Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Facilitation of the recycling process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of preparing micro-structured powder for bonded magnets having high coercivity and magnet powder prepared by the same

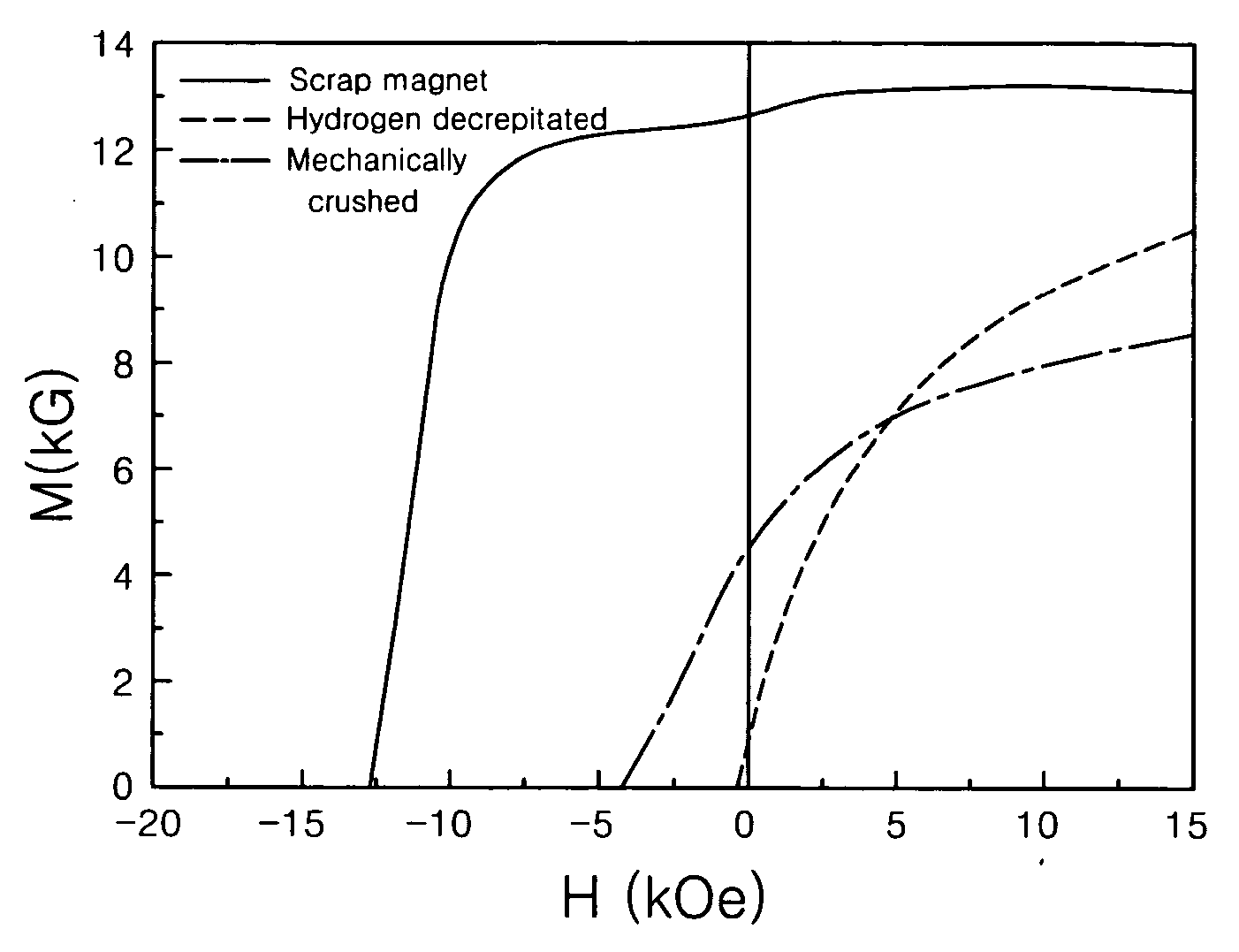

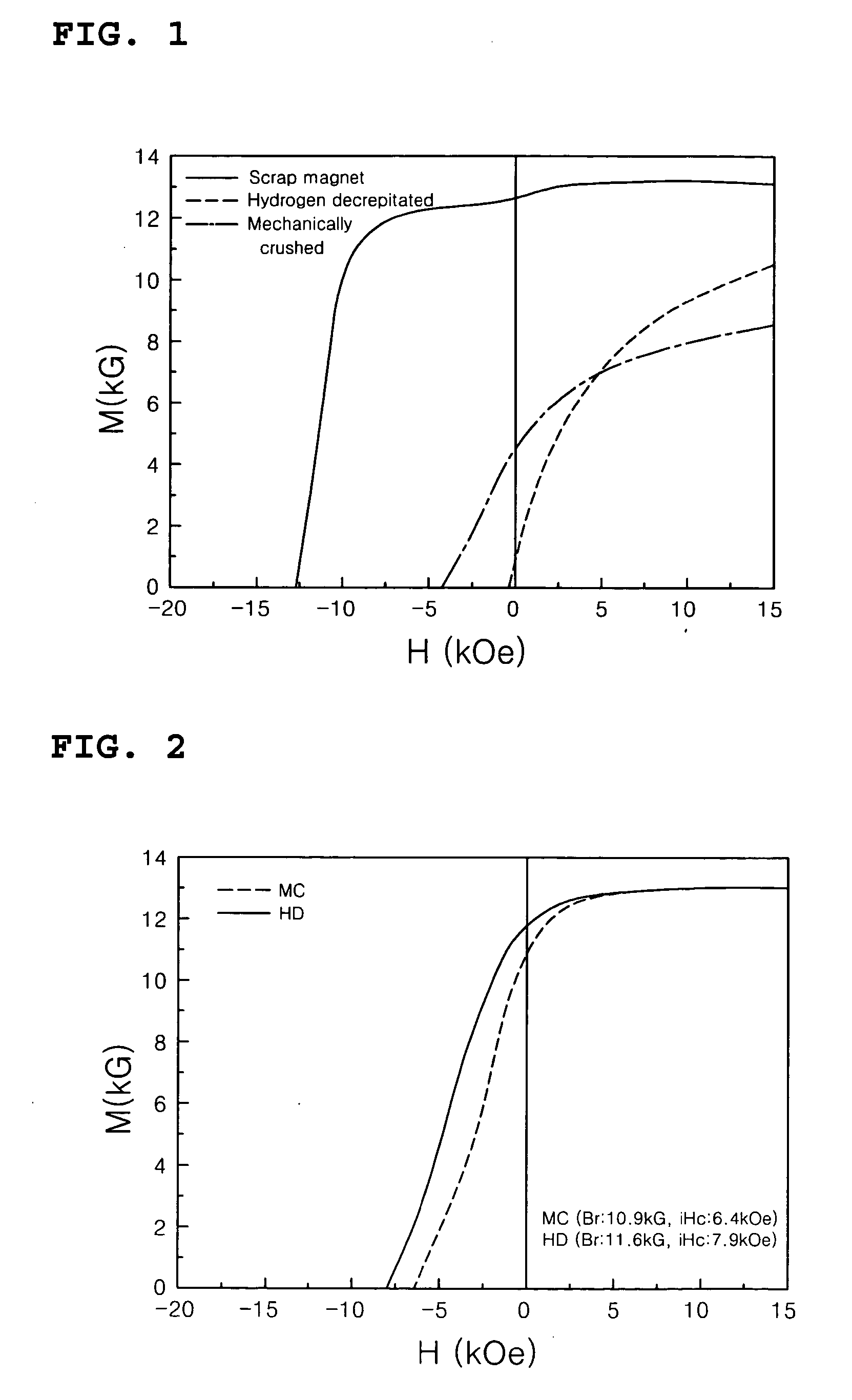

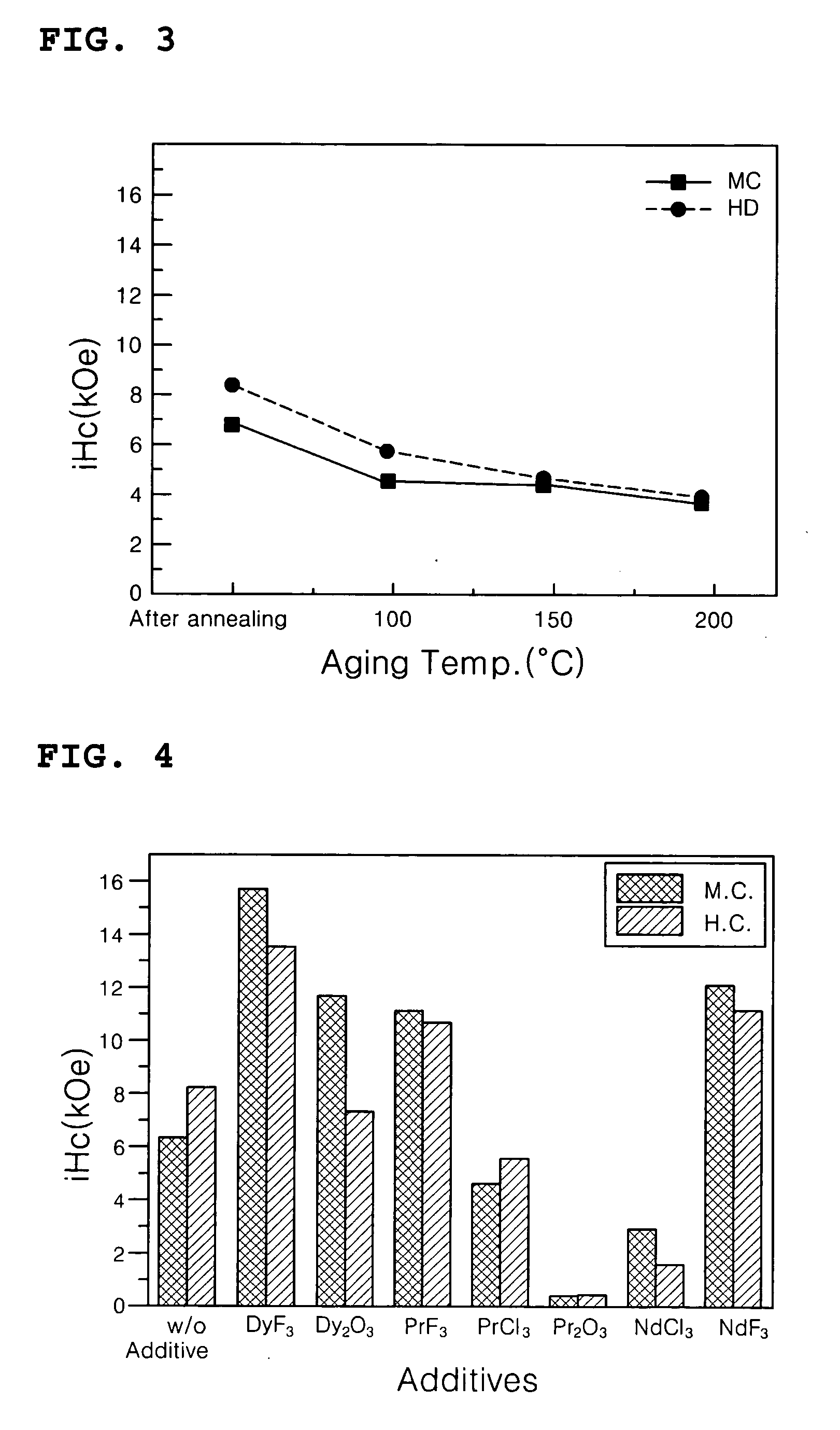

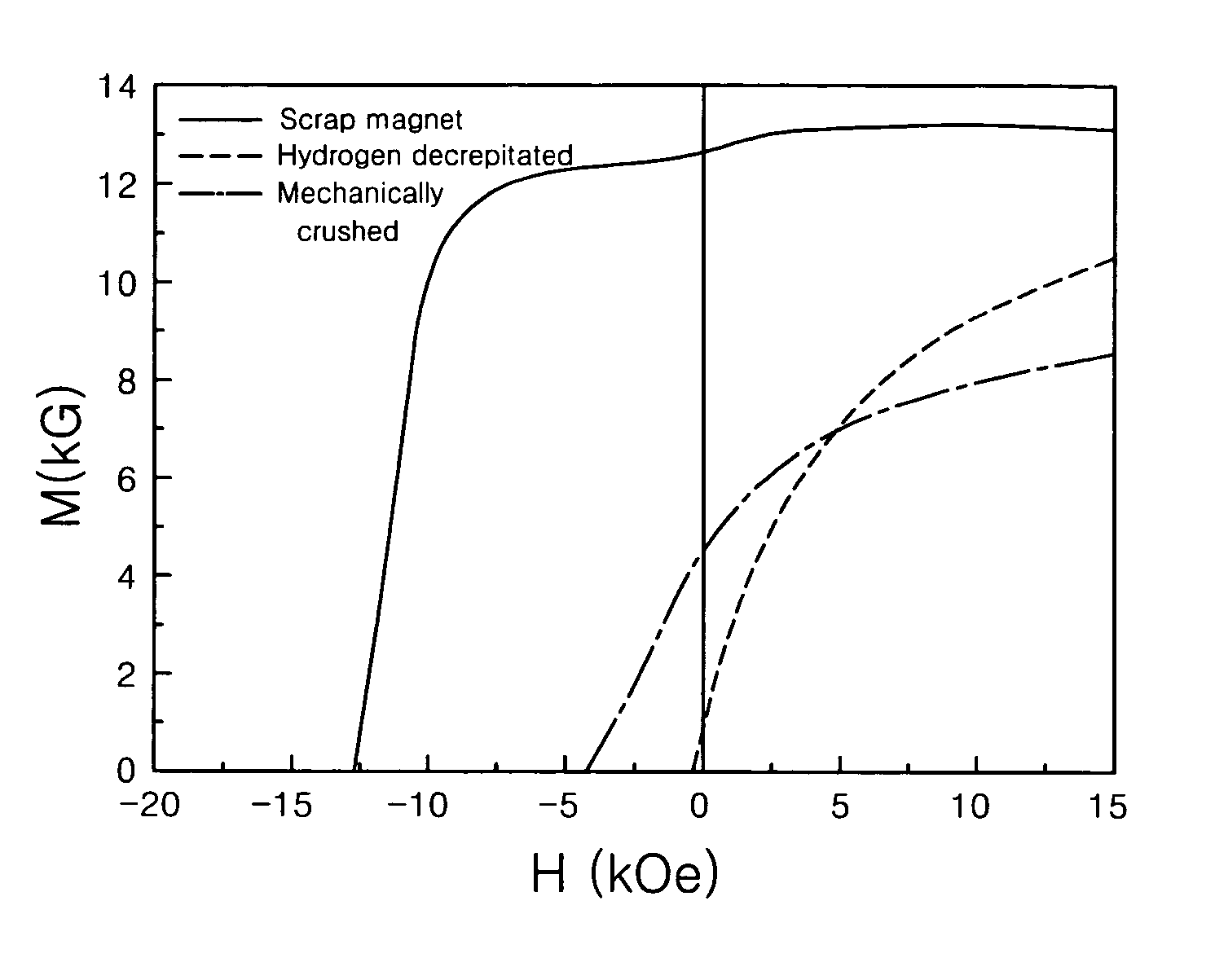

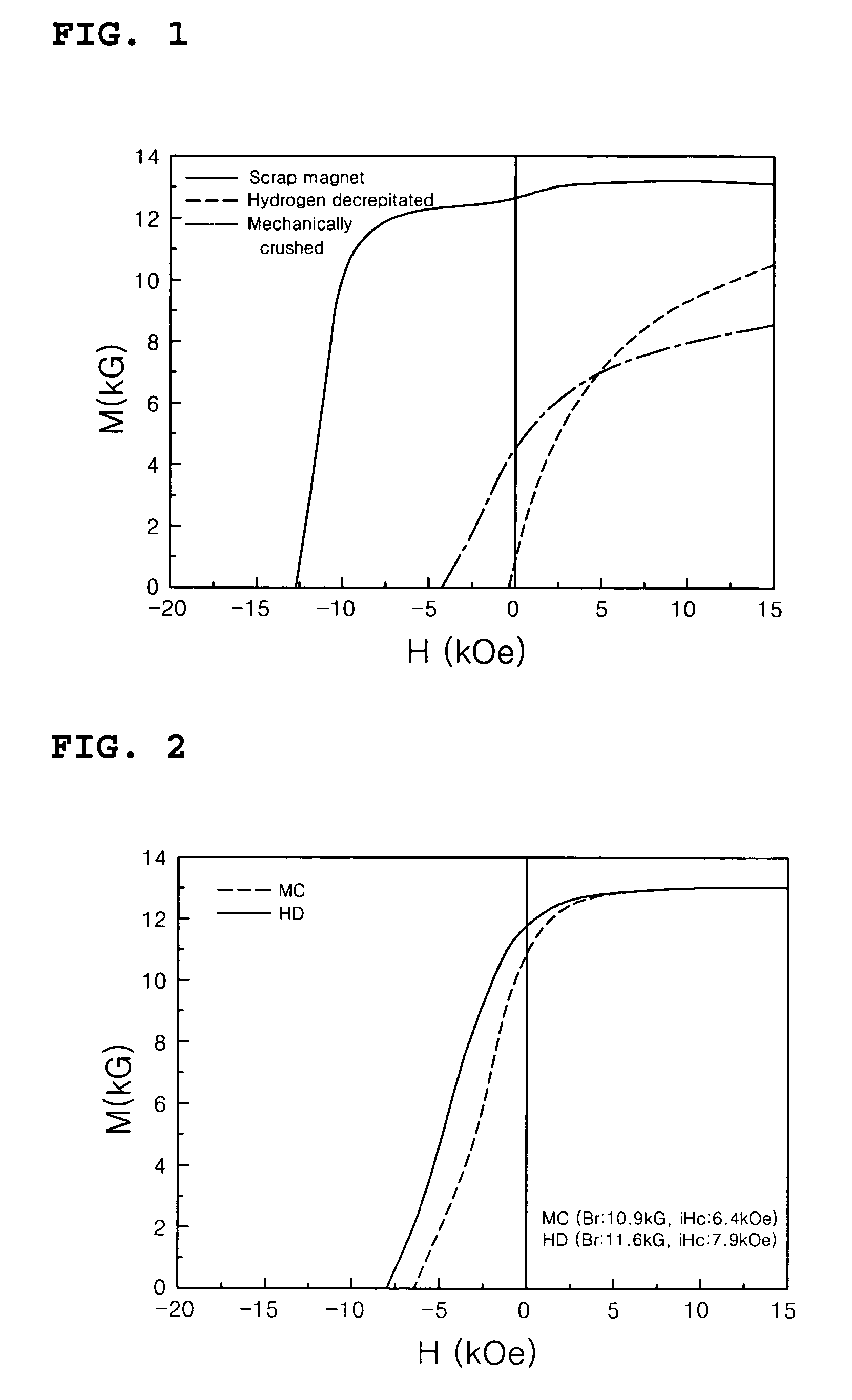

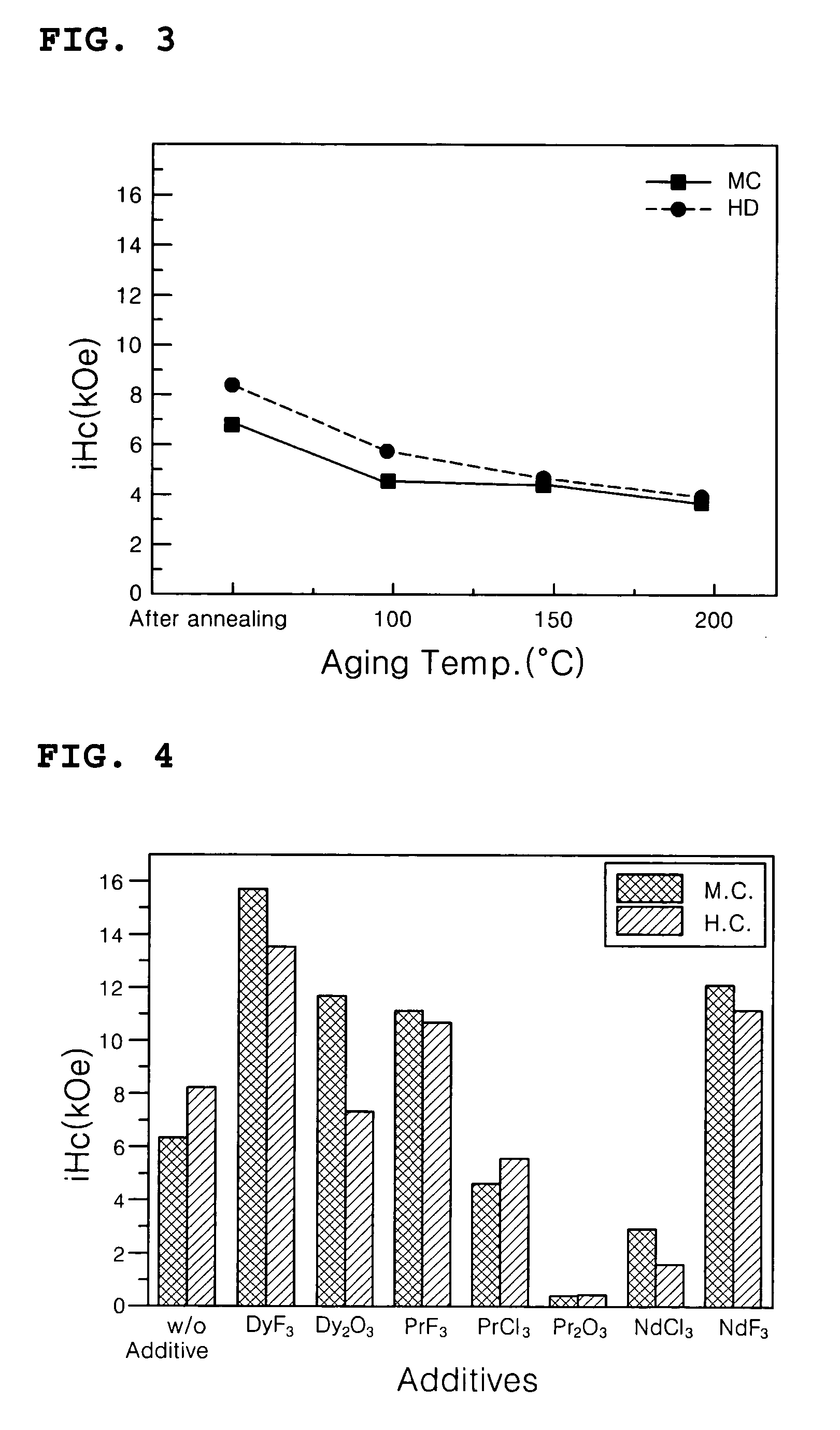

InactiveUS20050081959A1Reduce manufacturing costSimplified mass productionInorganic material magnetismRare earthGrain boundary

Disclosed is a method of preparing a micro-structured powder for bonded magnets having high coercivity, which is advantageous in terms of low preparation costs by recycling magnet scraps, simplified mass production, minimal environmental contamination by such a recycling process, and the preparation of stable anisotropic powders having high coercivity. Further, a magnet powder prepared by the above method is provided. The current method is characterized in that R—Fe—B type anisotropic sintered magnets or scraps thereof are crushed to prepare 50-500 μm sized magnet powders, which are then mixed with 1-10 wt % of rare earth fluoride (RF3) powders and thermally treated at high temperatures (500-1100° C.) in a vacuum or an inert gas, to cause the change of matrix-near surface and grain boundary of the powders. Thus obtained powders include a matrix phase having R2Fe14B crystal structure, a R-rich grain boundary phase containing rare earth fluoride, and other phases, in which the matrix phase has an average grain size of 1-20 μm, and the powders have an average size of 50-500 μm with superior magnetic characteristics of (BH)max≧20 MGOe and iHc≧5 kOe.

