Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

384results about How to "Environmental pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of preparing micro-structured powder for bonded magnets having high coercivity and magnet powder prepared by the same

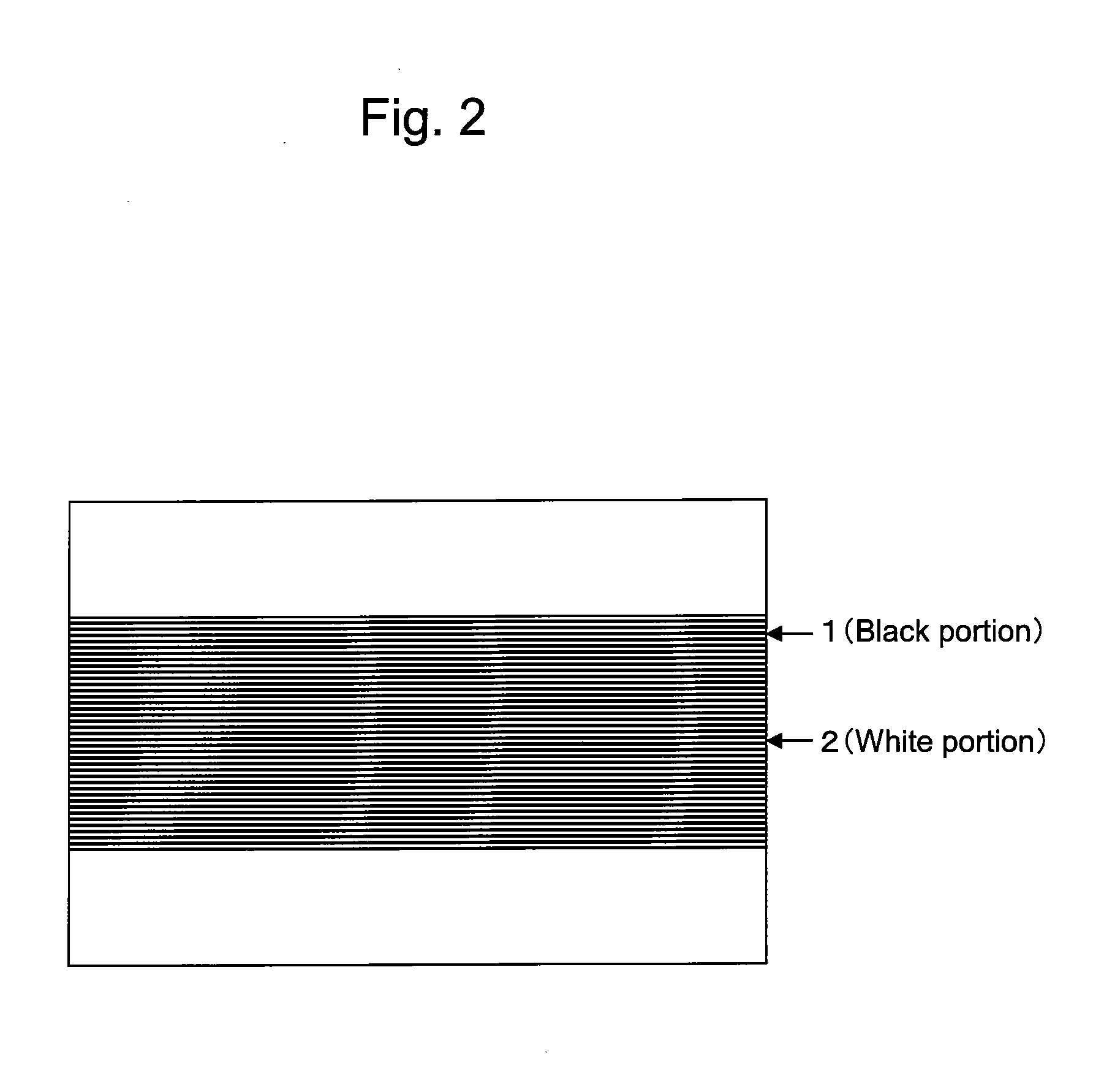

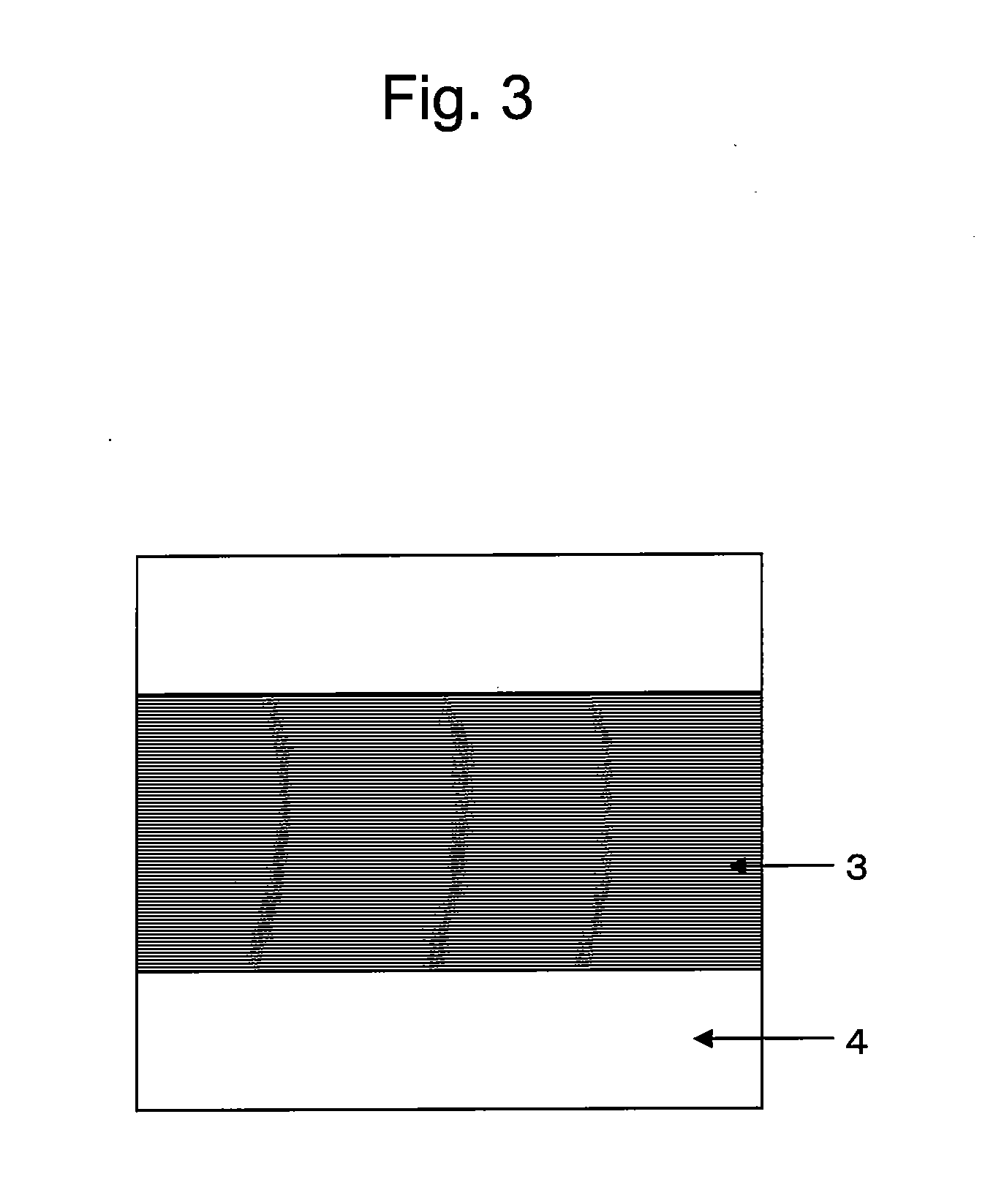

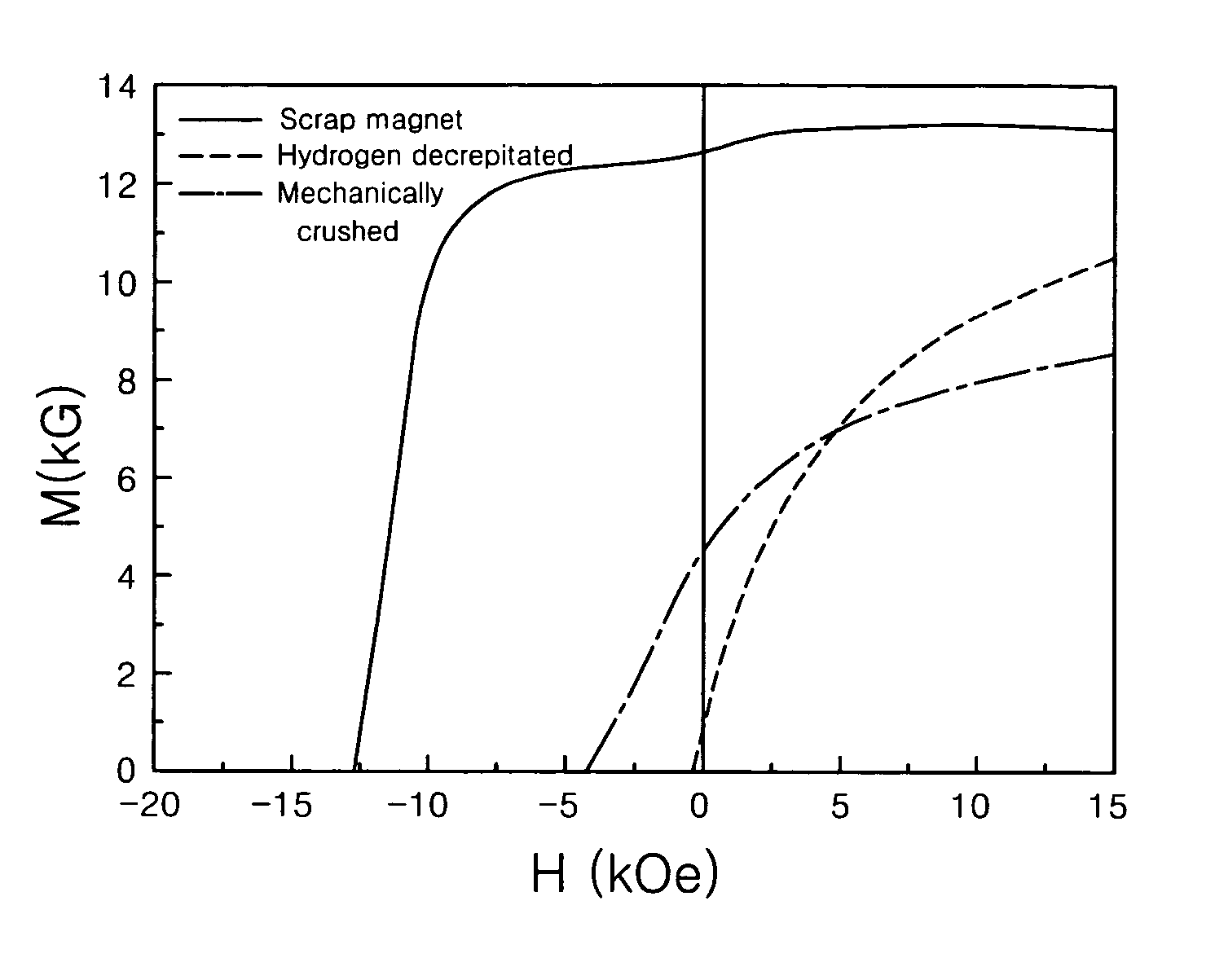

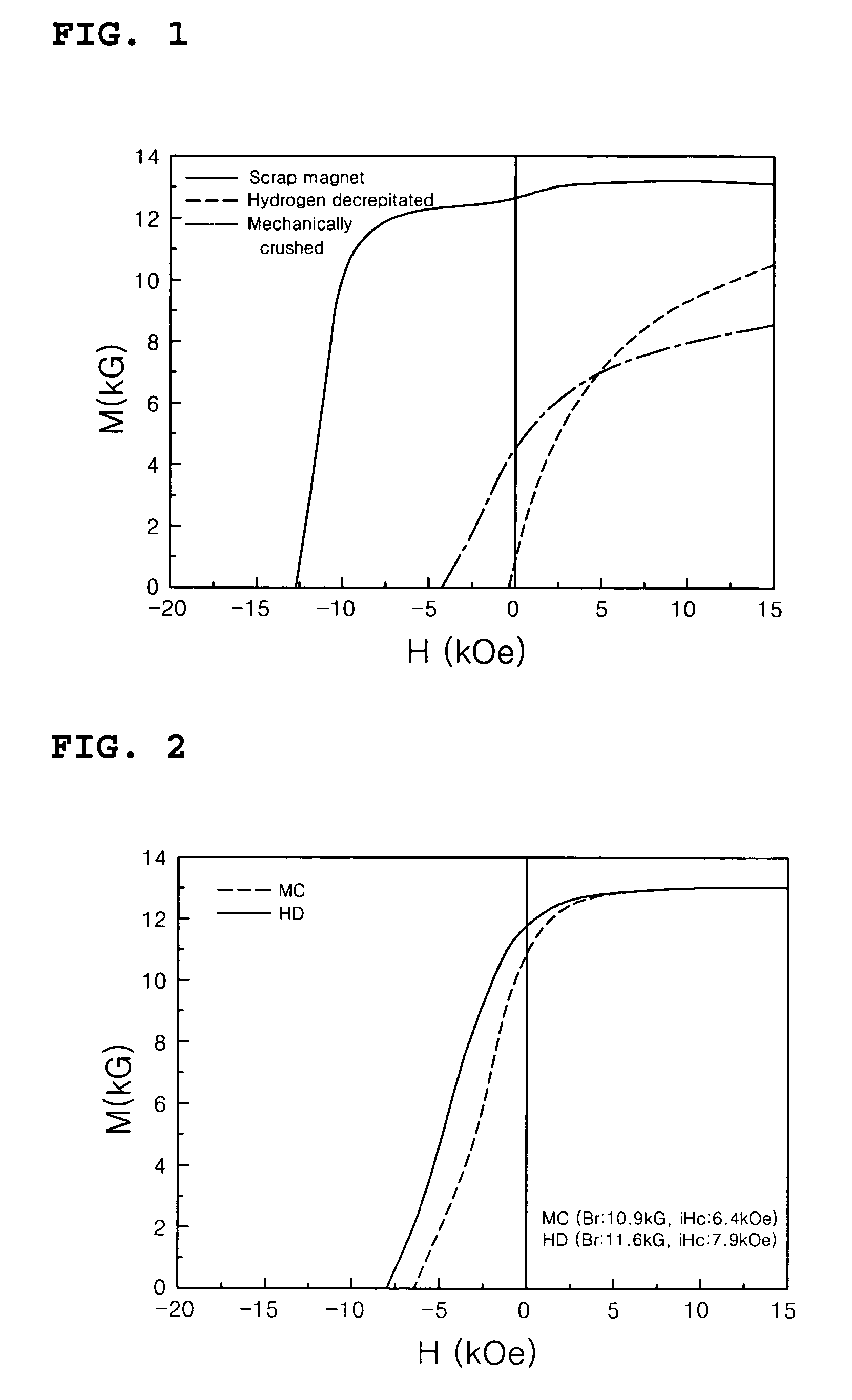

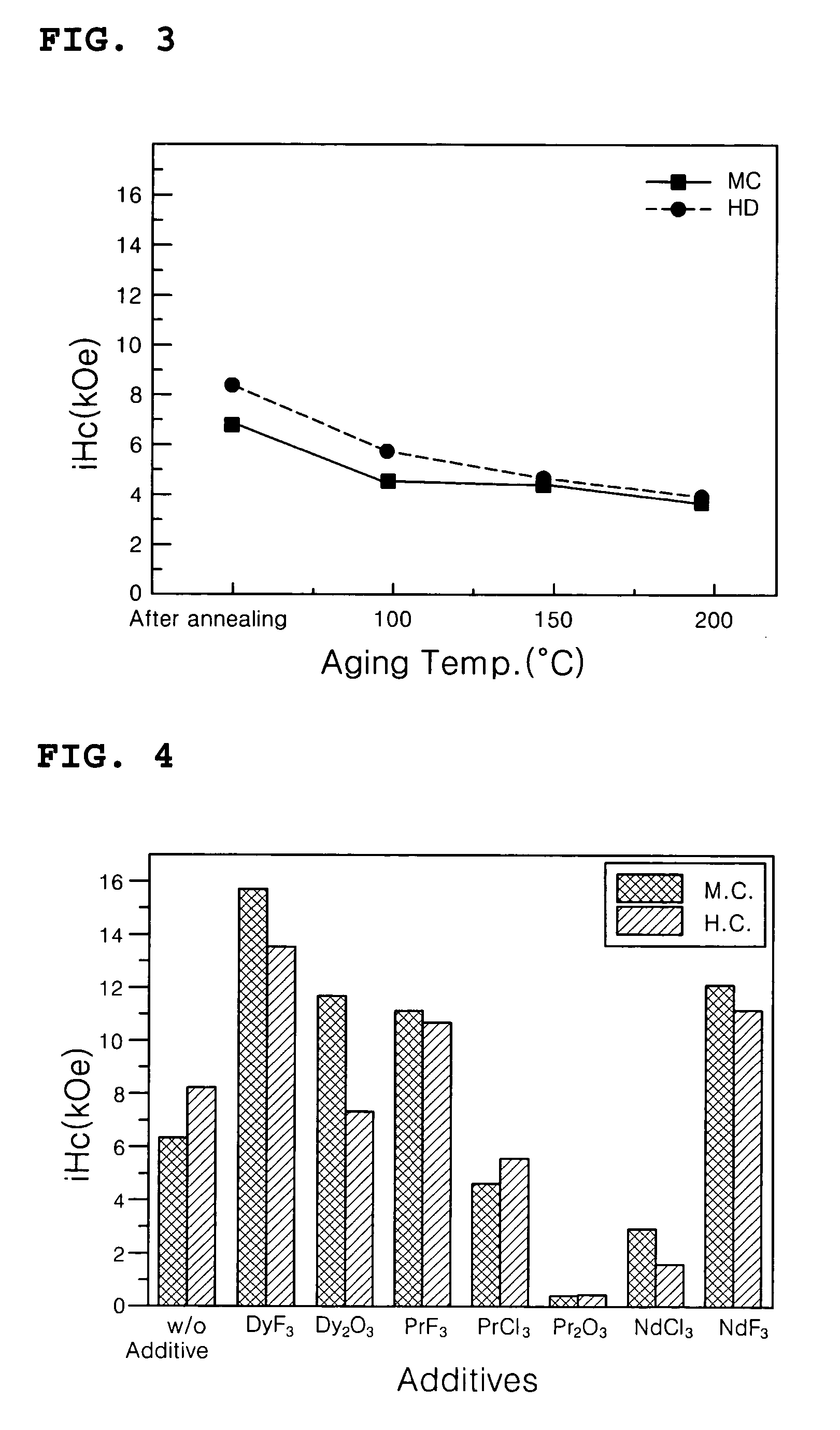

InactiveUS20050081959A1Reduce manufacturing costSimplified mass productionInorganic material magnetismRare earthGrain boundary

