Method for generating cement clinker by taking gold tailing slag as raw material

A technology for cement clinker and tailings slag, applied in the direction of cement production and process efficiency improvement, can solve problems such as hidden safety hazards, harm to the ecological environment, fine tailings particle size, etc., and achieve cost saving, low cost, and sustainable development. The effect of circular economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of cement clinker generation method that gold tailings slag is raw material, its scheme is:

[0032] S1, mix 800kg of gold tailings slag with 800kg of water, stir evenly and adjust into slag slurry;

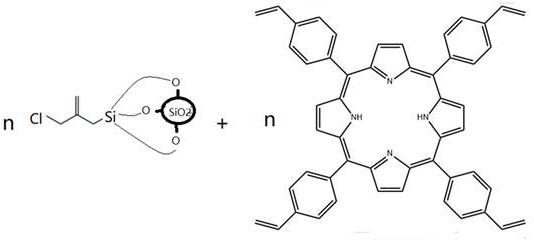

[0033] S2, adsorption, add 20kg adsorption phenolic resin in slag slurry, filter out adsorption phenolic resin after stirring and absorbing 150min, remove most of cyanide, described adsorption phenolic resin is prepared according to the following method:

[0034]Add 0.1kg of titanium dioxide to 10kg of 10% aqueous methanol solution, mix and stir for 5 minutes, then add 0.02kg of 2-(chloromethyl)allyltrimethoxysilane, control the temperature to 40°C, stir for 30 minutes and then filter. Dispersed to 8kg of allyl phenolic resin after washing, 0.05kg of 5,10,15,20-tetrakis(4-vinylphenyl)porphyrin, (CAS113477-21-7), 18kg of styrene, 2.1kg In the organic phase obtained by mixing isobutanol evenly, add 2.4 kg of initiator solution after stirring and reacting at 30°C for ...

Embodiment 2

[0042] A kind of cement clinker generation method that gold tailings slag is raw material, its scheme is:

[0043] S1. Mix 900kg of gold tailings slag with 1200kg of water, stir evenly and adjust into slag slurry;

[0044] S2, adsorption, add 25kg adsorption phenolic resin in slag slurry, filter out adsorption phenolic resin after stirring and adsorbing 180min, remove most of cyanide, described adsorption phenolic resin is prepared according to the following method:

[0045] Add 0.25kg of titanium dioxide to 15kg of 25% aqueous methanol solution, mix and stir for 7 minutes, then add 0.05kg of 2-(chloromethyl)allyltrimethoxysilane, control the temperature to 50°C, stir for 45 minutes and then filter. Dispersed to 12kg of allyl phenolic resin after washing, 0.11kg of 5,10,15,20-tetrakis(4-vinylphenyl)porphyrin, (CAS113477-21-7), 22kg of styrene, 2.3kg In the organic phase obtained by mixing isobutanol evenly, add 3.1 kg of initiator solution after stirring and reacting at 40°C ...

Embodiment 3

[0053] A kind of cement clinker generation method that gold tailings slag is raw material, its scheme is:

[0054] S1, mix 1000kg of gold tailings slag with 2000kg of water, stir evenly and adjust into slag slurry;

[0055] S2, adsorption, add 30kg adsorption phenolic resin in slag slurry, filter out adsorption phenolic resin after stirring and absorbing 240min, remove most of cyanide, described adsorption phenolic resin is prepared according to the following method:

[0056] Add 0.4kg of titanium dioxide to 20kg of 40% aqueous methanol solution, mix and stir for 10 minutes, then add 0.08kg of 2-(chloromethyl)allyltrimethoxysilane, control the temperature to 65°C, stir for 60 minutes and then filter. Dispersed to 16kg of allyl phenolic resin after washing, 0.18kg of 5,10,15,20-tetra(4-vinylphenyl) porphyrin, (CAS113477-21-7), 26kg of styrene, 2.6kg In the organic phase obtained by mixing isobutanol evenly, add 3.8 kg of initiator solution after stirring and reacting at 50°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com