Owner:JAHWA ELECTRONICS

Method of preparing micro-structured powder for bonded magnets having high coercivity and magnet powder prepared by the same

InactiveUS7163591B2Improve coercive forceReduce manufacturing costInorganic material magnetismRare earthContamination

Disclosed is a method of preparing a micro-structured powder for bonded magnets having high coercivity, which is advantageous in terms of low preparation costs by recycling magnet scraps, simplified mass production, minimal environmental contamination by such a recycling process, and the preparation of stable anisotropic powders having high coercivity. Further, a magnet powder prepared by the above method is provided. The current method is characterized in that R—Fe—B type anisotropic sintered magnets or scraps thereof are crushed to prepare 50–500 μm sized magnet powders, which are then mixed with 1–10 wt % of rare earth fluoride (RF3) powders and thermally treated at high temperatures (500–1100° C.) in a vacuum or an inert gas, to cause the change of matrix-near surface and grain boundary of the powders. Thus obtained powders include a matrix phase having R2Fe14B crystal structure, a R-rich grain boundary phase containing rare earth fluoride, and other phases, in which the matrix phase has an average grain size of 1–20 μm, and the powders have an average size of 50–500 μm with superior magnetic characteristics of (BH)max≧20 MGOe and iHc≧5 kOe.

Owner:JAHWA ELECTRONICS

Plastic Reclaimed From Infectious Medical Waste and Medical Devices Manufactured Therefrom

ActiveUS20110068036A1Facilitation of the recycling processImprove effectivenessSolid waste disposalPlastic recyclingMedical wasteMedical device

Methods of reclaiming plastic from infectious medical waste and manufacturing medical devices from reclaimed plastic are described. Medical devices made from plastic reclaimed from infectious medical waste are also described.

Owner:BECTON DICKINSON & CO

Reusable blister packaging for button batteries

ActiveUS20130161230A1Easily pulled offThin and lightPackage recyclingVenting meansButton batteryEngineering

Blister pack 1 for button battery comprising a blister foil 10 designed to provide at least an individual cup 12 for receiving a button battery, and an individual closure region 13 for each said individual cup 12. The closure region 13 receives a closure element 4 which is removably secured to the closure region 13.

Owner:RENATA

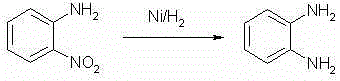

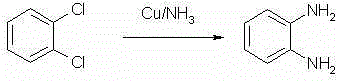

Green synthetic method of preparing o-phenylenediamine by reducing o-nitroaniline

ActiveCN105130821ARealize green and clean productionHigh reaction yieldOrganic compound preparationAmino compound preparationGreen cleaningO-nitroaniline

The invention relates to a green synthetic method of preparing o-phenylenediamine by reducing o-nitroaniline, wherein the method includes following steps: with o-nitroaniline as a substrate, dissolving the o-nitroaniline in water or in a mixed liquid composed of water and a co-solvent, and adding a supported catalyst under a carbon monoxide atmosphere, wherein the supported catalyst includes a supporter and a catalyst body supported thereon, and performing a reaction to prepare the o-phenylenediamine at 30-150 DEG C. In the method, the supported catalyst is used for preparing the o-phenylenediamine through reduction. The catalyst is high in selectivity and reaction yield and is mild in reaction condition. The method is environment-friendly in production system and less in treatment load of waste water, waste gas and solid waste, achieves green and clean production of the o-phenylenediamine, and is suitable for large-scale popularization.

Owner:江阴市华亚化工有限公司

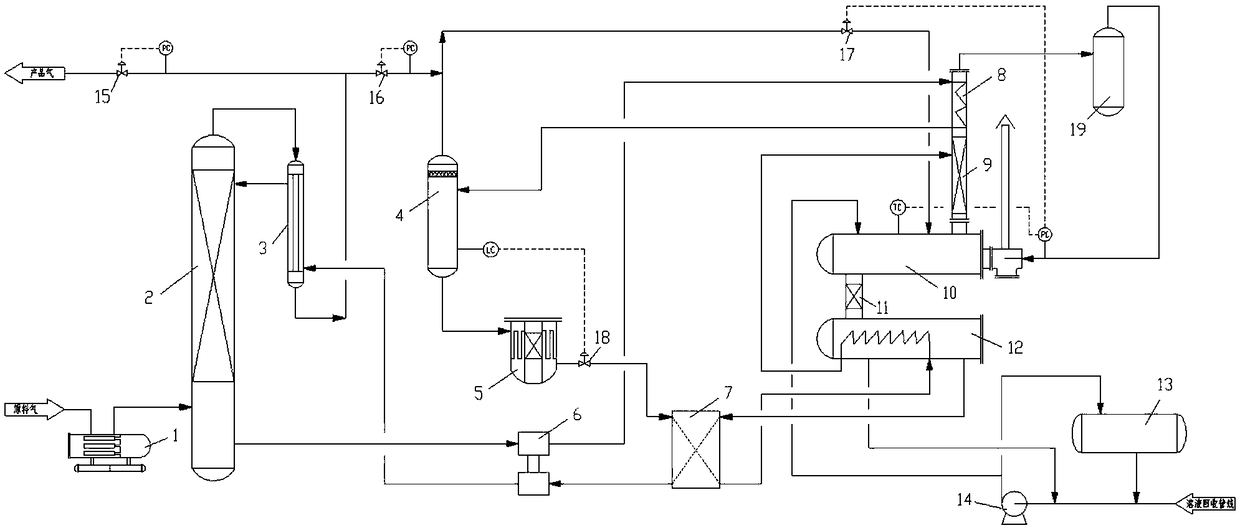

Integrated TEG (triethylene glycol) dehydration integrated process device and method

PendingCN108977247AHigh integrationLow regeneration energy consumptionGas treatmentDispersed particle separationReboilerProcess engineering

The invention discloses an integrated TEG (triethylene glycol) dehydration integrated process device and method. The device comprises a feed gas filtration separator, a TEG (triethylene glycol) absorption tower and a dry gas / barren solution heat exchanger; a liquid phase outlet at the bottom of the TEG (triethylene glycol) absorption tower is connected to a TEG (triethylene glycol) circulating pump; a pregnant solution outlet of the TEG (triethylene glycol) circulating pump is sequentially connected to a pregnant solution heat exchange coil, a flash tank, a TEG (triethylene glycol) solution filter and a barren / pregnant solution heat exchanger, a barren solution buffer tank and a pregnant solution rectifying column; a flashing steam outlet of the flash tank is connected to a TEG (triethylene glycol) fire tube type reboiler; the pregnant solution rectifying column, the fire tube type reboiler, a barren solution rectifying column and the barren solution buffer tank are connected together;and an outlet of the barren solution buffer tank, the barren / pregnant solution heat exchanger, the TEG (triethylene glycol) circulating pump, a dry gas / barren solution heat exchanger shell pass and aliquid phase inlet at the tower top of the TEG (triethylene glycol) absorption tower are sequentially connected. According to the integrated TEG (triethylene glycol) dehydration integrated process device and method, the process is simpler, highly integrated design is better facilitated, moving is easy, in addition, energy conservation and emission reduction are realized to a great extent, the operation cost is lowered, and the one-time investment is reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

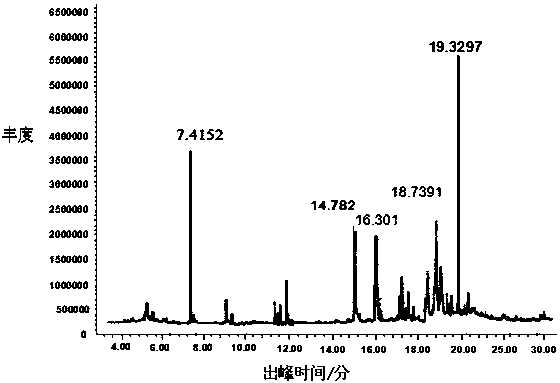

Method for preparing phenolic chemicals through thermo-chemical conversion of industrial lignin

InactiveCN102173980BLow priceObvious cost advantageOrganic compound preparationBulk chemical productionCellulosePtru catalyst

The invention provides a method for preparing phenolic chemicals through the thermo-chemical conversion of industrial lignin. The method is as follows: under the common functions of solid acid catalyst and hydrogen supply solvent, industrial lignin performs atmospheric thermo-chemical conversion in high boiling point organic reaction medium to prepare homogeneous low molecular weight organic matter with rich phenolic compounds such as phenol, methoxyphenol, dimethoxyphenol and 2-methoxy-4-methylphenol, and the organic reaction medium is recycled through the technologies such as vacuum distillation. The method has simple process, good stability and low production cost; and the yield of the prepared phenolic compounds is more than 54%. The method plays an important role in the high-valued comprehensive utilization of the renewable resource, namely ndustrial lignin; and the converted phenolic chemicals can be used to synthesize phenolic resin, prepare high efficiency cement water-reducing agent and further separate, purify and prepare bio-chemicals. Particularly, by adopting the method, the lignin in papermaking black liquid and preparation residue of biological fuel ethanol prepared from cellulose can be converted to phenolic chemicals; and the method has wide application prospect.