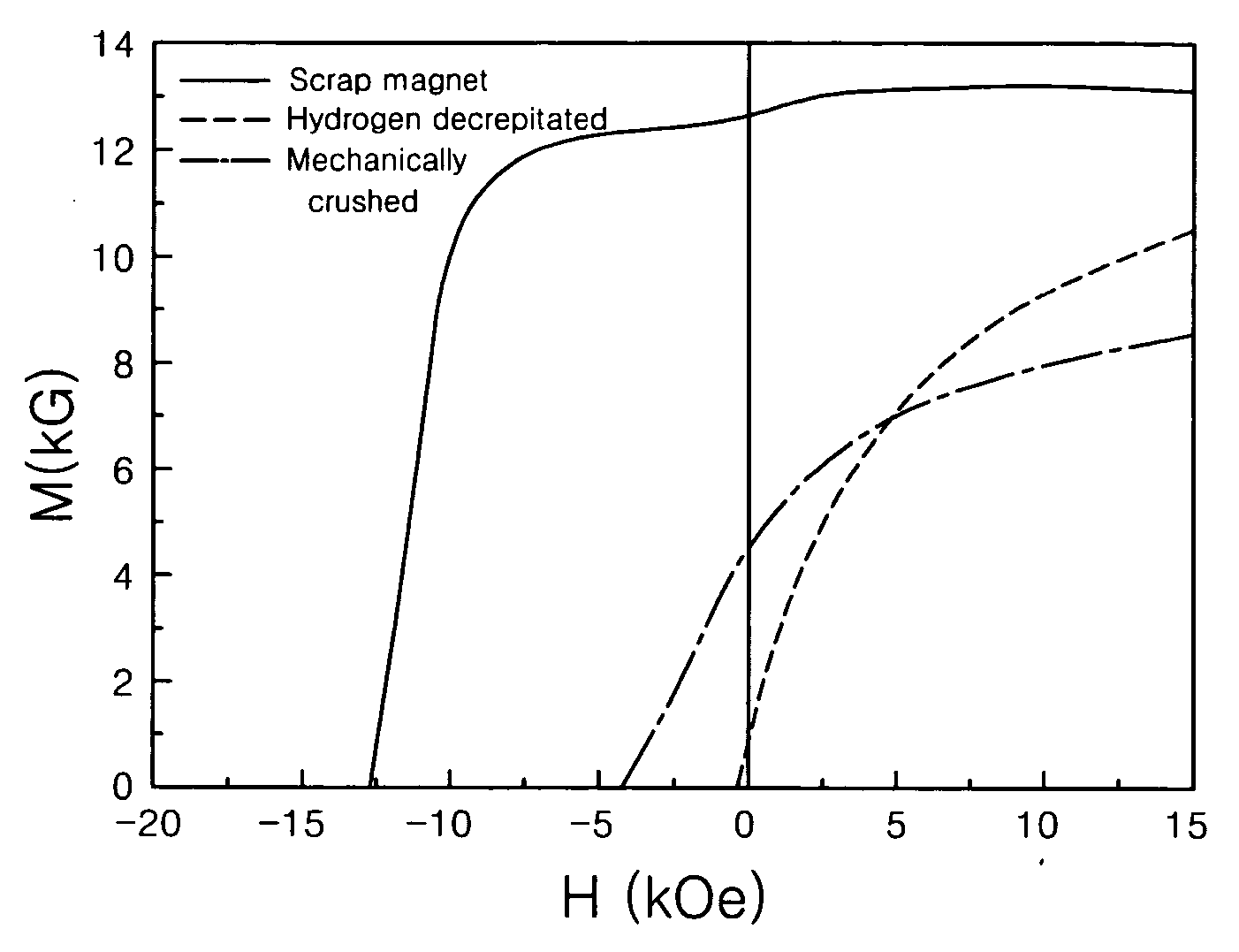

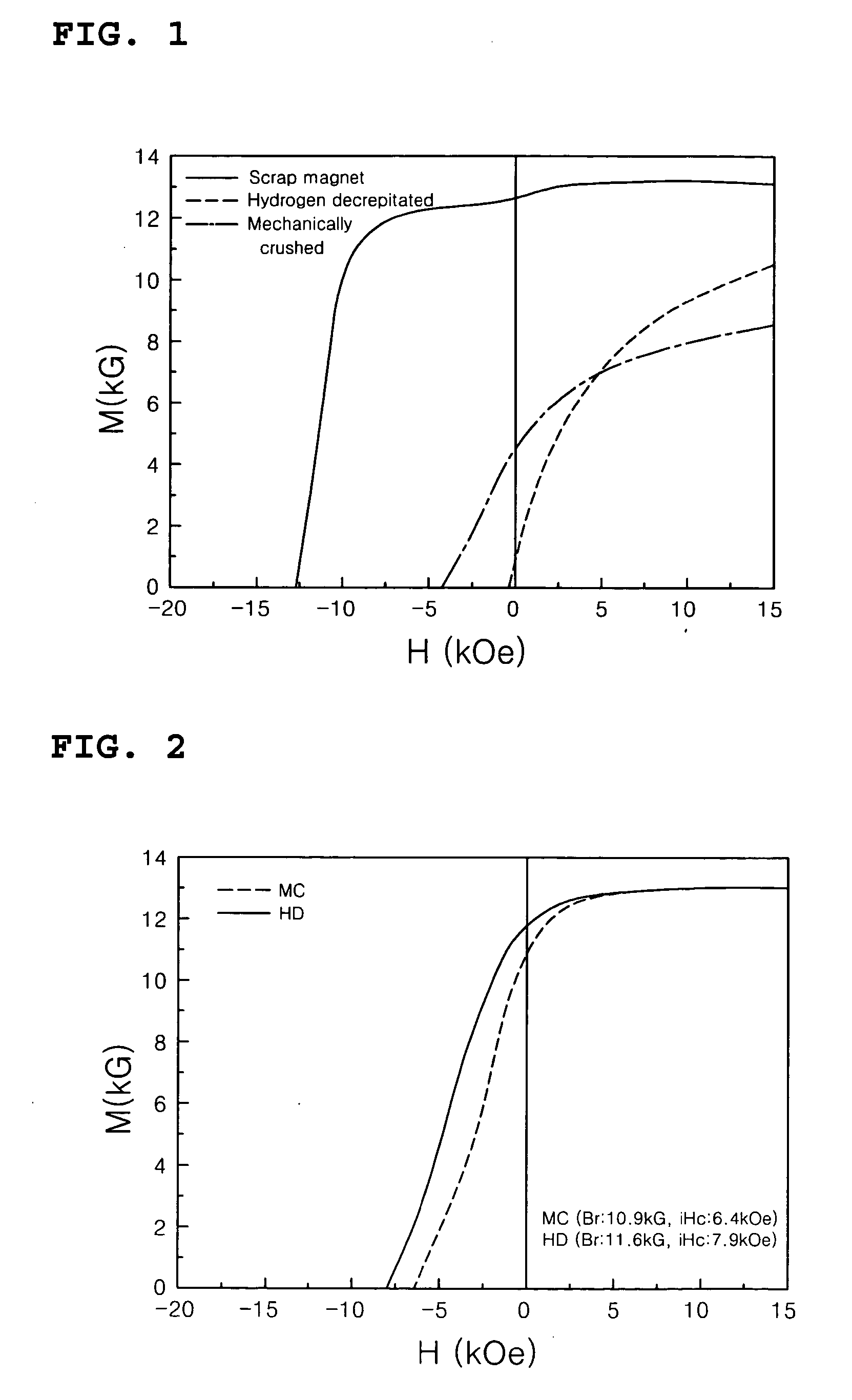

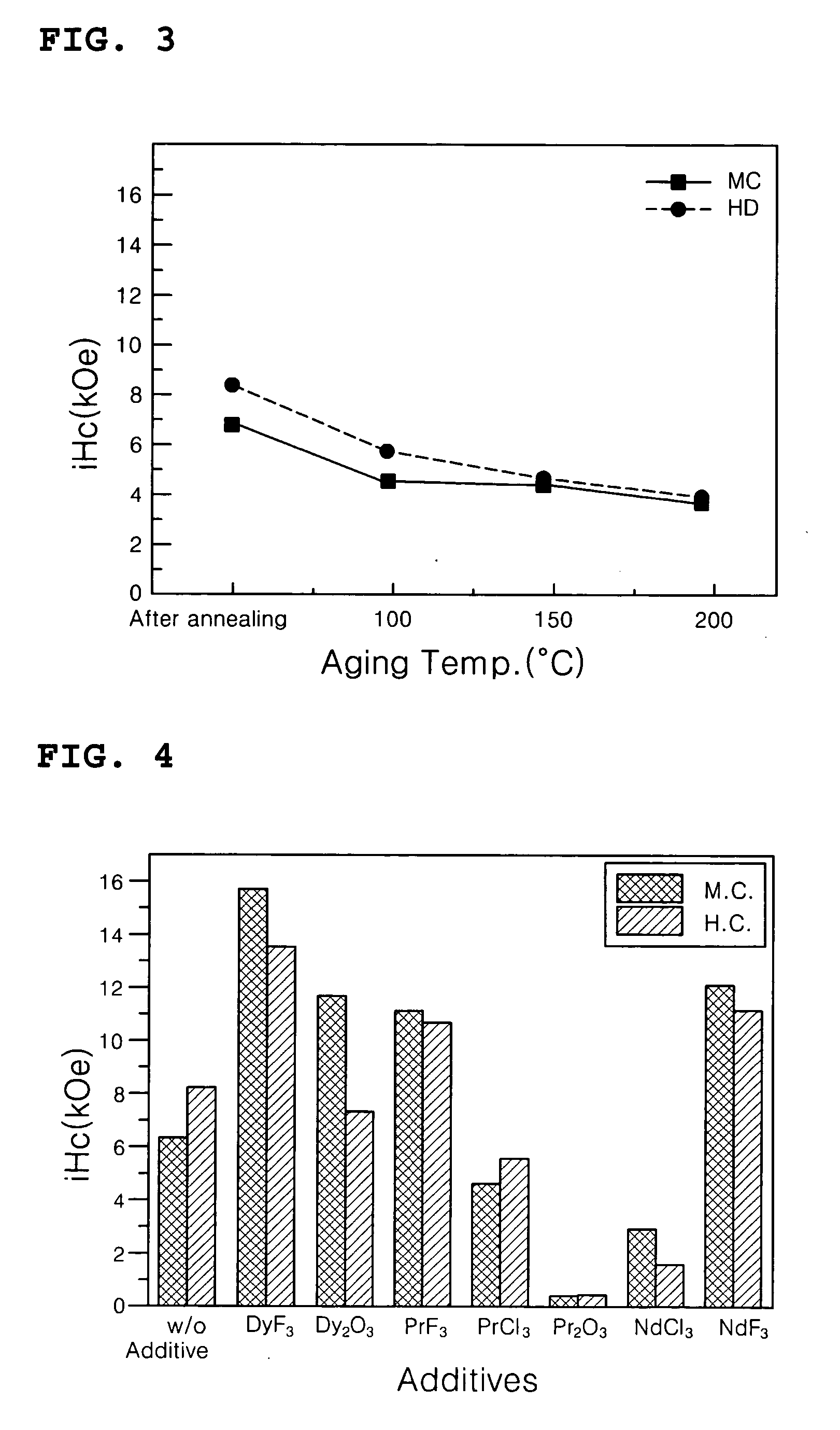

Disclosed is a method of preparing a micro-structured powder for bonded magnets having high coercivity, which is advantageous in terms of low preparation costs by recycling magnet scraps, simplified mass production, minimal environmental contamination by such a recycling process, and the preparation of stable anisotropic powders having high coercivity. Further, a magnet powder prepared by the above method is provided. The current method is characterized in that R—Fe—B type anisotropic sintered magnets or scraps thereof are crushed to prepare 50-500 μm sized magnet powders, which are then mixed with 1-10 wt % of rare earth fluoride (RF3) powders and thermally treated at high temperatures (500-1100° C.) in a vacuum or an inert gas, to cause the change of matrix-near surface and grain boundary of the powders. Thus obtained powders include a matrix phase having R2Fe14B crystal structure, a R-rich grain boundary phase containing rare earth fluoride, and other phases, in which the matrix phase has an average grain size of 1-20 μm, and the powders have an average size of 50-500 μm with superior magnetic characteristics of (BH)max≧20 MGOe and iHc≧5 kOe.

Owner:JAHWA ELECTRONICS

Molding material, prepreg and fiber-reinforced composite material, and method for producing fiber-reinforced molding substrate

InactiveUS20100068518A1Increase productivitySatisfactory dispersionCoatingsYarnPolymer scienceFiber bundle

This invention relates to: a molding material comprising a bundle of continuous reinforcing fibers (A), a polyarylene sulfide prepolymer (B) comprising at least 50% by weight of cyclic polyarylene sulfide and having the weight average molecular weight of less than 10,000 or polyarylene sulfide (B′) having the weight average molecular weight of 10,000 or greater and the degree of dispersion of 2.5 or lower, and thermoplastic resin (C); a prepreg comprising a resin composition comprising the polyarylene sulfide prepolymer (B) impregnated into a reinforcing fiber; and a method for producing a fiber-reinforced molding substrate comprising step (I) of continuously feeding a bundle of continuous reinforcing fibers, step (II) of combining cyclic polyarylene sulfide with the reinforcing fiber bundle, step (III) of heating the composite obtained in step (II) to subject the cyclic polyarylene sulfide to ring-opening polymerization to convert into polyarylene sulfide, and step (IV) of cooling the composite obtained in step (III) and withdrawing the same.

Owner:TORAY IND INC

Method of preparing micro-structured powder for bonded magnets having high coercivity and magnet powder prepared by the same

InactiveUS7163591B2Improve coercive forceReduce manufacturing costInorganic material magnetismRare earthContamination

Disclosed is a method of preparing a micro-structured powder for bonded magnets having high coercivity, which is advantageous in terms of low preparation costs by recycling magnet scraps, simplified mass production, minimal environmental contamination by such a recycling process, and the preparation of stable anisotropic powders having high coercivity. Further, a magnet powder prepared by the above method is provided. The current method is characterized in that R—Fe—B type anisotropic sintered magnets or scraps thereof are crushed to prepare 50–500 μm sized magnet powders, which are then mixed with 1–10 wt % of rare earth fluoride (RF3) powders and thermally treated at high temperatures (500–1100° C.) in a vacuum or an inert gas, to cause the change of matrix-near surface and grain boundary of the powders. Thus obtained powders include a matrix phase having R2Fe14B crystal structure, a R-rich grain boundary phase containing rare earth fluoride, and other phases, in which the matrix phase has an average grain size of 1–20 μm, and the powders have an average size of 50–500 μm with superior magnetic characteristics of (BH)max≧20 MGOe and iHc≧5 kOe.

Owner:JAHWA ELECTRONICS

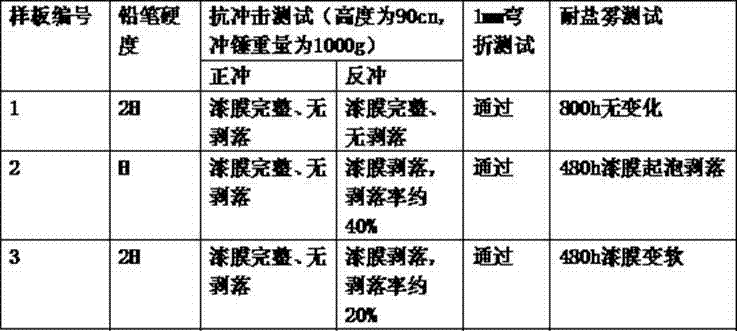

Chromium-free waterborne epoxy anticorrosion primer with excellent solvent oil resistant performance

ActiveCN102559010AImprove anti-corrosion performanceGood adhesionAnti-corrosive paintsEpoxy resin coatingsChromium freeEmulsion

The invention discloses chromium-free waterborne epoxy anticorrosion primer with excellent solvent oil resistant performance. The chromium-free waterborne epoxy anticorrosion primer comprises a component A and a component B, wherein the component A is a dispersoid formed by waterborne epoxy emulsion, pigment filler, and the like and the component B comprises a curing agent, cosolvent and the like. The chromium-free waterborne epoxy anticorrosion primer disclosed by the invention has the characteristics of good anticorrosion performance, large cohesive force, high strength, good water resistant performance, good solvent oil resistant performance, excellent mechanical performance, excellent flexibility, steady storage, and the like, can bear the influence of high-low temperature cycling, uses water as a dispersion medium, does not contain heavy metal such as chromium, is pollution-free to the environment, has low probability of shedding off and is convenient to construct.

Owner:MARINE CHEM RES INST CO LTD

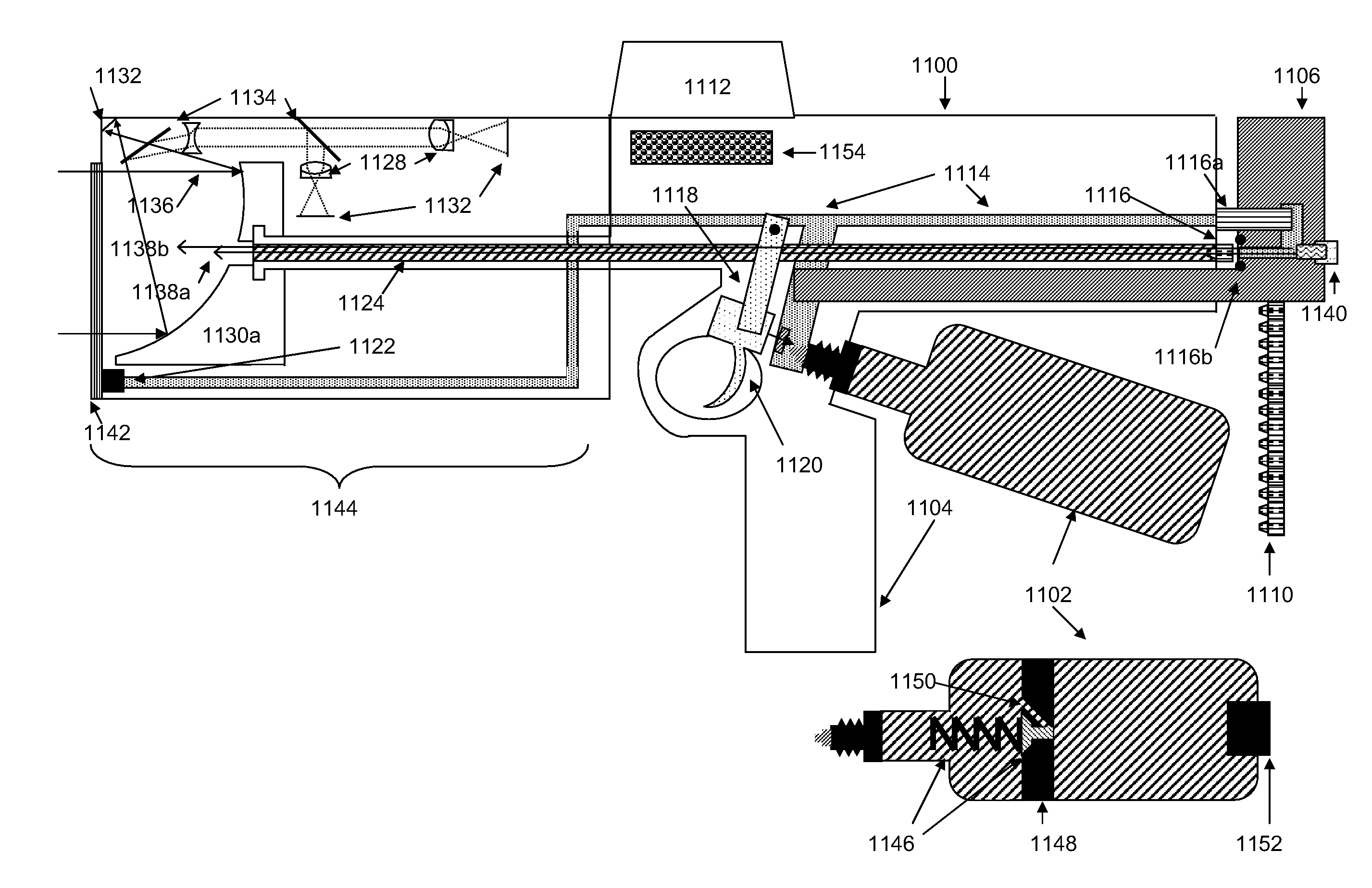

Velocity, internal ballistics and external ballistics detection and control for projectile devices and a reduction in device related pollution

InactiveUS7926408B1Boost velocityImprove accuracyAmmunition projectilesSighting devicesInternal ballisticsSignal modulation

Improvements to projectile devices (particularly air guns) include techniques for measuring and controlling the velocity of projectiles in the barrel and after leaving the barrel, allowing the use of non-toxic projectiles. Tracking of a projectile's flight by its unique sound and / or its unique electromagnetic signal or signal modulation are also provided, along with after-barrel guidance that can be used to improve accuracy. Control for discriminating between authorized and unauthorized users is also provided. A projectile device can also be used for inexpensive and harmless practice using optical and / or acoustic information gathered by targeting and imaging systems built into the device.

Owner:METADIGM L L C

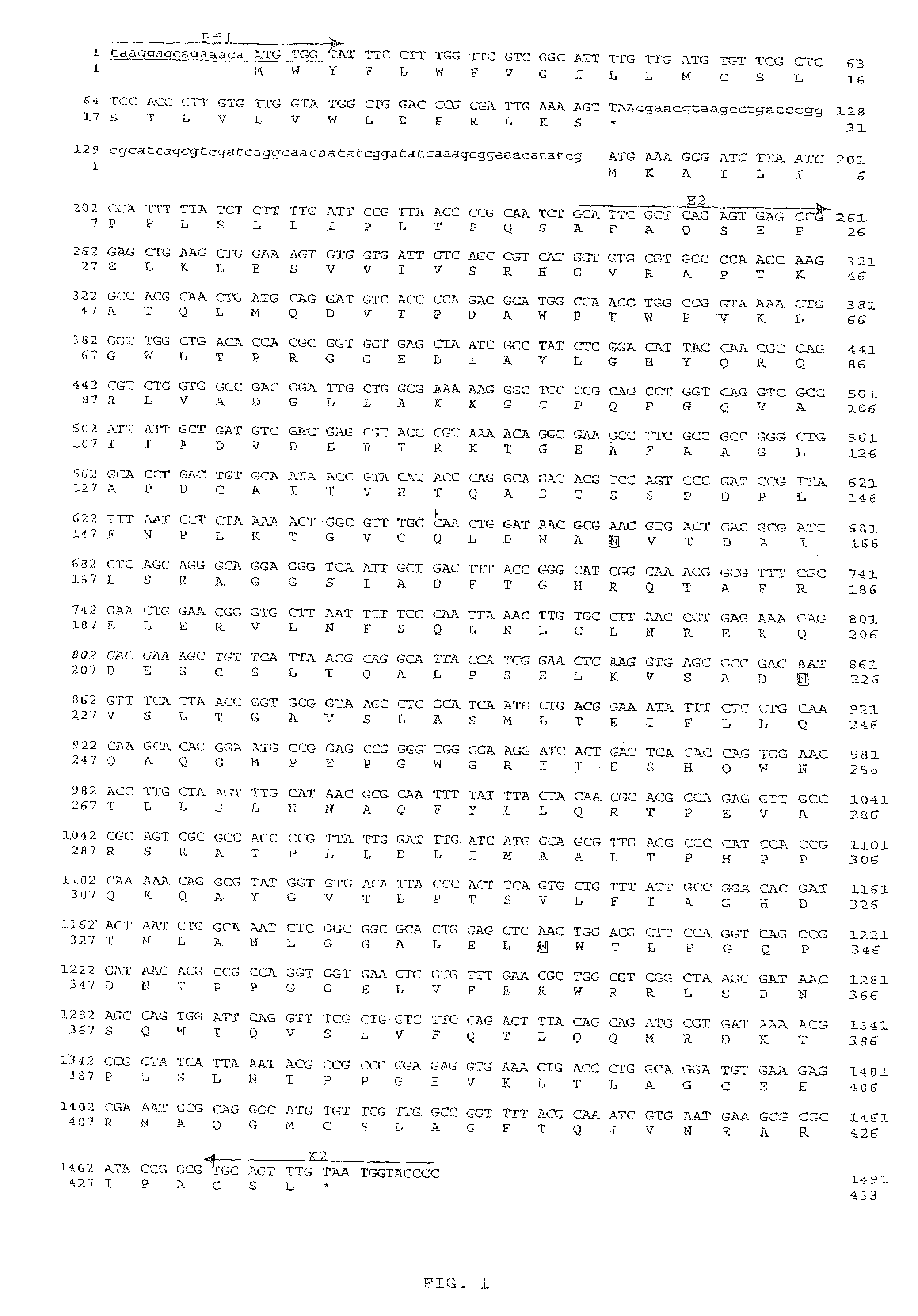

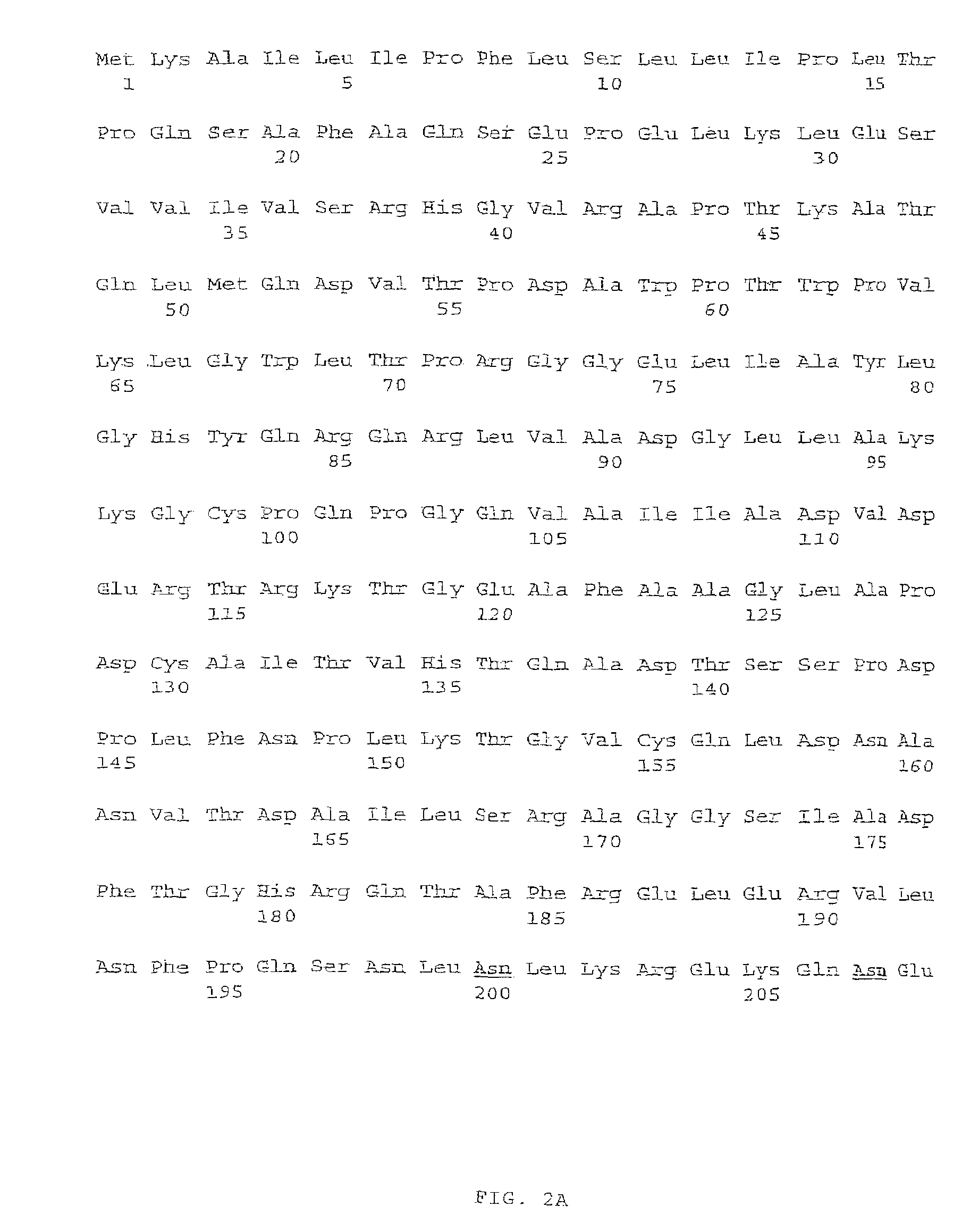

Phytase-containing animal food and method

InactiveUS7320876B2Lower requirementReduce environmental pollutionSugar derivativesBacteriaBiotechnologyYeast

A method is described for improving the nutritional value of a foodstuff comprising a source of myo-inositol hexakisphosphate by feeding the foodstuff in combination with a phytase expressed in yeast. The method comprises the step of feeding the animal the foodstuff in combination with a phytase expressed in yeast wherein the phytase can be selected from the group consisting of AppA1, AppA2 and a site-directed mutant of AppA. The invention also enables reduction of the feed to weight gain ratio and an increase bone mass and mineral content of an animal. A foodstuff and a feed additive comprising AppA2 or a site-directed mutant of AppA are also described.

Owner:CORNELL RES FOUNDATION INC +1

Molding material, prepreg and fiber-reinforced composite material, and method for producing fiber-reinforced molding substrate

InactiveUS7824770B2Excellent impregnationMaintain good propertiesSynthetic resin layered productsCoatingsFiber bundleShell molding

This invention relates to: a molding material comprising a bundle of continuous reinforcing fibers (A), a polyarylene sulfide prepolymer (B) comprising at least 50% by weight of cyclic polyarylene sulfide and having the weight average molecular weight of less than 10,000 or polyarylene sulfide (B′) having the weight average molecular weight of 10,000 or greater and the degree of dispersion of 2.5 or lower, and thermoplastic resin (C); a prepreg comprising a resin composition comprising the polyarylene sulfide prepolymer (B) impregnated into a reinforcing fiber; and a method for producing a fiber-reinforced molding substrate comprising step (I) of continuously feeding a bundle of continuous reinforcing fibers, step (II) of combining cyclic polyarylene sulfide with the reinforcing fiber bundle, step (III) of heating the composite obtained in step (II) to subject the cyclic polyarylene sulfide to ring-opening polymerization to convert into polyarylene sulfide, and step (IV) of cooling the composite obtained in step (III) and withdrawing the same.

