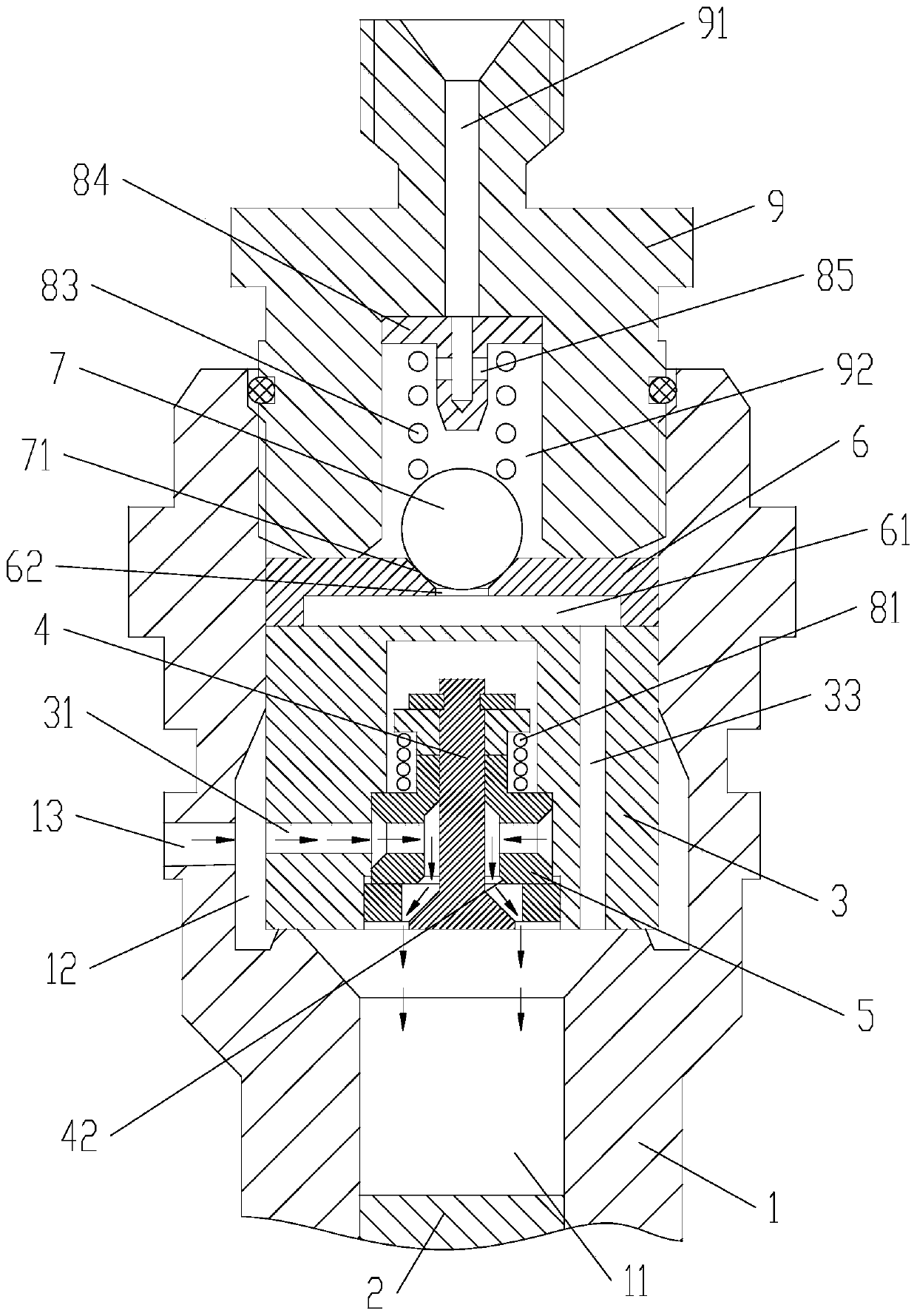

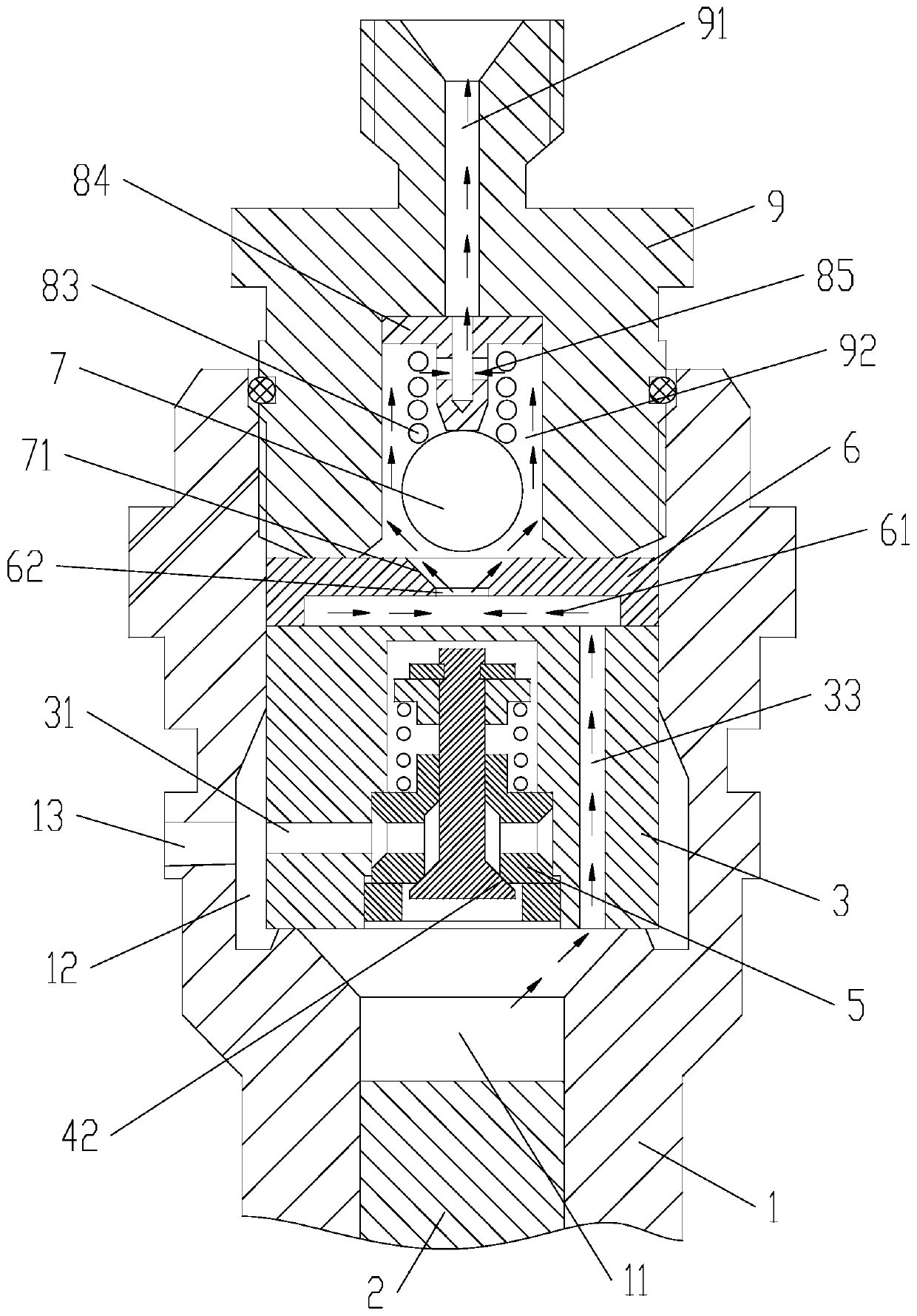

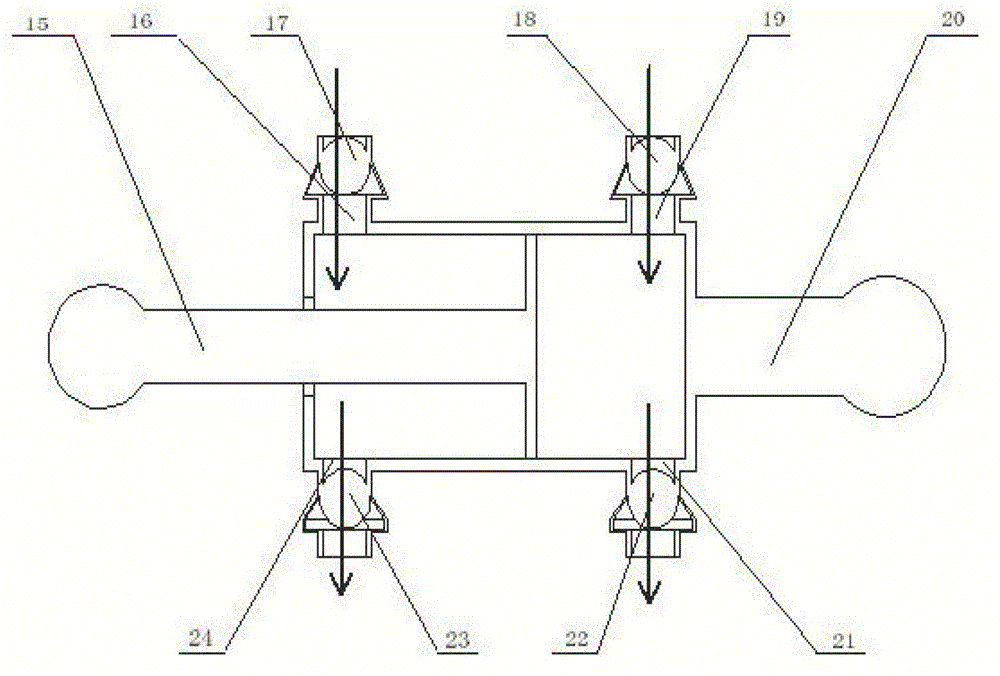

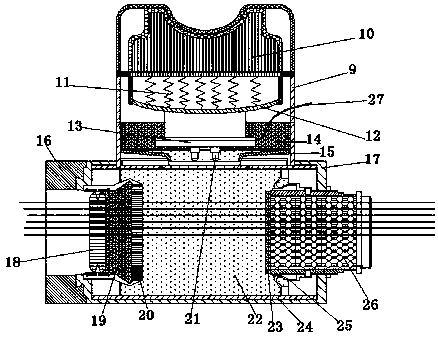

Common-rail high-pressure oil inlet/outlet valve assembly and common-rail high-pressure oil supply pump

PendingCN110748446ASimple structureImprove oil filling efficiencyMachines/enginesFuel injecting pumpsCommon railInlet valve

The invention relates to a common-rail high-pressure oil inlet / outlet valve assembly which comprises a plunger bushing; a plunger cavity, a connecting cavity and an oil inlet are formed in the plungerbushing; a plunger is inserted in the plunger cavity in a sliding manner; an oil outlet connector is mounted on the connecting cavity and is provided with a seventh oil passage; an oil inlet valve seat is mounted in the connecting cavity and is hermetically connected with the plunger cavity; a first oil passage and a second oil passage for communicating the oil inlet with the plunger cavity are formed in the oil inlet valve seat; the first oil passage is communicated with the plunger cavity; an oil inlet valve element is arranged on the second oil passage and is pressed against the second oilpassage to form a first seal surface; the first seal surface is used for opening or closing the second oil passage; an oil outlet valve seat is hermetically mounted between the oil inlet valve seat and the oil outlet connector; the oil outlet valve seat is provided with a fourth oil passage communicated with the first oil passage and the seventh oil passage; an oil outlet valve element is arranged on the fourth oil passage and is pressed against the fourth oil passage to form a second seal surface; and the second seal surface is used for opening or closing the fourth oil passage. The oil inlet / outlet valve assembly is simple in structure, the oil passages are reasonable in arrangement, the oil filling efficiency is high, and the sealing performance is high.

