Hydraulic transmission system for fracturing truck and fracturing truck

A technology of hydraulic transmission and fracturing truck, which is applied in transmission devices, fluid transmission devices, and production fluids, etc., can solve the problems of low rated speed of open pumps, low output pressure of large pumps, and low displacement of large pumps, and achieve optimization. Hydraulic pipeline support, the effect of high output maximum pressure and output maximum displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

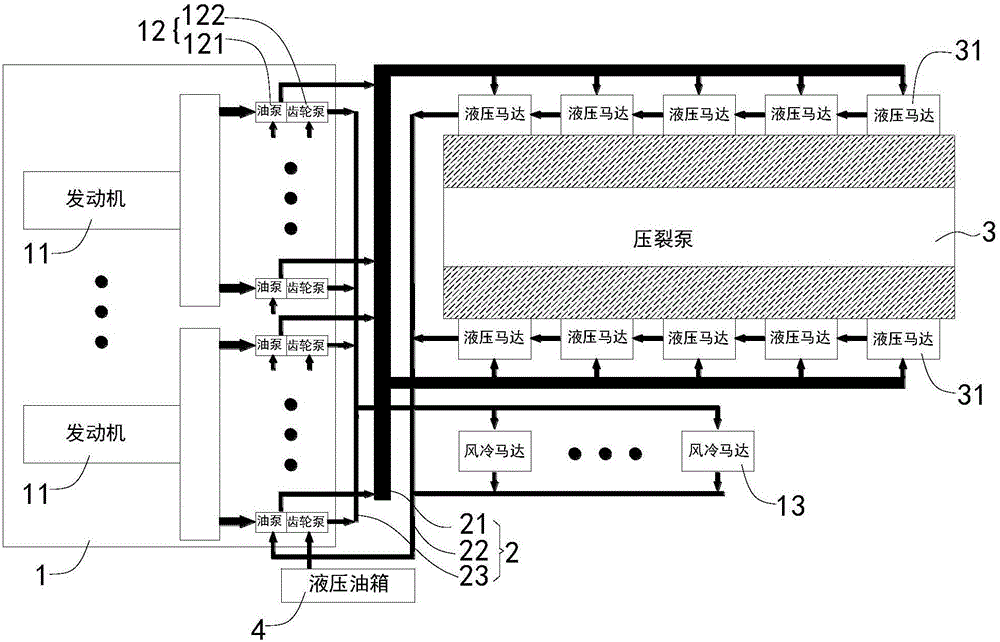

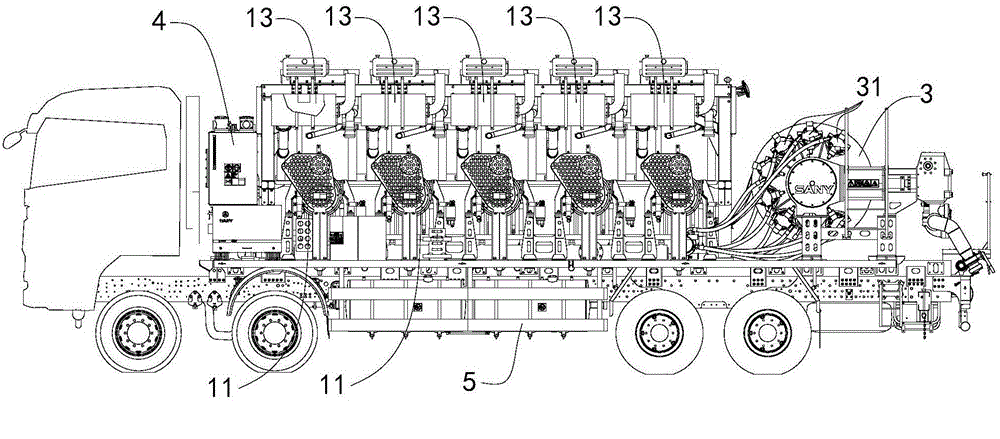

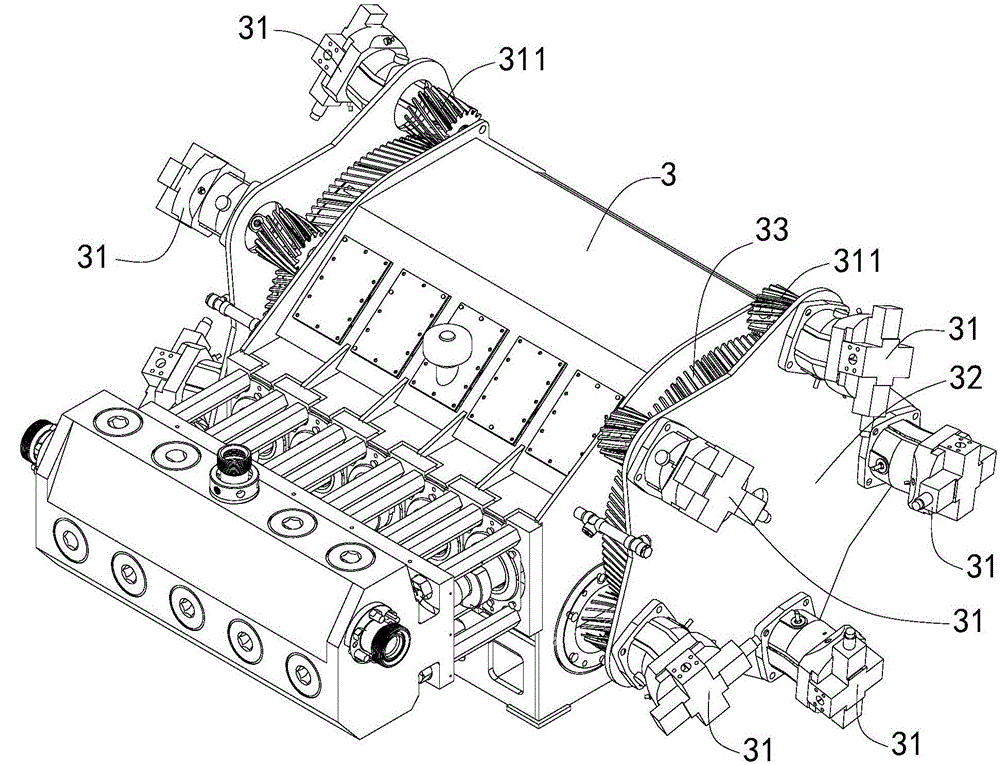

[0026] Such as figure 1 As shown, the hydraulic transmission system for the fracturing vehicle in this embodiment includes an engine unit 1, a hydraulic transmission oil circuit 2, a fracturing actuator 3, and a hydraulic oil tank 4. The engine unit 1 includes five engines 11, and the engines 11 drive and connect with Multiple groups of hydraulic drive units 12, the hydraulic drive unit 12 includes an oil pump 121 and a gear pump 122, the hydraulic transmission oil circuit 2 includes a first oil circuit 21, a second oil circuit 22 and a third oil circuit 23, and the fracturing actuator 3 is provided with There are ten hydraulic drivers 31 for driving the fracturing actuator 3, the oil pump 121, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com