Owner:TORAY IND INC

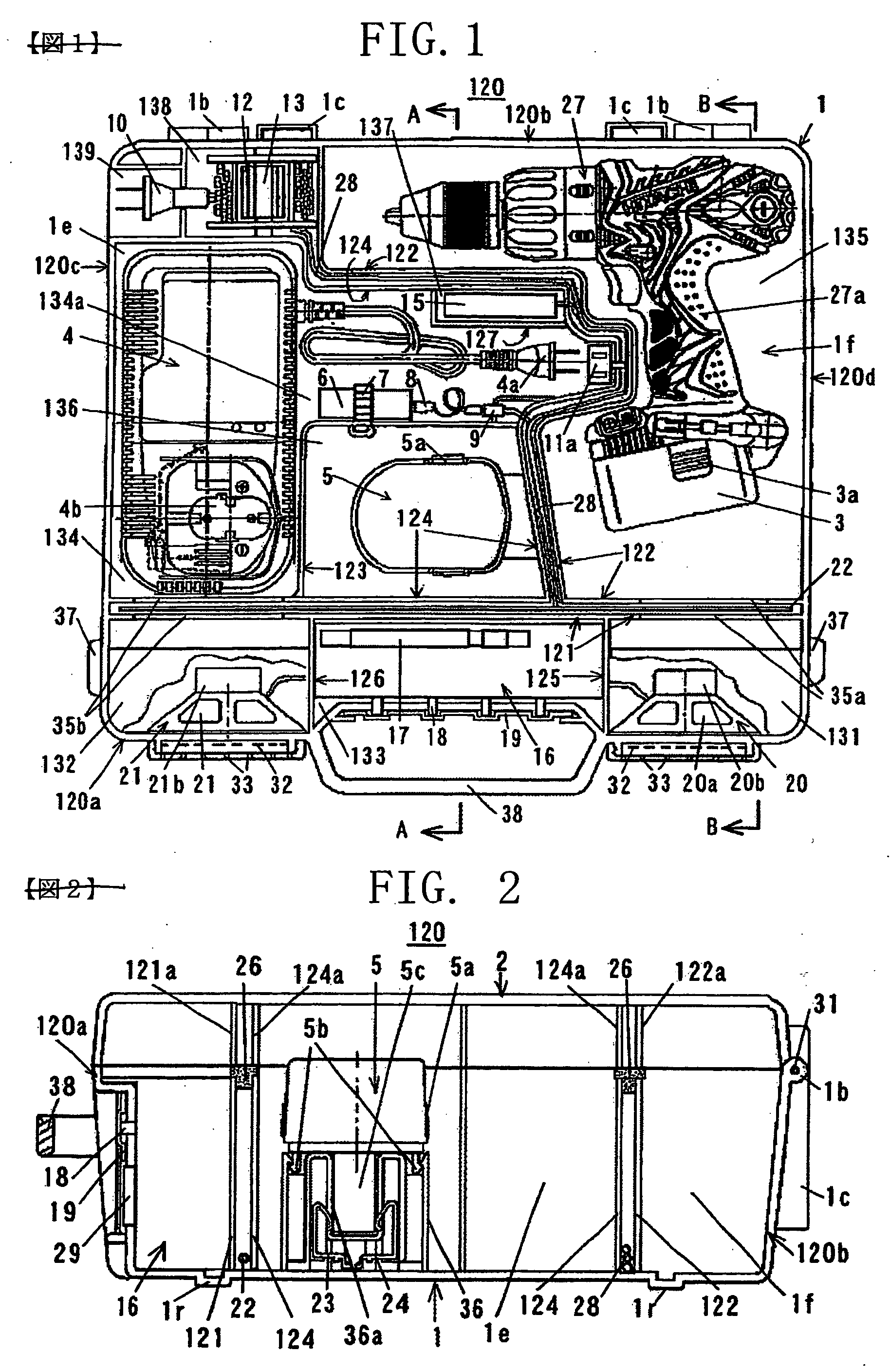

Tool storage case

InactiveUS20060170395A1Protection from damageAvoid separationBatteries circuit arrangementsElectric powerPower switchingEngineering

An electric device mounting type tool storage case that is easily transported together with other electric devices such as audio devices in addition to an electric tool body and can stand against contamination such as dust in the work site. An audio device as an electric device can be stored in the tool storage case which is used as an enclosure of a pair of speakers. Storage portions disposed in the tool storage case are partitioned by partition walls into a pair of sound channel spaces. In addition, a power switching circuit of an AC-DC converter power supply circuit or a battery DC power supply is formed in the tool storage case, and power wiring lines or inner wiring lines are disposed along the partition walls. While a cover case closes a storage case, electric devices such as an audio device or a charger are operated.

Owner:HITACHI KOKI CO LTD

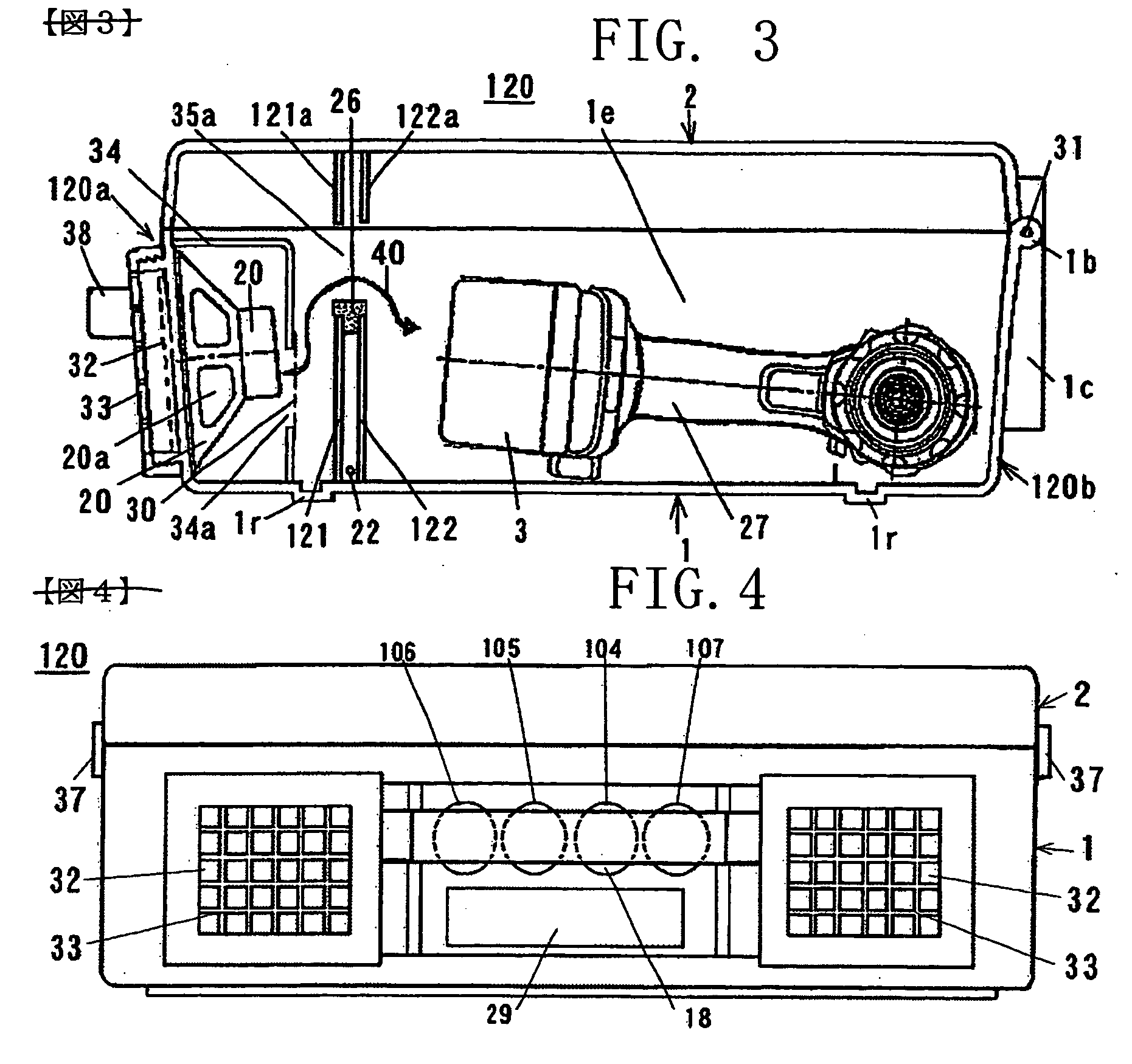

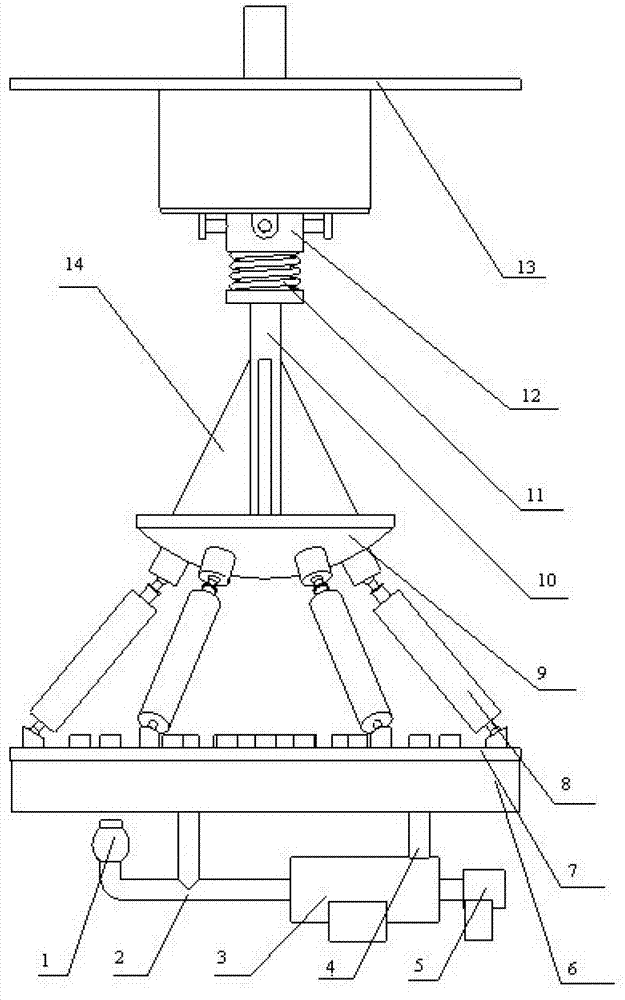

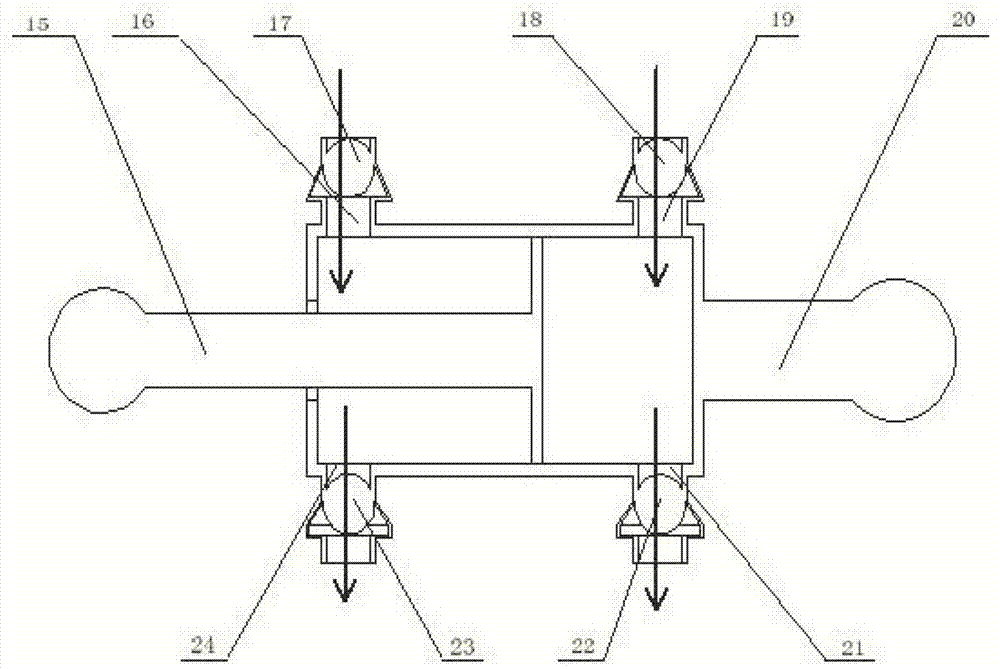

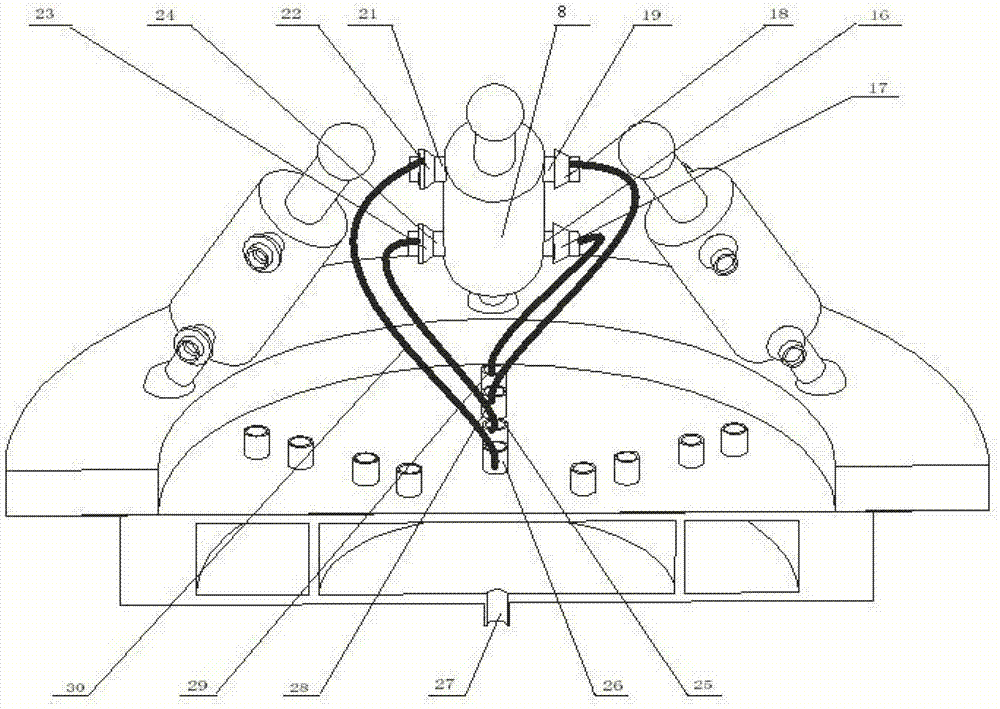

Multi-dimensional and parallel-swing sea wave power generation device

InactiveCN103306881AWon't be corrodedImprove sealingMachines/enginesEngine componentsHydraulic cylinderHydraulic motor

The invention discloses a multi-dimensional and parallel-swing sea wave power generation device. A top cover is fixedly connected with the top wall of a buoyancy box, one end of a three-degree-of-freedom movement pair is fixedly connected with the top cover, the other end of the three-degree-of-freedom movement pair is engaged with a swing rod, one end of the swing rod penetrates through the top wall of the buoyancy box and is fixedly connected with an outside device, the other end of the swing rod is fixedly arranged on an upper platform through the support of rib plates, a spring is fixedly connected with a shaft shoulder of the swing rod, six parallel hydraulic cylinders are arranged between the upper platform and a lower platform, piston rods of the six parallel hydraulic cylinders are hinged to the upper platform, cylinder bodies of the six parallel hydraulic cylinders are hinged to the lower platform, the lower platform is fixedly arranged on an oil mixture tank, the oil mixture tank is fixedly connected with the side wall of the buoyancy box, the oil mixture tank is connected with a hydraulic motor through a separating pipe and a return pipe, a generator is connected with the hydraulic motor, the generator and the hydraulic motor are arranged at the bottom of the buoyancy box, and an energy accumulator is connected with the hydraulic motor. The device has the characteristics that the service life is long, and the pollution is little; and while the energy of the sea wave in the transverse swinging is absorbed, the energy of the sea wave in the vertical direction can also be absorbed.

Owner:SHANGHAI JIAO TONG UNIV

Leukocyte classification hemolytic agent and kit thereof

ActiveCN103323582AAnalytical method is accurateInhibit persistent damageBiological testingWhite blood cellAnalysis method

The invention discloses a hemolytic agent for a blood cell analyzing device. The hemolytic agent can decompose erythrocytes and blood platelets in blood. The invention also discloses a leukocyte classification kit. The leukocyte classification kit comprises the hemolytic agent, a dilute and an inhibitor. The agent provided by the invention is the assorted agent suitable for XFA9500 fully-automatic five-classification blood cell analyzer produced by Nanjing Perlong medical equipment limited company; the agent contains no dye, so that the agent is environment-friendly; by adopting the agent, lymphocyte, monocyte, neutrophile granulocyte, eosinophilic granulocyte and basophilic granulocyte can be directly detected; furthermore, the analysis method is fast and accurate.

Owner:NANJING PERLONG MEDICAL EQUIP

Vapour explosion cracking method for cell wall of marine algae

InactiveCN1502273APromote digestion and absorptionHigh nutritional valueFood preparationNutritive valuesEngineering

The present invention relates to a steam explosion wall-breaking method of seaweed cell wall, and said method includes the following steps: (1). placing wet seaweed in steam explosion tank, introducing saturated steam until the tank interior temp is up to 80-100 deg.C, and retaining for 1-8 min.; (2). stopping steam supply, introducing high-pressure air into the steam explosion tank until tank interior pressure is up to 0.8-1.5 MPa; and (3). instantaneously reducing pressure and releasing so as to obtain seaweed product whose wall-broken rate is up to 100%. Said seaweed product can be used for preparing seaweed functional food with high nutritive value and good taste, agar and carrageen gum, etc.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

