Unconventional oil reservoir recovery ratio increasing method and system

It is an unconventional technology of recovery rate, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc. It can solve the problems of fast production decline, easy channeling, and low recovery rate of primary fracturing, and achieve improved The effect of sweeping volume, expanding the range of use, and improving the oil supply capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

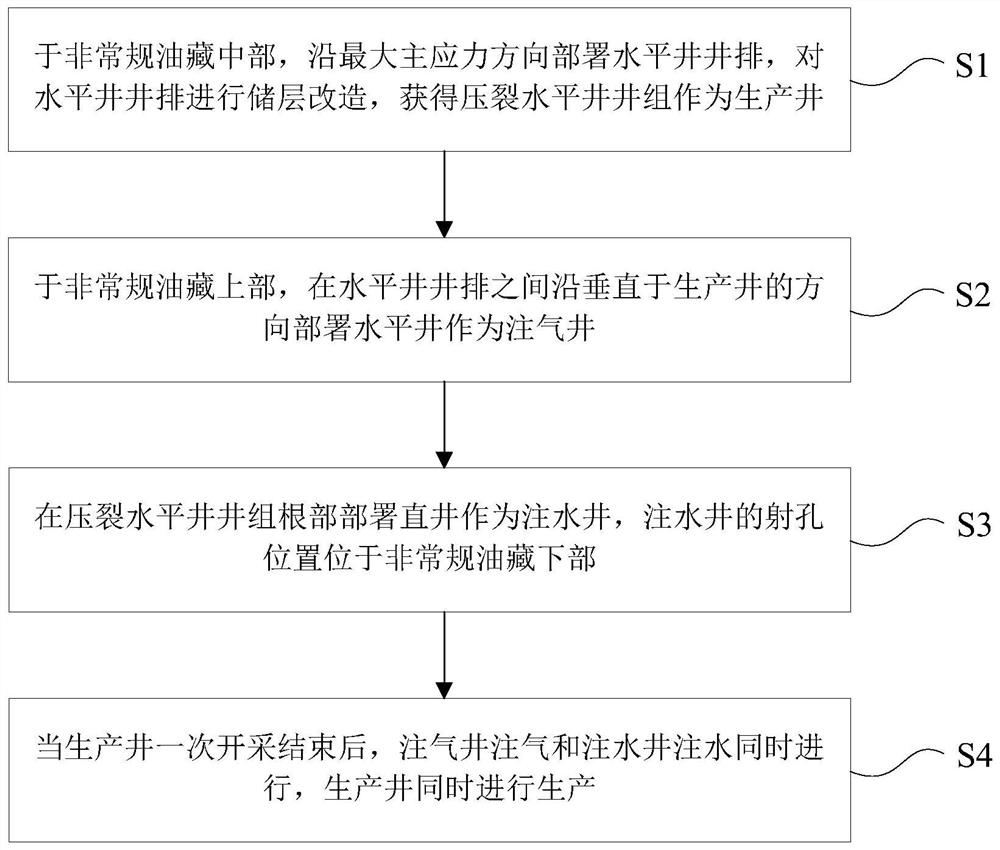

Method used

Image

Examples

Embodiment

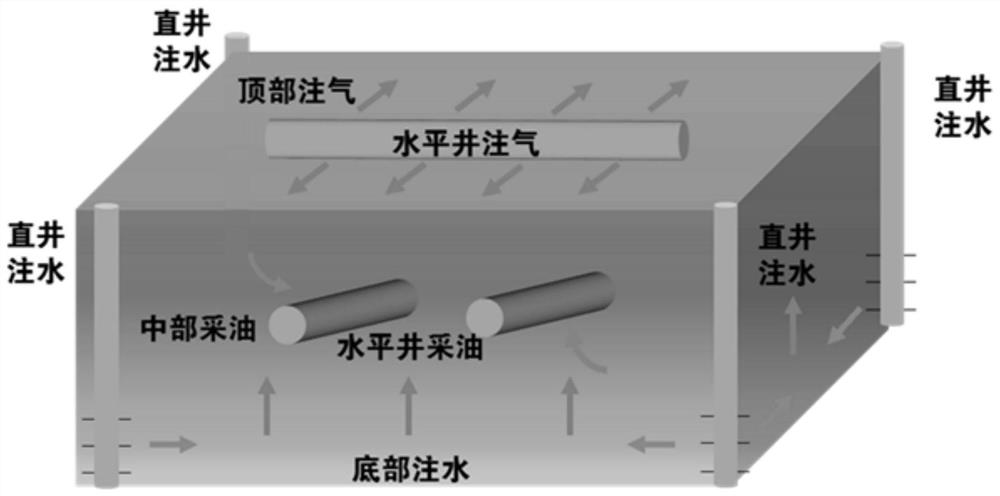

[0041] A horizontal well depletion development area in Changqing Oilfield, which is one of the tight oil test areas in Changqing Oilfield, the tight oil reservoir is Chang 7 layer, the buried depth of the reservoir is 2000-2600m, and the average