Owner:英嘉动力科技无锡有限公司

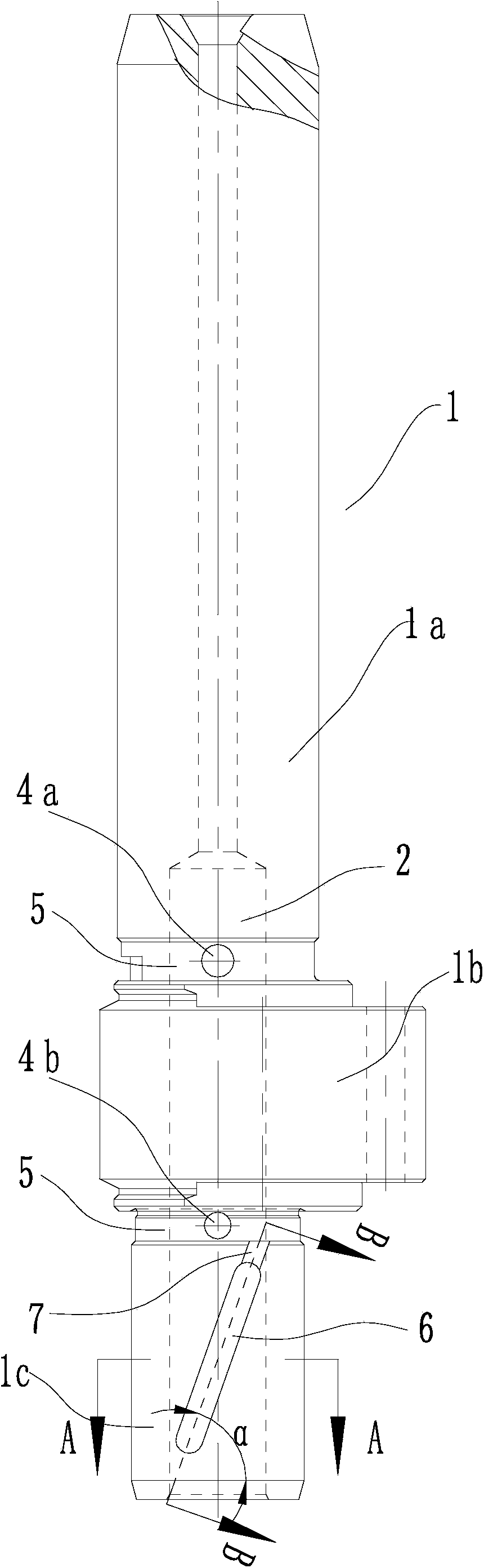

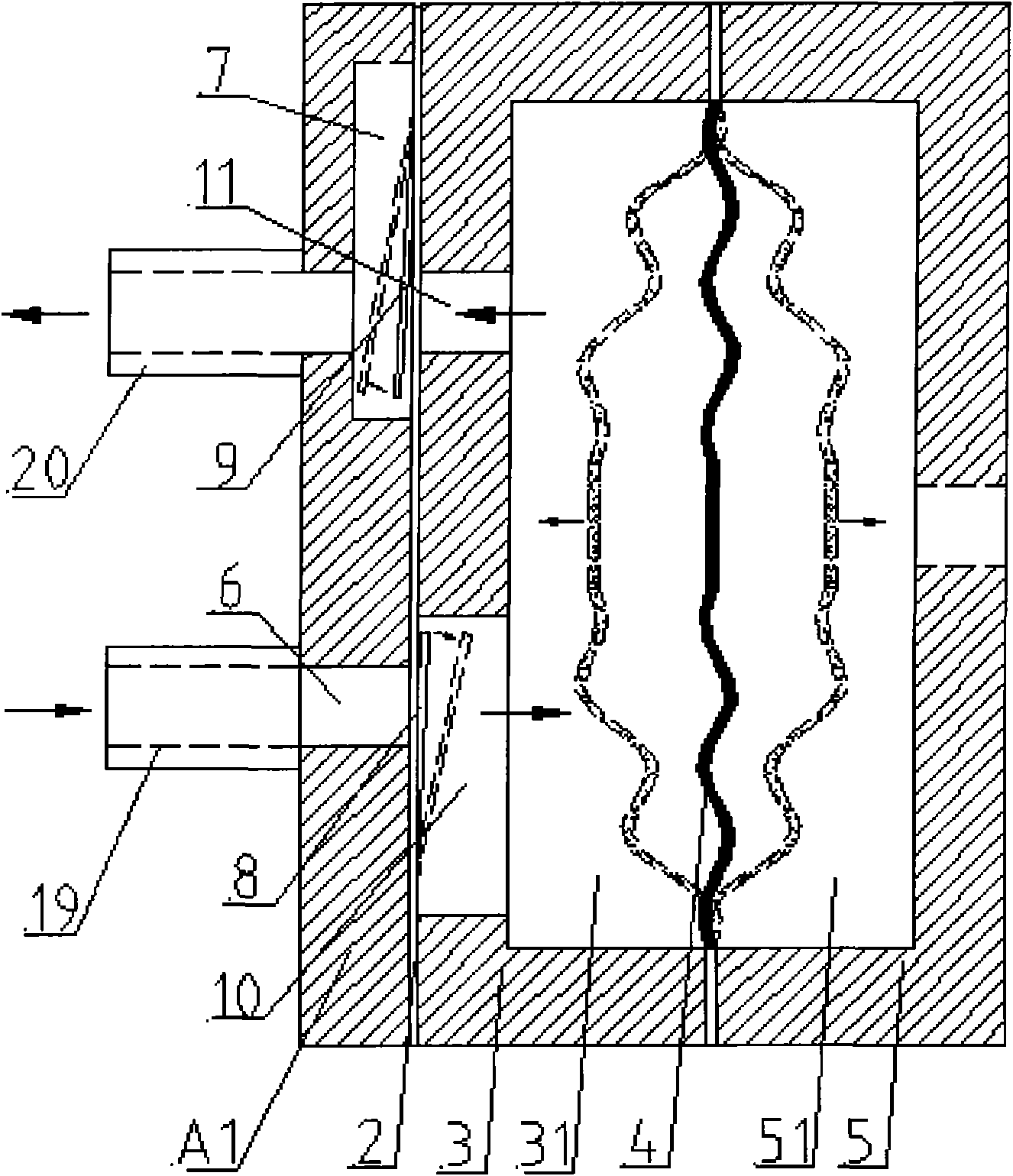

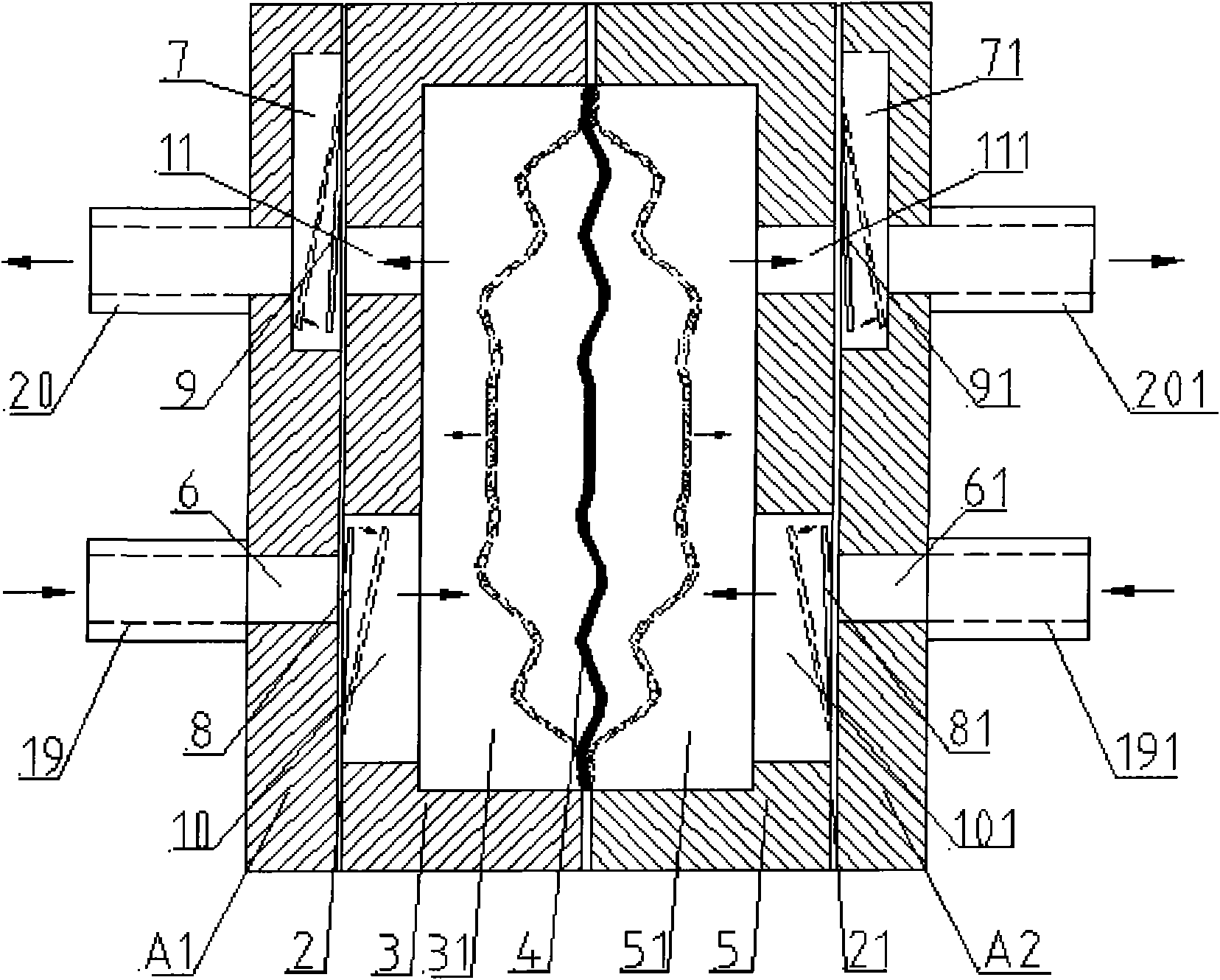

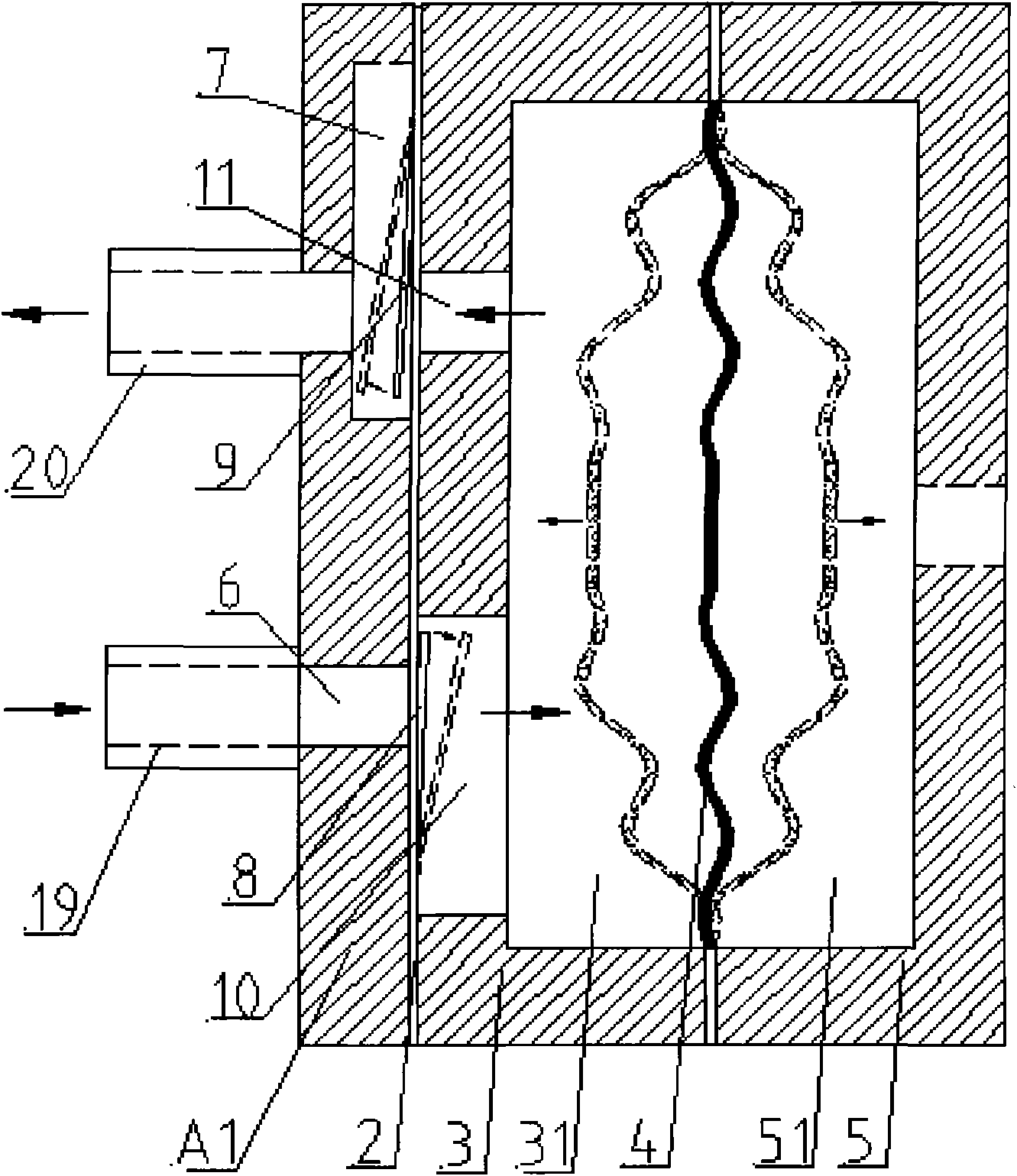

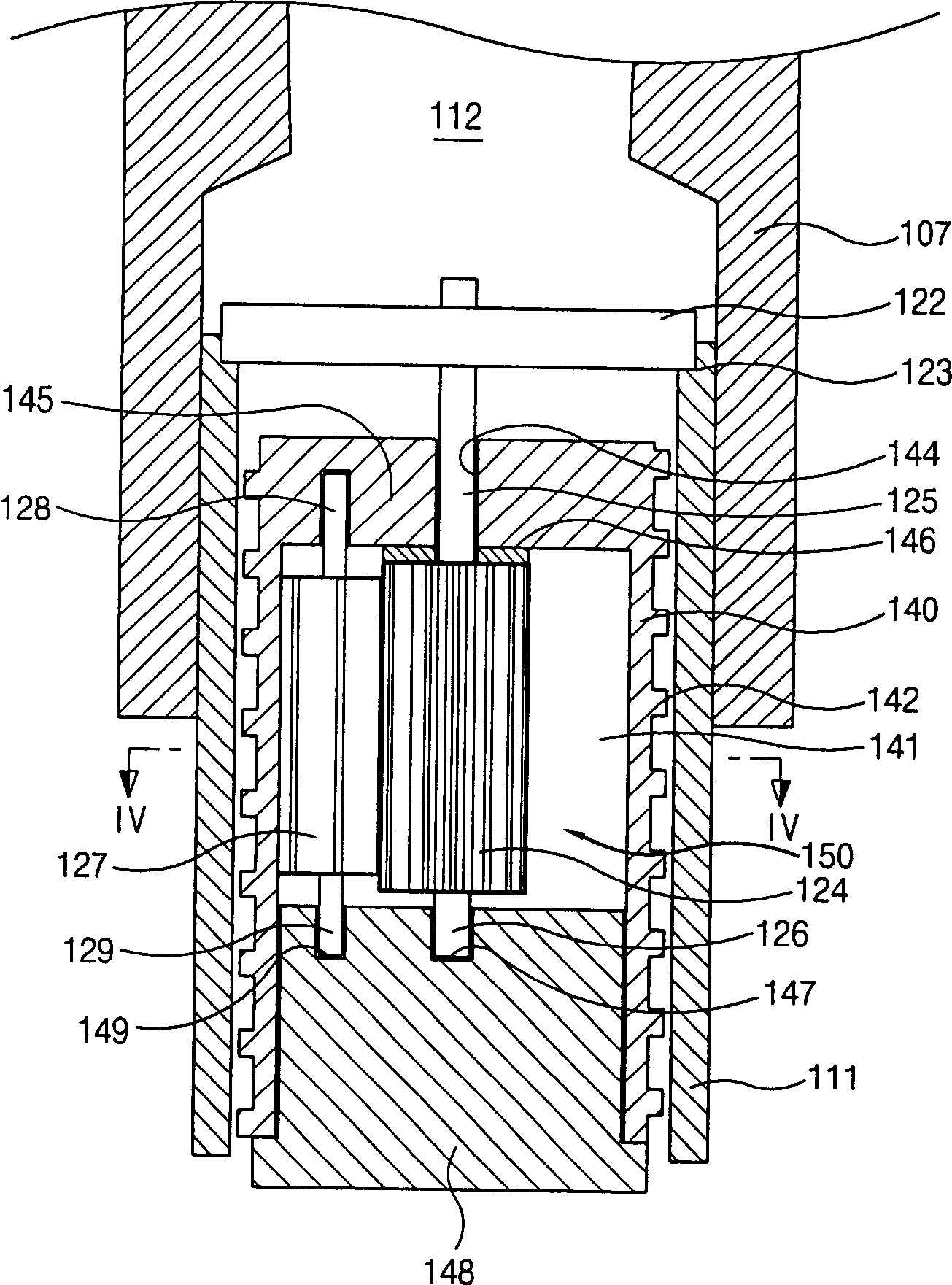

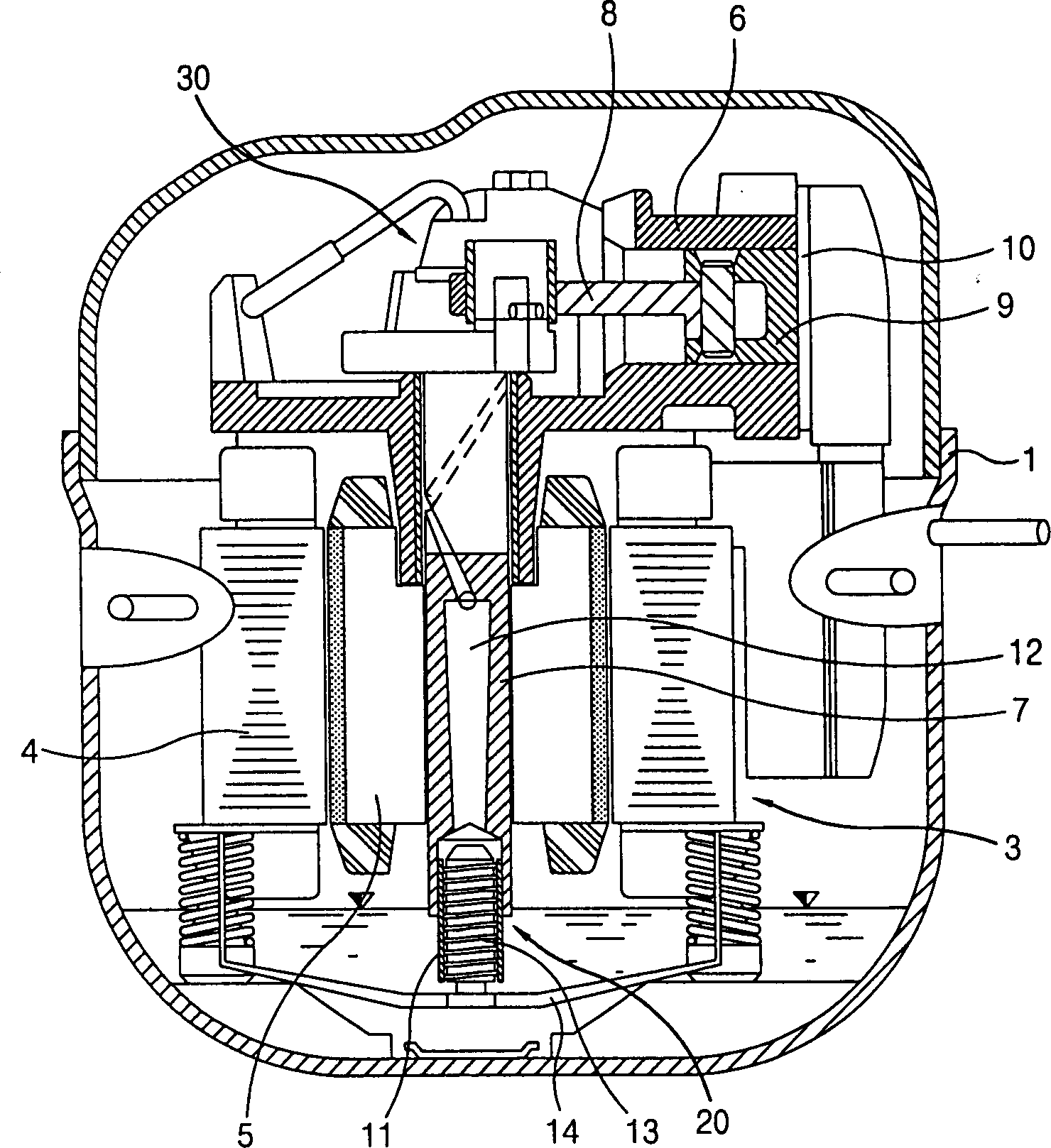

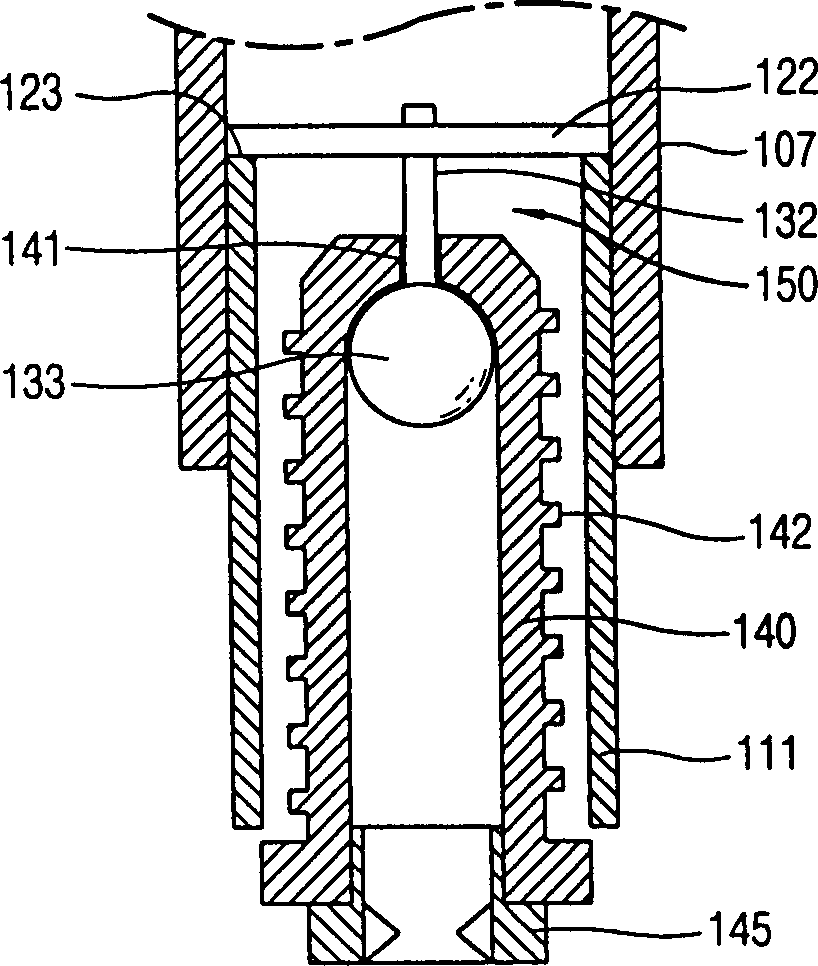

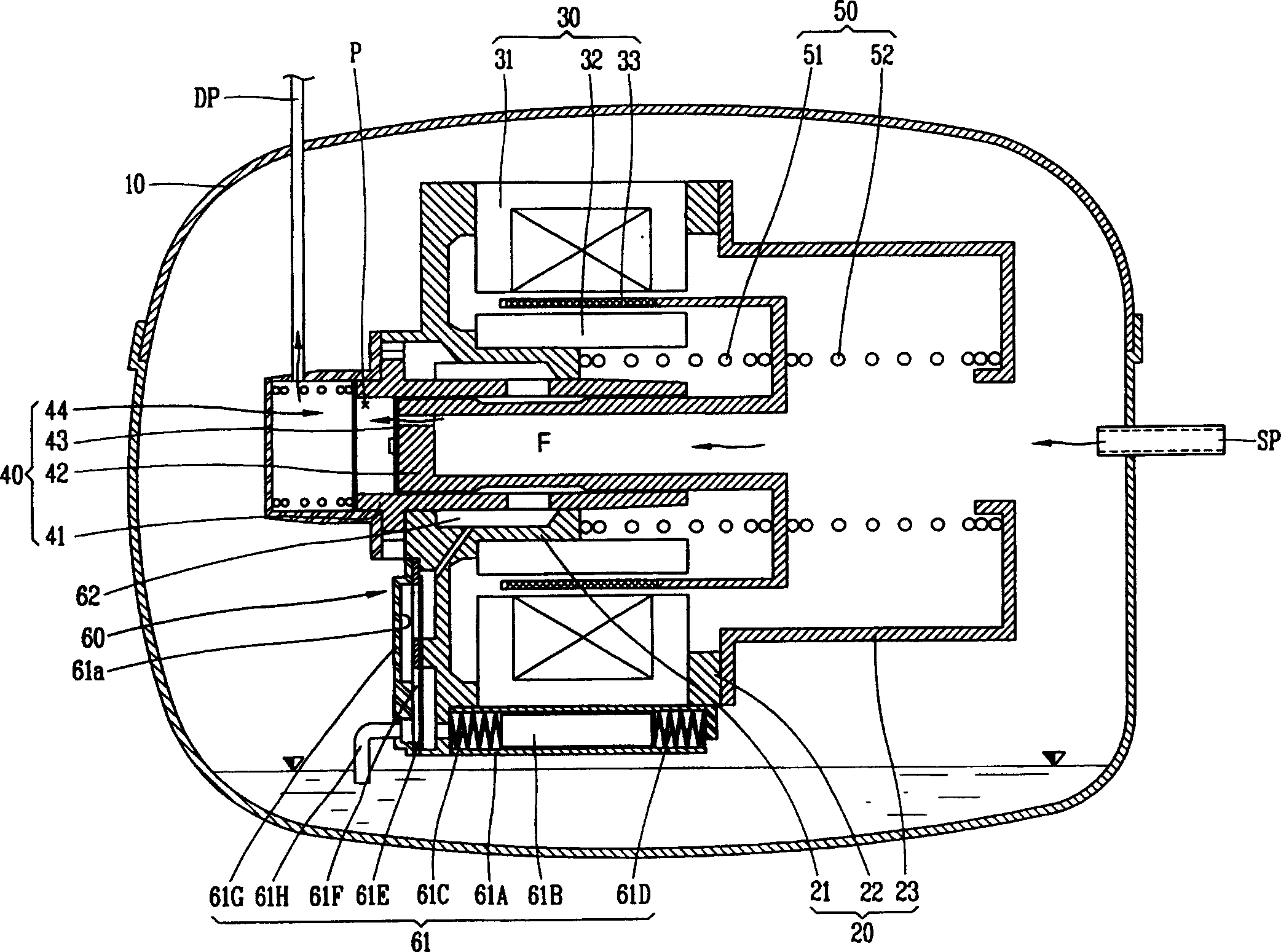

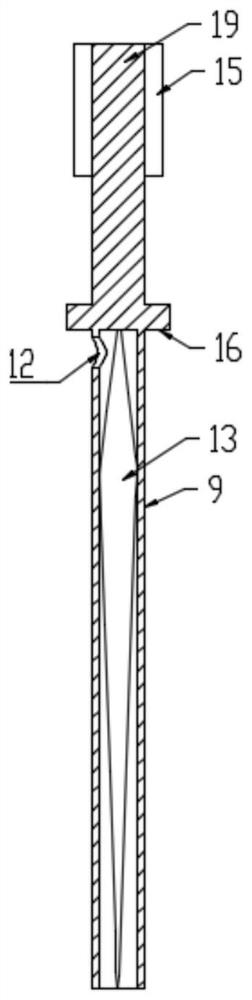

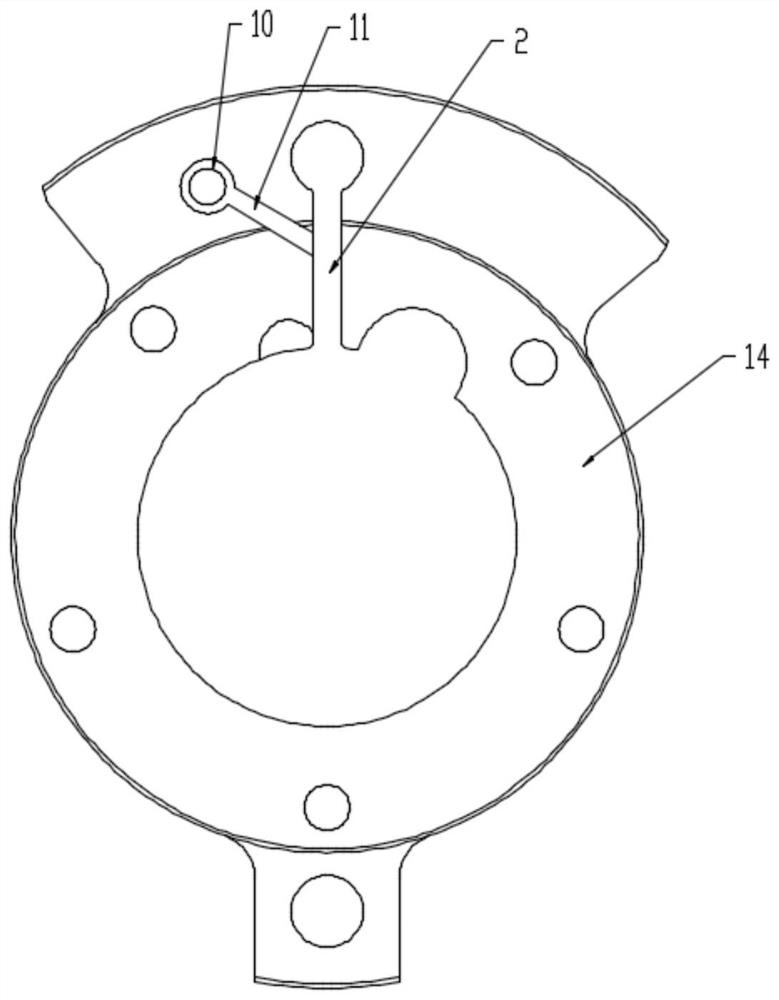

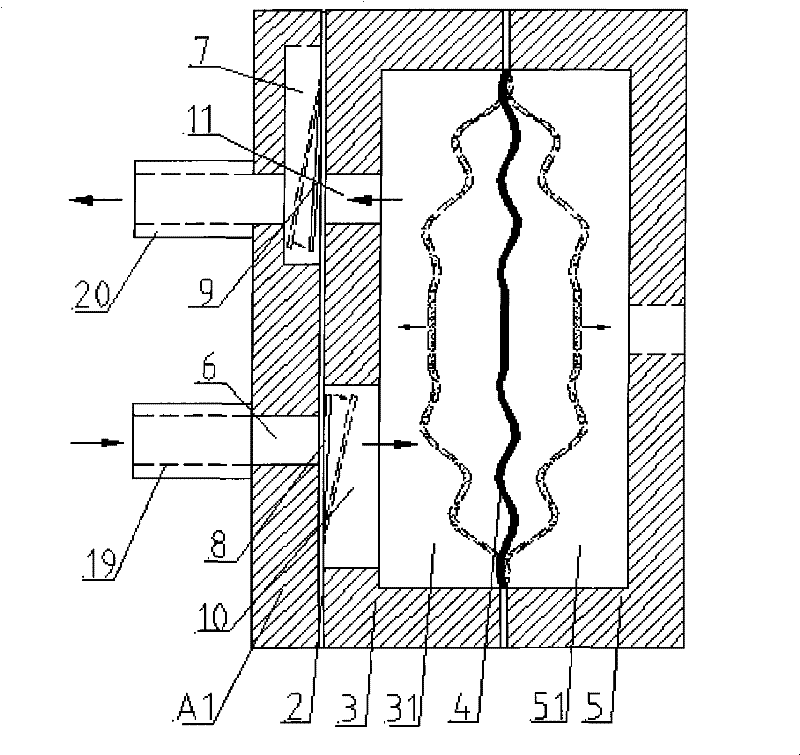

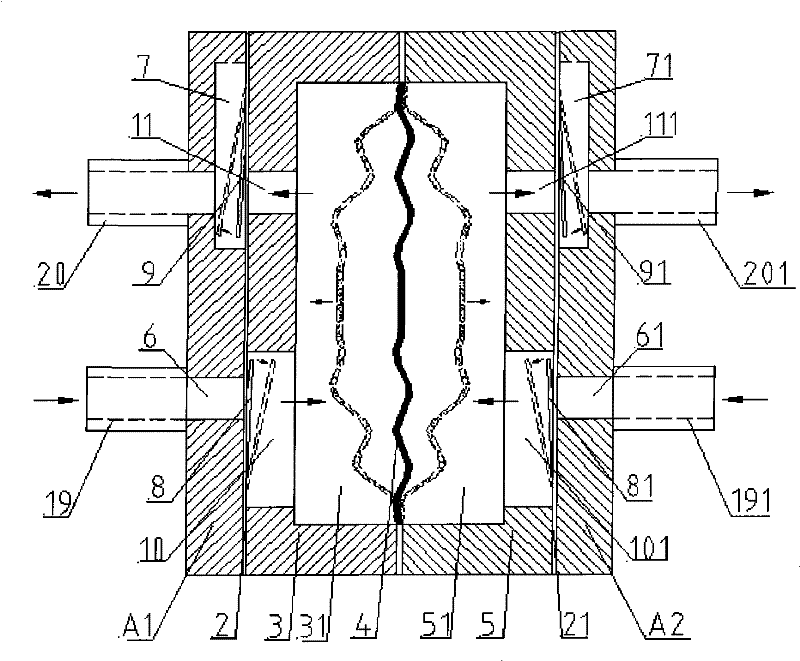

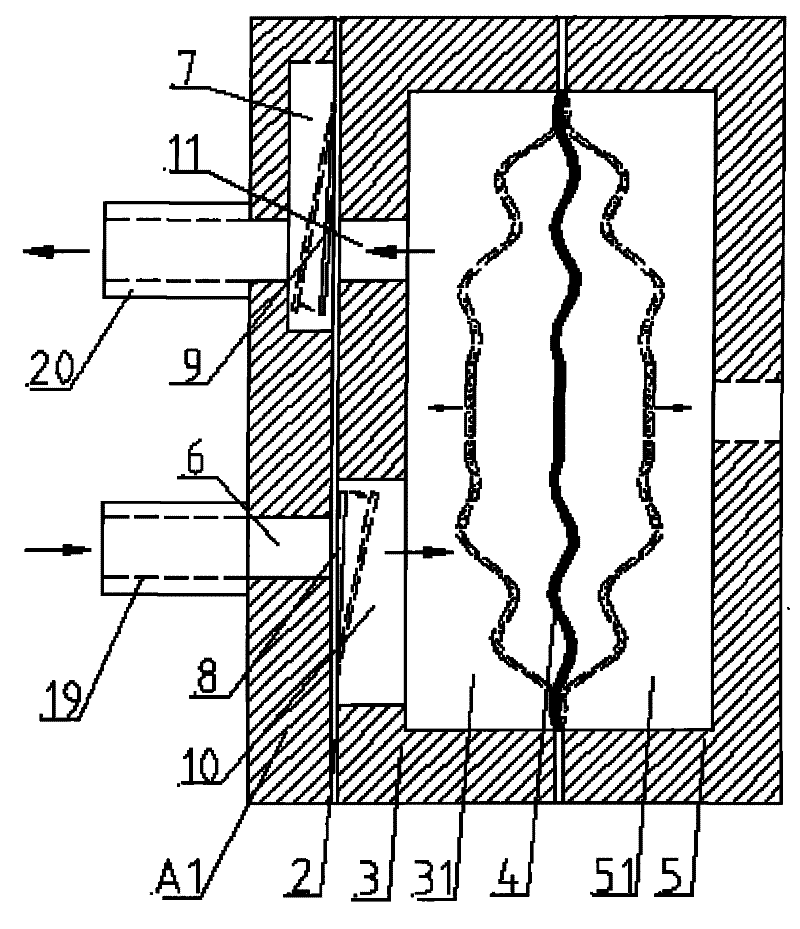

Oil supply device for linear compressor

InactiveCN101876310AImprove oil supply capacityPositive displacement pump componentsPositive-displacement liquid enginesReciprocating motionLinear compressor

The invention relates to an oil supply device for a linear compressor. The oil supply device comprises first and second grooves which are buckled with each other and clamp an elastic film therebetween, and a first end cover covering on an outer surface of the bottom of the first groove; the first and second grooves and the elastic film enclose to form a first cavity and a second cavity respectively; an oil supply through hole and an oil absorption through groove are formed at the bottom of the first groove; the first end cover is provided with an oil supply blind groove and an oil absorption through hole; the oil absorption through hole is communicated with the oil absorption through groove, and an end surface where the oil absorption through hole is communicated with the oil absorption through groove is provided with a one-way oil absorption valve opened toward a direction close to the first cavity; the oil supply through hole is communicated with the oil supply blind groove, and an end surface where the oil supply through hole is communicated with the oil supply blind groove is provided with a one-way oil supply valve opened toward a direction away from the first cavity; the centre of the elastic film is connected with a moving component of the compressor or provided with a balance weight. When the linear compressor works, the elastic film reciprocates so as to change the volume of the cavity; if the volume of the cavity is larger, negative pressure is generated in the cavity, so that the oil absorption valve is opened and the oil enters the cavity; and if the volume of the cavity is smaller, the pressure in the cavity is increased, so that an oil discharge valve is opened and the oil enters a cylinder of the compressor.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