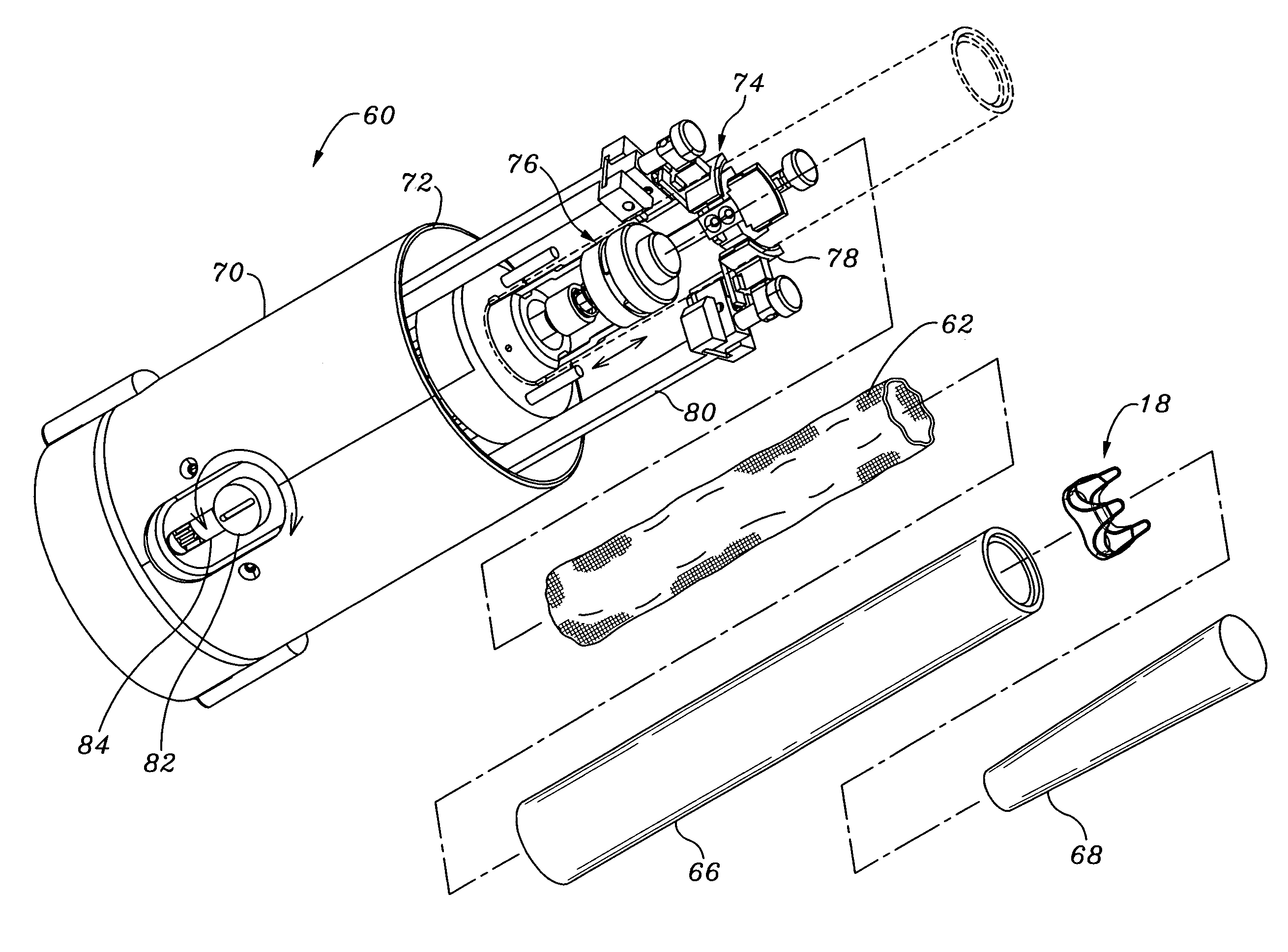

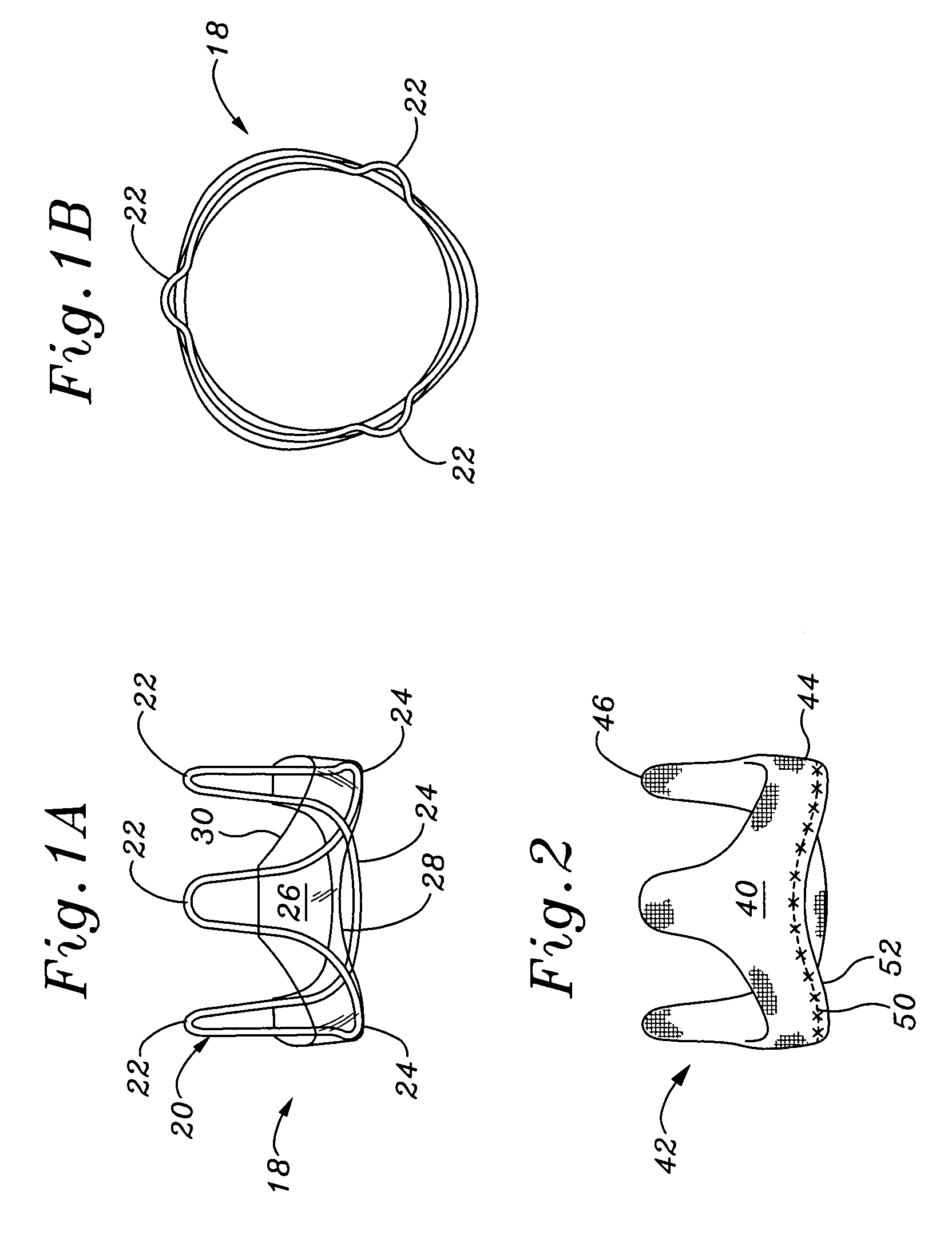

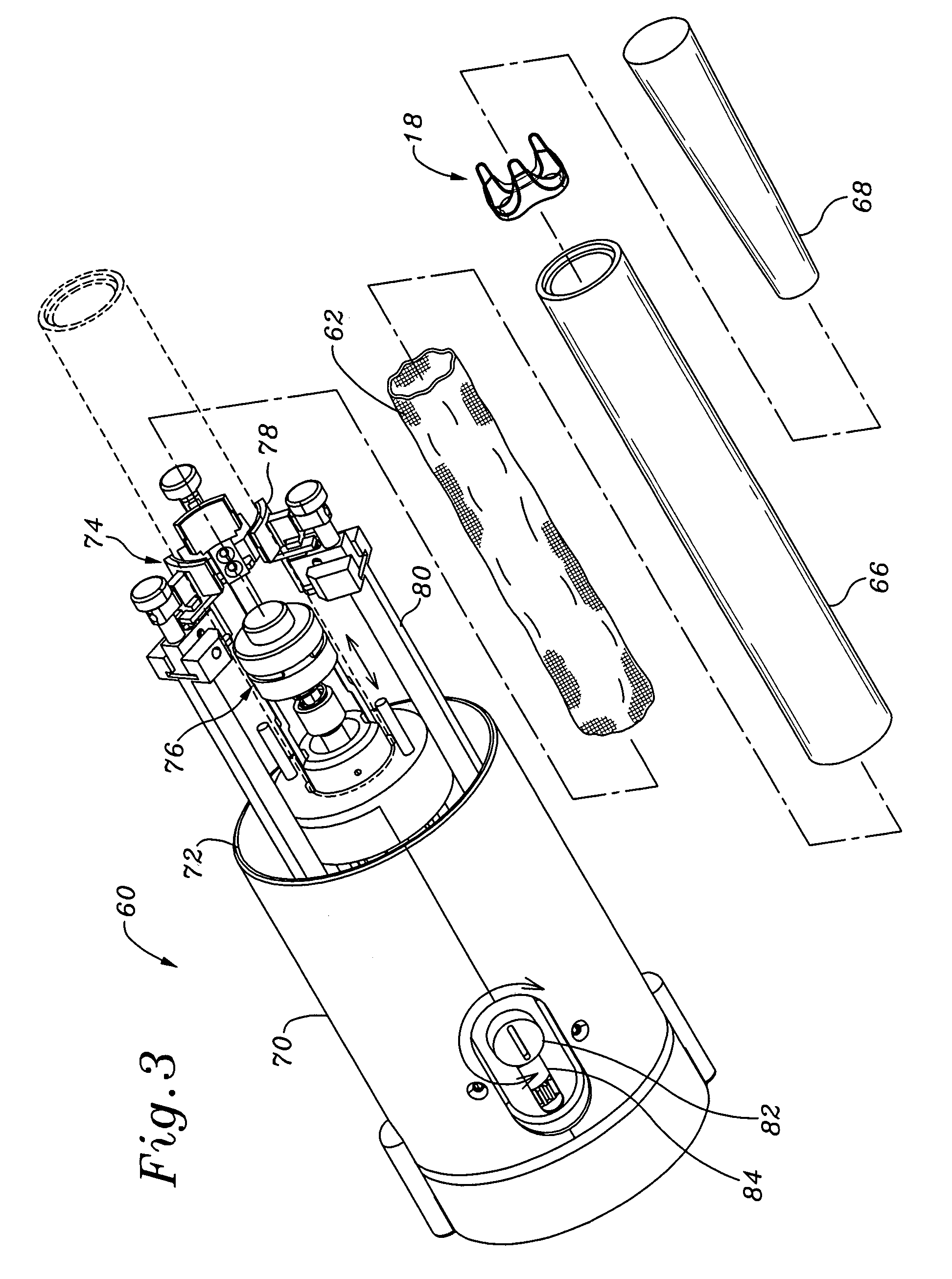

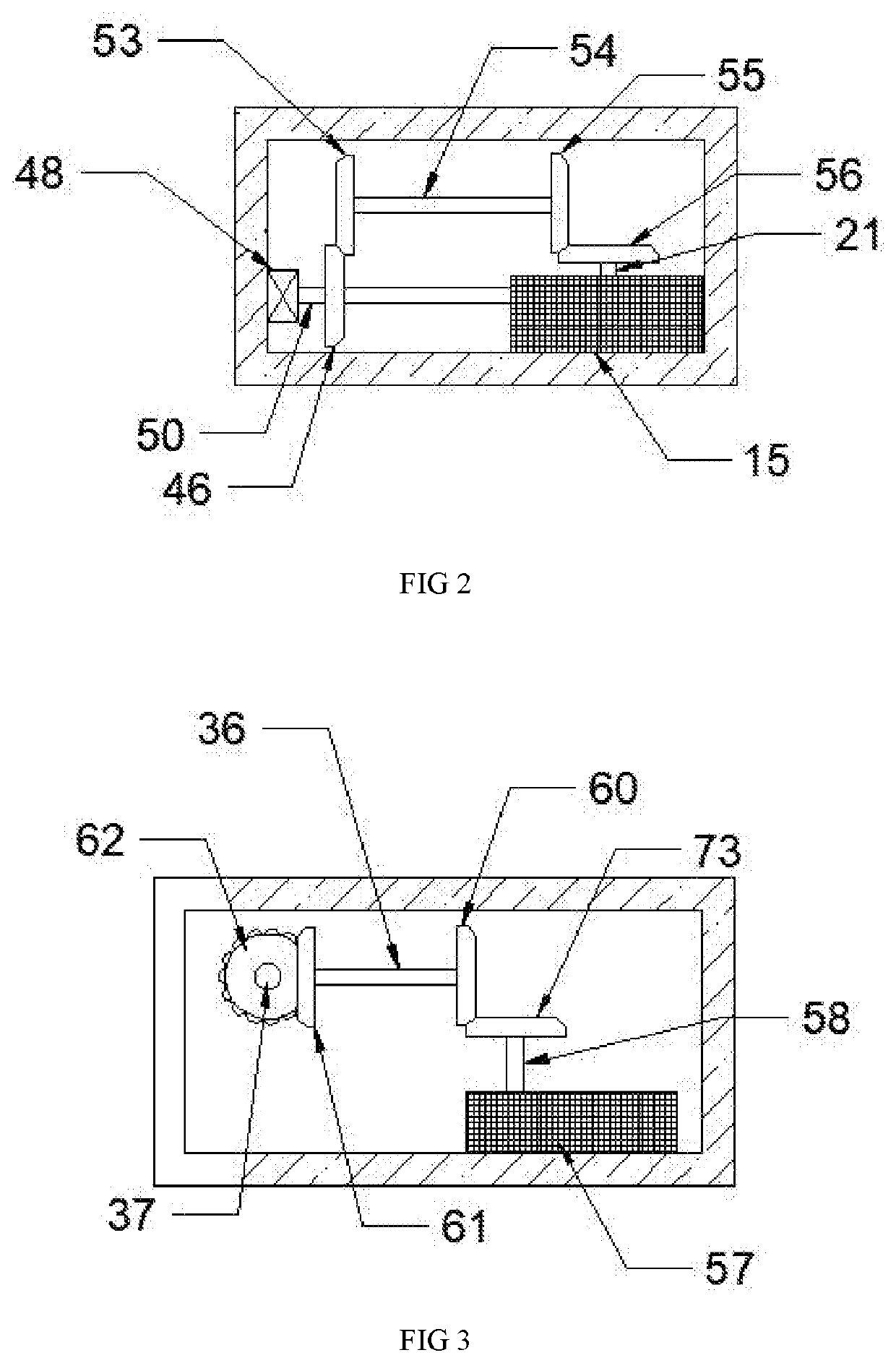

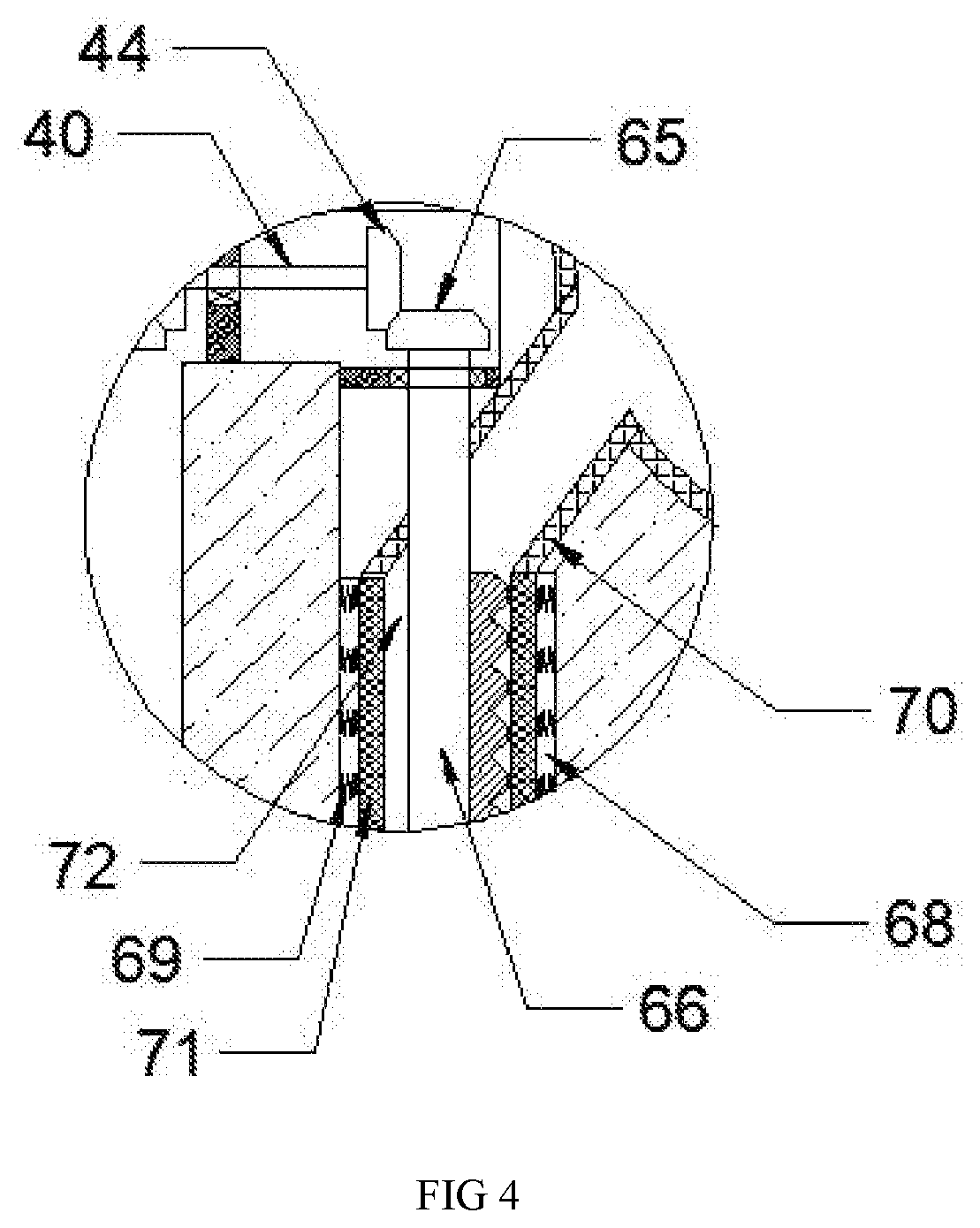

Systems and methods for assembling components of a fabric-covered prosthetic heart valve

ActiveUS7739971B2Significant of injurySignificant of stressWork-feeding meansHand sewingBobbinProsthetic valve

A system and method for assembling a prosthetic heart valve, including a procedure for tightly wrapping fabric around a heart valve support stent having a highly contoured undulating outflow edge. A mandrel retains tension without manual assistance in a tubular length of fabric wrapped over the support stent, and includes relatively axially movable inner and outer clamping mechanisms and a pedestal tube on which the support stent rests. The clamping mechanisms include clamps that pull the fabric only in the support stent cusps. The mandrel assembly may be placed in a chuck of a sewing machine system for automatically forming the seam. A small shuttle with bobbin thread reciprocates within a channel inside of the support stent and cooperates with the sewing machine needle to form a lock-stitch in the fabric tube. The mechanization of the fabric covering procedure greatly enhances manufacturing throughput and reduces ergonomic strain on workers.

Owner:EDWARDS LIFESCIENCES CORP

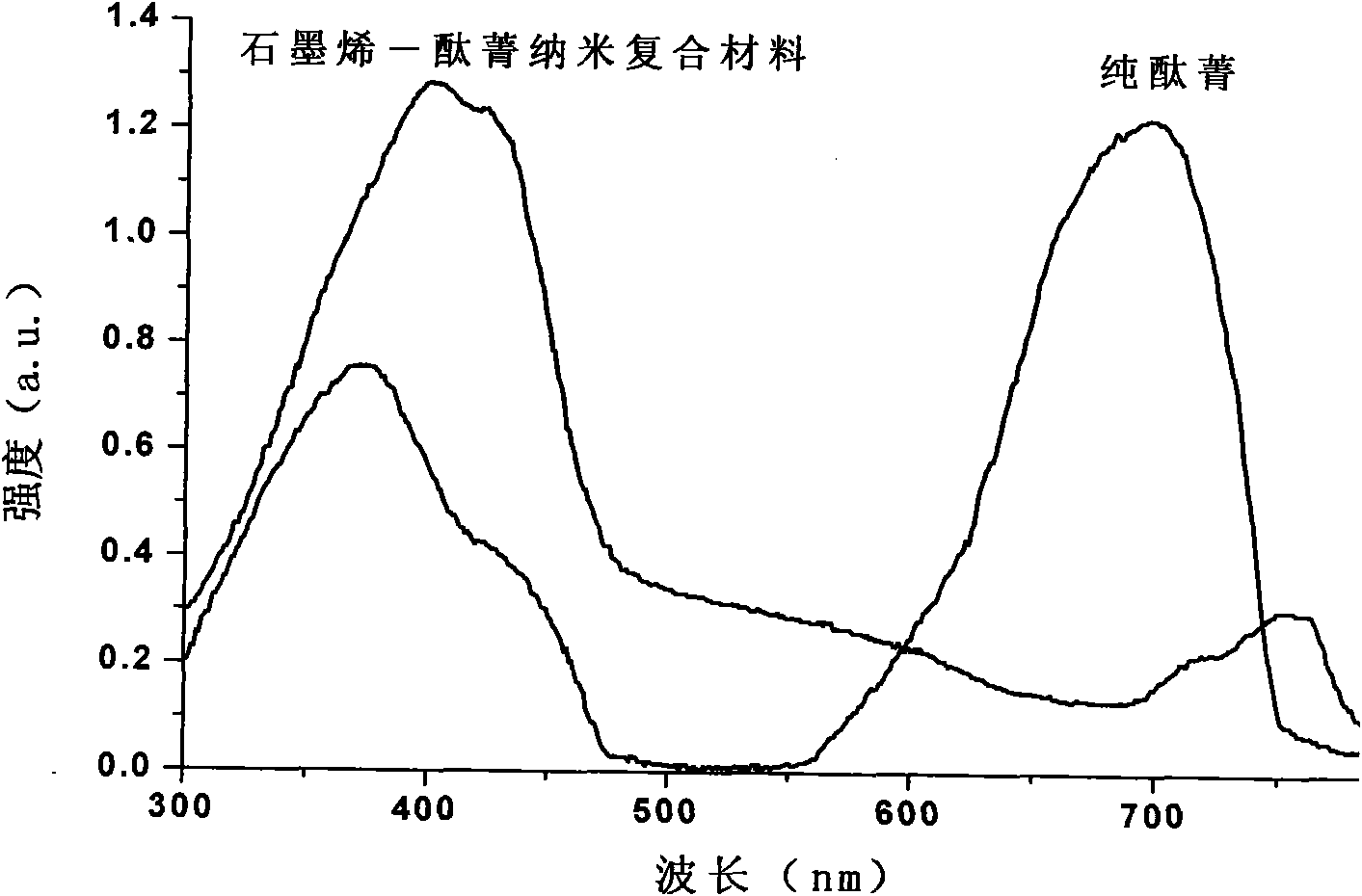

Method for preparing graphene-phthalocyanin nano composite material by mercaptan-alkene clicking chemical method

InactiveCN101648696AImprove solubilityImprove film formationNanostructure manufactureChemical industryChemical reaction

The invention belongs to the technical field of chemical industries, in particular to a method for preparing a graphene-phthalocyanin nano composite material by a mercaptan-alkene clicking chemical method. The method comprises the following steps: introducing a plurality of carbon-carbon double-bond functional group by chemically modified graphite oxide; selecting proper sulfydryl phthalocyanin; and preparing the functional graphene-phthalocyanin nano composite material at one step by mercaptan-alkene clicking chemical reaction. The invention does not use a heavy metal ion as a catalyst, solves the problems of loose combination, easy falling, and the like of a traditional phthalocyanin macromolecule on the surface of the grapheme and has favorable environmental protection and advancement.The method has the advantages of simplicity, convenience, one-step completion, no catalyst addition, low cost, no pollution to environment, wide application prospect, and the like. The graphene-phthalocyanin nano composite material product has higher photosensitivity, compatibility and thermostability and favorable dissolubility, film forming performance and photoelectric performance, is a new generation high-performance organic-inorganic nano composite photoelectric function material and can be applied to the fields of conducting materials, solar energy cell materials, photoelectric conducting materials, photoelectric converting materials, and the like.

Owner:TONGJI UNIV

Modified stalk material and its application

InactiveCN1412092AHigh strengthEnvironmental pollutionFlexible coversWrappersPhanerochaete chryosporiumChemistry

The present invention relates to a modified straw material, its production method and application. The production method of the modified straw material includes the following steps: 1. steam-blastingstraw to obtain steam-blasted straw; 2. inoculating the steam-blasted straw with culture liquor to make solid fermentation treatment to degrade lignin; 3. mixing the steam-blasted straw and air-driedstraw, making their mixture undergo the processes of thermosetting treatment and forming treatment so as to obtain the invented modified straw material which can be made into plate material or light packaging material instead of wood material, so that it possesses extensive application.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

