Self-lubricating crankshaft and rotary compressor, air conditioner and heat-pump water heater using same

A self-lubricating, crankshaft technology, applied in the crankshaft field, can solve the problems of not adapting to the operation of the compressor in the later period of its life, poor crankshaft operation adaptability, compressor failure and damage, etc., to achieve enhanced operation adaptability, reduced friction coefficient, reduced The effect of partial grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

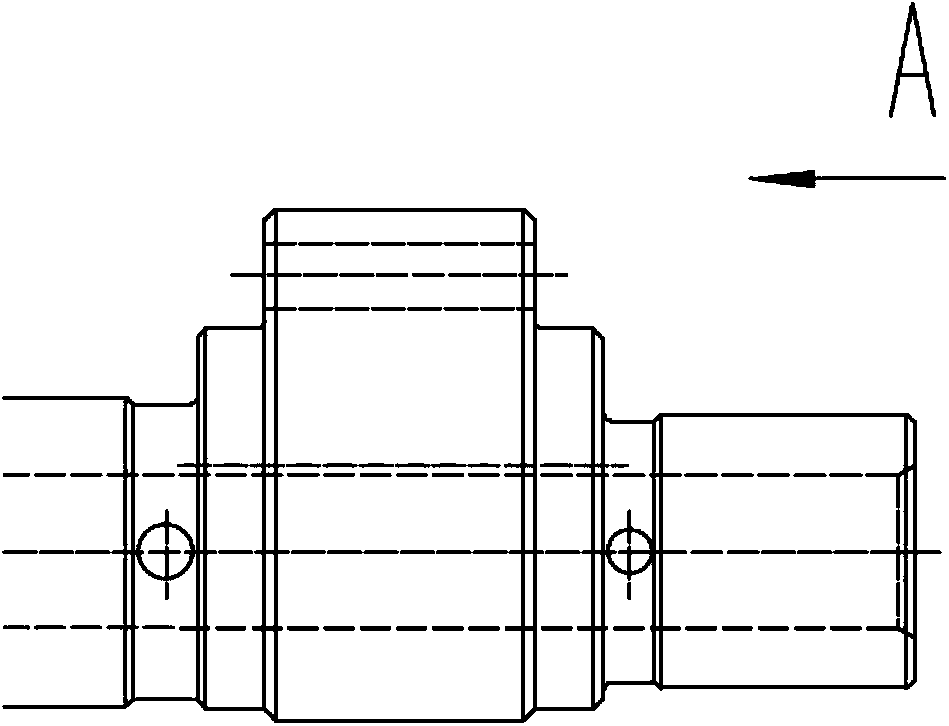

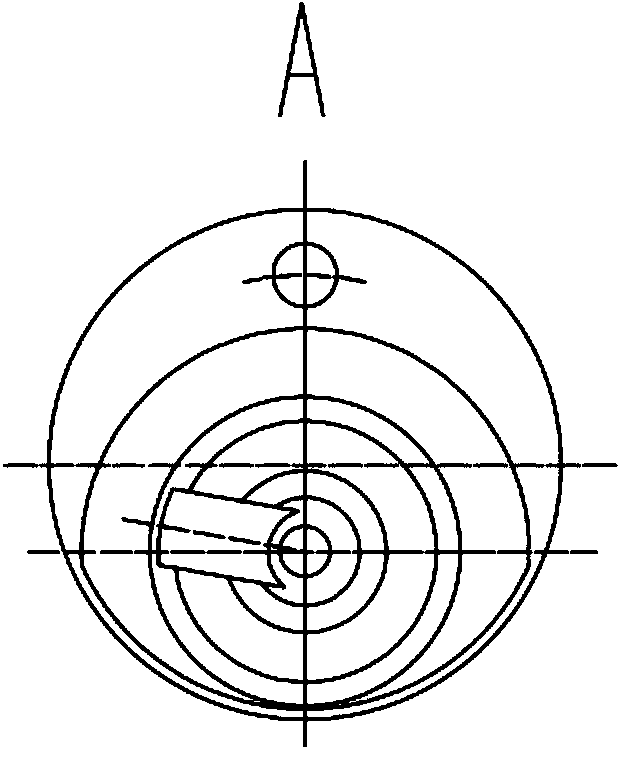

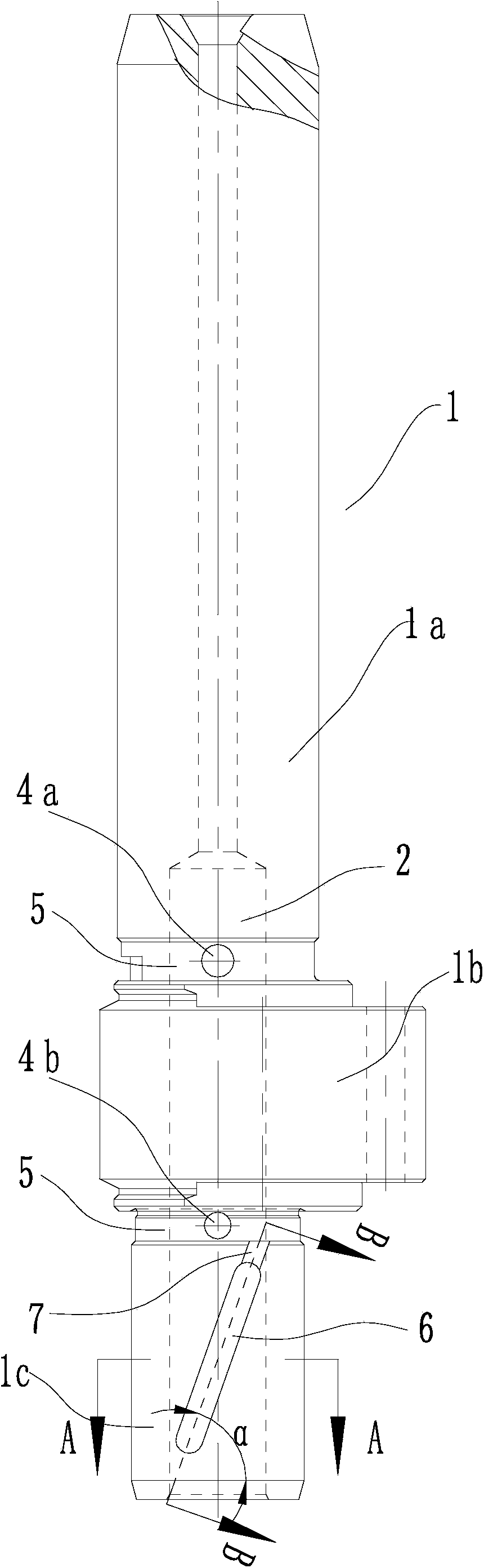

[0032] A self-lubricating crankshaft such as Figure 3 to Figure 5 As shown, the crankshaft 1 includes a major semi-axis 1a, an eccentric circle 1b and a minor semi-axis 1c. The eccentric circle 1b is located between the major semi-axis 1a and the minor semi-axis 1c, and an axial passage Hole 2, the top and bottom of the eccentric circle 1b are respectively provided with a first radial oil guide hole 4a and a second radial oil guide hole 4b communicating with the through hole 2, and the top and bottom of the eccentric circle 1b of the crankshaft 1 are respectively provided with a ring The tool relief groove 5, the first radial oil guide hole 4a and the second radial oil guide hole 4b are set in the annular tool relief groove 5; the oil in the through hole 2 passes through the first radial oil guide hole 4a and the second radial guide hole 4a. The oil hole 4b sprays oil to lubricate the main bearing assembled on the long semi-shaft and the auxiliary bearing assembled on the sho...

Embodiment 2