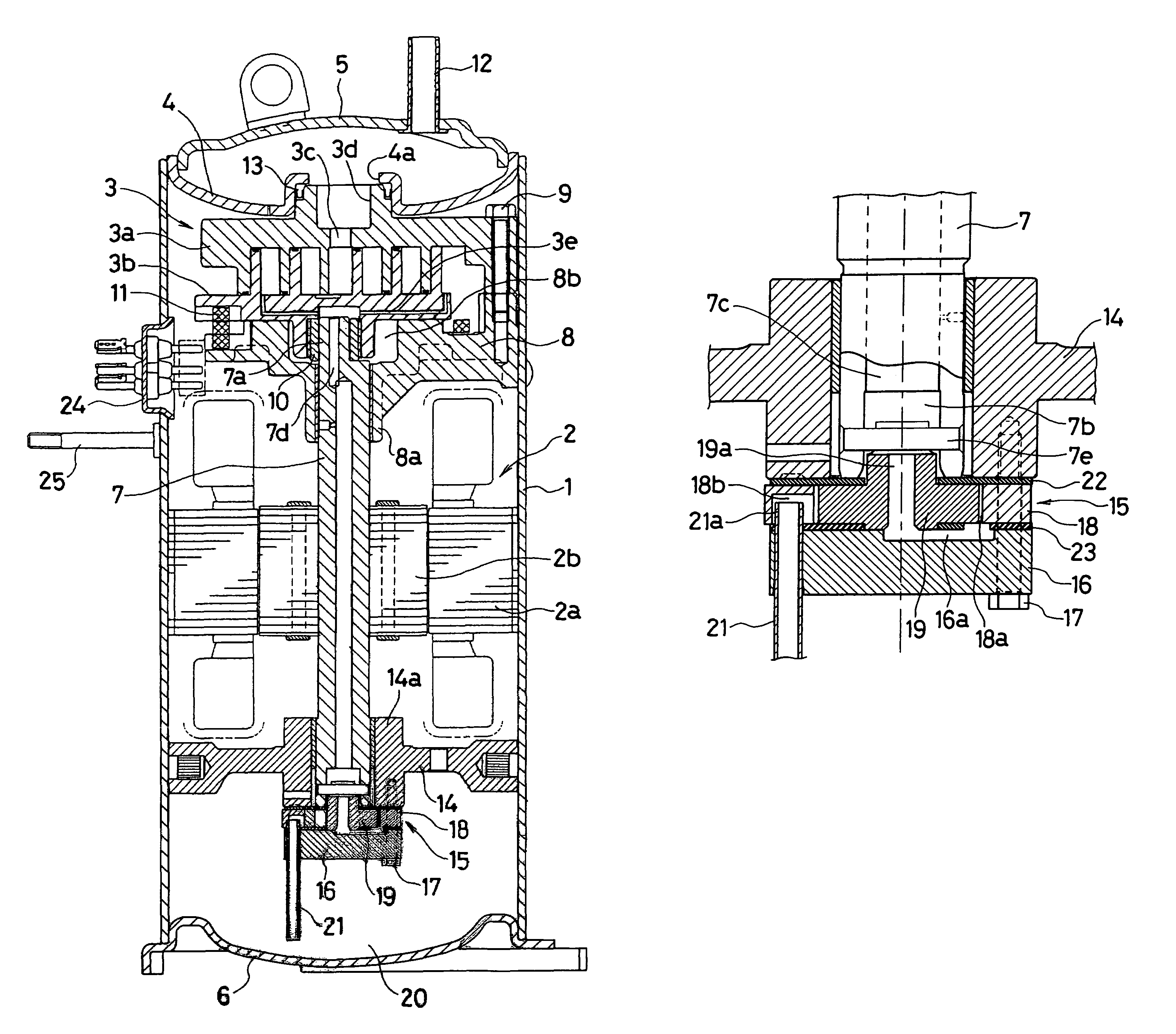

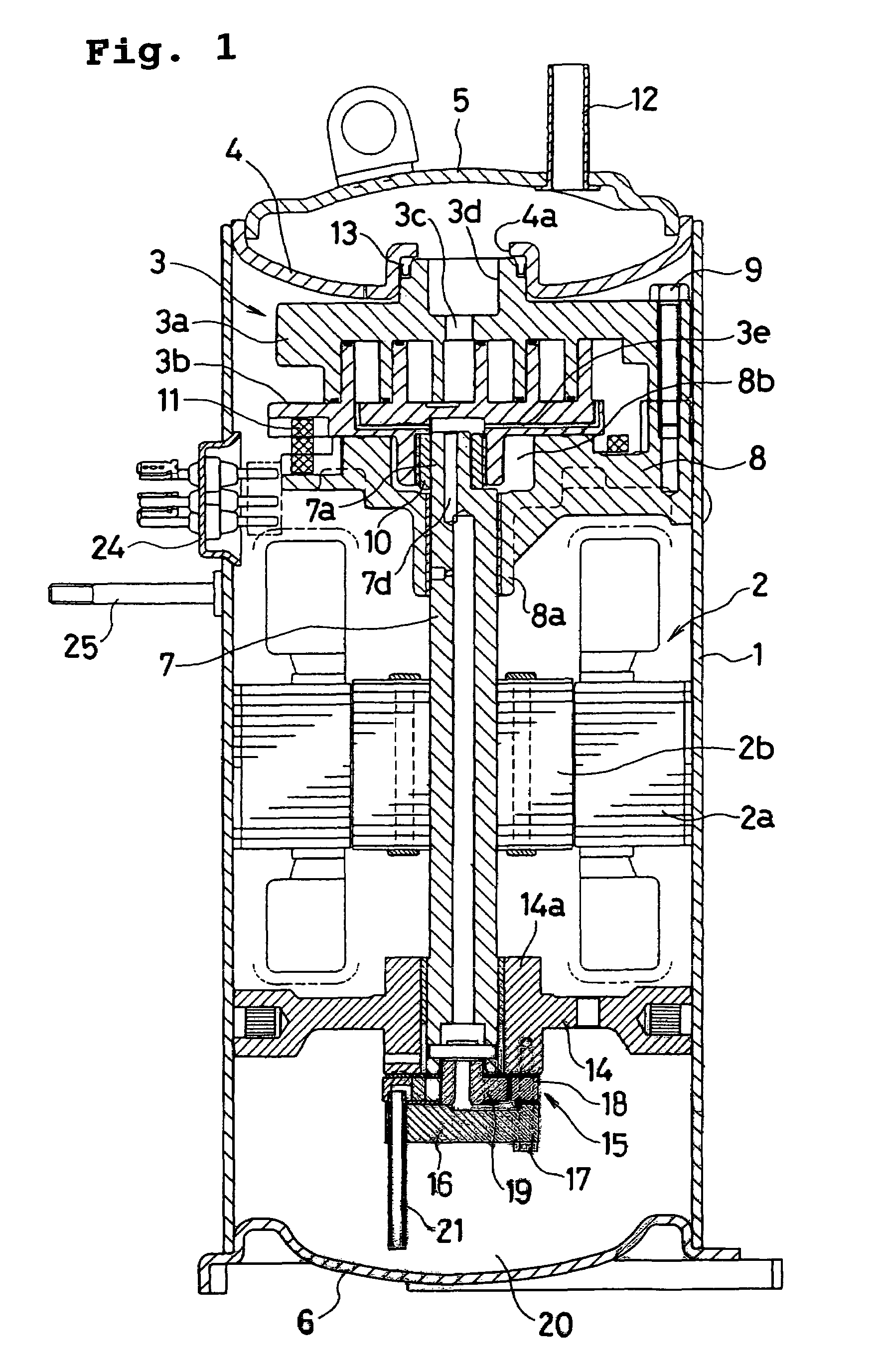

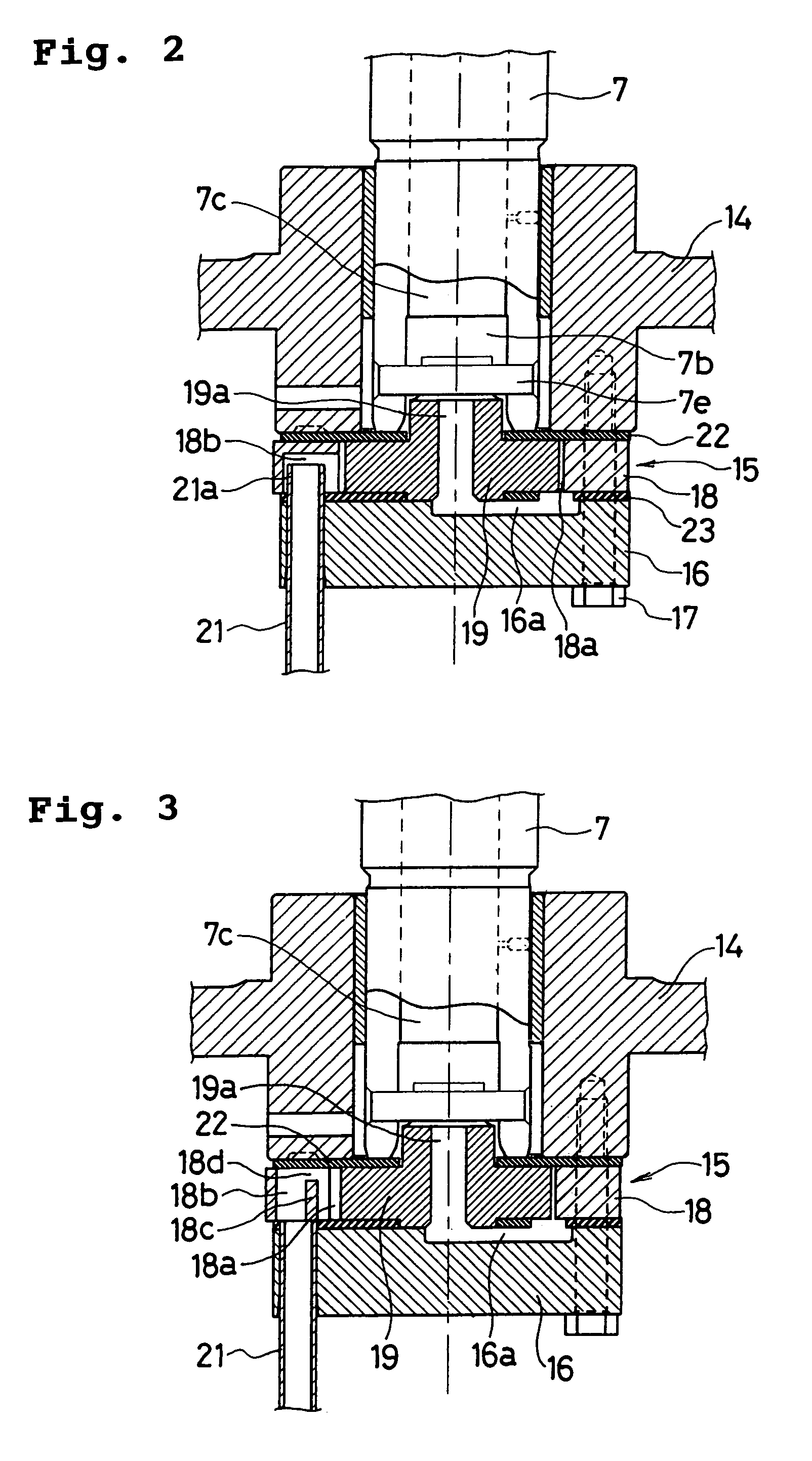

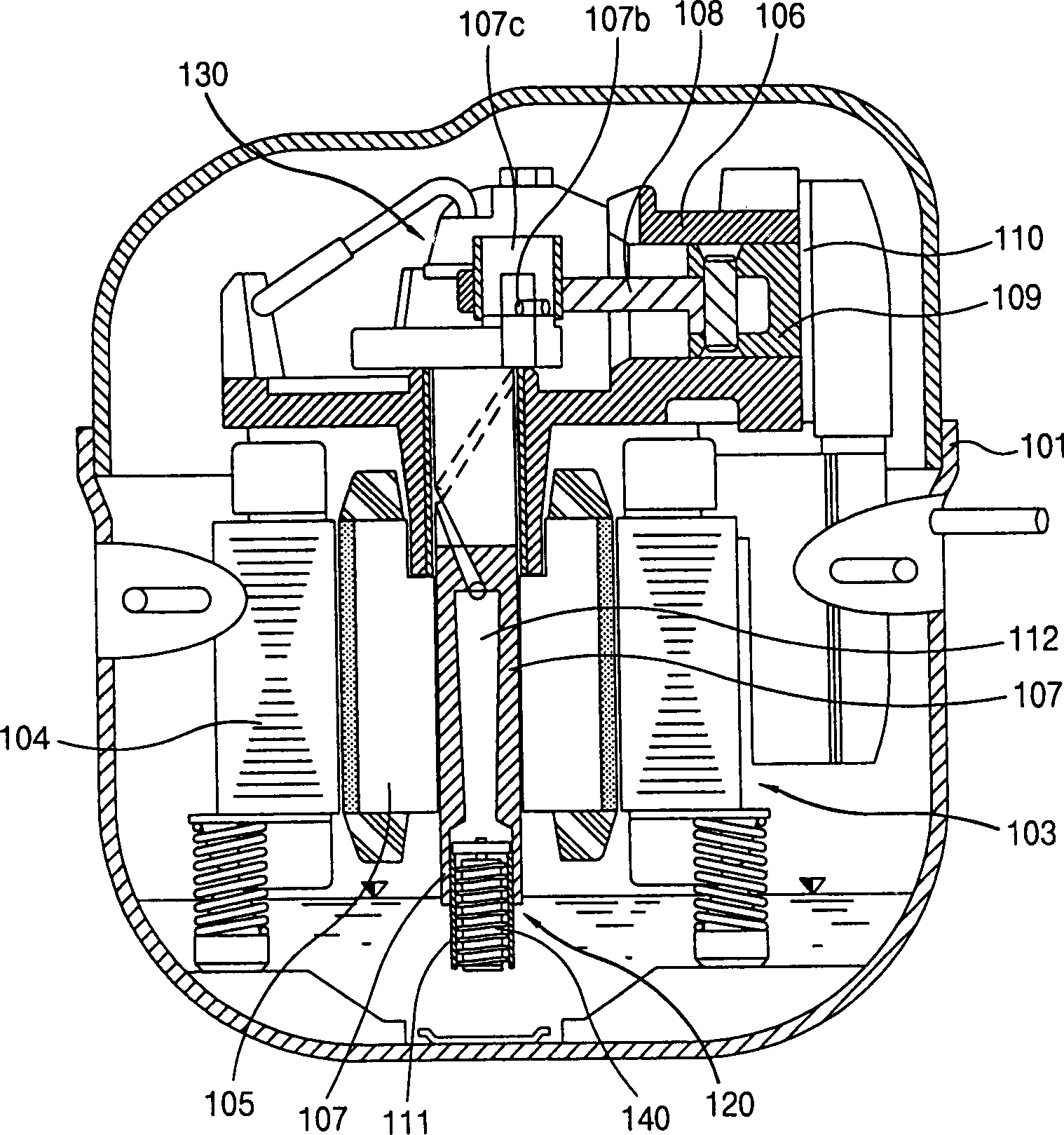

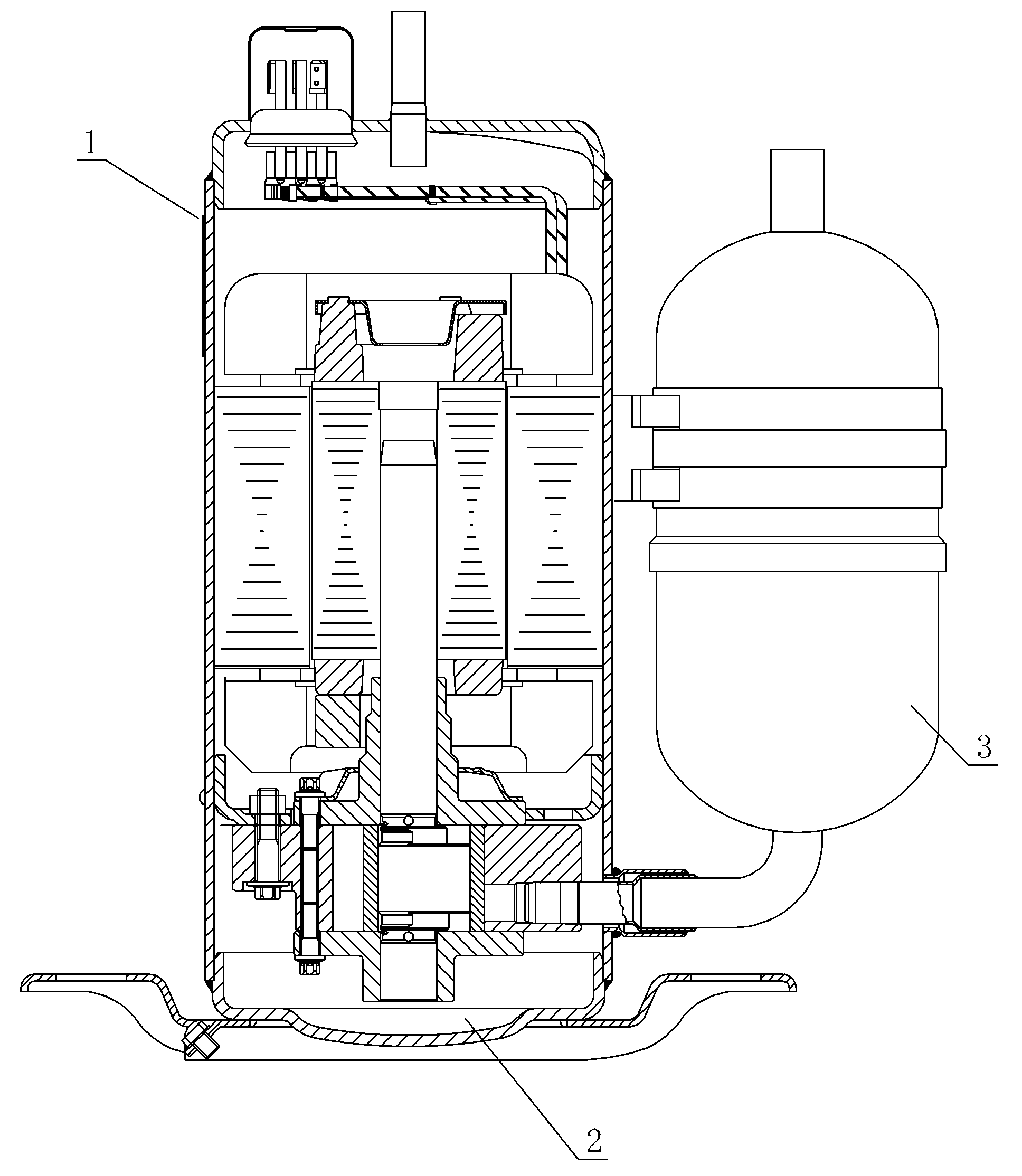

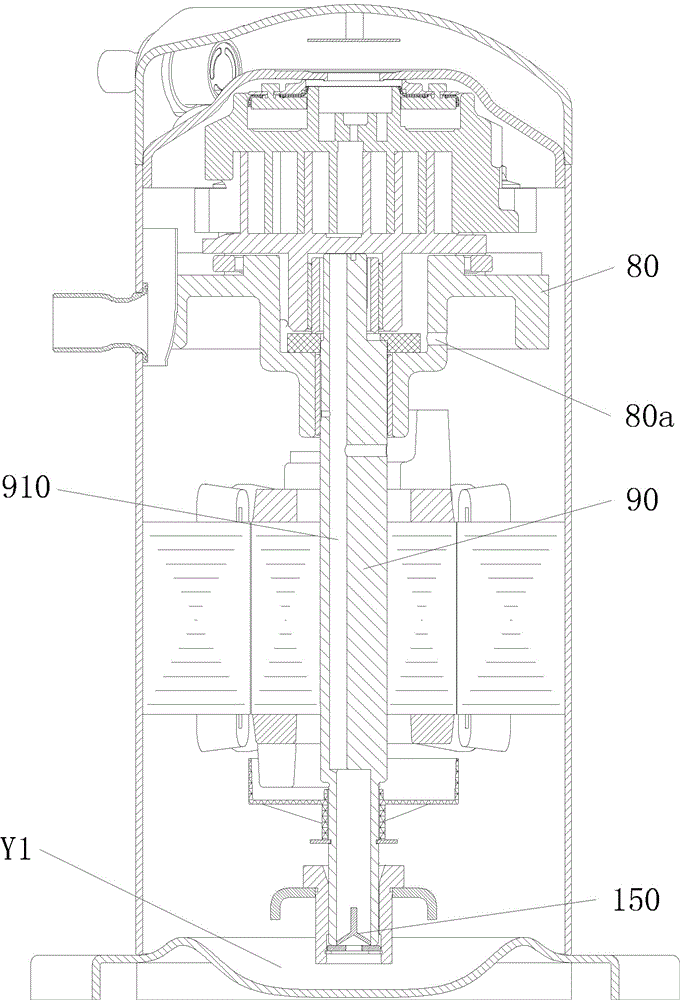

Compressor having an oil residue pool

InactiveUS7442018B2Improve oil supply capacityImprove sealingRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeInterior spaceEngineering

A compressor comprises, in a container body, an electric element, and a compressive element driven by the electric element. An oil storage is provided in the bottom, and an oil pump is provided to suck up oil from the oil storage. The oil pump includes a cylinder fixed to a lower support frame, a rotator axially installed on the lower end of a driveshaft and operative to rotate within an inner space of the cylinder, and a suction pipe having an upper end connected to a communication notch formed in the cylinder and a lower end inserted and arranged in the oil storage. In this compressor, the upper end of the suction pipe is protruded into the communication notch of the cylinder to configure an oil residue pool.

Owner:SANYO ELECTRIC CO LTD

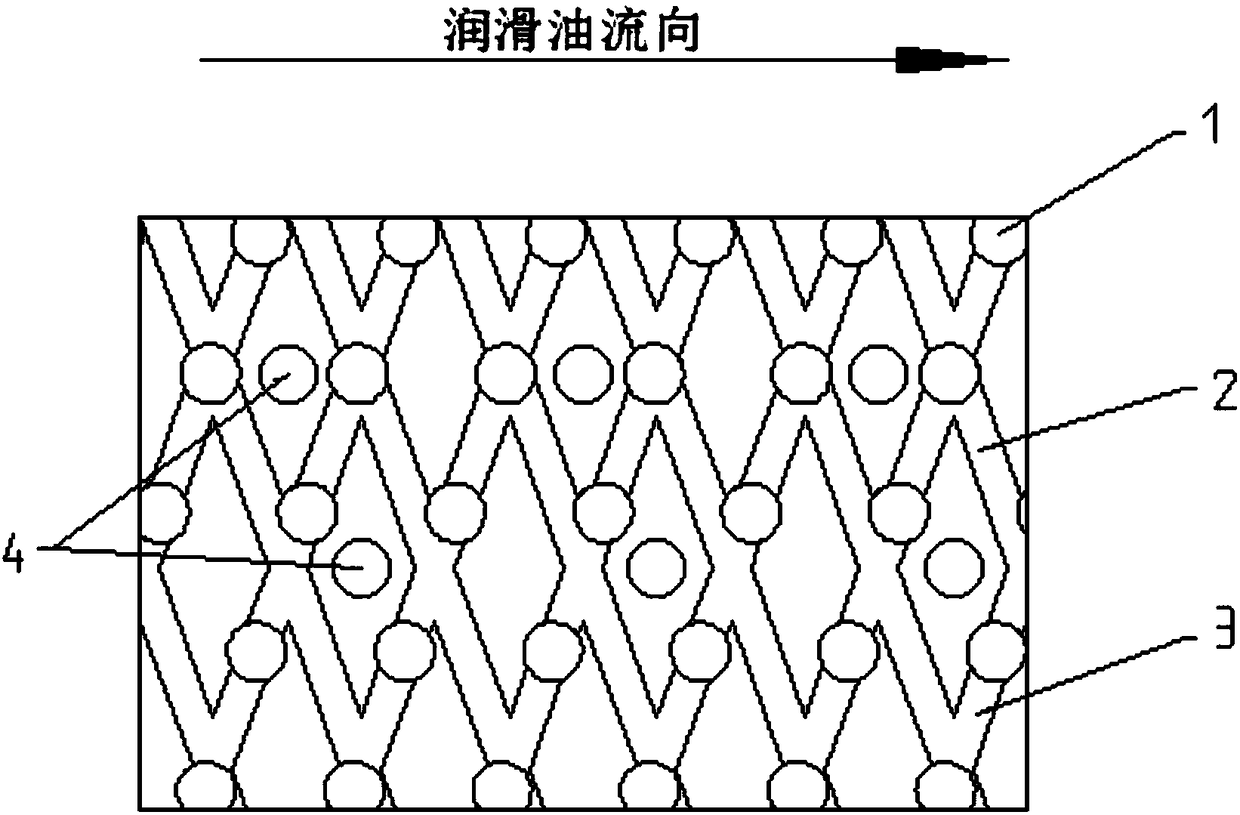

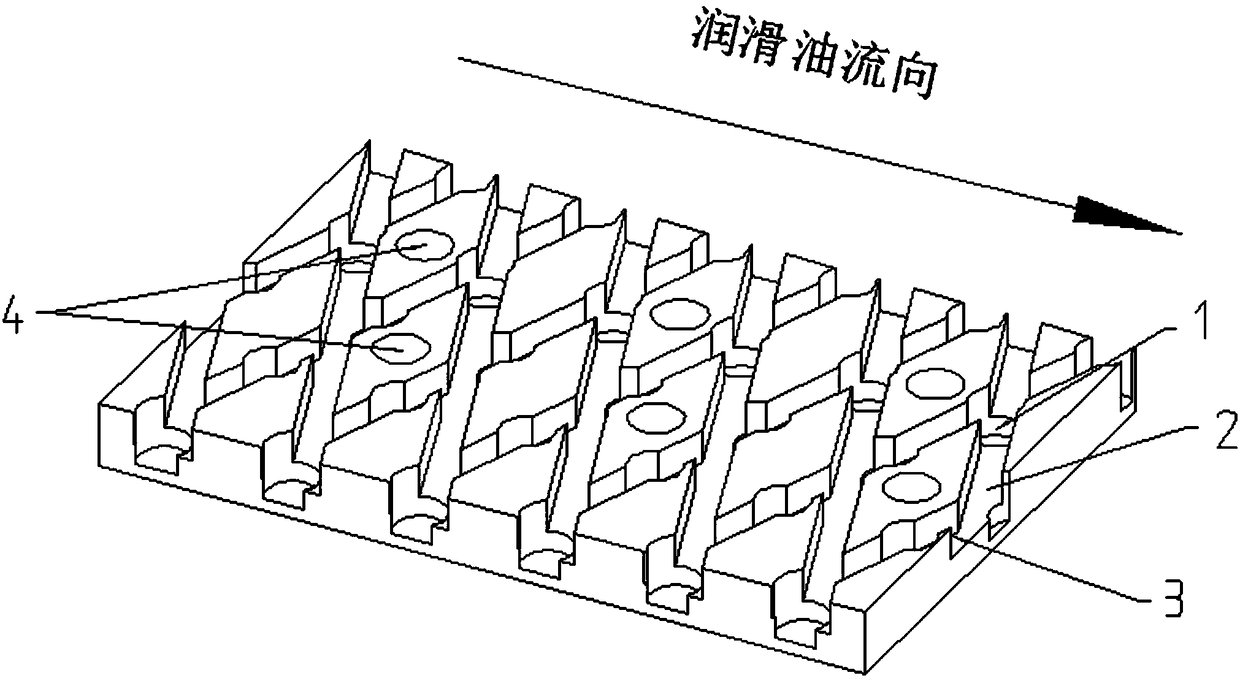

Composite surface structure friction pair

PendingCN108240398AImprove tribological performanceSpeed up the flowShaftsBearing componentsEngineeringSurface structure

The invention discloses a composite surface structure friction pair and belongs to the technical field of mechanical motion friction pair surfaces. The composite surface structure friction pair structurally comprises an upper surface friction pair and a lower surface friction pair. A composite surface structure is machined on the surface of the lower surface friction pair. The composite surface structure comprises a plurality of first grooves, a plurality of second grooves, a plurality of first pits and a plurality of second pits. The plurality of first grooves are arranged in parallel. The plurality of second grooves are arranged in parallel. The first grooves and the second grooves are arranged in a crossed mode to form a netted groove structure. The first pits are arranged along the netted groove structure in sequence so as to be communicated by the netted groove structure. The second pits are arranged in the centers of rhombic-shaped grids formed by the netted groove structure. Thecomposite surface structure friction pair changes the boundary lubrication state of an oil film through the surface structure machined on the surface of the motion friction pair, and the friction coefficient and wear extent are reduced.