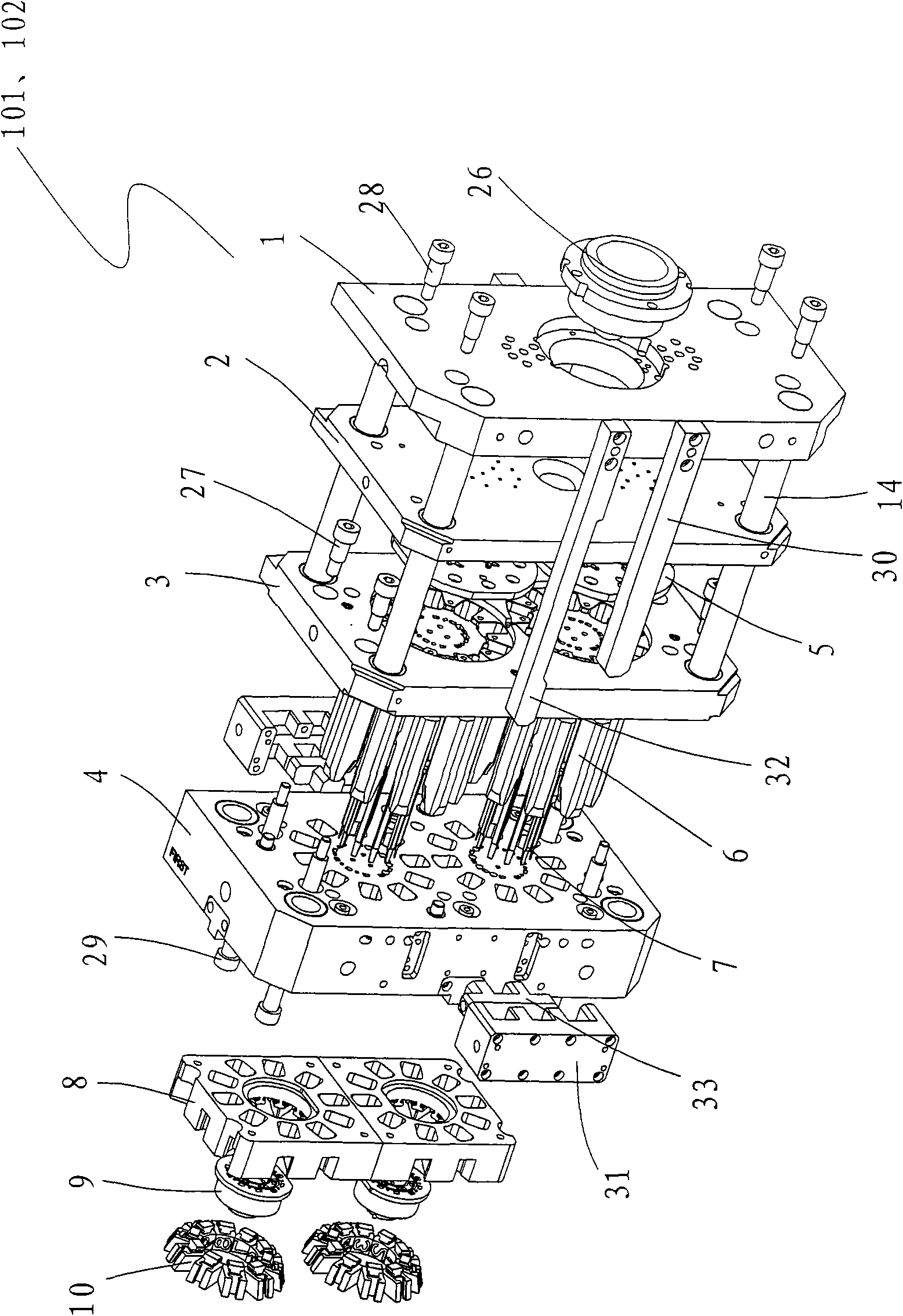

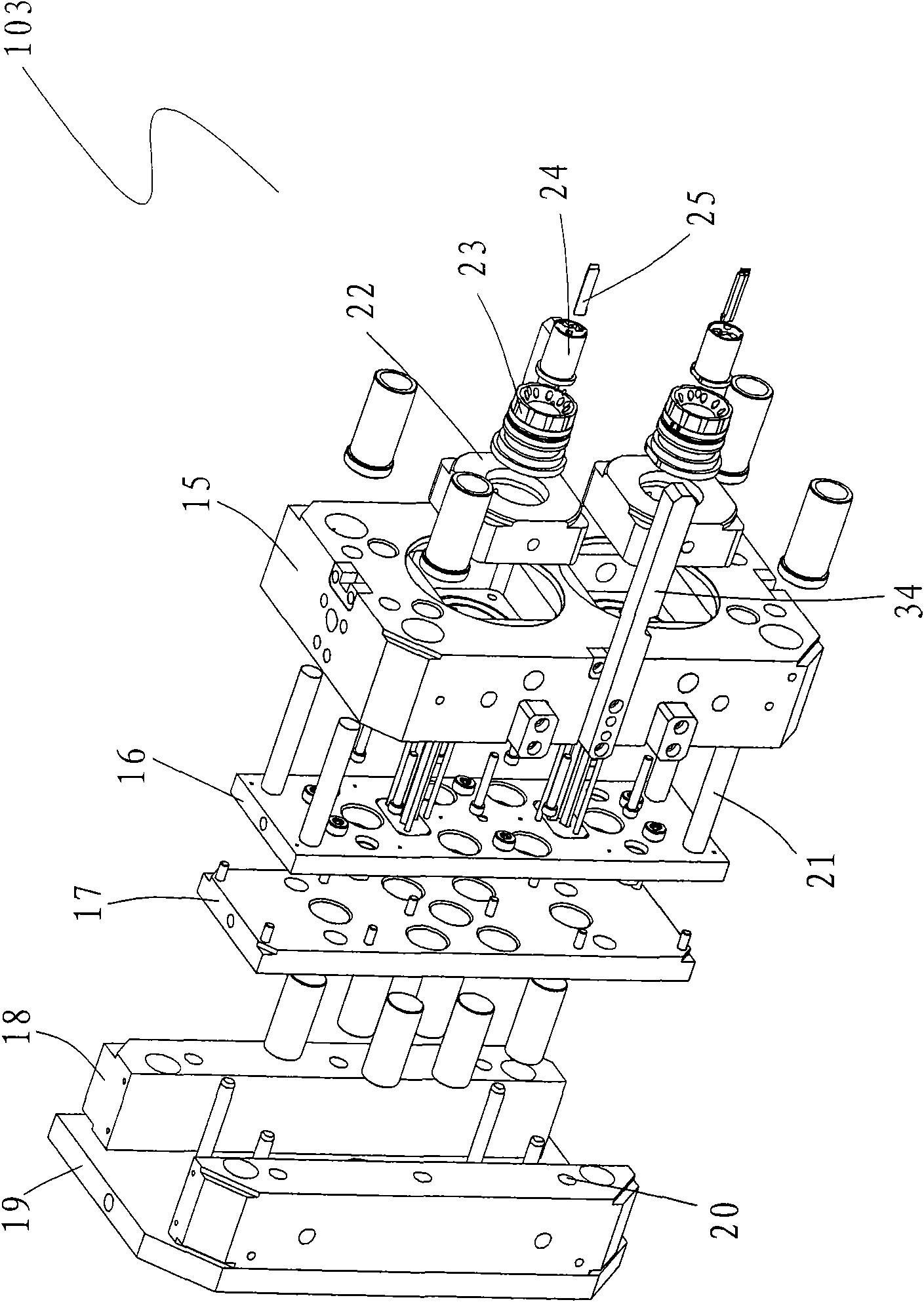

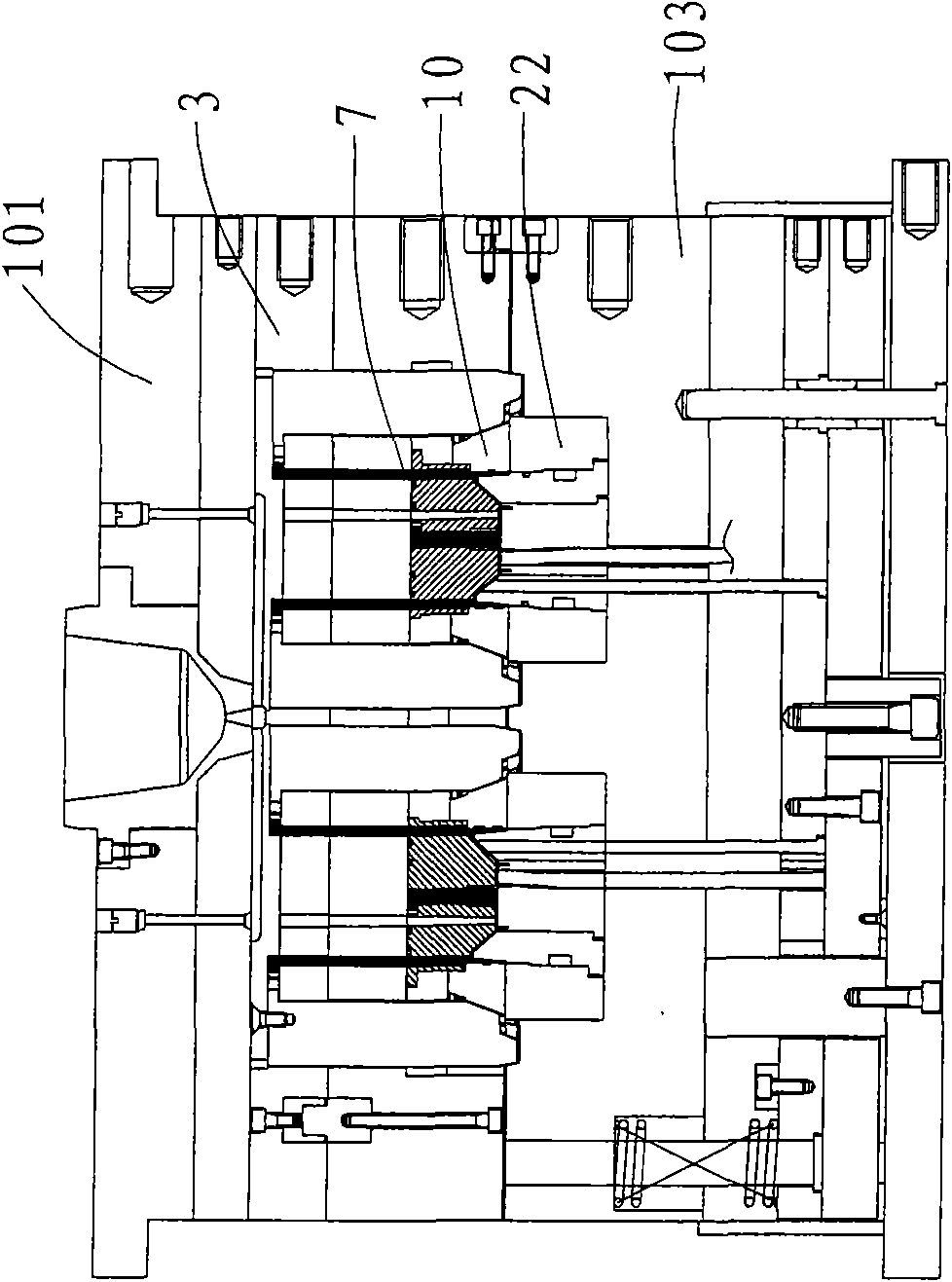

Injection moulding method of digit wheel and mould thereof

The invention discloses an injection moulding method of a digit wheel and a mould thereof. The method comprises the following steps: closing and molding a font front mould and a rear mould, opening the font front mould and the rear mould, rotating a rotating disc of a double-colored injection machine, rotating the rear mould to a second forming position, closing and molding the rear mould and a wheel body front mould, opening the wheel body front mould and the rear mould, pushing a product out, rotating the rear mould to a first forming position, and the like. The digit wheel mould comprises the front mould and the rear mould, wherein the front mould is a font core front mould, and the rear mould is a font core rear mould. By adopting the digit wheel mould, plastic digits on a digital display measuring meter can not be printed on the surface of the product by a rotary printing process any more, but the model product produced by directly adopting the digit wheel mould, therefore, not only the production process for producing the digit display measuring meter is reduced, the cost is saved, but also any pollution to the environment can not be generated, and the mould is very economicand practical.

Owner:宇科模具(厦门)有限公司

Rhododendron delavayi float seedling method

ActiveCN101822201AWide variety of sourcesLow costCultivating equipmentsSoilless cultivationRhododendron delavayiNutrient solution

The invention discloses a Rhododendron delavayi float seedling method, comprising the following steps: (1) constructing a float seedling pool: selecting a site, constructing a pool and building a shed; (2) preparing seedling substrate: firstly crushing muck and laterite, then adding fine sand, pearlite and plant ash, and mixing evenly in the process of preparing the seeding substrate, wherein the substrate comprises the muck, laterite, fine sand, pearlite and plant ash according to the volume ratio of 5:1:2:1.7:0.3; and sterilizing the well-mixed substrate (using fumigation), adding 10% of water to evenly wet, regulating the PH value of the substrate to be 5.5-6.0 (FeSO4 is used to decrease the PH value of the substrate when the substrate is alkaline, and NaOH solution is used to increase the PH value of the substrate when the substrate is acidic); (3) panning and sowing the substrate; and (4) preparing the Rhododendron delavayi float seedling nutrient solution. By adopting the flowerflow seedling substrate and nutrient solution provided by the invention to perform Rhododendron delavayi float seedling, the seed budding is neat, and the cultured seedling has favorable growth with no plant diseases and insect pests and strong resistance, thus being suitable for large-scale industrialized production of fine quality plantlets.

Owner:云南远益园林工程有限公司

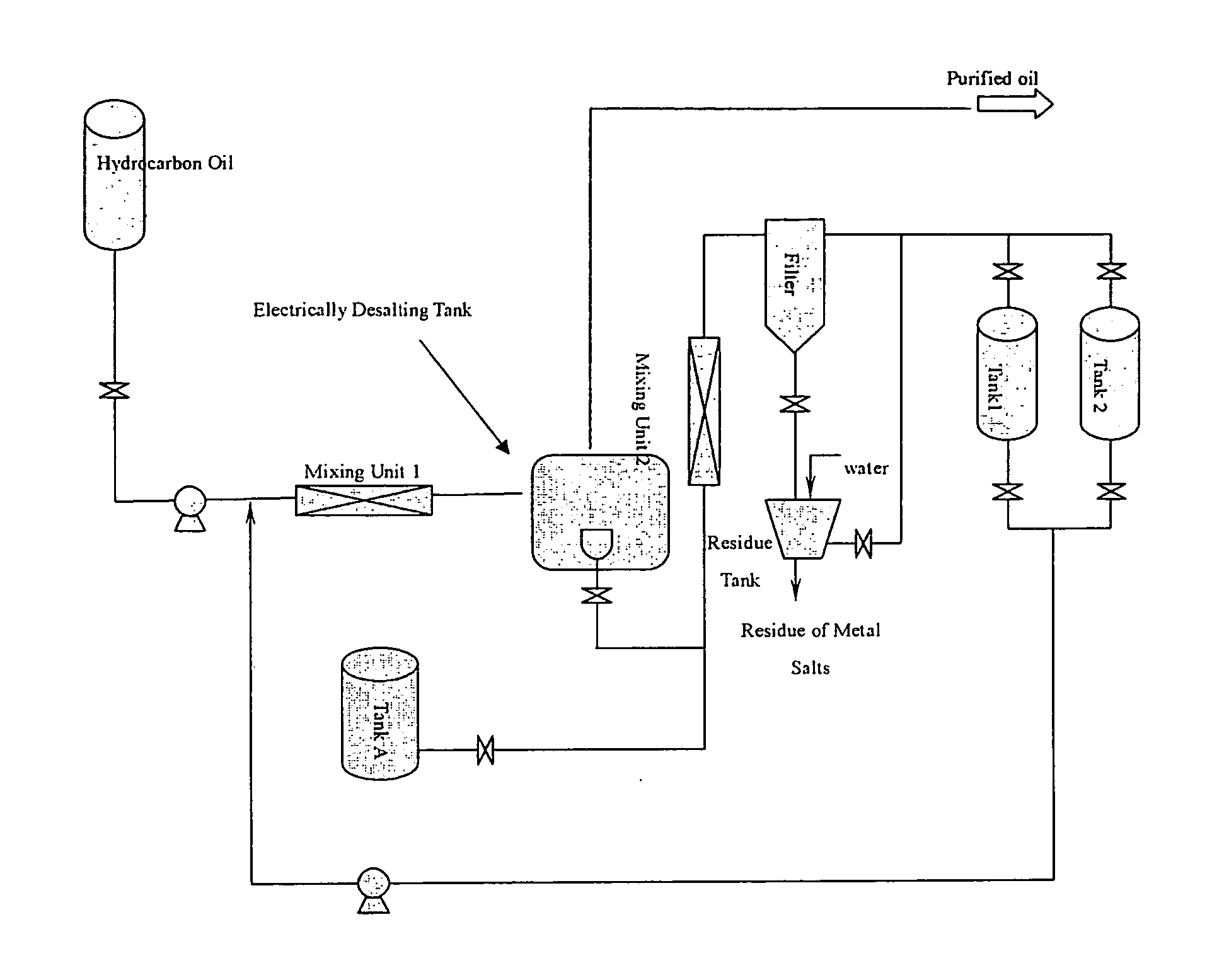

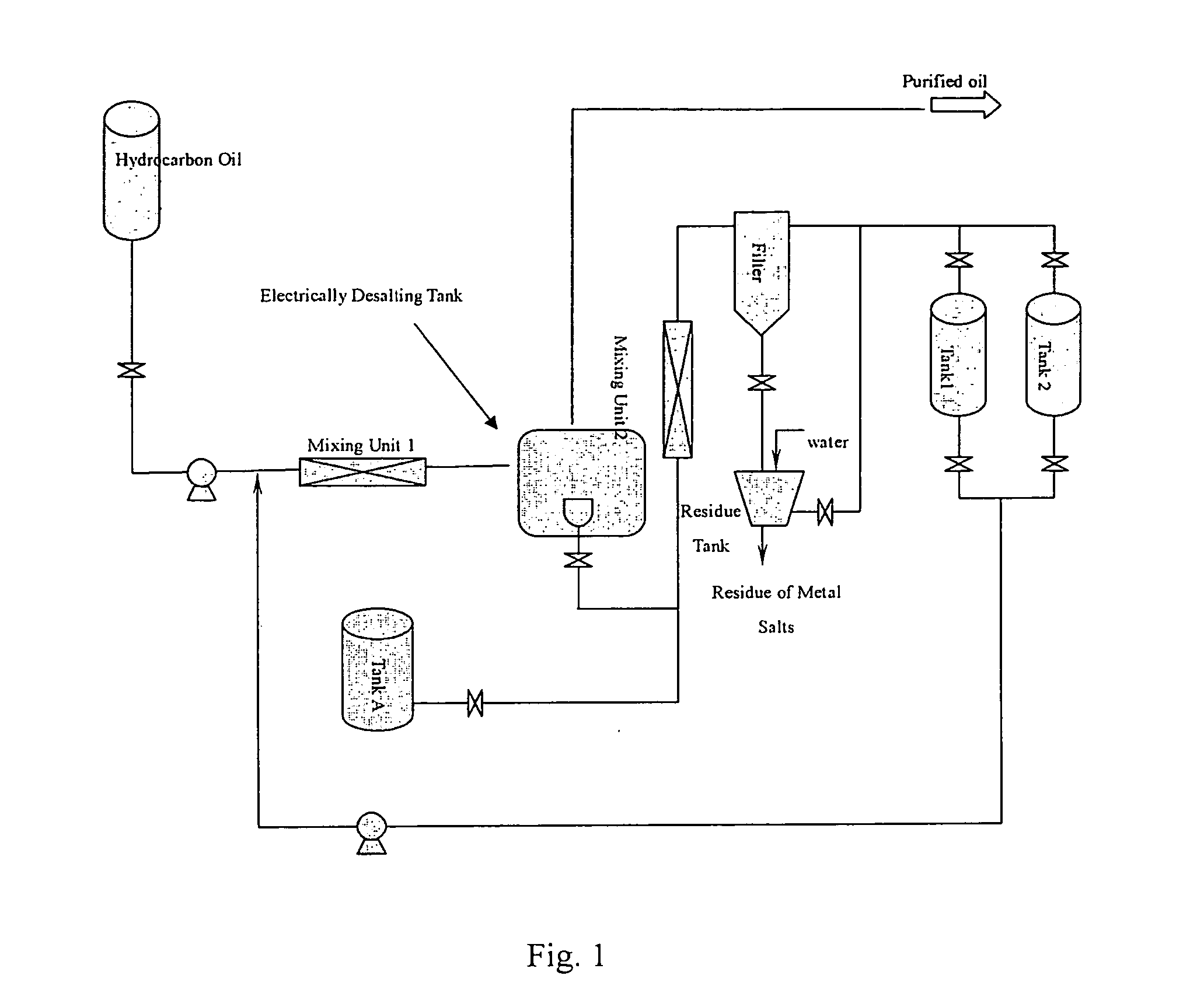

Recycling process for demetalization of hydrocarbon oil

ActiveUS20070062849A1Low costLess amountCalcium/strontium/barium carbonatesDewatering/demulsification with chemical meansCyclic processDisplacement reactions

A recycling process for the demetalization of hydrocarbon oil comprises recycling the following steps: a demetalizing composition for hydrocarbon oil or an aqueous solution thereof is sufficiently mixed with hydrocarbon oil in a desired proportion, and the resultant mixture is subjected to a conventional electrically desalting process to obtain a demetalized hydrocarbon oil and an aqueous desalted solution containing the desalted metal salts; the aqueous desalted solution containing the metal salts is then sufficiently mixed with a precipitating agent in a desired proportion and is subjected to a displacement reaction, and an aqueous solution containing the demetalizing composition is recovered by separating out the residue of the metal salts produced in the displacement reaction, which is poorly soluble or insoluble in water, with a solid-liquid separator; and the recovered aqueous solution containing the demetalizing composition for hydrocarbon oil, which meets the requirements for metal ions in demetalized hydrocarbon oil, is then mixed with hydrocarbon oil in a desired proportion for a next cycle. The present invention has the following advantages such as high efficiency of demetalization, reduction of pollution to the environment and the production cost as well as the metal salt product obtained by treating and collecting the desalted residue of the metal salt.

Owner:PETROCHINA KARAMAY PETROCHEMICAL CO LTD

Cleaning agent for machinery for food industry

InactiveCN1970713AGood biodegradabilityLow application costNon-ionic surface-active compoundsOther dairy technologyAdjuvantPOLYOXYETHYLENE ETHER

The invention discloses a food mechanic abluent of on-site food machine and pipe line, which comprises the following parts: 1-8% at least one component of proteinase, lipase or amylase, alkyl glycoside as surface activator, food-grade C12-C18, water loss sorbitol acid grease, polyoxyethylene water loss sorbitol acid grease, 0.5-1% at least one component of polyglycerol fatty acid ester or geoceric acid polyoxyethylene ester, 10-75% at least one component or two components of sodium carbonate or sodium hydrogen carbonate of alkali adjuvant.

