Preparation method for graphite surface SiC coating used for molten salt reactor

A molten salt reactor and graphite technology, applied in nuclear reactors, fast fission reactors, reactor fuel materials, etc., can solve the problems of high cost, long preparation cycle, unfavorable large-scale application, etc., and achieve low porosity, high density, The effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

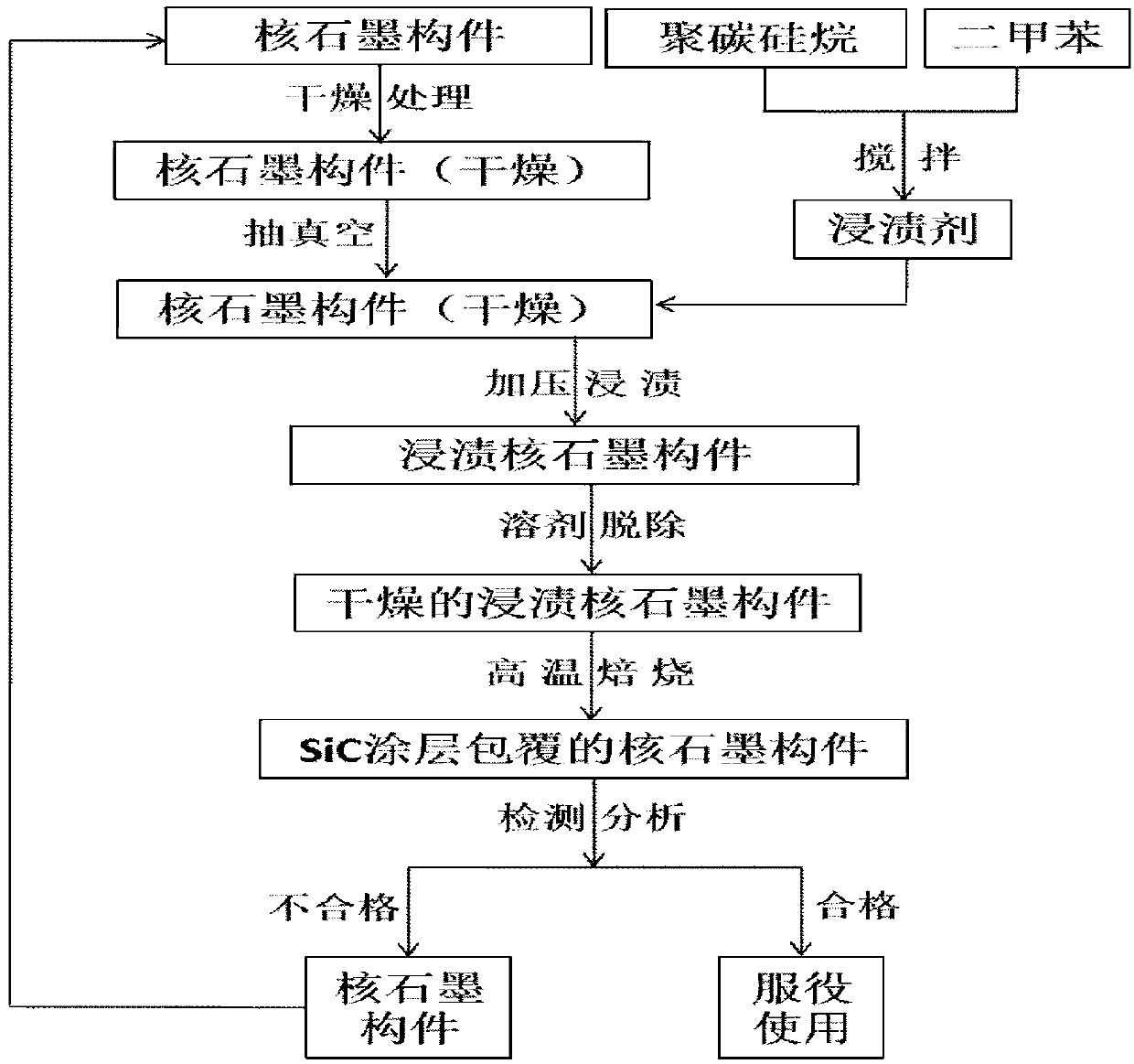

Method used

Image

Examples

Embodiment 1

[0040] 1. Prepare polycarbosilane impregnation solution: mix polycarbosilane and xylene at a weight ratio of 1:10 at 30°C and stir to disperse to obtain an impregnation solution for later use.

[0041] 2. After drying the nuclear graphite IG-110 component, place it in the impregnation equipment, raise the temperature to 30°C, keep the temperature constant and start vacuuming to reduce the internal pressure of the impregnation chamber to 0.01MPa and continue vacuuming for 1h.

[0042] 3. Add impregnation liquid to the impregnation equipment (it must be ensured that the liquid level of the impregnation liquid is 10mm higher than the top of the nuclear graphite component after the pressurization), and then pass high-pressure nitrogen into the impregnation equipment to pressurize to 0.5MPa, and maintain a constant high pressure for 3 hours. After the pressure is released, take out the nuclear graphite component and place it in a ventilated and dry place for 8 hours to allow the sol...

Embodiment 2

[0049] 1. Prepare polycarbosilane impregnation solution: mix polycarbosilane and xylene at a weight ratio of 1:5 at 40°C and stir to disperse to obtain an impregnation solution for later use.

[0050] 2. After drying the nuclear graphite IG-110 component, place it in the impregnation equipment, raise the temperature to 40°C, keep the temperature constant and start vacuuming to reduce the internal pressure of the impregnation chamber to 0.01MPa and continue vacuuming for 3 hours.

[0051] 3. Add an appropriate amount of impregnation liquid to the impregnation equipment (it must be ensured that the liquid level of the impregnation liquid is 15mm higher than the top of the nuclear graphite component after the pressurization), and then pass high-pressure nitrogen gas into the impregnation equipment to pressurize to 5MPa, and maintain a constant high pressure for 4h. After the pressure is released, take out the nuclear graphite component and place it in a ventilated and dry place to...

Embodiment 3

[0057] 1. Prepare polycarbosilane impregnation solution: mix polycarbosilane and toluene at a weight ratio of 1:2 at 50°C and stir to disperse to obtain an impregnation solution for later use.

[0058] 2. After drying the nuclear graphite IG-110 component, place it in the impregnation equipment, raise the temperature to 50°C, keep the temperature constant and start vacuuming to reduce the internal pressure of the impregnation chamber to 0.01MPa and continue vacuuming for 2 hours.

[0059] 3. Add an appropriate amount of impregnation liquid to the impregnation equipment (it must be ensured that the liquid level of the impregnation liquid is 15mm higher than the top of the nuclear graphite component after the pressurization is completed), and then pass high-pressure nitrogen into the impregnation equipment to pressurize to 5MPa, and maintain a constant high pressure for 5h. After the pressure is released, take out the nuclear graphite component and place it in a ventilated and dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com