Owner:UNIV OF JINAN

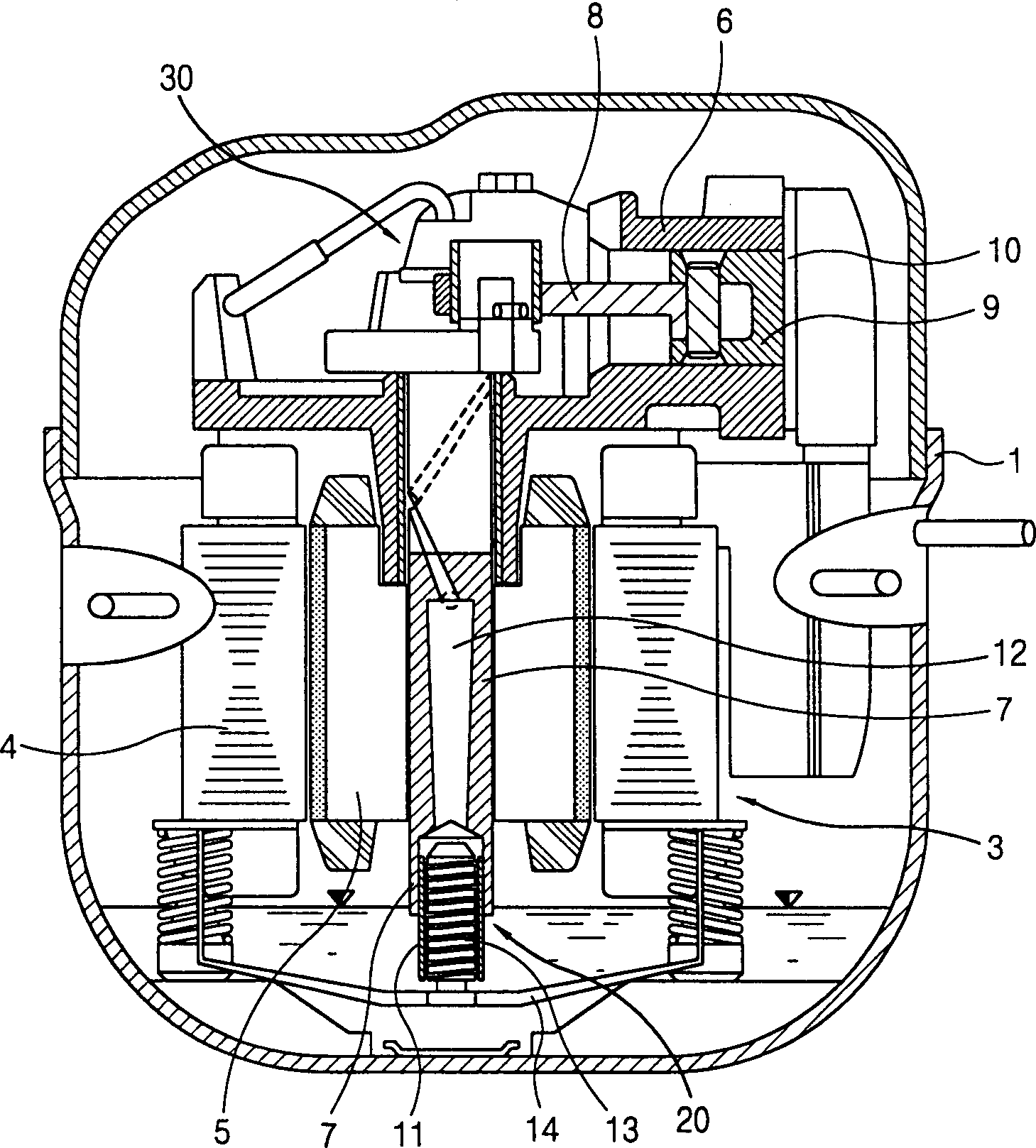

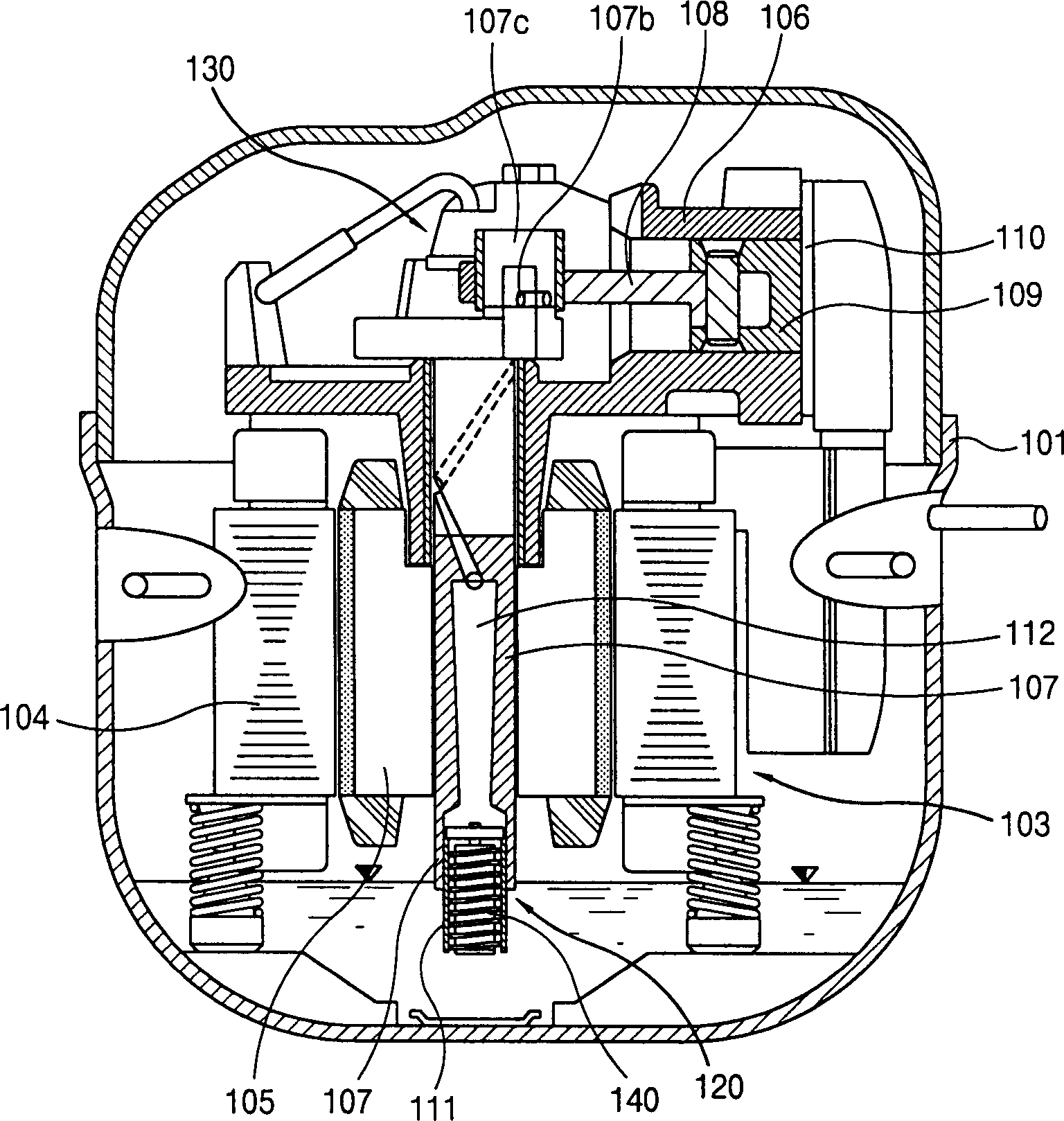

Oil supply device for hermetically sealed compressor

InactiveCN1386981AImprove oil supply capacityImprove performancePositive displacement pump componentsPiston pumpsRotation velocityCrankshaft

An oil supply device for a hermetic compressor, which comprises: a crankshaft connected with the motor rotor so as to rotate together with it and having a lubricating oil passage inside; a sleeve connected with the lower part of the crankshaft for It is integrated with the crankshaft and rotates together; an oil-absorbing member arranged to maintain a uniform interval with the inner peripheral surface of the above-mentioned sleeve, which rotates in the direction opposite to the rotation direction of the sleeve to complete the oil-absorbing work; and an oil-absorbing member for supporting the above-mentioned oil-absorbing member The rotation force transmission device of the component is used to make the oil-absorbing component rotate together with the sleeve, and the device receives the rotational force from the sleeve so that the oil-absorbing component rotates in the direction opposite to the direction in which the sleeve rotates. The increased relative rotational speed between the sleeve and the oil absorbing member increases the amount of oil supplied to the sliding parts and friction parts, thereby improving the lubricating performance of the compressor. When the compressor vibrates, the oil-absorbing member and the sleeve vibrate with the same amplitude, so that the gap between the sleeve and the oil-absorbing member can be kept uniform. Therefore, the present invention can improve the reliability of oil supply.

Owner:LG ELECTRONICS INC

Oil supply device for hermetically sealed compressor

InactiveCN1386980AImprove oil supply capacityPositive displacement pump componentsPiston pumpsEngineeringStationary state

An oil supply device for a hermetic compressor comprises: a crankshaft connected with a motor so as to rotate together with it and having a lubricating oil flow passage inside; a sleeve connected with the lower part of the crankshaft so as to become a One body, rotating together; an oil absorbing member arranged to maintain a uniform interval with the inner peripheral surface of the sleeve for oil absorption; and a supporting device for supporting the oil absorbing member to slide, the supporting device is connected between the sleeve and the oil absorbing member in order to maintain a static state. The oil-absorbing member is supported in such a way that it cannot rotate around the center of rotation of the sleeve, so that it is not affected by the vibration of the operating compressor, and a uniform gap is maintained between the inner peripheral surface of the sleeve and the oil-absorbing member, thereby Improve the reliability of fuel supply.

Owner:LG ELECTRONICS INC

Tension system

ActiveCN102912988ARealize intelligent processingReal-time sensing of displacement changesBuilding material handlingEngineeringForce sensor

The invention provides a tension system which comprises tension equipment, a hydraulic device and a computer, wherein the tension equipment comprises a jack as well as a pressure sensor and a displacement detection device which are arranged inside the cylinder of the jack; the hydraulic device is communicated with tension equipment fluid and comprises an oil pump unit and a controller; the controller controls the oil pump unit according to a received signal from the computer to drive the jack to execute tension operation; and moreover, the controller transmits information acquired by the pressure sensor and the displacement detection device to the computer for processing. The tension system is easy to operate, simple and compact in structure, low in cost, high in reliability and high in precision and is provided with automatic programs.

Owner:CHINA RAILWAYS CORPORATION +3

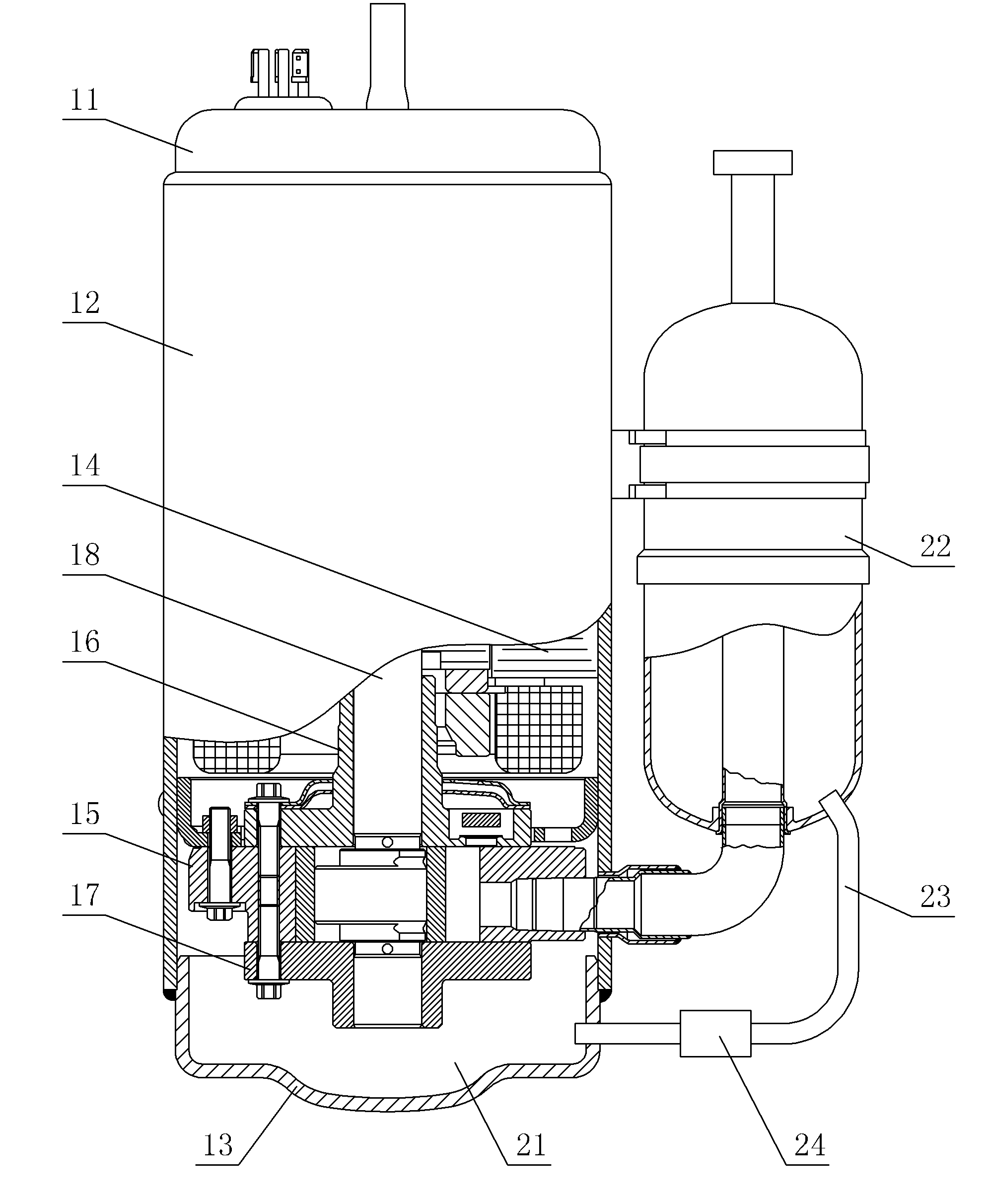

Oil surface lifting device of rotary compressor

InactiveCN102734169ARaise the oil levelImprove oil supply capacityRotary/oscillating piston pump componentsLiquid fuel engine componentsSurface levelPressure balance

An oil surface lifting device of a rotary compressor. The compressor includes a closed shell, an electrical machine mechanism arranged in the closed shell, a compression mechanism located under the electrical machine mechanism, and an oil tank arranged on the bottom of the closed shell. A reservoir for gas-liquid separation is arranged outside the compressor, and a connecting pipe is connected between the reservoir bottom and the internal oil pool of the compressor. The connecting pipe for oil return is arranged between the reservoir bottom and the oil tank of the compressor, and the connecting pipe is also provided with a control device to control the conducting and closing of the connecting pipe. When the compressor runs, the control unit closes the connecting pipe to ensure the normal operation of the compressor; and when the compressor is in an unsteady shutdown state, the control device opens the connecting pipe; because of the suction-exhaust pressure balance, lubricating oil stored in the reservoir directly returns to the oil tank of the compressor through the connecting pipe, thereby increasing the oil surface level of the oil tank, and improving oil supply capacity of the compressor in starting. The oil surface lifting device has advantages of simple structure and reliable operation.

Owner:GUANGDONG MEIZHI COMPRESSOR

Oil feeder for lubricant in reciprocal movement type compressor

InactiveCN1626799ASmooth pumpingReduce frictionPositive displacement pump componentsPumpsForeign matterReciprocating motion

The invention relates to a lubricating oil supply device of reciprocal compressor. It is characterized by that on two side surfaces of the lub oil piston in said reciprocal compressor a spring fixing portion is respectively formed, the above-mentioned lubricating oil spring can be placed and fixed on the above-mentioned spring fixing portion, so that the above-mentioned lub oil spring always can be relained in the orignial position, and said structure can make the lub oil spring be repeatedly comperssed and extended on the fixed position always so as to can raise oil supply performance.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

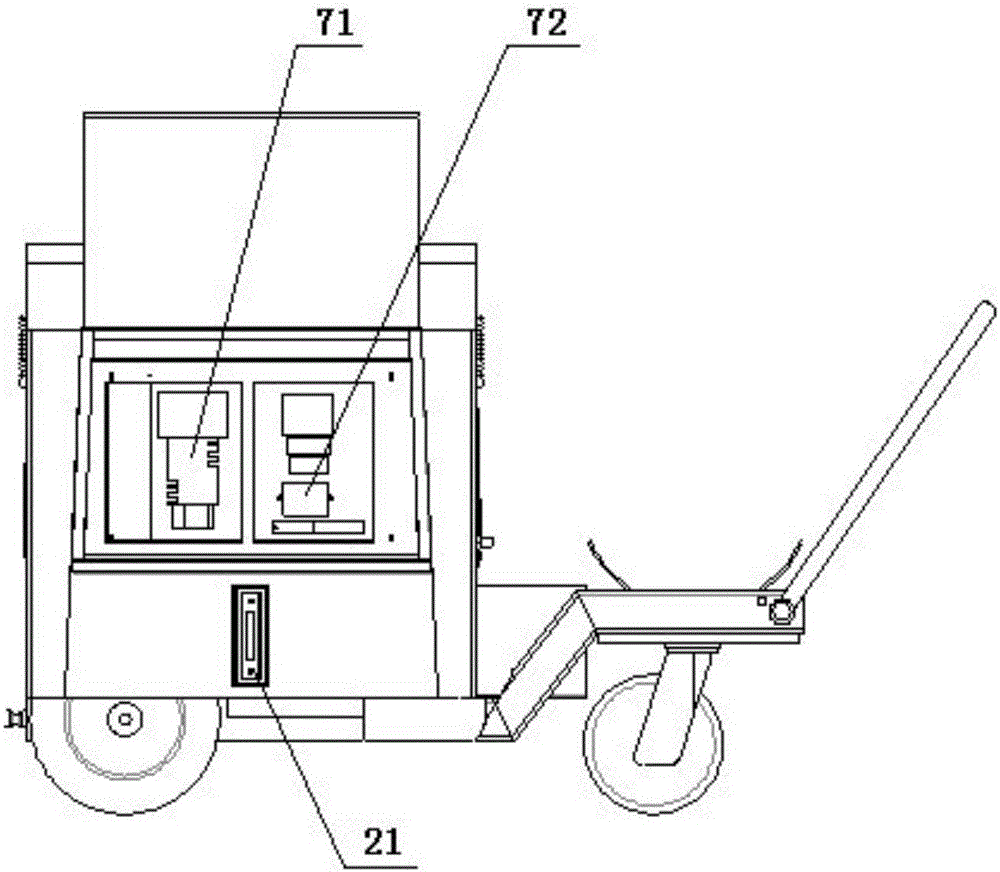

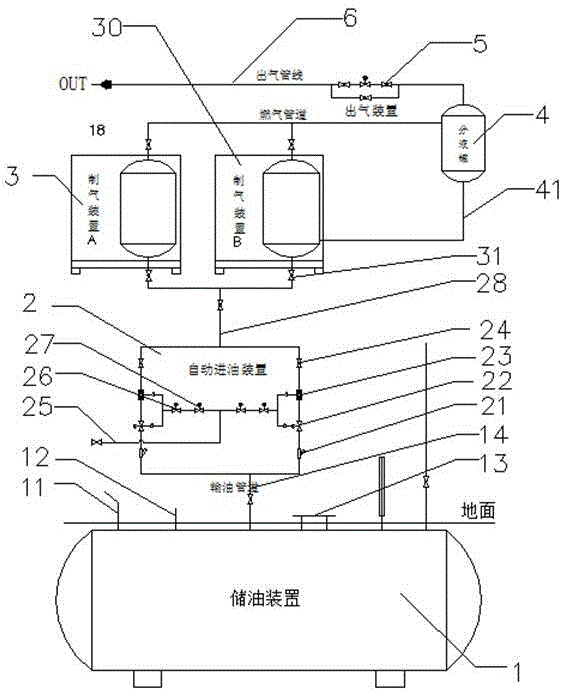

Intelligent independent oil produced natural gas supply device

InactiveCN106675680ARealize integrated intelligent controlAir supply volume is adjustableGaseous fuelsControl systemLiquid fuel

The invention belongs to the technical field of oil produced fuel gas supply, and specifically relates to an intelligent independent oil produced natural gas supply device. The intelligent independent oil produced natural gas supply device comprises an oil storage device, a two-way automatic oil inlet device, a plurality of gas producing devices, a gas outlet device, a monitoring and alarming system and a master control system. The device, compared with the prior art, has the advantage that the gas producing devices are flexibly installed, so as to meet users with different requirements for gas supply quantity; sufficient liquid fuel oil is supplied according to the requirements for gas supply quantity through cooperative application of the flow monitoring and alarming system, so that the gas producing capacity of the device is improved, the flexibility is high, independent local area network oil produced natural gas supply facilities can be formed, the whole control process can be uniformly controlled by the master control system according to the actual requirements of the users, and the device is high in intelligent level, stable in gas producing process and high in safety.