Owner:SOUTH CHINA UNIV OF TECH

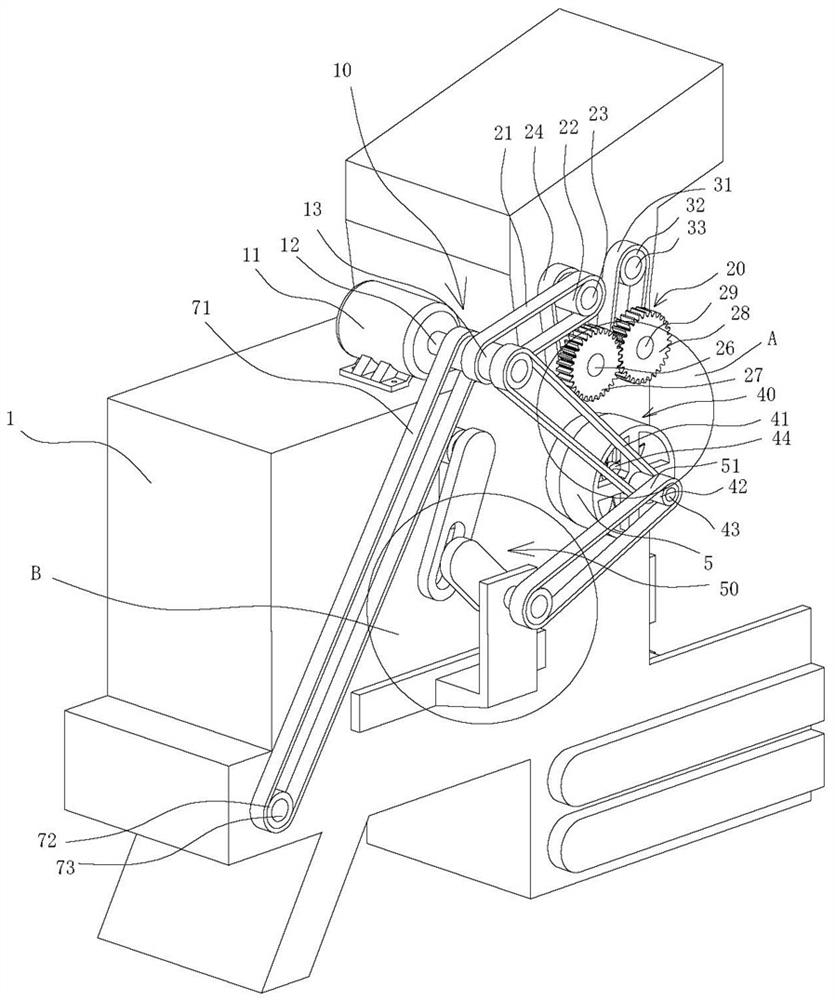

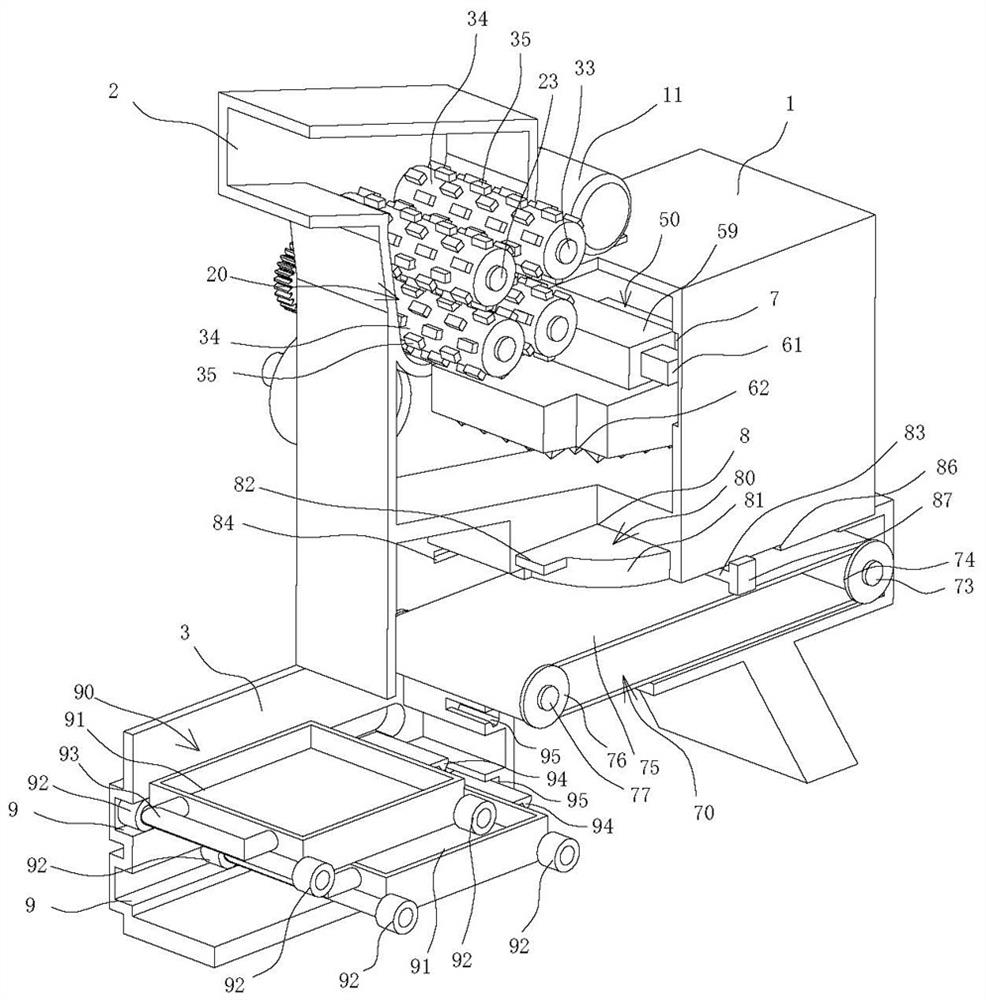

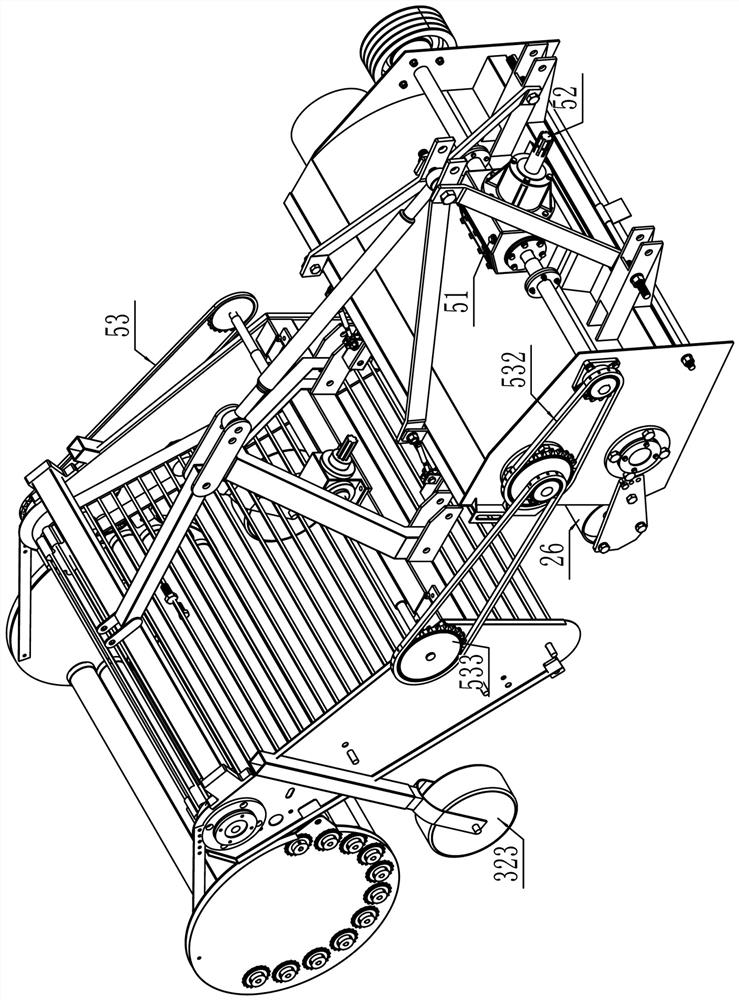

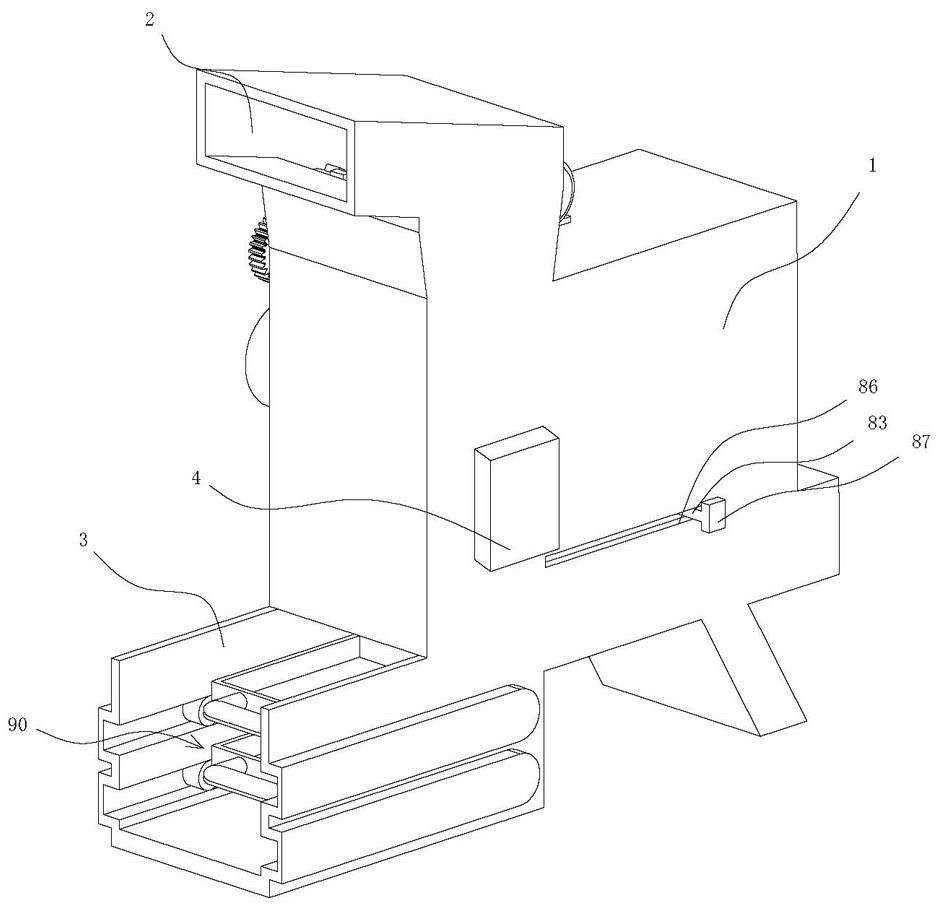

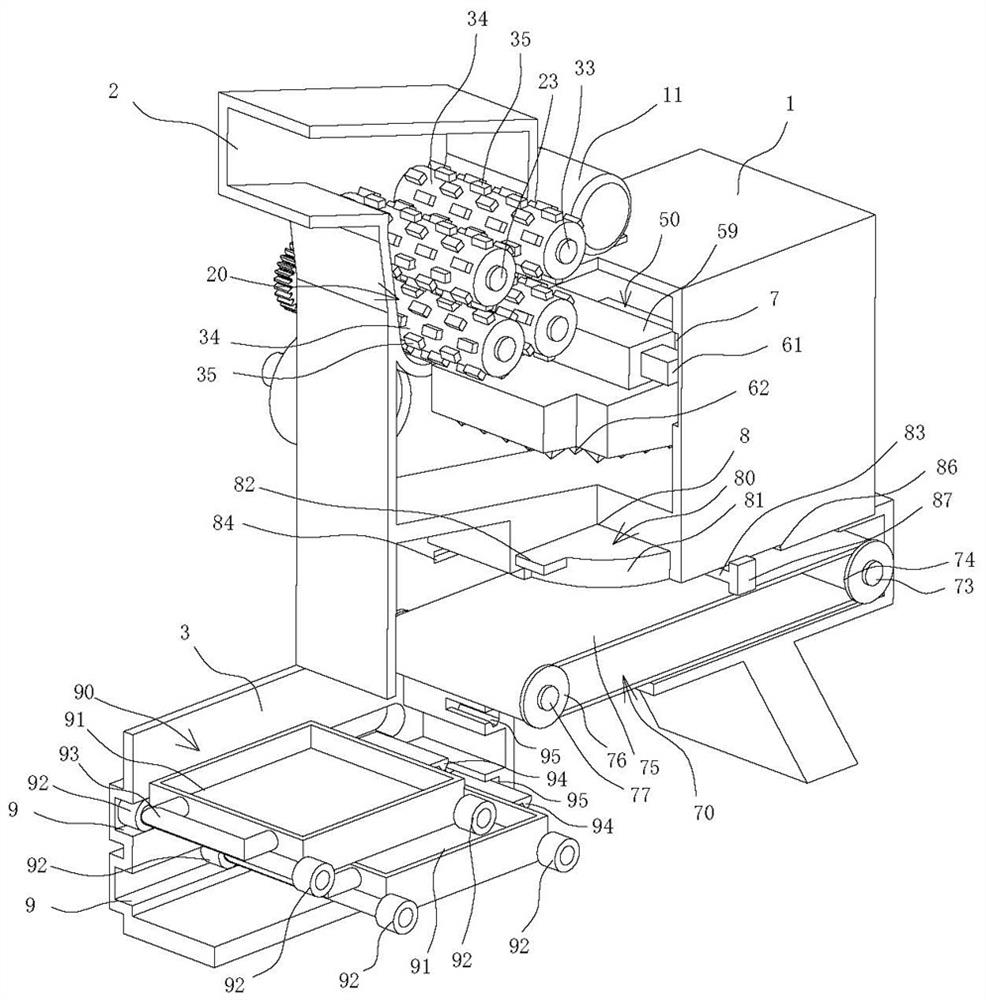

New energy automobile waste battery recovery device

ActiveCN111921673AEfficient crushingEasy to sieveWaste accumulators reclaimingCleaning using toolsNew energyBattery recycling

The invention discloses a new energy automobile waste battery recovery device which comprises a rack, wherein a feed inlet is formed in one end of the rack, a discharge hole is formed in the other endof the rack, and a discharge opening is formed in one side of the rack. The new energy automobile waste battery recovery device is characterized in that a power mechanism is arranged at one end of the rack, a crushing mechanism is arranged on one side of the power mechanism, an air flow screening mechanism is arranged on one side of the crushing mechanism, one end of the air flow screening mechanism is connected to the power mechanism, a smashing mechanism is arranged on one side of the air flow screening mechanism, a transfer mechanism is arranged on the other side of the power mechanism, amagnetic screening mechanism is arranged on one side of the transfer mechanism, and a storage mechanism is arranged at the discharge hole. The new energy automobile waste battery recovery device has the beneficial effects that the new energy automobile waste battery recovery device can crush and screen a waste battery periodically; primary screening can separate impurities such as diaphragm paperfragments in battery fragments effectively, and secondary screening can separate impurities such as metal materials with recovery value and crushed battery housings effectively, so that the recovery quality and the work efficiency of the new energy automobile waste battery recovery device are improved effectively.

Owner:SHAANXI RUIKAI ENVIRONMENTAL PROTECTION & TECH CO LTD

Reusable blister packaging for button batteries

ActiveUS9221589B2Easily pulled offThin and lightPackage recyclingVenting meansEngineeringBlister pack

Blister pack 1 for button battery comprising a blister foil 10 designed to provide at least an individual cup 12 for receiving a button battery, and an individual closure region 13 for each said individual cup 12. The closure region 13 receives a closure element 4 which is removably secured to the closure region 13.