Owner:沈阳宏迪科技有限公司

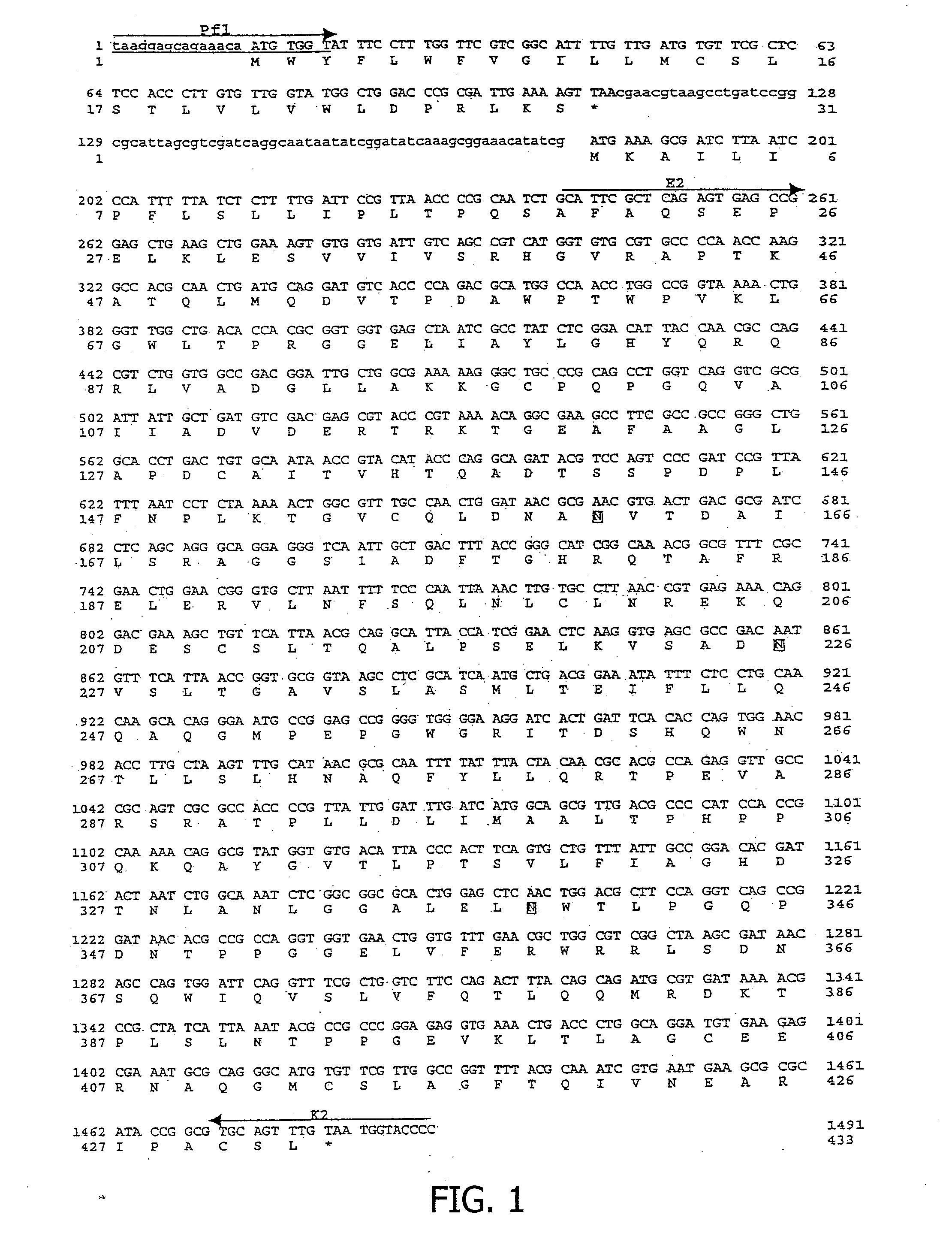

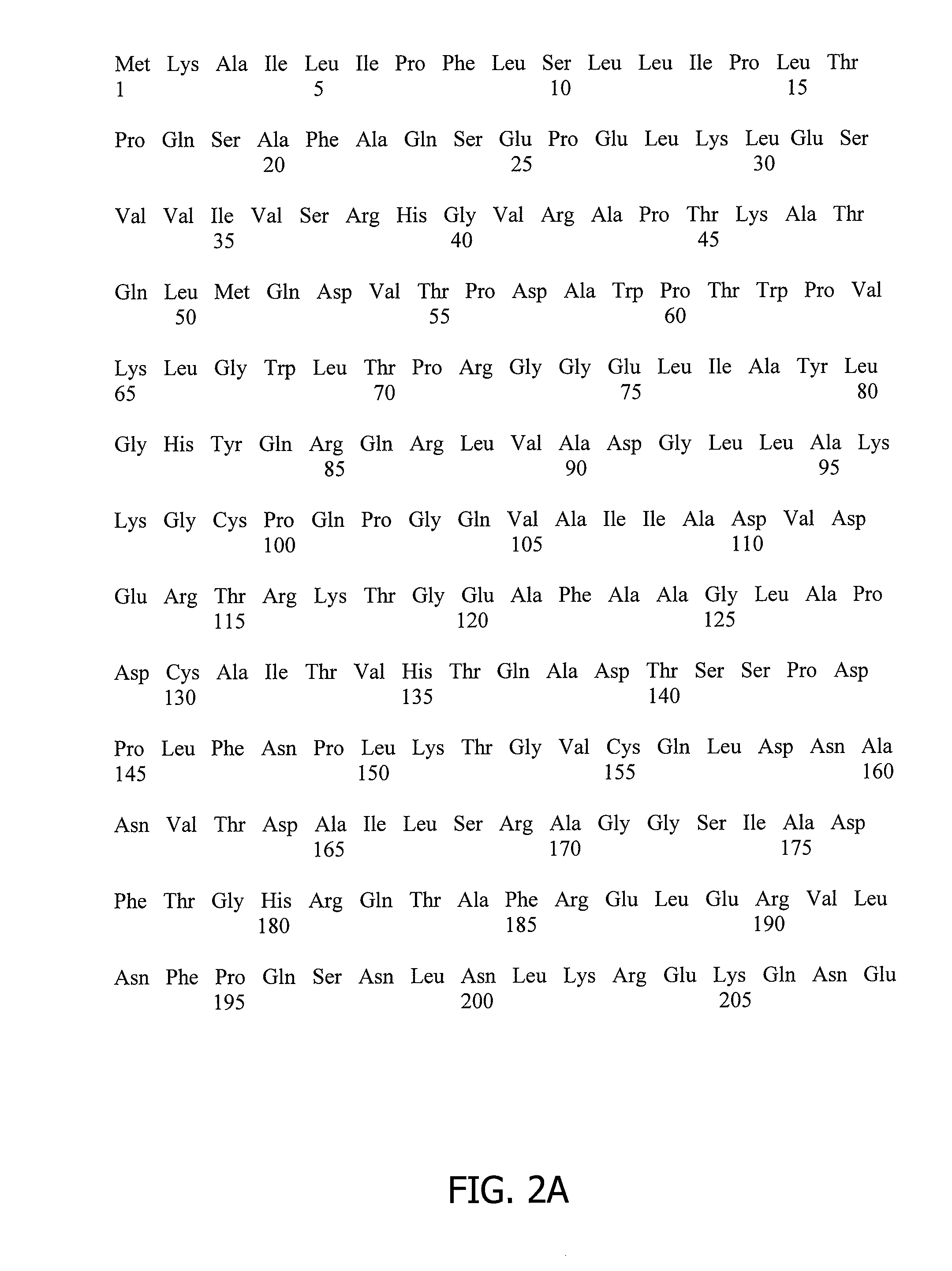

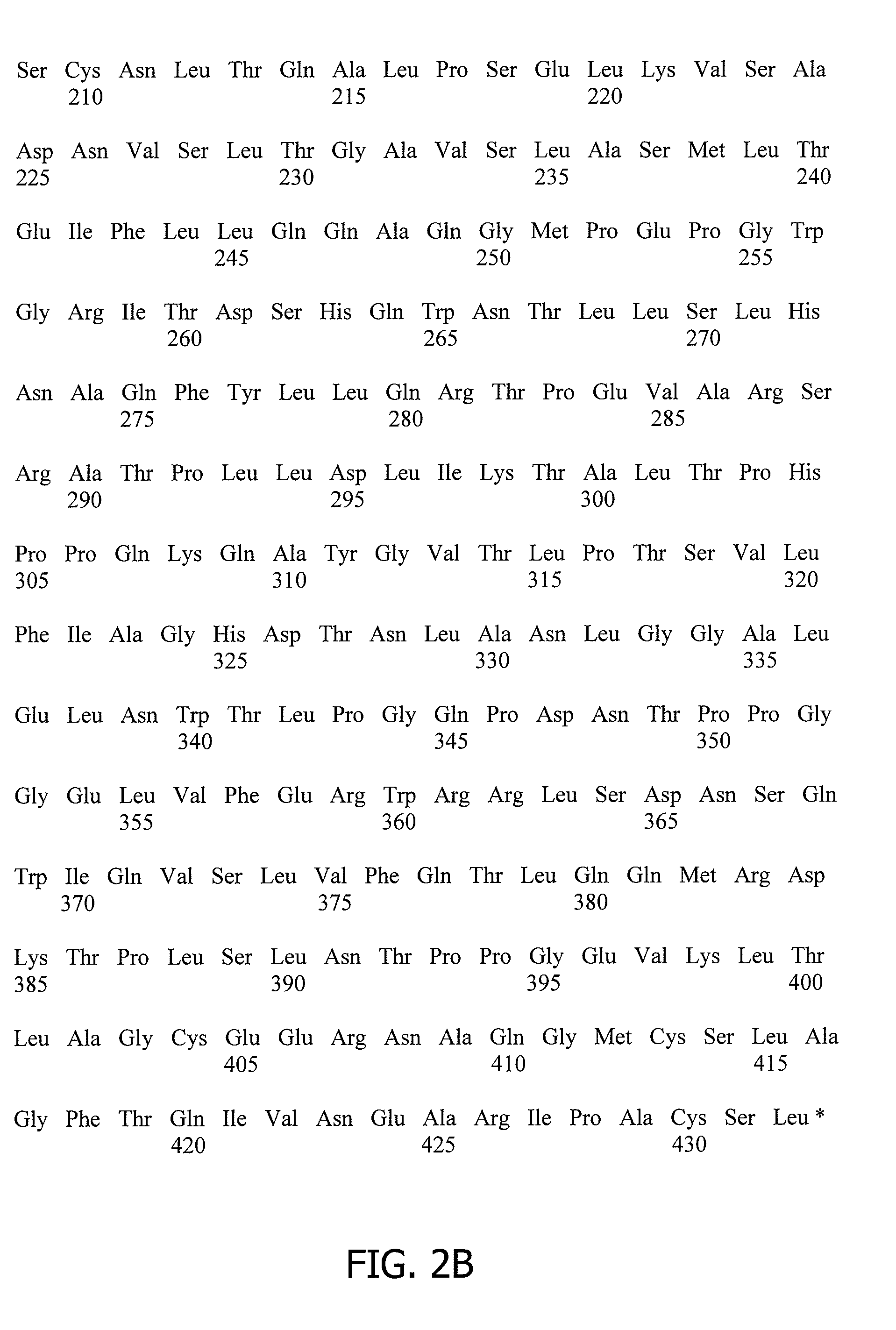

Phytase-containing animal food and method

InactiveUS20090074909A1Lower requirementReduce environmental pollutionMilk preparationBacteriaWeight gainingBiotechnology

A method is described for improving the nutritional value of a foodstuff comprising a source of myo-inositol hexakisphosphate by feeding the foodstuff in combination with a phytase expressed in yeast. The method comprises the step of feeding the animal the foodstuff in combination with a phytase expressed in yeast wherein the phytase can be selected from the group consisting of AppA1, AppA2 and a site-directed mutant of AppA. The invention also enables reduction of the feed to weight gain ratio and an increase bone mass and mineral content of an animal. A foodstuff and a feed additive comprising AppA2 or a site-directed mutant of AppA are also described.

Owner:CORNELL RES FOUNDATION INC +1

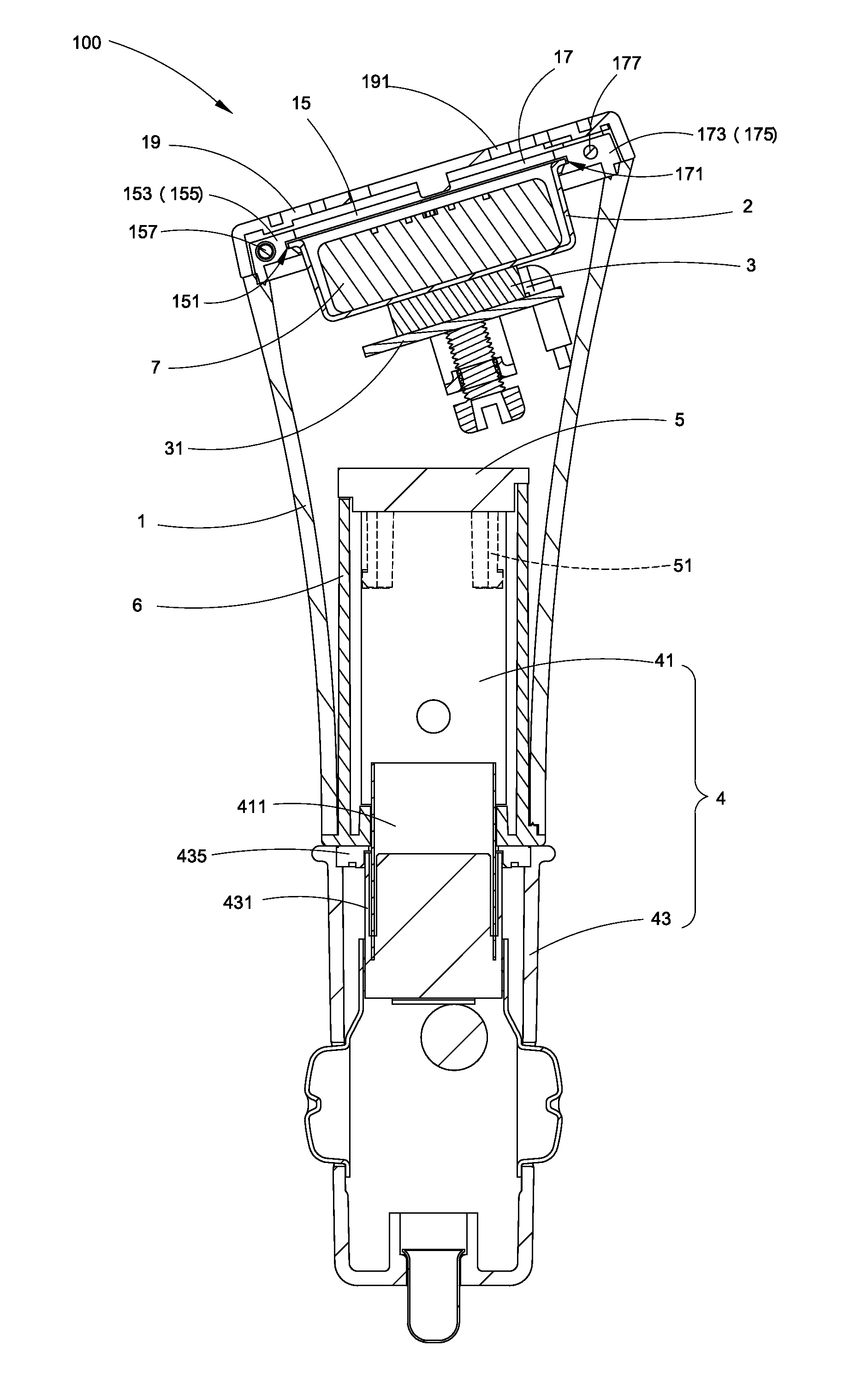

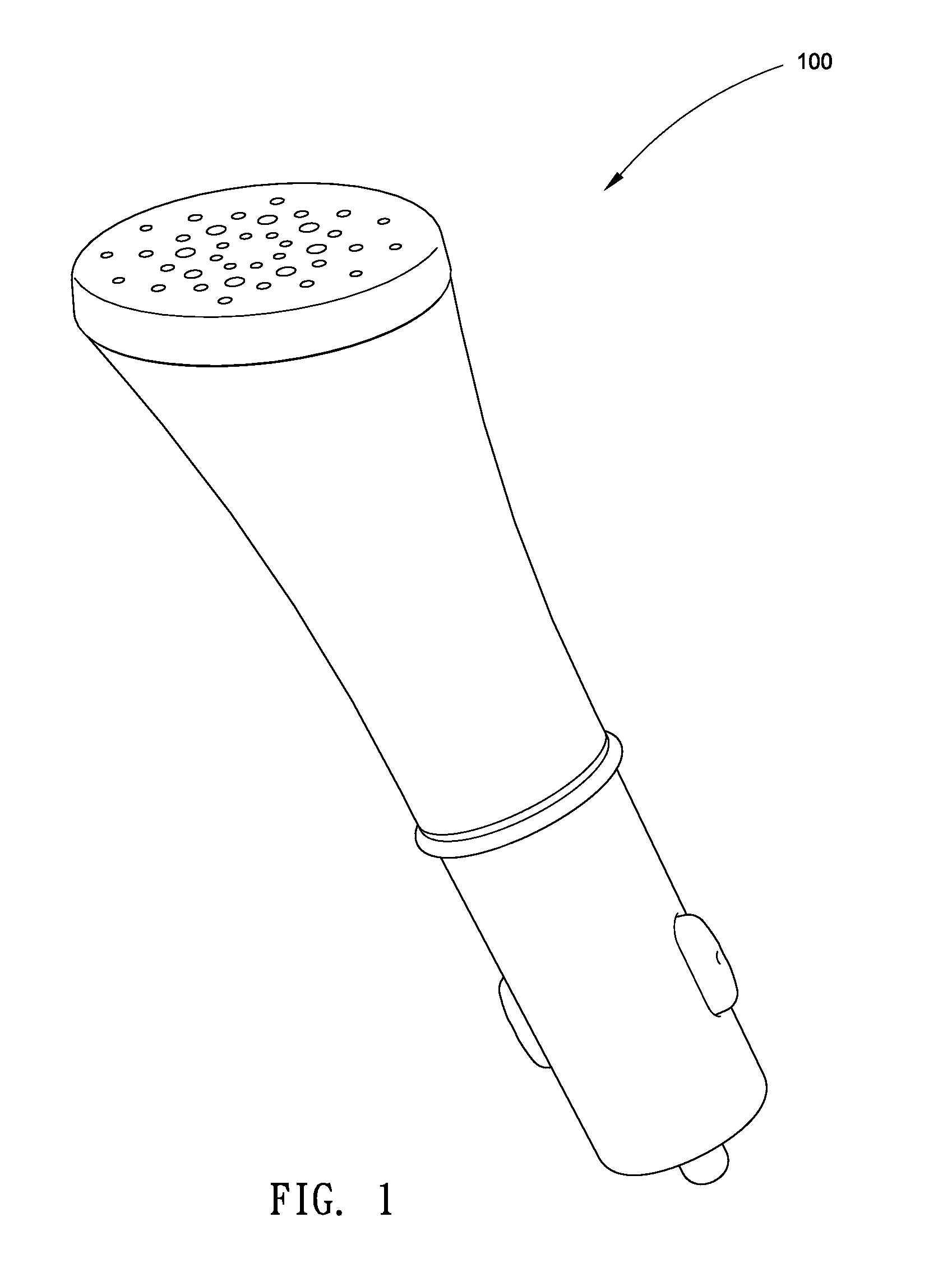

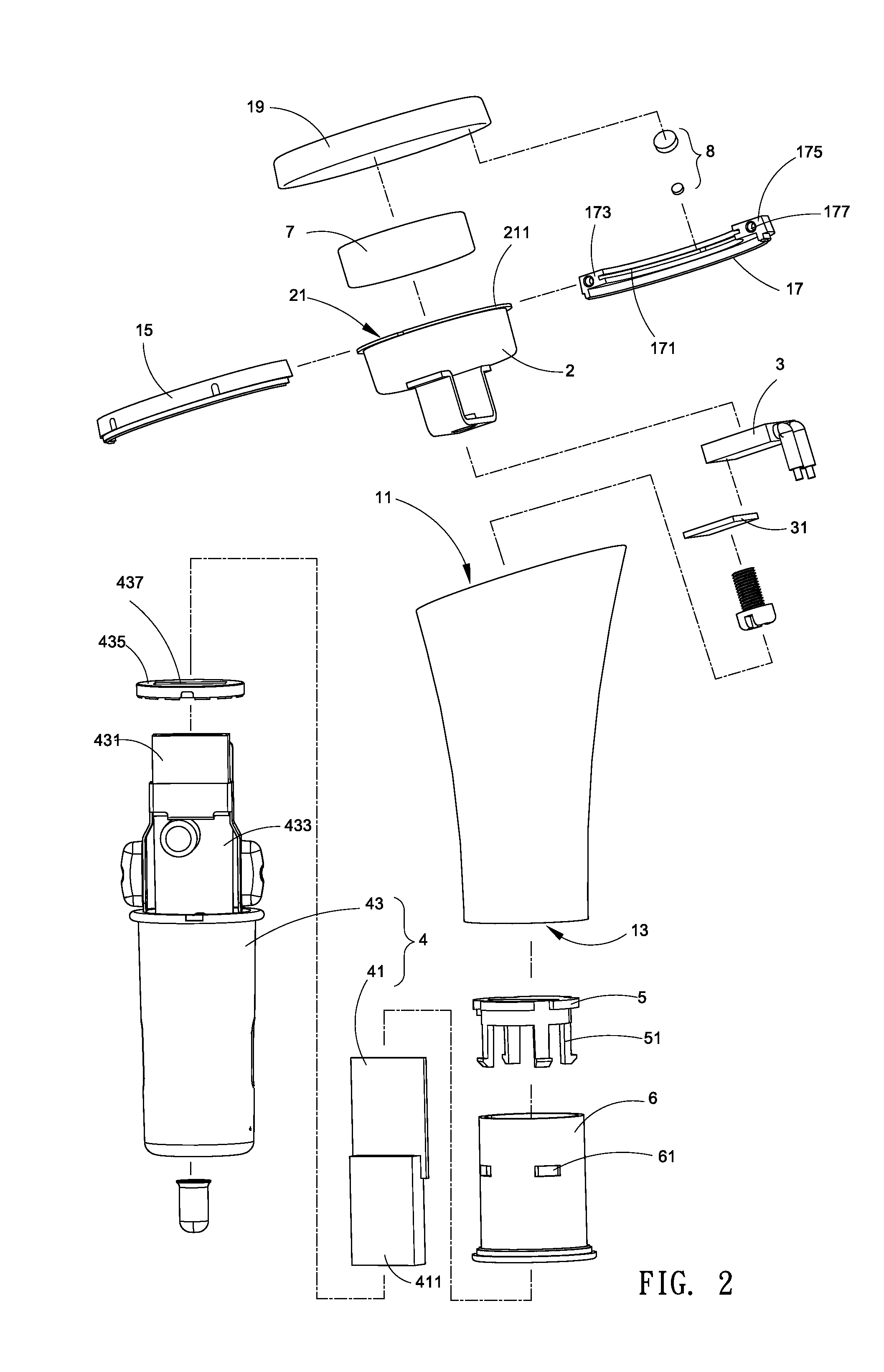

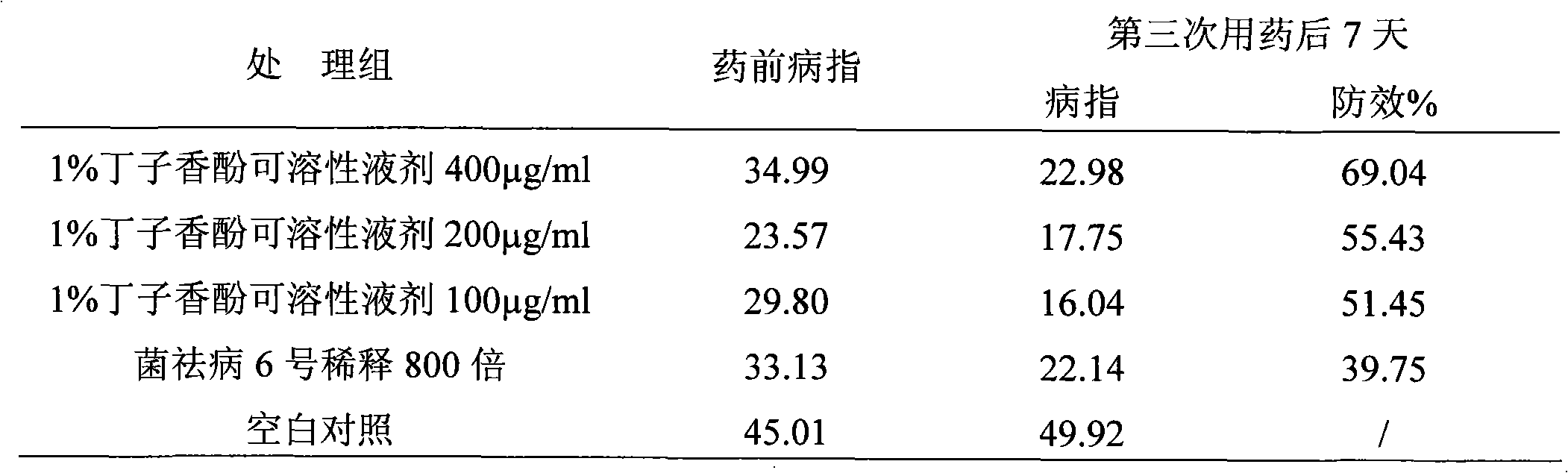

Aroma diffuser having a variable plugging device using an aroma stone

InactiveUS8787739B2Easy to useEnvironmental pollutionRespiratorsLighting and heating apparatusElectricityEngineering

An aroma diffuser is provided, including: a diffuser having a hollow housing, a heat conduction container disposed in the hollow housing, a resistor disposed under the heat conduction container, and a plugging device installed in a second opening of the hollow housing and electrically connected to the resistor; and an aroma stone disposed in the heat conduction container that absorbs essential oil. The aroma stone can be disposed after the essential oil evaporates completely. The plugging device is a car plug that can be combined with an aroma stone used in a car; or a USB device that can be combined with a mobile device, a notebook computer, a desktop computer or any appliance with a USB connection port. When supplied with power, the resistor generates heat, and the heat conduction container conducts the heat to the aroma stone for the aroma stone to diffuse scent.