Owner:安徽启东热能科技有限公司

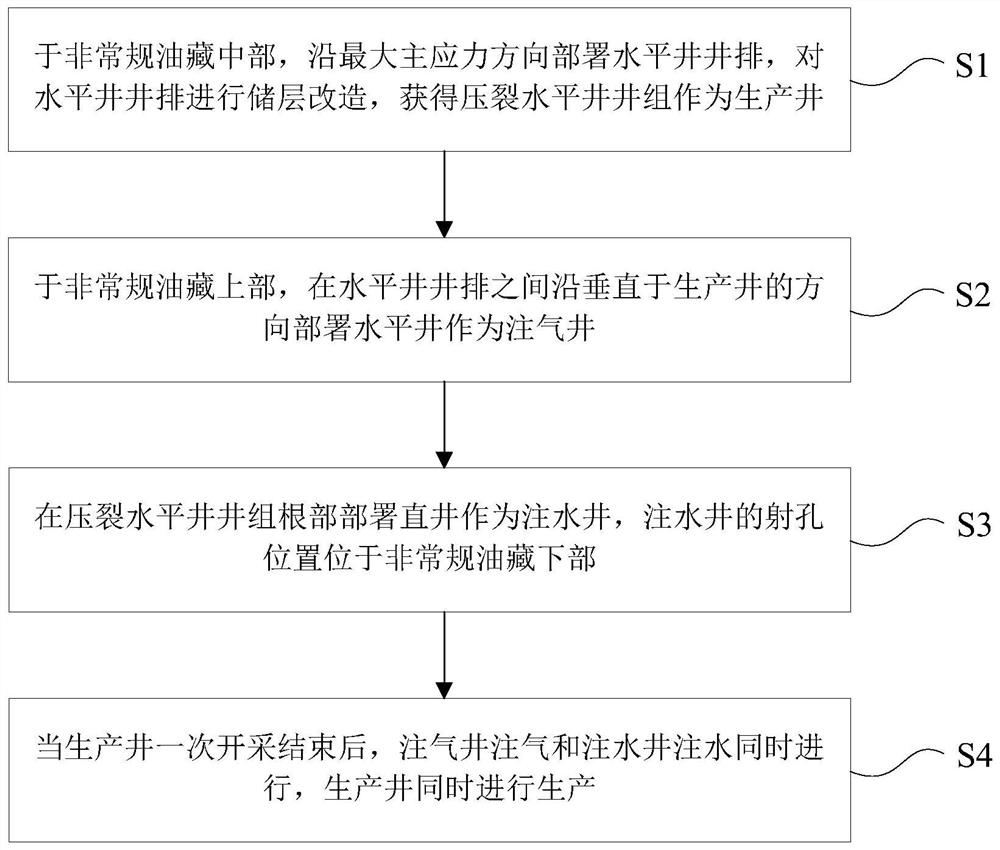

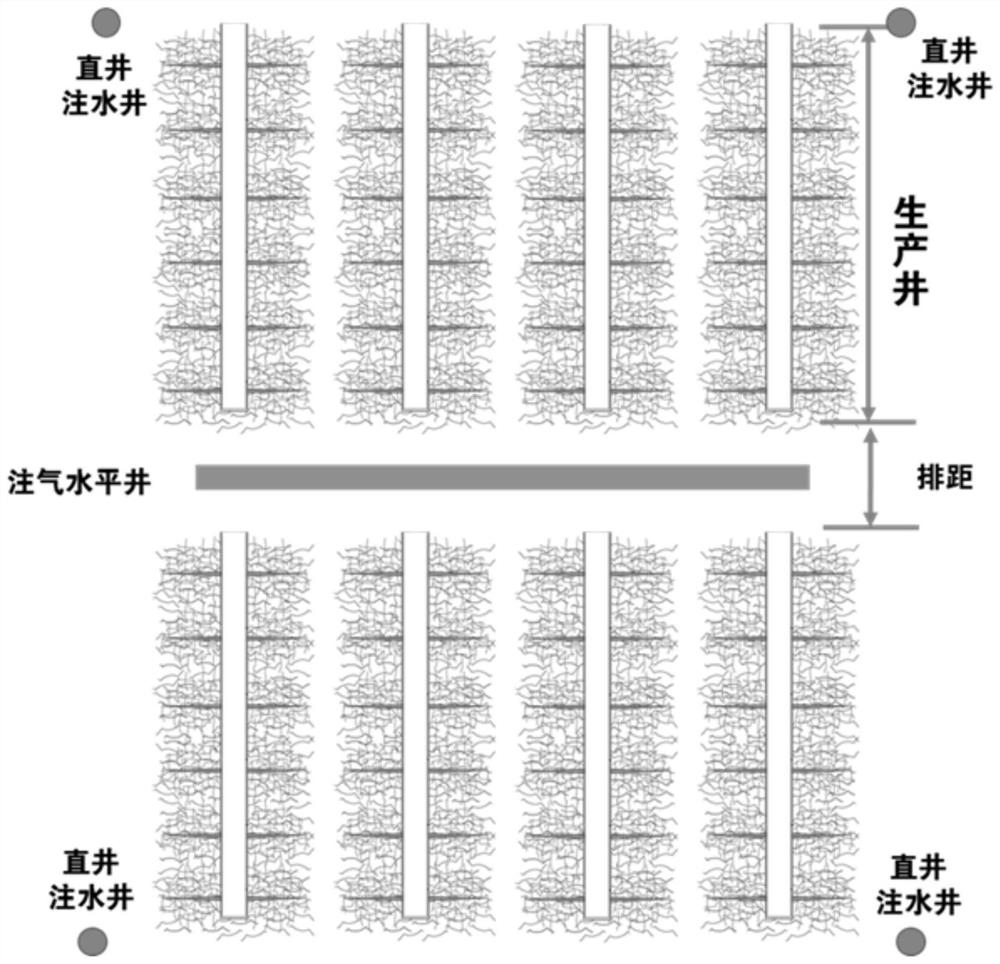

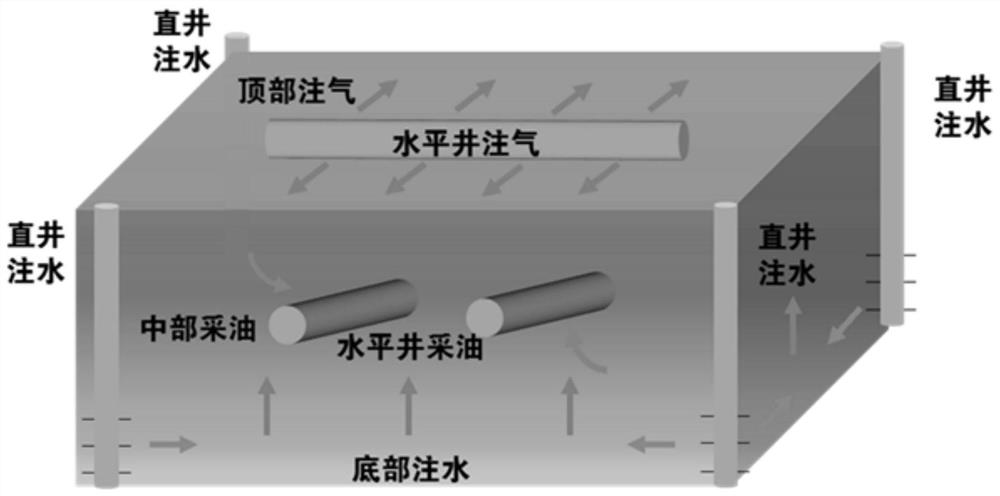

Unconventional oil reservoir recovery ratio increasing method and system

ActiveCN112240182AExpand the affected volumeImprove oil supply capacityFluid removalUnconventional oilInjection well

The invention discloses an unconventional oil reservoir recovery ratio increasing method and system. The method comprises the steps of deploying horizontal well rows in the middle of an unconventionaloil reservoir in the direction of the maximum principal stress, and carrying out the reservoir reconstruction of the horizontal well rows to obtain a fractured horizontal well group as a production well; deploying a horizontal well between the horizontal well rows in the direction perpendicular to the production well at the upper part of the unconventional oil reservoir as a gas injection well; deploying a vertical well at the root of the fractured horizontal well group as a water injection well, wherein the perforation position of the water injection well is positioned at the lower part of the unconventional oil reservoir; and after one-time production of the production well is finished, gas injection of the gas injection well and water injection of the water injection well are conductedsimultaneously, and the production well conducts production simultaneously. According to the method and system, by the adoption of the modes of gas injection from the top, water injection from the bottom and oil extraction from the middle, the longitudinal swept volume can be effectively increased, water injection and gas injection are combined, the advantages of two displacement media can be effectively played, gas injection and water injection complement each other and do not interfere with each other, and the recovery ratio can be increased.

Owner:PETROCHINA CO LTD

Sliding vane lubricating structure, compressor and refrigeration equipment

PendingCN113202767ARealize lubricating oil supplyImprove lubrication statusRotary piston pumpsRotary piston liquid enginesEngineeringRefrigeration plant

The invention provides a sliding vane lubricating structure, a compressor and refrigeration equipment. The sliding vane lubricating structure comprises an oil supply structure, the oil supply structure comprises an oil supply channel and an oil pump assembly, one end of the oil supply channel communicates with a bottom oil pool of the compressor, the other end of the oil supply channel communicates with a sliding vane groove, and the oil pump assembly is configured to be driven by exhaust of a pump body assembly of the compressor; and lubricating oil in the bottom oil pool is pumped into the sliding vane groove along the oil supply channel. According to the sliding vane lubricating structure, the oil supply channel for supplying oil to the sliding vane groove from the bottom oil pool is arranged in the compressor, the oil pump assembly is additionally arranged, the oil supply capacity of the oil supply channel is improved, and driving force is provided for the oil pump assembly by means of high-speed airflow exhausted by the pump body assembly; and an oil pumping mechanism pumps lubricating oil at the bottom of the compressor into the sliding vane groove formed in an air cylinder of a compression mechanism, lubricating oil supply to a sliding vane is achieved, it is guaranteed that the sliding vane is in a good lubricating state all the time, and the running stability and reliability of the compressor are improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

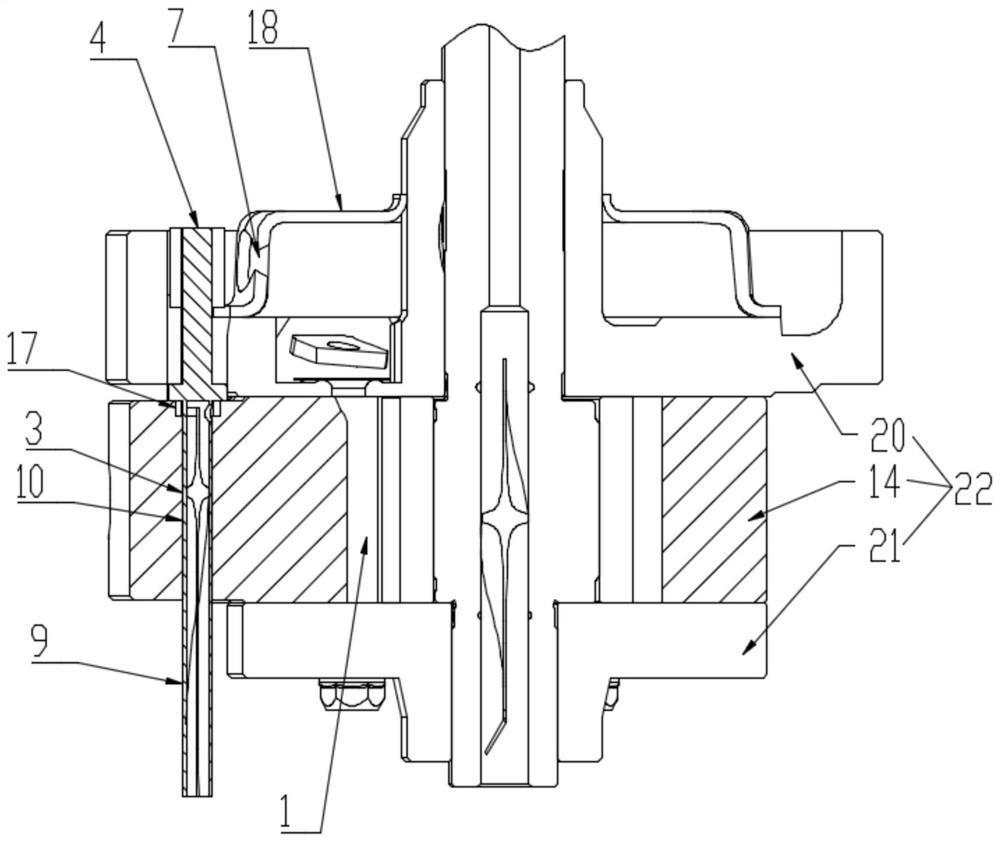

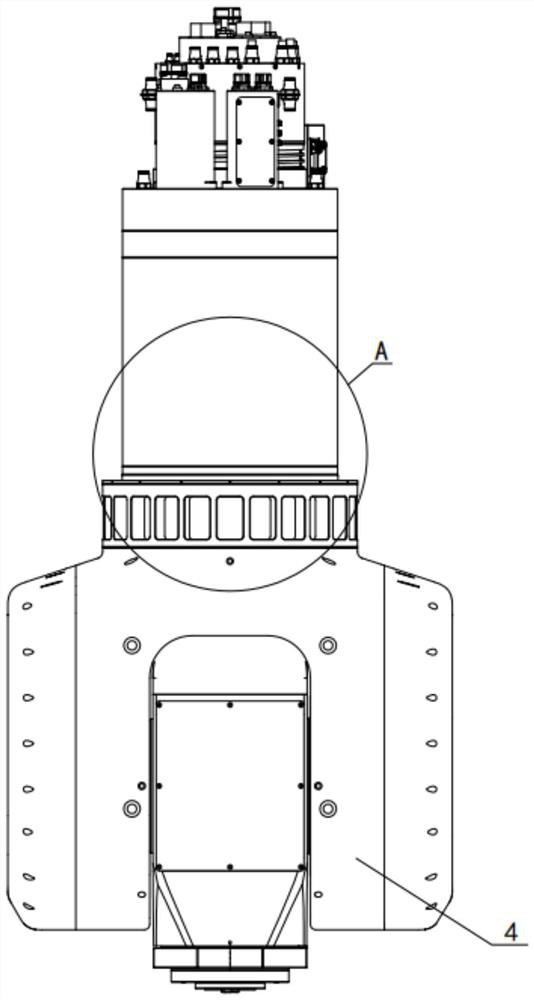

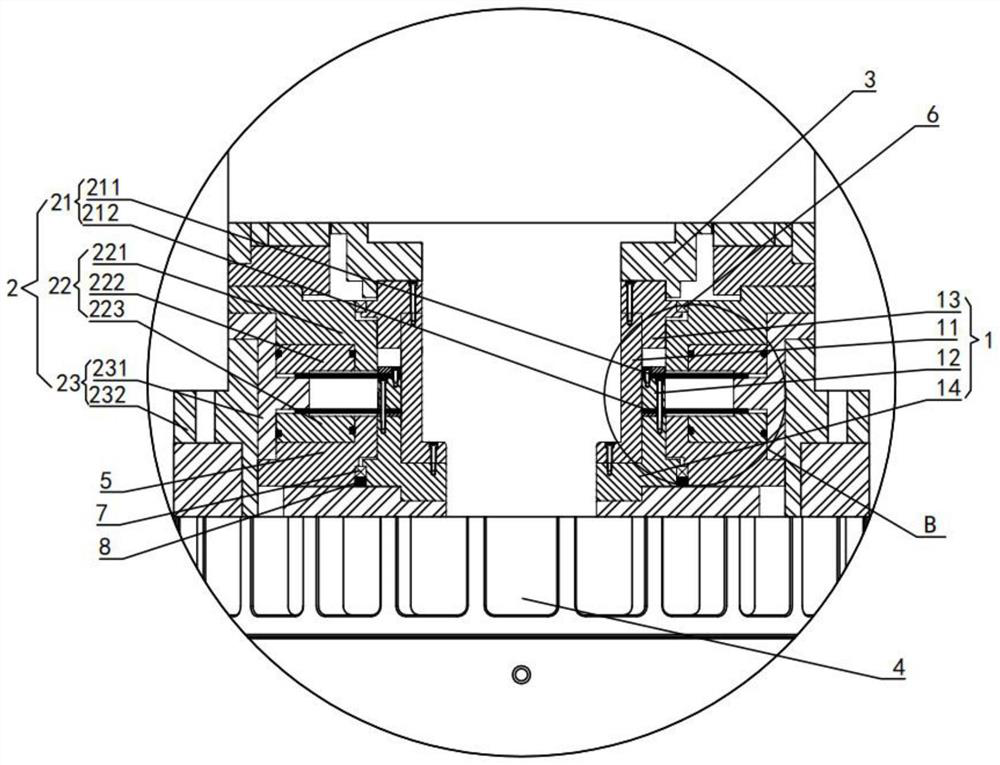

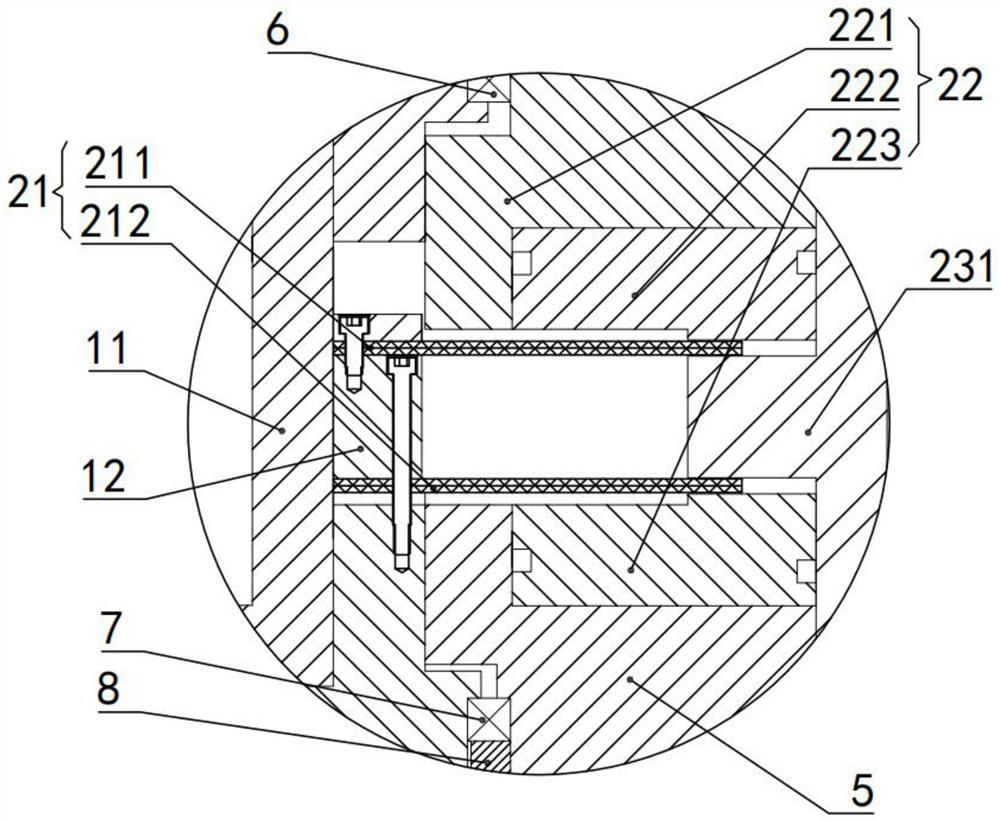

Head-swinging dual-compound braking device

ActiveCN113074198AEven by forceImprove stabilityAxially engaging brakesBrake actuating mechanismsPressure transmissionElectric machinery

The invention discloses a head-swinging dual-compound braking device. The head-swinging dual-compound braking device comprises a rotating mechanism, a brake mechanism, a motor rotor and a swing head main body, and is characterized in that the brake mechanism comprises a brake device, a driving device and a brake auxiliary assembly; the brake device comprises a first composite brake disc and a second composite brake disc; the driving device comprises an oil cylinder, a first piston cylinder arranged above the first composite brake disc and a second piston cylinder arranged below the second composite brake disc; the brake auxiliary assembly comprises a spacer bush; and an outer side flange part of the spacer bush is located between the first composite brake disc and the second composite brake disc. According to the head-swinging dual-compound braking device,The piston cylinders are driven by the oil cylinder to extrude the two composite brake discs; air in a cavity between the two composite brake discs is extruded; counter-acting force extrudes the inner sides of the composite brake discs; the composite brake discs are subjected to hydraulic and air pressure effects at the same time; stress on the composite brake discs can be more uniform; in addition, loss in the pressure transmission process can be effectively avoided; braking is more stable; and the braking effect is higher.

Owner:宁波天控五轴数控技术有限公司

Pulse oil supply type engine air cylinder block oil passage

InactiveCN105756743AConstant pressureImprove oil supply capacityMachines/enginesPressure lubricationCylinder blockCam

The invention discloses a pulse oil supply type engine air cylinder block oil passage. According to the structure, the tail end of a main oil passage of an engine air cylinder block is divided into a crankshaft bearing oil supply branch passage and a cam shaft oil supply branch passage, and the cam shaft oil supply branch passage is communicated with a cam shaft bearing hole in the engine air cylinder block; the crankshaft bearing oil supply branch passage is communicated with a crankshaft bearing; a lining is inlaid in the cam shaft bearing hole and provided with oil inlet and outlet holes; a groove is formed in the large-head end of a cam shaft, when the cam shaft rotates to one certain position, the cam shaft oil supply branch passage is communicated with a rocker arm oil supply passage, and at the moment the main oil passage can supply oil to the crank shaft bearing, the cam shaft and a rocker arm at the same time. Oil supply time periods are different through the cam shaft large-head end structure, intermittent oil supply is carried out, and therefore reduction of oil pressure is relieved. While high oil pressure is ensured, enough lubrication oil is supplied to other parts. Due to the fact that the rotating speed of the cam shaft is relatively high, oil can be supplied to the rocker arm one time when the cam shaft rotates a circle, and the pressure of the main oil passage can be kept basically stable.