Owner:RENATA

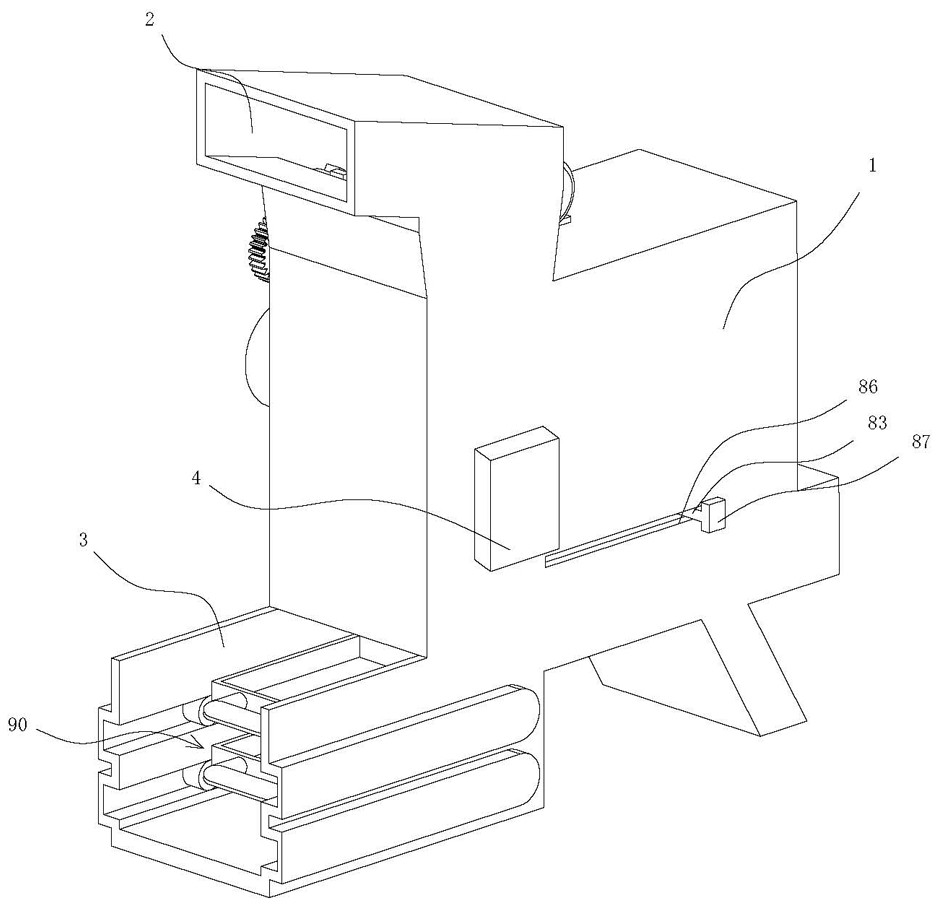

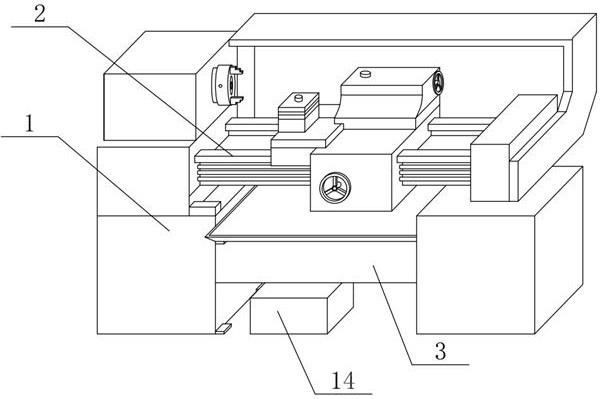

Intelligent chip removal type machine tool

InactiveCN112222934AFacilitation of the recycling processEasy to collectMaintainance and safety accessoriesProcess engineeringMetal powder

The invention discloses an intelligent chip removal type machine tool, comprising a machine tool body. A sliding rail is fixedly connected to the middle of the inner side of the machine tool body; a chip removal mechanism is fixedly connected to the inner side of the machine tool body; and a chip scraping mechanism is fixedly connected to the lower end of the sliding rail, is arranged at the upperend of the sliding rail, and comprises a bearing shell. Cutting chips falling onto a receiving hopper, used waste liquid formed by fusing cooling liquid and lubricating liquid and the like are scraped above a cleaning mechanism through the chip scraping mechanism; the waste liquid and the cutting chips are separated when falling into a screening mechanism; the waste liquid falls into a waste liquid barrel through a lower passing pipe; and the waste chips are smashed into powder through a crusher and then fall into a chip storage mechanism after being cleaned through the cleaning mechanism, sothat the chips generated by the machine tool can be collected and treated, the chips are directly machined into clean metal powder, and the subsequent recovery procedure is facilitated.

Owner:余储

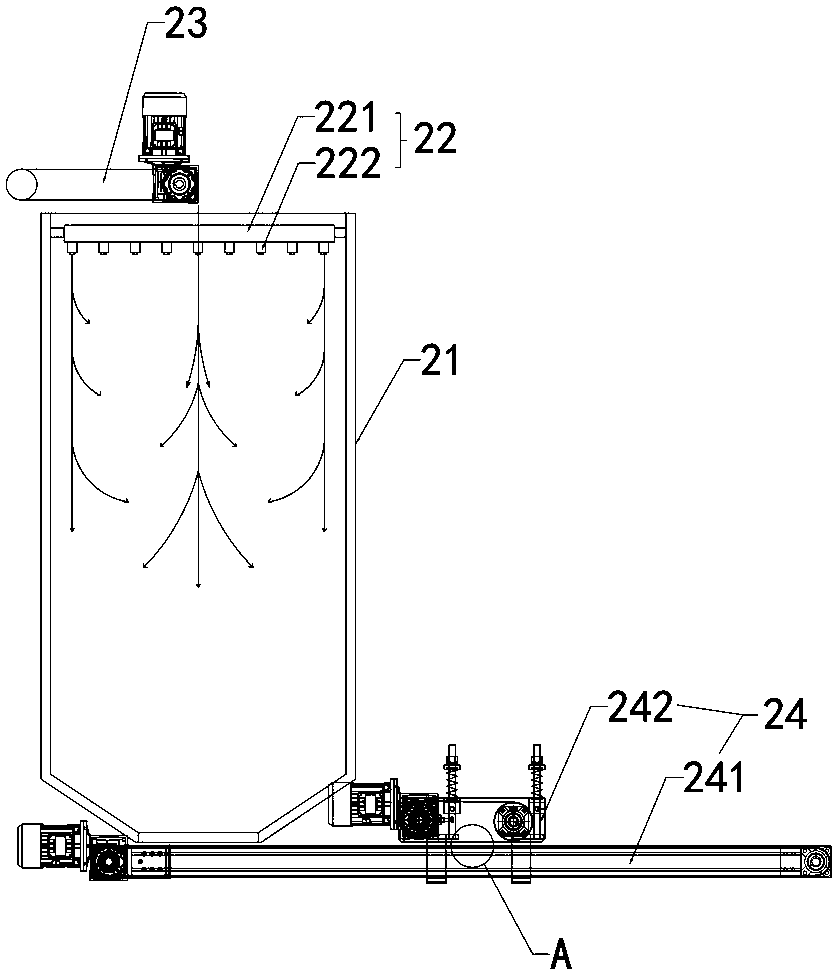

Ceramic tail powder material recycling treatment process and system

PendingCN108705657AFacilitation of the recycling processMeet production needsSievingScreeningMaterials preparationHardness

The invention discloses a ceramic tail powder material recycling treatment system. A sieving station, a humidifying station, an extruding station, a crushing and pelletizing station and a screening station are sequentially arranged along a tail powder material recycling treatment path, wherein tail powder materials are fed into the sieving station to be subjected to sieving and iron removing treatment so that sieved powder materials can be obtained; the humidifying station is provided with a humidifying device used for performing quantitative humidifying on the sieved powder materials, and therefore humidified powder materials with a preset water content are formed; the extruding station is provided with an extruding mechanism used for extruding the humidified powder materials to form blocky materials with proper hardness; the crushing and pelletizing station is provided with a crushing device used for performing crushing treatment on the blocky materials to form particle powder materials; and the screening station is provided with a device used for separating finished powder materials meeting the particle size requirement in the particle powder materials. The tail powder materialrecycling procedure is effectively improved, the production cost is greatly lowered, the finished powder materials meet the discharging requirement conforming to powder material preparation, and the characteristics that reentrainment of dust is avoided, cost is low, and direst inputting for production is achieved are achieved.

Owner:FOSHAN LANZHIJING SCI & TECH CO LTD

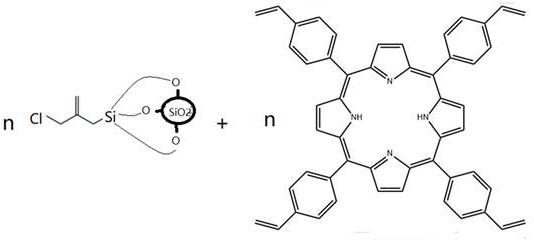

Method for generating cement clinker by taking gold tailing slag as raw material

ActiveCN113831032ALow costContributes to a sustainable circular economyCement productionCircular economyWaste treatment

The invention relates to the field of waste treatment, in particular to a method for generating cement clinker by taking gold tailing slag as a raw material. According to the invention, strongly basic anion exchange resin is adopted to adsorb and remove the toxic pollutant cyanide in the gold tailing slag, and inorganic matters are compounded in the strongly basic anion exchange resin, so that the settling property of the resin can be improved, the regeneration process after the resin is used is facilitated, and the purpose of saving the cost is achieved. The resin is ammoniated by triethylamine after chloromethylation, so that the material has higher adsorbability to cyanide, and the effect of removing the cyanide in waste residues is achieved. A cement kiln ingredient is prepared by calcining the removed gold tailing slag together with clay and other raw materials in a lime kiln, and the cement kiln ingredient can be widely applied to cement of various brands. According to the method, the advantages that the gold tailings are large in quantity and low in price and cost are utilized, waste is recycled by utilizing existing resources and cement kiln equipment and utilizing the residual value of the gold tailings, and development of sustainable circular economy is facilitated.

Owner:浙江红狮环保股份有限公司

Management system of motor vehicle violation punishments

InactiveCN101561901ASpeed up the recycling processSave manpower and material resourcesResourcesSingle pointSQL

The invention discloses a management system for motor vehicle violation punishments, which is provided with a server and a simple point entering unit, wherein the server is connected with a client computer through a transmission network, uses Visual Studio 2003 as a development platform and SQL Server2000 as a network database platform, and uses a C / S development module and an ADO.Net database of a three-layer structure system, and the ADO.Net database is connected with a public security network system; the single point entering unit is closely integrated with the public security network system and consists of data entering and data submission, and data entered at one place can be submitted at a plurality of places; and the development platform is provided with an addition data unit, an illegality inquiry statistic unit, a punishment management unit, a user setting unit and a data processing unit, and each unit is connected by operating the database. Through single point entering, the management system can perform automatic information processing on a punishment service of a traffic police department, has high automation degree, high speed and high accuracy, and can quickly finish violation notifications and punishments and accelerate the recovering flow of the punishments.