porosity of the reservoir is 7-9% , average permeability 0.1-0.2mD, original formation pressure 15.8MPa, formation crude oil viscosity 1.23mPa·s, density 0.74g / cm 3 , The gas-oil ratio is 75.40m 3 / t, saturation pressure 7.04MPa.

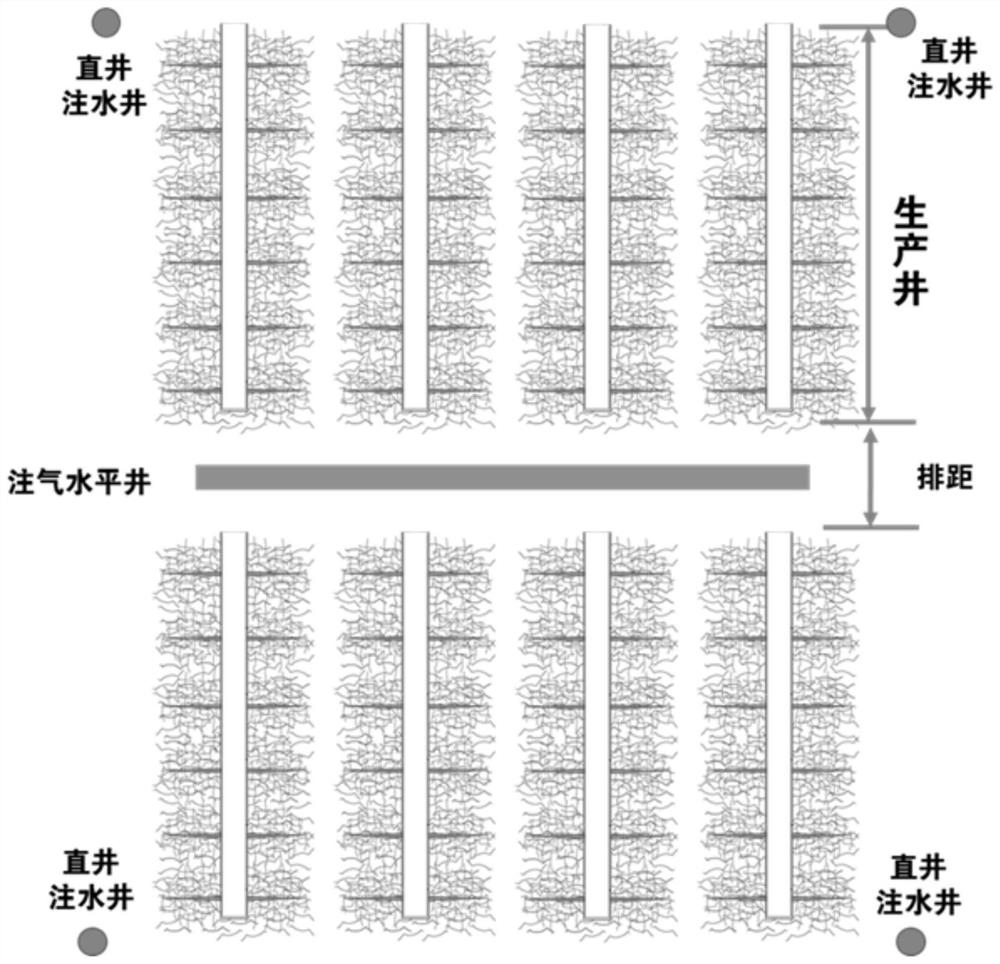

[0042] Step 1: Deploy horizontal well rows along the direction of maximum principal stress, all located in the middle of the reservoir, with a well spacing of 300m and a horizontal well length of 1200m. Reservoir stimulation of horizontal wells is carried out by adopting multi-stage multi-cluster volume fracturing method. The fracturing fluid is slick water fracturing fluid. There are 20 stimulation sections and the amount of sand added is 1500m 3 , 10000m of ground fluid 3 , the flowback rate is 40%, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com