Owner:DONGFENG CHAOYANG CHAOCHAI DIESEL ENVIRONMENTAL PROTECTION TECH CO LTD

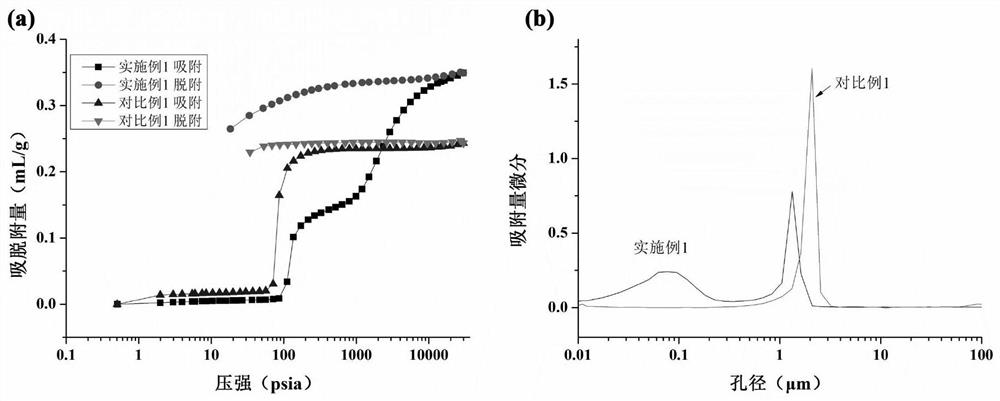

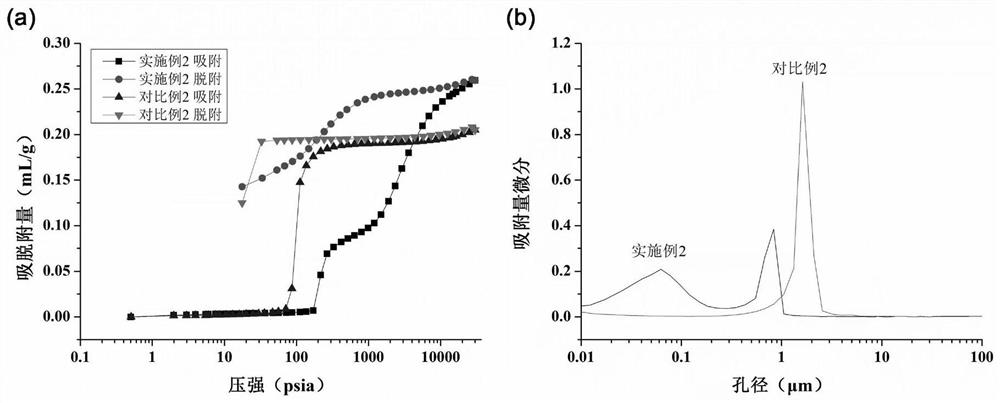

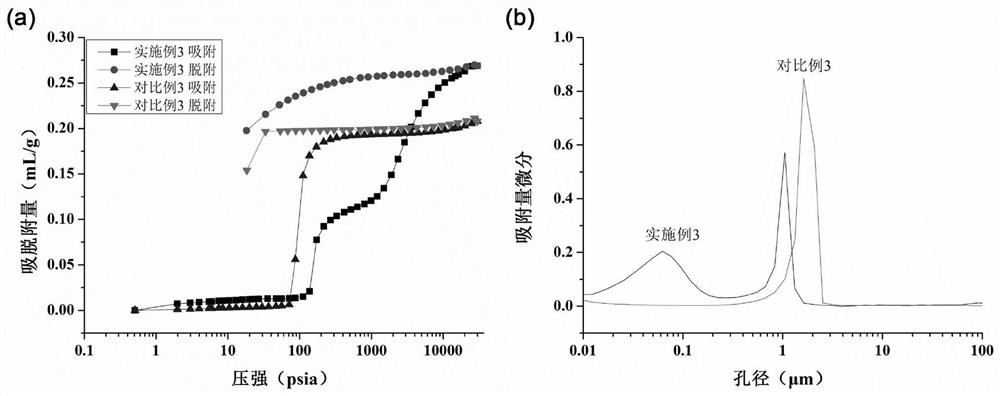

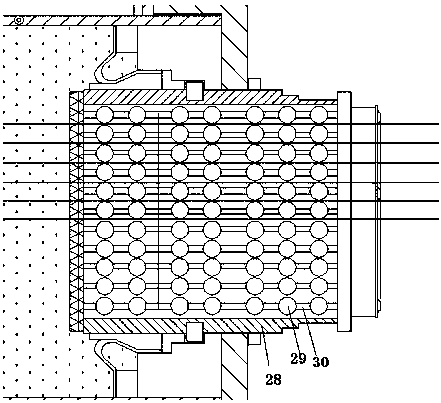

Two-stage porous polyimide material, preparation method thereof, two-stage porous polyimide retainer and application of two-stage porous polyimide retainer

ActiveCN113510891AHigh mechanical strengthImprove oil performanceBearing componentsDomestic articlesImidePolymer science

The invention provides a two-stage porous polyimide material, a preparation method thereof, a two-stage porous polyimide retainer and application of the two-stage porous polyimide retainer, and relates to the technical field of polymer retainers. The preparation method of the two-stage porous polyimide material provided by the invention comprises the following steps: dissolving rigid aromatic diamine, flexible aromatic diamine and aromatic dicarboxylic anhydride in a polar aprotic solvent, and carrying out condensation polymerization to obtain a polyamide acid mixed solution; mixing the polyamide acid mixed solution with a dehydrating agent, and carrying out imidization reaction to obtain polyimide molding powder; performing cold isostatic pressing on the polyimide molding powder to obtain a cold pressed blank; and carrying out hot isostatic pressing on the cold-pressed blank to obtain the two-stage pore polyimide material. A rigid-flexible monomer combination mode is adopted, the prepared two-stage porous polyimide material can realize intelligent regulation and control of oil containing and oil discharging according to different rotating speeds, the pressurization mode is more uniform, forming is convenient, and the preparation method is suitable for large-scale production.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Pulse oil-supply type oil duct of engine cylinder body

InactiveCN102588137AImprove oil supply capacityMeet lubricationLubrication of auxillariesCylinder headsCamLubrication

The invention discloses a pulse oil-supply type oil duct of an engine cylinder body. The structure of the pulse oil-supply type oil duct of the engine cylinder body is as follows: a cam shaft bushing is arranged inside a cam shaft bearing hole on the engine cylinder body; a section of an oil tank and an oil outlet are arranged on the cam shaft bushing; and a T-shaped oil hole is processed on the cam shaft. The oil tank and the oil outlet on the cam shaft bushing are respectively communicated with the cam shaft and a rocker arm oil supply channel when the cam shaft rotates to a certain position; a main oil duct can supply oil to a crank bearing, the cam shaft and a rocker arm at the same time. The oil tank on the cam shaft bushing is communicated with an oil supply branch channel of the cam shaft, but the oil outlet on the cam shaft bushing cannot be communicated with the oil supply channel of the rocker arm when the cam shaft rotates to deviate from the position. By ingenious designs of the cam shaft bushing and the cam shaft, the cam shaft can finish twice and two paths of oil supply with different oil supply quantities after rotating a circle. Lubrication of the rocker arm can be achieved, at the same time the pressure of the main oil duct is basically constant, and parts such as a crank, the cam shaft and the like are guaranteed to be fully lubricated.

Owner:合肥云内动力有限公司

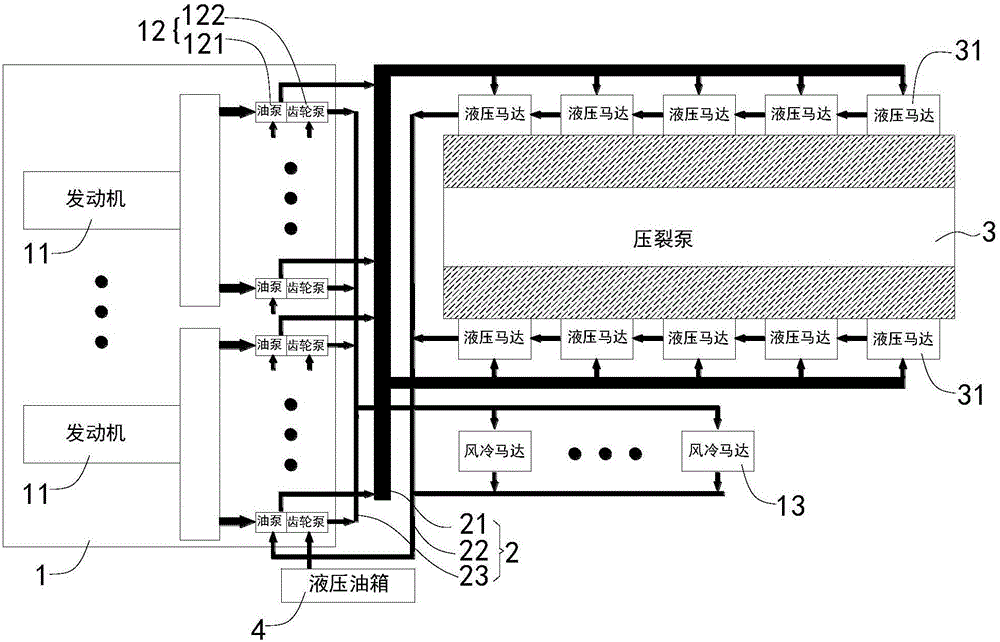

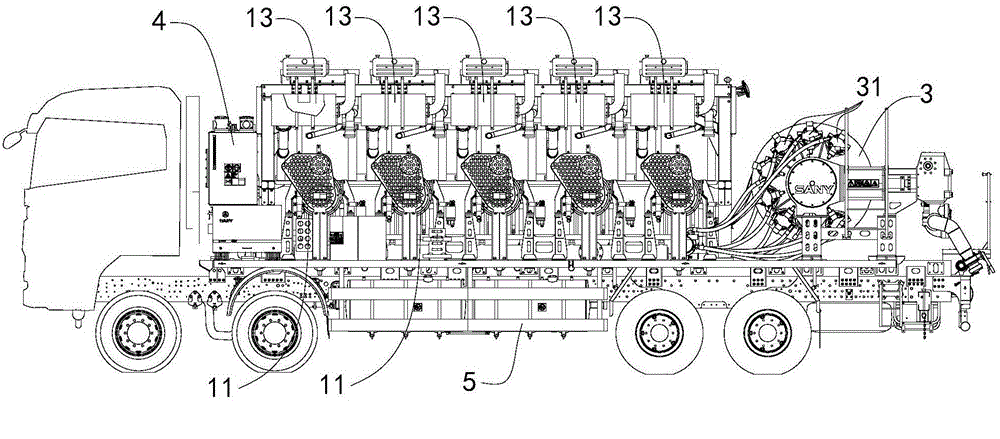

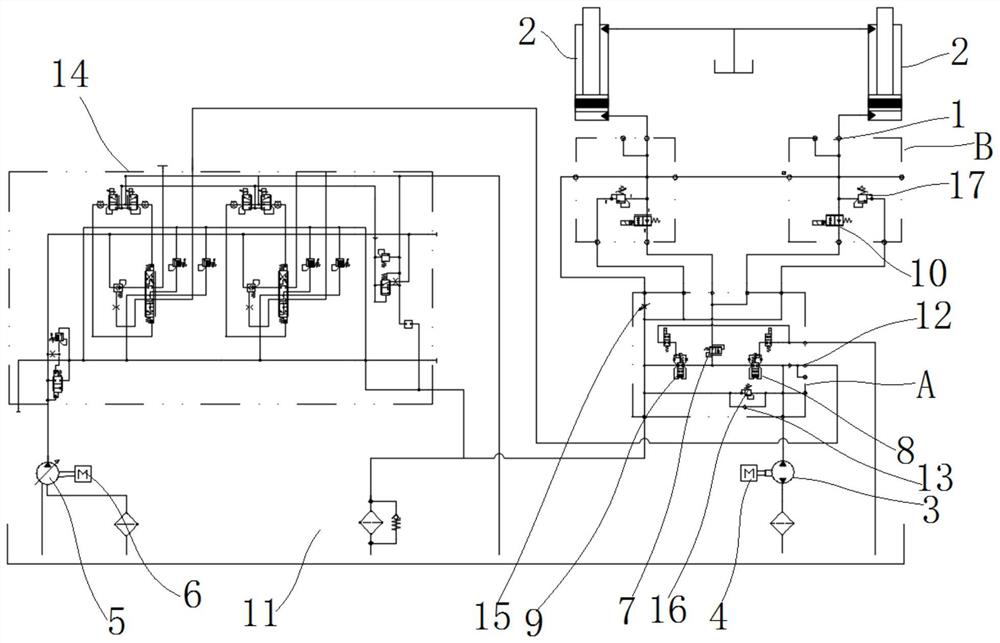

Hydraulic transmission system for fracturing truck and fracturing truck

ActiveCN105090423AImprove oil supply capacityStrong driving abilityFluid removalFluid gearingsTruckGear pump

The invention discloses a hydraulic transmission system for a fracturing truck and the fracturing truck. The hydraulic transmission system comprises an engine unit, a hydraulic transmission oil path, a fracturing executing mechanism and a hydraulic oil tank. The engine unit comprises at least one engine. The engines are in drive connection with at least one set of hydraulic drive unit. Each hydraulic drive unit comprises an oil pump and a gear pump. The hydraulic transmission oil path comprises a first oil path, a second oil path and a third oil path. The fracturing executing mechanism is provided with a plurality of hydraulic drivers. A closed oil path is formed by the oil pumps, the first oil path, the hydraulic drivers and the second oil path. Air cooling motors are arranged between the second oil path and the third oil path. The input ends of the gear pumps are communicated with the hydraulic oil tank, and the output ends of the gear pumps are collected through the third oil path and then communicated with the second oil path through the air cooling motors. The hydraulic transmission system has the beneficial effects that the oil supply capability is large, the drive capacity is high, the highest output pressure is high, and the maximum output delivery is large; and hydraulic pipelines are simple and easier to arrange, the weight is low, the size is small, using is flexible and convenient, and the oil tank is small in size.

Owner:SANY PETROLEUM INTELLIGENT EQUIP CO LTD

Hydraulic oil way for gantry lifting and potential energy recovery of electric empty box stacking machine

PendingCN112607673ASolve the inconvenience of recyclingImprove oil supply capacityServomotor componentsServomotorsEngineeringEnergy recovery

The invention discloses a hydraulic oil way for gantry lifting and potential energy recovery of an electric empty box stacking machine. The hydraulic oil way comprises a working connector for communicating with a working cavity of a working oil cylinder; a forward-reverse rotation oil pump; a main motor in mechanical transmission connection with the forward-reverse rotation oil pump so as to drive the forward-reverse rotation oil pump to work in an electric mode to supply oil, and return oil to drive the forward-reverse rotation oil pump to rotate in a power generation mode to generate power; an auxiliary oil pump; an auxiliary motor for driving the auxiliary oil pump to work to supply oil; and a hydraulic control proportional valve, wherein one side of the hydraulic control proportional valve communicates with the working connector, the other side of the hydraulic control proportional valve communicates with a port in one side of a first control switch valve set, and communicates with an oil tank through a second control switch valve set, a port in the other side of the first control switch valve set communicates with the forward-reverse rotation oil pump, and communicates with the auxiliary oil pump through a first one-way valve, and therefore the auxiliary oil pump can supply oil to the first control switch valve set. The problem that energy is not convenient to recover during oil return of an existing working oil cylinder can be effectively solved.

Owner:HANGCHA GRP

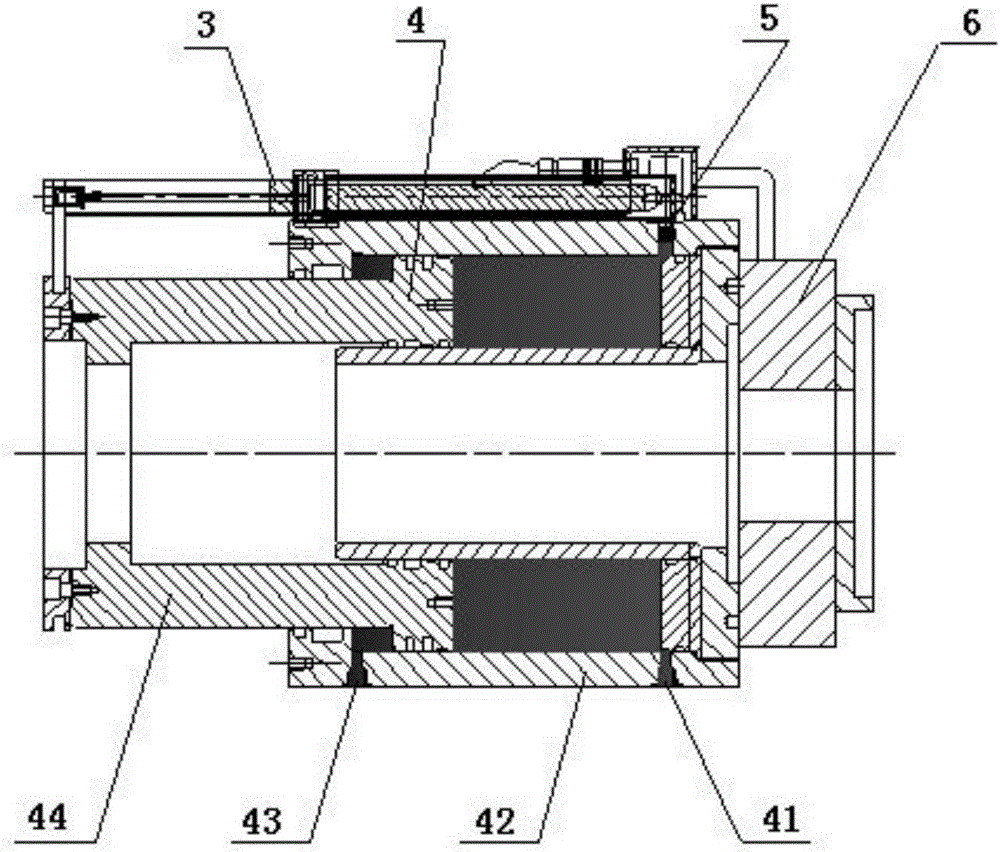

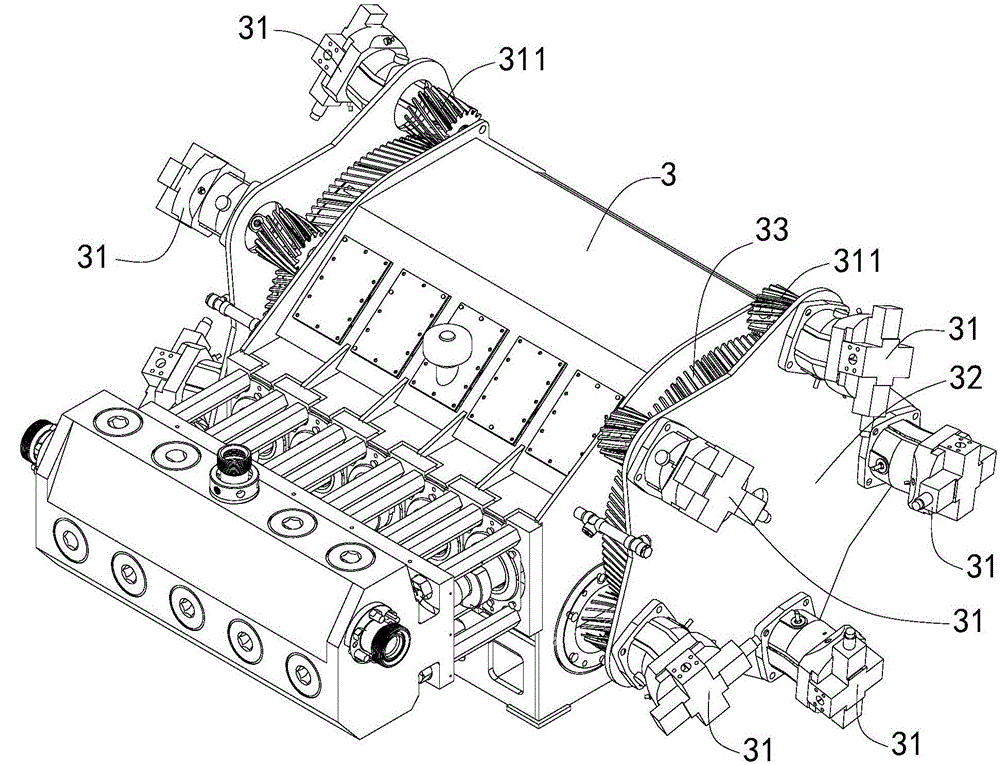

Multi-dimensional parallel swing wave power generation device

InactiveCN103306881BWon't be corrodedImprove sealingMachines/enginesEngine componentsHydraulic cylinderHydraulic motor

The invention discloses a multi-dimensional and parallel-swing sea wave power generation device. A top cover is fixedly connected with the top wall of a buoyancy box, one end of a three-degree-of-freedom movement pair is fixedly connected with the top cover, the other end of the three-degree-of-freedom movement pair is engaged with a swing rod, one end of the swing rod penetrates through the top wall of the buoyancy box and is fixedly connected with an outside device, the other end of the swing rod is fixedly arranged on an upper platform through the support of rib plates, a spring is fixedly connected with a shaft shoulder of the swing rod, six parallel hydraulic cylinders are arranged between the upper platform and a lower platform, piston rods of the six parallel hydraulic cylinders are hinged to the upper platform, cylinder bodies of the six parallel hydraulic cylinders are hinged to the lower platform, the lower platform is fixedly arranged on an oil mixture tank, the oil mixture tank is fixedly connected with the side wall of the buoyancy box, the oil mixture tank is connected with a hydraulic motor through a separating pipe and a return pipe, a generator is connected with the hydraulic motor, the generator and the hydraulic motor are arranged at the bottom of the buoyancy box, and an energy accumulator is connected with the hydraulic motor. The device has the characteristics that the service life is long, and the pollution is little; and while the energy of the sea wave in the transverse swinging is absorbed, the energy of the sea wave in the vertical direction can also be absorbed.