Owner:刘黎明

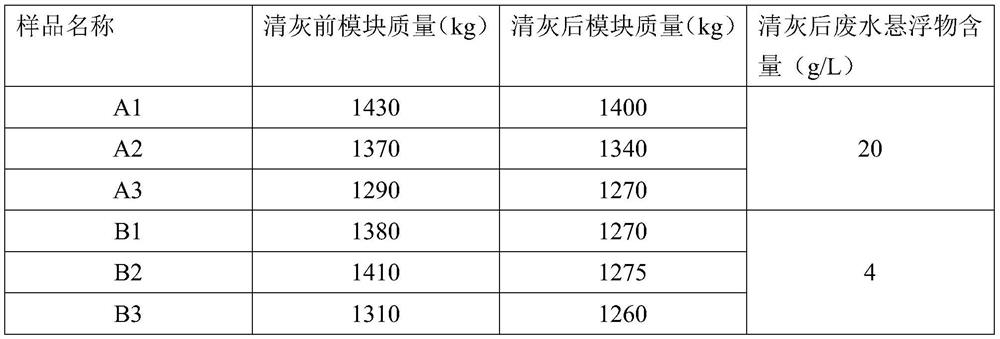

Ash removal method for regeneration pretreatment of plate-type denitration catalyst

PendingCN113441190ARealize purging one by oneReduce difficultyDispersed particle separationCatalyst regeneration/reactivationPtru catalystEnvironmental engineering

The invention discloses an ash removal method for regeneration pretreatment of a plate-type denitration catalyst. The ash removal method comprises the following steps: (1) dry-process ash removal via compressed-air purging: disassembling a catalyst module, removing accumulated ash on the surface of a catalyst unit body, putting the catalyst unit body into an automatic ash blowing equipment room, conducting blowing with compressed air in the windward side and the leeward side of the catalyst unit body separately, and placing the catalyst unit body having been subjected to ash removal in a module box again; (2) wet-process ash removal via automatic spraying: starting an automatic spraying and washing line to spray and wash the catalyst module; (3) ash removal via high-pressure water gun flushing: flushing the windward side of the catalyst module via a high-pressure water gun under the condition that the high-pressure water gun and the windward side of the catalyst module forms an angle of 90 degrees, then flushing a module box shell, hoisting the catalyst module, and conducting flushing from the leeward side of the catalyst module by using the high-pressure water gun. The method can be used for comprehensively and thoroughly removing accumulated ash on the outer surface of the catalyst and the pore channels of the catalyst, and follow-up catalyst regeneration difficulty is reduced.

Owner:SUZHOU XIRE ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD +1

PVC pipe recovery equipment

InactiveCN112109243AAvoid skiddingReduce security risksPlastic recyclingDrying gas arrangementsStructural engineeringCrusher

The invention relates to the technical field of PVC pipe recovery, in particular to PVC pipe recovery equipment. The PVC pipe recovery equipment comprises four supporting legs, and further comprises acontroller, a crushing mechanism and a drying mechanism; the drying mechanism is arranged at the tops of the four supporting legs and used for drying crushed waste PVC pipe fragments; the drying mechanism comprises a drying box, a filtering basket, an air blowing assembly and two traction assemblies; the crushing mechanism comprises a crushing box, an extrusion assembly and a crushing assembly; the controller is fixedly arranged on the outer wall of the crushing box; the crushing box is fixedly arranged at the top of a material receiving opening; the extrusion assembly is arranged at the topof the inner side of the crushing box; the crushing assembly is arranged at the bottom of the inner side of the crushing box; and the air blowing assembly and the extrusion assembly are electrically connected with the controller. According to the PVC pipe recovery equipment, PVC pipes can be prevented from slipping or being clamped, thorough crushing is achieved, meanwhile, the drying speed is higher, drying is more thorough, and the next recovery procedure can be carried out conveniently.

Owner:刘季祥

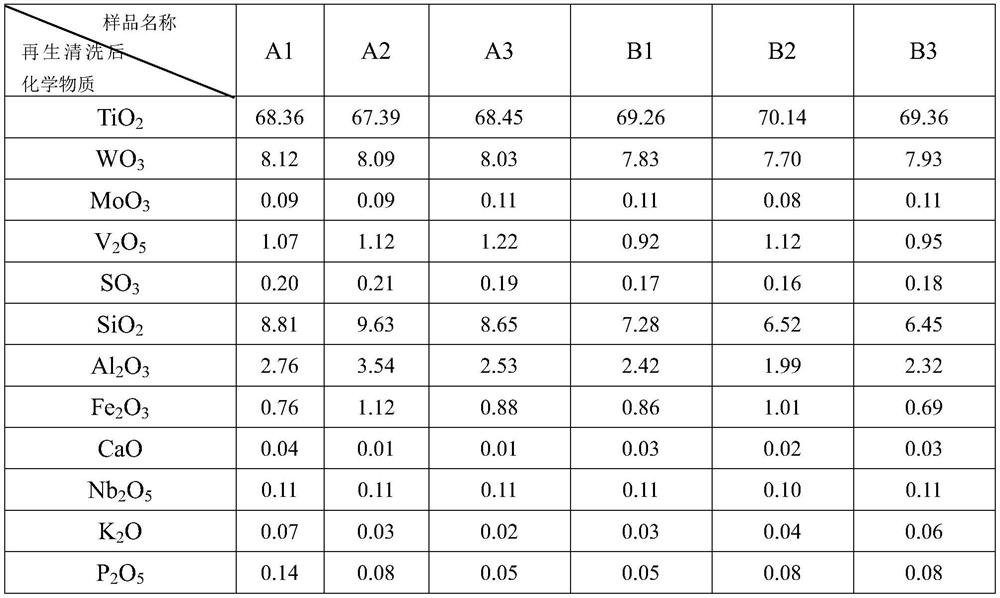

Self-unloading type residual film recycling machine for straw smashing and returning to field and lifting chain bundling and using method

ActiveCN112868294ASimple structureFunctionalSpadesClimate change adaptationHydraulic cylinderPlastic mulch

The invention relates to a self-unloading type residual film recycling machine for straw smashing and returning to field and lifting chain bundling and a using method. The residual film recycling machine comprises a rack, a straw smashing and returning-to-field device and a residual film picking and conveying device, wherein the straw smashing and returning-to-field device and the residual film picking and conveying device are arranged on the rack, a residual film bundling self-unloading device is arranged behind the residual film picking and conveying device, the straw smashing and returning-to-field device comprises a smashing shell, the front end of the smashing shell is connected with the machine tool through a three-point suspension mechanism, a stubble cleaning mechanism is arranged on the lower portion in the smashing shell, and a horizontal conveying mechanism is arranged above the stubble cleaning mechanism; the residual film picking and conveying device comprises a film lifting shovel and an inclined conveying mechanism, and the film lifting shovel is used for separating mulching films from the ground, so that the mulching films are conveyed upwards under the action of the inclined conveying mechanism; and the residual film bundling self-unloading device comprises a film collecting box with a top opening, a film collecting box connecting rod and a hydraulic cylinder, the film collecting box is arranged behind the residual film picking and conveying device through the film collecting box connecting rod, the hydraulic cylinder is arranged outside the film collecting box, one end of the hydraulic cylinder is connected with the film collecting box, and the other end of the hydraulic cylinder is connected with the inclined conveying mechanism.

Owner:GANSU AGRI UNIV

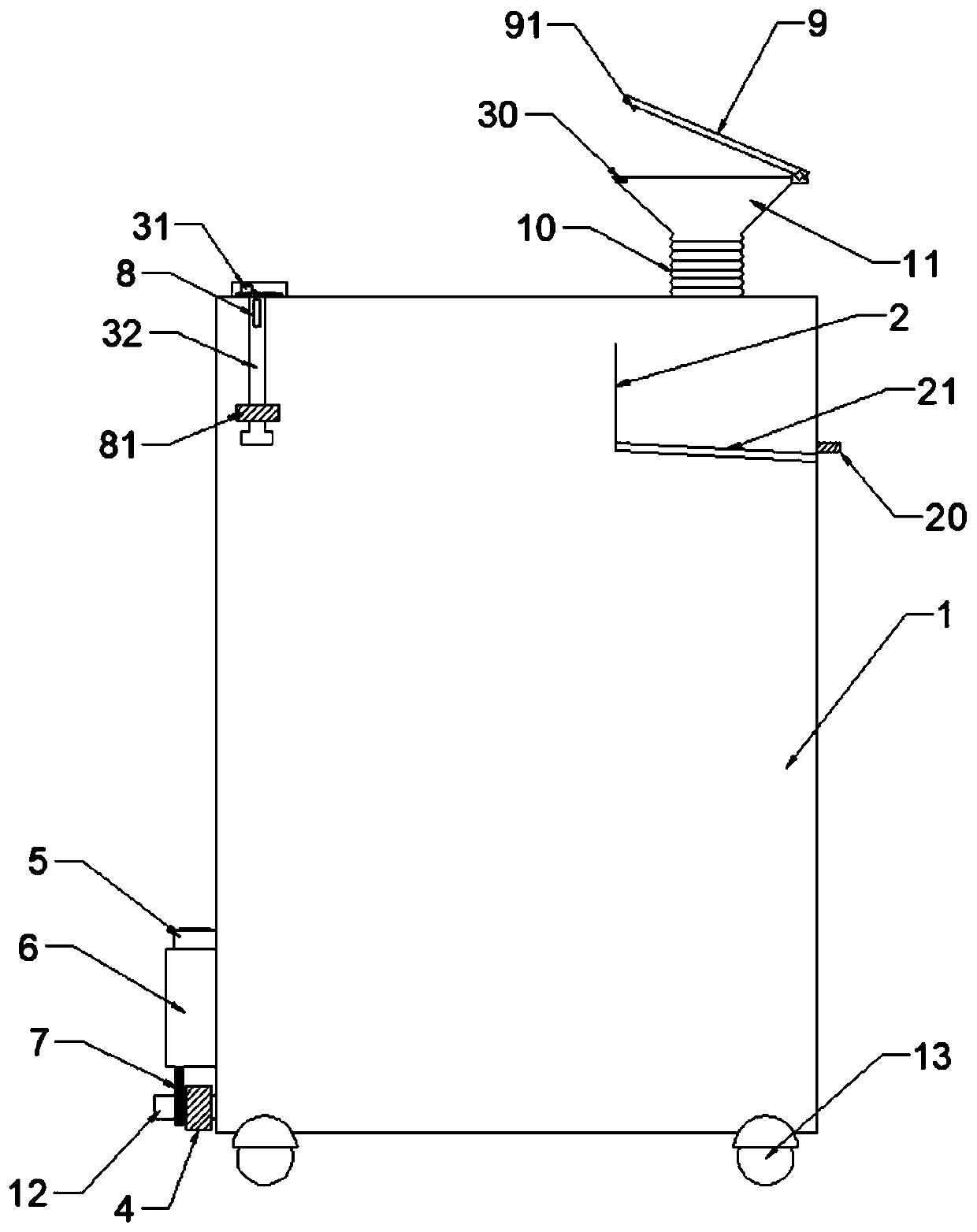

Automobile engine oil recycling device and method

PendingCN110371537AImprove the recycling processRecycling formalRefuse receptaclesInformation transmissionSlag

The invention discloses an automobile engine oil recycling device and method. The automobile engine recycling device comprises a recycling barrel. The top of the recycling barrel is provided with an oil inlet, and the oil inlet is provided with an upper cover. The upper portion of the recycling barrel is provided with a partition layer and a liquid level alarming device. The liquid level alarmingdevice is linked with the upper cover. The partition layer is located under the oil inlet. A slag discharging groove is formed in the bottom of the partition layer, and an oil outlet is formed in thelower portion of the recycling barrel. An electromagnetic valve and an electronic flow meter which are connected with a circuit module are assembled at the position of the oil outlet, and a power source is used for supplying power to the electromagnetic valve, the electronic flow meter and the circuit module. The circuit module comprises a communication module conducting bidirectional signal transmission with a cloud server. A two-dimensional code is arranged on the recycling barrel for an APP end to scan and recognize, and the cloud server serves as a medium between the APP end and the communication module for bidirectional information transmission. Engine oil only enters the device but not exits from the device in the engine oil recycling process, people must hold an official account forscanning the two-dimensional code, the cloud server is used for starting the engine oil recycling device for fixed-point engine oil recycling, it is ensured that the engine oil is not secondarily used or discharged in a mess, and the automobile repairing market environment is purified.

Owner:广东新润环保技术研发有限公司

A new energy vehicle waste battery recycling device

ActiveCN111921673BEfficient crushingEasy to sieveWaste accumulators reclaimingCleaning using toolsElectrical batteryNew energy

The invention discloses a waste battery recovery device for new energy vehicles, which comprises a frame, one end of the frame is provided with a material inlet, the other end of the frame is provided with a discharge port, and one side of the frame is provided with a discharge port, which is characterized in that : One end of the frame is equipped with a power mechanism, one side of the power mechanism is equipped with a crushing mechanism, one side of the crushing mechanism is equipped with an airflow sieving mechanism, one end of the airflow sieving mechanism is connected with the power mechanism, and one side of the airflow sieving mechanism is equipped with a crushing mechanism. The other side of the power mechanism is provided with a transmission mechanism, one side of the transmission mechanism is provided with a magnetic sieving mechanism, and a material storage mechanism is provided at the discharge port. Sieve treatment, primary sieving can effectively separate impurities such as diaphragm paper fragments in battery debris, and secondary sieving can effectively separate metal materials with recycling value from broken battery casings and other impurities, effectively improving The recovery quality and working efficiency of the present invention.

