Head-swinging dual-compound braking device

A compound braking and driving device technology, applied in the direction of brake types, axial brakes, brake actuators, etc., can solve problems such as poor braking effect, failure to meet energy supply requirements, and difficult air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

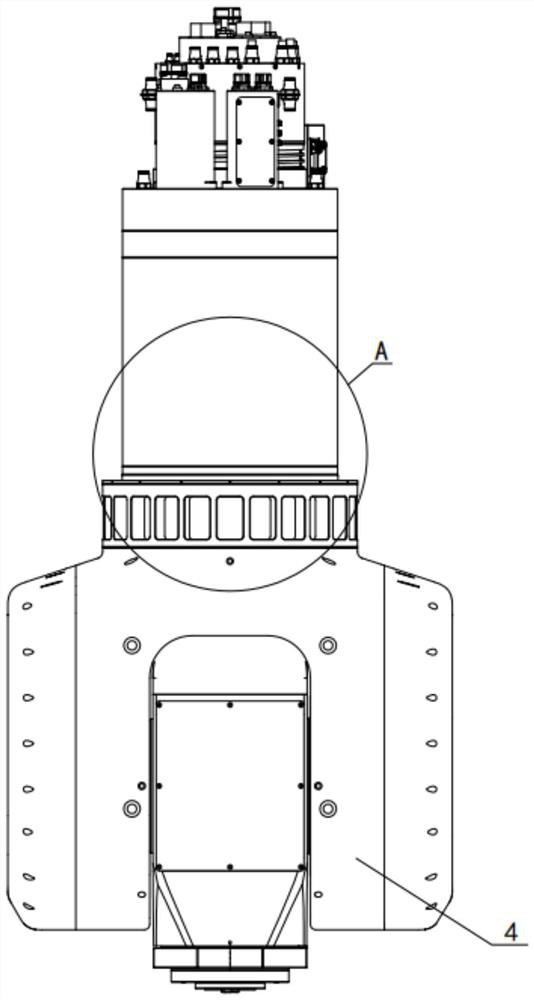

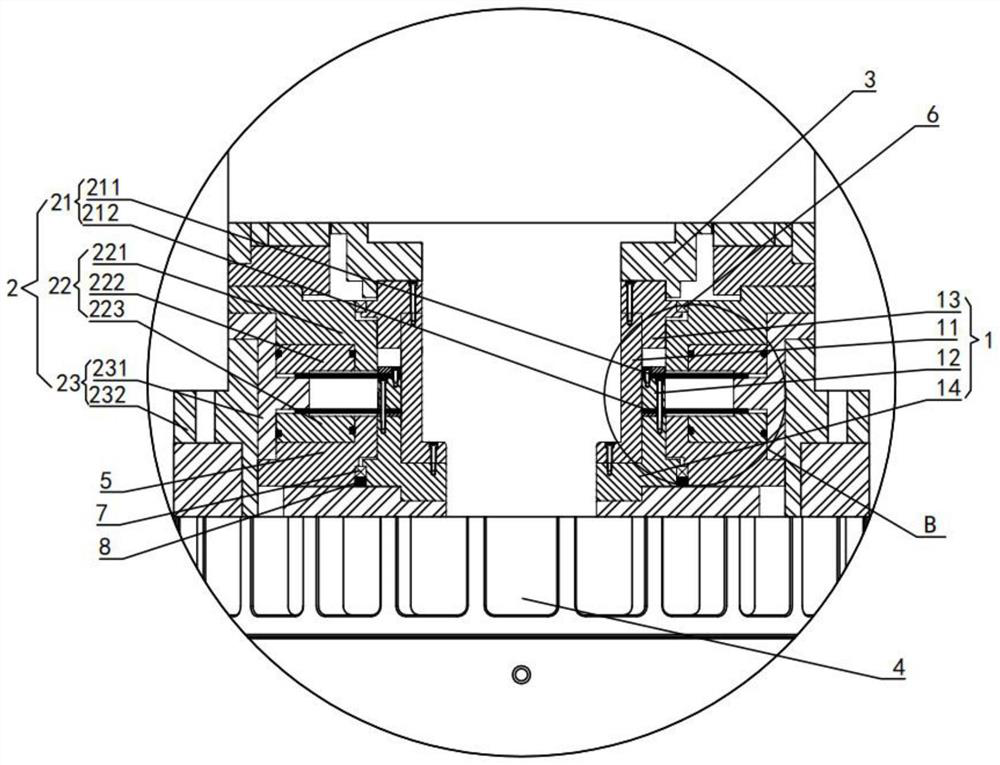

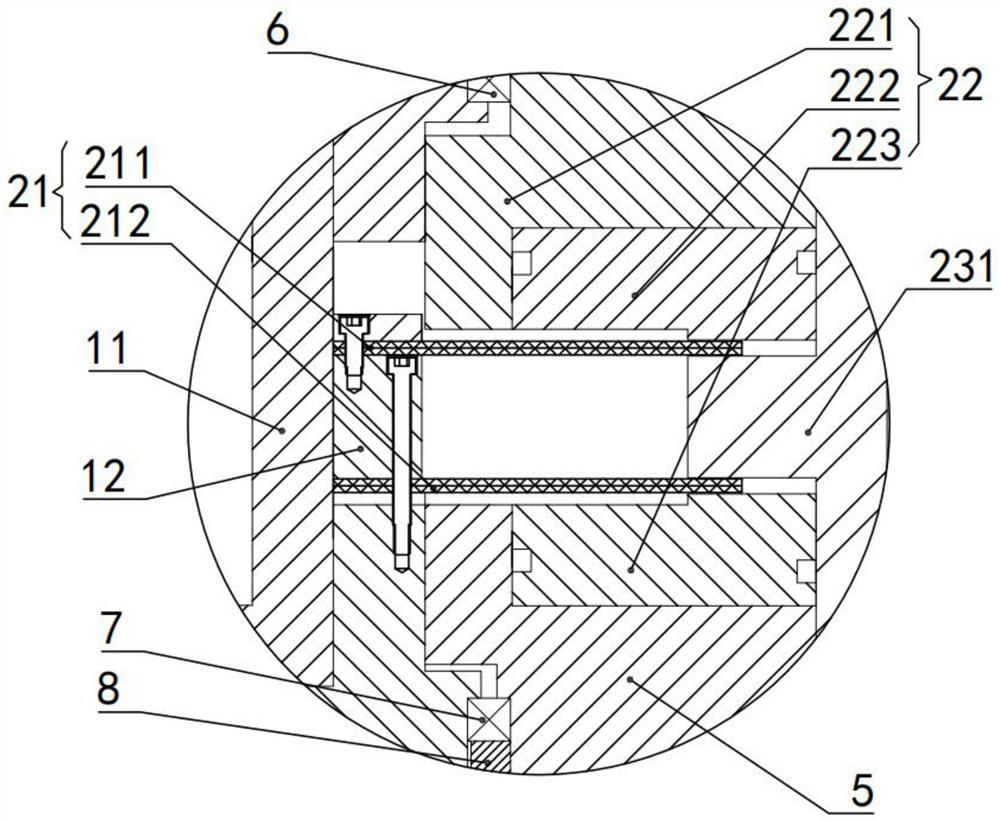

[0024] refer to Figure 1-3 As shown, the present invention discloses a double composite braking device for swinging head, comprising: a rotating mechanism 1, a braking mechanism 2, a motor rotor 3 and a swinging head main body 4; one end of the rotating mechanism 1 is fixedly connected to the bottom of the motor rotor 3 end, and the other end is fixedly connected to the input end of the swing head main body 4; the brake mechanism 2 includes a brake device 21, a drive device 22 and a brake auxiliary assembly 23; the brake device 21 includes a first composite brake disc 211 and The second composite brake disc 212; the first composite brake disc 211 and the second composite brake disc 212 are fixedly connected to the outside of the rotating mechanism 1 at intervals; the output ends of the driving device 22 are respectively located above the first composite brake disc 211 and below the second composite brake disc 212; the inner side of the brake auxiliary assembly 23 is fixedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com