Automobile engine oil recycling device and method

An engine oil recovery device and automobile technology, applied in garbage collection, household appliances, applications, etc., can solve problems such as improper recovery of waste engine oil, ineffective control of waste engine oil, and incomplete recycling of waste engine oil, etc., to achieve recycling safety , The effect of promoting green economic development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

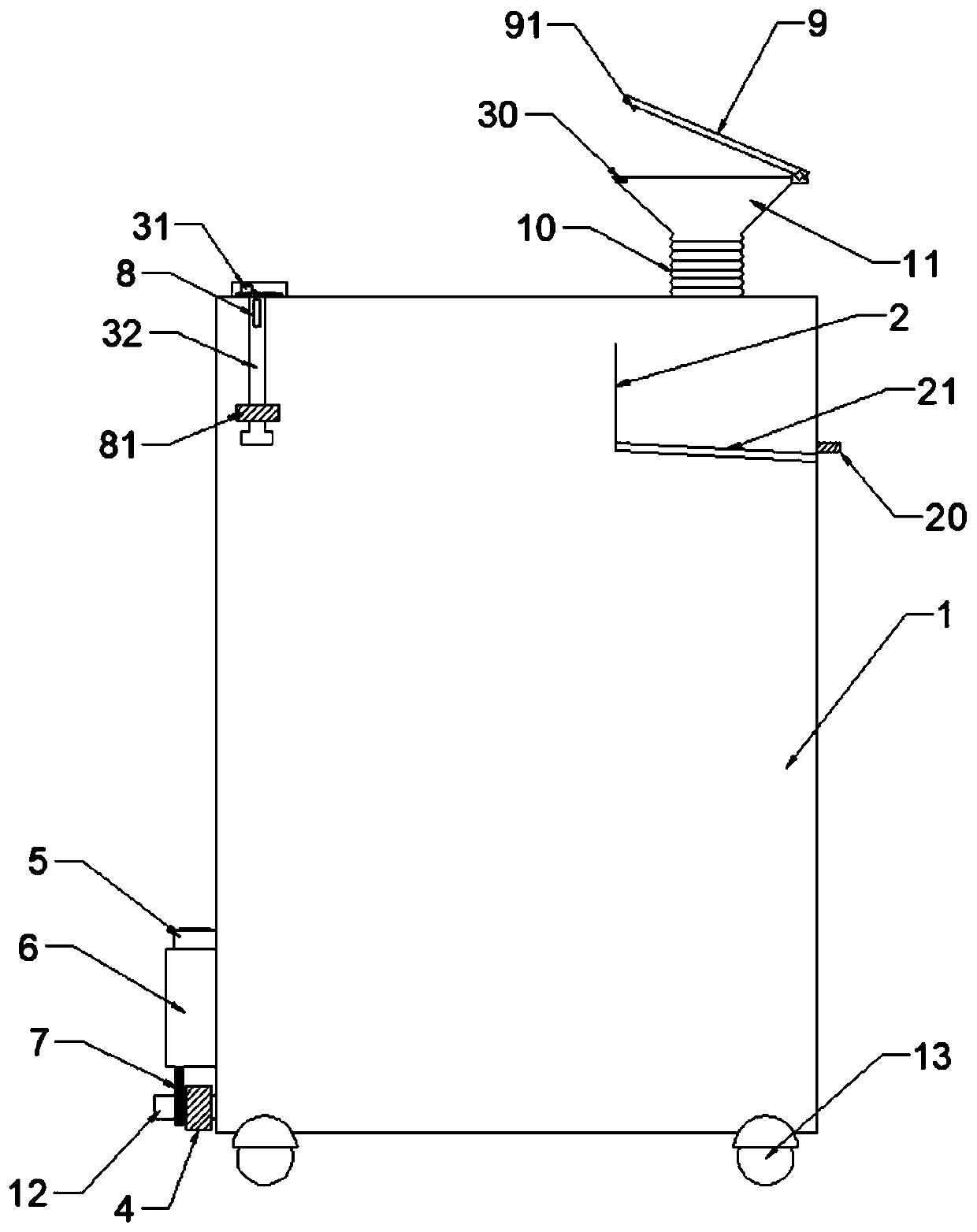

[0025] refer to figure 1 As shown, an automobile engine oil recovery device and method thereof has a recovery barrel 1, and an oil inlet 11 is arranged on the top of the recovery barrel 1. The automobile usually needs to be lifted to discharge waste engine oil, so the oil inlet 11 opens upward, and the oil inlet 11 The oil port 11 is preferably trumpet-shaped. The pulley 13 should be configured at the bottom of the recovery bucket 1, which can be easily moved to the bottom of the lifted car for oil recovery.

[0026] The oil inlet 11 is connected to the recovery barrel 1 through the telescopic tube 10, the telescopic tube 10 is preferably a snakeskin tube, and the oil inlet 11 can be stretched so as to be directly aligned with the oil shell at the bottom of the car for oil collection.

[0027] The upper part of the recovery barrel 1 is provided with a partition 2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com