Owner:SHAANXI RUIKAI ENVIRONMENTAL PROTECTION & TECH CO LTD

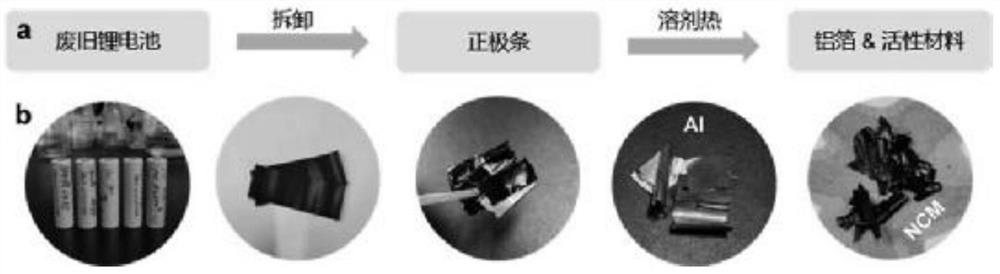

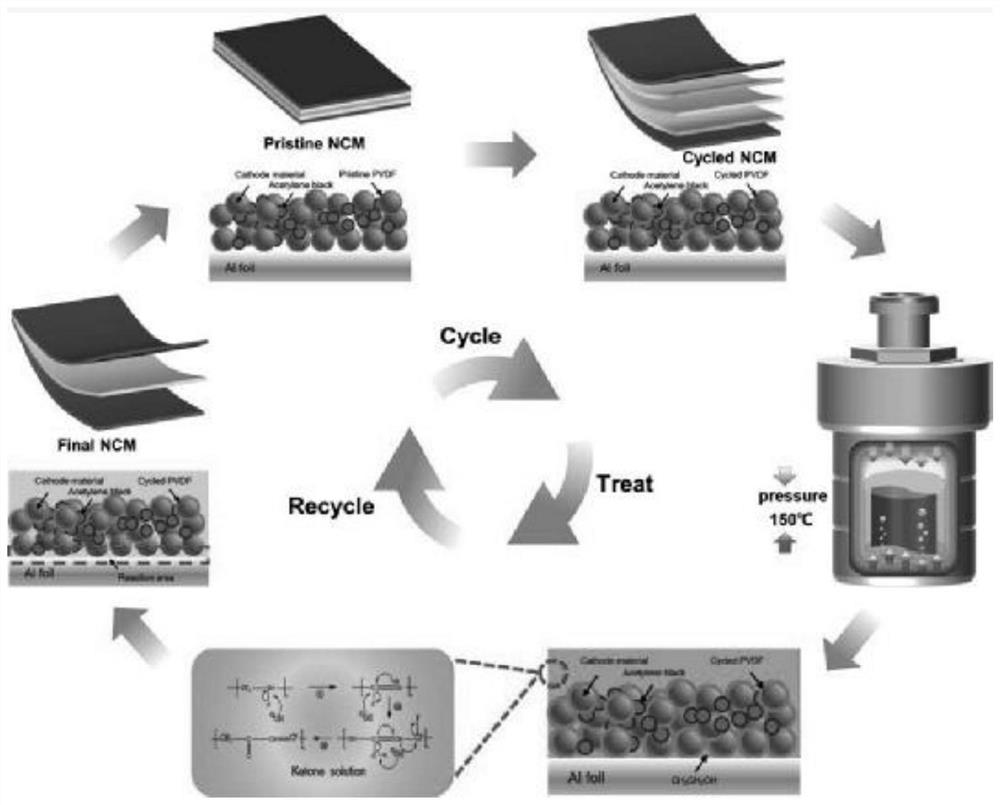

Solvothermal pretreatment method and application of waste lithium battery positive electrode material

PendingCN114512738AAchieve fixed separationEasy to operatePositive electrodesWaste accumulators reclaimingElectrolytic agentPretreatment method

The invention provides a solvothermal pretreatment method of a waste lithium battery positive electrode material, a waste lithium battery positive electrode plate uses PVDF as a binder, and the method comprises the following steps: disassembling a waste lithium battery, removing residual electrolyte on the surface of an electrode, and obtaining a positive electrode strip; immersing the positive electrode strip in a certain amount of alcohol solvent, and processing for 40-150 minutes at the temperature of 120-180 DEG C, so that the positive electrode material and the aluminum foil current collector are separated, the positive electrode material falls off in a sheet shape, and the aluminum foil sheet is kept complete; and taking out the separated aluminum foil and positive electrode material from the organic solvent, and recovering to obtain the positive electrode active material. The solvothermal pretreatment method of the waste lithium battery positive electrode material provided by the invention has the advantages of simple process, high efficiency, environmental protection, low cost and the like. The invention also provides a lithium battery positive electrode material and a lithium battery.

Owner:CENT SOUTH UNIV

Recovery of contaminant free battery materials

PendingUS20220271355A1Improved electrolyte removal/recycling processEasy to separateSolid separationWaste accumulators reclaimingElectrical batteryMechanical engineering

A method for producing clean black mass, anode or cathode for subsequent recycling is provided, the method comprising subjecting an intact battery to a shredding process to produce an aggregate, wherein the smallest particle generated is between 2.5 percent and 40 percent of original battery size. Also provided is a shredder for minimizing aggregation of whole batteries, the shredder comprising a shaft defining a longitudinal axis and a latitudinal axis; and a plurality of teeth disposed on said knives which fit on said shaft at an angle to the latitudinal axis selected from 15 degrees and 45 degrees, wherein the teeth have a first proximal end integrally molded to the shaft and a second free distal end.

Owner:UCHICAGO ARGONNE LLC

Method for selectively purifying and removing copper and cadmium by automatic control of electric potential

PendingCN112063855AOptimize the recycling processReduce unit consumptionPhotography auxillary processesElectrolysis componentsAutomatic controlPhysical chemistry

The invention discloses a method for selectively purifying and removing copper and cadmium by automatic control of electric potential. The method for selectively purifying and removing copper and cadmium by automatic control of electric potential comprises the following steps of providing a solution containing copper ions and cadmium ions; adding zinc powder into the solution containing copper ions and cadmium ions for replacement to remove copper, and carrying out solid-liquid separation to obtain a liquid after replacement to remove copper and copper slag, wherein the adding amount of the zinc powder in a process of replacement to remove copper is controlled by means of electric potential at a reaction endpoint; and adding the zinc powder into the liquid after replacement to remove copper for liquid after replacement to remove cadmium, and carrying out solid-liquid separation to obtain a liquid after replacement to remove cadmium and sponge cadmium, wherein the adding amount of the zinc powder in a process of replacement to remove cadmium is controlled by means of electric potential at a reaction endpoint. The method achieves a purpose of removing impurities precisely by judgingthe replacement reaction endpoints of copper and cadmium impurities in the solution in an electric potential measuring mode and extracting copper and cadmium in the solution in steps, so that a cadmium recovery treatment step is optimized, the unit consumption and the production cost of the zinc powder are reduced, and the production control level is improved and the economical benefit is increased.

Owner:云南云铜锌业股份有限公司

Straw crushing and returning to the field and lifting, chain, roll, baling, self-unloading residual film recycling machine and its use

The invention relates to a straw crushing and returning to the field and lifting chain roll bundle self-unloading residual film recycling machine and its use method. The residual film recycling machine includes: a frame, a straw crushing and returning device arranged on the frame and a residual film picking up Residual film roll and bundle self-unloading device is installed behind the conveying device, residual film picking and conveying device; the straw crushing and returning device includes a crushing shell, the front end of which is connected to the machine tool through a three-point suspension mechanism, and a stubble removal mechanism, There is a horizontal conveying mechanism above the stubble removal mechanism; the residual film picking and conveying device includes: a film lifting shovel and an inclined conveying mechanism, the film lifting shovel is used to separate the mulch from the ground, so that the mulch is transported upward under the action of the inclined conveying mechanism; the residual film The roll-and-bundle self-unloading device includes a film collecting box with an open top, a film collecting box connecting rod and a hydraulic cylinder. The film collecting box is set behind the residual film picking and conveying device through the film collecting box connecting rod, and the hydraulic cylinder is set outside the film collecting box. , one end of which is connected to the film collecting box, and the other end is connected to the inclined conveying mechanism.

Owner:GANSU AGRI UNIV

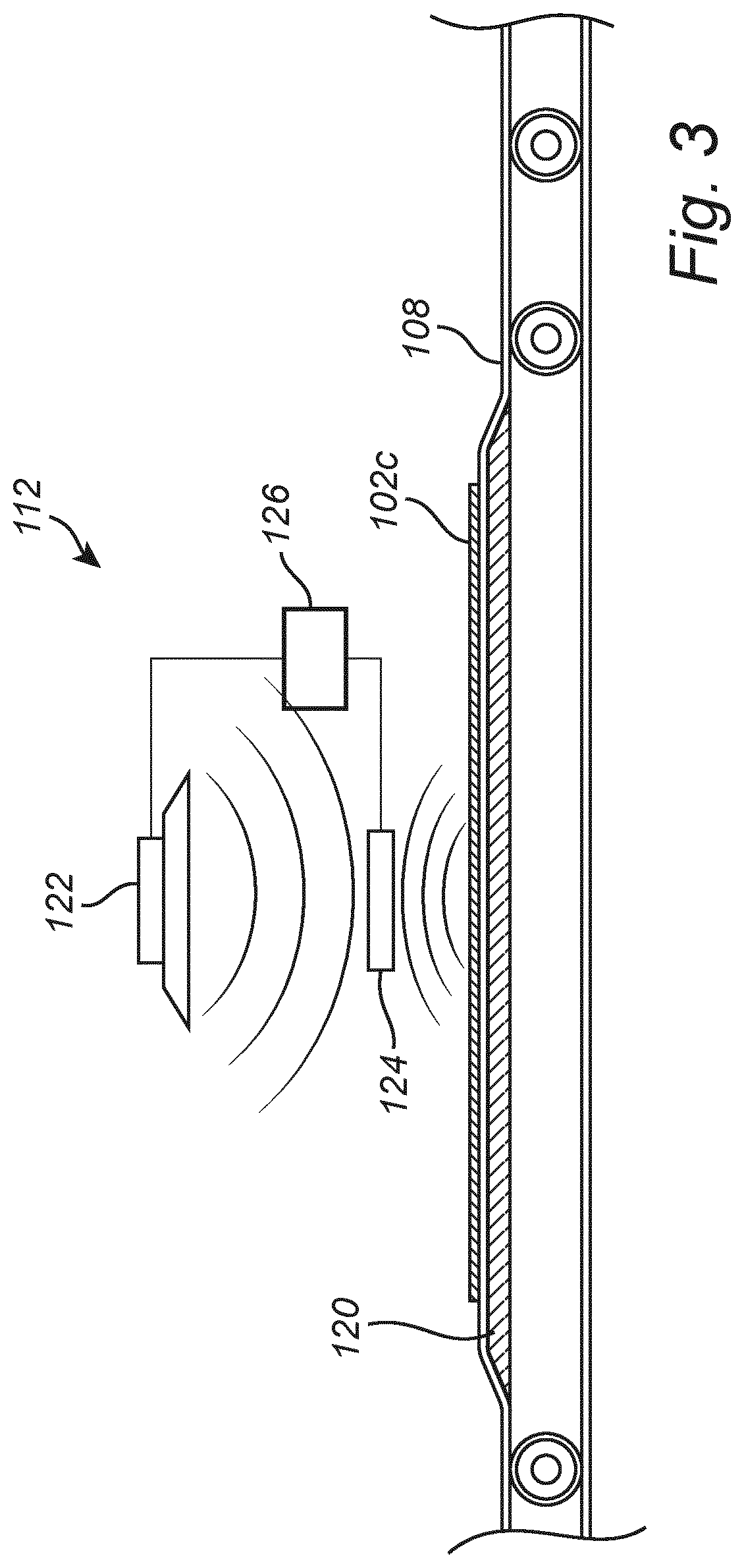

System and method for recycling planar objects

ActiveUS20220080464A1Simple methodReduce material wasteImage analysisPlastic recyclingFiberConverters

A system for recycling planar objects including compressed mineral fiber material includes: a conveyor arranged to covey the planar objects through a number of stations at least including a thickness measurement station and a sound measurement station. The sound measurement station includes a sound reflecting surface arranged to back a first major surface of a planar object, a sound emitter arranged to emit sound towards the sound reflecting surface, a sound receiver arranged to receive sound reflected from the sound reflecting surface, and a converter arranged to determine a property related to sound absorption. A sorting station is arranged to sort the planar objects based on determined properties in to a plurality of fractions.

