Technology for treating high-arsenic copper material

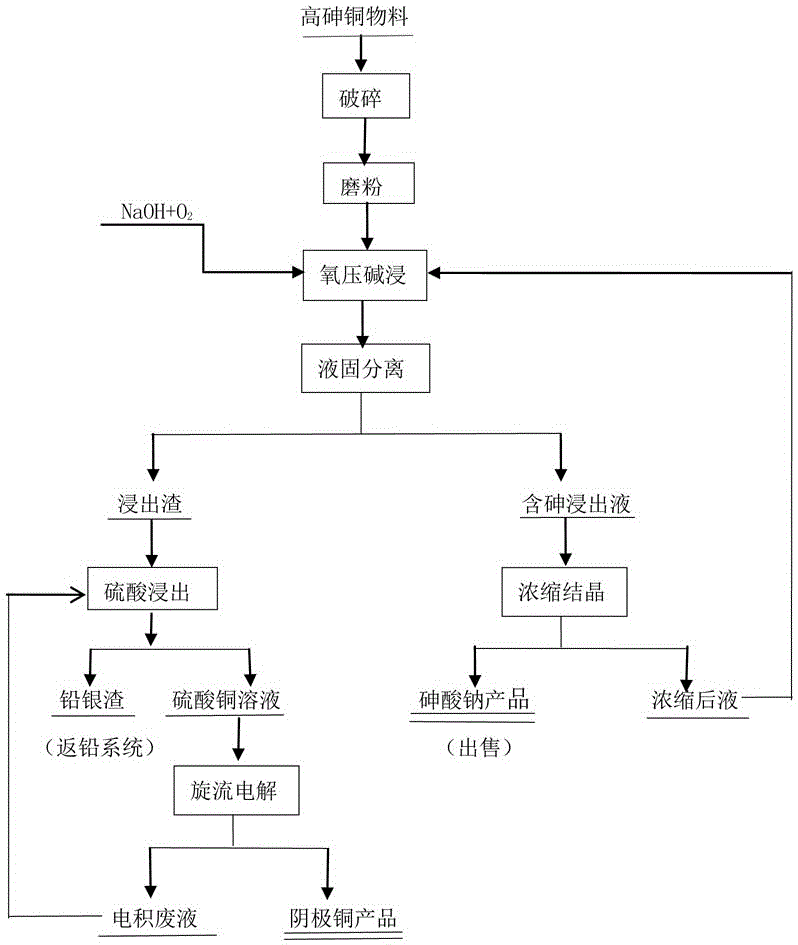

A copper material and process technology, which is applied in the field of processing high-arsenic copper materials, can solve the problems of easy explosion, reduce the efficiency of swirl electrolysis and affect the quality of cathode copper products, etc., and achieve convenient operation, easy industrial continuous production, and significant economy. benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 500 g of high-arsenic copper material (Pb10.61%; Cu 49.66%; As15.85%; S 1.34%; Ag 0.7623%; Fe 0.43%) was crushed and ground to a particle size of -120 mesh and mixed with sodium hydroxide in proportion Slurry is carried out, and then poured into an autoclave. During the leaching process, oxygen-enriched water is continuously introduced and the technical conditions are controlled: the concentration of sodium hydroxide is 180g / L, the volume-to-mass ratio of liquid to solid is 4:1 mL / g, the temperature is 90°C, the adjustment and Maintain pressure at 1.0 MPa, stirring speed at 600 r / min, and reaction time at 2.5 hours. After the oxidation leaching is completed, discharge the ore slurry out of the autoclave for liquid-solid separation, and leaching the leaching residue with sulfuric acid at atmospheric pressure. Control technical conditions: sulfuric acid concentration 150g / L , a liquid-solid ratio of 6:1, a temperature of 55°C, a stirring speed of 500 r / min, and a reaction ...

Embodiment 2

[0028] 500 g of high-arsenic copper material (Pb9.35%; Cu 52.08%; As17.73%; S 0.86%; Ag 0.5722%; Fe 0.82%) was crushed and ground to a particle size of -120 mesh and mixed with sodium hydroxide solution according to Slurry is adjusted according to the ratio, and then poured into the autoclave. During the leaching process, oxygen-enriched water is continuously introduced and the technical conditions are controlled: the concentration of sodium hydroxide is 200g / L, the ratio of liquid to solid is 4:1 mL / g, the temperature is 95°C, adjustment and maintenance The pressure is 0.8 MPa, the stirring speed is 600 r / min, and the reaction time is 3 hours. After the oxidation leaching is completed, the ore slurry is discharged out of the autoclave for liquid-solid separation, and the leaching residue is subjected to sulfuric acid atmospheric pressure leaching. The control technical conditions: sulfuric acid concentration 120 g / L, The liquid-solid ratio was 8:1, the temperature was 50°C, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com