Impact-resistant anti-wear agent for hydraulic concrete

A technology of hydraulic concrete and wear-resistant agent, which is applied in the engineering field, can solve the problems of unmatched concrete durability, poor concrete crack resistance, and high concrete elastic modulus, and achieves the effects of convenient construction, crack prevention, and improved deformation capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

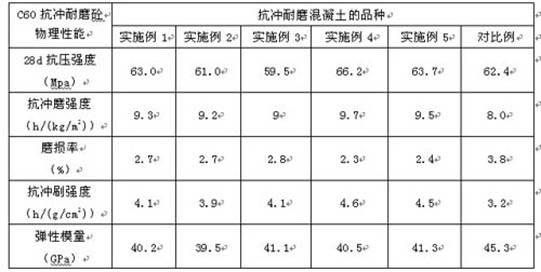

Examples

Embodiment 1

[0030] Example 1: 64kg of copper slag, 11kg of nano silicon dioxide, 4kg of polycarboxylate water reducer, 21kg of redispersible latex powder are poured into a mixer for mixing and stirring, stirring time is 10-15 minutes, stirring After uniformity, it can be packaged as impact and wear-resistant agent.

Embodiment 2

[0031] Embodiment 2: the copper slag of 41kg, the nano-calcium carbonate of 14kg, the polycarboxylate superplasticizer of 5kg, 40kg, the rubber powder that order number is 100 objects are poured into the blender and mixed and stirred, stirring time 10-15 minutes, stirred After uniformity, it can be packaged as impact and wear-resistant agent.

Embodiment 3

[0032] Example 3: Pour 55kg of blast furnace slag, 13kg of nano-iron oxide, 5kg of naphthalene-based water reducing agent, and 27kg of rubber powder with a mesh number of 100 into a mixer for mixing and stirring for 10-15 minutes, after stirring evenly , can be packaged as anti-impact and wear-resistant agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com