Owner:SAINT GOBAIN ECOPHON

Method for recycling building materials

InactiveUS20050126456A1Emission reductionReduce investmentCremation furnacesCement productionCement kilnBuilding material

A method of recycling building materials is described, including the steps of introducing the building material into a cement kiln or a boiler, and combusting a combustible portion of the building material as a fuel within the kiln or boiler. The noncombustible portion of the building material is incorporated into a clinker material within the kiln or used to reduce emissions form the boiler.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

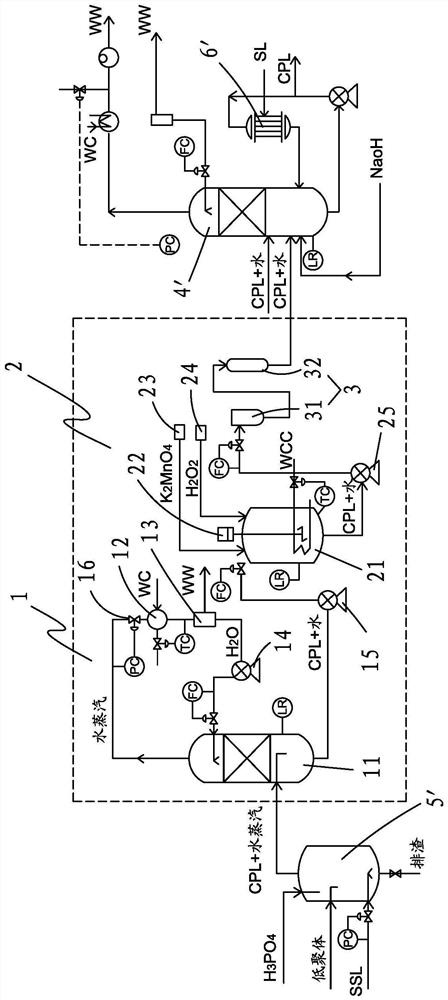

System and method for improving quality of recovered caprolactam and improving recovery process

PendingCN114452924AFacilitation of the recycling processWon't clogSolid sorbent liquid separationChemical/physical/physico-chemical stationary reactorsChemical treatmentO-Phosphoric Acid

The invention relates to the field of polymerization, in particular to a system and a method for improving the quality of recovered caprolactam and improving a recovery process. The system is additionally arranged on a depolymerization substance evaporation pipeline from a depolymerization tower to a water pre-removal tower, and comprises washing equipment, chemical treatment equipment and filtering separation equipment which are connected in sequence. Depolymers evaporated from the depolymerization tower firstly enter the washing equipment to be washed, cooled and collected, then enter the chemical treatment equipment to be subjected to oxidation-reduction treatment on phosphoric acid and oligomers in washing liquid, finally enter the filtering separation equipment, are subjected to yellow removal, impurity removal and metal ion separation and then return to the water pre-removal tower. According to the invention, phosphoric acid and oligomer are fully solved, waste is turned into wealth, and pipeline equipment of a pre-dehydration and rectification system is not blocked by phosphate and oligomer any more; the quality of the recycled CPL finished product is greatly improved, the index UV value and PN value of the recycled CPL finished product can be greatly improved and become stable, the color is slightly yellow and disappears, the content of impurities and metal ions is greatly reduced, and the pH value becomes more stable and easier to control.

Owner:CHANGLE LIHENG POLYAMIDE TECH +1

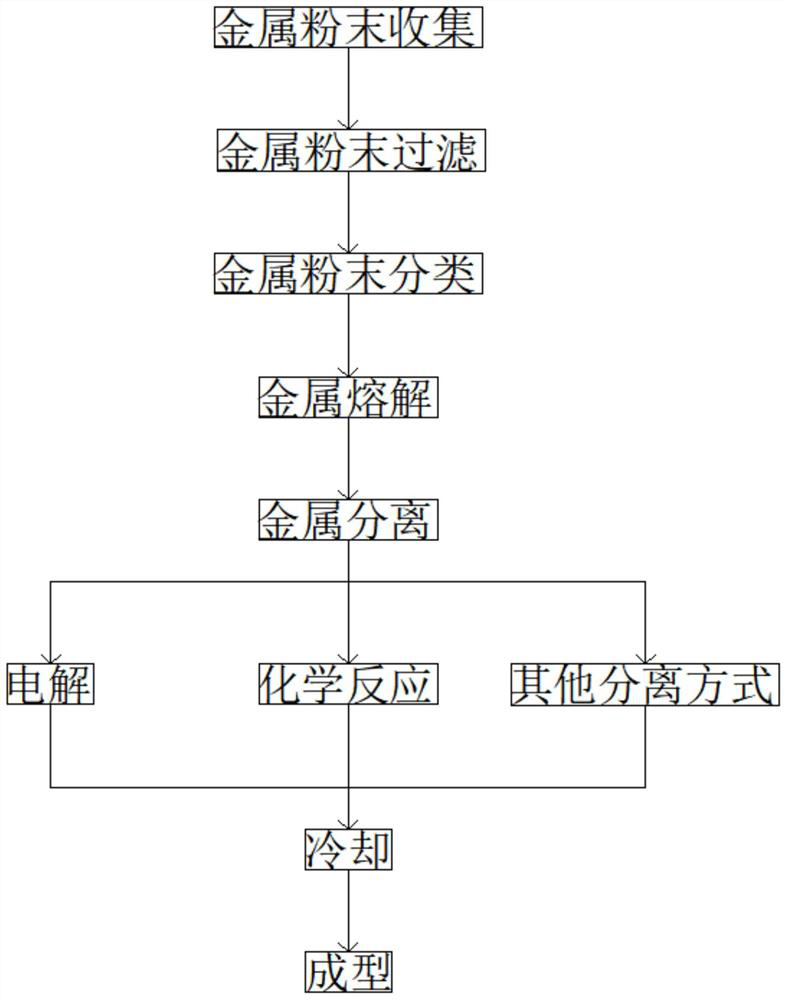

Metal powder treatment system for metal cutting machine

InactiveCN113564369AFacilitation of the recycling processImprove resource utilizationPhotography auxillary processesElectrostatic separationChemical reactionElectrolysis

The invention relates to the technical field of metal powder, and discloses a metal powder treatment system for a metal cutting machine. The system comprises metal powder collection and metal powder filtration, wherein metal powder is collected through the metal powder collection, then the metal powder is filtered and screened, metal powder generated during cutting of metal made of different materials is classified, the metal is dissolved to form liquid, metal separation is conducted on liquid metal, the metal separation comprises electrolysis, a chemical reaction and other separation modes, the liquid metal is cooled, and the cooled metal forms solid metal. According to the system, a recovery rate of the metal powder can be increased, diseases caused by the fact that workers suck the metal powder are avoided, impurity mixing in a metal powder recovery process is reduced, and meanwhile a purity of recovered metal is improved.

Owner:苏州盛易久智能科技有限公司

Method for selectively extracting lithium from waste lithium-ion battery materials

ActiveCN110835683BSimple recycling processFacilitation of the recycling processWaste accumulators reclaimingProcess efficiency improvementLithium iron phosphatePhysical chemistry

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

Classifying and recycling device for waste milk tea cups

InactiveCN111422525AAchieve separationReduce processingWaste collection and transferRefuse receptaclesProcess engineeringPiston rod

The invention discloses a classifying and recycling device for waste milk tea cups. The device comprises a classifying box and a classifying cavity formed in the classifying box, an opening is formedin the upper portion of the classifying cavity, air cylinders in bilateral symmetry are arranged in the classifying cavity, piston rods are arranged on the opposite sides of the left air cylinder andthe right air cylinder, and extrusion plates are fixedly connected to the opposite ends of the left piston rod and the right piston rod; and an electric guide rail is arranged on the left wall of theclassifying cavity, a sliding block is arranged in the electric guide rail, a rotatable rotating rod is arranged in the sliding block, a clamping device is fixed to the right side of the rotating rod.The waste milk tea cups are placed in the classifying and recycling device, so that straws, cup covers, cup bodies and solid and liquid in the cup bodies are separated; and the purpose of classifiedcollection and storage can be achieved, the subsequent garbage treatment amount is reduced, the garbage recycling process is convenient, and environmental pollution is reduced.

Owner:JINHUA XUANYA ENVIRONMENTAL PROTECTION TECH CO LTD

A kind of green synthetic method of reducing o-nitroaniline to prepare o-phenylenediamine

ActiveCN105130821BRealize green and clean productionHigh reaction yieldOrganic compound preparationAmino compound preparationSynthesis methodsGreen cleaning

Owner:江阴市华亚化工有限公司

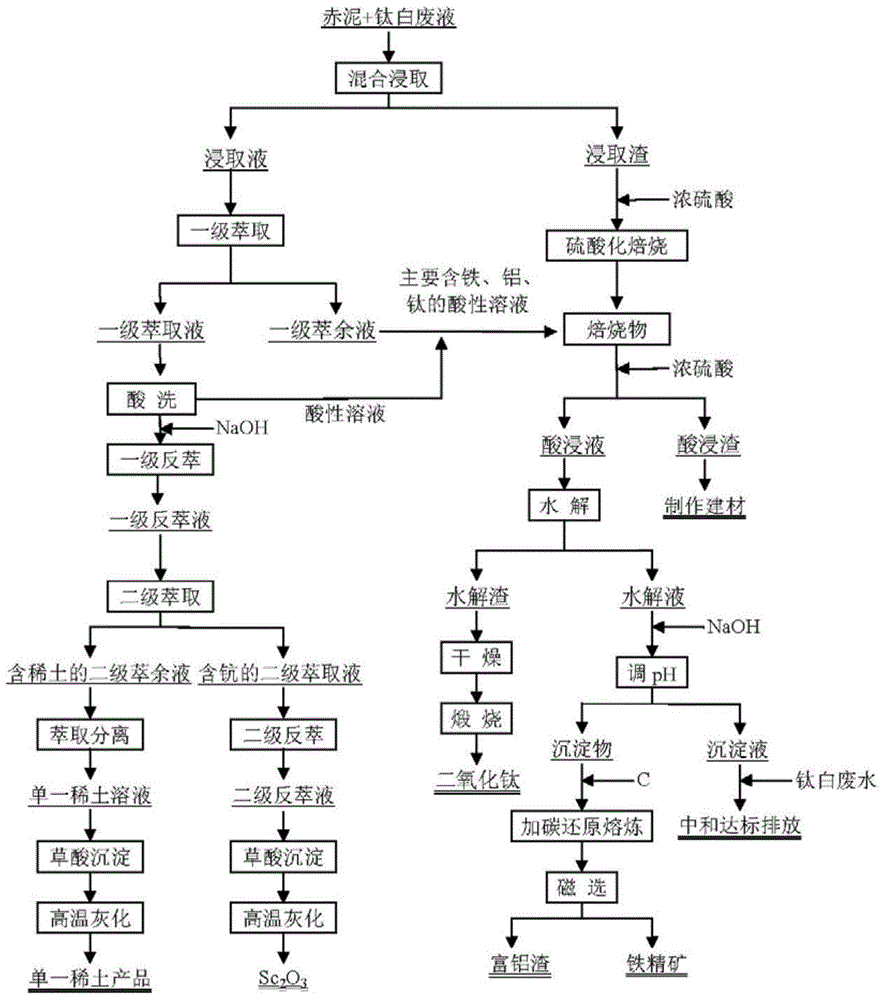

Method for comprehensive recovery and treatment of red mud waste residue and titanium dioxide waste liquid

ActiveCN103614563BSolve the emission problemSolve environmental problemsProcess efficiency improvementHigh concentrationRed mud

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com