Integrated TEG (triethylene glycol) dehydration integrated process device and method

A process device and rich liquid technology, which is applied in chemical instruments and methods, separation methods, gas fuels, etc., can solve the problems of low degree of device integration, complicated process flow, difficult to skid and relocate, and reduce the one-time investment and operating costs, simple process, and easy relocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

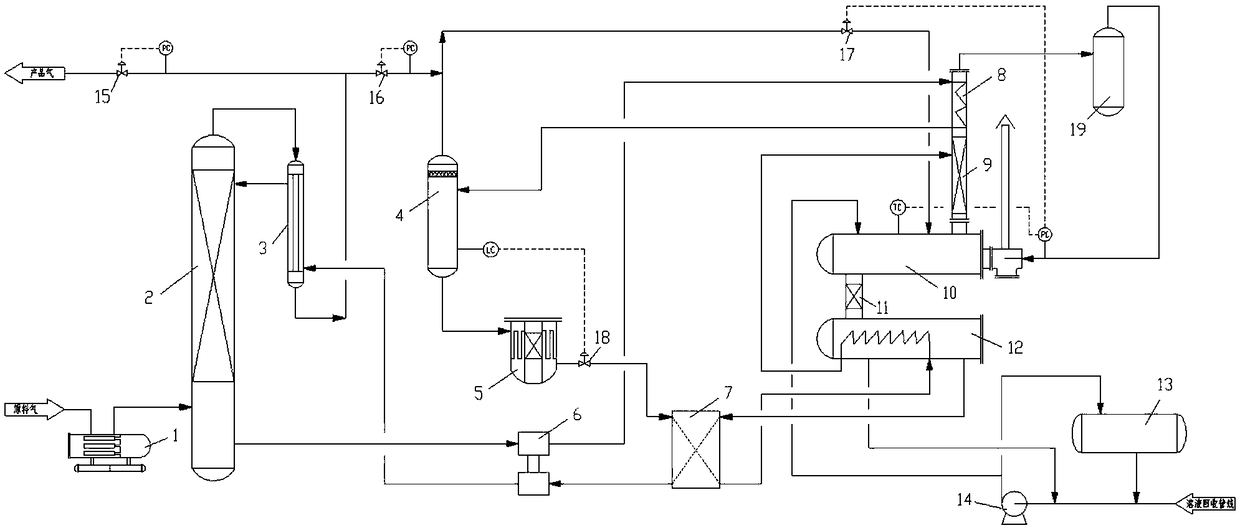

[0025] An integrated TEG dehydration integrated process device, such as figure 1 As shown, it includes: feed gas filter separator 1, TEG absorption tower 2, dry gas / lean liquid heat exchanger 3, flash tank 4, TEG solution filter 5, TEG circulation pump 6, lean / rich liquid heat exchanger 7. Rich liquid heat exchange coil 8, rich liquid rectification column 9, fire tube reboiler 10, lean liquid rectification column 11, lean liquid buffer tank 12, TEG replenishment tank 13, TEG replenishment pump 14, product gas Pressure regulating valve 15, fuel gas supplementary gas pipeline regulating valve 16, flash gas pipeline pressure / temperature cascade control regulating valve 17, flash tank liquid level regulating valve 18, waste gas liquid separation tank 19, etc., among which:

[0026] TEG absorption tower 2 inlet is connected to feed gas filter separator 1, TEG absorption tower 2 top gas phase outlet is connected to dry gas / lean liquid heat exchanger 3 tube side, TEG absorption tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com