[0035] Such as Figure 6 to Figure 8 As shown, the difference from Embodiment 1 is that the lower end of the spiral oil guide groove 6 in the axial direction forms a slot 8 that runs through the entire inner wall surface of the through hole 2 and the outer surface of the short semi-shaft 1c of the crankshaft 1, and along the axial direction of the crankshaft 1 An inclined surface is formed between the upper edge of the groove hole 8 in the direction and the bottom end of the spiral communication groove 6, which changes the oil pumping direction of the bottom surface of the spiral oil guide groove 6, so that the oil pump pressure is stronger and the oil pump effect is better. At the same time, the angle range of the angle γ' formed between the lower end surface of the slotted hole 8 and the center line of the through hole 2 of the short half shaft 1c of the crankshaft 1 is preferably 50° to 70°, which is also convenient for the impurities produced by the wear and tear of the cra...

Embodiment 3

[0037] Such as Figure 9 to Figure 11As shown, the difference from Embodiment 1 is that the upper and lower ends of the spiral oil guide groove 6 in the axial direction respectively form a communication hole 9 that runs through the entire inner wall surface of the through hole 2 and the outer surface of the short half shaft 1c of the crankshaft 1, and the spiral oil guide groove The bottom surface of 6 is arranged parallel to the axial direction, and the through hole 2 leads to the spiral oil guide groove 6 through two communication holes 9, so as to selectively pump oil to different parts of the short half shaft 1c of the crankshaft 1, the pump oil pressure is strong, and the oil pump effect is good . In addition, the angle γ″ formed by the lower end surface of each communication hole 9 and the center line of the through hole 2 at the short half axis of the crankshaft 1 is preferably 50° to 70°, which is also convenient for impurities produced by the wear of the crankshaft an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com