Lubricating oil composition

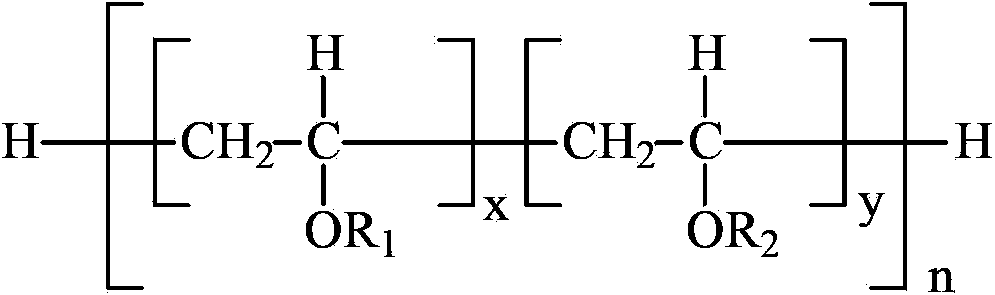

A lubricating oil composition and composition technology, applied in lubricating compositions, petroleum industry, additives, etc., can solve the problems of low thickening ability, low shear stability, and poor viscosifying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] 56 g of toluene, 0.1 g of isobutanol and 0.42 g of boron trifluoride etherate were placed in a 500 ml glass flask equipped with a U-shaped tube, dropping funnel, spherical condenser, thermometer and stirrer. A mixture of 60 g of vinyl ethyl ether and 80 g of vinyl isobutyl ether was put into the dropping funnel and added dropwise to the flask over 2 h. The reaction started during the dropwise addition, and the temperature of the reaction solution rose. The temperature of the reaction solution was kept at about 25°C by cooling with an ice-water bath. After the dropwise addition was complete, the reaction solution was stirred for another 30 min. Then, the reaction mixture was transferred to a washing vessel and washed three times with 500 ml of aqueous sodium hydroxide solution (6%) and then with water to render the mixture neutral. The solvent and residual starting material were removed under vacuum to obtain the polymer product. 1.4 g of amorphous nickel catalyst and...

Embodiment 2

[0065] 48 g of isooctane, 0.3 g of isobutanol and 1.2 g of boron trifluoride etherate were charged into a 500 ml glass flask equipped with a U-shaped tube, dropping funnel, spherical condenser, thermometer and stirrer. A mixture of 140 g of vinyl ethyl ether and 20 g of vinyl isobutyl ether was put into the dropping funnel and added dropwise to the flask over 2 h. The reaction started during the dropwise addition, and the temperature of the reaction solution rose. The temperature of the reaction solution was kept at about 35°C by cooling with an ice-water bath. After the dropwise addition was complete, the reaction solution was stirred for another 30 min. Then, the reaction mixture was transferred to a washing vessel and washed three times with 500 ml of aqueous sodium hydroxide solution (6%) and then with water to render the mixture neutral. The solvent and residual starting material were removed under vacuum to obtain the polymer product. 2.8g of amorphous nickel catalyst...

Embodiment 3

[0067] 81 g of isooctane, 0.05 g of ethanol and 0.8 g of aluminum trichloride were placed in a 500 ml glass flask equipped with a U-shaped tube, dropping funnel, spherical condenser, thermometer and stirrer. A mixture of 10 g of vinyl ethyl ether and 150 g of vinyl isohexyl ether was put into the dropping funnel and added dropwise to the flask over 2 h. The reaction started during the dropwise addition, and the temperature of the reaction solution rose. The temperature of the reaction solution was kept at about 40°C by cooling with an ice-water bath. After the dropwise addition was complete, the reaction solution was stirred for another 30 min. Then, the reaction mixture was transferred to a washing vessel and washed three times with 500 ml of aqueous sodium hydroxide solution (6%) and then with water to render the mixture neutral. The solvent and residual starting material were removed under vacuum to obtain the polymer product. 2.1g of Raney nickel catalyst and 70g of pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com