Bridge prestress tensioning system

A prestressing and tensioning technology, applied in bridges, bridge materials, bridge construction, etc., can solve problems such as the influence of viscosity and impurities, steel strand impact, hydraulic oil viscosity changes, etc., so as to improve the accuracy of measurement and prevent Effect of leakage or pressure drop, prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

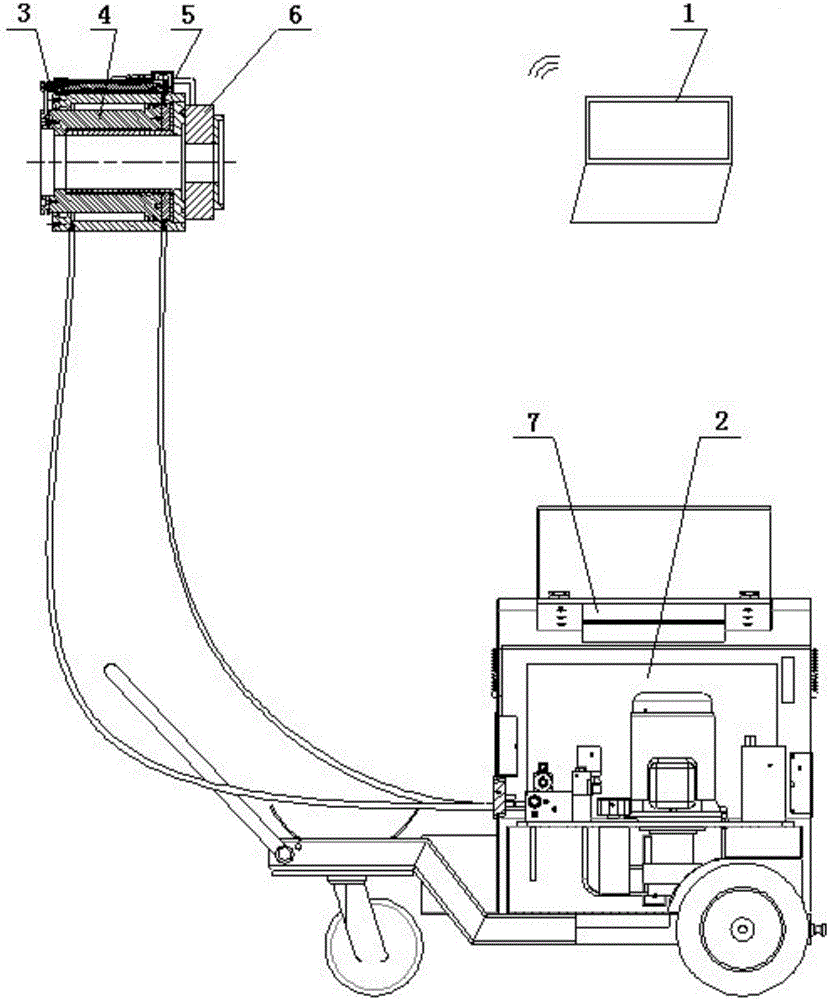

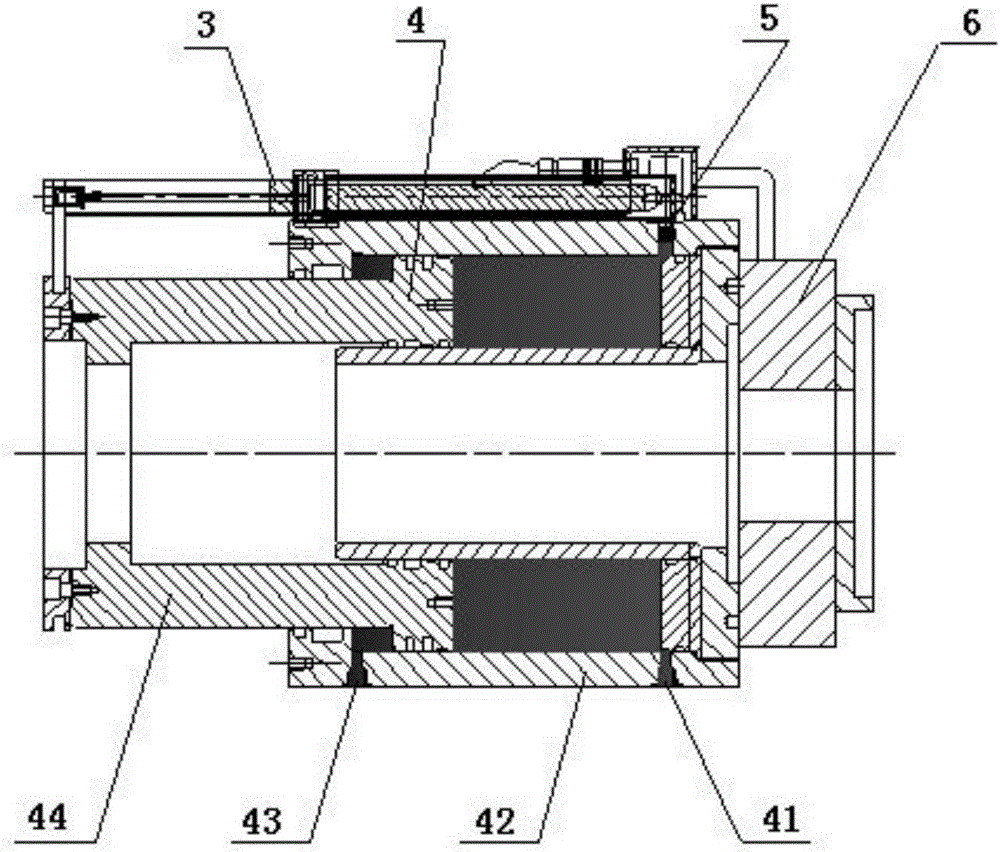

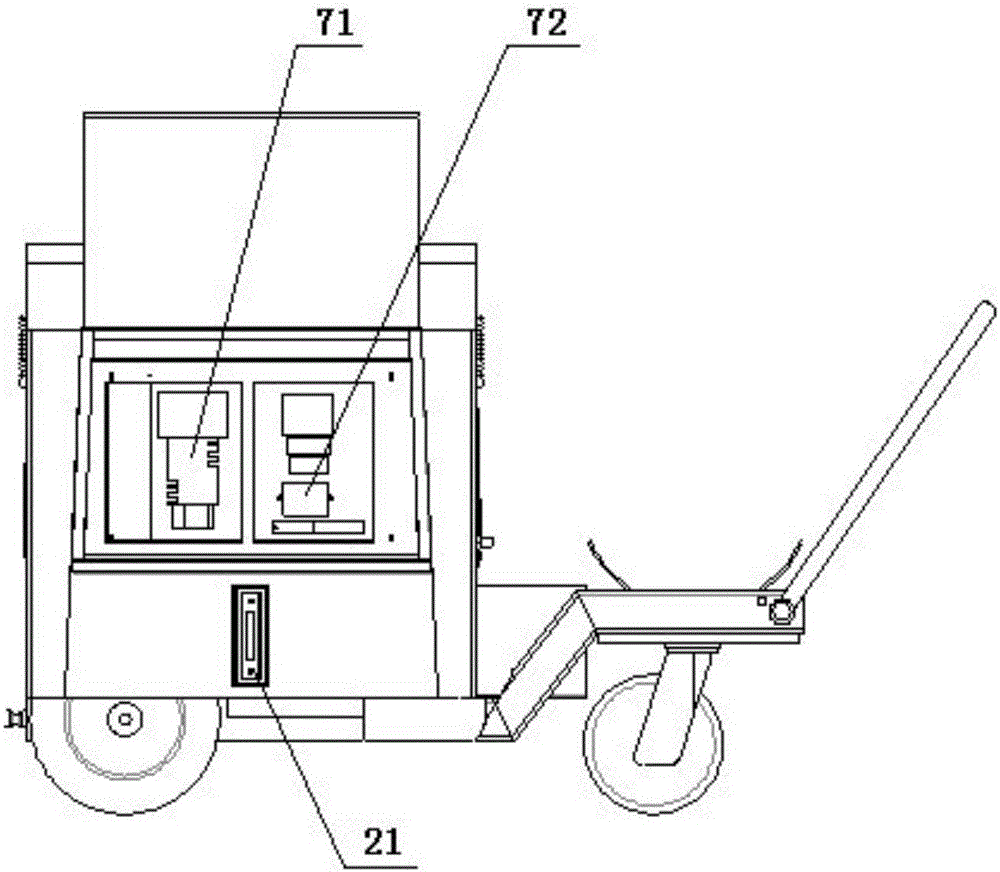

[0035]With reference to accompanying drawing, the present invention is achieved in that a kind of bridge prestress tensioning system, it comprises computer unit 1, tensiometer 2, displacement sensor 3, jack 4, pressure sensor 5, force sensor 6 and controller 7; The displacement sensor 3 is arranged on the outside of the cylinder 42 of the jack 4 and is connected with the piston rod 44 for measuring the extension length of the piston rod 44, and the pressure sensor 5 is arranged on the inner wall of the cylinder 42 of the jack 4 for measuring the length of the cylinder 42. 4. The pressure value of the hydraulic oil in the oil inlet chamber 41. The force sensor 6 is arranged on the base of the cylinder 42 of the jack 4 and connected with the beam body 8 to measure the stress value when the jack 4 stretches the steel strand 81; The tensioner 2 includes a temperature sensor 26 arranged on the side wall of the oil tank for measuring the temperature of the hydraulic oil, and the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com