Owner:SERENE HOUSE INT ENTERPRISE

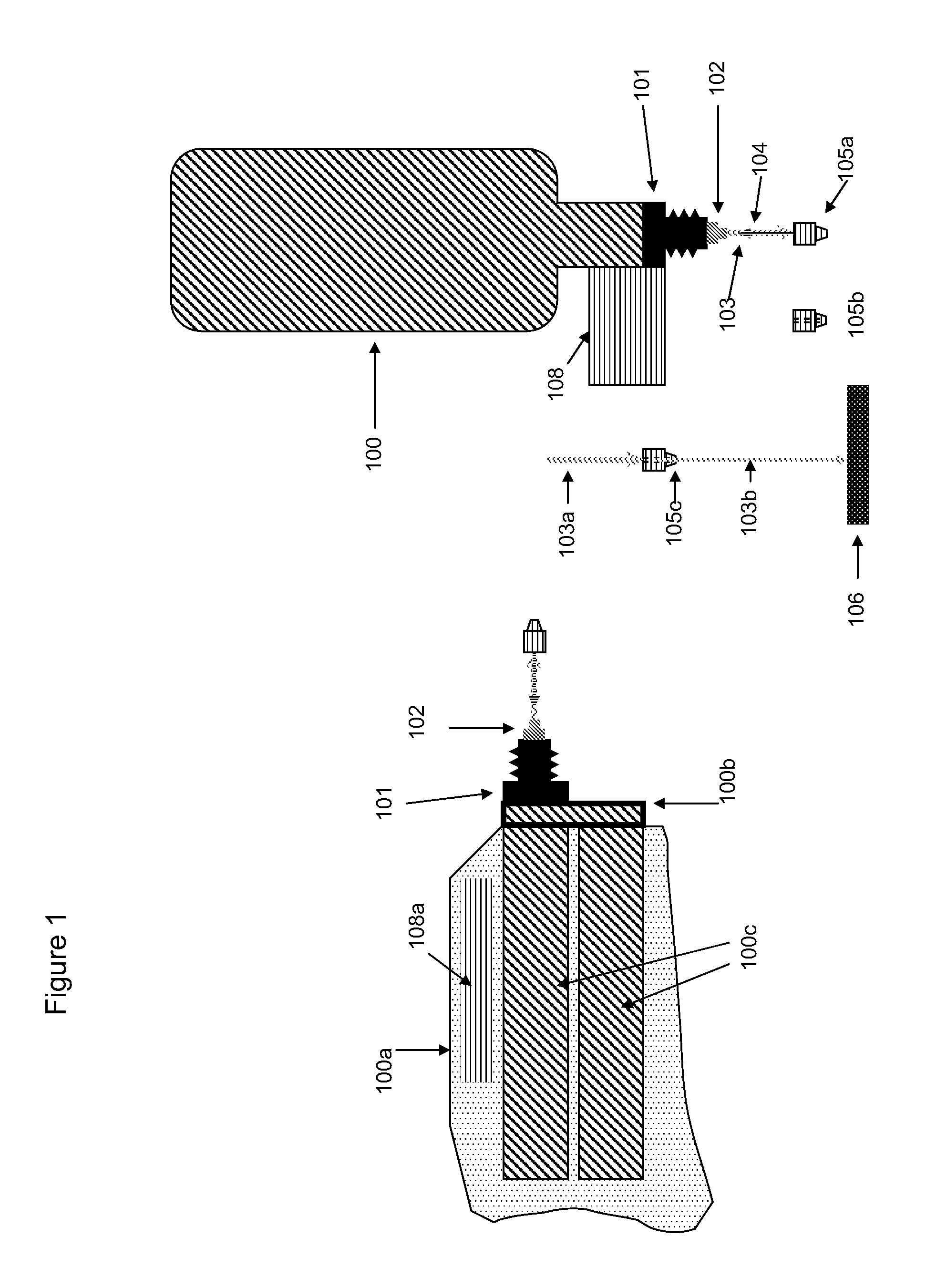

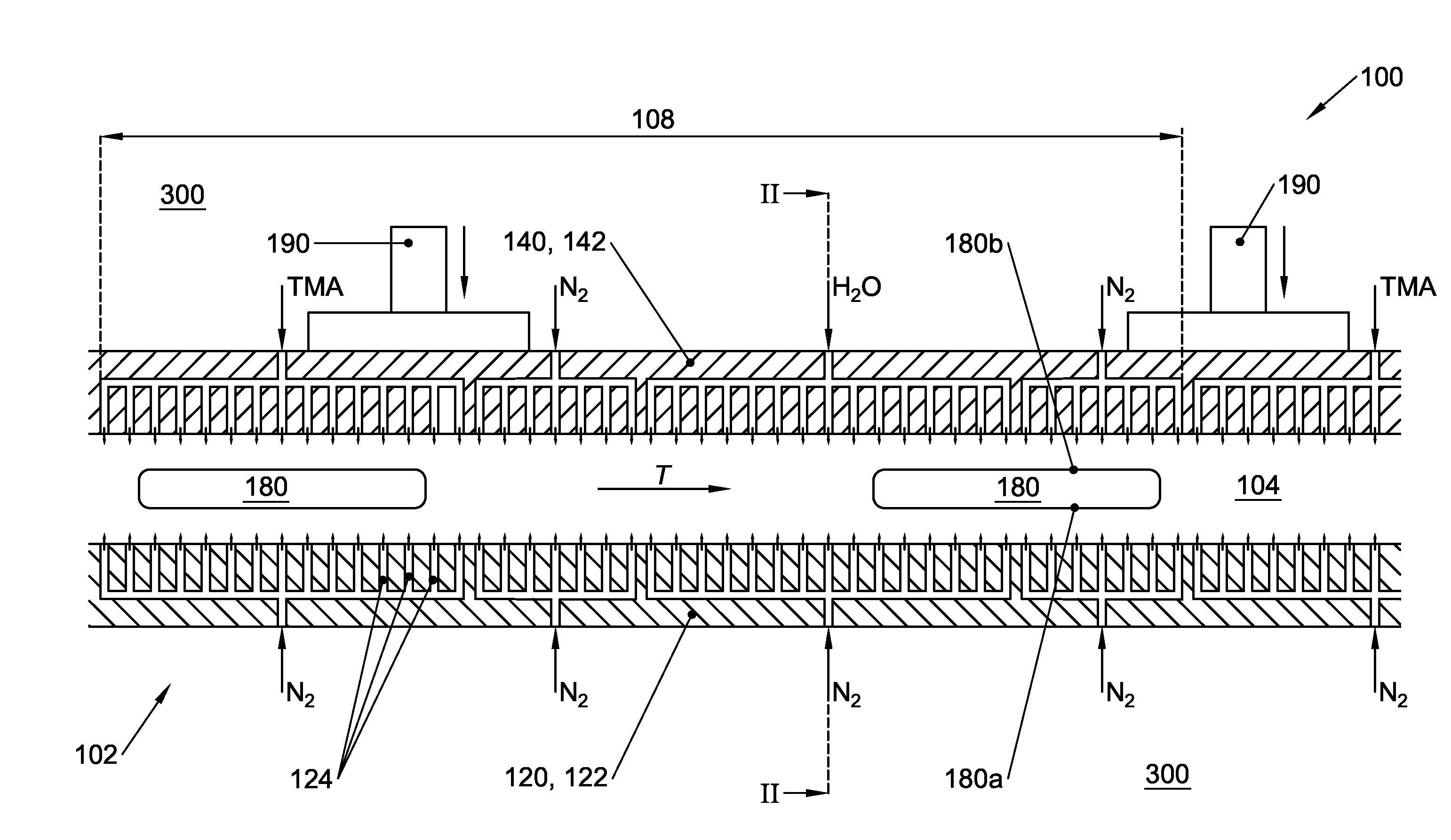

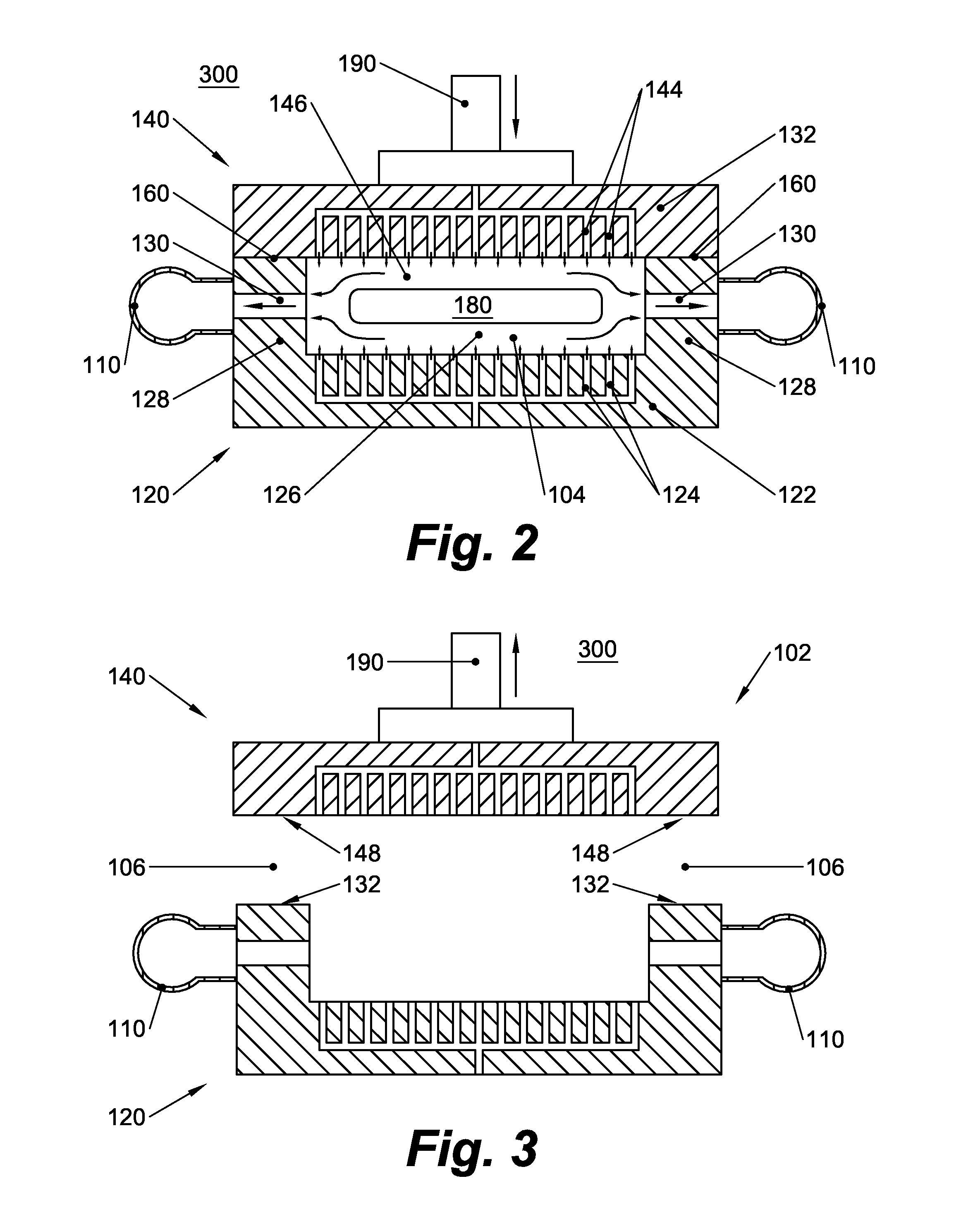

Substrate processing apparatus

ActiveUS20160281233A1Easy accessEasy to disassembleConveyorsSemiconductor/solid-state device manufacturingPlanar substrateEngineering

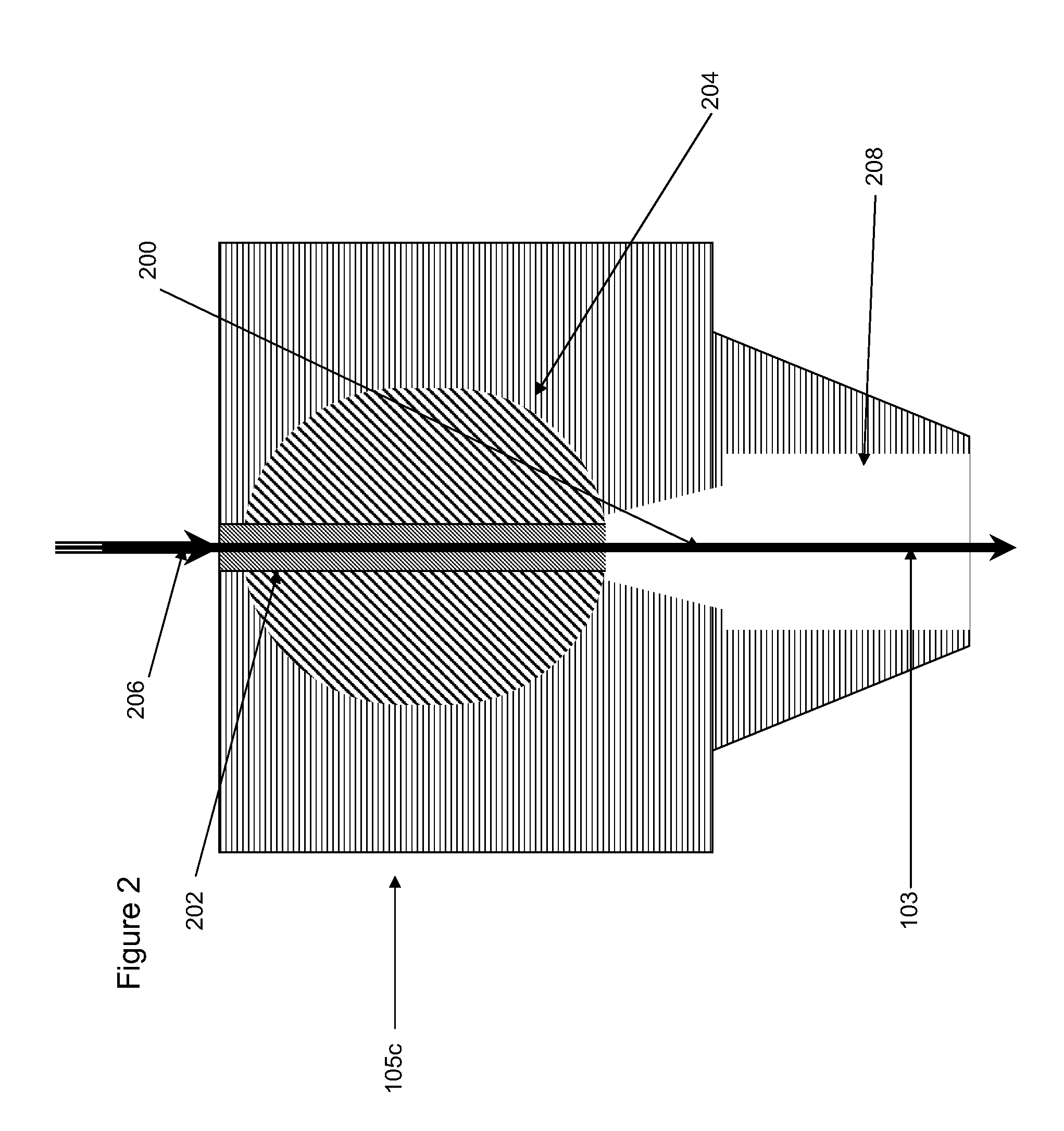

A substrate processing apparatus (100) comprising a process tunnel (102) including a lower tunnel wall (122), an upper tunnel wall (142), and two lateral tunnel walls (128), said tunnel walls being configured to bound a process tunnel space (104) that extends in a longitudinal transport direction (7) and that is suitable for accommodating at least one substantially planar substrate (180) oriented parallel to the upper and lower tunnel walls (122, 142), the process tunnel being divided in a lower tunnel body (120) comprising the lower tunnel wall and an upper tunnel body (140) comprising the upper tunnel wall, which tunnel bodies (120, 140) are separably joinable to each other along at least one longitudinally extending join (160), such that they are mutually movable between a closed configuration in which the tunnel walls (122, 128, 42) bound the process tunnel space (104) and an open configuration that enables lateral maintenance access to an interior of the process tunnel.

Owner:ASM INTERNATIONAL

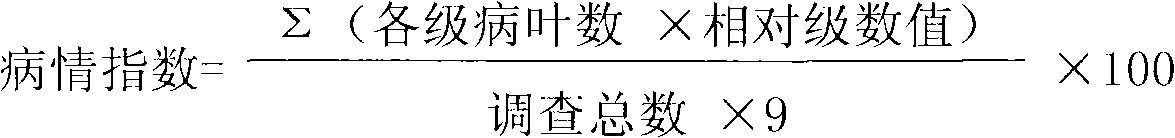

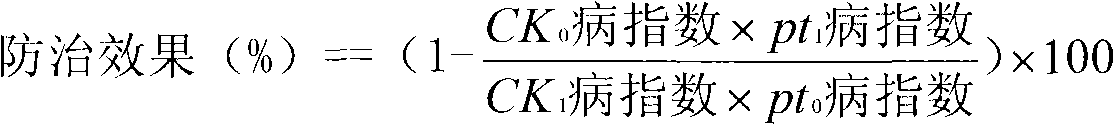

Application of eugenol in preparing pesticide preventing and treating crop virosis

The invention discloses an application of eugenol used as a main active component in preparing pesticide preventing and treating crop virosis. The experiment research shows that the eugenol provided by the invention has a very good preventing and treating function to the virosis of various crops and has wide antivirus spectra, the effective component of the eugenol of the invention is a natural, green and environment-friendly active component extracted and obtained from traditional Chinese medicines, has the preventing and treating function to the crop virosis and does not pollute the environment, and the invention takes the eugenol as the main active component to prepare pesticide with medicament forms, such as eugenol soluble liquid or eugenol microemulsion and the like, and has convenient use and storage and good stability.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Aroma diffuser having a variable plugging device using an aroma stone

InactiveUS20140124594A1Easy to useEnvironmental pollutionLiquid surface applicatorsSpray nozzlesElectricityEngineering

An aroma diffuser is provided, including: a diffuser having a hollow housing, a heat conduction container disposed in the hollow housing, a resistor disposed under the heat conduction container, and a plugging device installed in a second opening of the hollow housing and electrically connected to the resistor; and an aroma stone disposed in the heat conduction container that absorbs essential oil. The aroma stone can be disposed after the essential oil evaporates completely. The plugging device is a car plug that can be combined with an aroma stone used in a car; or a USB device that can be combined with a mobile device, a notebook computer, a desktop computer or any appliance with a USB connection port. When supplied with power, the resistor generates heat, and the heat conduction container conducts the heat to the aroma stone for the aroma stone to diffuse scent.

Owner:SERENE HOUSE INT ENTERPRISE

Flux compositions for sintering Ni-Zn ferrite material

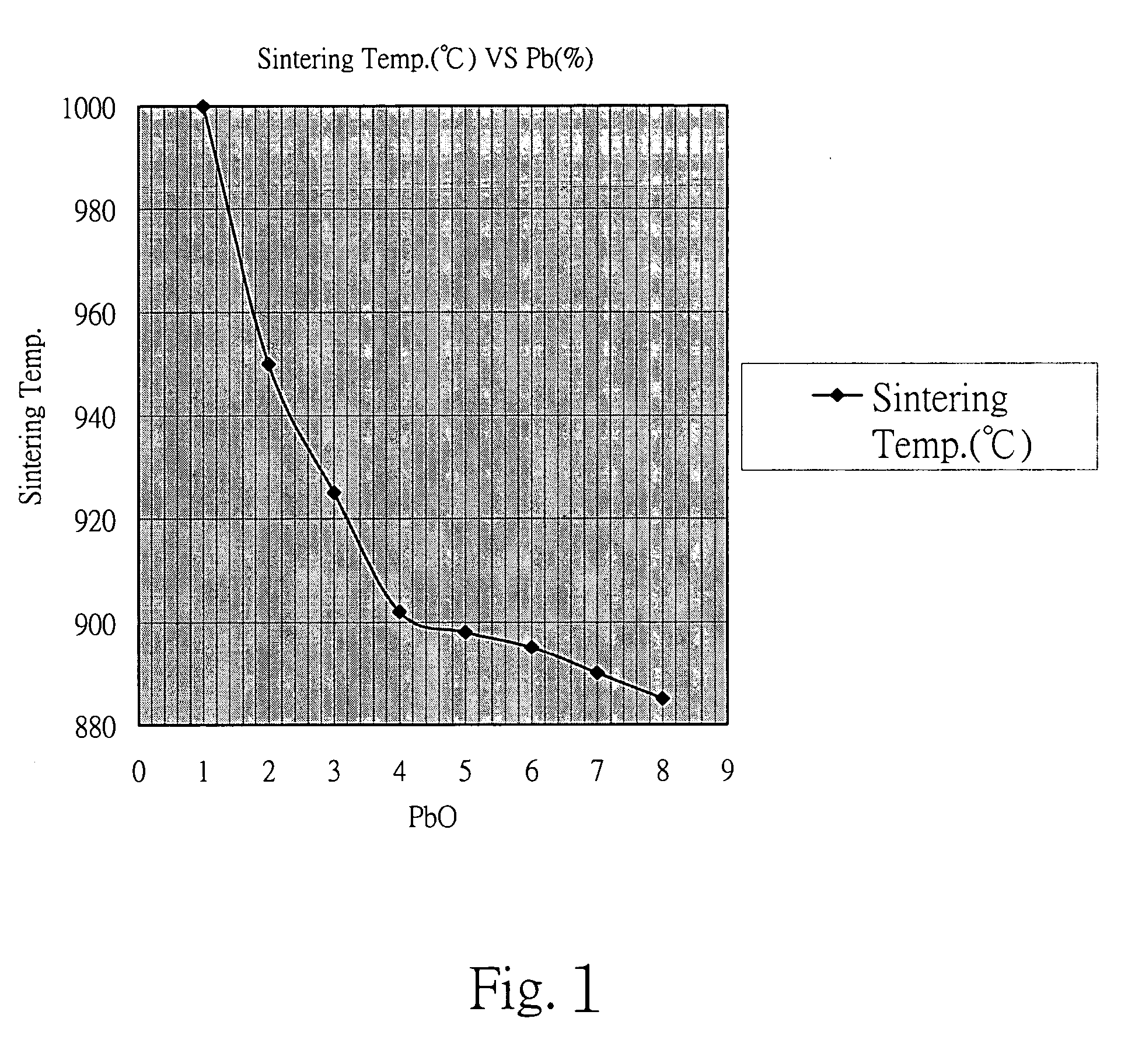

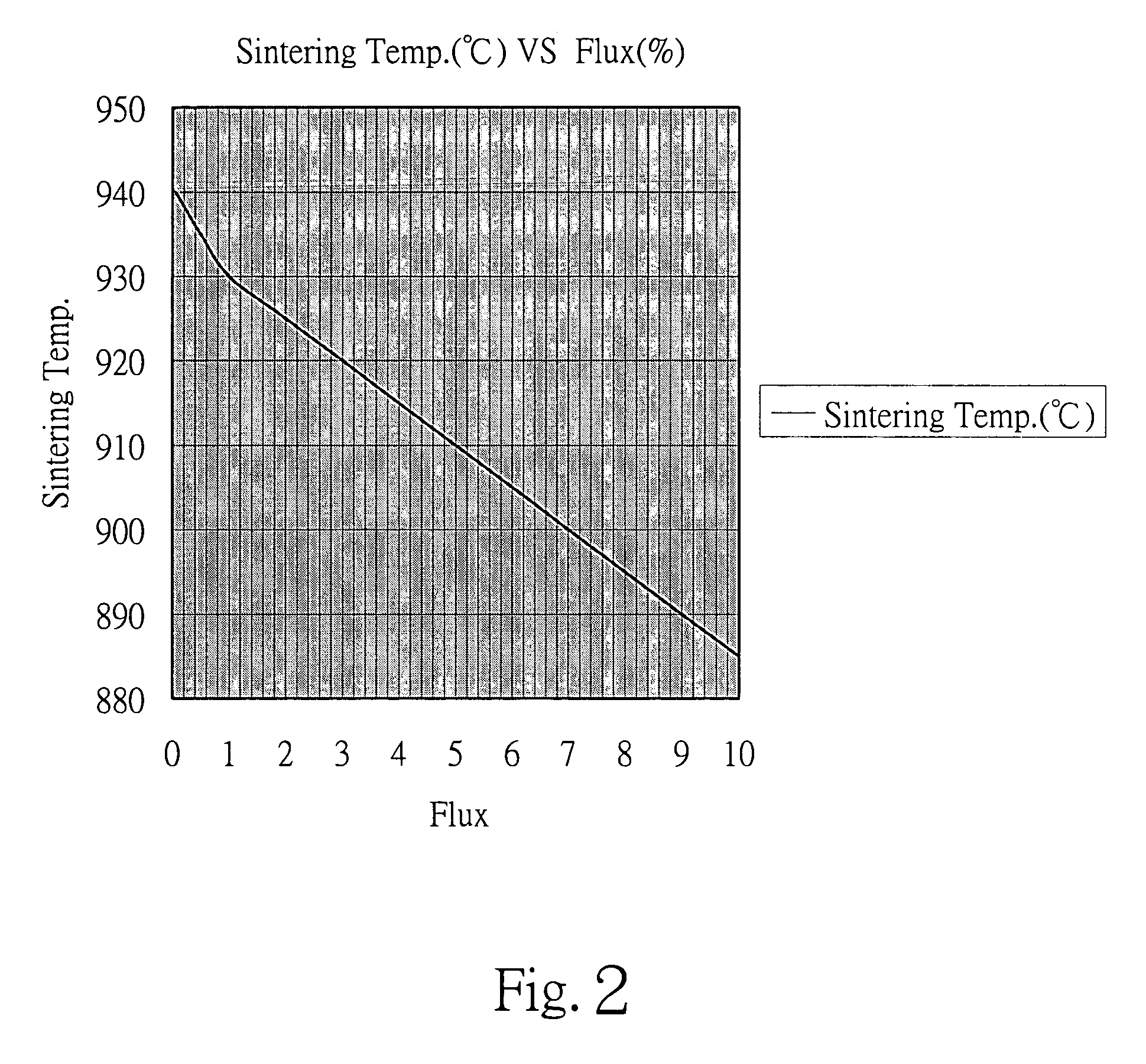

InactiveUS20050034633A1Lower sintering temperatureMaintain effective electric propertyOther chemical processesInorganic material magnetismPotassiumCopper oxide

Flux compositions for sintering Ni—Zn ferrite material are disclosed in the present invention, each flux composition basically and selectively has zinc oxide (ZnO), silicon dioxide (SiO2), boric oxide (B2O3), bismuth trioxide (Bi2O3), aluminum oxide (Al2O3), potassium trioxide (K2O3), barium oxide (BaO), sodium oxide (Na2O), calcium oxide (CaO), and magnesium oxide (MgO). Each flux composition is added into a mixture of Ni—Zn ferrite material composed of ferric oxide (Fe2O3), nickel oxide (NiO), zinc oxide (ZnO), cupric oxide (CuO) and cobalt oxide (CoO) and ranges from 0.05 to 10 weight percent based on the total weight of the Ni—Zn ferrite material. The flux compositions of the present invention decrease sintering temperature when the ferrite material is sintered and contain no lead (Pb) element so as to reduce toxic pollutants.

Owner:CHILISIN ELECTRONICS

Small waste material processing device

InactiveUS20200147618A1Prevent sewer cloggingSaving maintenance costGrain treatmentsShaping pressWaste processingWastewater

A small-scale waste processing device includes a housing, wherein a conveying cavity is provided in the housing, a screw is rotatably provided in the conveying cavity, a rotating cavity is provided in the housing, and the rotating cavity and the conveying The cavity is connected, and a rotating block is rotatably provided in the rotating cavity. A squeezing mechanism is provided in the rotating block. A first filter is fixedly arranged on the right wall of the rotating cavity. The present invention can pass kitchen wastes through Most of the water is squeezed out, and then the water in the waste is thrown out by throwing water to make the waste more dehydrated. The discharged waste water can be directly discharged to the sewer, which avoids clogging of the sewer and saves maintenance costs. The dehydrated waste passes through Grinding and squeezing makes it difficult to make full use of the packing space during the later packing process of waste materials, and at the same time avoids the leakage of waste water from the waste materials, causing pollution to the environment.