Owner:SHANGHAI JIAO TONG UNIV

A new type of optical cable manufacturing equipment

ActiveCN108828742BSo as not to damageImprove the preparation effectFibre mechanical structuresBiochemical engineeringOptical fiber cable

The invention discloses a novel optical cable manufacturing device which can ensure the coating uniformity and stability of factice in the manufacturing process of an optical cable. A method of usingthe oil immersion pad is used for coating so as to achieve a good coating effect. A vibration component is disposed to not only improve the oil supply performance of an oil supply head, but also provide vibration for the oil immersion pad so that the factice on the oil immersion pad is stably immersed in the oil. An oil-scraping component scrapes the oil by a holding frame and an oil-scraping ballso as to achieve good oil-scraping uniformity and high efficiency, guides an optical cable, does not damage the optical cable, and improves the manufacturing effect of the optical cable. Further, thecable-laying frame of the novel optical cable manufacturing device is provided with a plurality of reels in order to lay cables of different colors and basically realize the manufacture of various types of optical cables.

Owner:NANTONG MEIMING CHINLON

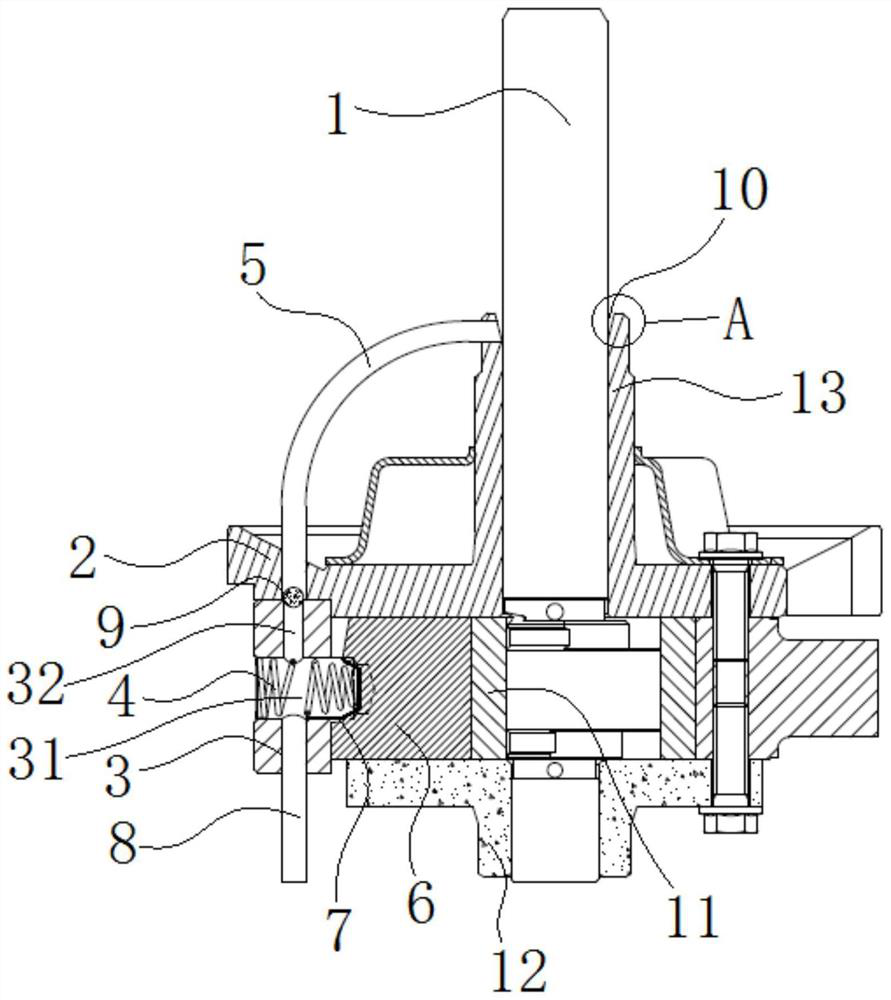

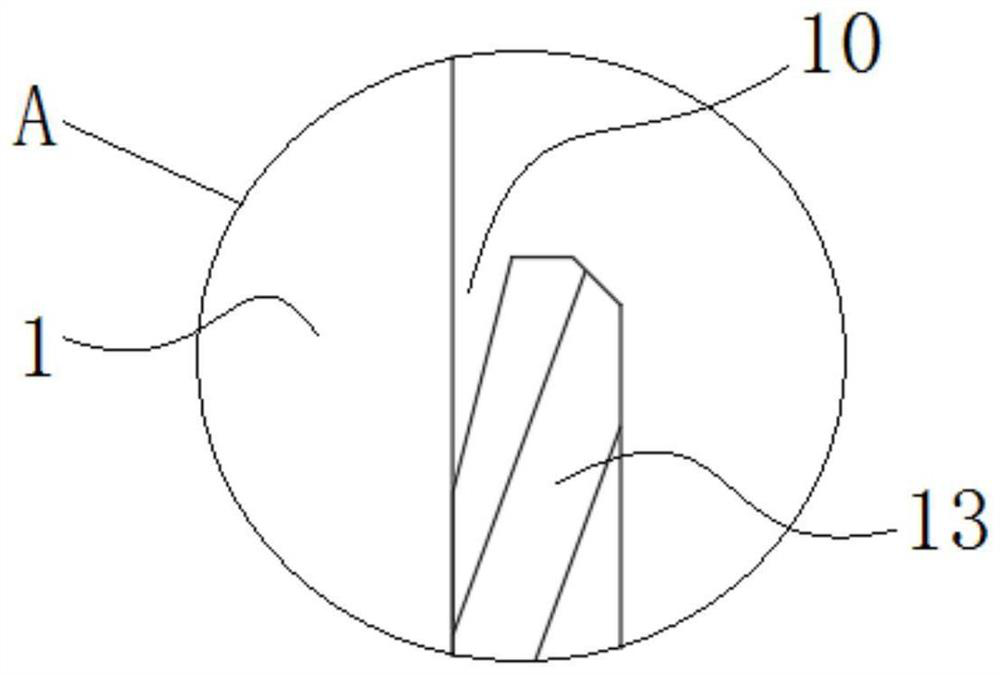

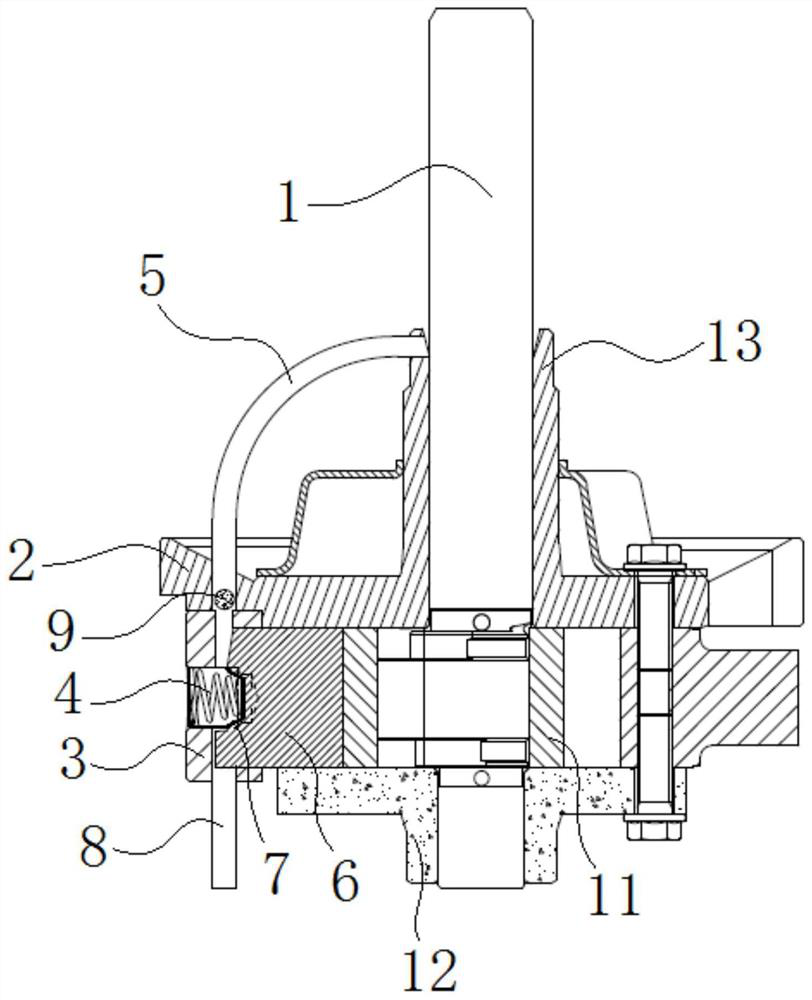

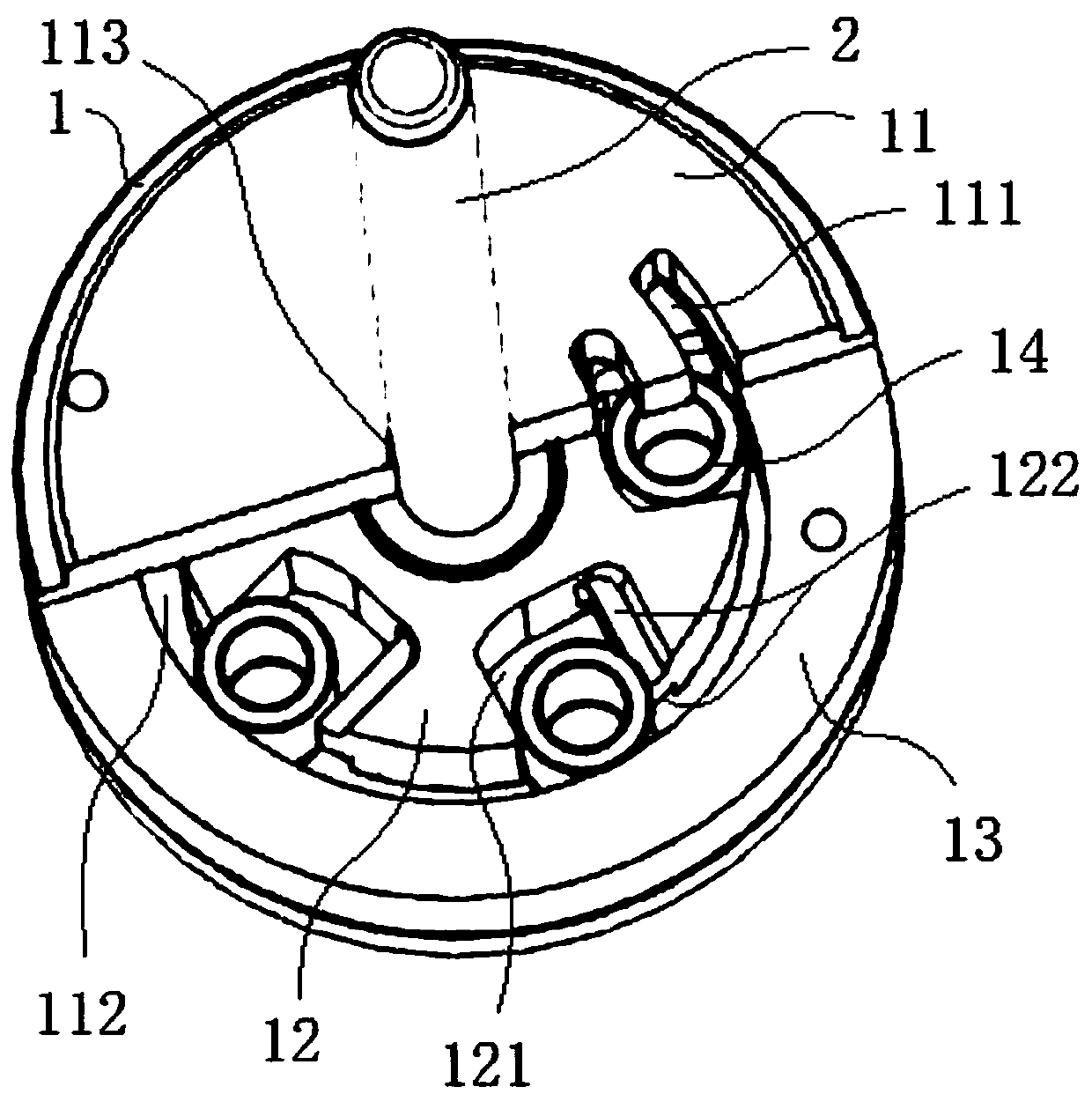

A rotary mechanical oil pump structure, a compressor oil pump structure and a rotary compressor

ActiveCN110848134BImprove oil supply capacityExpand the range of pump oilRotary piston pumpsRotary piston liquid enginesReciprocating motionEngineering

The invention provides a rotary machine oil pump structure, a compressor oil pump structure and a rotary compressor; the rotary machine oil pump structure includes a cylinder and a drive mechanism; the moving parts can reciprocate in the cylinder under the action of the drive mechanism; A pump oil chamber is formed, and the pump oil chamber is connected upward to an oil pipe, and the other end of the oil pipe is connected to the lubrication part of the rotating machine; the volume of the pump oil chamber can change periodically with the reciprocating motion of the moving parts; the drive mechanism passes through Rotate to drive the moving parts to do reciprocating motion, so that the moving parts squeeze the oil pump cavity for oil discharge or oil absorption; the solution provided by the invention can solve the problems of difficult low-frequency oil pumping, insufficient low-frequency lubrication and easy wear of existing compressors , so that the height of the compressor pump oil is no longer affected by the operating frequency of the compressor, and the oil supply capacity of the compressor pump oil is improved to ensure the lubrication effect.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

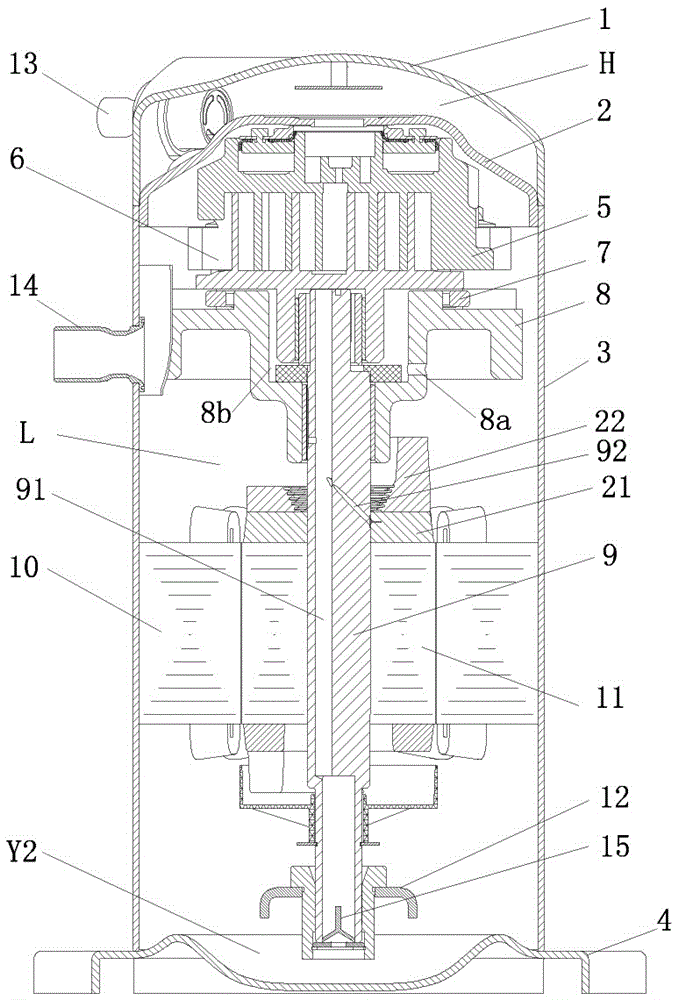

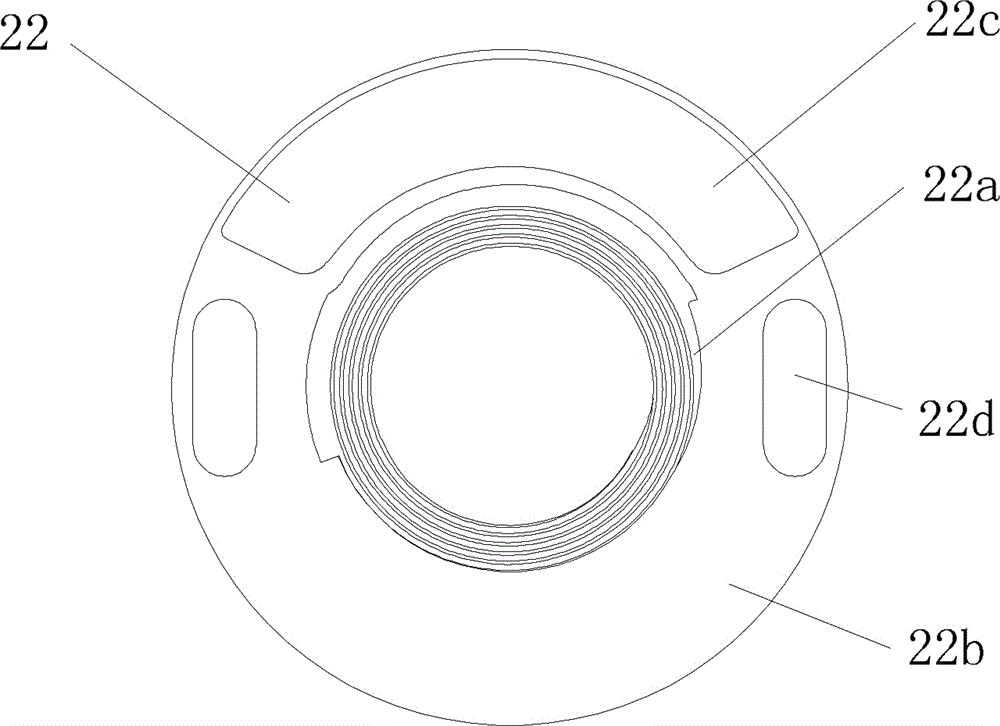

A scroll compressor

ActiveCN103375407BShorten the timeImprove oil supply capacityRotary piston pumpsRotary piston liquid enginesEngineeringCrankshaft

Owner:BYD CO LTD

Diesel roller pump for passenger vehicles

PendingCN111075713AMeet the needs of useSimple structureRotary piston pumpsRotary/oscillating piston combinationsElectric machineryControl theory

The invention provides a diesel roller pump for passenger vehicles, and belongs to the technical field of roller pumps. The diesel roller pump for the passenger vehicles comprises a housing, a motor component and a pump body component; a pump cavity is formed in an oil discharge plate of the pump body component, a planet wheel with an armature shaft connected to the motor component is arranged inthe pump cavity, and the oil discharge plate is of an integrated structure, so that the processing is convenient, product gaps are effectively avoided, the precision consistency is high, friction andnoise problems are prevented, and the service life is prolonged; in addition, a plurality of roller grooves with rollers are arranged on the edge of the planet wheel, grooves are formed in each rollergroove and in the front end surface of the back end surface of the planet wheel, at the same time, in the movement direction of the planet wheel, the grooves are formed in the front sides of the rollers in the current roller grooves, volume cavities in the roller grooves and in two radial sides of the rollers communicate through the grooves, so that the pressure in the two volume cavities is balanced, the oil supply performance is improved, noise is eliminated, the service life is prolonged, and the needs of the passenger vehicles are met.

Owner:SHANGHAI JTR AUTOMOTIVE COMPONENT CO LTD

Pulse oil-supply type oil duct of engine cylinder body

InactiveCN102588137BImprove oil supply capacityMeet lubricationLubrication of auxillariesCylinder headsCamLubrication

Owner:合肥云内动力有限公司

Oil supply device for linear compressor

InactiveCN101876310BImprove oil supply capacityPositive displacement pump componentsPositive-displacement liquid enginesReciprocating motionLinear compressor

The invention relates to an oil supply device for a linear compressor. The oil supply device comprises first and second grooves which are buckled with each other and clamp an elastic film therebetween, and a first end cover covering on an outer surface of the bottom of the first groove; the first and second grooves and the elastic film enclose to form a first cavity and a second cavity respectively; an oil supply through hole and an oil absorption through groove are formed at the bottom of the first groove; the first end cover is provided with an oil supply blind groove and an oil absorption through hole; the oil absorption through hole is communicated with the oil absorption through groove, and an end surface where the oil absorption through hole is communicated with the oil absorption through groove is provided with a one-way oil absorption valve opened toward a direction close to the first cavity; the oil supply through hole is communicated with the oil supply blind groove, and an end surface where the oil supply through hole is communicated with the oil supply blind groove is provided with a one-way oil supply valve opened toward a direction away from the first cavity; the centre of the elastic film is connected with a moving component of the compressor or provided with a balance weight. When the linear compressor works, the elastic film reciprocates so as to change the volume of the cavity; if the volume of the cavity is larger, negative pressure is generated in the cavity, so that the oil absorption valve is opened and the oil enters the cavity; and if the volume of the cavity is smaller, the pressure in the cavity is increased, so that an oil discharge valve is opened and the oil enters a cylinder of the compressor.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com