Owner:LOU TIANYA

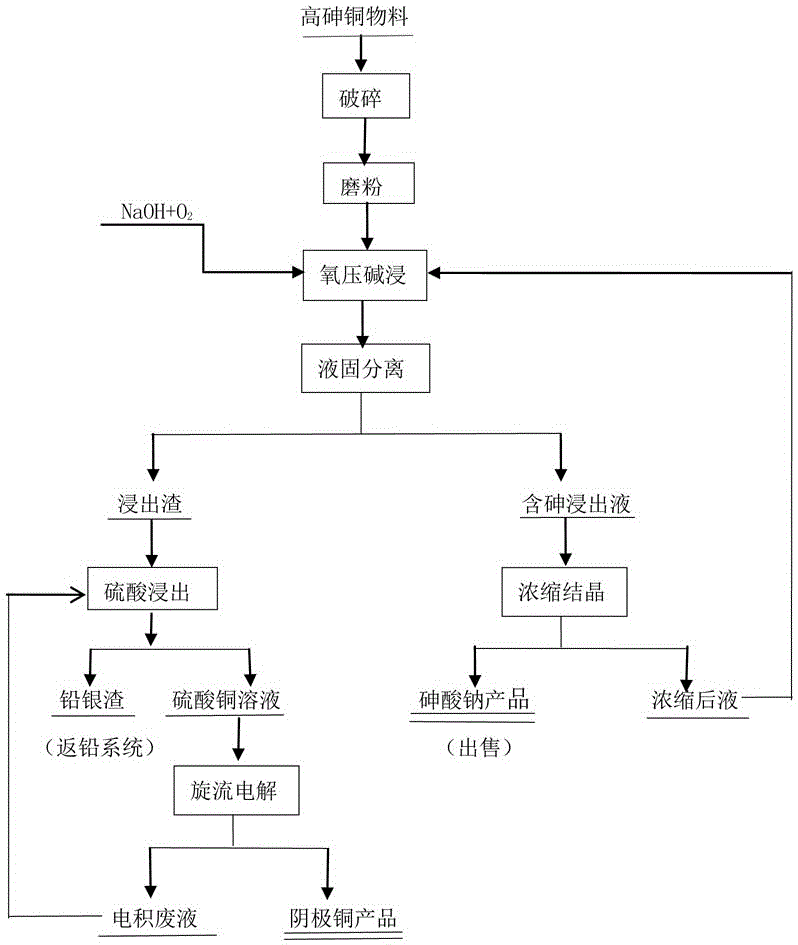

Technology for treating high-arsenic copper material

ActiveCN106555058AEnvironmental pollutionNo pollution to the environmentPhotography auxillary processesProcess efficiency improvementElectrolysisCopper sulfate

The invention discloses a technology for treating a high-arsenic copper material. The technology comprises the steps that the high-arsenic copper material is subjected to crushing, grinding, sodium hydroxide mixing and oxidizing leaching, copper in the high-arsenic copper material is oxidized and left in residues in a residual mode along with lead and noble metal of gold, silver and platinum, arsenic enters a solution in a sodium arsenate mode, leachate is subjected to concentration and crystallization, a sodium arsenate product is obtained, and a concentrated solution returns to be subject to oxygen-pressure alkali leaching; leached residues are subjected to sulfuric-acid atmospheric pressure leaching, copper enters the solution in a copper sulfate mode, acid adjustment is conducted, and vortex electrolysis is directly conducted for extracting copper; electrodeposited waste liquid is recycled; and lead and the noble metal enter lead and silver residues, and valuable elements of Pb, Ag and Au are comprehensively recycled. The technology belongs to a clean metallurgy process, is low in equipment corrosion-resistant requirement, free of pollution to environment, easy to operate and high in comprehensive recycling degree of metal and has the advantages of being higher in practicability and adaptability to raw materials and the like.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

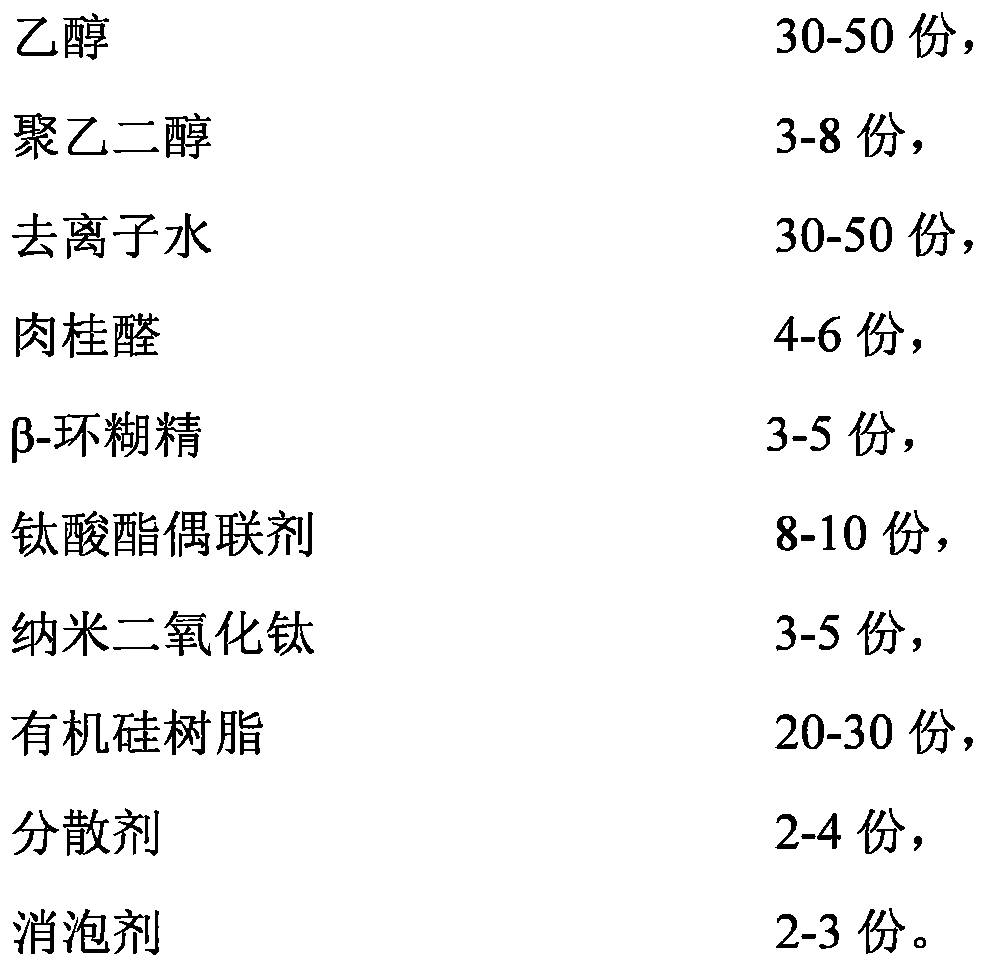

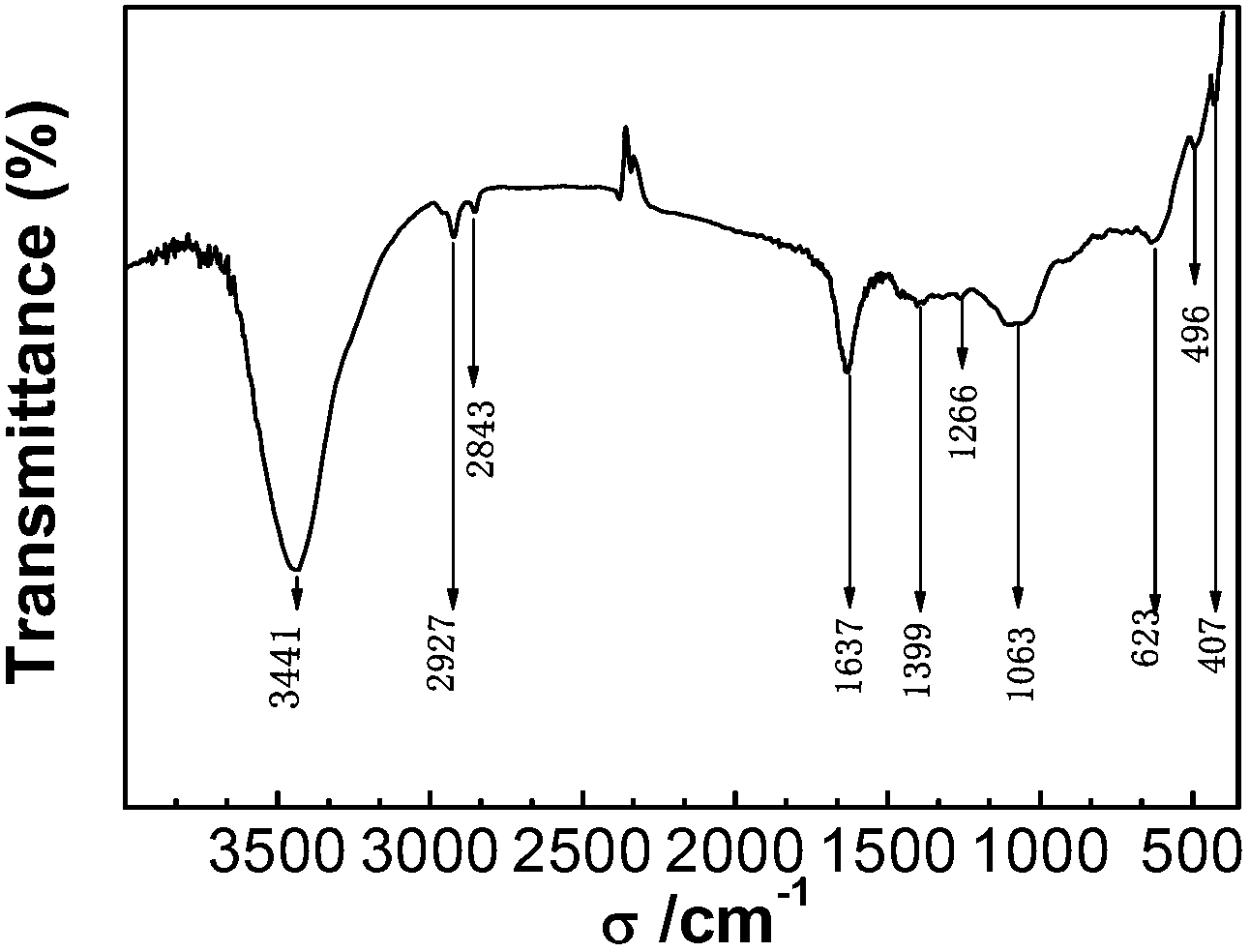

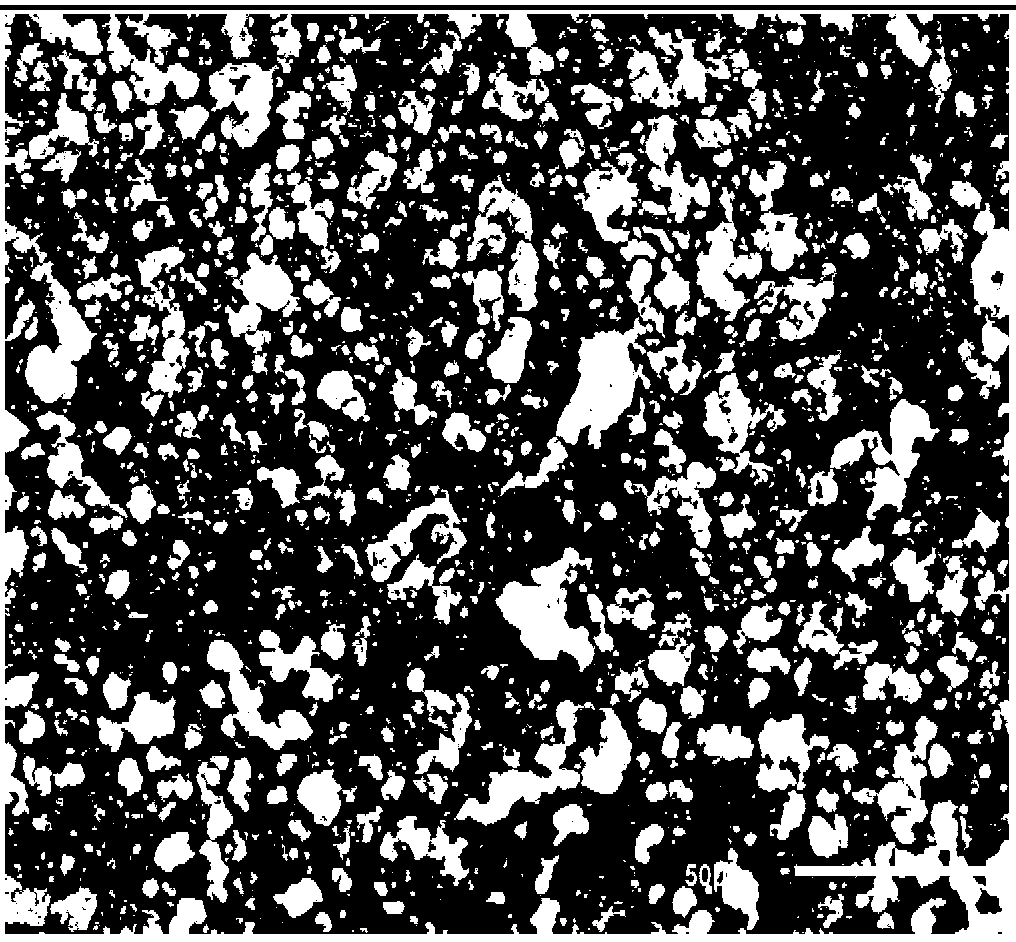

Antibiotic environmentally-friendly film and production method thereof

ActiveCN105925175AImprove the bactericidal effectIncreased durabilityAntifouling/underwater paintsSynthetic resin layered productsEugenolPolyethylene glycol

The invention discloses an antibiotic environmentally-friendly film and a production method thereof. The antibiotic environmentally-friendly film sequentially comprises a PET layer, an antibiotic layer, a PE layer and a sterilization coating layer from inside to outside, wherein the antibiotic layer is produced from polylactic acid, hydroxypropyl acrylate, acryloyl chloride, trifluoropropylmethyldichlorosilane, vinyltriisopropoxysilane, hydroxypropyl methyl cellulose, chitosan, eugenol, polyvinyl alcohol, an emulsifier, an initiator and deionized water, and the sterilization coating layer is produced from ethanol, polyethylene glycol, deionized water, cinnamaldehyde, beta-cyclodextrin, a titanate coupling agent, nanometer titanium dioxide, organosilicone resin, a dispersant and an antifoaming agent. The antibiotic environmentally-friendly film produced in the invention has the advantages of good sterilization and antivirus effects, good durability, long service life and no pollution to environment.

Owner:广东保特信新材料科技有限公司

Method for preparing novel conductive composite anticorrosive coating

ActiveCN102703945AIncreased corrosion potentialNo corrosionElectrolytic organic material coatingPolypyrroleCopper electrode

The invention relates to a method for preparing a novel conductive polypyrrole / polyaniline composite anticorrosive coating. The method comprises the following steps of: dissolving p-toluenesulfonic acid into water, regulating the pH value of a solution to be an appropriate value, and adding pyrrole and aniline monomers to obtain a mixed solution; performing electrochemical synthesis by using a three-electrode system, wherein copper is taken as a working electrode, a platinum sheet is taken as an auxiliary electrode, and a reference electrode is a saturated calomel electrode; and performing electrochemical polymerization under certain electrical parameters by cyclic voltammetry to obtain a layer of conductive polypyrrole / polyaniline composite anticorrosive coating on the surface of the copper electrode. The conductive polymer coating generated on the surface of the copper has high adhesion and is uniform and compact; medium corrosion ions can be effectively hindered from penetrating the coating and permeating into the surface of a metal matrix for a long time; the composite coating effectively improves the corrosion potential of a copper matrix and reduces corrosion current; and in addition, after the prepared coating is damaged, a layer of passivating film can be quickly generated on the surface of the matrix so as to ensure that metal is free of corrosion.

Owner:常熟市通顺纺织有限责任公司

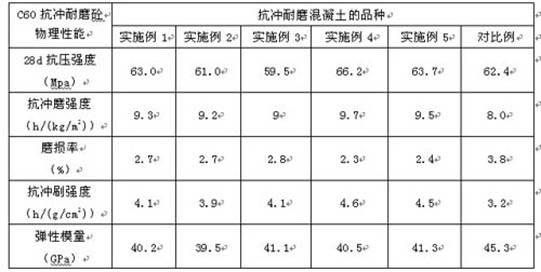

Impact-resistant anti-wear agent for hydraulic concrete

The invention provides an impact-resistant and anti-wear agent for hydraulic concrete, which mainly comprises a nano material, slag, latex powder, rubber powder, a water reducing agent, fibers, an exciting agent and a defoaming agent. The impact-resistant anti-wear agent is suitable for places such as water conservancy projects, roads and airport pavements requiring high impact-resistant and anti-wear concrete, has the functions of resisting crack, reducing water, reinforcing and reducing elasticity, and excellent mixing and constructing properties. The impact-resistant and anti-wear agent has the advantages of increasing concrete impact-resistant and anti-wear properties, prolonging maintenance period and reducing maintenance cost.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE +1

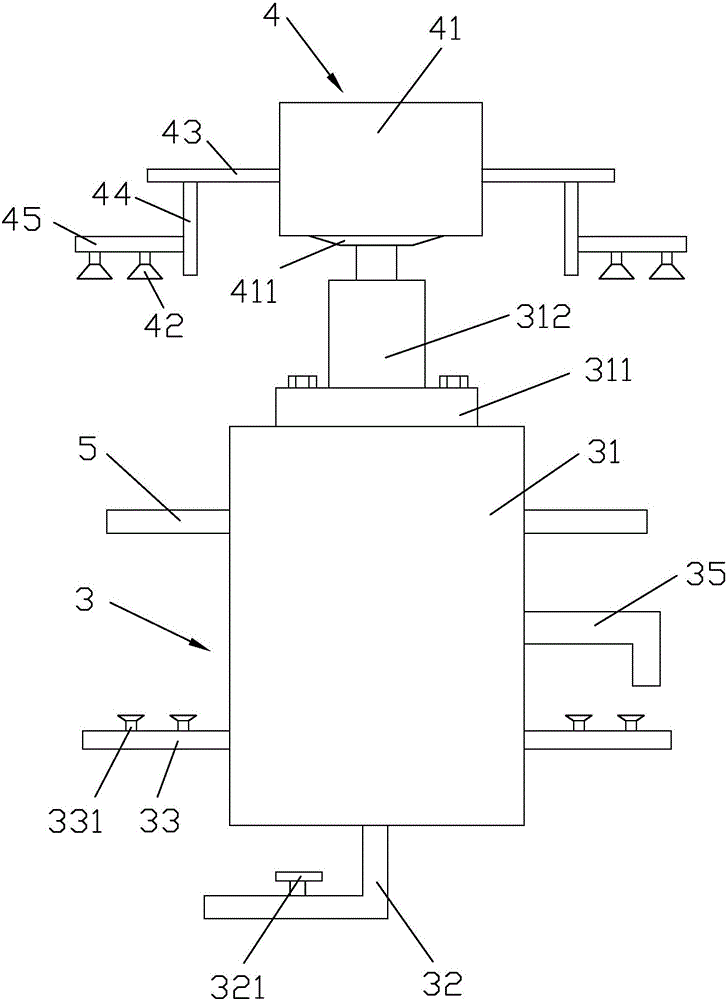

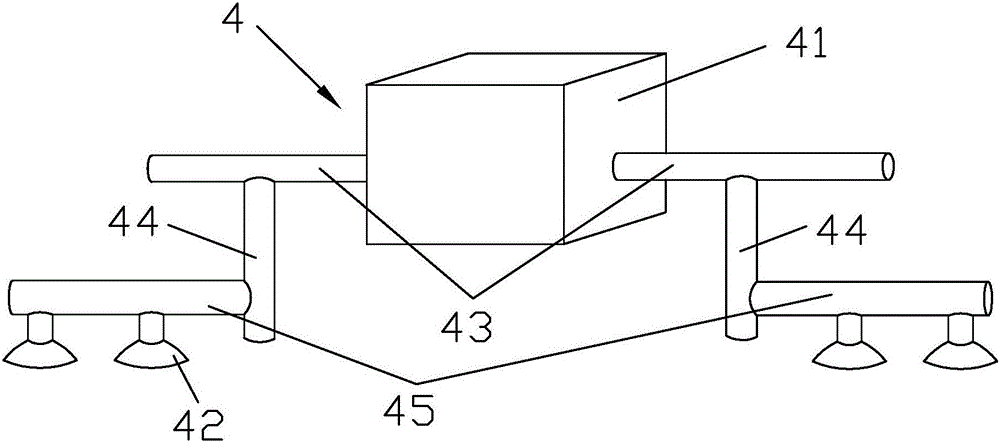

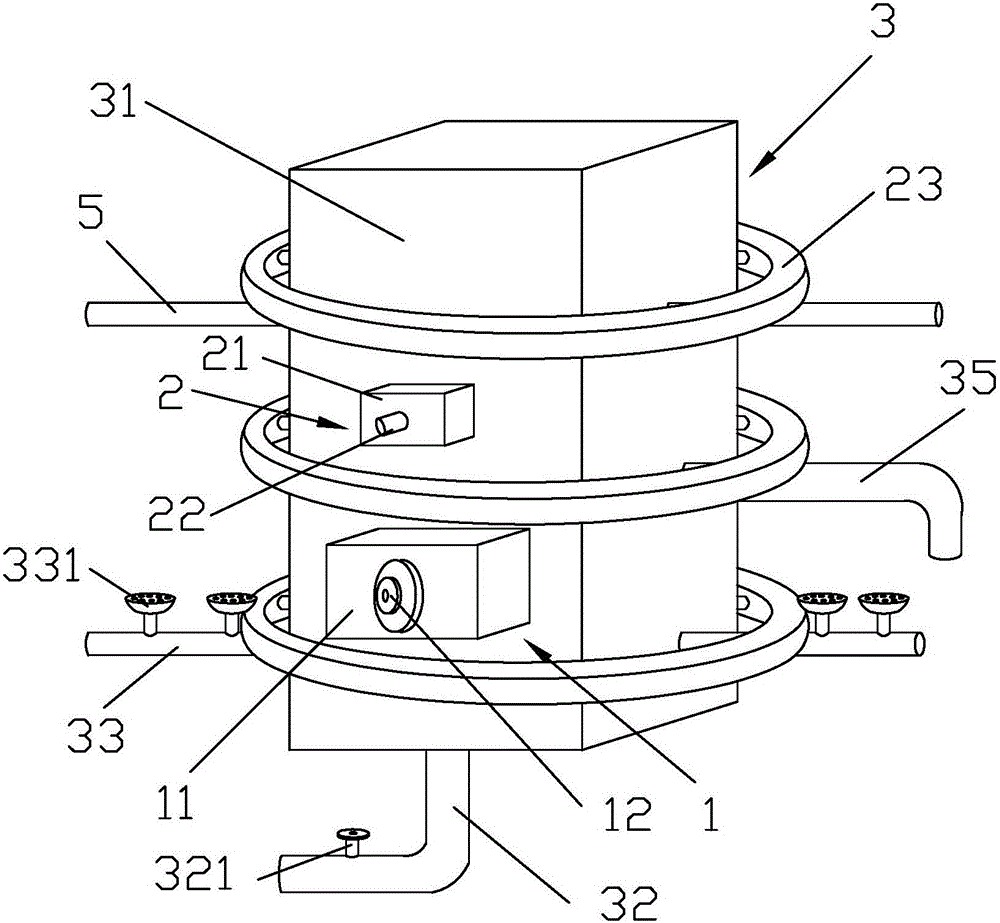

System and method for landscape fishpond purification treatment

ActiveCN106082533AExpand the range of suctionImprove water quality treatment effectWater cleaningTreatment using aerobic processesWater qualityEnvironmental engineering

The invention mainly discloses a system and method for landscape fishpond purification treatment. According to the technical scheme, the system comprises a water quality monitoring device, a water purification device and a water surface decontamination device, the water purification device comprises a shell, a water inlet pipe, an aerator pipe, a blowdown pipe and a water outlet pipe, a filtering area, an active mud area and a sterilization area are arranged in the shell from inside to outside in sequence in a nested mode, and both the water inlet pipe and the blowdown pipe are connected with the filtering area; the water outlet pipe is connected with the sterilization area, the two ends of the aerator pipe are located outside the active mud area and the shell respectively, and the water surface decontamination device comprises a collection box, a stain adsorption head and a stain adsorption pipe. The method comprises the steps of 1, installing the water purification device; 2, installing the water surface decontamination device; 3; conducting water quality detection; 4, conducting water purification; 5, conducting water surface purification; 6, conducting detection again; 7, cleaning the devices. The system is reliable in performance, water purification can be conducted automatically, water quality purification efficiency is high, treatment time and period are short, and normal operation of a fishpond system is guaranteed.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com